Page 1

Instruction Manual

Tornado SHO

Model No. 3007, 3007A, 3007EX

© 2018 Gold Medal Products Co.

Part No. 43143

10700 Medallion Drive, Cincinnati, Ohio 45241-4807 USA

Page 2

DANGER

DANGER

WARNING

WARNING

WARNING

WARNING

Tornado SHO Model No. 3007, 3007A, 3007EX

SAFETY PRECAUTIONS

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury, or death. Any alterations to this equipment

will void the warranty and may cause a dangerous condition. This appliance

is not intended to be operated by means of an external timer or separate

remote-control system. NEVER make alterations to this equipment. Read the

Installation, Operating, and Maintenance Instructions thoroughly before

installing, servicing, or operating this equipment.

008_051514

014_020416

Floss head rotates at high speeds. Operator MUST keep hands and face

clear of the floss head to avoid injury. Operator must wear eye protection.

Keep all spectators at a reasonable distance, and use a Floss Bubble for

added customer protection.

015_062714

Keep all foreign objects out of floss head. To avoid eye injury, DO NOT fill

floss head with sugar while the head is on and rotating.

016_010914

Burn Hazard. DO NOT touch spinner head. Allow to cool before cleaning or

servicing. Avoid contact with molten sugar.

006_092414

ALWAYS wear safety glasses when servicing this equipment.

Page 2

010_010914

gmpopcorn.com

Page 3

WARNING

WARNING

WARNING

WARNING

Tornado SHO Model No. 3007, 3007A, 3007EX

SAFETY PRECAUTIONS (continued)

No user serviceable parts inside. Refer servicing to qualified service

personnel.

Read and understand operator’s manual and all other safety instructions

before using this equipment. To order copies of the operator’s manual go to

gmpopcorn.com or write to Gold Medal Products Co., 10700 Medallion Drive,

Cincinnati, OH 45241 USA 1-(800)-543-0862

DO NOT allow direct contact of this equipment by the public when used in

food service locations. Only personnel trained and experienced in the

equipment operation may operate this equipment.

Carefully read all instructions before operation.

011_051514

022_060215

012_010914

This machine is NOT to be operated by minors.

007_010914

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

Note: Improvements are always being made to Gold Medal’s equipment. This

information may not be the latest available for your purposes. It is critical that you

call Gold Medal’s Technical Service Department at 1-800-543-0862 for any

questions about your machine operations, replacement parts, or any service

questions. (Gold Medal Products Co. does not assume any liability for injury due to

careless handling and/or reckless operation of this equipment.) General images

may be used in manual for reference only.

Page 3

gmpopcorn.com

Page 4

Tornado SHO Model No. 3007, 3007A, 3007EX

INSTALLATION INSTRUCTIONS

Inspection of Shipment

After unpacking, check thoroughly for any damage which may have occurred in transit. Claims

should be filed immediately with the transportation company. The warranty does not cover

damage that occurs in transit, or damage caused by abuse, or consequential damage due to the

operation of this machine, since it is beyond our control.

Setup

Your new floss machine unit is completely assembled and tested at the factory. Remove all

packing material and tape before starting operation.

1. You MUST remove the 4 shipping brackets placed around the motor mount casting

before operation. To do so, remove the bolts that hold the brackets in; this can be done

with any wrench or socket. Failing to do so may result in damage to your floss

machine or in personal injury.

2. Make sure the floss ribbon (heating element) located inside the head assembly has not

shaken out of the band during transportation. If the ribbon is out of the band, push it

back into place manually.

Shipping Brackets

(Remove all 4)

Bands

Floss Ribbon seen

Correctly Sitting in

the Bands

Page 4

gmpopcorn.com

Page 5

DANGER

CAUTION

Tornado SHO Model No. 3007, 3007A, 3007EX

Electrical Requirements

The following power supply must be provided for your Floss Machine:

3007, 3007A: 120 Volts, 2400 Watts, 60 Hz.

3007EX: 230 Volts, 2400 Watts, 50 Hz.

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

A certified electrician must furnish sufficient power for proper machine operation and install any

supplied receptacle. We recommend this equipment be on a dedicated and protected circuit.

Failure to wire properly will void the warranty and may result in damage to the machine. It is Gold

Medal Products Co.’s recommendation that this machine be plugged directly into a wall outlet. The

use of extension cords is not recommended due to safety concerns, and may cause sacrificed

and/or reduced performance. Make sure cord is located to prevent a trip hazard or unit upset.

008_051514

Before You Plug In Machine

1. Make sure all machine switches are in the OFF position before plugging the equipment

into the receptacle.

2. Make sure the wall outlet can accept the grounded plugs (where applicable) on the

power supply cord.

3. The wall outlet must have the proper polarity. If in doubt, have a competent

electrician inspect the outlet and correct if necessary.

4. DO NOT use a grounded to un-grounded receptacle adapter (where applicable).

5. Install the unit in a level position.

If the supply cord is damaged, it must be replaced by Gold Medal Products Co.,

its service agent or similarly qualified persons in order to avoid a hazard.

039_080614

Page 5

gmpopcorn.com

Page 6

Tornado SHO Model No. 3007, 3007A, 3007EX

Installation of Floss Stabilizer

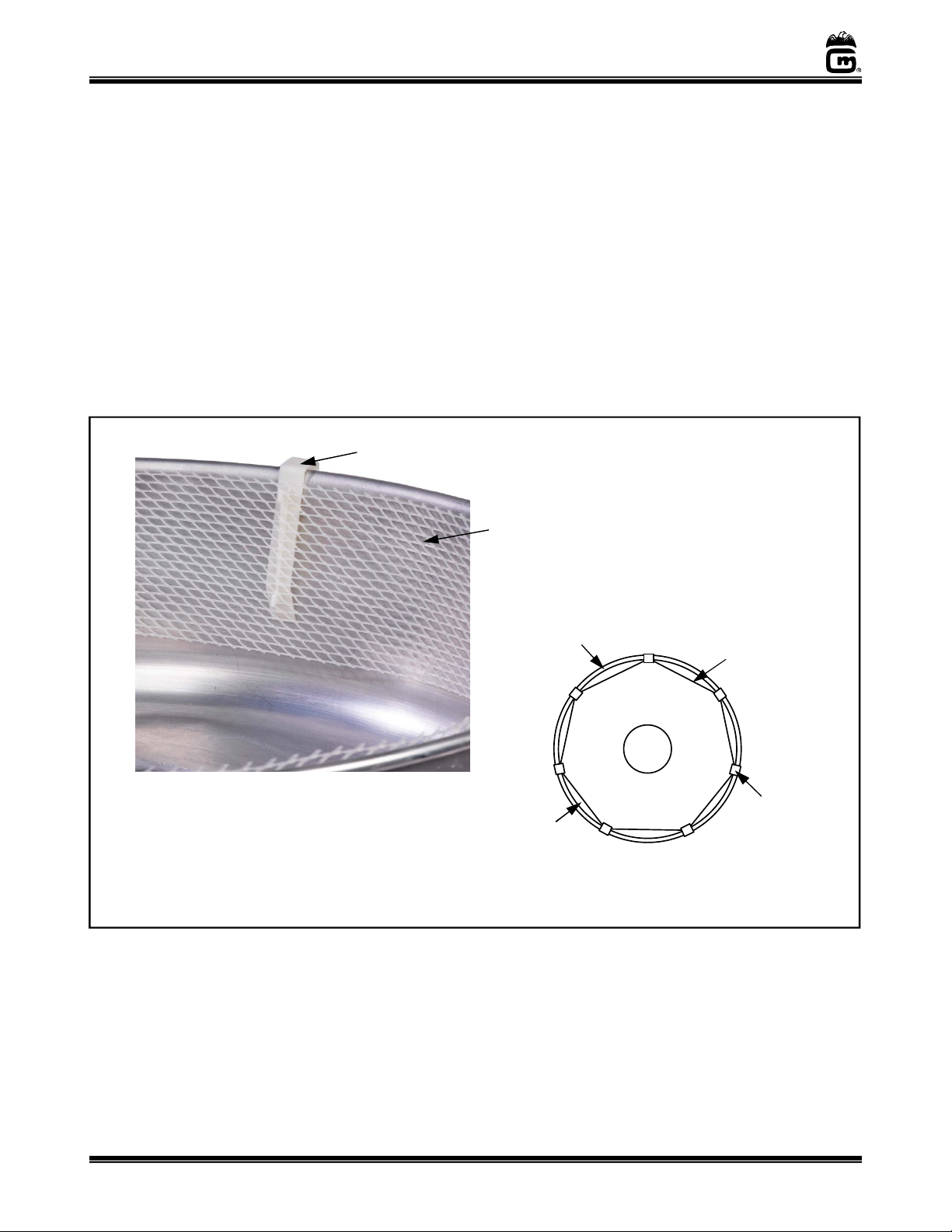

Place Floss Machine Pan on unit and install Whirl Grip Floss Stabilizer as shown below.

1. Place a Non-Metallic Whirl Clip over the rim of the Floss Pan. The out facing hooks go

to the inside of the Floss Pan.

2. Hang the Non-Metallic screening material onto the up facing hook with the screening

approximately flush with the top of the pan. Gently pull the screening down and

attach to the down facing hook on the clip to secure screen in place.

3. Check the clip spacing for proper operation.

4. Continue this process with all clips, keeping equal spacing around the pan.

Non-Metallic Whirlgrip Clip

Non-Metallic Screening Material

(Whirl Grip Floss Stabilizer)

Floss Pan

Air space is required between

pan and stabilizer for proper

operation.

Whirl Grip

Floss Stabilizer

Clips (number

of clips varies

by model)

Top View of Pan

Page 6

gmpopcorn.com

Page 7

Tornado SHO Model No. 3007, 3007A, 3007EX

OPERATING INSTRUCTIONS

Controls and Their Functions

MAIN SWITCH

Turns motor “on” or “off” and supplies voltage to the heat switch.

HEAT SWITCH

Turns voltage to the heating element (ribbon) “on” or “off”.

HEAT CONTROL KNOB

Increases or decreases voltage to heating element (ribbon) using a graduated dial.

Motor and

Master Switch

Heat Switch

Heat Control Knob

Page 7

gmpopcorn.com

Page 8

Tornado SHO Model No. 3007, 3007A, 3007EX

Sugar for Your Candy

Ready to Use Flossugar

Our ready to use Flossugar is the preferred sugar for your new cotton candy machine; however

100% pure cane or beet sugar will do just fine. Our Flossugar gives you good rich colors, and

great flavors, too. It is packed in handy half-gallon sealed cartons, with an E-Z pour spout for

filling your machine. Flossugar comes in many flavors, and you can easily change flavors for

greatest variety, and best sales.

Mix Your Own

If you want to mix your own, use our Flossine®, and please follow our directions. If you want a

deeper color, slightly dampen the mixed sugar. Use a tablespoon of water per five pounds of

sugar, sprinkle water over sugar, and mix well. DO NOT USE EXCESS COLOR! Too much color

will ruin the element on your machine and could create a bitter taste to the candy. There is a

limit as to how dark you can make cotton candy. That’s because cotton candy is 98% air, and we

cannot color the air.

Sugar Considerations

Today 99% of the sugar manufactured is extra fine granulated, which does have some small

particles which can slip thru the ribbons without being melted. If this becomes objectionable, you

can seek out medium coarse or sanding sugars. The larger crystal size will require a little more

heat to melt.

Read the label on the bag of sugar, today we see some free flowing sugars for restaurants. Free

flowing sugars contain cornstarch which will burn onto your element/band clogging them

rapidly. We have also seen some off-brand sugars that are a blend of sugar and dextrose or corn

syrup. This product makes very poor cotton candy. Please make sure you get good sugar for

your cotton candy machine.

Page 8

gmpopcorn.com

Page 9

Tornado SHO Model No. 3007, 3007A, 3007EX

MACHINE OPERATION

Settings Test

CAUTION

Floss head operates at high speeds. Operator MUST keep

hands and face clear of the floss head to avoid possible

injury. Keep all spectators at a reasonable distance, and

use a Floss Bubble for added customer protection.

1. Follow the guidelines described in the Electrical Requirements Section for supplying

power to machine.

2. With main switch still off, fill floss head. Always fill it 90% full with sugar. This 90%

level is necessary to obtain a balanced condition in the floss head. DO NOT OVERFILL!

Excessive vibration will occur if overfilled. Before turning the power on, manually turn

the head to balance out the sugar. This will eliminate excessive vibration of the head.

Important: NEVER add sugar when motor is running.

3. Turn the Main Switch and Heat Switch “ON”.

4. Turn the Heat Control Knob clockwise to maximum setting to initiate the fastest

possible warm up.

5. The machine should start making floss in a few seconds. When the unit starts making

floss, you must reduce the heat setting. Turn the Heat Control Knob counter clockwise

to eliminate smoking. If you operate the unit at "startup" setting, you will carbonize

the ribbon.

CAUTION

Never operate the equipment for a prolonged period of

time with the HEAT CONTROL in a position that causes

the sugar to smoke. This will result in excessive

carbonization of the ribbon (heat element). If you smell

burning sugar or see smoke, reduce the heat.

6. Once you find the ideal setting for the HEAT CONTROL, operate with the setting near

this position each time.

When completing operation for the day (or any prolonged period), follow the instructions

in the Shutdown Procedure/Cleaning and Care section of this manual.

Page 9

gmpopcorn.com

Page 10

CAUTION

WARNING

USE FLOSS CONE TO COLLECT COTTON CANDY

.

Tornado SHO Model No. 3007, 3007A, 3007EX

Making Floss

Pick a cone, if it sticks in the stack of cones, twist it off the stack.

Keep hands away from spinning head!

031_021914

Hold an inch or two of the pointed end of the cone between two fingers and a thumb. With a light

flicking action, roll cone in the web of floss building up in the pan. Lift the cone up with the ring

of floss attached and rotate the cone to wrap the floss. DO NOT roll floss while the cone is inside

the pan. This will pack the floss too tightly. See steps 1 thru 8 shown below.

If the floss fails to stick to the cone, pass the cone near the spinner head to pick up a “starter” of

melted sugar. Lift the cone out of the pan and wrap the floss with a "figure eight" movement of

the hand. This leaves giant pockets and makes the final product appear larger. Make sure room

humidity is not too high, or product will be "heavy".

1. Grip cone as shown. 2. Break into web of

floss with the cone.

3. Wind the sugar onto

the cone.

4. Lift web of floss from

the pan and roll onto

the cone.

5.

6.

• DO NOT PUT HANDS OR OBJECTS IN ROTATING SPINNER HEAD.

• DO NOT FILL SPINNER HEAD WITH SUGAR WHILE IT IS ROTATING.

• WEAR EYE PROTECTION.

• DO NOT PUT HANDS NEAR ROTATING SPINNER HEAD.

•

7.

Page 10

8.

032_021914

gmpopcorn.com

Page 11

Tornado SHO Model No. 3007, 3007A, 3007EX

FLOATER ADJUSTMENTS

In operation, the floss will collect on the FLOSS STABILIZER. If the floss collects “low” on the

stabilizer, twist the front (leading) edge of the leather floaters down. You get more lift and the

floss will collect higher.

Form leather floaters as shown below. This creates a lifting action to float the floss higher on the

outside wall of the floss pan.

Rotation

Leather Floater

Leading Edge of

Leather Floaters

seen twisted down

Page 11

gmpopcorn.com

Page 12

DANGER

WARNING

Tornado SHO Model No. 3007, 3007A, 3007EX

Shut Down Procedure/

Care and Cleaning

Shut Down Procedure

When completing operation for the day (or any prolonged period), run all the sugar out of the

floss head. When empty, turn the heat to highest position for approximately one minute to

“clean” the band by baking off remaining sugar. NEVER put water in the floss head.

Care and Cleaning

Machine must be properly grounded to prevent electrical shock to personnel.

DO NOT immerse in water. DO NOT clean appliance with a water jet.

Always unplug the equipment before cleaning or servicing.

025_111616

Burn Hazard. DO NOT touch spinner head. Allow to cool before cleaning or

servicing. Avoid contact with molten sugar.

006_092414

Good sanitation practice demands that all food preparation equipment be cleaned regularly (only

use non-toxic, food grade cleaners). A clean looking, well-kept machine is one of the best ways of

advertising your product.

Follow the directions below to clean and sanitize the unit each day after use.

1. Unplug the machine and wait for the floss head to cool down to room temperature.

2. Make sure to clean all pans/accessories in order to sanitize them before each use.

3. Wipe all surfaces with a clean, damp cloth.

4. Wipe the stainless steel parts with a clean cloth and cleaner designed for stainless

steel, such as Gold Medal Watchdog Stainless Cleaner (Item No. 2088).

DO NOT use oven cleaners or abrasive materials as they will damage parts of the

machine.

Page 12

gmpopcorn.com

Page 13

Nylon

Acorn Nut

Tornado SHO Model No. 3007, 3007A, 3007EX

Floss Bands and Ribbons

Gold Medal Floss Bands are designed to give long life and trouble-free service with little care.

DO NOT scratch the band. Gold Medal Floss Ribbons (heat elements) are made of nickel wire

with insulation at the terminal point and on the lead wires. They are designed to be as reliable as

the bands; however, the ribbons must be handled carefully. DO NOT stretch the ribbon or it will

not function properly.

Disassembly and Removal of Floss Band

Lock Nut

Terminal Guard

Floss Ribbon

(Heating Element)

Floss Band

Element Lead

Wire and

Retaining Screws

Reference next page for

reassembly instructions.

Single Ribbon View

General images shown for reference, Models may vary.

1. Unplug the machine from the power source and allow floss head to cool completely.

2. Remove all sugar from the head of the machine before disassembling. If needed,

carefully turn the machine on its side and shake the sugar out.

3. Remove the four spinner cap retainer screws and spinner cap. In some cases, the

sugar has caused the cap and band to stick together. Applying gentle pressure with the

heel of the hand should free the parts for removal.

4. Remove the nylon acorn nut, lock nut, and terminal guard.

5. Remove the element lead wire retaining screws (using a 1/4” (9.5mm) nut driver),

which fasten the element lead wires to the terminals. This will allow the band and

ribbon(s) to be removed. DO NOT PULL OR STRETCH RIBBON(S) TO REMOVE. (See

next page for reconnecting element leads.)

Double Ribbon View

6. If there is excessive sugar buildup, soak the band and ribbon(s) in hot water until the

sugar dissolves. When the sugar has been removed, tap the band in the palm of your

hand to loosen the ribbon(s) for removal.

Page 13

gmpopcorn.com

Page 14

element

Tornado SHO Model No. 3007, 3007A, 3007EX

7. Inspect, then clean or replace the band and ribbon(s). The primary reason for ribbon

replacement is carbon build up inside the ribbon; an additional hot water soak may

help remove some of the carbon buildup.

8. When the sugar has been removed, allow the band and element(s) to air dry overnight.

Note: For models with separate heat and motor switches, the best way to dry the floss

head after reassembly is to spin it dry for 10 minutes WITHOUT HEAT (use

motor switch only).

Reassembly of Floss Band – Units with Terminal Assemblies

(See next page for Export Units with Terminal Jumper.)

1. Reinstall band and ribbon(s) on the spinner head; ALWAYS attach one ribbon element

lead to each terminal assembly (see image below).

2. Reassemble terminal guard, lock nut, and nylon acorn nut.

3. When reinstalling the spinner cap, DO NOT OVERTIGHTEN SCREWS. Initially snug

down each screw evenly, be careful not to over apply pressure on any single point and

crack the band coating. Once snug, tighten all screws evenly to secure spinner cap to

floss head.

Terminal Assemblies

CORRECT

Connect ONE ribbon element lead

to EACH terminal assembly.

Double Ribbon Floss Head with Terminal Assemblies

INCORRECT

DO NOT connect both ribbon

leads to the same terminal assembly.

General double ribbon view shown for reference, Models may vary.

Page 14

gmpopcorn.com

Page 15

Export Floss Head

Stainless Steel

Screw

Jumper

Stainless Steel

Screw

Tornado SHO Model No. 3007, 3007A, 3007EX

Reassembly of Floss Band – Export Units with Terminal Jumper

(See previous page for Units with Terminal Assemblies.)

1. Reinstall band and ribbon(s) on the spinner head; for each element, ALWAYS attach

one element lead to a brass stud, and one lead to a stainless steel screw as shown in

image below. ALWAYS attach Jumper to the stainless steel screws.

2. Reassemble terminal guard, lock nut, and nylon acorn nut.

3. When reinstalling the spinner cap, DO NOT OVERTIGHTEN SCREWS. Initially snug

down each screw evenly, be careful not to over apply pressure on any single point and

crack the band coating. Once snug, tighten all screws evenly to secure spinner cap to

floss head.

Ribbon Element Leads

Double Ribbon with Terminal Jumper

Brass Studs

Ribbon Element Leads

(ALWAYS attach to the

Stainless steel screws)

Page 15

gmpopcorn.com

Page 16

Tornado SHO Model No. 3007, 3007A, 3007EX

TROUBLESHOOTING

Low Production

• Check for excessive carbon on the ribbons. Follow the instructions for removing and

cleaning band and ribbon if needed.

• Check heat control for correct setting.

• Check the line voltage. A primary reason for low production and poor equipment

performance is low line voltage. Have an electrician check the line voltage and add

new lines for all of the various equipment you have plugged into the electric circuit if

there is not enough current for the requirement listed on the equipment nameplate.

• Check the ribbons. For machines with two ribbons, one burned out or shorted ribbon

will cut production in half.

• Foreign objects in the head assembly may short out a ribbon or cause an out-of-

balance condition.

Excessive Smoke

• Check heat control setting. After warm up, equipment should make good floss at a

reduced setting. Never let the machine operate with the heat so high it produces

smoke or if you can smell burned sugar. This condition quickly fills the ribbon with

carbonized sugar.

• Check the product mixture being used. For best results, use nothing with a cornstarch

base.

• Check the band and ribbon for excessive sugar build up and remove if needed as

described Floss Bands and Ribbons section.

Excessive Vibration

• If the equipment is new, verify that shipping bolts have been loosened and packing

materials were removed from the machine.

• When adding sugar to the floss head, always fill it 90% full to obtain a balanced

condition in the head and eliminate vibration. DO NOT add sugar with motor running!

• Check for stretched or uneven suspension springs.

• Run the sugar completely out, then check for foreign objects or sugar lumps in the

head assembly.

Page 16

gmpopcorn.com

Page 17

DANGER

DANGER

WARNING

CAUTION

Tornado SHO Model No. 3007, 3007A, 3007EX

MAINTENANCE INSTRUCTIONS

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury, or death. Any alterations to this equipment

will void the warranty and may cause a dangerous condition. This appliance

is not intended to be operated by means of an external timer or separate

remote-control system. NEVER make alterations to this equipment. Read the

Installation, Operating, and Maintenance Instructions thoroughly before

installing, servicing, or operating this equipment.

008_051514

014_020416

No user serviceable parts inside. Refer servicing to qualified service

personnel.

THE FOLLOWING SECTIONS OF THIS MANUAL ARE INTENDED ONLY

FOR QUALIFIED SERVICE PERSONNEL WHO ARE FAMILIAR WITH

ELECTRICAL EQUIPMENT. THESE ARE NOT INTENDED FOR THE

OPERATOR.

011_051514

027_010914

Page 17

gmpopcorn.com

Page 18

Tornado SHO Model No. 3007, 3007A, 3007EX

ORDERING SPARE PARTS

1. Identify the needed part by checking it against the photos, illustrations, and/or

parts list. (General images may be used in manual for reference only.)

2. Use only approved replacement parts when servicing this unit.

3. When ordering, please include part number, part name, and quantity needed.

4. Please include your model number, serial number, and date of manufacture (located

on the machine nameplate/data plate) with your order.

5. Address all parts orders to:

Parts Department

Gold Medal Products Co.

10700 Medallion Drive

Cincinnati, Ohio 45241-4807

Or, place orders by phone or online:

Phone: (800) 543-0862

(513) 769-7676

Fax: (800) 542-1496

(513) 769-8500

E-mail: info@gmpopcorn.com

Web Page: gmpopcorn.com

Page 18

gmpopcorn.com

Page 19

3007

3007A

3007EX

4

PAN SUPPORT

4

42049

42049

42049

STRAIN RELIEF SR-7W-2

1

67060

15

5/16 WASHER

8

74134

74134

74134

Tornado SHO Model No. 3007, 3007A, 3007EX

Exterior View

1

14

15

2

13

3

4

5

12

16

11

6

17

10

7

8

Qty.Part DescriptionItem

1 7IN SPINNER HEAD COMPLETE 1 43131 43131 43131EX

2 BRUSH COVER 2 42008NM 42008NM 42008NM

3 MOTOR CASTING 1 42034 42034 42034

5 RUBBER FEET 3/4IN HIGH 8 47155 47155 47155

6 NAME & INSTRUCTION PLATE 1 43134 43134 43134

7 CIRCUIT BREAKER 15 AMP 1 47364 47364

8 HANDLE 1 67069 67069 67069

STRAIN RELIEF#SR-9P-2 1 47026 47026

9

10 POWER SUPPLY CORD 1 47603 47603 42369

11 RUBBER PAD 4 75243 75243 75243

12 SUPPORT ANGLE, SHIPPING 4 48019 48019 48019

13 8-32 HEX M/S NUT 4 74149 74149 74149

14 5/16 ACORN NUT 4 77610 77610 77610

16 SUSPENSION SPRING 4 20006 20006 20006

17 5/16 FLANGE NUT 4 49317 49317 49317

5

Part Number

9

Page 19

gmpopcorn.com

Page 20

3007

3007A

3007EX

30 AMP TOGGLE SWITCH

VOLT METER 220V

1

48034

KNOB RHEOSTAT

2 3 4

Tornado SHO Model No. 3007, 3007A, 3007EX

Front Panel

1

Qty.Part DescriptionItem

1

3 POSITION TOGGLE SWITCH

2

(Heat Switch)

VOLT METER 1 43009 43009

3

4

1 43141 43141 43141

1 43142 43142 43142

1 48027 48027 48027

Part Number

Page 20

gmpopcorn.com

Page 21

26

13

15

Tornado SHO Model No. 3007, 3007A, 3007EX

Spinner Head Assembly

2A

7” Spinner Head Complete

9

10

12

21

22

19

17

18

11, 11A

3

14

20

16

2

27

23

1

4

5

6

8

7

24

25

Page 21

gmpopcorn.com

Page 22

Tornado SHO Model No. 3007, 3007A, 3007EX

Spinner Head Assembly – Parts List

Qty.Part DescriptionItem

7" SPINNER HEAD COMPLETE 1 43131 43131 43131EX

SPINNER HEAD BOTTOM ONLY 1 43008 43008 43008EX

1 LEATHER FLOATER 2 20010 20010 20010

2 10-24 X 3 1/8 PH PAN M/S 2 43132 43132 43132

2A 10-24 X 3 PHIL PAN M/S 2 89760 89760 89760

3 SPINNER CAP 1 43014 43014 43014

4 GASKET DELUXE TORNADO 2 43130 43130 43130

5 BAND INSULATOR 2 42400 42400 42400

6 STUD INSULATOR 1-15/16 IN 4 43133 43133 43133

7 HEAD CASTING 1 43015 43015 43015

8 7 IN RIBBON ASSY 120V 9A 2 43028 43028 43028

9 7 IN SINGLE FLOSS BAND 2 42401 42401 42401

10 PRODUCTION ENHANCER 1 43129 43129 43129

11 ACORN NUT NYLON 1/4-20 1 48041 48041 48041

11A 1/4-20 SERRATED LOCK NUT 1 46311 46311 46311

12 PHENOLIC TERMINAL GUARD 1 42303 42303 42303

13 PHENOLIC INSULATOR TERML 1 42304 42304

TERMINAL ASSY 2 42305 42305

14

TOP TERMINAL INSULATOR 1 42367

BOTTOM TERMINAL INSULATOR 1 42368

8-32 X 1/4 HX HD WHIZLOCK 4 42045 42045

15

10-32 X 1/2 PHIL FLAT M/S 2 59052

16 SLIP RING 5/8 INCH 2 20020HD 20020HD 20020HD

17 CENTER PHENOLIC WASHER 1 42026 42026 42026

18 BOTTOM PHENOLIC WASHER. 1 20054 20054 20054

19 STUD INSULATOR 1-3/32 IN 1 42029 42029 42029

20 TOP PHENOLIC WASHER 1 42025 42025 42025

21 STUD INSULATOR 5/8`` 1 42030 42030 42030

22 SET SCREW 1/4-20 X 2 1 42311 42311 42311

23 HEAD STUD 3 1/2 LG, BRASS 2 42032 42032 42032

24 HEX NUT #10-32 BRASS 4 42301 42301 42301

25 #10 INTERNAL TOOTH WASHER 4 12573 12573 12573

26 INSULATOR SLEEVE 1 42028 42028 42028

27 STUD INSULATOR 1-3/4`` 1 42037 42037 42037

3007 3007A 3007EX

Part Number

Page 22

gmpopcorn.com

Page 23

2

SCREW BRUSH SPRING

4

20052

20052

20052

8

BRUSH PAD

4

42035

42035

42035

9

MOTOR CASTING

1

42034

42034

42034

Motor Spacer Not Shown

Tornado SHO Model No. 3007, 3007A, 3007EX

Brush Assembly and Motor

2

3

1

8

4

5

Note: Motor is located in

the Motor Mount Casting

(see item 9 above)

P/N 67207 (3007EX Only)

7

6

9

10

Qty.Part DescriptionItem

1 BRUSH ASSEMBLY W/BRUSH 4 42320 42320 42320

3 SPRING BRUSH TENSION 4 20033 20033 20033

4 BRUSH HOLDER 4 20032 20032 20032

5 CARBON BRUSH 4 20034 20034 20034

6 BUSHING, SNAP .500 IN 4 47236 47236 47236

7 INSULATOR BRUSH HOLDER 4 48017 48017 48017

MOTOR, 1/3 HP 115VAC 1 48669

10

MOTOR, 1/2 HP 1 55013

MOTOR, 1/3 HP 230 VAC 1 48669EX

3007 3007A 3007EX

Part Number

Page 23

gmpopcorn.com

Page 24

3

FINGER GUARD

1

47200

47200

EXHAUST BLOWER 120V,60CY

TERMINAL BLOCK

HEAT CONTROL

VOLT METER

30 AMP TOGGLE SWITCH

CIRCUIT BREAKER 15 AMP

1

Tornado SHO Model No. 3007, 3007A, 3007EX

Unit Interior 3007, 3007A

10

2

3, 11

4

5

9

1 TRANSFORMER 1 43006 43006

2 RELAY, 30A DPST 120V 55219 55219

4

5

6

7

8 3 POSITION TOGGLE SWITCH - Heat Switch 1 43142 43142

9

10

11 BLOWER PLUG AND CORD 1 47199 47199

8 6

7

Qty.Part DescriptionItem

1 48018 48018

1 42006 42006

1 42020 42020

1 43009 43009

1 43141 43141

1 47364 47364

Part Number

3007 3007A

Page 24

gmpopcorn.com

Page 25

2

FINGER GUARD

1

47200

7

Tornado SHO Model No. 3007, 3007A, 3007EX

Unit Interior 3007EX (Export)

1 3, 11 2

4

5

6

10

9

8

Part No.

Qty.Part DescriptionItem

3007EX

1 TRANSFORMER 1 43011

3 EXHAUST BLOWER 220V, 50CY 1 48037

4 FILTER, EMI 20 AMP 1 48695

5 3uF 250 VAC CAPACITOR 1 55527

6 TERMINAL BLOCK 1 42006

7 HEAT CONTROL, VARI 220V 1 43010

8 VOLT METER 220V 1 48034

9 3 POSITION TOGGLE SWITCH (Heat Switch) 1 43142

10 30 AMP TOGGLE SWITCH 1 43141

11 BLOWER PLUG AND CORD 1 47199

Page 25

gmpopcorn.com

Page 26

3007

3007A

3007EX

3

FLOSS STABILIZER (Web)

1

43032

43032

43032

3007

3007A

1

RECPT POWER SUPPLY

1

47211

47211

Tornado SHO Model No. 3007, 3007A, 3007EX

Floss Pan and Whirlgrip Stabilizer

1

3

2

4

1 FLOSS PAN 1 42040 42040 42040

WHIRLGRIP STABILIZER (Includes Floss

2

Stabilizer and Clips)

4 WHIRLGRIP CLIPS 6 77470 77470 77470

Accessories – Model 3007, 3007A

Qty.Part DescriptionItem

1 3010 3010 30120

Part Number

1

2

Qty.Part DescriptionItem

2 RECPT COVER 1 47377 47377

Part Number

Page 26

gmpopcorn.com

Page 27

Tornado SHO Model No. 3007, 3007A, 3007EX

WIRING DIAGRAMS

Model No. 3007

Page 27

gmpopcorn.com

Page 28

Tornado SHO Model No. 3007, 3007A, 3007EX

Model No. 3007A

Page 28

gmpopcorn.com

Page 29

Tornado SHO Model No. 3007, 3007A, 3007EX

Model No. 3007EX (Export)

Page 29

gmpopcorn.com

Page 30

Tornado SHO Model No. 3007, 3007A, 3007EX

WARRANTY

Gold Medal Products Co. warrants to the original purchaser each item of its manufacture to

be free of defects in workmanship and material under normal use and service. Gold Medal

Products Co.’s obligation under this warranty is limited solely to repairing or replacing parts,

f.o.b. Cincinnati, Ohio, which in its judgment are defective in workmanship or material and

which are returned, freight prepaid, to its Cincinnati, Ohio factory or other designated point.

Except for “Perishable Parts” on specific machines, the above warranty applies for a period

of two (2) years from the date of original sale to the original purchaser of equipment when

recommended operating instructions and maintenance procedures have been followed. These

are packed with the machine. Parts warranty is two (2) years, labor is six (6) months.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR

IMPLIED, AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON OUR PART,

INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY. THERE ARE

NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

HEREOF. In no event shall Gold Medal Products Co. be liable for special, incidental or

consequential damages. No claim under this warranty will be honored if the equipment covered

has been misused, neglected, damaged in transit, or has been tampered with or changed in any

way. No claim under this warranty shall be honored in the event that components in the unit at

the time of the claim were not supplied or approved by Gold Medal Products Co. This warranty

is effective only when electrical items have been properly attached to city utility lines only at

proper voltages. This warranty is not transferable without the written consent of Gold Medal

Products Co.

The term “Original Purchaser” as used in this warranty shall be deemed to mean that person,

firm, association, or corporation who was billed by the GOLD MEDAL PRODUCTS CO.,

or their authorized distributor for the equipment.

THIS WARRANTY HAS NO EFFECT AND IS VOID UNLESS THE ORIGINAL

PURCHASER FIRST CALLS GOLD MEDAL PRODUCTS CO. AT 1-800-543-0862 TO

DISCUSS WITH OUR SERVICE REPRESENTATIVE THE EQUIPMENT PROBLEM,

AND, IF NECESSARY, FOR INSTRUCTIONS CONCERNING THE REPAIR OR

REPLACEMENT OF PARTS.

NOTE: This equipment is manufactured and sold for commercial use only.

10700 Medallion Drive, Cincinnati, Ohio 45241-4807 USA

gmpopcorn.com

Phone: (800) 543-0862 Fax: (800) 542-1496

(513) 769-7676 (513) 769-8500

© 2018 – The text, descriptions, graphics, layout, and other material in this publication are the exclusive property of

Gold Medal Products Co. and shall not be used, copied, reproduced, or published in any fashion, including website

display, without its express written consent.

Page 30

gmpopcorn.com

Loading...

Loading...