Page 1

ShaveMaster II

Block Ice Shaver

Instruction Manual

Model #1005

Part No. 12354

Revised June 1996

Cincinnati, OH 45241-4807 USA

Page 2

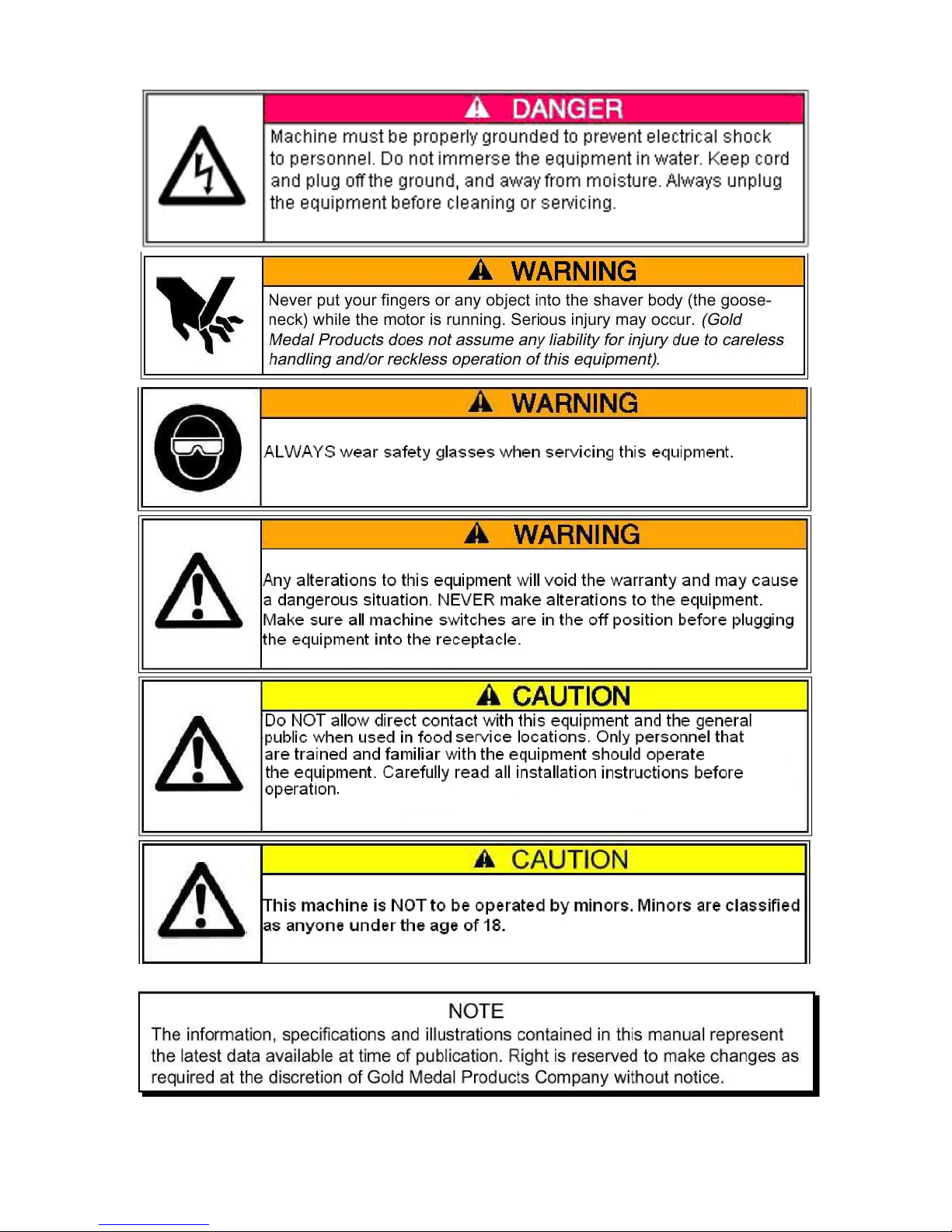

SAFETY PRECAUTIONS

Page 3

ShaveMaster II

HOW TO OPERATE THE SHAVEMASTER II

MAIN SHAFT

Rotates when motor is "ON".

Keep fingers away.

Step 1: LOCKING KNOB

Pull and turn to "unlock"

main shaft. Be sure the

motor is "OFF".

Step 4: SHA VING

PRESSURE KNOB

Rotate clockwise "finger

tight" to put pressure on

the ice block.

Step 5: BLADE FINENESS

KNOB

Rotate to minimum

shaving height for

fine snow.

Step 2: HAND WHEEL

for main shaft.

Rotate to maintain

height.

Step 3: ICE COMP ARTMENT

FRONT DOOR LA TC H

Open door latch and place

block of ice in center, then

close and relatch door.

Step 7: ON–OFF SWITCH

Now start shaving

process here or by using

#1008 Foot Switch.

Step 6: HAW AIIAN ICE CUP

Hold Hawaiian Ice Cup an

inch or two below shaved

ice discharge area then

"shape" by hand. Always

wear food handler gloves.

1

MODEL #1005

Page 4

ShaveMaster II

SPECIFICATIONS

Dimensions: 28" High x 11" Wide x 20" Deep

Shipping Weight: 83 Lbs.

Electrical Requirement: 120 Volts, 60 Hz, 4.7 Amps, 1 Phase

Shaving Capacity: 4.4 – 5.5 Lbs./Min.

RPM: 250 rpm

Shaving Plate Diameter: 9 ¾"

Ice Block Capacity: 6" x 6" x 5 ½"

Accessories: Ice Mold with Lid, Ice Pick, Drain Tray, Food Approved Gear Lube

Optional Accessories: Foot Switch, Plastic Ice Pan

OPERATING INSTRUCTIONS

1. Make sure the machine is installed on a sturdy, level and waterproof surface.

2. Do not use the ice block directly from the freezer; the shaved ice will not be fluffy and can

cause excessive wear to your blade. Allow ice to soften ½ hour prior to shaving.

3. Pull and turn the main shaft locking knob so that you can raise the main shaft by turning the

handwheel. Once the ice block holder is raised upward, return the locking knob to the "LOCK"

position.

4. Open the front shield by releasing the safety latch and pulling forward.

5. Place a square or cylindrical ice block on the shaving platter, centering the block.

6. Place the locking knob to the free position and lower the main shaft by turning the hand wheel

until the spikes are imbedded in the ice.

7. Close the front shield (make sure the main power switch is turned "OFF") and reattach the

safety latch, locking the front and rear shields together.

8. Turn the Shaving Pressure Knob clockwise until it comes to a stop.

9. Turn "ON" the main power switch. The motor will not run if the front shield is open or not

properly closed.

10. Slowly turn the knob, located below the shaving platter, until you get the fineness of shaved

ice you desire.

SHAVING PRESSURE KNOB (located on front of machine)

1. This knob adjusts the amount of pressure which is applied downward onto the block of ice.

Turning the knob clockwise will increase the amount of shaved ice produced and will vary

the texture from very fine to coarse as the pressure is being applied.

2. When you need to raise and lower the main shaft, release the pressure by turning the

knob counterclockwise.

SHAVING TEXTURE KNOB (located on the underside of the blade platter)

1. Lower the shaver blade before adding the block of ice to the shaving platter. If the blade is

too high it could accidentally release the block out of the holder.

2. For coarse shaved ice, turn the knob clockwise. For finer shaved ice, turn the knob

counterclockwise.

2

MODEL #1005

Page 5

ShaveMaster II

ICE BLOCK FREEZING SUGGESTIONS

1. Use Gold Medal's plastic Ice Mold with Lid (Part No. 1085) to freeze blocks of ice.

2. Fill the container with cool tap water to a ½" from the top rim of the container.

3. Firmly press the lid onto the container until the lid snaps shut.

4. Set your frezer to a temperature range of 10-15º F. Fill your freezer with as many ice

molds as possible by stacking one on another. This will slow down the freezing process

and prevent cracking.

5. Let the water freeze completely for approximately 24-30 hours for best shaving results.

6. After the water has frozen, remove the block from the plastic container and place it into

Gold Medal clear bags (Part No. 3064) so you can use the ice mold container to freeze

more ice.

CLEANING INSTRUCTIONS

Wipe the exterior of the machine with a soft cloth that has been dipped into a mixture of mild dish

detergent and warm water. Remove excess water or soap spots with a soft cloth.

CLEANING THE INTERIOR OF THE SHAVING CHAMBER

1. Open the front shield of the shaving chamber and remove the shield by lifting it upward.

2. Raise the main shaft by rotating the handwheel. Turn and pull the locking knob until the main

shaft is held in the raised position.

3. Remove the (2) wing bolts on the underside of the shaving platter. Raise the shaving platter

and remove it from its holder.

4. Dismantle the blade assembly by unscrewing the (2) blade fastening screws which will

allow you to remove the blade and blade holder.

5. Remove the shaving texture knob from the threaded shaft.

6. Unscrew the (2) screws fastening the blade assembly to the shaving platter and remove the

remaining parts.

7. Dismantle all of the blade assembly parts. Wash the parts in a mild detergent and water

solution. Towel dry all of the items after rinsing off the soap.

8. Reassemble the unit in reverse order.

3

MODEL #1005

Page 6

ShaveMaster II

MAINTENANCE INSTRUCTIONS

THE FOLLOWING SECTIONS OF THIS MANUAL ARE INTENDED ONLY FOR QUALIFIED SERVICE PERSONNEL WHO

ARE FAMILIAR WITH ELECTRICAL EQUIPMENT. THESE ARE

NOT INTENDED FOR THE OPERATOR.

Adequate eye protection must be used when servicing this

equipment to prevent the possibility of injury.

Do NOT immerse the equipment in water.

Unplug your machine before servicing.

OILING THE MAIN DRIVE SHAFT AND CRANK

1. The main shaft must be kept lubricated at all times with Gold Medal food approved Gear

Lube (Part No. 1110). Do NOT use vegetable oil for lubrication; as the oil hardens, it will

prevent the main shaft from rotating.

2. Completely raise the main shaft and apply the supplied tube of food approved gear lube to

the teeth of the shaft. Apply oil to the center of the shaft with one small pass.

3. To oil the crank, remove the plastic dome and oil through the two small oiling holes located

on the top section of the casting. This will allow the handwheel shaft to rotate easily.

REPLACING WORN SHAVER BLADE

1. Remove the (2) wing bolts fastening the shaving platter to the mount casting. Remove the

platter from the mount casting and place it on a clean, level surface, flat side down.

2. Loosen the two screws fastening the shaver blade to the blade holder until the blade slips

out; remove the blade.

3. Turn the blade height adjustment knob so that the blade holder is in the lowest position.

Turn the knob back one full turn so the blade will go below the surface when completely

lowered.

4. Install new or re-sharpened blade exactly the same direction it was removed.

5. Blade should be installed with an even amount of space between the blade and groove.

6. Firmly tighten the two screws holding the clamp to the blade.

7. Place the blade platter back on the mount casting with the blade facing frontward.

8. Replace the (2) wing bolts, tighten firmly.

4

MODEL #1005

Page 7

ShaveMaster II

ASSEMBLING THE BLADE COMPONENTS AFTER CLEANING OR,

ADJUSTING BLADE IF MACHINE DOES NOT SHAVE.

1. Remove the (2) ¼-20 Thumb Screws from the underside of the Shaving Platter.

2. Remove the Shaving Platter from Support Casting and place it on a smooth flat surface

preferably a table or counter top.

3. Turn the “Blade Adjustment” knob clockwise until the knob is fully tightened.

4. Turn the knob back counter-clockwise a ½ revolution.

5. With a screwdriver, loosen the (4) ¼-20 slotted/knurled screws holding the Blade Clamp

and Shaving Base.

6. Let the Shaving Blade rest on your table or counter as you adjust it for straightness.

7. Before you tighten the (2) ¼-20 slotted/knurled screws which fastens the Shaving Base to

the Shaving Platter, make sure that the gap between the blade and rectangular slot in the

Platter is approximately 1/8” the entire length of the blade.

8. Firmly tighten the (2) screws for the shaving Base.

9. Before you tighten the Blade Clamp screws, make sure that the Blade is touching the table

top and is straight in the rectangular slot. Tighten the (2) screws with your screw driver.

10. Make sure all screws are securely tightened before placing it back on the machine.

11. Place the Shaving Platter back on the Support Casting, replacing the two thumb screws.

Exploded View

Maintain even blade spacing. Assemble on flat surface.

The blade is

extremely

sharp!

Note orientation of blade prior to installation.

5

MODEL #1005

Page 8

PROBLEMS CAUSES SOLUTIONS

Main shaft fails to turn with main

power switch on.

TROUBLESHOOTING

Cord not properly plugged in.

Broken power cord.

Motor drive belt broken. Replace worn belt.

Front shield is open. Close front shield and latch.

ShaveMaster II

Plug cord into properly.

Replace power cord.

Lower blade with adjustment

knob.

Remove shaving platter and

readjust blade height evenly.

Lower clamp down with force.

Turn ice block over to flat side.

Turn the shaving pressure knob

clockwise.

Turn the shaving pressure knob

counterclockwise.

Ease the tension by turning the

shaving pressure knob

counterclockwise.

Ice block jumps out of clamp.

Shaved ice is too fine.

Shaved ice is too coarse.

Very hard to raise and lower the main

drive shaft with the handwheel.

Blade is raised too high.

Blade is higher near center

than outside of platter.

Spikes not firmly embedded in

the ice block.

Shaver blade is too low. Raise blade into ice with knob.

Tension adjustment of brake

is too weak.

Shaver blade is too high. Lower blade from ice with knob.

Tension adjustment of brake

is too strong.

Blade is dull. Replace or sharpen blade.

Brake tension is too tight.

ORDERING SPARE PARTS

1.Identify the desired part by checking it against the photos, illustrations, and/or the parts list.

2.When ordering, please include part number, part name, and quantity desired.

3.Please include your model name and machine serial number (located on the machine

nameplate) with your order.

4.Address all parts orders to:

Parts Department

Gold Medal Products Co.

10700 Medallion Drive

Cincinnati, Ohio 45241-4807

or, place orders at:

(513) 769-7676

Fax: (513) 769-8500

E-mail: goldme19@eos.net

6

MODEL #1005

Page 9

SHAVEMASTER II ASSEMBLY

ShaveMaster II

7

MODEL #1005

Page 10

PARTS LIST – SHAVEMASTER II ASSEMBLY

Item No. Part No. Description

1 12115 Rocker Switch, SPST

2 12302 Bellow, Gear Protector

3 12305 Upper Mount Casting

4 12306 Gear Housing

5 12308 Brake Shoe

6 12309 Blade Platter

7 12310 Blade Holder

8 12399 Pivot Bracket, Blade

9 12312 Blade Mount

10 12313 Shield Holder, Casting

11 12314 Base Casting

12 12315 Platter Mount, Casting

13 12317 Drain Pan, Plastic

14 12318 Shaft, Brake Adjustment

15 12320 Cap, Main Shaft

16 12321 Main Drive Shaft

17 12322 Ice Block Clamp

18 12324 Cover, Safety Switch

19 12325 Top Cover, Dome

20 12326 Shield, Front, Assembly

21 12327 Shield, Rear, Assembly

22 12328 Shaver Blade

23 12332 Shaft, Blade Pivot

24 12333 Knob, Blade Pivot

25 12334 Dome Support Bracket

26 12335 Motor Mount Plate

27 12339 Sheave, Small

28 12340 V-belt

29 12342 Retainer Plate, Bellows

30 12343 Rear Cover

31 12345 Spring, Brake Tension

32 12347 Spring, Blade Pivot

33 12348 Knob, Shaving

34 12349 Hand Wheel

35 12350 Clamp, Bellows (2)

ShaveMaster II

8

MODEL #1005

Page 11

ShaveMaster II

PARTS LIST – SHAVEMASTER II ASSEMBLY (continued

Item No. Part No. Description

36 12353 Tube Spacer

37 12357 Worm Gear Assembly

12329 Worm Gear

38 12359 Gear Lock Assembly

39 12360 Switch, Door Safety

40 12361 Bracket, Safety Switch

41 12364 Knob, Brake Adjustment

42 12365 Hinge Mt, Plate Assembly

43 12368 Knob, Hand Wheel

44 12369 Tube, Hand Wheel Pivot

45 12370 Decal, Front Cover

46 12371 Large Sheave Assembly

47 12377 Main Wrapper, Stainless Steel

48 12390 Decal, Warning

49 12391 Drain Hose

50 12394 Retainer Assembly

51 22038 Lead-in cord

52 39022 Drive Motor, 120V

53 40488 Foot, Plastic

54 49138 Hinge, Left Female

55 49141 Hinge, Left Male

56 12380 Thumb Screw

57 12319 Knob, Shaft Lock

58 12425 Bearing Holder Assembly

1110 Tube Petrogel

22020 Ice Pick

1085 Ice Mold with Lid

12430 Decal, Rear Cover

)

9

MODEL #1005

Page 12

ELECTRICAL SCHEMATIC

ShaveMaster II

10

MODEL #1005

Page 13

WARRANTY

WE WARRANT to the original purchaser the Gold Medal equipment sold by us to

be free from defects in material or workmanship under normal use and service. Our

obligation under this warranty shall be limited to the repair or replacement of any

defective part for a period of six (6) months from the date of sale to the Original

Purchaser with regard to labor and two (2) years with regard to parts and does not

cover damage to the equipment caused by accident, alteration, improper use, voltage, abuse, or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED

OR IMPLIED, AND OF ALL OTHER OBLIGA TIONS OR LIABILITIES ON OUR

PART, INCLUDING THE IMPLIED WARRANTY OF MERCHANTIBILITY.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE F ACE HEREOF. W e neither assume, nor authorize any other person

to assume for us, any other obligation or liability in connection with the sale of said

GOLD MEDAL equipment or any part thereof.

The term “Original Purchaser” as used in this warranty shall be deemed to mean that

person, firm, association, or corporation who was billed by the GOLD MEDAL

PRODUCTS COMPANY, or their authorized distributor for the equipment.

THIS WARRANTY HAS NO EFFECT AND IS VOID UNLESS THE ORIGINAL

PURCHASER FIRST CALLS GOLD MEDAL PRODUCTS COMP ANY AT 1-800428-2676 TO DISCUSS WITH OUR SERVICE REPRESENT ATIVE THE EQUIPMENT PROBLEM, AND, IF NECESSARY, FOR INSTRUCTIONS CONCERNING THE REPAIR OR REPLACEMENT OF P ARTS.

NOTE: This equipment is manufactured and sold for commercial use only.

GOLD MEDAL PRODUCTS COMPANY

10700 Medallion Drive

Cincinnati, OH 45241-4807 USA

Loading...

Loading...