Page 1

© 2019 Gold Medal Products Co.

Part No. 110241

Instruction Manual

10700 Medallion Drive, Cincinnati, Ohio 45241-4807 USA

PopClean® Elite PopperTM

-600 Series (Touch Screen Control)

For -6XX Series PopClean Models beginning with:

2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

72” Updraft Model

72” Downdraft Model

Page 2

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 2

gmpopcorn.com

Table of Contents

SAFETY PRECAUTIONS .................................................................................................................................................... 3

INSTALLATION INSTRUCTIONS .................................................................................................................................... 5

Inspection of Shipment ................................................................................................................................................................................. 5

Manual .................................................................................................................................................................................................................. 5

Model Description ........................................................................................................................................................................................... 6

Items Included with this Unit .................................................................................................................................................................... 7

Setup ..................................................................................................................................................................................................................... 8

Chute Installation .......................................................................................................................................................................................... 10

Electrical Requirements ............................................................................................................................................................................. 11

Fire Suppression System (some Exports excluded) .................................................................................... 14

System Operation and Maintenance ..................................................................................................................................................... 14

Connecting to a Building Alarm System .............................................................................................................................................. 15

Components for the Fire Suppression System ................................................................................................................................. 16

Nozzle and Fusible Link Locations ........................................................................................................................................................ 17

Filter System ............................................................................................................................................................... 19

Filter Types ...................................................................................................................................................................................................... 19

Filter System Error Code Explanation Table .................................................................................................................................... 20

Updraft Filters ................................................................................................................................................................................................ 22

Downdraft Filters .......................................................................................................................................................................................... 23

OPERATING INSTRUCTIONS ....................................................................................................................................... 24

Controls and Their Functions .................................................................................................................................................................. 24

Introduction to the Touch Screen Control ....................................................................................................... 25

Initial Startup – User Configuration ................................................................................................................... 28

QUICK Reference Popping Instructions ............................................................................................................ 31

EXPANDED Reference Popping Instructions .................................................................................................. 32

Navigating the Touch Screen Control ................................................................................................................ 35

N1 Cook (Recipe Selection) ...................................................................................................................................................................... 36

N2 Training ...................................................................................................................................................................................................... 38

N3 Cleaning/ Oil Pump ............................................................................................................................................................................... 38

N4 Reports ....................................................................................................................................................................................................... 39

N5 Home Screen ............................................................................................................................................................................................ 39

N6 Equipment Controls Screen ............................................................................................................................................................... 40

N7 Settings Screen ........................................................................................................................................................................................ 42

N7.1 Oil Level Cal. ........................................................................................................................................................................................ 43

N7.2 Oil Pump Cal. ....................................................................................................................................................................................... 44

N7.3 Recipes ................................................................................................................................................................................................... 46

N7.4 Load Count Reset ............................................................................................................................................................................... 48

N7.5 Upload Recipes ................................................................................................................................................................................... 48

N7.6 Download Recipes .............................................................................................................................................................................. 49

N7.7 View Cook .............................................................................................................................................................................................. 49

N7.8 Upload Cook .......................................................................................................................................................................................... 50

N7.10 User Configuration .......................................................................................................................................................................... 50

N7.11 User Configuration .......................................................................................................................................................................... 52

Care and Cleaning ..................................................................................................................................................... 53

Troubleshooting ....................................................................................................................................................... 57

Error Code Explanation Table ................................................................................................................................................................. 57

General Unit Troubleshooting ................................................................................................................................................................. 59

AGITATOR SET COLLAR ADJUSTMENT ................................................................................................................... 62

ORDERING FILTERS AND ACCESSORIES ................................................................................................................. 63

WARRANTY ....................................................................................................................................................................... 65

Page 3

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 3

gmpopcorn.com

SAFETY PRECAUTIONS

DANGER

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

008_051514

DANGER

Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury, or death. Any alterations to this equipment

will void the warranty and may cause a dangerous condition. This appliance

is not intended to be operated by means of an external timer or separate

remote-control system. NEVER make alterations to this equipment. Read the

Installation, Operating, and Maintenance Instructions thoroughly before

installing, servicing, or operating this equipment.

014_020416

WARNING

To avoid burns, DO NOT touch the kettle or any heated surface.

DO NOT place or leave objects in contact with heated surfaces.

013_092414

WARNING

ALWAYS wear safety glasses when servicing this equipment.

010_010914

WARNING

No user serviceable parts inside. Refer servicing to qualified service

personnel.

011_051514

WARNING

Read and understand operator’s manual and all other safety instructions

before using this equipment. To order copies of the operator’s manual go to

gmpopcorn.com or write to Gold Medal Products Co., 10700 Medallion Drive,

Cincinnati, OH 45241 USA 1-(800)-543-0862

022_060215

Page 4

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 4

gmpopcorn.com

WARNING

DO NOT allow direct contact of this equipment by the public when used in

food service locations. Only personnel trained and experienced in the

equipment operation may operate this equipment.

Carefully read all instructions before operation.

012_010914

WARNING

This machine is NOT to be operated by minors.

007_010914

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

Note: Improvements are always being made to Gold Medal’s equipment. This information

may not be the latest available for your purposes. It is critical that you call Gold Medal’s

Technical Service Department at 1-800-543-0862 for any questions about your

machine operations, replacement parts, or any service questions. (Gold Medal

Products Co. does not assume any liability for injury due to careless handling and/or

reckless operation of this equipment.) General images may be used in manual for

reference only.

Page 5

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 5

gmpopcorn.com

INSTALLATION INSTRUCTIONS

Inspection of Shipment

After unpacking, check thoroughly for any damage which may have occurred in transit. Claims

should be filed immediately with the transportation company. The warranty does not cover

damage that occurs in transit, or damage caused by abuse, or consequential damage due to the

operation of this machine, since it is beyond our control (reference warranty in back of manual).

Manual

Instruction Manual (Part No. 110241) and Parts Manual (Part No. 110242) are provided with

each unit. The manuals cover -600 Series PopClean Elite Poppers beginning with the Model

Series shown below and features a Touch Screen Control Panel:

2011, 2848, 2860, 2872, and 2873 (for 32 oz. Pop-O-Golds)

2911, 2948, 2960, 2972, and 2973 (for 52 oz. Medallions)

The Instruction Manual contains initial setup, installation, and operating instructions for the unit.

Read and understand the Instruction Manual and all other safety instructions before using this

equipment. To order copies of the Instruction Manual (Part No. 110241) or Parts Manual (Part

No. 110242), go to gmpopcorn.com or write to Gold Medal Products Co., 10700 Medallion Drive,

Cincinnati, OH 45241 USA 1-(800)-543-0862.

The Parts Manual contains maintenance and spare parts information intended for qualified

service personnel only; it is not intended for the operator. Qualified service personnel must use

the Parts Manual in combination with the Instruction Manual when servicing the unit for all

installation, operating, cleaning, maintenance, and spare parts replacement information.

Keep the manuals accessible, local inspectors may need to reference the information when

inspecting the popper unit.

This manual covers units with a Touch Screen Control Panel

Page 6

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 6

gmpopcorn.com

Model Description

The Elite Series PopClean Popper has a uni-body, stainless steel construction, available as an

Updraft or Downdraft Model with either a 32 oz. or 52 oz. Kettle. The Updraft Model exhausts out

the top of the unit. The Downdraft Model exhausts through ductwork which extends down the

side of the unit and vents out a large exhaust door in the cabinet base.

Elite Series PopClean Poppers equipped with an automatic Fire Suppression System have a

manual pull station (some Exports exclude Fire Suppression System). Individual popper features

vary by model, thus images provided throughout the manual are for general overall model

reference only.

Other features and options:

• Touch Screen Control Panel.

o Butterfly or Mushroom Recipes – standard on all units.

o Salt/Sweet (pop in salt or sweet mode) – standard on all units.

o Ability to pop a large or small size batch of popcorn – standard on all units.

• Oil Dispense Unit option (B.I.B or Bucket Pump).

• Butterfly Corn Screen or Mushroom Corn Screen option.

• Sign option (LED or LED Neon) reversible from Front Counter (customer side) to Back

Counter (operator side) of popper.

• Deep Well (ability to adjust corn storage area) – standard on units over 36” (not

available on 36” units).

The 32 oz. and 52 oz. popper units are available in the sizes listed below. Twin Models have 2

kettles, a dual updraft system, and 2 linked Fire Suppression Systems (some Exports excluded).

32 oz. Kettle Model Series: 2011 (36”), 2848 (48”), 2860 (60”), 2872 (72”), 2873 (72” Twin)

52 oz. Kettle Model Series: 2911 (36”), 2948 (48”), 2960 (60”), 2972 (72”), 2973 (72” Twin)

Updraft Unit

Downdraft Unit

Exhaust duct

on side of unit.

Exhaust vents out

cabinet base.

Exhaust vents

out top of unit.

Page 7

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 7

gmpopcorn.com

Items Included with this Unit

29.6 cc Flavacol

Measure (PN 47681)

Incl. with 32 oz. units,

and 52 oz. units for

Flexi-Pop.

32 oz. Corn Cup

(PN 67905-32)

Incl. with 32 oz. units,

and 52 oz. units for

Flexi-Pop.

18 oz. Corn Cup

(PN 67905-18)

Incl. with 32 oz. units

for Flexi-Pop.

52 oz. Corn Cup

(PN 17757-52)

Incl. with 52 oz.

units only.

Tube Brush (PN 47380)

Flavacol Container

(PN 41752)

1/4 Cup Flavacol

Measure (PN 47169)

Incl. with 52 oz. units.

Jet Scoop

(PN 2072)

50 AMP Receptacle

(PN 82920)

Receptacle Cover

(PN 82922)

Receptacle and Cover included

with Domestic units ONLY.

Page 8

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 8

gmpopcorn.com

Setup

The Elite Series PopClean popper has been adjusted, inspected, and tested at the factory. The

Kettle is hard wired in the unit, and the exhaust filters are pre-installed and ready for use.

Installation of popper should be performed by qualified service personnel. Read and perform all

Setup steps prior to operating the unit.

1. Remove all packaging and tape.

2. Install unit on a level surface. Sufficient clearance is needed on the side of the popper

with the power supply cord routed from the base.

Units WITH Fire Suppression: A minimum 18” (457.2 mm) clearance is required

between any opening or exhaust duct and a combustible surface, per NFPA 96

Version 2017.

Units WITHOUT Fire Suppression: The Popper must be installed with a minimum 6”

(152.4 mm) clearance to combustible surfaces on the operator’s side and on

top of machine. Updraft models require a minimum of 13” (330.2 mm)

clearance on top of unit for filter access (or appropriate space for popper unit to

be moved to access filters).

3. The unit is equipped with rolling casters. The two casters on the operator (controls)

side have a locking/unlocking feature.

4. The main power cord is located in the cabinet base. Domestic units have a wall

receptacle provided (Twin Models have 2 plugs and 2 receptacles). A secondary,

smaller power cord, located in the cabinet base, is provided for powering the oil

dispense unit (discussed in Step 7).

Before plugging in machine, have a certified electrician install the wall receptacle and

follow all requirements listed in the Electrical Requirements section of this manual.

Units WITHOUT Fire Suppression: Skip to Step 7.

Units WITH Fire Suppression:

With power to the unit, the popper will NOT operate until the ANSUL

system has been charged and activated by an ANSUL Certified

Representative. If connecting the system to the building alarm, see next step

prior to having the ANSUL system activated.

5. If the Fire Suppression System is to be connected to the building alarm, contact a

qualified alarm system technician to make the connection prior to having the Fire

Suppression System armed. (Reference Connecting to a Building Alarm System in the

Fire Suppression System section of this manual.)

6. Have an Ansul Certified Representative charge and activate the Fire Suppression

System (reference the Fire Suppression System section of this manual).

For a local representative, go to www.Ansul.com.

When system is activated, and the Power Switch is turned ON, the cabinet lighting and

sign will turn on. (The unit will not turn on if the fire suppression system is not activated.)

Note: As the popper unit is plugged in (when the Fire Suppression System is armed) a

distinct click can be heard as the Fire Suppression relay kicks in.

Page 9

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 9

gmpopcorn.com

7. The small power cord (6 pin Jones Plug) is the oil pump harness which supplies power

to the oil dispense unit. The load cell wire harness connects the oil level indicator on

the Touch Screen Control to the load cell sensor for the oil dispense unit.

8. To connect the oil dispense system to the popper, refer to the Bag-in-a-Box or Bucket

Pump Instruction Manual included with the unit. (Generally, poppers with a Bag-in-aBox option are shipped with the oil dispense unit pre-installed. Bucket Pump units are

shipped separately and must be installed during setup of the unit).

Note: Once popper installation is complete, and the oil dispense unit is attached, the

Oil Level (located on the digital display) can be calibrated. Reference Initial

Startup – User Configuration section of this manual.

9. Open the cabinet base and remove all accessory items from the pull out corn drawer.

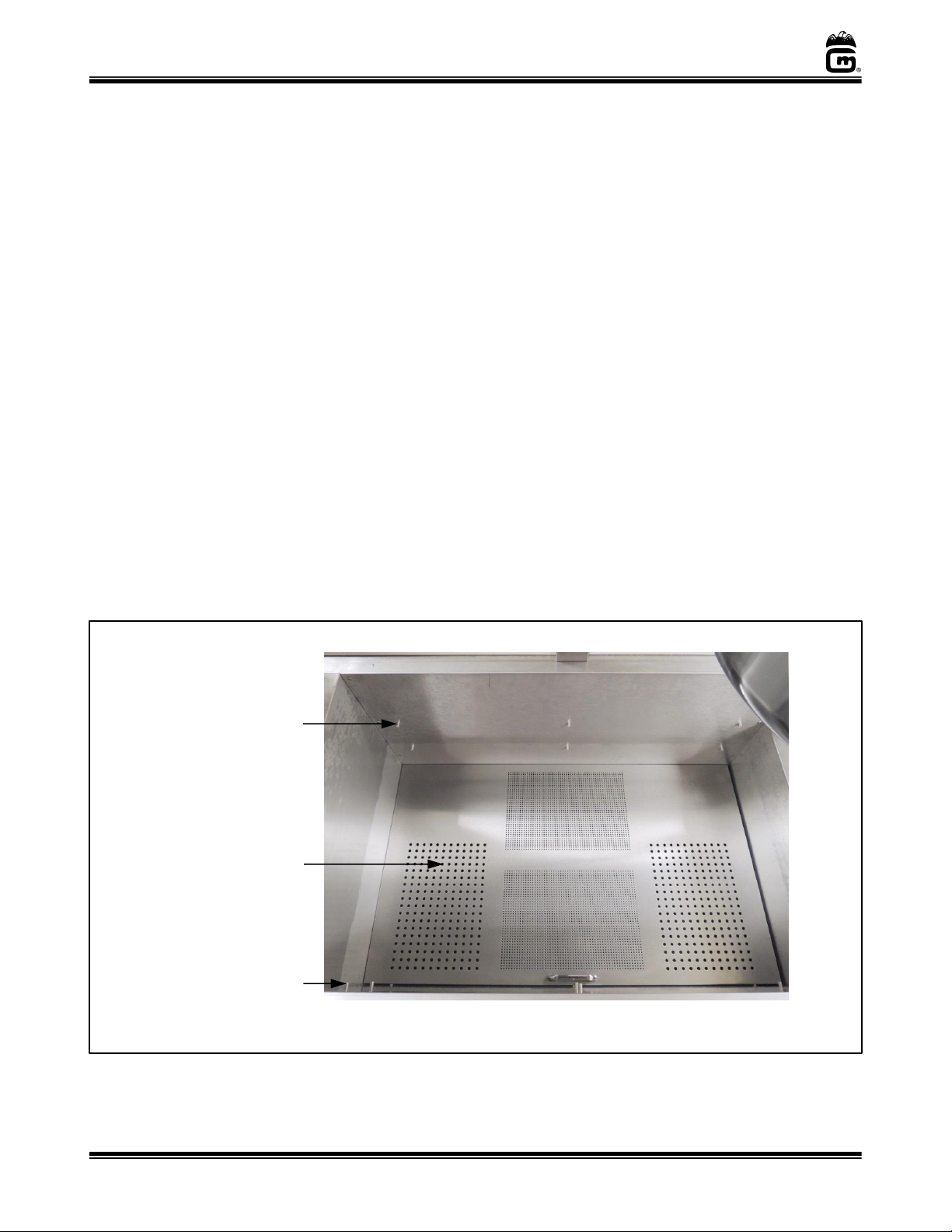

10. Units with a Deep Well (48”, 60”, 72” Models only): By default, the unit is shipped

from the factory with the corn pan in a deep well position. If needed, the corn pan may

be raised to an elevated position using the 3 front pins and the 3 back pins as a rest

(see image below).

11. Units with a RH or LH Chute Option: Reference next section for chute installation.

12. After setup, the unit should be cleaned. The kettle has a food grade protective coating

applied to the cooking surfaces, this coating must be removed prior to operating the

unit (see Care and Cleaning section of this manual).

Corn Pan

Deep Well Corn Bin View

3 Back Pins

Used to elevate the Corn Pan

for a shallower Corn Bin.

3 Front Pins

Used to elevate the Corn Pan

for a shallower Corn Bin.

Page 10

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 10

gmpopcorn.com

Chute Installation

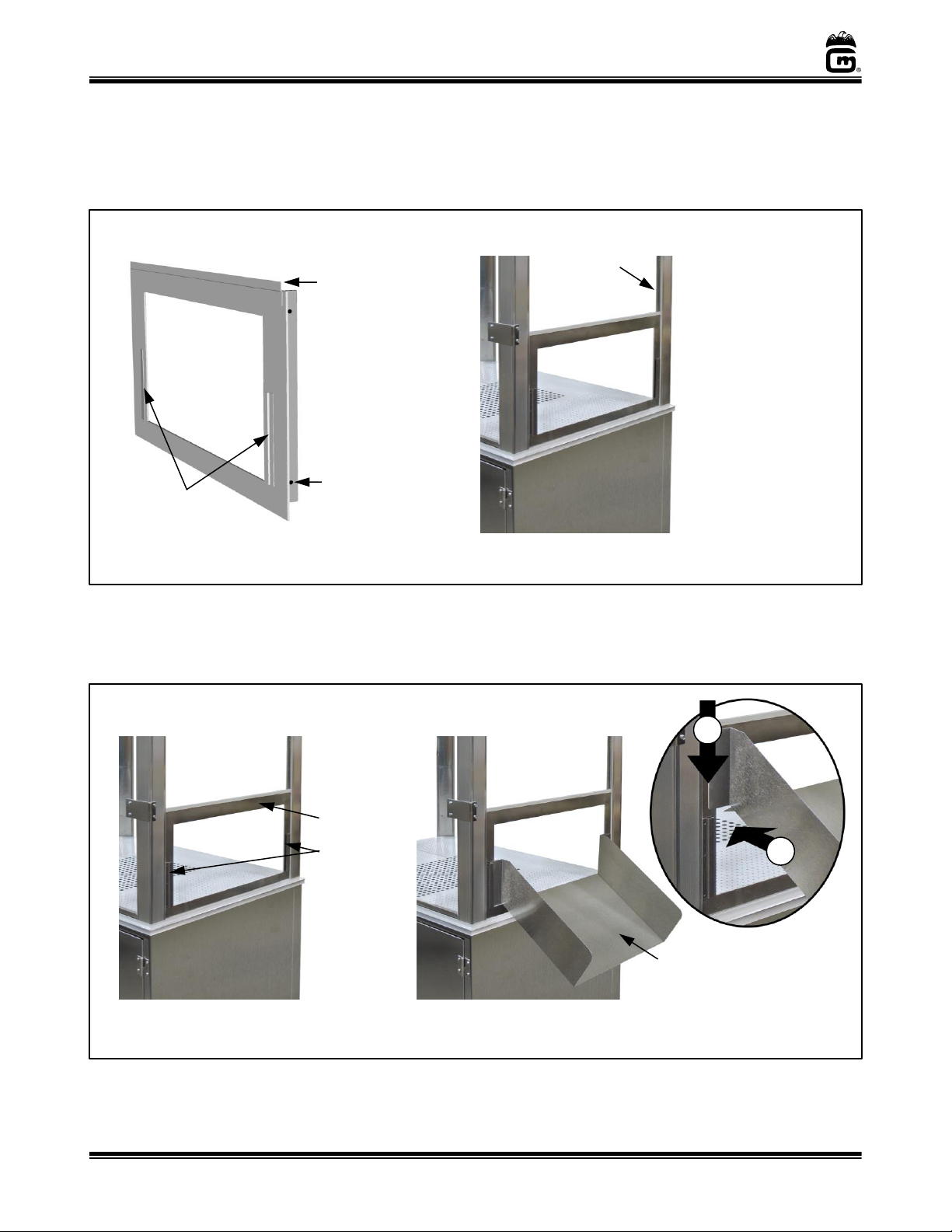

RH or LH Chute option - General RH images shown for installation reference only. Install Chute

Plate in popper cabinet (reference images below).

To install the Chute, position it in the plate opening as shown below, then slide the chute down

into the holding brackets. For use, have a holding bin in place to accept the popped corn from the

chute.

RH Chute shown

installed

Step 1: Position chute end into the side plate as shown.

Step 2: Slide Chute down into the brackets to install.

1

2

Chute Plate

Chute

Brackets

Chute Plate Installation

Chute Brackets

Top channel to

hold glass.

Use bracket holes

to mount Chute to

popper corner

posts.

Chute Plate View

To install Chute Plate:

Remove 2 corner post

screws on each side,

then reuse screws to

fasten the Chute Plate

in position as shown.

Corner Post

Chute Installation

Page 11

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 11

gmpopcorn.com

Electrical Requirements

Emissions listing for Updraft and Downdraft units:

Updraft: 3.6 mg particulates/cubic meter of exhaust air

Downdraft: 1 mg particulates/cubic meter of exhaust air

The following power supply must be provided:

Note: Twin Models have two kettles, a dual updraft system, and two linked fire

suppression systems (some Exports exclude Fire Suppression System). Two plugs,

one for each side of popper, are supplied with Twin Models (Domestic units

include two wall receptacles).

DOMESTIC UNITS: 120/208 or 120/240 V~, 60 Hz

(reference unit Data Plate for Wattage requirement)

Twin Models are supplied with two plugs, one for each side of popper.

Domestic units are designed to operate on single phase, 50 AMP, 4 wire supply, 120/208

or 120/240 V~ (2 Hot, 1 Neutral, 1 Ground). All electrical components in this machine are

120 V (motors, heat elements, lights, etc.) and therefore require “Hot to Neutral” connection

(NOT “Hot to Hot”). A 50 AMP wall receptacle (NEMA 14-50) is supplied with the machine.

The receptacle will accept the attachment plug on the machine and must be used; reference

the Receptacle Wiring Diagram for NEMA 14-50 for receptacle installation instructions.

EXPORT UNITS: 220-230 V~, 50/60 Hz (reference unit Data Plate for Wattage requirement)

Potential Electrical Variations: 220 V~, 60 Hz

Twin Models are supplied with two plugs, one for each side of popper.

Export units are designed to operate on single phase, 16 AMP, 4 wire supply, 230 V~

(2 Hot, 1 Neutral, 1 Ground). All electrical components in this machine are 230 V (motors,

heat elements, lights, etc.) and therefore require “Hot to Neutral” connection (NOT “Hot to

Hot”). A certified electrician must supply and install the wall receptacle for this unit;

reference the Receptacle Wiring Diagram for Export Units.

Australia - 52 oz. units are designed to operate on single phase, 36 AMP, 2 wire supply,

plus ground. All electrical components in machine are 230 V (motors, heat elements,

lights, etc.) A certified electrician must supply and install the wall receptacle for this unit.

DANGER

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

008_051514

A certified electrician must furnish sufficient power for proper machine operation and install any

supplied receptacle (reference unit Data Plate for model specific Volts AC, Hertz, and Wattage

Page 12

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 12

gmpopcorn.com

requirements). We recommend this equipment be on a dedicated and protected circuit. Failure

to wire properly will void the warranty and may result in damage to the machine. It is Gold Medal

Products Co.’s recommendation that this machine be plugged directly into a wall outlet. The use of

extension cords is not recommended due to safety concerns, and may cause sacrificed and/or

reduced performance. Make sure cord is located to prevent a trip hazard or unit upset.

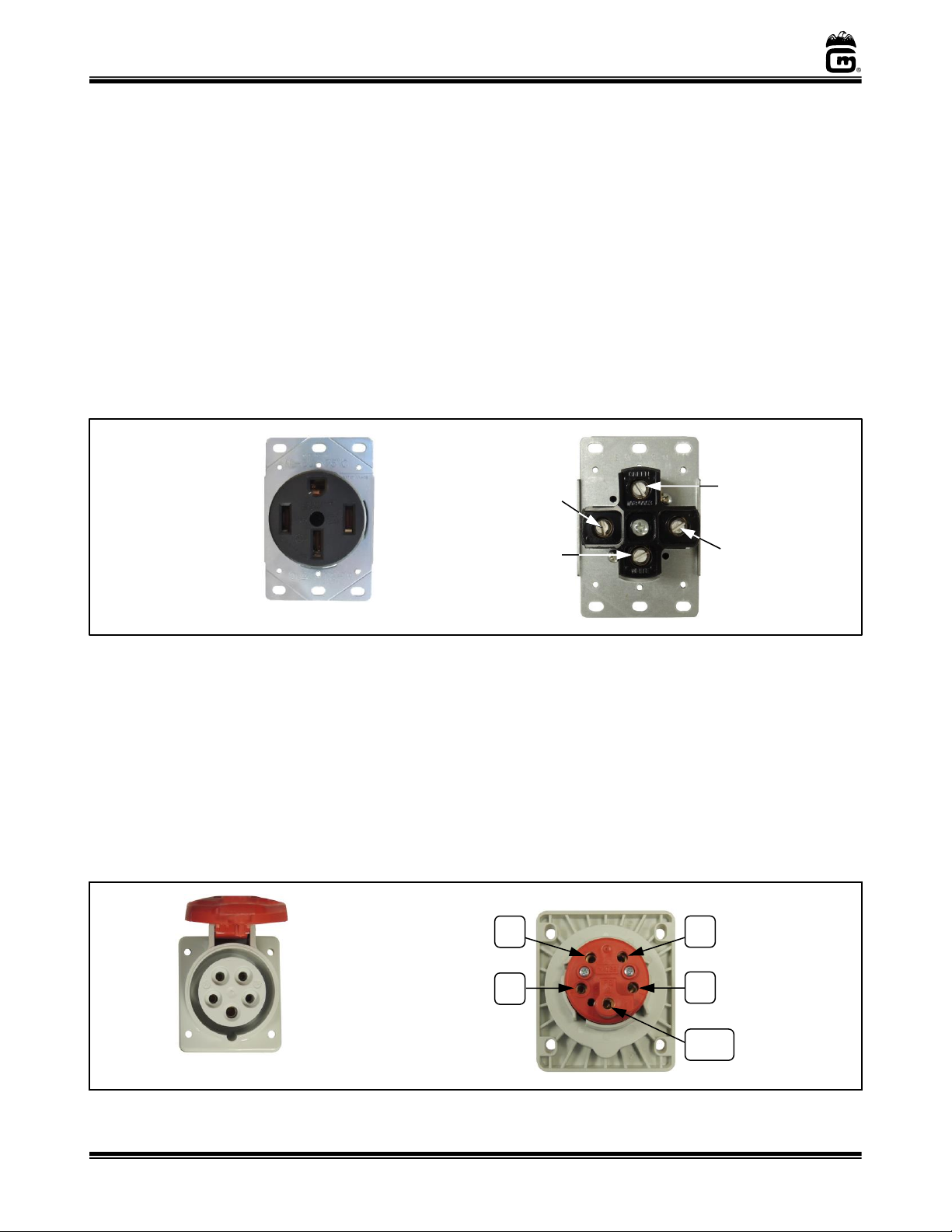

Receptacle Wiring Diagram for NEMA 14-50 (Domestic)

A certified electrician must follow the IMPORTANT instructions below for installation of the

NEMA 14-50 Receptacle (Gold Medal Item No. 82920) provided with the unit.

If the receptacle is wired incorrectly, the heat elements/kettle and other electrical components

could be at 208 or 240 V potential instead of the needed 120 V, resulting in excessive temperatures

in the heat elements (i.e.: kettle) and possible fire, and/or damage to electrical components.

Receptacle Wiring Diagram (for Export Units – except Australia)

A certified electrician must supply and install the required wall receptacle for this unit, follow

the IMPORTANT instructions shown.

This unit is designed to operate on single phase, 16 AMP, 4 wire supply. All electrical

components in this machine are 230 V. If the receptacle is wired incorrectly, the heat

elements/kettle and other electrical components could be at 400 V potential instead of the

needed 230 V, resulting in excessive temperatures in the heat elements (i.e.: kettle) and possible

fire, and/or damage to electrical components.

3P+N+E IEC 309 Receptacle - Front and Back View

PE-G

L2

L1

Connect to Black

(Hot) Wire

Connect to Brown

(Hot) Wire

Connect to

Green/Yellow

(Ground) Wire

Connect to Blue

(Neutral) Wire

L3

N

Not Used

(If 5 wires provided,

connect Grey here.)

NEMA 14-50 Receptacle - Front and Back View

Connect to Green

(Ground) Wire

Connect to Red

(Hot) Wire

Connect to Black

(Hot) Wire

Connect to White

(Neutral) Wire

Page 13

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 13

gmpopcorn.com

Before You Plug In Machine

1. Make sure all machine switches are OFF before plugging equipment into receptacle.

2. Make sure wall outlet can accept the grounded plugs (where applicable) on the power

supply cord.

3. The wall outlet must have the proper polarity. If in doubt, have a competent

electrician inspect the outlet and correct if necessary.

4. DO NOT use a grounded to un-grounded receptacle adapter (where applicable).

5. Install unit in a level position.

CAUTION

If the supply cord is damaged, it must be replaced by Gold Medal Products Co.,

its service agent or similarly qualified persons in order to avoid a hazard.

039_080614

Page 14

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 14

gmpopcorn.com

Fire Suppression System

(some Exports excluded)

Information in this section is intended for reference use by an Ansul Certified Representative ONLY,

for units equipped with a Fire Suppression System (some Exports exclude Fire Suppression System).

The Elite Series PopClean Poppers must be properly installed observing all minimum clearances

(reference Setup section) and have all electrical requirements met prior to the activation of the

Fire Suppression System (reference Electrical Requirements section). If the system is to be

connected to the building alarm, contact a qualified alarm system technician to make the

connection prior to having the Fire Suppression System activated (reference below Connecting

to a Building Alarm System).

The Elite Series Popper is equipped with an ANSUL R-102 Fire Suppression System. All

components are in accordance with the Ansul R-102 specifications and are tested and approved

by Intertek-ETL to U.L. Standard 710B.

The Fire Suppression System is fully assembled and a tank is provided for the liquid fire

suppressant agent, ANSULEX (the tank must be charged with agent by an Ansul Certified

Representative ONLY). The unit will not turn on if the Fire Suppression System is not activated.

As the popper unit is plugged in (when the Fire Suppression System is armed) a distinct click can

be heard as the Fire Suppression System relay kicks in.

Note: Machine will not operate until the Ansul System has been charged and

activated by an Ansul Certified Representative. For a local representative, go

to www.Ansul.com. If connecting to the building alarm system, this “tie-in”

must be made prior to activating the Fire Suppression System.

System Operation and Maintenance

In the event of a fire, the system will automatically activate the Fire Suppression System;

however, if the operator chooses, they can operate the system by pulling the manual pull. The

automatic system utilizes temperature rated fusible links found throughout the Fire Suppression

System. A link (or multiple links) will break in a fire and trigger the automatic Fire Suppression

System to deploy. These links must be inspected and/or serviced by an Ansul Certified

Representative ONLY.

Maintenance must be routinely performed on this system (and in the event of a fire), by an Ansul

Certified Representative; they will advise on the frequency of inspections required. The

representative will thoroughly inspect the entire Fire Suppression System, replace any needed

components, then recharge the system, and ensure it is operational. In the event the system has

been discharged, the Ansul Certified Representative will need to flush the pipes and reactivate

the system.

Page 15

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 15

gmpopcorn.com

Connecting to a Building Alarm System

The Fire Suppression System is equipped with the necessary components to be connected into

the building’s alarm system (optional). Have a qualified alarm system technician make the

connection. Once “tied in”, the building alarm will be activated if the Fire Suppression System is

triggered.

The alarm system connections are located in the fire suppression components compartment in

the base of the popper. To access this compartment, remove the oil dispense unit, then remove

the cover plate to view the limit switches. The left limit switch is for the popper, the right switch

is for wiring the building alarm (optional). Once the alarm connection is complete, the unit can

be charged and activated.

Limit Switch

for Popper

Connecting to a Building Alarm

Limit Switch for Building

Alarm Connection

Normally

Closed

Normally

Open

Common

Limit Switch Side View

Fire Suppression Components

Compartment – Interior View

CO2 Cartridge

Interlock Switch

(this switch is not

used)

Page 16

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 16

gmpopcorn.com

Components for the Fire Suppression System

The following information is intended for reference use by an Ansul Certified Representative ONLY.

Spray Nozzles – Two types used (1N and 2W). Nozzles located near the kettle, in filter system,

and near oil dispense unit. Reference Nozzle and Fusible Link Locations section for

individual nozzle type and location on either an Updraft or Downdraft Model.

1N Spray Nozzle (Gold Medal Part No. 62001; Ansul Part No. 419346)

2W Spray Nozzle (Gold Medal Part No. 62786; Ansul Part No. 439840)

All nozzles must be equipped with a blow off cap to protect the spray opening (Gold

Medal Part No. 62004; Ansul Part No. 433208). Cap should be kept on nozzle at all times,

unless forced off during a system deployment.

280°F High Temperature Fusible Link (Gold Medal Part No. 62064; Ansul Part No. 439087) -

Reference Nozzle and Fusible Link Locations section for individual link location on either

an Updraft or Downdraft Model.

Updraft Models (single kettle) – 2 high temperature links used (one for the kettle)

Updraft Models (twin kettle) – 3 high temperature links used (one for each kettle)

Downdraft Models (single kettle) – 3 high temperature links used (one for the kettle)

3 Gallon Tank (Gold Medal Part No. 62513; Ansul Part No. 429862) – Agent tank is located in

the fire suppression component’s compartment, behind the oil dispense unit in the cabinet

base. To open compartment, remove the oil dispense unit, then remove the access panel.

CO2 Cartridges

Ansul Part No. 101-20 is the CO2 cartridge used on single kettle, Elite Series Poppers.

Ansul Part No. 101-30 is the CO2 cartridge used on twin kettle, Elite Series Poppers.

Manual Pull Station – (Gold Medal Part No. 62009; Ansul Part No. 434618)

Page 17

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 17

gmpopcorn.com

Nozzle and Fusible Link Locations

Each Updraft and Downdraft PopClean Popper is equipped with spray nozzles and temperature

rated fusible links located throughout the Fire Suppression System. This section describes the

nozzle and link types and locations on Updraft and Downdraft Models.

280°F Fusible Link

High temperature rated link

for first response to a kettle

fire (one for each kettle).

Fire Damper

In the event of a fire in the blower compartment,

the Fire Damper will close to prevent flames

from escaping the unit.

Updraft Models – Spray Nozzle and Fusible Link Locations

Updraft units have 2 Fusible Links (3 Fusible Links on Twin Models) and 5 Spray Nozzles (9 Spray

Nozzles on Twin Models).

2W Spray Nozzle

(two nozzles used

for each kettle)

2W Spray Nozzle

2W Spray

Nozzle

Link

1

Link

2

280°F Fusible Link

High temperature rated

link (located in cabinet

base) for oil supply fire

detection. To access,

remove oil dispense unit.

1N Spray Nozzle

Page 18

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 18

gmpopcorn.com

Downdraft Models – Spray Nozzle and Fusible Link Locations

Downdraft units have 3 Fusible Links and 6 Spray Nozzles.

280°F Fusible Link

High temperature rated

link for first response

to a kettle fire (located

above kettle).

2W Spray Nozzle

(two nozzles used

for kettle)

2W Spray Nozzles

2W Spray

Nozzle

280°F Fusible Link

High temperature rated link

(located in ductwork) for filtration

system fire detection. To access,

remove the Baffle Filter.

Link

1

Link

2

280°F Fusible Link

High temperature rated

link (located in cabinet

base) for oil supply fire

detection. To access,

remove oil dispense

unit.

Fire Damper

In the event of a fire in the blower

compartment, the Fire Damper

will close to prevent flames from

escaping the unit. To access, open

the vented panel door.

1N Spray Nozzle

Link

3

Page 19

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 19

gmpopcorn.com

Filter System

The popper is equipped with an efficient 3 stage filtration system. All filters must be installed

correctly, the filter door must be closed, and NO filter system errors shown on the display for the

Filter System and Kettle Heat to operate.

Note: Unit has a Filter Timeout feature which automatically shuts the Filter System off

after an allotted period of idle time (no popcorn popped). Default timeout is 15

minutes (to adjust the timeout setting, refer to Navigating the Touch Screen

Control section N7.10 User Configuration).

Each filter and the filter door have a corresponding interlock switch which must be engaged for

the kettle to heat. A filter/interlock issue will be indicated on the display (reference the Filter

System Error Code Explanation Table on next page).

Always keep a spare set of filters on hand. When the display shows a Change Filter Error (indicating

insufficient filter efficiency), THE FILTER SYSTEM AND KETTLE HEAT WILL NOT OPERATE

until the Box and/or HEPA Filters are changed.

Generally, the HEPA Filter will last longer than the Box Filter. When the display indicates Change

Filter, replace the Box Filter; the next time Change Filter is indicated, replace both filters

(depending on usage, this scenario may not always occur). Reference the Updraft or Downdraft

Filter section accordingly for filter access and installation.

Note: Popping sugar corn will greatly reduce the life of the filters.

Filter Types

Updraft Filters

Baffle Filter

(Filter is washable.)

Updraft Box Filter (12x24x4)

(Replaceable ONLY, DO NOT

attempt to clean this filter.)

HEPA Filter

(Replaceable ONLY, DO NOT

attempt to clean this filter.)

Baffle Filter

(Filter is washable.)

Filter Plug shown installed.

Filter Plug is reusable.

Downdraft Filters

(Replaceable ONLY,

DO NOT attempt to

clean this filter.)

Filter Plug

HEPA Filter

(Replaceable ONLY, DO NOT

attempt to clean this filter.)

Downdraft

Box Filter

Page 20

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 20

gmpopcorn.com

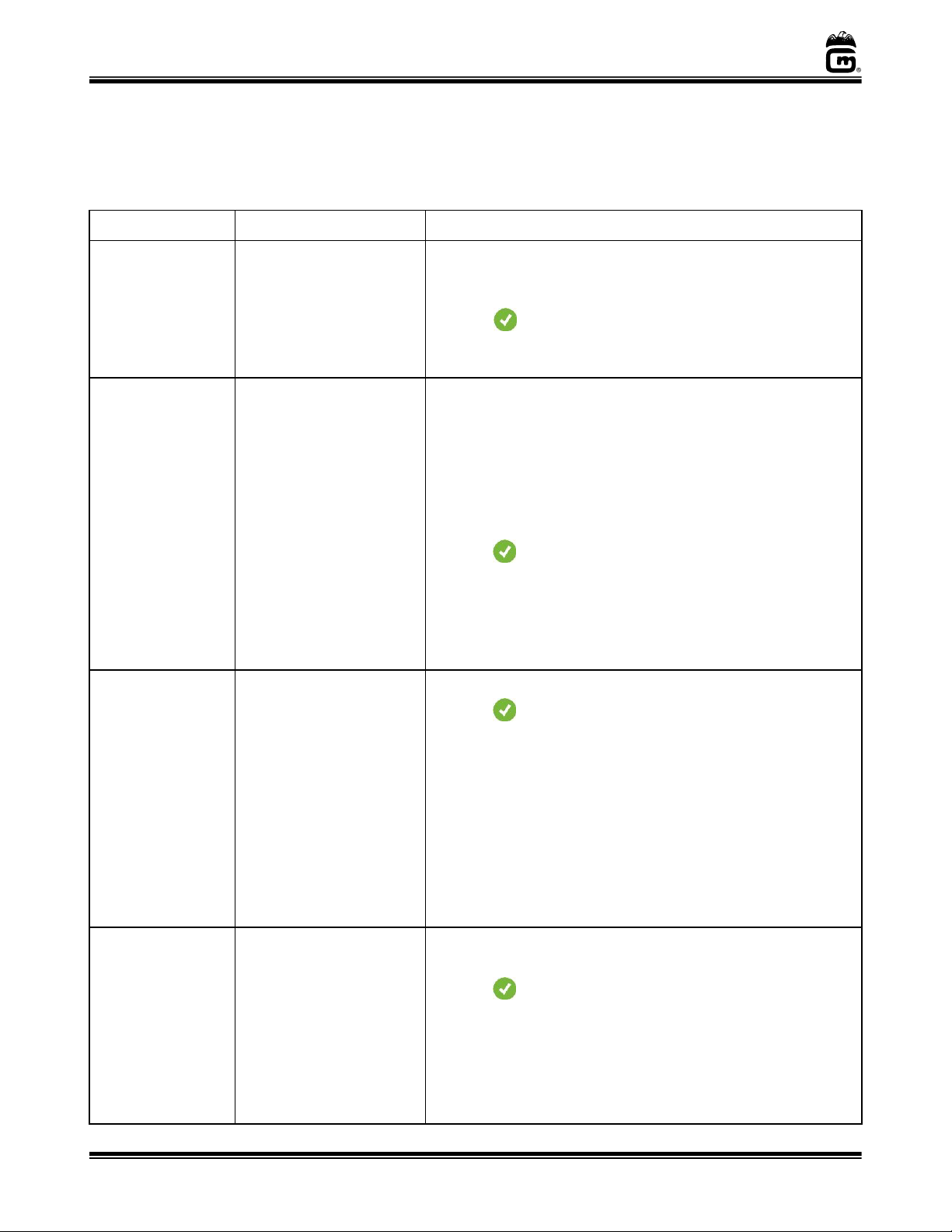

Filter System Error Code Explanation Table

After changing a filter(s) or correcting a filter system error code, turn the Power Switch OFF

then back ON to reset the display screen.

Error Code

Display View

Explanation - Solution

Error Code 10

Check Filter

E10

Error: Check Filter

(Filters need to be cleaned

soon.)

Indicates pressure switch detects Box and HEPA Filter

efficiency is reduced to less than 80%. Unit will still operate

but have replacement filters available for use when needed.

• Press (OK) to return to cooking screen.

• Otherwise, error screen goes away when cooking screen

advances to the next phase.

Error Code 11

Change Filters

Change Filters

Air filters need to be

changed!

Indicates pressure switch detects Box and HEPA Filter

efficiency is reduced to less than 75%. When a Change Filter

error is displayed, THE FILTER SYSTEM AND THE KETTLE

HEAT WILL NOT OPERATE until the Box and/or HEPA Filters

are changed.

If the Change Filters error occurs during a popping cycle, THE

FILTER SYSTEM AND KETTLE HEAT ARE SHUT OFF AND

COOKING IS STOPPED.

• Press (OK) to go to Settings screen (for service

technician or manager only, passcode required to access

additional screens).

• Otherwise, turn machine OFF, change the Box and HEPA

Filters, then turn machine back ON. Reference the Updraft

or Downdraft Filter section accordingly.

Error Code 12

Filter Door Open

E12

Error: Filter Door open

(Turn machine OFF and

check filter door on top of

machine. If problem

persists, call Service.)

Indicates the Filter Door interlock switch is NOT engaged.

• Press (OK) to go to Settings screen (for service

technician or manager only, passcode required to access

additional screens).

• Otherwise, turn machine OFF, fix issue as noted below, then

turn machine back ON.

To fix a Filter Door issue (reference the Updraft or

Downdraft Filter section accordingly):

• Make sure the door is closed so the door tab engages

the interlock switch.

• Make sure EACH compression knob is fully twisted

clockwise to lock it in place.

Error Code 13

Baffle Filter

E13

Error: Baffle Filter

(Turn machine OFF and

verify baffle filter is in

place. If problem persists,

call Service.)

Indicates the Baffle Filter is not installed, or the interlock

switch is NOT engaged.

• Press (OK) to go to Settings screen (for service

technician or manager only, passcode required to access

additional screens).

• Otherwise, turn machine OFF, install the baffle filter or

make sure it engages the interlock, then turn machine back

ON. Reference the Updraft or Downdraft Filter section

accordingly for instructions on filter installation.

Page 21

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 21

gmpopcorn.com

Error Code 14

Box Filter

E14

Error: Box Filter

(Turn machine OFF and

verify baffle filter is in

place. If problem persists,

call Service.)

Indicates the Box Filter is not installed, or the interlock switch

is NOT engaged.

• Press (OK) to go to Settings screen (for service

technician or manager only, passcode required to access

additional screens).

• Otherwise, turn machine OFF, install the box filter or make

sure it engages the interlock, then turn machine back ON.

Reference the Updraft or Downdraft Filter section

accordingly for instructions on filter installation.

Error Code 15

HEPA Filter

E15

Error: HEPA Filter

(Turn machine OFF and

verify HEPA filter is in

place. If problem persists,

call Service.)

Indicates the HEPA Filter is not installed, or the interlock

switch is NOT engaged.

• Press (OK) to go to Settings screen (for service

technician or manager only, passcode required to access

additional screens).

• Otherwise, turn machine OFF, install the HEPA filter or

make sure it engages the interlock, then turn machine back

ON. Reference the Updraft or Downdraft Filter section

accordingly for instructions on filter installation.

Page 22

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 22

gmpopcorn.com

Updraft Filters

After changing filter(s) or correcting a filter system error code, turn the Power Switch OFF then

back ON to reset the display screen. Allow kettle to cool completely before accessing filters.

BAFFLE FILTER

To Remove the Baffle Filter:

1. Lift filter towards top of popper.

2. Swing bottom end clear of mounting

brackets and remove filter.

3. Reinstall in reverse order. Filter

holes should face outward to properly

drain into grease tray; make sure a

clean grease tray is in place. Ensure the

filter engages the interlock switch.

4. RESTART popper to clear error.

BOX FILTER and HEPA FILTER

To remove the Box Filter:

1. Rotate the six Compression Knobs counter-

clockwise, then lift off the Filter Door (door

MUST be reinstalled, so tab engages interlock,

then FULLY turn knobs clockwise to close).

2. Lift Box Filter out to remove (see image above).

To reinstall: Carefully slide the Box Filter in and

ensure the filter engages the interlock switch.

All filters MUST be properly installed, and all interlocks MUST be engaged for the popper to

operate. The display will show a filter system issue - to continue operation, recheck the indicated

filter or filter door and ensure the interlocks are engaged (reference images below).

2

1

Install Filter with

holes facing out.

Baffle Filter

Grease Tray

Baffle Filter Interlock

Compression Knob

Filter Door (Door Tab MUST engage Interlock)

Box Filter

HEPA Filter

Box Filter

Interlock

Filter Door Interlock

(Door Tab MUST engage)

HEPA Filter Interlock

To remove the HEPA Filter:

3. With the Box Filter removed, shift the

HEPA Filter over until it clears the door

opening, then lift out to remove.

4. Carefully reinstall in reverse order

and ensure filters engage interlock

switches.

5. RESTART popper to clear error.

Page 23

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 23

gmpopcorn.com

Downdraft Filters

After changing filter(s) or correcting a filter system error code, turn the Power Switch OFF then

back ON to reset the display screen. Allow kettle to cool completely before accessing filters.

08

All filters MUST be properly installed, and all interlocks MUST be engaged for the popper to

operate. The display will show a filter system issue. To continue operation, recheck the indicated

filter or filter door and ensure the interlocks are engaged.

BAFFLE FILTER

To remove the Baffle Filter:

1. Lift filter towards top of popper.

2. Swing bottom end clear of mounting

brackets and remove filter.

3. Reinstall in reverse order. Filter

holes should face outward to

properly drain into grease tray; make

sure a clean grease tray is in place.

Ensure the filter engages the interlock

switch.

4. RESTART popper to clear error.

BOX FILTER and HEPA FILTER

To remove the Box Filter:

1. Rotate the three Compression

Knobs counter-clockwise to open

the Filter Door (close door to

engage interlock, then FULLY turn

knobs clockwise).

2. Slide Box Filter out to remove.

When reinstalling Box Filter: The

Filter Plug must be oriented on the

side shown to activate the Interlock

Switch. Carefully slide filter in along

guide rails ensuring the Filter Plug

correctly engages the interlock

switch.

To remove the HEPA Filter:

3. With the Box Filter removed, lift the

HEPA Filter up until it clears the

door opening, then remove.

4. Carefully reinstall in reverse order;

ensure filters engage interlock

switches.

5. RESTART popper to clear error.

2

1

Baffle Filter

Install Filter with

holes facing out.

Compression Knobs

Filter Door

Filter Plug (When reinstalling, ensure Interlock

Switch correctly engages Filter plug.)

Grease Tray

Box

Filter

Baffle Filter Interlock

HEPA Filter Interlock

HEPA Filter

Box Filter Interlock

Door

Interlock

Page 24

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 24

gmpopcorn.com

OPERATING INSTRUCTIONS

Controls and Their Functions

MAIN POWER SWITCH

Two position, ON/OFF rocker switch - supplies power to the display, sign, and interior

cabinet lights. LED switch light ON indicates there is power to these features. (Twin

Models have an additional left hand side Power Switch and Touch Screen to control the

LH Kettle, LH Oil Unit, and LH Filter System.)

CIRCUIT BREAKERS

Two mini Circuit Breakers are located on the control panel, to protect the popper unit from

an overload condition. If unit is plugged in, but the kettle agitator or oil system does not

come on when activated, then the circuit breaker(s) may be tripped. (Reference the

Troubleshooting section of this manual).

USB PORT

Used for updating software and to upload/download information for the machine ONLY. This

is NOT a charging port!

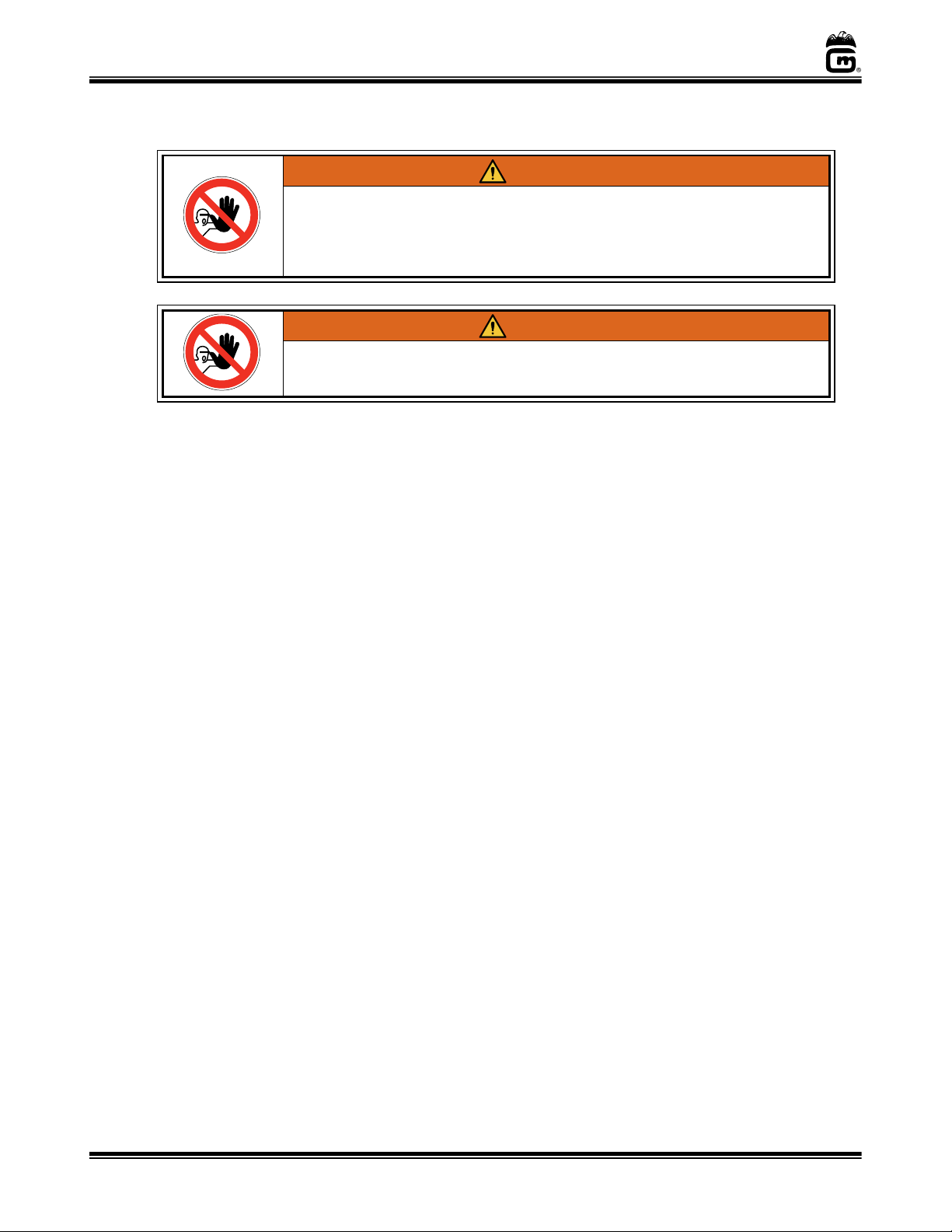

TOUCH SCREEN CONTROL PANEL

The Touch Screen Control Panel provides easy screen navigation through popper functions

to pop popcorn and adjust unit settings. Reference Introduction to the Touch Screen

Control section on the next page for a basic description of the equipment and controls.

MANUAL PULL (for Fire Suppression System – some Exports excluded)

Pull Station for the operator to manually activate the Fire Suppression System.

Note: In the event of a fire, the system will automatically activate the Fire Suppression

System; however, if the operator chooses, they can operate the system by pulling

the manual pull.

Control Panel View

Fire Suppression Manual Pull

(if equipped)

Circuit Breakers

Touch Screen Control

USB Port

(this is NOT a charging port)

Main Power

Switch

Page 25

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 25

gmpopcorn.com

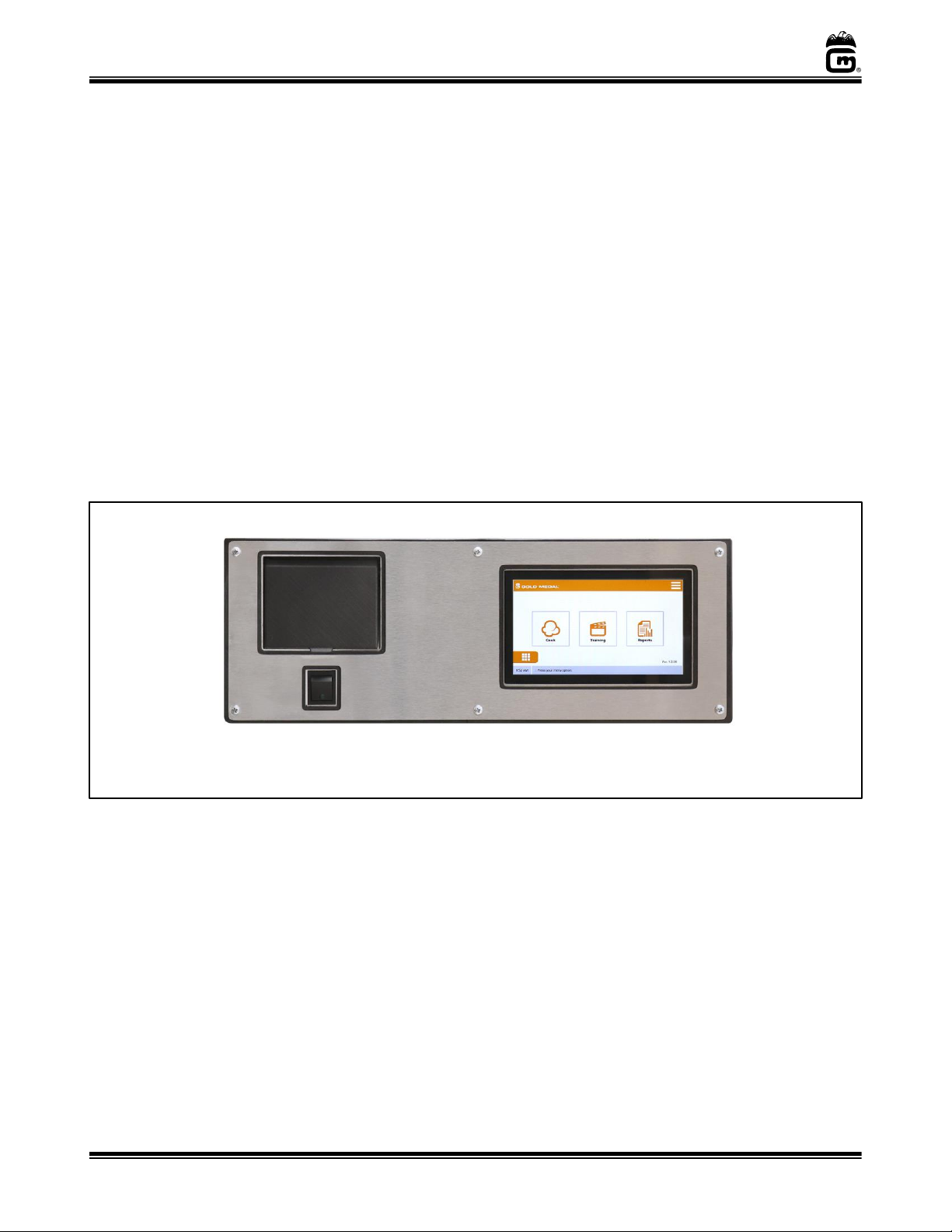

Introduction to the Touch Screen Control

The popper is equipped with a Touch Screen Control Panel. This section introduces the control

and provides basic screen descriptions to navigate the control for general operation. For an

expanded description and for programming needs, reference Navigating the Touch Screen

Control section.

The control can be set up for use in STANDARD MODE or THEATER MODE.

• Standard Mode (default setting): Allows menu access to operator for screen navigation

and programming.

• Theater Mode: Allows operator access to popping corn functions only; selecting a recipe

and access to all other functions requires a Manager’s passcode.

Splash Screen: Screen viewable upon turning the Power Switch ON (shows countdown for

initializing system).

Home Screen: Customized for STANDARD or THEATER Mode

To change mode, reference Navigating the Touch Screen Control section N7.10 User Configuration. (Theater

Mode requires a Manager’s Passcode to access the Main Menu.)

Equipment Button

Manually turn

equipment OFF/ON

(reference next page)

Status Bar (reference for operation

prompts and popper status)

Clock

Software Version

Function Selection

(Operations available

within a Mode – blocked

operations are dimmed)

Menu Button

(Standard Mode)

Lock Button

(Theater Mode)

Requires Manager’s

Passcode to access.

Page 26

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 26

gmpopcorn.com

Equipment Controls Screen: Manually activate/deactivate an equipment selection.

The Equipment Control screen is accessible from various screens to manually activate or deactivate an

equipment selection. To manually change a selection, reference the information below. For a full

description of each equipment control, reference Navigating the Touch Screen Control section N6

Equipment Controls.

FILTER SYSTEM – Equipped with a timeout feature which automatically shuts the Filter System off after an

allotted period of idle time (no popcorn popped). If the Filter System is turned off during a cook cycle,

the kettle heat will shut off.

KETTLE HEAT – Automated by the cooking cycle (blocked from manual operation, selection is always dimmed).

STIR MOTOR (in kettle) – If the Stir Motor is turned off during a cook cycle, the kettle heat will shut off.

POPCORN CRISPER – Powers crisper in corn staging area (for Twin Units - RH Touch Screen controls the crisper).

OIL MASTER – Supplies power to the oil unit (Bag-in-a-Box or Bucket Pump).

Important Note: To stop oil flow at any time, turn Oil Master OFF.

To Pop Corn:

When a recipe is selected the equipment is automatically turned ON. The Kettle Heat, Stir Motor, and

Filter System MUST BE ON to pop corn. To manually turn the crisper OFF for a cook cycle, reference

the instructions below.

Manually turn Popcorn Crisper OFF/ON and continue a cook cycle:

Any manual adjustments made on this screen will revert to the default setting after each batch of

popcorn is popped.

1. Select desired recipe (on Recipe Selection screen).

2. Press OK to proceed to Cook screen and begin kettle heating.

3. Once on the Cook screen, press the Equipment Button.

4. Press Popcorn Crisper button to turn it OFF/ON, then exit to return to cook screen with kettle

heating.

IF Filter System or Stir Motor is turned OFF during a cook cycle, the kettle heat will shut OFF

and the cook cycle will stop (on exit, the screen reverts to Recipe Selection).

Exit Button

(returns to

previous screen)

Selection Indicator

Light (ON indicates

selection is active)

Equipment Selection

(press to activate/

deactivate)

Blocked selection(s) are

dimmed.

Note: For ALL selections, allow adequate time for the

selection(s) to register prior to exiting the screen.

If Filter System or Stir Motor are

turned OFF during a cook cycle,

the kettle heat will shut OFF!

Page 27

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 27

gmpopcorn.com

Cook (Recipe Selection Screen):

Standard Mode – Press button to select a Corn Type, Flavoring, and Load Size, then press OK to proceed.

Theater Mode – (Recipe selections are preset) Press OK to proceed.

Recipe Selected

(Displays corn type,

flavor, load size, and oil

volume.)

To adjust oil volume:

Reference Navigating

the Touch Screen

Control section N7.3

Recipes.

OK (Accept

recipe, proceed

to Cook screen)

Select a Corn Type

(Butterfly or Mushroom)

Select a Flavoring

(Salt or Sweet)

Select a Load Size

(Large or Small)

Cook Screens: A cook cycle is started, kettle begins heating.

Pause Button

(Stops heating and

returns to Recipe

Selection screen)

Current Temp

(Displays the

current kettle

temperature)

Popping Cycle Status (Visual indicator of cycle

progression from preheating through kettle dump)

Oil Reserve

(Displays approx.

percentage of oil

remaining)

Equipment Button

(Manually turn

equipment OFF/ON)

Cook Screens Progress through the Cook Cycle

Press OK to proceed through the cook cycle, otherwise a warning signal may be indicated, then kettle

heat will shut down.

Dump Kettle

Prepare

Ingredients

Add Corn &

Flavacol

Dispense Oil

Add Flavoring

(Sweet Mode Only)

Page 28

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 28

gmpopcorn.com

Initial Startup – User Configuration

The Elite Touch Screen PopClean Popper has been programmed at the factory with default

system settings for operation mode, oil calibration, recipe settings, and additional unit settings.

For Initial Startup of a New Unit

1. User Configuration - For initial setup of a new unit (or for replacement software boards)

review the default settings shown below and adjust (if needed). For a full description of each

setting, reference Navigating the Touch Screen Control section N7.10 User Configuration.

To open User

Configuration

Screens:

Operation (Default Setting)

Option

User Config.

Screen 1

1. Unit Name:

Enter name for unit, if desired.

2. Operational Mode: (default is Standard)

• STANDARD Mode: Allows menu access to the

operator for screen navigation, recipe selection, and

programming.

• THEATER Mode: Allows operator access to popping

corn functions ONLY; selecting a recipe and access

to all other functions requires a Manager’s password.

Standard or Theater

3. Temperature Mode: (default is °F)

°F or °C

4. Screensaver: (default is ON)

ON or OFF

5. Screensaver timeout (minutes): (default is 15 min.)

Press ▲ or ▼ to adjust.

6. Filter timeout (minutes): (default is 15 min.)

(number of minutes without a cook cycle, before filter

system is automatically shut OFF).

Press ▲ or ▼ to adjust.

7. Crisper System ON/OFF: (default is Automatic)

(Crisper turns ON automatically when a cook cycle is

started).

Manual or Automatic

8. Time: (preset at factory, displayed in Status Bar).

Select to enter time (00:00).

9. Date: (preset at factory)

Select to enter date

(00/00/0000).

10. Clock Type: (default is 12 Hour)

12 Hour or 24 Hour

11. Beep Volume: (preset at factory)

Slider adjusts from low to high.

12. Brightness: (preset at factory)

Slider adjusts from low to high.

13. Cook Log Date: (synchronizes the cook cycle date

when any user configuration date change is made)

Press Set Cook Log – Today

To EXIT Config.

Press Menu button , then select Home.

3 1 4 5 2

Press to

show User

Config. Screen 2

Page 29

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 29

gmpopcorn.com

2. Oil System Calibration - Allows popper to display percentage of oil remaining in oil unit. For a

full description, reference Navigating the Touch Screen Control section N7.1 Oil System Calibration.

To open OiL level

Calibration Screen:

Bag-In-A-Box

Oil Calibration:

1. Load 1 FULL box of oil, then

press OK (sets oil at 0%).

2. Load 2nd FULL box of oil, then

press OK (sets oil at 100%).

3. Press OK to confirm

calibration complete.

Bucket Pump

Oil Calibration:

1. Have an EMPTY bucket of oil

in unit, then

press OK (sets oil at 0%).

2. Load a FULL bucket of oil

in unit, then

press OK (sets oil at 100%).

3. Press OK to confirm

calibration complete.

3. Oil Pump Calibration - Sets oil volume dispensed in 10 seconds of pump run time. For a full

description, reference Navigating the Touch Screen Control section N7.2 Oil Pump Calibration.

Bag-In-A-Box - On Settings screen, select Oil Pump Calibration.

Allow kettle to cool completely prior

to taking volume measurements.

Calibrate B.I.B.

Oil Pump:

1. Hold a cup under the oil delivery

tube in popper, press OK.

2. Press OK to dispense oil

(hold cup till dripping ends).

3. Compare oil measurement to

volume shown.

4. If correct, press OK; RESTART unit.

If needed, adjust vol. shown,

press ▲ or ▼ to match volumes,

then press OK, then RESTART unit.

1 2 3

Press ▲ or ▼ to adjust.

OK Button

OK Button

Page 30

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 30

gmpopcorn.com

Bucket Pump - On Settings screen, select Oil Pump Calibration.

Allow kettle to cool completely prior

to taking volume measurements.

Calibrate Bucket

Pump:

1. Hold a cup under the oil delivery

tube in popper, press OK.

2. Press OK 1 to begin dispensing oil.

Press OK 2 when oil STARTS flowing

(hold cup till dripping ends). Button

shows time it took to prime the

oil line.

3. Compare oil measurement to

volume shown.

4. If correct, press OK; RESTART unit.

If needed, adjust volume shown.

Press ▲ or ▼ to match volumes,

then press OK; RESTART unit.

Press ▲ or ▼ to adjust.

Seconds to prime oil

line (ex: 19 = 1.9 sec.).

Page 31

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 31

gmpopcorn.com

QUICK Reference

Popping Instructions

This is a QUICK reference for popping instructions. For a full description of each cooking screen,

reference EXPANDED Instructions on next page.

1. Turn Power Switch ON.

2. On Home Screen, press Cook.

Note: Reference Status Bar for operation prompts.

3. Theater Mode (Recipe is preselected): Press OK to proceed.

Standard Mode: Select recipe desired.

Press OK.

4. Kettle begins preheating.

5. Prepare Corn and Flavacol

(DO NOT add Flavacol for SWEET Mode.)

On prompt, load corn and Flavacol, then close lid.

Press OK

6. Press OK to dispense oil automatically, OR

Manually pour in oil (DO NOT press OK if oil is added manually).

7. If applicable, add Sweet Flavoring.

Press OK

Caution: Do not open kettle lid to add sugar if popping has

started as injury may result.

8. Dump the kettle.

Press OK

9. To repeat the same recipe: Press OK for YES;

Press X for NO

1

3

2

Page 32

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 32

gmpopcorn.com

EXPANDED Reference

Popping Instructions

This section provides a full description for each cooking screen shown in the Popping Instruction

Quick Reference on the previous page. Use the corn, salt, and oil measure provided to prepare

ingredients per Gold Medal recommendations below.

Popcorn popped in coconut oil stays fresh longer and does not leave black deposits in the kettle

like other oils. Use only top quality, fresh popcorn from reputable suppliers.

Salted Popcorn: Use flavored and colored coconut oil.

Glaze Pop: Use white coconut oil (colored oil can change the popcorn color). Glaze Pop cooks

directly in the kettle. DO NOT use popcorn seasoning salt when popping Glaze Pop.

Raw Popcorn Charge:

Use large or small corn measure provided according to load size (reference

Step 3 below for 52 oz. Sweet Mode notes).

Oil Volume:

Oil volume is approx. 30% of corn amount.

Flavacol (Salt) Amount:

Use large or small Flavacol scoop provided (DO NOT add Flavacol for SWEET Mode)

Glaze Pop/Sugar Amount:

Use amount equal to 1/2 the quantity of corn (reference instructions on product).

Note: When using coconut oil, be sure the oil is liquid. To check oil, reference Navigating

the Touch Screen Control section N3 Cleaning/Oil Pump.

1.

Turn Power Switch ON.

2.

On Home Screen, Press Cook.

(Theater Mode – blocked selections are greyed out/locked.)

Note: Reference Status Bar for operation prompts and

popper status information.

3.

Theater Mode (Recipe is preselected): Press OK to proceed.

Standard Mode: Select Recipe desired.

3.1 Select a Corn Type (Butterfly or Mushroom)

3.2 Select a Flavoring (Salt or Sweet)

3.3 Select a Load Size (Large or Small)

3.4 Press OK to proceed.

Raw Corn used per Load Size:

Kettle Size

Large Load

Small Load

52 oz. Kettle

52 oz.

32 oz.

32 oz. Kettle

32 oz.

18 oz.

Notes for 52 oz. Kettles ONLY:

• In Mushroom-SWEET Recipe, a LARGE LOAD uses 32 oz. of corn; SMALL LOAD uses 20 oz. of corn.

• Tip for Mushroom-SALT Recipe: If desired popping result is not being achieved when popping a

large 52 oz. load, then try popping a small 32 oz. load.

1 3 2

For 52 oz. SWEET,

see note below.

Page 33

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 33

gmpopcorn.com

4.

Kettle begins preheating (the Filter System, Kettle Heat, Stir Motor,

Popcorn Crisper, and Oil Master automatically turn ON).

4.1 If desired, manually turn Popcorn Crisper OFF(ON),

reference steps below.

4.2 To stop the cycle, press Pause Button.

Manually turn Popcorn Crisper OFF(ON):

1. Press Equipment Button to bring up Equipment Controls.

2. Press Popcorn Crisper button to turn it OFF(ON), then

press X to return to cook screen with kettle heating.

IF Stir Motor or Filter System are turned OFF during a

cook cycle, the kettle heat will shut off and cycle will stop.

5.

Corn and Flavacol

5.1 Prepare Corn for load size (see table in Step 3) and

Flavacol (use large or small scoop provided accordingly).

DO NOT add Flavacol/salt for SWEET Mode.

5.2 On prompt, Load corn and Flavacol (for Salt Mode only);

then close lid.

• If corn is not loaded, Status Bar turns yellow and beep

becomes a solid tone to indicate action is needed.

• If corn is still not loaded, Status Bar turns red

indicating kettle will be shut down (after a kettle

shutdown error, press lock button to exit and

return to Home Screen).

5.3 Press OK, to continue the popping cycle.

6.

Add Oil.

6.1 On prompt: Press OK to dispense oil automatically, OR

manually pour in oil, then close lid. DO NOT press OK if

oil is added manually (the kettle will sense that oil has

been added and cooking will continue).

• If oil is not loaded, Status Bar turns yellow and beep

becomes a solid tone to indicate action is needed.

• If oil is still not loaded, Status Bar turns red

indicating kettle will be shut down (after a kettle

shutdown error, press lock button to exit and

return to Home Screen).

6.2 Press OK, to continue the popping cycle.

Notes for Oil Volume and Oil Reserve Amount:

• Oil volume dispensed for each recipe is preset. To adjust the default oil volume setting, refer to

Navigating the Touch Screen Control section N7.3 Recipes.

• As you are popping corn, note the approximate oil reserve remaining. To reload oil, reference the

Instruction manual for the oil unit.

Oil Reserve

(approx. percent remaining)

Equipment Button

Pause Button

Page 34

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 34

gmpopcorn.com

7.

If applicable, add Sweet Flavoring.

7.1 On prompt, add Glaze Pop, then close lid (use amount

equal to half the quantity of raw corn or reference

recommended amount on product).

Caution: Do not open kettle lid to add sugar if popping has

started as injury may result.

If popping has started, finish the cycle without

sugar. Then, on following batches, add sugar

right after adding oil (this scenario may require

extra cleaning).

When using sugar, use Compound “S” to help keep the

kettle clean.

• If flavoring is not loaded, Status Bar turns yellow to

indicate action is needed.

• If flavoring is still not loaded during the prompt,

screen returns to popping cycle and FLAVORING

SHOULD NOT BE ADDED.

7.2 Press OK, to continue the popping cycle.

8.

Dump the kettle.

8.1 On prompt, dump the kettle.

• If kettle is not dumped, Status Bar turns yellow and

beep becomes a solid tone to indicate action is needed.

• If kettle is still not dumped, Status Bar turns red

indicating kettle will be shut down (after a kettle

shutdown error, press lock button to exit and

return to Home Screen).

8.2 Press OK.

9.

Screen prompts to repeat recipe, YES or NO?

To repeat the same recipe, press OK.

To change recipe or stop cooking, press X

If no selection is made the screen reverts to the Home

screen.

10.

When finished popping for the day, turn off any un-needed equipment (if needed, Oil Master may be left on to

prevent coconut oil from congealing).

Page 35

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 35

gmpopcorn.com

Navigating the Touch Screen Control

Navigation instructions on operating the Touch Screen Control Panel can be set up for use in

STANDARD MODE or THEATER MODE.

• Standard Mode (default factory setting): Allows menu access to screen navigation and

programming.

• Theater Mode: Allows operator access to popping corn functions ONLY, and blocks

access to all other popper functions without a Manager’s Passcode.

This section expands on the introductory section which provided general instructions to turn

equipment ON/OFF and introduced the cook screens. (Reference Introduction of the Touch

Screen Control located at the beginning of the Operating Instructions).

This Navigation section covers the in-depth information on each control feature, on adjusting

default unit settings, calibrating oil, etc.

Navigating the Touch Screen Control

Menu Screen: Overall control navigation.

For each selection, reference the corresponding Navigation section (ex: N1 for Cook)

in the navigation index shown on next page.

N1

N2

N3

N4

N5

N6

N7

Home Screen

Menu Button

Theater Mode: Press

and enter Manager’s

Passcode (4653) to access

the main menu.

Menu Screen

Standard Mode: Press to access the main menu.

Page 36

Instruction Manual - Touch Screen 2011, 2848, 2860, 2872, and 2873 (32 oz. Pop-O-Golds)

PopClean Elite Popper -600 Series 2911, 2948, 2960, 2972, and 2973 (52 oz. Medallions)

Page 36

gmpopcorn.com

Navigation Section Index

N1 Cook (Recipe Selection Screen)

N1.1 Cook Screens (Cooking Cycle)

N2 Training (Training Videos)

N3 Cleaning / Oil Pump (Pump Purging)

N4 Reports

N4.1 Cook Cycle - Past 7 Days

N5 Home

N6 Equipment Controls

• Filter System

• Kettle Heat

• Stir Motor

• Popcorn Crisper

• Oil Master

N7 Settings

N7.1 Oil System Calibration (Oil Level Cal.)

N7.2 Oil Pump Calibration

N7.3 Recipes

N7.4 Load Count Reset

N7.5 Upload Recipes

N7.6 Download Recipes

N7.7 View Cook

N7.8 Upload Cook

N7.9 N/A

N7.10 User Configuration

Unit Name

Operational Mode (Standard or Theater)

Temperature Mode (°F or °C)

Screensaver (ON or OFF)

Screensaver Timeout (Minutes)

Filter Timeout (Minutes)

Crisper System ON/OFF

Time

Date

Beep Volume

Brightness

Cook Log Date

N7.11 Maintenance

N7.12 Corporate Engineering

N1

Cook

(Recipe

Selection)

Cook (Recipe Selection Screen):

Standard Mode – Press button to select a Corn Type, Flavoring, and Load Size, then

press OK to proceed.

Theater Mode – (Recipe selections are preset) Press OK to proceed.

Recipe Selected

(Displays corn type,

flavor, load size, and

oil volume.)

To adjust oil volume:

Reference Navigating

the Touch Screen

Control section N7.3