Gold Medal Mighty-Mite 2035BG, Mighty-Mite 2035NG, Mighty-Mite 2035DC Instruction Manual

Mighty–Mite

a

Instruction Manual

Part No. 74570

Revised June 1996

Model #2035BG (Bottle Gas

Model #2035DC (DC Motor, Bottle Gas

Model #2035NG (Natural Gas

)

)

)

Cincinnati, OH 45214-2089 USA

GAS SAFETY PRECAUTIONS

a

Mighty–Mite

a

This instruction booklet is very thorough and complete. Please take the time to read this entire

booklet before attemting to operate the appliance.

Your Mighty-Mite Commercial Popper is the finest 14 Oz. gas popper ever built. The special alloy

steel kettle is extra heavy to prevent burnouts or warping, and is made from excellent heat conducting steel. Your Mighty-Mite has an extra heavy duty motor equipped with an extra fan and air

tunnel to direct cooling over the motor at all times allowing the motor to run cooler under heavier

popping conditions.

UNPACKING AND ASSEMBLY

After unpacking your Mighty-Mite, set it on a counter where you intend to use it and remove all

the tape. Make sure clearances around and overhead the appliance comply with the marking

on the data plate for the location you have selected. Attach the counterweight assembly as

per Drawing D-4957.

INSTALLATION

When installing your new Mighty-Mite Commercial Gas Popper, you must conform with local

codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1-1980.

Gas is safe when used properly, but can be very dangerous

when used improperly. We suggest that installation be carefully

made by only a qualified service person. Gas companies have

competent service people to provide safe installation.

When selecting a location for your new Mighty-Mite, pay close attention to the installation clearances. The MINIMUM clearance for the sides is 6 inches; the MINIMUM top, back and frontal

clearance is 30 inches. This unit is certified for use on combustible surfaces.

The appliance and its individual shutoff valve must be disconnected from the gas supply piping

during pressure testing of that system at pressures greater than 0.5 psig (3.45 kPa).

During any pressure testing of the gas supply piping system at pressures equal to or less than 0.5

psig (3.45 kPa), the appliance must be isolated from the gas supply piping system by closing its

individual manual shutoff valve.

This unit must be grounded in accordance with local codes; or, in the absence of local codes,

withthe National Electric Code - ANSI/NFPA No. 70-1981. Secure grounded wire to ground lug

provided inside the cabinet wiring junction box.

When wiring your new Mighty-Mite, refer to the wiring diagram located inside of the cabinet and in

this Instruction Manual (Drawing No. A-74500 for AC Model; Drawing No. A-74511 for DC Model).

1

ALL MODELS #2035

Mighty–Mite

a

After installation all gas connections must be checked for leaks with a soap solution. When gas

connection is complete, wire the unit to the power source which will carry the current specified on

the unit's data plate.

Do NOT use a match or flame to check for leaks – you may

cause a fire or explosion!

TYPES OF GAS

The nameplate is marked at the factory to indicate the type of gas the appliance uses: either,

LP or propane for Liquified Petroleum Gas, or NAT or NG for Natural Gas. If necessary the

unit can be altered to change fuels, but we suggest a qualified service person do the work.

Please have your service person refer to the

Maintenance and Repair

section of this manual.

ALTITUDE RANGE

The factory has sized the burner orifices for an elevation up to 2000 feet above sea level. For

high altitude operation, please contact Gold Medal Engineering for the proper orifice size.

GAS PRESSURE

We have determined that optimum popping results occur when the gas pressure is adequate.

For LP gas, we recommend a pressure setting of 10 inches water column (6 oz. per square

inch); and, for Natural Gas, 4 inches water column (2 oz. per square inch). The pressure is

measured at the appliance while the main burner is ignited. A pressure regulator is supplied to

deliver the optimum pressure for both types of gas when the unit is changed from the original

factory specification. Follow the instructions in the

gas requirements are maintained by properly sized piping. Be sure the piping is properly sized

to supply the needed pressure.

Maintenance and Repair

section. Adequate

2

ALL MODELS #2035

Mighty–Mite

a

LIGHTING AND SHUTDOWN INSTRUCTIONS

1. Turn the handle of the gas safety valve to the "PILOT" position.

2. Push down the red reset button, depress the spark igniter and repeat until the pilot lights.

Hold the red reset button for about 30-45 seconds or until the pilot remains burning when

the button is released.

3. Turn the main handle to the "ON" position. The main burner should now ignite from the

pilot burner.

4. If you want to turn off both the pilot and the main burner, pull lock on safety and turn to the

"OFF" position.

If pilot is turned out, a five minute shut down period is required

before attempting to relight.

AIR ADJUSTMENT ON BURNER

After your main burner has been lit according to the directions above, you might have to make

some air adjustment in order to get the best flame. The Air Adjustment Cap should be turned

to give more or less air. A blue flame is desired for optimum heat.

TO POP POPCORN

Turn the main burner on and put oil in the kettle. You can let oil heat slightly before adding the

popcorn and salt. We recommend 14 ounces of popcorn, 4 ½ ounces of high quality coconut oil,

and Flavacol salt to give the best results. A good measure of oil and Flavacol is the secret to top

quality popcorn; popcorn that brings you more repeated sales. If you are in a commercial

pre-pop operation, this is even more important; good quality pre-pop commands a higher price. To

your customer, it is well worth the slight extra price.

Yes, you can put more corn into the kettle, but this will lenghten the popping cycle and your

overall production will decrease. You can make smaller batches, if necessary, but always use a

corn to oil ration of 3:1. When using a smaller batch you might turn the burner down slightly to

prevent it form getting too hot.

IF THE FLAME GOES OUT

A 5 minute shutdown period is required before attemting to relight.

1. Check to see if you are out of gas.

2. Check to see if the thermocouple is in the proper position.

At no time during a power failure is there to be an attempt to operate

this unit. In the case that a power failure occurs during operation, the

gas supply is to be turned OFF until power failure has subsided. Then,

and only then, should a relight attempt be made per the

Shutdown Instructions

Lighting and

.

3

ALL MODELS #2035

MAINTENANCE INSTRUCTIONS

a

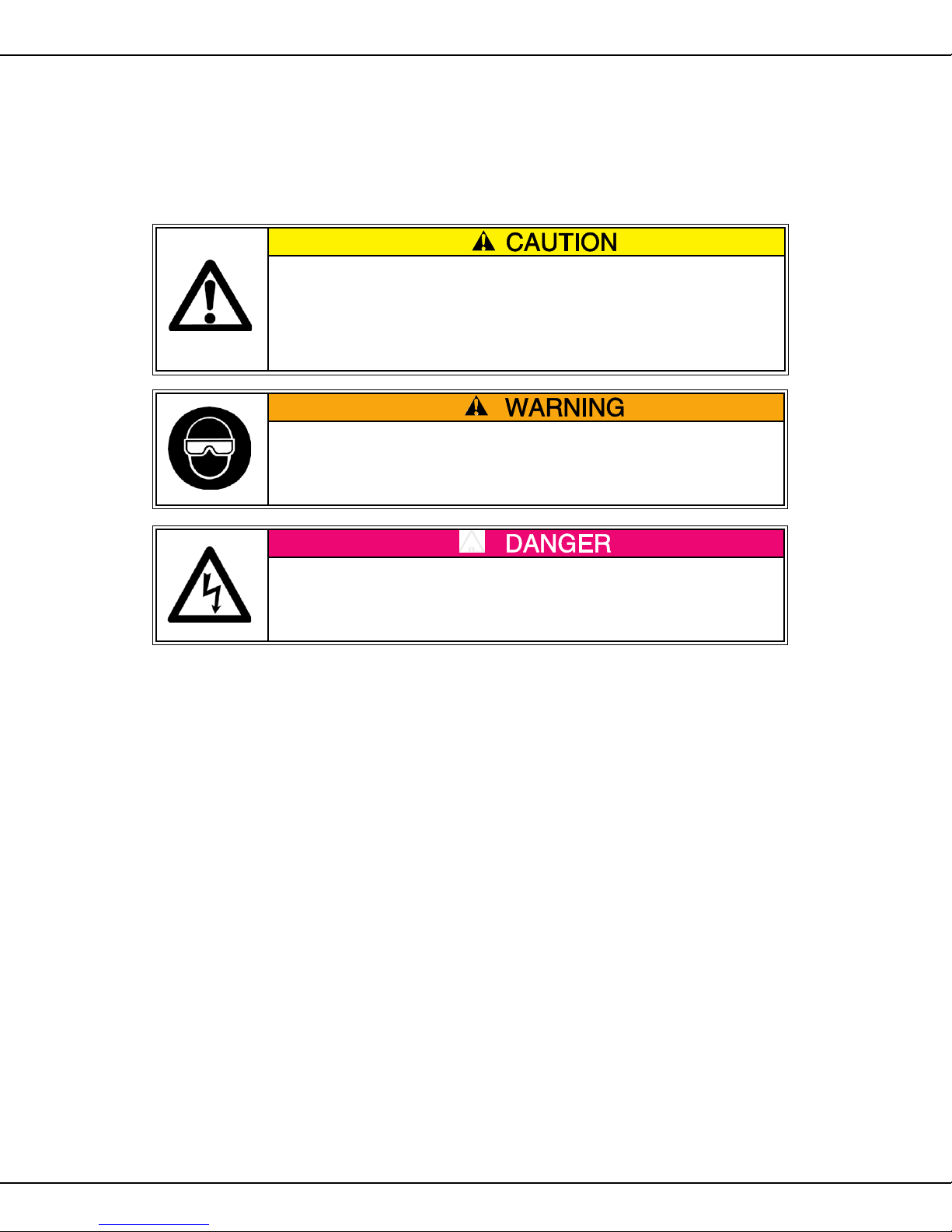

THE FOLLOWING SECTIONS OF THIS MANUAL ARE INTENDED ONLY FOR QUALIFIED SERVICE PERSONNEL WHO

ARE FAMILIAR WITH ELECTRICAL EQUIPMENT. THESE ARE

NOT INTENDED FOR THE OPERATOR.

Adequate eye protection must be used when servicing this

equipment to prevent the possibility of injury.

Mighty–Mite

Do NOT immerse the equipment in water.

Unplug your machine before servicing.

LUBRICATION REQUIREMENTS

DRIVE MOTOR

This is a sealed bearing type motor and requires no lubrication.

GAS CONVERSION

1.Disconnect the power supply at the fuse box or breaker.

2.Turn off the gas supply.

3.Refer to drawing number D-5019.

4.Place the kettle in the dump position. Remove the retainer screws. Remove the burner

(Part No. 74558) to expose the burner orifice hood. Replace the main burner hood with the

appropriate part number for the intended type of gas.

A.Part # 74629 (#61) for LP gas.

B.Part # 74630 (#53) for Natural Gas.

5.Replace the pilot burner orifice with the appropriate part number for the intended type of

gas.

Pilot Burner Part No. 74028

A.Part No. 74029 (.011 Dia. Holes) for “LP” Gas.

6.Remove the hex cap on the pressure regulator and position the appropriate end of the red

plug down. “LP” for Liquefied Petroleum Gas, and “NAT” for Natural Gas. Replace the

hex cap. (Instructions continued next page.)

B.Part No. 74531 (.018 Dia. Holes) for Natural Gas. (“NAT”)

Pilot Burner Part No. 57031

A.Part No. 74029 (.011 Dia. Holes) for "LP” Gas.

B.Part No. 74030 (.023 Dia. Holes) for Natural Gas. (“NAT”)

4

ALL MODELS #2035

Loading...

Loading...