Gold Medal Karmel King 2620, Karmel King 2621, Karmel King 2630, Karmel King 2631 Instruction Manual

Page 1

Part No. 18736

Revised: February 2009

KARMEL KING

Instruction Manual

Models: 2620 & 2621 (240 Volt)

2630 & 2631 (208 Volt)

Page 2

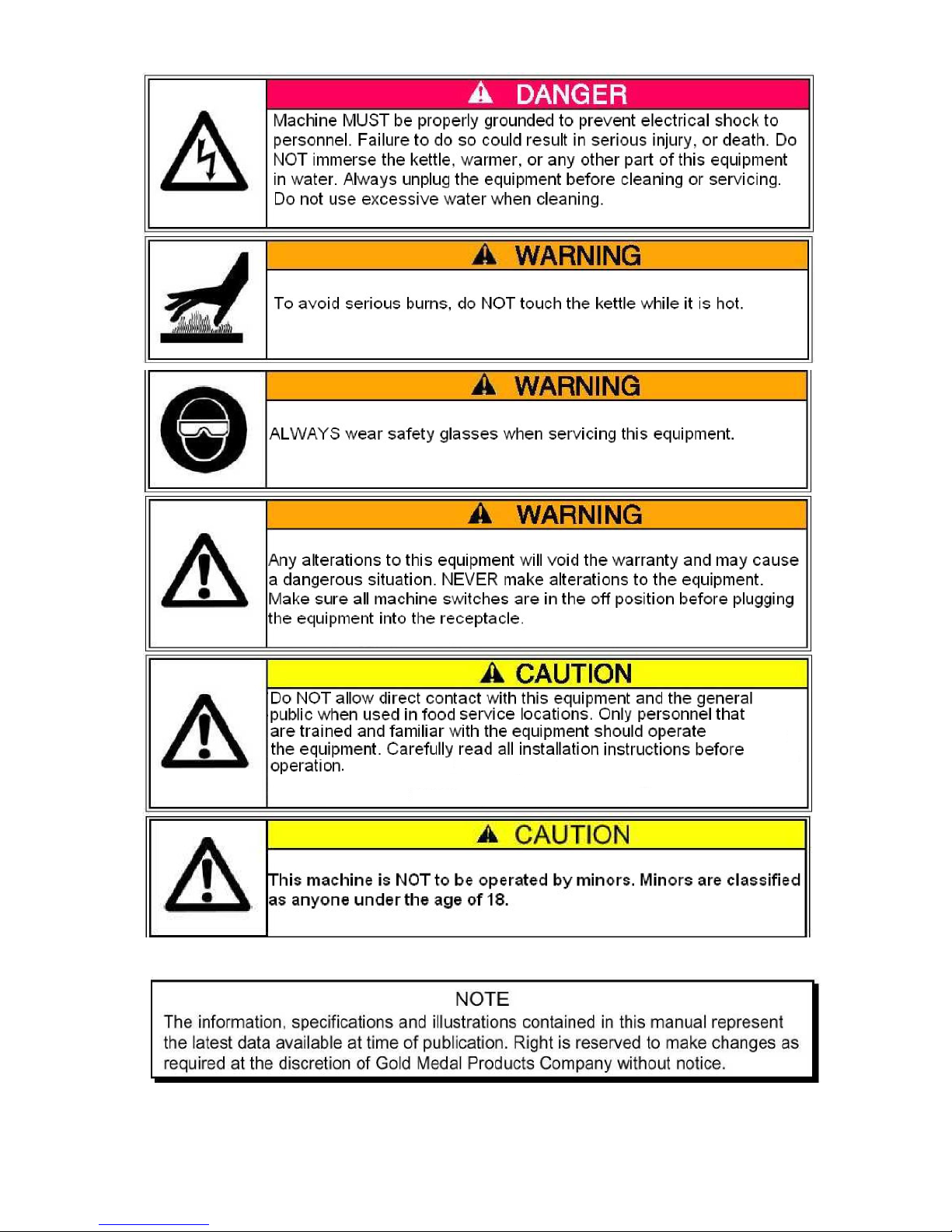

SAFETY PRECAUTIONS

Page 3

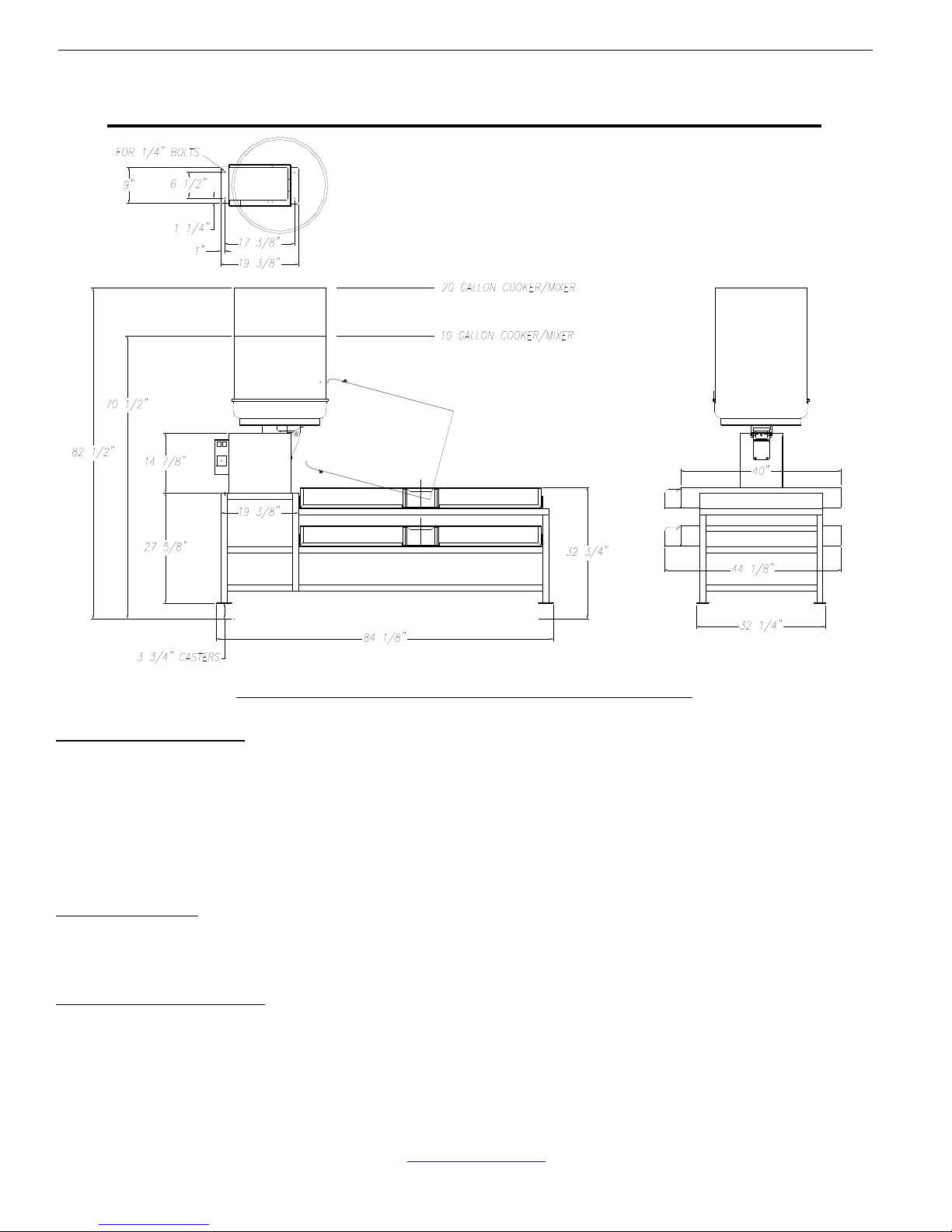

___________________________________ KARMEL KING

Mark 10, Karmel King (20 Gallon), and 2622 Rolling Truck

Left Hand Mark 10 (2411E) or Karmel King (2621) on 2622 truck shown

Electrical Specifications:

Mark 10 (2410E - RH, 2411E - LH) - 120/208v or 120/230v 4 wire (2 hot, 1 neutral, 1 ground) 60

Hz.

5520 watts 30 amp plug & receptacle ( NEMA L14-30P & L14-30R )

Karmel King/Models: 2620 RH, 2621 LH – 240v (2 hot, 1 ground) 50/60Hz.

7100 watts 50 amp plug & receptacle 50 amp plug ( NEMA 6-50P & 6-50R )

Karmel King/ Models: 2630 RH, 2631 LH – 208v (2 hot, 1 ground) 50/60Hz.

6760 watts 50 amp plug & receptacle 50 amp plug ( NEMA 6-50P & 6-50R )

Other Dimensions:

As shown.

40´x 60” Cooling Pan should be located approximately 3-5” below the Corn Treat Mixer Base

Model 2622 (Rolling Table)

Includes Casters

Includes (1) cooling pan ( order p/n 48845 for extra cooling pan)

e-mail: www.gmpopcorn.com

Gold Medal Products Co.

10700 Medallion Drive

Cincinnati, Ohio 45241-4807

Phone: 513-769-7676 fax: 513-769-8500

9/05

MODEL # 2620,2621,2630, AND 2631 3

Page 4

___________________________________ KARMEL KING

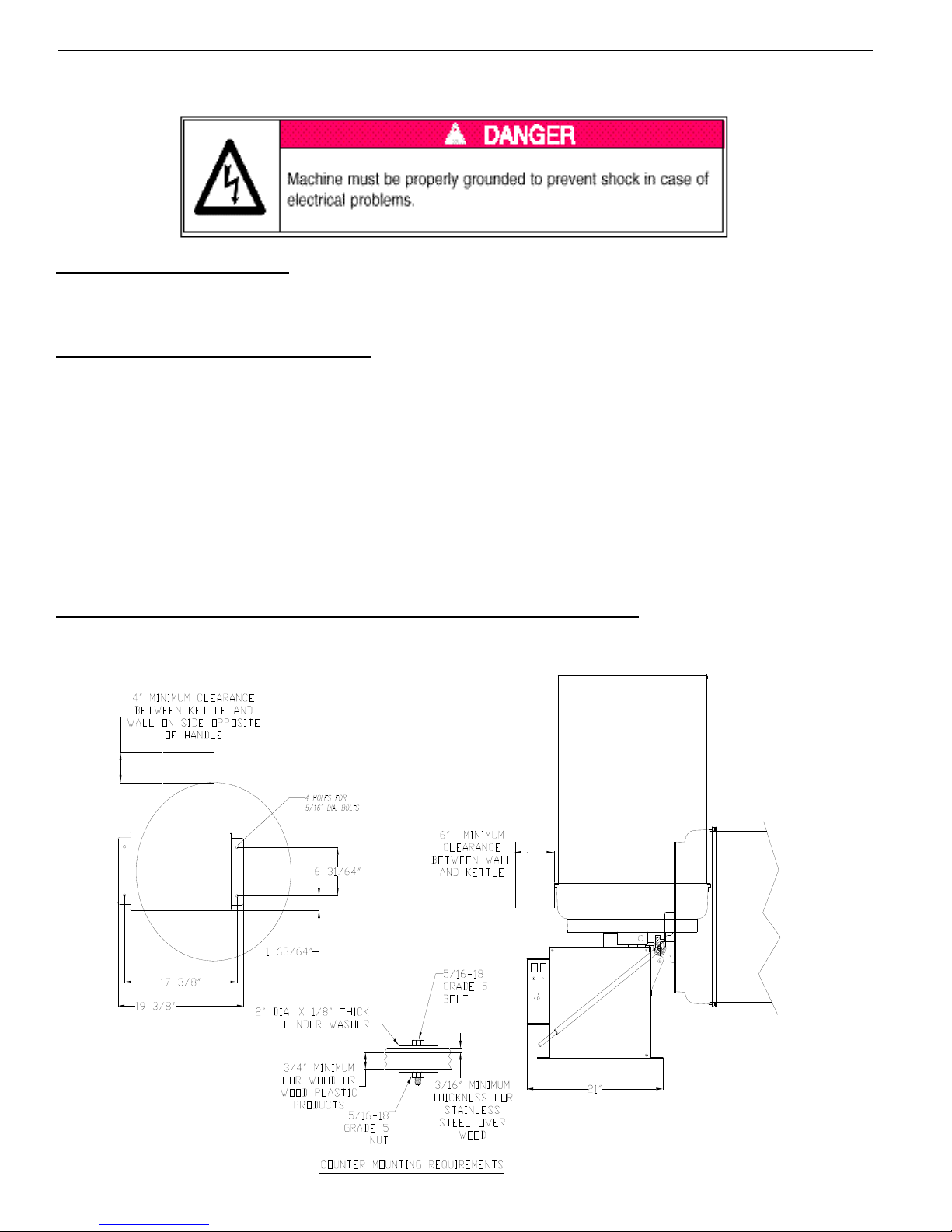

INSTALLATION

CHECKING SHIPMENT

Unpack the shipping crate and check thoroughly for any damage which may have occurred in

transit. Any claims should be filed immediately with the transportation company.

ELECTRICAL REQUIREMENTS

Voltage for the 2620 AND 2621 is 240 volt, 3-WIRE ( 2 HOT, 1 GROUND) 60 cycle single phase. A wall

receptacle is supplied with the machine. This receptacle will accept the attachment plug on your machine

and must be used. The machine will draw a maximum of 30amps. Your electrician must finish sufficient

current for the proper operation of your machine. We recommend that this machine be fused on a line by

itself.

Voltage for the 2630 AND 2631 is 208 volt, 3-WIRE ( 2 HOT, 1 GROUND) 60 cycle single phase. A wall

receptacle is supplied with the machine. This receptacle will accept the attachment plug on your machine

and must be used. The machine will draw a maximum of 30amps. Your electrician must finish sufficient

current for the proper operation of your machine. We recommend that this machine be fused on a line by

itself.

COUNTER MOUNTING REQUIREMENTS/INSTRUCTIONS

MODEL # 2620,2621,2630, AND 2631 4

Page 5

___________________________________ KARMEL KING

CONTROLS AND THEIR FUNCTION

HEAT SWITCH

This rocker switch in the “ON” position energizes the heating elements in the bottom of the kettle.

MOTOR SWITCH

With this rocker switch in the “ON” position, the agitator motor will run continuously.

HEAT CONTROL

The machine comes from the factory preset at 280°F. If more or less heat is required, remove the silver hole

plug or cover plate located on the front panel of the control box. This will allow you to access the heat

control adjustment potentiometer. Turn the potentiometer clockwise to increase the temperature, and

counter-clockwise to decrease.

To calibrate the heat control for corn treat, Fill the mixing bowl with a one inch depth of corn oil. Use an

accurate thermometer to measure the temperature of the oil in the mixing bowl. Turn the motor on to stir the

oil while it heats. When the oil reaches 280F slowly turn the potentiometer counter clockwise until the

buzzer sounds. If the buzzer sounds before the temperature reaches 280F, slowly turn the potentiometer

clockwise until the buzzer stops and continue to turn an additional 1/8 of turn.

Note: The sound of the buzzer always signals temperature cut-off.

CARE AND CLEANING

STEAM CLEANING

The easiest way to clean the kettle is to pour 8 ounces of water into the kettle while it is still hot. Place the

lid back on the kettle. Let it steam for approximately ten minutes. Remove the lid and dump out the water.

You will probably have to steam the kettle twice to remove all traces of product. Releasing the draw latch

makes the mixing drum easy to remove for cleaning. The mixing drum can be taken to the sink to clean.

The cabinet of your machine should be wiped cleaned daily; or more, depending on your usage.

MODEL # 2620,2621,2630, AND 2631 5

Page 6

___________________________________ KARMEL KING

NEW PADDLE & HUB SEAL KIT INSTALLATION

1. Unscrew the wing bolts and remove both mix paddles.

2. Remove the old hub seal assembly.

3. Clean the area around the center hub. Clean up all food and carbon residue.

4. Remove any burrs on the top edge of the center hub. Use a fine grit emery paper to lightly sand the

surface. If the burrs are not removed, damage may occur to the hub assembly during installation.

5. Lightly lubricate the center hub of the kettle with a small amount of vegetable oil to allow for easy

installation of the hub seal assembly.

6. Slide the hub seal assembly down the agitator shaft. Apply pressure to ease the assembly over the

center hub of the kettle until it seats properly. (See diagram below.)

7. After the hub seal assembly has been properly installed, place the new mix paddle on the bottom and

one existing paddle on the top of the agitator shaft.

8. Replace the wing bolts and finger tighten.

MODEL # 2620,2621,2630, AND 2631 6

Page 7

___________________________________ KARMEL KING

MAINTENANCE INSTRUCTIONS

MODEL # 2620,2621,2630, AND 2631 7

Page 8

___________________________________ KARMEL KING

ORDERING SPARE PARTS

1. Identify the needed part by checking it against the photos, illustrations, and/or the parts list.

2. When ordering, please include part number, part name, and quantity needed.

3. Please include your model name, serial number, and date of manufacture (located on the machine

nameplate) with your order.

4. Address all parts orders to:

Parts Department

Gold Medal Products Co.

10700 Medallion Drive

Cincinnati, Ohio 45241-4807

or, place orders at:

(800) 543-0862

(513) 769-7676

Fax: (513) 769-8500

E-mail: info@gmpopcorn.com

Web Page: www.gmpopcorn.com

MODEL # 2620,2621,2630, AND 2631 8

Page 9

___________________________________ KARMEL KING

INSTRUCTIONS FOR MAKING CARAMEL CORN

1. Turn the heat switch "ON".

2. Add 24-28 ounces of water, (4) 22 oz. packages of Gold Medal Caramel Corn Mix, and (16) cups of

granulated sugar.

NOTE: When using the Gold Medal "One Step" Caramel Corn Mix, do NOT add granulated sugar.

3. Turn the motor switch "ON" and mix for approximately one minute. Turn the motor switch "OFF". The

motor will continue to cycle with the motor switch off. (With the heat switch "ON" the motor will run for 30

seconds every minute.)

4. Add four (16) ounce of sticks coconut oil or vegetable oil.

5. Allow the mix to cook until the buzzer sounds at 280° F product temperature.

6. Turn the heat switch "OFF".

7. Turn the motor switch "ON".

8. Add twenty gallons of pre popped corn.

9. Allow the corn to mix for approximately thirty (30) seconds with the kettle in the upright position.

10. Move the kettle to the mix position and mix the popcorn until it is thoroughly coated.

11. Dump the caramel corn into the cooling pan.

MODEL # 2620,2621,2630, AND 2631 9

Page 10

___________________________________ KARMEL KING

PARTS LIST

2620 2621 2630 2631

Part No Part No Part No Part No Description

46488 46488 46488 46488 Tilt Lever

48842 48842 RH Dump Bar Assy.

74660 74660 74660 74660 Torsion Spring

74661 74661 74661 74661 Collar

48839 48839 48839 48839 Hub-For Tilt Lever

48826 48826 48826 48826 Drive Coupling

46152 46152 46152 46152 Kettle Rest

48811 48811 48811 48811 Mixing Paddle

48819 48819 48819 48819 Mixing Drum

89810 89810 89810 89810 Lead In Cord

48813 48813 RH Control Box Weldment

48816 48816 48816 48816 Pedestal Welded Assy.

42006 42006 42006 42006 Terminal Block

42798 42798 42798 42798 Switch, Lighted Rocker

89858 89858 Relay - 240 Volt, DPDT

46120 46120 46120 46120 Buzzer Signal

48301 48301 48301 48301 Capacitor Strap

48880 48880 48880 48880 Kettle Drive Motor

46498 46498 Heat Element 2700W

48650EX 48650EX Heat Element 1800W

48887 48887 Heat Element 2100W

48818 48818 48818 48818 Motor Mount

48825 48825 48825 48825 Agitator Shaft

48809 48809 48809 48809 Kettle

48817 48817 48817 48817 Bottom Cover Plate

68010 68010 68010 68010 RTD Heat Sensor

82219 82219 82219 82219 Thermostat Kettle L-510

48812 48812 48812 48812 Kettle Mount Bracket Casting

46326 46326 46326 46326 500 ohm Potentiometer

48688EX 48688EX 48688EX 48688EX Percentage Timer

55057 55057 55057 55057 RTD Temperature Control

46646 46646 46646 46646 Hub Seal Assy.

48882 48882 LH Dump Bar Assy.

48814 48814 LH Control Box Weldment

69863 69863 Heat Element 1800W

69864 69864 Heat Element 2700W

69865 69865 Heat Element 2100W

62059EX 62059EX Contactor - 2 Pole, 40 Amp

MODEL # 2620,2621,2630, AND 2631 10

Page 11

___________________________________ KARMEL KING

ELECTRICAL SCHEMATIC

MODELS 2620,2621,2630, & 2631

MODEL # 2620,2621,2630, AND 2631 11

Page 12

WARRANTY

WE WARRANT to the original purchaser the Gold Medal equipment sold by us to

be free from defects in material or workmanship under normal use and service. Our

obligation under this warranty shall be limited to the repair or replacement of any

defective part for a period of six (6) months from the date of sale to the Original

Purchaser with regard to labor and two (2) years with regard to parts and does not

cover damage to the equipment caused by accident, alteration, improper use, voltage,

abuse, or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRAN TIES EXPRESSED

OR IMPLIED, AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON OUR

PART, INCLUDING THE IMPLIED WARRANTY OF MERCHANTIBILITY.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION

ON THE FACE HEREOF. We neither assume, nor authorize any other person

to assume for us, any other obligation or liability in connection with the sale of said

GOLD MEDAL equipment or any part thereof.

The term “Original Purchaser” as used in this warranty shall be deemed to mean that

person, firm, association, or corporation who was billed by the GOLD MEDAL

PRODUCTS COMPANY, or their authorized distributor for the equipment.

THIS WARRANTY HAS NO EFFECT AND IS VOID UNLESS THE ORIGINAL

PURCHASER FIRST CALLS GOLD MEDAL PRODUCTS COMPANY AT 1-800543-0862 TO DISCUSS WITH OUR SERVICE REPRESENTATIVE THE

EQUIPMENT PROBLEM, AND, IF NECESSARY, FOR INSTRUCTIONS

CONCERNING THE REPAIR OR REPLACEMENT OF PARTS.

GOLD MEDAL PRODUCTS COMPANY

10700 Medallion Drive

Cincinnati, Ohio 45241-4807 USA

www.gmpopcorn.com

Phone: 1-800-543-0862

Fax: 1-800-542-1496

© The text, descriptions, graphics and other material in this publication are the proprietary

and exclusive property of Gold Medal Products Company and shall not be used, copied,

reproduced, reprinted or published in any fashion, including website display, without its

express written consent.

Loading...

Loading...