Page 1

EXPORT MACHO POP

a

Instruction Manual

Models 2553EX & 2554EX

Part No. 69915EX

Revised: December 2008

Cincinnati, OH 45241-4807 USA

Page 2

SAFETY PRECAUTIONS

a

Page 3

MACHO POP

a

INSTALLATION INSTRUCTIONS

Inspection of Shipment:

Unpack all cartons and check thoroughly for any damage that may have occurred during transit.

Damage claims should be filed immediately with the transportation company. Gold Medal is not

responsible for damage that occurs in transit.

Setup:

Electrical Requirements:

Your electrician must furnish sufficient current for proper machine operation. We recommend this

popper be on a dedicated and circuit protected line. Failure to wire properly will void the

warranty and can result in damage to the heat elements, light, motor and etc.

Before Plugging in the Machine:

Your new Macho Pop Popcorn Machine is completely assembled and tested at the factory.

Remove all packing material and tape before starting operation.

The following power supply must be provided:

230 VAC, 50 Hz., 20 Amp Fused Circuit

The 2554EX has a current draw of 7.4 Amps at 1700 Watts.

The 2553EX has a current draw of 10 Amps at 2300 Watts.

It is Gold Medal Products Company’s recommendation that this machine be plugged directly

into a wall outlet. The use of extension cords is not recommended due to safety reasons and

the popper’s performance will be sacrificed/reduced.

1. Make sure that the wall outlet can accept the three (3) prong grounded plug on the power

supply cord.

2. The wall outlet must have the proper polarity. If in doubt, have a competent electrician

inspect the outlet and correct if necessary.

3 MODELS: 2553EX & 2554EX

Page 4

MACHO POP

(Use the supplied corn measure cup.)

a

Operating Instructions – Controls and Their Functions

Oil System Master Switch (2553EX Only):

Sends power to the oil pump, either the Bucket Pump or Bag-in-a-Box models. The

warmer/blower on the oil pump is activated. The warmer/blower on the oil pump will keep

coconut popping oil liquid if the doors on the base are kept closed. It may be desirable to

keep this switch on at night, if you have problems keeping the coconut oil liquid. Coconut oil

will congeal at temperatures below approximately 76º F [24º C].

“Red” Oil Dispense Momentary Switch (2553EX Only):

When pushed, will dispense the predetermined amount of oil into the kettle. See page 5 of

this manual for oil setting instructions.

Light & Warmer Switch:

This switch operates the interior light, the lighted sign, and the corn deck freshener

heat elements.

Kettle Motor Switch:

This switch operates the popcorn agitator shaft. This switch must be ON at all times

when popcorn (popped and un-popped) exist in the kettle. This switch also activates

the exhaust fan.

Kettle Heat Switch:

This switch turns on the heat element located in the popcorn kettle by sending power

to the “Big Eye” – electronic control system.

Yellow Light & Audible Signal (LOAD – DUMP) :

The Macho Pop is equipped with the state-of-the-art “B

“watches your popcorn machine” to deliver optimum popping performance.

The “Big Eye” control will signal the operator to:

1. Load the corn and oil or

2. Dump the popped corn from the kettle or

3. Turn off the kettle heat switch if they are done popping corn

ig Eye” electronic control that

Amount of Popcorn and Oil:

The Macho Pop is equipped with a 16 ounce corn measure cup. Gold Medal

Products Company recommends the use of flavored and colored coconut oil.

Coconut oil does not leave black deposits in the kettle like other oils.

Corn Charge: 16 Oz. (355 ml)

Oil Charge: 4-5 Oz.

Flavacol (Salt): 4 Tablespoons (11 cc. – Use the supplied salt scoop.)

4 MODELS: 2553EX & 2554EX

Page 5

MACHO POP

installed on the top box.

a

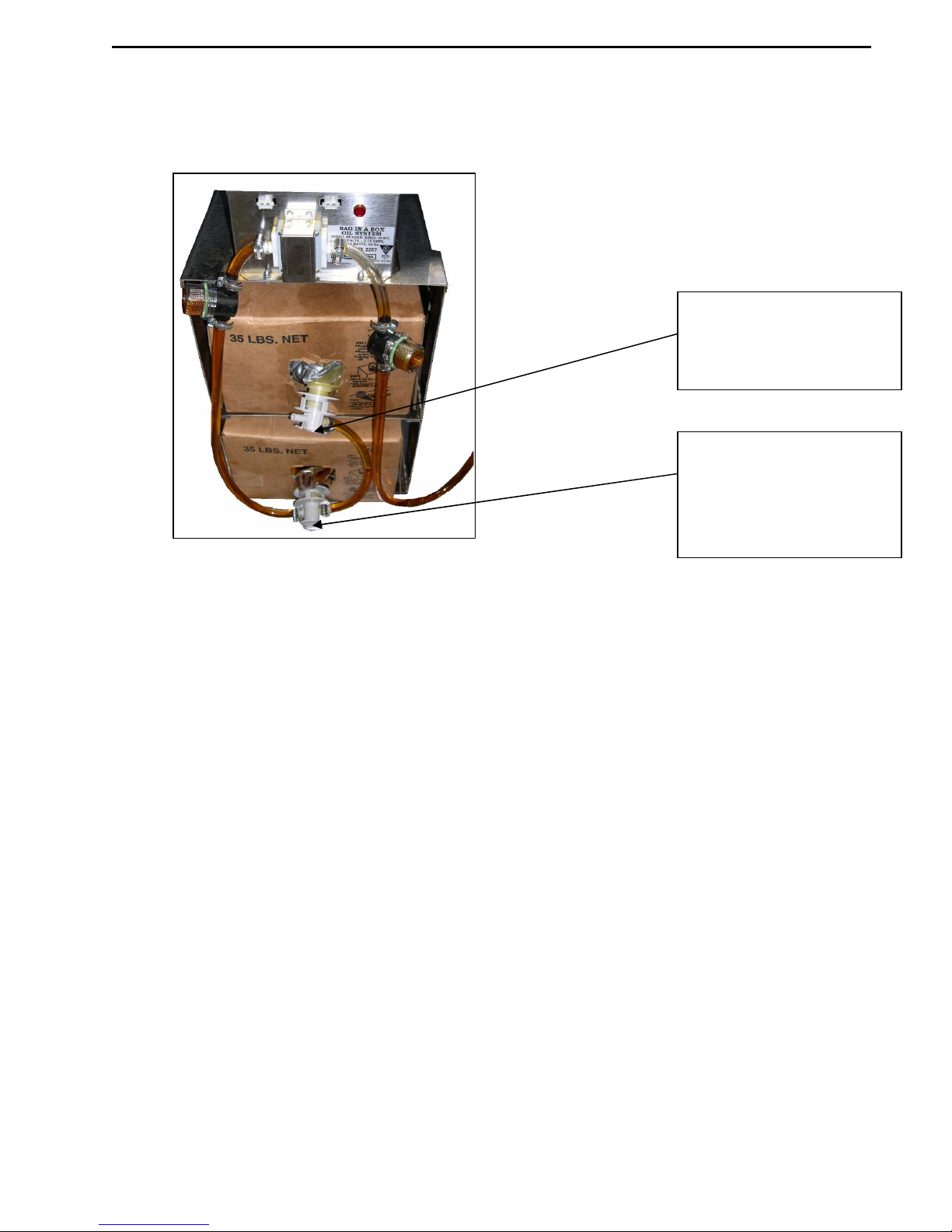

Setting the Amount of Popping Oil with a Gold Medal BIB

System

In March 2003, we introduced the model 2257EX with the E-Z Set control.

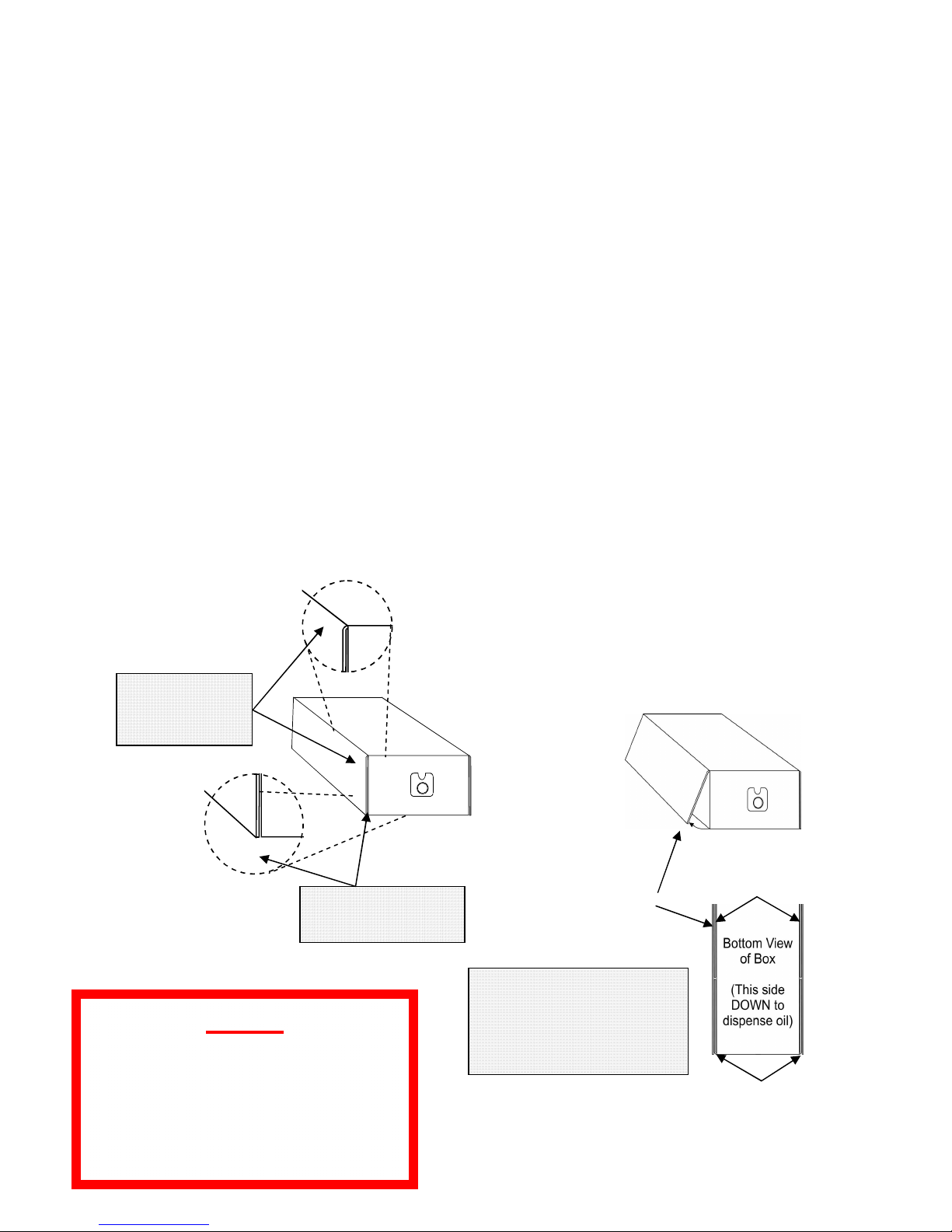

Note: When connecting the bag-in-box

system, you must be sure to connect the

bag connectors as shown in the picture

to the left.

With this system, it is not necessary to set a timer. To adjust the oil amount, follow these

instructions:

Holding the RED Oil Dispense push button (on the popper) down while turning on the Oil System

Master switch (on the popper) puts the unit in the program mode. The oil light (on the popper) will

start to blink off and on indicating that the timer is in the program mode.

When in the program mode press and release the oil Dispense switch to start the oil flowing.

When the correct amount of oil has been dispensed into the measuring cup push the oil

Dispense switch again to stop the oil flow. The oil amount can be “topped off” by pushing the oil

Dispense switch on/off as many times as needed to finalize the oil amount. Turning the Oil

System Master switch off and then back on puts the unit in the regular mode. The unit will now

dispense the “programmed” amount of oil when the oil Dispense switch is pushed. The oil light

will light only when the oil pump is on.

The dead-leg connector

(With only one hose

connected to it) must be

The Pass-thru connector

The Pass-thru connector

(With two hoses

(With two hoses

connected to it) must be

connected to it) must be

installed on the bottom

installed on the bottom

box.

box.

You will need to perform this procedure with the oil lines full of oil. Otherwise, you are setting both

e amount of oil that goes in the kettle and the amount of oil required to fill the lines. Just fill the

th

lines using the process above, then reset the amount as described above.

NOTES:

Model 2257DX is has the capability of “remembering” two different settings for poppers with the

“Salt/Sweet” option or “Flexi-Pop option.

- For Salt/Sweet models, just put the switch in the “salt” position, and set the oil amount as

described above. Then put the switch in the “sweet” position and repeat the setting procedure. The

pump will remember both settings.

- For Flexi-Pop models, just put the “Load” switch in one position, 32oz. for example, then set the oil

amount. Then put the load switch in the other position, 18oz. for example. And repeat the setting

procedure.

- Model 2457 is the heated line option for the 2257EX pump.

5 MODELS: 2553EX & 2554EX

Page 6

Preventing and Troubleshooting Oil Delivery Issues

This edge is

from this edge.

The bottom of the side

TOP

Front

Side Flap

TOP

Looking at the box from the

NOTE

a

It may occur at times that the Bag-In-Box oil pumping system does not deliver oil to the kettle, or

delivers it in incorrect amounts. This section is intended to list the most common causes of these

problems, and the procedures necessary to prevent and, if necessary, correct them.

Oil Temperature – Coconut oil becomes a solid at temperatures above the average room

temperature.

For this reason, it is necessary to ensure that the oil has been permitted to come to working

temperature before attempting to pump it through the system. If the machine has not been used for

several days, the oil master switch should be turned on the night before it is expected that the

machine will be used. For machines which are in daily use, even if not round the clock, leave the oil

master switch on at all times and keep the base cabinet doors closed to prevent the oil from

becoming solid.

Bag-In-Box Mounting – Because the bag’s dispensing connector is offset toward the bottom of the

box, to permit free oil flow and complete emptying of the oil from the bag, the box should never be

mounted upside down. Most boxes supplied will be clearly marked as to which side should be up

during dispensing. (Note that in some cases the box is intended to be stored with one side up, but to

be turned and used in dispensing with the other side up.) Be sure to double check to ensure that the

box is mounted in the correct dispensing orientation.

You may encounter boxes with no clear markings to indicate dispensing orientation. A reliable guide

in this case (and also for those boxes which are marked), is the direction that the top side flap of the

corrugated box is folded. When the box is properly mounted for dispensing, the top side flap will fold

down from the top edge of the box, so that if one were to attempt to separate the flap it would be

necessary to pull up from the bottom edge. See the illustrations below.

seamless. The side

flap folds down

The Bag-In-Box oil pumping system is NOT

designed to function when the bag has

been removed from the box. Service

results in such a situation are

unpredictable. Do not attempt to operate

the system with a bag which has been

removed from the box.

flap can be seen to be

open, not seamless,

Top Side Flap

bottom, the front and rear side

flaps can be seen folded along

the side of the box toward the

middle, and the outer, top side

flap folded down to cover them.

Rear Side Flap

Page 7

MACHO POP

2. Holding the bag connector, slide

a

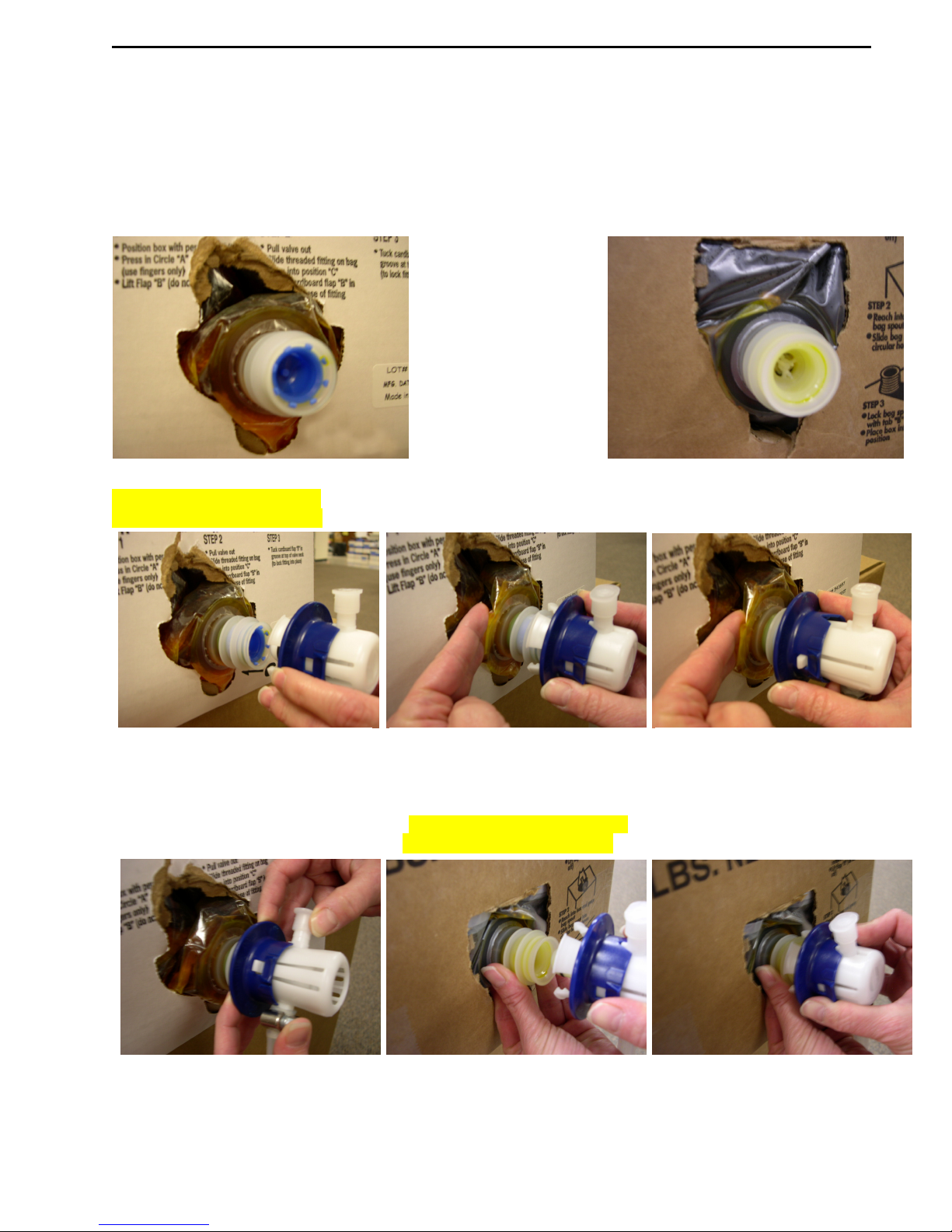

Bag and Hose Connector Issues – There are two different types of dispensing nozzles employed

on the Bag-In-Box oils, as well as two different types of connectors installed on the oil pumping

system hoses which connect to the bag’s dispensing nozzles. The particular combination of

connectors in your system will determine the appropriate method for connecting the Bag-In-Box oil

bag to the system hosing. These combinations will be illustrated and explained in the following

section.

Bag Dispensing Nozzle – Blue Insert Bag dispensing Nozzle – White

Insert

Blue Insert Bag Nozzle with

Blue/White Hose Connector

1. With the blue collar on the hose

connector retracted toward

crosspiece, slide hose connector

shell onto bag nozzle.

White Insert Bag Nozzle with

Blue/White Hose Connector

4. Place fingers behind flange and

use thumbs to slide the crosspiece

forward into the nozzle. Oil flow is

initiated.

2. Holding the bag nozzle behind

the flange, slide the blue collar

forward to lock the hose connector

onto the bag nozzle.

1. With the blue collar on the hose

connector retracted toward

crosspiece, slide hose connector

shell onto bag nozzle.

3. Connector shown with shell

correctly engaged and collar

forward in lock position.

the blue collar forward to lock the

hose connector onto the bag

nozzle.

7 MODELS: 2553EX & 2554EX

Page 8

MACHO POP

connector from Gold Medal.

NOTE

:

nozzle is now ready to be use

d with a blue hose connector.

a

3. Connector shown with shell

correctly engaged and collar

forward in lock position. Oil flow

commences. Do not slide

crosspiece forward.

White Insert Bag Nozzle

with Gray Hose Connector

3. Connector shown with shell

correctly engaged and plunger

forward in lock position. Oil flow

commences.

3. Connector shown with shell

correctly engaged and plunger

forward in lock position. Since the

White Insert Bag Nozzle is not

designed to work with the insert

pressed forward, this configuration

may or may not work. If it does

not, remove the gray hose

connector and order the blue hose

Blue Insert Bag Nozzle

with Gray Hose Connector

1. Grasp the bag nozzle and slide

the gray hose connector on from

the side.

1. Grasp the bag nozzle and slide

the gray hose connector on from

the side.

If the oil does not flow after engaging plunger on gray hose

connector, or if the crosspiece is inadvertently pushed forward when

using the blue hose connector with the white insert nozzle, the nozzle

center slider insert will be left pushed back into the bag, as shown

above left.

To correct this, place fingers behind nozzle as shown above

right. You will feel the center slider protruding slightly into the bag.

Holding the nozzle body from the front, press the slider from the back

side of the nozzle until it snaps outward into its correct position. The

2. With the hose connector in

place, place fingers behind flange

on connector and press plunger

forward to lock.

2. With the hose connector in

place, place fingers behind flange

on connector and press plunger

forward to lock.

8 MODELS: 2553EX & 2554EX

Page 9

MACHO POP

a

Popping Instructions:

1. Turn both the KETTLE HEAT and KETTLE STIR MOTOR switches ON.

2. Wait until the Yellow Light and Audible Signal activate.

3. Load both a full corn/oil charge and Flavacol Seasoning Salt into the kettle. Close

the lids.

4. When the corn has finished popping, the Yellow Light and Audible Signal will “tell

you” to dump the kettle.

Remember:

If the Yellow Load - Dump light is turned on and the Signal is sounding one of the

following actions should be taken:

1. Load the corn and oil or

2. Dump the popped corn from the kettle or

3. Turn off the kettle heat switch when popping of corn is complete

On the final kettle of corn, it is a good idea to turn the KETTLE HEAT switch OFF just

as the lids are forced open by the popping corn. This procedure saves electricity

since the kettle has plenty of heat, and eliminates smoke/odor from any oil residue

that remains after you have finished popping.

When you are finished popping, make sure “KETTLE HEAT” and “KETTLE MOTOR”

switches are turned “OFF”.

NEVER LEAVE THE HEAT ON WHEN YOU ARE NOT POPPING CORN.

9 MODELS: 2553EX & 2554EX

Page 10

MACHO POP

a

Care and Cleaning

DAILY:

Clean the Kettle

1. As you pop corn, wipe the kettle with a clean cloth. It is easy to keep the outside clean

when the kettle is warm and the oil is not baked on. CAUTION: The hot kettle will cause

burns if you touch it with your hand. Allow the kettle to cool for at least 1 hour before

attempting to clean.

2. Every night, mix a gallon of Heat’n Kleen solution (2 tablespoons per gallon of water).

Add 16 oz. of this solution into the kettle. Turn on the kettle heat. When the water starts

to boil, turn off the kettle heat, and allow the solution to work over-night.

3. The next morning, dump the solution into a bucket and wipe the inside of the kettle with

a cloth. Make sure all of the solution goes into the bucket, and that you do not spill any

into the interior cabinet of the machine.

NOT immerse the kettle in water or any other cleaning solution, this will void the

DO

warranty.

Clean the Popcorn Machine

1. Wipe the stainless steel parts with a clean cloth and cleaner designed for stainless steel.

Do not use oven cleaners, as they will damage parts of the machine..

2. Ammonia cleaners will damage the plastic doors. Use only non-ammonia cleaners,

such as Gold Medal’s – Watchdog Glass Cleaner – item number 2588.

10 MODELS: 2553EX & 2554EX

Page 11

MACHO POP

a

Filter Cleaning Instructions

Your popcorn machine is equipped with an efficient and durable filtration

system. However, the filter should be cleaned every 1-2 weeks to maintain

efficiency. Follow the steps below for proper filter cleaning:

1. The filter is located on the inside of the popcorn machine, directly

above the popping kettle.

2. Remove the filter by gripping the filter itself, and pulling straight down.

(As shown below.)

3. Clean the filter in warm soapy water, and allow to dry overnight.

Replace the filter by putting it into the slot, and pushing upward. (As

shown below) Make sure the filter frame is flush with the roof of the

machine. (As shown above)

11 MODELS: 2553EX & 2554EX

Page 12

MACHO POP

a

MAINTENANCE INSTRUCTIONS

12 MODELS: 2553EX & 2554EX

Page 13

MACHO POP

a

ORDERING SPARE PARTS

1. Identify the needed part by checking it against the photos, illustrations, and/or the parts list.

2. When ordering, please include part number, part name, and quantity needed.

3. Please include your model name, serial number, and date of manufacture (located on the

machine nameplate) with your order.

4. Address all parts orders to:

Parts Department

ld Medal Products Co.

Go

10700 Medallion Drive

Cincinnati, Ohio 45241-4807

or, place orders at:

(800) 543-0862

(513) 769-7676

Fax: (513) 769-8500

E-mail: info@gmpopcorn.com

Web Page: www.gmpopcorn.com

13 MODELS: 2553EX & 2554EX

Page 14

MACHO POP

a

Temperature Control

The Macho Pop has a electronic kettle control with 2 thermocouples, one

for control and one for limit. There are no mechanical thermostats in this

kettle.

There are (4) factory adjustments on the control:

Control temperature – do not adjust this one

Signal to dump – If you want the signal to dump to be a little sooner

or later you can adjust the potentiometer marked “kettle dump”.

CW is sooner, CCW is later.

The patented overshoot circuit is tuned for the kettle, do not

this potentiometer.

The audible signal to dump has three options; full volume, half

volume, no sound (just the yellow light). Adjustments are by jumper

positions. This is set to full volume from the factory.

adjust

It does not matter which TC

goes to A or B. It does matter

that the yellow leads go to the

positive terminals.

Remove this

jumper for no

sound

Remove this

jumper for lower

volume

The control temperature is set

at 460F, DO NOT ADJUST

The overshoot is set at (-20%), full

CW position, DO NOT ADJUST

This is the “Kettle

Dump” adjustment, and

is factory set to signal

when the kettle is ready

to dump. Turning CW

will signal sooner, CCW

will signal later. If you

need to adjust, make

very small adjustments.

14 MODELS: 2553EX & 2554EX

Hot Lead is

at L1,

Neutral lead

at L2.

Page 15

MACHO POP

Kettle

with Bonded On

Terminal Shunt Bar

Gasket 16oz

Dump Handle Assy

Kettle Cord Assy

Kettle Shell S.S.

Junction Box

a

Kettle Assembly – (Complete Kettle Assembly 56100XE)

p/n 47102

p/n 62305

Elements

p/n 55167

p/n 47393

p/n 41131

p/n 77864

p/n 41598

15 MODELS: 2553EX & 2554EX

Page 16

MACHO POP

Retaining Ring

Spur Gear

Oil Tube W/Funnel

p/n

41239

Set Collar

Front Kettle Lid

Crossbar Assy.

(2553

EX

uses 41

086)

Th

readed Block

Needle Bearing

Crossbar Bushing

Rear Kettle Lid

10-32X ½” Screw

Agitator Shaft Assy.

a

p/n 49701

p/n 47060

(2553EX Only)

p/n 47326

p/n 41123

p/n 41180

p/n 61167

p/n 47106

p/n 41093

p/n 47097

p/n 41120

p/n 40717

16 MODELS: 2553EX & 2554EX

Page 17

MACHO POP

Door

s (2)

Lexan Front Panel

Old Maid Pan

Rubber Feet

Unimaxx Kettle

56101E)

Corn Pan

p/n

50186

See page 19 for

Optional Salt

-

Switch Plate

50090)

Lighted Rocker

p/n 42798

Dome

Oil Switch and

Pilot Light, Amber

230V

Warmer Element

a

Cabinet Parts

Sweet Switch

p/n 48615

p/n 69854

p/n 50179

p/n 50180

Weldment

Switches

(2) req’d – Not

Shown

p/n 40557

p/n 40276

p/n 55039EX

door hardware.

p/n 56100XE

(2553 uses p/n

p/n 41282

Pump Button

(2553EX only)

Rocker is p/n 42798

Red Push Button is

p/n 41031

p/n 50087

(2553EX uses p/n

17 MODELS: 2553EX & 2554EX

Page 18

MACHO POP

Reflector Flood, 65W

Filter Box

Fluorescent Light

p/n

16264

Lamp Holder

Kettle Drive

p/n

47067

Gear Block

Hang

e

r Arm

p/n 47262

Hang

e

r Arm Rear

Spur Gear

Sign, Lighted

p/n 41301

Receptacle Assy

Exhaust

Blower

Temperature

p/n 41001

a

p/n 67194

p/n 47060

Front

p/n 47228

p/n 41671

p/n 69851

Control

p/n 55177

p/n 48037

Motor

p/n 47047

Tube

18 MODELS: 2553EX & 2554EX

Dome

Page 19

MACHO POP

a

Door Hardware

8-32 X 3/8” Screws for

Male Hinges

p/n 42044

Screws and magnets for Door Knobs (Not Shown)

Screws p/n 42044 / Magnets p/n 50013

Door Knobs

p/n 41013

Left Hand

Male Hinges

p/n 41349

Left Hand

Female Hinges

p/n 61359

8-32 X 1/2” Screws for

Female Hinges

p/n 47141

8-32Acorn Nuts for

Screws

p/n 47702

Right Hand

Female Hinges

p/n 61373

Right Hand

Male Hinges

p/n 41350

19 MODELS: 2553EX & 2554EX

Page 20

MACHO POP

a

ELECTRICAL SCHEMATIC

20 MODELS: 2553EX & 2554EX

Page 21

WARRANTY

WE WARRANT to the original purchaser the Gold Medal equipment sold by us to

be free from defects in material or workmanship under normal use and service. Our

obligation under this warranty shall be limited to the repair or replacement of any

defective part for a period of six (6) months from the date of sale to the Original

Purchaser with regard to labor and two (2) years with regard to parts and does not

cover damage to the equipment caused by accident, alteration, improper use, voltage,

abuse, or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRAN TIES EXPRESSED

OR IMPLIED, AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON OUR

PART, INCLUDING THE IMPLIED WARRANTY OF MERCHANTIBILITY.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION

ON THE FACE HEREOF. We neither assume, nor authorize any other person

to assume for us, any other obligation or liability in connection with the sale of said

GOLD MEDAL equipment or any part thereof.

The term “Original Purchaser” as used in this warranty shall be deemed to mean that

person, firm, association, or corporation who was billed by the GOLD MEDAL

PRODUCTS COMPANY, or their authorized distributor for the equipment.

THIS WARRANTY HAS NO EFFECT AND IS VOID UNLESS THE ORIGINAL

PURCHASER FIRST CALLS GOLD MEDAL PRODUCTS COMPANY AT 1-800543-0862 TO DISCUSS WITH OUR SERVICE REPRESENTATIVE THE

EQUIPMENT PROBLEM, AND, IF NECESSARY, FOR INSTRUCTIONS

CONCERNING THE REPAIR OR REPLACEMENT OF PARTS.

GOLD MEDAL PRODUCTS COMPANY

10700 Medallion Drive

Cincinnati, Ohio 45241-4807 USA

www.gmpopcorn.com

Phone: 1-800-543-0862

Fax: 1-800-542-1496

© The text, descriptions, graphics and other material in this publication are the proprietary

and exclusive property of Gold Medal Products Company and shall not be used, copied,

reproduced, reprinted or published in any fashion, including website display, without its

express written consent.

Loading...

Loading...