Page 1

Part No. 67833

Econo-16

Models 2024, 2024ST

16oz. Popcorn Machine

Instruction Manual

Cincinnati, OH 45241-4807 USA

Page 2

16 oz. Econo-16

2

DANGER

DANGER

WARNING

WARNING

WARNING

WARNING

SAFETY PRECAUTIONS

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury, or death. Any alterations to this equipment

will void the warranty and may cause a dangerous condition. This appliance

is not intended to be operated by means of an external timer or separate

remote-control system. NEVER make alterations to this equipment. Read the

Installation, Operating, and Maintenance Instructions thoroughly before

installing, servicing, or operating this equipment.

008_051514

014_020416

To avoid burns, DO NOT touch the kettle or any heated surface.

DO NOT place or leave objects in contact with heated surfaces.

ALWAYS wear safety glasses when servicing this equipment.

No user serviceable parts inside. Refer servicing to qualified service

personnel.

Read and understand operator’s manual and all other safety instructions

before using this equipment. To order copies of the operator’s manual go to

gmpopcorn.com or write to Gold Medal Products Co., 10700 Medallion Drive,

Cincinnati, OH 45241 USA 1-(800)-543-0862

013_092414

010_010914

011_051514

022_060215

Models #2024, 2024ST

Page 3

16 oz. Econo-16

3

WARNING

WARNING

SAFETY PRECAUTIONS (continued)

DO NOT allow direct contact of this equipment by the public when used in

food service locations. Only personnel trained and experienced in the

equipment operation may operate this equipment.

Carefully read all instructions before operation.

This machine is NOT to be operated by minors.

Note: Improvements are always being made to Gold Medal’s equipment. This information may

not be the latest available for your purposes. It is critical that you call Gold Medal’s Technical

Service Department at 1-800-543-0862 for any questions about your machine

operations, replacement parts, or any service questions. (Gold Medal Products Co. does

not assume any liability for injury due to careless handling and/or reckless operation of this

equipment.) General images may be used in manual for reference only.

012_010914

007_010914

Models #2024, 2024ST

Page 4

16 oz. Econo-16

4

DANGER

INSTALLATION INSTRUCTIONS

Inspection of Shipment

After unpacking, check thoroughly for any damage which may have occurred in transit. Claims should be

filed immediately with the transportation company. The warranty does not cover damage that occurs in

transit, or damage caused by abuse, or consequential damage due to the operation of this machine, since it

is beyond our control (reference warranty in back of manual).

Manual

Read and understand the operator’s manual and all other safety instructions before using this equipment.

To order copies of the operator’s manual go to gmpopcorn.com or write to Gold Medal Products Co., 10700

Medallion Drive, Cincinnati, OH 45241 USA 1-(800)-543-0862.

Model Description

Model 2024: 16 oz. Econo-16 Popper with LED cabinet lighting, and a red dome.

Model 2024ST: 16 oz. Econo-16 Popper with LED cabinet and sign lighting, and stainless steel dome.

Setup

This unit has been tested at the factory.

1. Remove all packaging and tape prior to operation.

2. Place the unit on a sturdy, level base.

3. The door knobs are shipped facing the inside of the machine. Re-adjust knobs to face the

outside of the machine.

4. After setup, unit should be cleaned prior to use (see Care and Cleaning section of this manual).

Electrical Requirements

The following power supply must be provided:

Model 2024 and 2024ST: 120 V~, 1900 W, 60 Hz

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

A certified electrician must furnish sufficient power for proper machine operation and install any supplied

receptacle. We recommend this equipment be on a dedicated and protected circuit. Failure to wire properly

will void the warranty and may result in damage to the machine. It is Gold Medal Products Co.’s

recommendation that this machine be plugged directly into a wall outlet. The use of extension cords is not

recommended due to safety concerns, and may cause sacrificed and/or reduced performance. Make sure

cord is located to prevent a trip hazard or unit upset.

008_051514

Models #2024, 2024ST

Page 5

16 oz. Econo-16

5

CAUTION

Before You Plug In Machine

1. Make sure all machine switches are OFF before plugging equipment into receptacle.

2. Make sure wall outlet can accept the grounded plugs (where applicable) on the power supply

cord.

3. The wall outlet must have the proper polarity. If in doubt, have a competent electrician inspect

the outlet and correct if necessary.

4. DO NOT use a grounded to un-grounded receptacle adapter (where applicable).

5. Install unit in a level position.

If the supply cord is damaged, it must be replaced by Gold Medal Products Co.,

its service agent or similarly qualified persons in order to avoid a hazard.

039_080614

Models #2024, 2024ST

Page 6

16 oz. Econo-16

6

Kettle Size

Popcorn Charge

Oil Charge

Flavacol (Salt)

OPERATING INSTRUCTIONS

CONTROLS AND THEIR FUNCTIONS

LIGHT SWITCH

Operates cabinet lighting (and sign lighting for Model 2024ST).

WARMER SWITCH

Operates the heaters for the heated corn pan.

KETTLE HEAT SWITCH (and Indicator Light)

Operates the heating elements in the popping kettle. The Indicator Light will turn ON when the Kettle

Heat Switch is ON.

KETTLE MOTOR SWITCH

Operates the kettle agitator motor.

Popping Instructions

Amount of Popcorn and Oil – Salted Popcorn

The popper is equipped with a corn, salt, and oil measure. We recommend flavored and colored coconut oil.

Popcorn popped in coconut oil stays fresh longer and does not leave black deposits in the kettle like other

oils. Use only top quality, fresh popcorn from reputable suppliers.

16 oz. 16 oz. (473 ml) 5 oz. (148 ml) 1.5 Tblsp. (20cc)

For best results use Mega-Pop® 16 oz. premeasured pouches (Item# 2846).

Popping Standard (Salted) Popcorn

1. Turn all switches ON.

2. To determine when kettle is ready to pop corn (about 4 minutes), test pop three kernels of corn

in one ounce (30 ml) of popping oil. When kernels pop, kettle is ready.

3. Lift kettle lid and load Mega-Pop® premeasured popcorn and oil pouch, or pour in popcorn and

Flavacol, then add oil in premeasured amount; close lid.

4. When corn has finished popping, gently dump the popcorn.

5. On final kettle of corn, turn Kettle Heat Switch OFF just as lids are forced open by the popping

corn. This procedure saves electricity, since kettle has plenty of heat, and helps eliminate

smoke/odor from any oil residue that remains after popping has stopped.

6. When finished popping, turn KETTLE HEAT and KETTLE MOTOR switches OFF.

NEVER LEAVE THE HEAT ON WHEN YOU ARE NOT POPPING CORN!

Models #2024, 2024ST

Page 7

16 oz. Econo-16

7

DANGER

WARNING

Care and Cleaning

Machine must be properly grounded to prevent electrical shock to personnel.

DO NOT immerse in water. DO NOT clean appliance with a water jet.

Always unplug the equipment before cleaning or servicing.

To avoid serious burns, DO NOT touch the kettle while it is hot!

Good sanitation practice demands that all food preparation equipment be cleaned regularly (only use nontoxic, food grade cleaners). A clean looking, well-kept machine is one of the best ways of advertising your

product.

Note: It is extremely important to follow all cleaning procedures, otherwise parts damage and

equipment failure will result. The warranty does not cover parts that are damaged due to

improper cleaning.

025_111616

028_082715

Daily Kettle Cleaning Instructions

CAUTION: A hot kettle will cause burns if you touch it with your hand. Allow kettle to cool at least 1

hour before attempting to clean. DO NOT use ice or water to cool down a hot kettle!

Severe kettle damage will result!

1. When cool, wipe outside of kettle with a clean, soft cloth. DO NOT use oven cleaners or abrasive

materials as they will damage the kettle.

2. Every night, mix Gold Medal’s Heat’n Kleen solution (Item No. 2095), 2 tablespoons per gallon of

water. It is not necessary to use the entire gallon at once; only use enough to fill the kettle 1/2

inch deep.

3. Turn kettle heat ON. When water starts to boil, turn kettle heat OFF.

4. Allow to cool at least 1 hour, then dump solution into a bucket and wipe inside of kettle with a

clean cloth. Make sure all solution goes into the bucket; do not spill any in the interior of

machine.

For an extra dirty kettle, the process may be repeated; or, after turning kettle heat OFF, allow

solution to sit in kettle overnight. The next morning, dump solution into a bucket and wipe inside

of kettle with a clean cloth.

5. With unit OFF and unplugged, wipe kettle lead cord with a clean SLIGHTLY damp cloth. DO NOT

get moisture into the kettle lead-in cord, severe damage will result.

Daily Unit Cleaning Instructions

1. Turn machine OFF, unplug unit and allow it to cool before attempting to clean.

2. Clean all pans/accessories in order to sanitize them before each use.

3. Take a clean, SLIGHTLY damp cloth and wipe excess grease from glass and cabinet.

Models #2024, 2024ST

Page 8

16 oz. Econo-16

8

4. Wipe stainless steel parts with a clean cloth and cleaner designed for stainless steel, such as

Gold Medal Watchdog Stainless Cleaner (Item No. 2088).

DO NOT use oven cleaners or abrasive materials as they will damage parts of machine.

5. Clean glass panels with glass cleaner. Gold Medal Watchdog Glass Cleaner (Item No. 2588) is

recommended.

Ammonia cleaners will damage plastic doors/panels. Use only non-ammonia cleaners, such as

Gold Medal Watchdog Glass Cleaner (Item No. 2588).

6. The popcorn machine is equipped with an efficient and durable filtration system. The filter should

be cleaned every week to maintain maximum efficiency. Clean filter in warm soapy water, then

rinse and allow to dry overnight. Reinstall filter to its original position.

Models #2024, 2024ST

Page 9

16 oz. Econo-16

9

Issue

Possible Cause

Solution

Power to the Unit

Kettle Does Not Heat

Long Popping Cycles

Kettle Agitator Shaft not

Troubleshooting

A. Power to the Unit A. Make sure the unit’s power cord is plugged

in.

A. Power to the Kettle A. Make sure kettle lead-in cord is plugged in

and twisted to lock into the kettle receptacle.

B. Kettle Heat Switch B. Have a qualified service person check the

voltage to and from the Kettle Heat Switch; if

switch is defective, replace it.

C. Heating Element C. Heating element in the kettle may be burned

out. Check with a qualified service person for

inspection/repair.

A. Low Voltage A. If the machine is operated on low voltage,

(Longer than 4 minutes for

Salt Popcorn)

B. Inadequate Supply Lines B. Inadequately sized electrical supply lines or

C. Inferior Corn C. Inferior quality corn would result in longer

A. Kettle Motor Switch A. If the kettle agitator shaft is not rotating,

Rotating

B. Kettle Agitator Shaft/Stir

Blade not rotating. (Unit

must be OFF,

unplugged and cool

prior to checking or

adjusting the agitator

assembly.)

this could cause the kettle not to reach the

proper operating temperature. Check with a

qualified electrician.

use of extension cord, in addition to being a

fire hazard, would also prevent the kettle

from reaching the proper operating

temperature. Check with a qualified

electrician.

popping cycles. Use only top quality hybrid

popcorn from reputable suppliers. Even

then, if you let your corn pick up moisture or

dry out, your popping cycles will be slow.

DO NOT pop corn. Make sure the Kettle

Motor Switch is ON. If the switch is ON, and

the shaft is not rotating, the switch or motor

may be faulty, contact qualified service

personnel for inspection/repair.

B. If the kettle agitator shaft is not rotating,

DO NOT pop corn.

• Kettles with a FIXED Stir Rod – check

the clearance between the shaft with

welded stir blade and the kettle bottom; it

should be a minimum of 1/32” (thickness of

a dime).

To make shaft adjustments, reference the

Agitator Set Collar Adjustment section.

Models #2024, 2024ST

Page 10

16 oz. Econo-16

10

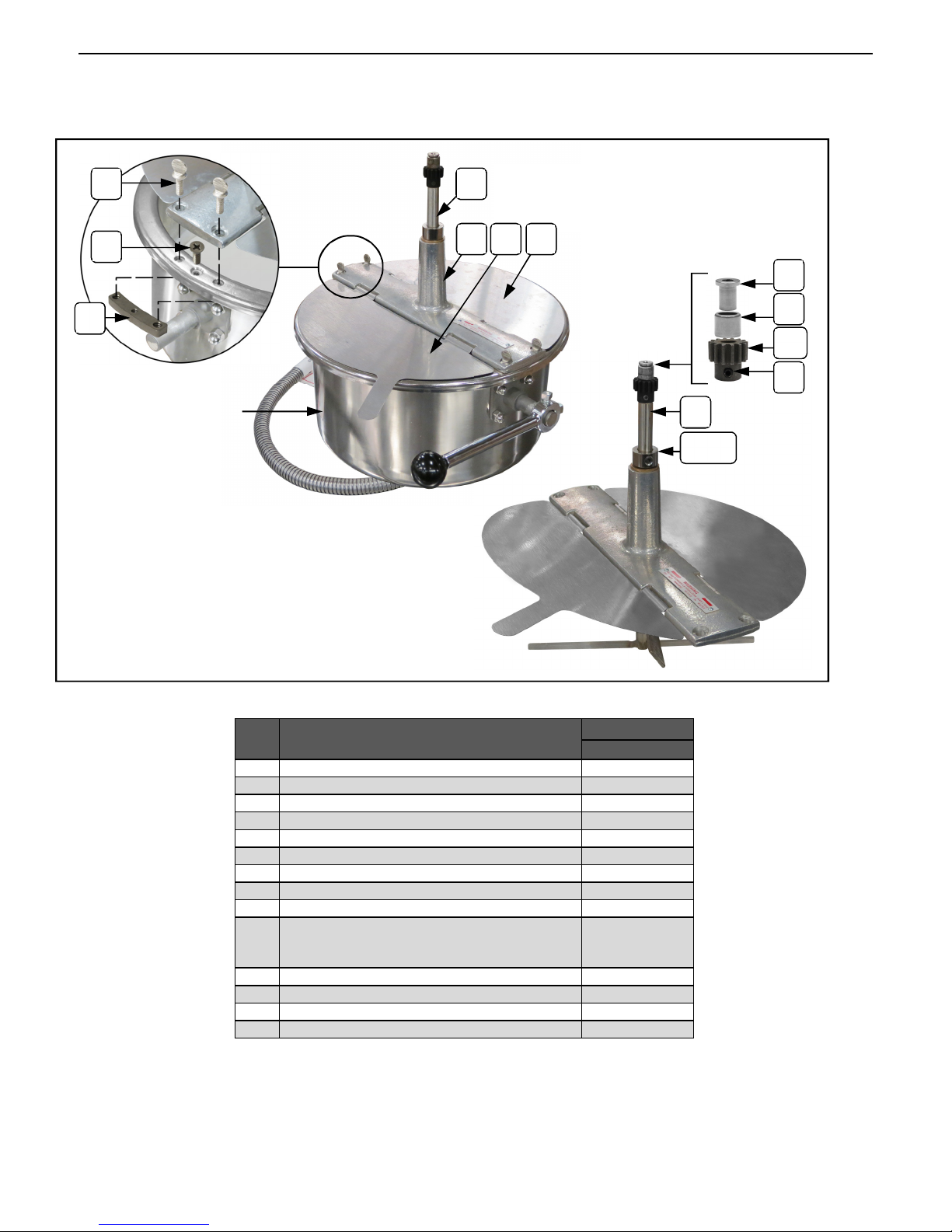

Agitator shown for general

Step 4: Adjust clearance

Kettle Cook

Set Collar w/Set Screw

Step

5: Adjust clearance to

Agitator Set Collar Adjustment

The following instructions describe how to properly adjust set collars on an agitator assembly with a fixed

stir rod.

Agitator Assembly with a FIXED Stir Rod

Steps to Adjust Set Collars on Agitator with a Fixed Stir Rod

Agitator assembly is adjusted while fastened to the kettle (image shown for general reference only).

Step 1. Turn machine OFF, unplug unit, and allow it to cool completely before attempting to

adjust the agitator height.

Step 2. Loosen the set screw in the set collar above the crossbar and below the crossbar.

Step 3. Place a 1/32” gauge (thickness of a dime) under the base of the agitator shaft to adjust

clearance between the kettle cook surface and the shaft; reference image shown. Once adjusted,

re-tighten the set screw in the set collar above the crossbar to secure shaft in place.

Step 4. Adjust clearance between the bottom of

the crossbar and the lower set collar to 1/32”

(thickness of a dime); reference image shown.

Once adjusted, re-tighten set screw to secure in

place.

Step 5. To check for proper adjustment, make

sure the stir rod is parallel to the kettle cook

surface (it should be close - but not touching).

Step 6. Spin the agitator shaft by hand to ensure

it spins freely and is not dragging the bottom of

the kettle.

thickness of a dime.

image reference only (lids not

shown for clarity).

above Crossbar

Crossbar

Lower Set Collar

Agitator Shaft

to thickness of a dime.

Models #2024, 2024ST

Stir Rod (welded to shaft)

Surface

Page 11

16 oz. Econo-16

11

DANGER

DANGER

WARNING

CAUTION

MAINTENANCE INSTRUCTIONS

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury, or death. Any alterations to this equipment

will void the warranty and may cause a dangerous condition. This appliance

is not intended to be operated by means of an external timer or separate

remote-control system. NEVER make alterations to this equipment. Read the

Installation, Operating, and Maintenance Instructions thoroughly before

installing, servicing, or operating this equipment.

008_051514

014_020416

No user serviceable parts inside. Refer servicing to qualified service

personnel.

THE FOLLOWING SECTIONS OF THIS MANUAL ARE INTENDED ONLY

FOR QUALIFIED SERVICE PERSONNEL WHO ARE FAMILIAR WITH

ELECTRICAL EQUIPMENT. THESE ARE NOT INTENDED FOR THE

OPERATOR.

011_051514

027_010914

Models #2024, 2024ST

Page 12

16 oz. Econo-16

12

ORDERING SPARE PARTS

1. Identify the needed part by checking it against the photos, illustrations, and/or

parts list. (General images may be used in manual for reference only.)

2. Use only approved replacement parts when servicing this unit.

3. When ordering, please include part number, part name, and quantity needed.

4. Please include your model number, serial number, and date of manufacture (located on the

machine nameplate/data plate) with your order.

5. Address all parts orders to:

Parts Department

Gold Medal Products Co.

10700 Medallion Drive

Cincinnati, Ohio 45241-4807

Or, place orders by phone or online:

Phone: (800) 543-0862

(513) 769-7676

Fax: (800) 542-1496

(513) 769-8500

E-mail: info@gmpopcorn.com

Web Page: gmpopcorn.com

Models #2024, 2024ST

Page 13

16 oz. Econo-16

13

55199

1 1/4-20 X 1 THUMB SCREW

47691

2 8-32 X 1/2 PHILL FLAT M/S ZINC

20066

3 THREADED BLOCK

61167

4 LID & AGITATOR ASSEMBLY (Complete Assy.)

41181

5 CROSSBAR ASSEMBLY

41180

6 FRONT LID

41123

7 REAR LID

41120

8 AGITATOR BEARING HUB

43434

9 NEEDLE BEARING

47106

SPUR GEAR KIT (Includes 2 gears with set

11 10-32 X 3/16 SET SCREW

41742

12 AGITATOR SHAFT ASSEMBLY

41093

13 ½ ID X 7/8 OD SET COLLAR

47326

14 ¼-20 X 3/16 SET SCREW

47751

55199 Overall Kettle

55199 Overall Kettle55199 Overall Kettle

55199 Overall Kettle

55199E Ag. Assy.

55199E Ag. Assy.55199E Ag. Assy.

55199E Ag. Assy.

Complete Agitator Assembly

Complete Agitator Assy.

See Kettle Bottom

Assy. section for parts

breakdown (includes

Handle Assembly and

16 oz. Kettle Assembly (55199) – Agitator Assembly View

55199E Exp. Views

55199E Exp. Views

55199E Exp. Views55199E Exp. Views

1111

2222

3333

Kettle Lead).

Complete Kettle Assembly

4444

(Includes Lids)

5555 6666 7777

12

12

1212

13, 14

13, 14

13, 1413, 14

8888

9999

10*

10*

10*10*

11

11

1111

*See Parts

List note.

Item

10*

(Includes Lids)

Part Description

screws. Always replace Agitator Spur Gear and

Kettle Drive Motor Gear as a set.)

Part Number

47059K

Models #2024, 2024ST

Page 14

16 oz. Econo-16

14

Top Lock Nut

-

Fastens

each thermostat and ground.

55199 Kettle Element

55199 Kettle Element55199 Kettle Element

55199 Kettle Element

55199EX Kettle Bottom Assy.

55199EX Kettle Bottom Assy.55199EX Kettle Bottom Assy.

55199EX Kettle Bottom Assy.

55199E exp. views

55199E exp. views55199E exp. views

55199E exp. views

Kettle Bottom Assembly View

16 oz. Kettle Assembly (55199) – Kettle Bottom Assembly

Install Lock Nut with triangle

in UP position (as shown).

ONE TIME USE ONLY,

1111

2222

3333

4444

Use high temp

red Loctite on

the three flange

nuts.

10

10

1010

11

11

1111

12

12

1212

REPLACE NUT if removed.

9999

8888

Element View

21

21

20

20

2121

2020

18*

18*

18*18*

*Dump Handle

Assembly

(includes Knob)

22

22

2222

23

23

2323

13

13

1313

14

14

1414

15

15

1515

16

16

1616

6666

5555

Kettle Conduit

17

17

1717

Label (not shown)

7777

24

24

2424

25, 26

25, 26

25, 2625, 26

19

19

1919

Models #2024, 2024ST

Page 15

16 oz. Econo-16

15

55199

16OZ KETTLE BOTTOM ASSY (Complete Assy.)

55200

TRANSFER PLATE ASSY (beneath heat

2 KETTLE GASKET

41598

3 KETTLE

WELDMENT

67892

4 8-32 SERRATED FLANGE NUT

5 ¼ -

20 SERRATED LOCK NUT

46311

6 ELEMENT CLAMP (6 required)

67894

7 1550 TUBULAR HEAT ELEMENT

67014

8 LIMIT THERMOSTAT SHIELD

67959

8-32 TOP LOCK NUT (always replace if

482 F

THERMOSTAT (includes two 6

-

32

11 THERMOSTAT SHUNT BAR

47193

550 F THERMOSTAT (includes two 6

-

32

KETTLE SHELL ASSEMBLY (has Pivot Pins

14 KETTLE LEAD ASSEMBLY

47361

8-32 x 3/8 SLT HWHW M/S

(fastens Nameplate

16 JUNCTION BOX

47393

17 KETTLE CONDUIT LABEL

82840

DUMP HANDLE ASSEMBLY (assembly includes

19 DUMP HANDLE KNOB

47110

20 DUMP HANDLE

47707

21 3 1/8 X ½ WOODRUFF KEY

41730

22 5/16

– 18 X ½ SQ HD SCREW

47725

23 5/16

– 18 X 3/8 SQ HD SCREW (holds key)

47662

24 PIVOT PIN

41426

25 1/4-20 ACORN NUT

42229

26 1/4-20 X 3/8 BUTTON HEAD

12492

16 oz. Kettle Bottom Assembly (55199) – Parts List

Item

1

element)

9

removed)

10

screws)

12

screws)

13

attached)

15

to Jct. Box, and fastens Jct. Box to Kettle)

Part Description

Part Number

67944

67943

76708

77108

41081

42044

18

Handle, Knob, 2 SQ HD Screws, and Key)

47102

Models #2024, 2024ST

Page 16

16 oz. Econo-16

16

See Kettle

section.

Switch Box

Pilot Light 125V Red

p/n

41033

Switch, Toggle

Kettle Receptacle

p/n

47327

Circuit Breaker 15A

p/n

47364

See Complete Door

Red Dome 2024

Hanger Arm Front,

Plexiglas Door

predrilled for hardware)

Drop Panel Assembly

Old Maid Pan

Magnetic Catch

Rubber Foot

Gear Block Assy.

Spur Gear Kit

Hanger Arm Rear,

Bottom Corn Pan

LED Bulb

20 W

Power Supply

Air Chute

5 Layer Grease

20 W Power Supply Brkt

*

CAUTION: If supply cord is damaged, it must be replaced by Gold Medal Products Co.,

its service agent, or similarly qualified persons in order to avoid a hazard.

20A Lead

-

In Cord

Cabinet Interior View

p/n 55394 (2024)

Assembly

p/n 55625

60 W Power Supply

p/n 55586 (2024ST)

p/n 41527

Filter p/n 41250

p/n 75100

(For 2024ST, see

Lighted Dome

Assembly section.)

(general images shown for parts reference only)

SPST (4) p/n 47201

p/n 55414 (2024)

60 W Power Supply Brkt

p/n 55624 (2024ST)

p/n 47561

Magnetic Catch

Bracket p/n 41340

p/n 41004

p/n 67194

Assy p/n 47262

Assy p/n 47228

Assembly 120V

p/n 47450

(Includes Corn Pan

and Heat Element)

p/n 41282

(not shown)*

p/n 47580

Assembly

p/n 47059K

(Includes 2 gears with

set screws. Always

replace Agitator Spur

Gear and Kettle Drive

Motor Gear as a set.)

Hardware Kit section

for parts breakdown.

p/n 47600A

(Doors DO NOT come

p/n 41017

p/n 41838

Models #2024, 2024ST

Page 17

16 oz. Econo-16

17

47054

47055

1 DOOR KNOB

41013

41013

2 8-32 X ½ SCREWS PH PAN W/SEMS

47124

47124

3 ACORN NUT #8

-32

47702

47702

4 TEE BOLT

75267

75267

5 MALE HINGE SHORT LEFT

41349

6 FEMALE HINGE LONG LEFT

41352

7 FEMALE

HINGE LONG RIGHT

41351

8 MALE HINGE SHORT RIGHT

41350

Complete Left Hand Door

Complete Right Hand Door

Door Hardware Kits – Individual Component Breakdown

1111

2222

3333

4444

2222

3333

8888

Hardware Kit (P/N 47054)

(contains all parts shown above)

7777 6666 5555

Hardware Kit (P/N 47055)

(contains all parts shown above)

Item

Part Description

Part Number

Models #2024, 2024ST

Page 18

16 oz. Econo-16

18

2024ST

1 DOME ASSEMBLY

61000

2 POPCORN SIGN

111873

3 8-32 PAN HD (Mounts

the LED Strip)

74141

4 LED STRIP COOL WHITE

(2 REQUIRED)

55379

5 MOLDED PLUG

47726

Model 2452 image

Model 2452 imageM odel 2452 image

Model 2452 image

Dome Assembly (2024ST only)

Front Sign View

1111

3333 4444

Interior View - LED Strip

General lighting image shown for reference only.

Item

Part Description

2222

Molded Plug seen here

5555

(Molded Receptacle shown

on Dome Interior View.)

For LED Power Supply,

see Cabinet Interior

View section.

Part Number

Models #2024, 2024ST

Page 19

16 oz. Econo-16

19

Kettle Drive Motor

,

Terminal Block, 8

Kettle

R

eceptacle

p/n

47327

Circuit Breaker 15A

p/n

47364

For controls, see

Blower Box

For LED Lighting

and Power

Exhaust Blower,

Molded

Receptacle Wire

Harness

p/n 6100

7

Dome Interior - Motor Plate Assembly

Supply, see Cabinet Interior

View for parts breakdown.

Assembly p/n 41006

115V p/n 41015

Terminal p/n 47208

Cabinet Interior View.

General image shown for reference only.

120V p/n 47038

Models #2024, 2024ST

Page 20

16 oz. Econo-16

20

ELECTRICAL SCHEMATIC

Models #2024, 2024ST

Page 21

16 oz. Econo-16

21

10700 Medallion Drive, Cincinnati, Ohio 45241

-

4807 USA

WARRANTY

Gold Medal Products Co. warrants to the original purchaser each item of its manufacture to

be free of defects in workmanship and material under normal use and service. Gold Medal

Products Co.’s obligation under this warranty is limited solely to repairing or replacing parts,

f.o.b. Cincinnati, Ohio, which in its judgment are defective in workmanship or material and

which are returned, freight prepaid, to its Cincinnati, Ohio factory or other designated point.

Except for “Perishable Parts” on specific machines, the above warranty applies for a period

of two (2) years from the date of original sale to the original purchaser of equipment when

recommended operating instructions and maintenance procedures have been followed. These

are packed with the machine. Parts warranty is two (2) years, labor is six (6) months.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR

IMPLIED, AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON OUR PART,

INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY. THERE ARE

NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

HEREOF. In no event shall Gold Medal Products Co. be liable for special, incidental or

consequential damages. No claim under this warranty will be honored if the equipment covered

has been misused, neglected, damaged in transit, or has been tampered with or changed in any

way. No claim under this warranty shall be honored in the event that components in the unit at

the time of the claim were not supplied or approved by Gold Medal Products Co. This warranty

is effective only when electrical items have been properly attached to city utility lines only at

proper voltages. This warranty is not transferable without the written consent of Gold Medal

Products Co.

The term “Original Purchaser” as used in this warranty shall be deemed to mean that person,

firm, association, or corporation who was billed by the GOLD MEDAL PRODUCTS CO.,

or their authorized distributor for the equipment.

THIS WARRANTY HAS NO EFFECT AND IS VOID UNLESS THE ORIGINAL

PURCHASER FIRST CALLS GOLD MEDAL PRODUCTS CO. AT 1-800-543-0862 TO

DISCUSS WITH OUR SERVICE REPRESENTATIVE THE EQUIPMENT PROBLEM,

AND, IF NECESSARY, FOR INSTRUCTIONS CONCERNING THE REPAIR OR

REPLACEMENT OF PARTS.

NOTE: This equipment is manufactured and sold for commercial use only.

gmpopcorn.com

Phone: (800) 543-0862 Fax: (800) 542-1496

(513) 769-7676 (513) 769-8500

© 2017 – The text, descriptions, graphics, layout, and other material in this publication are the exclusive property of

Gold Medal Products Co. and shall not be used, copied, reproduced, or published in any fashion, including website

display, without its express written consent.

Models #2024, 2024ST

Loading...

Loading...