Gold Medal Tornado 3005SS, Whirlwind 3008SS, Tornado, Deluxe Whirlwind, 3008SS Instruction Manual

...Page 1

Tornado Model 3005SS

Whirlwind

Model 300

8SS

Part No. 42117

Tornado

Deluxe

Whirlwind

and

Instruction Manual

Model No. 3005SS and 3008SS

Cincinnati, OH 45241-4807 USA

Page 2

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

1

DANGER

DANGER

cause property damage, injury, or death. Any alterations to this equipment will

WARNING

WARNING

WARNING

WARNING

and

SAFETY PRECAUTIONS

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

Improper installation, adjustment, alteration, service, or maintenance can

void the warranty and may cause a dangerous condition. NEVER make

alterations to this equipment. Read the Installation, Operating, and

Maintenance Instructions thoroughly before installing, servicing, or operating

this equipment.

008_051514

014_051514

Floss head rotates at high speeds. Operator MUST keep hands and face

clear of the floss head to avoid injury. Operator must wear eye protection.

Keep all spectators at a reasonable distance, and use a Floss Bubble for

added customer protection.

015_062714

Keep all foreign objects out of floss head. To avoid eye injury, DO NOT fill

floss head with sugar while the head is on and rotating.

016_010914

Burn Hazard. DO NOT touch spinner head. Allow to cool before cleaning or

servicing. Avoid contact with molten sugar.

006_092414

ALWAYS wear safety glasses when servicing this equipment.

010_010914

LL MODELS

Page 3

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

2

WARNING

WARNING

WARNING

WARNING

and

SAFETY PRECAUTIONS (continued)

No user serviceable parts inside. Refer servicing to qualified service

personnel.

Read and understand operator’s manual and all other safety instructions

before using this equipment. To order copies of the operator’s manual go to

gmpopcorn.com or write to Gold Medal Products Co., 10700 Medallion Drive,

Cincinnati, OH 45241 USA 1-(800)-543-0862

DO NOT allow direct contact of this equipment by the public when used in

food service locations. Only personnel trained and experienced in the

equipment operation may operate this equipment.

Carefully read all instructions before operation.

011_051514

022_060215

012_010914

This machine is NOT to be operated by minors.

007_010914

Note: Improvements are always being made to Gold Medal’s equipment. This information

may not be the latest available for your purposes. It is critical that

you call Gold Medal’s Technical Service Department at 1-800-543-0862 for any

questions about your machine operations, replacement parts, or any service

questions. (Gold Medal Products Co. does not assume any liability for injury due

to careless handling and/or reckless operation of this equipment.)

LL MODELS

Page 4

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

3

and

INSTALLATION INSTRUCTIONS

INSPECTION OF SHIPMENT

After unpacking, check thoroughly for any damage which may have occurred in transit. Claims should be

filed immediately with the transportation company. The warranty does not cover damage that occurs in

transit, or damage caused by abuse, or consequential damage due to the operation of this machine, since it

is beyond our control (reference warranty in back of manual).

MANUAL

Read and understand the operator’s manual and all other safety instructions before using this equipment.

To order copies of the operator’s manual go to gmpopcorn.com or write to Gold Medal Products Co., 10700

Medallion Drive, Cincinnati, OH 45241 USA 1-(800)-543-0862.

SETUP

Remove all tape and other packing material.

Remove the shipping support angles which protect the suspension springs during transit.

Retain these for future use when you transport the machine.

LOCATION

Place the floss machine in the Unifloss Stand or on a suitable table or bench. Ventilation around

the machine is important to insure long life of the components. Be sure to allow a minimum of

six inches around each side and no restrictions from supplies or debris in and around ventilation

openings.

Wash the floss pan thoroughly with soap and water. Install the floss pan on the machine with the

floss head extending up through the center of the pan. Push down on the bottom of the pan to

insure it is seated firmly on the pan supports.

As a last precaution before plugging in the machine, look inside the head assembly and make

sure the floss ribbons (heating elements) have not shaken out of the band during transportation.

If the ribbons are out of the band, they can be easily pushed back into place with your index

finger.

LL MODELS

Page 5

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

4

DANGER

CAUTION

and

ELECTRICAL REQUIREMENTS

The following power supply must be provided:

3005SS and 3008SS: 120 V~, 2400 W, 60 Hz

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

A certified electrician must furnish sufficient power for proper machine operation and install any supplied

receptacle. We recommend this equipment be on a dedicated and protected circuit. Failure to wire

properly will void the warranty and may result in damage to the machine. It is Gold Medal Products Co.’s

recommendation that this machine be plugged directly into a wall outlet. The use of extension cords is

not recommended due to safety concerns, and may cause sacrificed and/or reduced performance. Make

sure cord is located to prevent a trip hazard or unit upset.

008_051514

BEFORE YOU PLUG IN MACHINE

1. Make sure all machine switches are in the OFF position before plugging the equipment into

the receptacle.

2. Make sure the wall outlet can accept the grounded plugs (where applicable) on the power

supply cord.

3. The wall outlet must have the proper polarity. If in doubt, have a competent electrician

inspect the outlet and correct if necessary.

4. DO NOT use a grounded to un-grounded receptacle adapter (where applicable).

5. Install the unit in a level position.

If the supply cord is damaged, it must be replaced by Gold Medal Products Co.,

its service agent or similarly qualified persons in order to avoid a hazard.

039_080614

LL MODELS

Page 6

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

5

and

CONTROLS AND THEIR FUNCTIONS

TORNADO AND DELUXE WHIRLWIND CONTROLS

MOTOR SWITCH

DPST switch which serves as a master OFF-ON switch and energizes the cooling fan and

spinner head drive motor.

NOTE: The drive motor is equipped with an internal centrifugal safety switch which makes

contact when the floss spinner head reaches approximately 2050 RPM, thus completing the

heat circuit. This mechanism provides a safety circuit for the heating ribbons in the case of a

motor malfunction.

HEAT SWITCH

Three position DPDT switch: Emergency, Off, Normal

Emergency (Red position)

This position applies the fixed transformer to increase the line voltage 35 volts (increase

the heat in the spinner head) and provide for faster heating. This position should be used

when low supply voltage conditions exitst. While this position is ordinarily used for startup under normal operating conditions, it might also be used in situations where the

ribbons or equipment have had extensive use.

Off

With the switch in this position, the floss ribbons will not heat.

Normal (Blue position)

This position applies the fixed transformer to decrease the line voltage by 35 volts

(decrease the heat to the spinner head) and provide a normal operating range.

HEAT CONTROL

This is a variable transformer used to provide finer control across the pre-selected range of

the heat switch. It increases or decreases the voltage to the spinner head (raising or lowering the heat to the head). On the door panel surrounding the heat knob are red and blue

graduated scales from 1 to 9 designed to correspond with the setting of the heat switch. For

example, if the heat switch is set to normal (blue), adjustments to the ribbon temperatures

using the heat control are made reading the blue scale. The greater the number, the greater

the heat.

X-15R WHIRLWIND CONTROLS

MAIN POWER AND MOTOR SWITCH

DPST switch which serves as a master OFF-ON switch and energizes the cooling fan and

spinner head drive motor. NOTE: The drive motor is equipped with an internal centrifugal

safety switch which makes contact when the floss spinner head reaches approximately

2050 RPM, thus completing the heat circuit. This mechanism provides a safety circuit

for the heating ribbons in the case of a motor malfunction.

HEAT RANGE SWITCH

This is a 4-position tap switch with "A", "B", "C" and "OFF" positions. The "A" position corresponds to the highest heating potential, "B" is an intermediate range, and "C" corresponds to

the coolest position.

HEAT CONTROL FINE TUNING

This is a rheostat which allows you to make small, incremental adjustments to the spinner head

ribbon temperatures. The higher the number, the greater the voltage and temperature.

LL MODELS

Page 7

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

6

DANGER

WARNING

and

MAKING FLOSS

1. Before operating your machine, read this section on how to make floss.

2. Using a damp cloth, moisten the inside of the floss pan. This will cause the floss to adhere to

the sides of the pan. The Whirlgrip Floss Stabilizer Model No. 3010 works more effectively to

prevent floss from leaving the pan and is offered by Gold Medal at a modest price. See the

illustration on page 6 which shows proper installation of the Whirlgrip Floss Stabliizer.

3. After reading this entire section, operate your machine as described in the operating

instructions for your machine following this section.

4. Pay attention to the direction of the floss as it is spun out of the head. It should be thrown

against and adhere to the sides of the floss pan. Attached to the top plate of the spinner head

are two floaters, these give additional air current for floss control. By twisting the leading edge

of the floaters down, you get more lift and the floss will go upward. With the leading edge up,

the floss will go down. A little practice should give you good control in any climatic condition.

5. To pick up floss: Once you practice awhile, anyone can be an expert at rolling the web of

cotton candy onto the cone. First, pick up the cone. If it sticks in the stack of cones, do not

pull, but twist it off the stack. Hold an inch or two of the pointed end of the cone between your

two fingers and your thumb. With a light flicking action, break the web of floss that is building

up in the pan. Usually some floss will stick to the cone. Lift up the cone with the ring of floss

attached and, by rotating the cone, wind the floss onto it. Do NOT roll floss onto the cone

while it is inside the pan. This will just pack the floss onto the cone, causing you to use more

floss to fill the cone, and result in less cones of floss per load of sugar. For additional help,

reference Floss Making Procedures section.

If you experience difficulty in getting the floss to stick to the cone, it will be helpful to pass the

cone over a damp sponge. One pass over the sponge should cause the floss to stick, allowing

easier floss pick-up. Many experienced operators prefer to lift the ring out of the pan and, with a

flick of the wrist, turn the ring into a figure eight and whip it around the cone. This leaves giant air

pockets and makes it appear that you are serving a larger portion.

Shut Down Procedure

When completing operation for the day (or any prolonged period), run all the sugar out of the

floss head. When empty, turn the heat to highest position for approximately one minute to

“clean” the band by baking off remaining sugar. NEVER put water in the floss head.

Cleaning Instructions

Machine must be properly grounded to prevent electrical shock to personnel.

DO NOT immerse in water.

Always unplug the equipment before cleaning or servicing.

025_020314

Burn Hazard. DO NOT touch spinner head. Allow to cool before cleaning or

servicing. Avoid contact with molten sugar.

Unplug the machine and wait for the floss head to cool down to room temperature. Wipe all

surfaces with a clean, damp cloth. Make sure all parts are dry before resuming operation.

006_010914

LL MODELS

Page 8

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

7

and

SUGAR FOR YOUR COTTON CANDY

Our ready to use FLOSSUGAR is the preferred sugar for your new cotton candy machine, but

and 100% pure Cane or Beet Sugar will do just fine. Our FLOSSUGAR gives you good rich

colors, and great flavors, too. It is packed in handy half-gallon sealed cartons, with E-Z pour

spout for filling your machine. FLOSSUGAR comes in 8 flavors, and you can easily change

colors for greatest variety, and best sales.

If you want to “Mix Your Own”—use our FLOSSINE, and please follow our directions. If you

want a deeper color, slightly dampen the mixed sugar—use a tablespoon of water per five

pounds of sugar—sprinkle water over sugar, and mix well. DO NOT USE EXCESS COLOR—

too much color will mess up the ribbons on your machine, and could impart a bitter taste to the

candy. There is a limit as to how dark you can make cotton candy-that’ s because it is 98% air;

and we cannot color the air.

Today 99% of the sugar manufactured is “Extra Fine Granulated” which does have some small

particles which can slip thru the ribbons without being melted. If this becomes objectionable,

you can seek out Medium Coarse, or sanding sugars. The larger crystal size will require a little

more heat to melt. Read the label on the bag of sugar—today we see some “Free Flowing”

sugar for restaurants, and it contains cornstarch, which will burn onto your ribbons, clogging

them rapidly. We have also seen some cheap off-brand “sugar” which is a blend of sugar and

dextrose or corn syrup. This product makes very poor cotton candy. Please make sure you get

good sugar for your cotton candy machine.

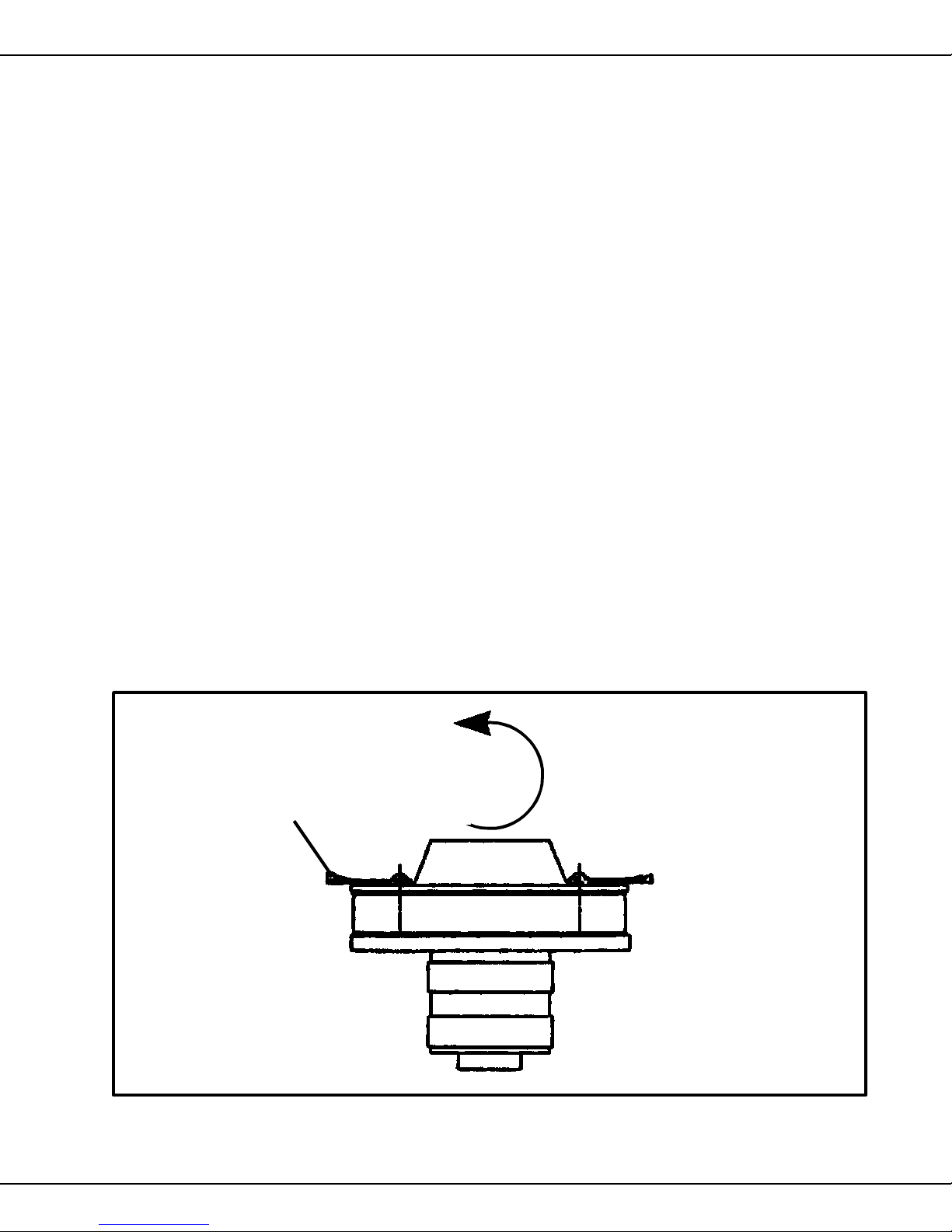

FLOATER ADJUSTMENT

Form leather floaters as shown. This creates a lifting action to float the floss across the gap to the

side of the floss pan.

Leather

Floater

ROTATION

LL MODELS

Page 9

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

8

and

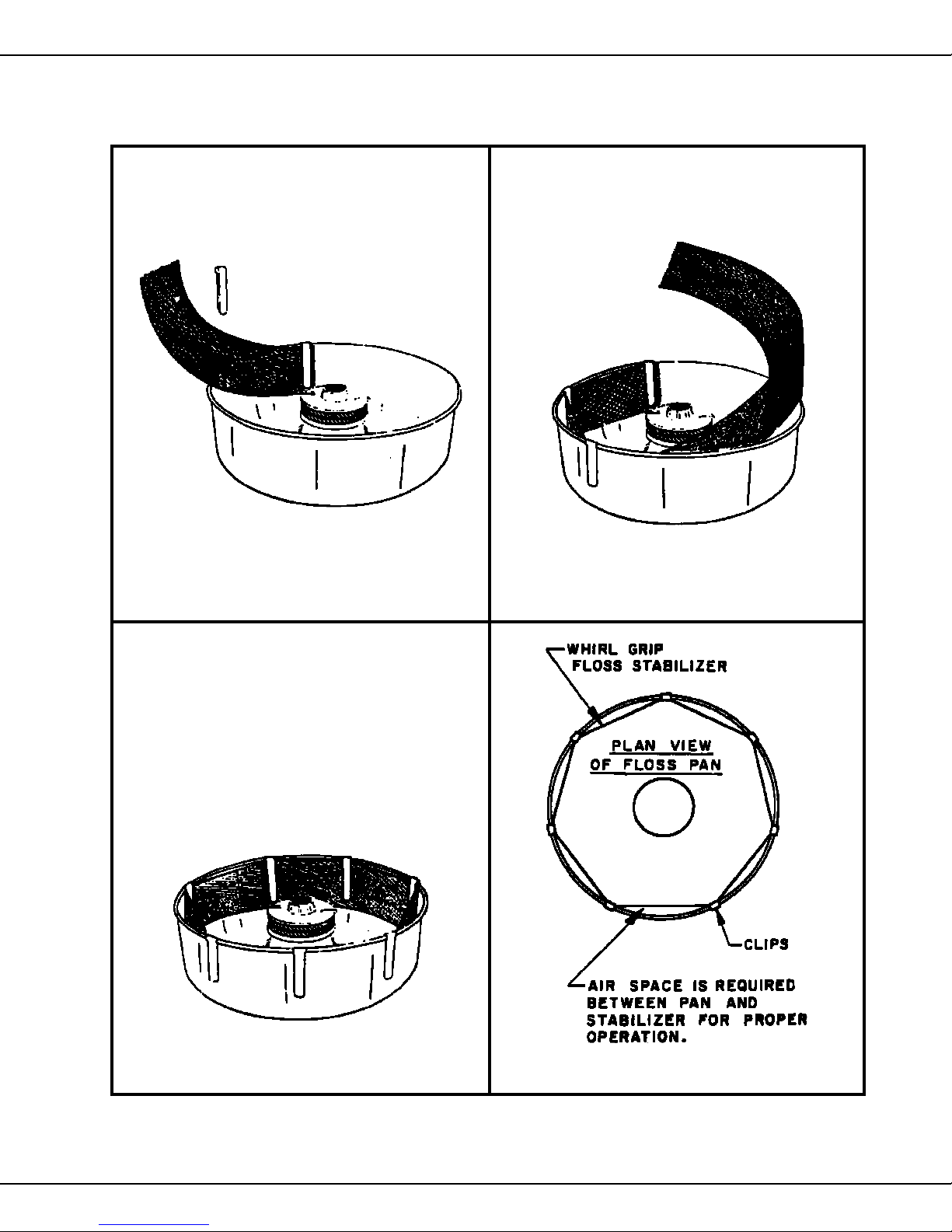

INSTALLATION OF WHIRL GRIP FLOSS STABILIZER

1

2

3

4

LL MODELS

Page 10

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

9

and

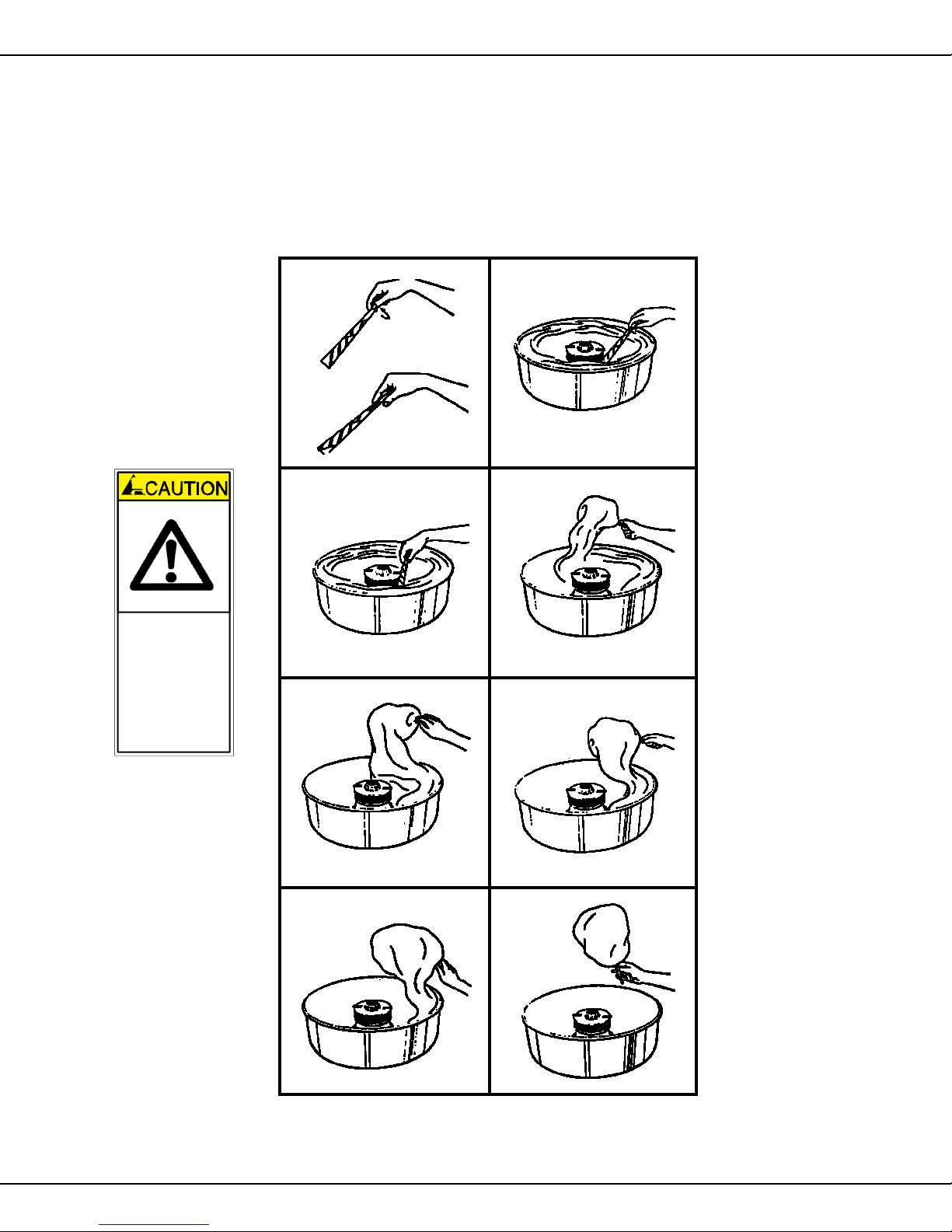

FLOSS MAKING PROCEDURES

Add Flossugar only while motor is off. Then, manually spin the head to balance.

Keep hands

away from

spinning

head!

This will eliminate excessive vibration of the head.

When adding sugar, always fill about 90% full.

DO NOT OVERFILL!

1

Grip Rotation

Wind the web of

sugar onto the cone

3

Break into web of floss

with the cone.

5

Remember:

Let the machine do the work.

2

Grip cone as shown.

4

Lift web of floss from the

pan and roll onto the cone.

6

7 8

LL MODELS

Page 11

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

10

and

OPERATING INSTRUCTIONS

TORNADO AND DELUXE WHIRLWIND

1. Plug in floss machine.

2. Before turning on the motor switch and with the spinner head stationary, fill floss head

about 90% full with sugar. Do NOT overfill! Whenever you add sugar to the floss head,

always fill it abour 90% full. This is necessary to obtain a balanced condition in the floss

head or excessive vibration will occur. Never add sugar when motor is running. After

adding Flossugar, manually rotate head to balance.

3. Flip Motor Switch to On position.

4. Flip the Heat Switch to Emergency position. This is for a fast warm up. Turn Heat Control

up until voltmeter indicator arrow moves into the red start area.

5. The machine should begin to make floss in a matter of a few seconds. After floss is being

produced, place Heat Switch in Normal position. Adjust the Heat Control until the voltmeter

X-15R WHIRLWIND

indicator arrow moves into the green run area.

CAUTION

Never operate equipment for prolonged period of time with the

Heat Control in a position that causes the sugar to smoke. This

will result in excessive carbonization of the ribbon (heat element).

If you smell burning sugar or see smoke, reduce the heat.

6. Once you find the ideal setting for the Heat Control, you should be able to operate near this

position each time.

7. Read the section in this manual on Making Floss before going into full production

1. Plug in floss machine.

2. Before turning on the main power and motor switch, and with the spinner head stationary, fill

the floss head about 90% full with sugar. Do Not Over Fill! Whenever you add sugar to the

floss head, always fill the head about 90% full. This is necessary to obtain a balanced condi

tion in the floss head and eliminate excessive vibration. Never Add Sugar When Motor Is

Running. After Adding flossugar manually rotate head to balance.

3. turn the Main Power and Motor Switch to the On position.

4. Turn Heat Range Switch to position "A". Rotate Heat Control Fine Tuning Knob to Maximum

position (No. 8). This setting will produce the fastest possible warm up.

5. You should start making floss in a few seconds. When the unit gets up to heat, it will probably

start to smoke. Reduce the Heat Control Fine Tuning setting to eliminate the smoke. If you

cannot eliminate the smoking in this manner, turn the Heat Range Switch to position "B" and

set the Heat Control Fine Tunning to postion No. 8 once more. If smoking continues reduce

the Heat Control Fine Tuning setting. If necessary, repeat once more with the Heat Range

Switch on "C".

NOTE:

6. Once you find the ideal Heat Range Switch and Heat Control Fine Tuning positions, you

should be able to operate near these positions each time you operate.

7. Read the section on Making Floss before going into full production.

You can fine tune in all three heat range positions.

LL MODELS

Page 12

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

11

and

INDOOR COTTON CANDY SUCCESS TIPS

1. The Unifloss Stand: Choose either the complete Unifloss Stand or the top half only and

mount it onto your Snack-N-Treat Bar. The Unifloss Stand plus the Whirl Grip Floss

Stabiizer effectively eliminates all indoor objections. In addition, the new Animated

Motion Sign Effectively helps merchandise the cotton candy.

2. Candy Floss Is Clean: In fact, it is "poly clean" when you sell cotton candy in poly bags.

Cotton candy is never sticky in poly bags. Always make cotton candy on attractive

striped cones and put the floss cone and all in the bag. The "Kid Appeal" comes from

having a circus style serving on the cone. If you sell cotton candy as a pad, you lose this

appeal.

3. Always Use A Printed Cotton Candy Bag: This tends to package the end product more

attractively. It only cost a tenth of a cent more to go first class a tenth of a cent is all it

cost to make every sale a walking advertisement for building your profits.

4. Use The Automatic Floss Bagger: It's as handy as having three hands. The bag is

opened by a stream of air. Hold it open with your free hand and stuff the floss in the bag

cone and all.

5. To Sell More Cotton Candy, you should always rotate your colors often. The easiest

way is to use Flossugar in the eight exciting color-flavor combinations. Simply pour from

the handy half gallon carton into the floss head and presto, you have a new color. Always

change colors as the floss head runs out of sugar.

6. Always Display Cotton Candy: Both the Floss Display Board and the Cotton Candy Tree

hold enough bagged cotton candy to allow you to produce three complete loads-each

a different color. Always display more than one color on the board-it helps to sell more.

7. Point Of Purchase Signs: Paper ppoint of purchase signs are included with each case

of cones.

8. In Store Promotions: it always pays to be able to use the public announcement system

to help announce to the buying public the location of the cotton candy department.

Secondary Display Boards Loaded with product in high traffic areas will also help stimulate

sales. Always suggest the multiple sale - carry one-sixth bushel brown kraft bags to help

your customers carry out a half dozen at a time.

9. External Promotions: coupons in your ad for free Cotton Candy-or for cents off-always pull

in shoppers and build store profits. Free Ad Mats are yours for the asking.

LL MODELS

Page 13

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

12

and

INSTALLING A UNIFLOSS STAND

There are two halves to a Unifloss Stand. For free-standing installations, use the base and

merely set the top half on it as shown in the drawing below. For In Counter installations,place

the top sectioin of the Unifloss Stand over a cutout in your counter top. A shelf is requiered

under the counter to set the floss machine on. For counter top cutout size and shelf location,

request drawing numbers B-3374 and C-3418 from Gold Medal Products Company.

After the top half of the Unifloss Stand is in position, tilt the floss machine and position the

spinner head in the center of the cutout. NOTE: Make sure shipping support angles are re-

moved as indicated in the installation section of this manual.

Place the spun aluminum pan over the floss head of the machine. Recenter the machine to

provide equal spacing around the pan and cutout.

After connecting the power supply cords, you are ready to make cotton candy. See Operating

Instruction in this manual.

Unifloss Stand

LL MODELS

Page 14

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

13

DANGER

DANGER

cause property damage, injury, or death. Any alterations to this equipment will

WARNING

CAUTION

and

MAINTENANCE INSTRUCTIONS

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

Improper installation, adjustment, alteration, service, or maintenance can

void the warranty and may cause a dangerous condition. NEVER make

alterations to this equipment. Read the Installation, Operating, and

Maintenance Instructions thoroughly before installing, servicing, or operating

this equipment.

008_051514

014_051514

No user serviceable parts inside. Refer servicing to qualified service

personnel.

011_051514

THE FOLLOWING SECTIONS OF THIS MANUAL ARE INTENDED ONLY

FOR QUALIFIED SERVICE PERSONNEL WHO ARE FAMILIAR WITH

ELECTRICAL EQUIPMENT. THESE ARE NOT INTENDED FOR THE

OPERATOR.

027_010914

LL MODELS

Page 15

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

14

and

FLOSS BANDS AND RIBBONS

The Gold Medal Floss Bands are made of high strength material with a dielectric coating for

insulating of the bands and are designed to give long and trouble-free service. Nevertheless

damage will result if subjected to undue pressure from over-tightening of the floss head screws,

dropping of the bands, or striking the bands sharply. If a chip or crack appears inside contact

areas where the ribbons are positioned, the band must then be replaced since the insulating

capacity of the band is lost.

Never use a

gasket which is

fractured as

centrifugal force

can cause it to

be thrown off

with considerable force.

Gold Medal Floss Ribbons (Heat Elements) are made of nickel nikrome wire with

ceramic insulation at the terminal point and on the lead wires. They are designed

to be as reliable as the Gold Medal Floss Bands, however, ther are certain cautions which must be exercised in the handling of the ribbons. The most common

problem with the ribbon is stretching. Once it is stretched it will not fit inside the

band properly. The ceramic insulator on the lead wires will break if the wires are

bent sharply. Therefore, make all bends gradually when installing the ribbons.

Head gaskets are made of quality gasket material and offered at a cost which will

allow equipment owners to replace them when removing and replacing the band.

LL MODELS

Page 16

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

15

and

REMOVAL OF FLOSS BANDS AND RIBBONS

1. Unplug this unit before servicing!

2. Remove all sugar from the head of the machine before disassembling. If the unit is

inoperative, it will be necessary to turn the machine onto its side and shake the sugar

out.

3. Remove the (4) spinner cap retainer screws and spinner cap. In some cases, you may

find that the sugar has caused the cap and band to stick together. Gentle pressure with

the heel of the hand should free the parts for removal.

4. Remove the retaining screws or nuts used to secure the ribbon leads from the termi

nals. A ¼-inch nut driver will be helpful here. At this point, both the ribbon leads and

bands can be removed from the spinner head.

5. After removing them from the head, run hot water over the band and ribbons to remove

the carbonized sugar. In cases where there is an excessive build up of sugar, it may be

necessary to soak the band and ribbons in hot water until the sugar dissolves. Bump the

band inthe palm of your hand to loosen the ribbons for removal.

At this point, you are ready to inspect, clean and/or replace your bands and ribbons. If the

ribbon has been removed for cleaning, an additional soaking in hot water should remove the

rest of the carbon build up. If the carbon persist in sticking to the ribbons, it must be burned

off by inducing electric current through the ribbon. First, turn the ribbon inside out so that the

lead wires are pointed outward, and place the ribbon on a non-conductive surface

such as a brick or china plate before hook up. Hook up a test cord (an extension

cord with clips that can be connected to the ribbon lead wires). Plug the test cord

in and let the ribbon glow a cherry red. Do NOT allow the cord to remain plugged

in longer than a minute. Unplug and allow to cool for a couple minutes. While it is

still unplugged, shake it a couple of times and you should see pieces of carbon

In 230 Volt, 50

Hz countries, do

NOT connect

this heat

element to full

line current. It is

designed to

operate on 120

Volts maximum.

fall away. Repeat the process and you will find that almost all of the carbon will

burn up and fall away.

LL MODELS

Page 17

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

16

and

REPLACEMENT

1. Using a damp cloth remove sugar build up on the spinner head casting and make sure

the new gasket sits properly on the casting.

2. Make sure the bands are dry before installing, being sure the band sits properly on the

gasket.

3. Install the ribbons in the bands and connect the eyelets of the ribbon lead wires go to the

terminal strips, being sure that the lead wires go to seperate terminals (One lead wire

from the ribbon on one terminal and the other lead wire on the other terminal). Caution

must be taken in forming the ribbon leads not to breakthe ceramic beads and insulators.

4. Make sure the ribbon is securely seated in the band and replace the lead wire retainer

screws. When tightening the screws be sure the lead wires do not bend, since this will

pull the ribbon away from the band.

5. Install the head gasket, spinner cap, floaters and spinner capretainer screws, but draw

down the screws just enough to retain the spinner cap. Rotate the head assembly by

hand, just enough to note any out of balance condition in the band and spinner cap. If

there is a noticeable wobble in the cap and band, move the spinner cap and band until

the head seems to travel in a true circle.

BRUSHES AND SLIP RINGS

Slip Rings are made of quality bronze and should give long service providing they receive

periodic maintenance. Recommended cleaning and inspection time is after every 500

pounds of sugar. Inspect rings for pits, discoloration and excessive wear. Rings should not

be flush with the phenolic parts and or worn unevenly. Inspect brushes for proper seating,

wear, and free movement. Brushes should not be allowed to wear down smaller than ½".

INSPECTION, CLEANING AND MAINTENANCE

1. Unplug the machine before cleaning and servicing.

2. Place motor and heat switches in off position. Remove the retainer screws and brush

cover. Using a damp cloth and blunted instrument (such as a wooden dowel) remove all

sugar accumulation. Be sure to remove all sugar from around the motor shaft as any

sugar getting into the motor will destroy motor parts.

3. Visually inspect rings and brushes for above mentioned discrepancies. Then correct

them as instructed below.

4. If brushes are worn below ½" long, they should be replaced. The brush terminal nut

may be removed with an 11/32" open end wrench.

5. When brushes are sitting correctly and the rings are in a good non pitted condition, they

will be light gray color. when they are pitted, burned or in need of attention, they will be

dark black and have a burned appearence. Pull the brushes back from the slip rings but

not all the way out of the brush holder. Allow the brush spring to hold the brush in this

position. Insert a strip of Emery Cloth against the slip ring. (Emery cloth is available from

Gold Medal). While holding the ends of the emery cloth, plug in the machine and turn the

motor switch On. By pulling gently on the ends of the emery cloth and moving them

slowly up and down, the rings will be sanded. Apply just enough pressure to throroughly

clean surface. Stop the motor, remove dust by blowing on part surfces be sure to re

move all emery dust, as abrasive action may cause problems later. Rings should now

be bright in color and have no pits.

LL MODELS

Page 18

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

17

Examine the rings closely, as pits will cause an arching which will quickly destroy the

brushes and rings. Repeat the sanding process if necessary to insure a good surface for

the brushes. If surface is clean and smooth you can then install the brushes back against

the rings and replace the inspection cover. The equipment is ready for operation. Let the

motor run about five minutes before turning on power to the head. This will build up a thin

layer of carbon on the rings and reduce the possibility of arcing while the brushes are

wearing in.

and

6. If rings are worn excessively or have pits tht sanding will not remove, they should be re

placed. The replacement of slip rings is considered more involved than normal field

maintenance. To be done correctly, you should have machine shop facilities. Head

assemblies may be returned to Gold Medal to have this maintenance performed. We

furnish a rebuilt head assembly if you do not have the time to send in the one from your

machine. For open account customers, we will ship the rebuilt head on a Memo basis for

full list price. When your head asembly is rebuilt, we will credit off the unit sent, and bill you

and we keep yours. For customers who do not have credit established, send us the full

price of the head assembly we will send you a rebuilt unit at once. When repairs are made

on your head assembly, we will charge them to your account and send you a check for

your refund promptly.

Floss Head

LL MODELS

Page 19

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

18

and

REPLACING SLIP RINGS

1. Unplug before servicing.

2. Remove band and ribbons as outlined in Maintenance - Floss Bands and Ribbons.

3. Remove the head assembly by first taking out the set screw between slip rings with a

3

/

" allen wrench. Remove the nylon nut and terminal guard. Using a 1/8" allen wrench,

32

turn the jack screw in the center of the head. This will push the head off of the motor

shaft. Do NOT use hammer on the head, as you run the risk of breaking the head, we

suggest you stop. Package the machine and send it to us for repair; it is cheaper than

buying a new head assembly.

4. Remove the four nuts from the slip ring studs and it will be possible to pull the ring and

phenolic parts from the head casting.

5. Remove phenolic parts and unscrew the slip ring studs from the slip rings. These must

be replaced correctly in order to get the assembly together again.

6. Thread one slip ring stud into one slip ring, allowing approximately one inch to protrude

through. This will be the top ring. Thread the other slip ring stud through the other ring,

allowing it to protrude approximately two inches. This will be the bottom ring. Now reassemble the phenolic parts and rings on the head casting in the order that they were

disassembled. Replace the nuts on the studs and tighten.

7. Attempt to replace the retaining set screw. If it meets with resistance, the parts are not in

exactly the same position as they were originally. This necessitates the drilling and

tapping of a new hole for the set screw (Tap Size No. 10-24 Thread).

8. The entire head assembly must now be chucked in a lathe and a cut taken off the slip

rings. They should be taken down approximately .010 to .015 thousandths of an inch or

until they run true and there are no pit holes visible. NOTE: We suggest a ¾-inch

diameter rod chucked in a lathe chuck and turned to 0.625 in. diameter. Then clamp the

head to the pin with the set screw and turn the slip rings.

LL MODELS

Page 20

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

19

and

TROUBLESHOOTING

Gold Medal Floss Equipment requires very little maintenance, most of which can be accomplished

with a few simple hand tools and testing equipment.

TOOLS

Common screwdriver - medium size

Phillips screwdriver - medium size

7

/

" Nut driver

16

¼" Nut driver

3

/

" & 7/64" Allen wrench

32

Strips of 180-J Emery Cloth -1" by approximately 20" (Available from Gold Medal)

TEST EQUIPMENT

Circuit testing device (one of any of the following)

Neon Light tester

Voltmeter with lead wires

IF EQUIPMENT IS DEAD ELECTRICALLY

Check power supply, is the machine plugged in and the switch turned on? Check electric

outlet and protective devices-fuse. Circuit breaker, etc. Will another appliance operate from

the same outlet? Check the outlet with a circuit tester.

If you are sure of current at your wall outlet, then the problem is probably in the equipment.

After checking over the mentioned items and the equipment is still inoperative, the trouble is

in one of the components. It is best to have them checked by a competent electrician or

returned to Gold Medal for repair. However, here is a simple check you can perform to

determine which component is at fault.

Disconnect motor lead wires and induce current directly into the motor. If the motor runs,

you have a faulty motor switch. If the motor fails to run, it is the faulty part. When removing

wires be sure to remember which terminals they came from and that you return them to the

correct terminals.

IF MOTOR RUNS, BUT EQUIPMENT FAILS TO PRODUCE FLOSS

On equipment without a voltmeter, a circuit tester can be used to determine if you have

current to the brushes. Remove the brushes. With the equipment plugged in and switches

on, touch a lead wire from the circuit tester to the inside of the brush holder. If the tester

shows current to the brushes, your problem is in the head assembly.

1. Check the floss head to make sure there is sugar present.

2. Check the brushes-are they sitting flush against the slip rings and bear no evidence of

arcing?

3. Check connections on the brush lead wires.

4. Check ribbons for excessive carbonization-the ribbons may be completely clogged with

carbon, disassemble the band and ribbons as described previously in this manual.

LL MODELS

Page 21

A

#3005SS,

#3008SS

, 3015

T

ornad

o

Whirlwin

d Flos

s Machine

20

If these procedures are followed and the problems still have not been located, it is necessary to check the control components; i.e. heat and motor switches, heat controls, and fixed

transformers, if applicable. The servicing by an electrician is encouraged for this procedure.

However, if you have a continuity tester or voltmeter with lead wires, it may be possible to

find the faulty component by using the process of elimination. Use the wiring diagrams

provided for all necessary wire tracing.

and

5. With the equipment plugged in and switches in the normal operating positions, check for

current flow into or out of each component. If there is evidence that a component is

defective. It may be helpful to look for evidence of arcing or burning. Frequently, a fault

component will bear evidence of excessive heat.

LOW PRODUCTION

1. A primary reason for low production is excessive carbon on the ribbons. Follow the

instructions for removal and cleaning of bands and ribbons.

2. Check heat control for correct setting. Metered equipment has marked graduations on

the voltmeter which indicate points where the equipment should operate most efficiently.

3. Check the line voltage. A primary reason for low production and poor working of

equipment is low line voltage. Have an electrician check the line voltage and add new

lines if there is not enough current for the requirement listed on the equipment name

plate. NOTE: The Tornado and Deluxe Whirlwind equipment have the ability to increase

the line voltage approximately 20%.

4. Check the ribbons. One burned out or shorted ribbon will cut production in half.

5. Foreign objects in the head assembly may short a ribbon or create an out of balance

condition.

EXCESSIVE SMOKE

1. Check heat control setting. After warm up, equipment should make good floss at a

reduced setting. NOTE: Never run the machine with the heat so high as to see smoke

or smell sugar burning.

2. Check the mixture of the product being used in the head. Use nothing with a

cornstarch base-do not over use Flossine-be sure sugar is dry and free of

lumps.

3. Check the band and ribbons for excessive carbon build up and remove it as

previously stated in this manual.

EXCESSIVE VIBRATION

1. If the equipment is new, check for shipping bolt or packing material accidentally left in the

machine.

2. Whenever you add sugar to the floss head, you should always fill it completely. This is

necessary to obtain a balanced condition in the head and eliminate vibration. Do NOT

add sugar with motor running!

3. Check for stretched are uneven suspension springs.

4. Check for foreign objects are lumps of sugar in the head assembly. Run the sugar

completely out for this.

5. Loosen the spinner cap retainer screws. Tighten and balance the head as previously

described.

LL MODELS

Page 22

Tornado

Whirlwind

Floss

Machine

and

ORDERING SPARE PARTS

1. Identify the needed part by checking it against the photos, illustrations, and/or

parts list.

2. Use only approved replacement parts when servicing this unit.

3. When ordering, please include part number, part name, and quantity needed.

4. Please include your model number, serial number, and date of manufacture (located

on the machine nameplate/data plate) with your order.

5. Address all parts orders to:

Parts Department

Gold Medal Products Co.

10700 Medallion Drive

Cincinnati, Ohio 45241-4807

Or, place orders by phone or online:

Phone: (800) 543-0862

(513) 769-7676

Fax: (800) 542-1496

(513) 769-8500

E-mail: info@gmpopcorn.com

Web Page: gmpopcorn.com

Page 23

Tornado

Whirlwind

Floss

Machine

and

CABINET

ASSEMBLY

23

ALL MODELS #3005SS, #3008SS, 3015

Page 24

T

ornad

o

Whirlwin

d Flos

s Machine

1 42040

42040

42040

Floss

Pan

2 42008

42008

42008

Brush

Cover

48020

48020

48020

Warning

Tag

5 20029

20029

20029

Main

Moto

r 120V

42063

42063

42063

Sugar

Seal

(MAC

Motor)

42107

42107

42107

Suga

r Seal

(Baldo

r Motor)

3

6 42310

42310

42310

Bottom

Cover

7 42049

42049

42049

Pan Support

3

10

42022

42022

48027

Heat

Control

Knob

12

47155

47155

47155

¾" High

Rubbe

r Feet

13

43148

43148

43148

Stainless

Steel

Door

Assembly

42052

42052

42052

Shipping

Carton

-

Pan

47377

47377

47377

Powe

r Suppl

y Cove

r Plate

and

PARTS LIST – CABINET ASSEMBLY

Deluxe

Item No.

Tornado

Part No.

Whirlwind

Part No.

3 48019 48019 48019 Shipping Support Angle

4 20006 20006 20006 Suspension Spring

42046 42046 42046 Sugar Seal (GE Motor)

X-15R

Part No.

Description

20051 20051 20051

9 42065 42065 n/a

/8" Hex Motor Mount Bolt

/

" Dia. Plastic Plug

16

11 42042 42042 42042 #8-32 Door Mount Screw

14 n/a 47364 47364 15 Amp Circuit Breaker

PARTS NOT SHOWN

42048

42048

42048

Shipping Carton - Unit

47211 47211 47211 Power Supply Receptacle

Tornado Unit

3005SS

Deluxe Whirlwind Unit

24

ALL MODELS #3005SS, #3008SS, 3015

3008SS

Page 25

Tornado

Whirlwind

Floss

Machine

and

X-15R WHIRLWIND

ASSEMBLY

4

8

14

15

16

17

25 ALL MODELS #3005SS, #3008SS, 3015

Page 26

Tornado and Whirlwind Floss Machine

2 48031

Resister

3 45396

Snap

Bushing

20034

Carbo

n Brush

6 20052

Brus

h T

ensio

n Sprin

g Screw

8 48017

Brus

h Holde

r Insulator

9 42034

Motor

Mount

Casting

48018

Exhaus

t Blowe

r,

120V

11

43012

Stainles

s Stee

l Case

Assembly

12

47026

Strai

n Relie

f #SR

-9P-2

13

42006

Termina

l Block

15

48033

Hea

t Rang

e Tap Switch

48028

Tap Switch

Bar Knob

17

48029

Rheostat

, 120V

PARTS LIST – X-15R WHIRLWIND

Item No. Part No. Description

1 47236 Snap Bushing #SB-500-6

4 42320 Brush Assembly with Brush

BRUSH ASSEMBLY PARTS LISTING

5 20033 Brush Tension Spring

7 42035 Brush Pad

10 47200 Finger Guard

20032 Brush Holder

47199 Blower Plug and Cord

47603 Lead-In Cord, 120V

14 43141 Motor Switch

16 48010 Voltmeter, 120V

46081 30 Amp Relay Switch

26

ALL MODELS #3005SS, #3008SS, 3015

Page 27

Tornado

AND

Whirlwind Floss Machine

3005SS TORNADO & 3008SS DELUXE WHIRLWIND

2

·--

18

17

15

12

13

14

27

ALLM

ODEIS #3005SS,#3008SS

Page 28

T

ornad

o

Whirlwin

d Flos

s Machine

2 45396

45396

Snap

Bushing

#SB

-

875-10

3 43006

43006

Transforme

r,

120V

4 42320

42320

Brus

h Assembl

y with

Brush

20034

20034

Carbo

n Brush

5 20033

20033

Brush

T

ension Spring

6 20052

20052

Brus

h T

ensio

n Sprin

g Screw

7 42035

42035

Brus

h Pad

8 48017

48017

Brus

h Holde

r Insulator

9 42034

42034

Motor

Mount

Casting

10

47200

47200

Finger

Gaurd

48018

48018

Exhaus

t Blowe

r,

120V

47199

47199

Blowe

r

Plug and Cord

11

43019

n/a Blue

Case

Assembly

n/a 42001

Red Case

Assembly

43012

43012

Stainles

s Stee

l Case

Assembly

12

42069

42069

Transformer

Support

Bracket

13

47603

47603

Lead

-In

Cord,

120V

47026

47026

Strai

n Relie

f #SR

-9P-2

14

42006

42006

Termina

l Block

15

43141

43141

Motor

Switch

16

43142

43142

Hea

t Switch

17

43009

42019

Voltmeter

18

42020

42020

Heat

Control

n/a 55219

Switch

, Rela

y 120V

and

PARTS LIST – TORNADO and DELUXE WHIRLWIND

Deluxe

Tornado Whirlwind

Item No. Part No. Part No. Description

1 47236 47236 Snap Bushing #SB-500-6

BRUSH ASSEMBLY PARTS LISTING

20032 20032 Brush Holder

28

ALL MODELS #3005SS, #3008SS , 3015

Page 29

Tornado

Whirlwind

Floss

Machine

and

WHIRLWIND FLOSS HEAD

ASSEMBLY

29

ALL MoDELS

#3005SS,

#3008SS, 3015

Page 30

T

ornad

o

Whirlwin

d Flos

s Machine

2 42213

Floss

Band,

5"

Double

3 42327

5" Ribbon Assembly

5 20010

Leathe

r Floaters

7 42053

Spinne

r Hea

d Casting

8 42032

Slip

Ring

Stud

, 3½"

Long

10

42304

Phenolic

Terminal

Insulator

12

42026

Cente

r Phenoli

c W

asher

13

20054

Bottom

Phenolic

Washer

15

42029

Stud

Insulato

r Phenolic

, 13/32"

16

42030

Stud

Insulato

r Phenolic

,

5/8"

17

42028

Insulator

Sleeve

18

42305

Termina

l Assembly

20

42303

Terminal

Guard

Phenolic

22

48041

Acorn

Nut 1/4-20 Nylon

23

42301

Hex Nut #10-32 Brass

and

PARTS LIST - WHIRLWIND LOW PROFILE FLOSS HEAD

Item No. Part No. Description

1 42062 Spinner Cap

4 42216 Phenolic Band Insulator

6 42041 Head Screw, #10-24 x 2"

9 20020 Slip Ring, 1¼" ID, 2½" OD

11 42025 Top Phenolic Washer

14 42037 Stud Insulator Phenolic, 1¾"

19 42308 Stud Insulator Phenolic

21 42311 Set Screw, 1/4-20

24 42215 Washer #10 External Tooth

COMPONENT PARTS NOT SHOWN ON DRAWING

74143 Hex Nut #10-32 Zinc

42325 Spinner Head Complete Assembly

42318 Spinner Head Bottom Assembly

42200 Complete Set of Phenolic Parts

20008 Band Replacement Kit

The following part is for use with the X-15R to make it compatible with X-15R Export Model.

48039 X-15R Conversion Kit 220V

30

ALL MODELS #3005SS, #3008SS, 3015

Page 31

Tornado

Whirlwind

Floss

Machine

and

TORNADO FLOSS HEAD

ASSEMBLY

31

ALL MODELS

#3005,

#3008AND

#3015

Page 32

T

ornad

o

Whirlwin

d Flos

s Machine

2 20050

Scre

w #10-24 x

2¼"

3 43014

Spinne

r Cap

5 48041

Acorn

Nut 1/4-20, Nylon

7 42303

Phenolic

Terminal

Guard

8 74143

Hex Nut

#10-32

11

42217

Phenolic

Band

Insulator

13 Botto

m T

ermina

l Insulator

14

42037

Stud

Insulator

Phenolic

16

42026

Cente

r Phenoli

c W

asher

18

42215

Washer

#10 External

Tooth

19

74143

Hex Nut

#10-32

21

42028

Insulator

Sleeve

23

20020

Slip

Ring

24

42030

Stud

Insulator

Phenolic

26

42308

Stud

Insulator

Phenolic

28 T

erminal

Jumper

Assembly

and

PARTS LIST - TORNADO LOW PROFILE FLOSS HEAD

Item No. Part No. Description

1 20010 Leather Floaters

4 43028 7" Ribbon Assembly

6 42311 Set Screw, 1/4-20 x 2"

9

12

15 42025 Top Phenolic Washer

17 20054 Bottom Phenolic Washer

Screw #10-32 x ½"

Top Terminal Insulator

20 42032 Head Stud Brass 3½" LG

22 42029 Stud Insulator Phenolic

25 43015 Head Casting

27 42214 7" Double Floss Band

AVAILABLE PARTS NOT SHOWN

42070 10-24 x ½" Cup Point Set Screw

43026 Spinnerhead Complete Assembly Ready to Use

43008 Spinnerhead Bottom Assembly Ready to Use

42200 Complete Set, Phenolic Parts for Bottom

32

ALL MODELS #3005, #3008 AND #3015

Page 33

T

ornad

o

Whirlwin

d Flos

s Machine

Wiring Diagram - Model 3005SS

33

and

ALL MODELS #3005, #3008 AND #3015

Page 34

T

ornad

o

Whirlwin

d Flos

s Machine

Wiring Diagram - Model 3008SS

34

and

ALL MODELS #3005SS, #3008SS, 3015

Page 35

10700 Medallion Drive, Cincinnati, Ohio 45241

-

4807 USA

Gold Medal Products Co. warrants to the original purchaser each item of its manufacture to

be free of defects in workmanship and material under normal use and service. Gold Medal

Products Co.’s obligation under this warranty is limited solely to repairing or replacing parts,

f.o.b. Cincinnati, Ohio, which in its judgment are defective in workmanship or material and

which are returned, freight prepaid, to its Cincinnati, Ohio factory or other designated point.

Except for “Perishable Parts” on specific machines, the above warranty applies for a period

of two (2) years from the date of original sale to the original purchaser of equipment when

recommended operating instructions and maintenance procedures have been followed. These

are packed with the machine. Parts warranty is two (2) years, labor is six (6) months.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR

IMPLIED, AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON OUR PART,

INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY. THERE ARE

NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

HEREOF. In no event shall Gold Medal Products Co. be liable for special, incidental or

consequential damages. No claim under this warranty will be honored if the equipment covered

has been misused, neglected, damaged in transit, or has been tampered with or changed in any

way. No claim under this warranty shall be honored in the event that components in the unit at

the time of the claim were not supplied or approved by Gold Medal Products Co. This warranty

is effective only when electrical items have been properly attached to city utility lines only at

proper voltages. This warranty is not transferable without the written consent of Gold Medal

Products Co.

The term “Original Purchaser” as used in this warranty shall be deemed to mean that person,

firm, association, or corporation who was billed by the GOLD MEDAL PRODUCTS CO.,

or their authorized distributor for the equipment.

THIS WARRANTY HAS NO EFFECT AND IS VOID UNLESS THE ORIGINAL

PURCHASER FIRST CALLS GOLD MEDAL PRODUCTS CO. AT 1-800-543-0862 TO

DISCUSS WITH OUR SERVICE REPRESENTATIVE THE EQUIPMENT PROBLEM,

AND, IF NECESSARY, FOR INSTRUCTIONS CONCERNING THE REPAIR OR

REPLACEMENT OF PARTS.

NOTE: This equipment is manufactured and sold for commercial use only.

Phone: (800) 543-0862 Fax: (800) 542-1496

(513) 769-7676 (513) 769-8500

© 2015 – The text, descriptions, graphics, layout, and other material in this publication are the exclusive property of

Gold Medal Products Co. and shall not be used, copied, reproduced, or published in any fashion, including website

display, without its express written consent.

WARRANTY

gmpopcorn.com

35

ALL MODELS #3005SS, #3008SS, 3015

Loading...

Loading...