Page 1

Corn Treat

- Digital

2175DEL, 2175DER

Instruction Manual

Model No. 2174DEL, 2174DER

10700 Medallion Drive, Cincinnati, Ohio 45241-4807 USA

© 2015 Gold Medal Products Co.

Part No. 110106

Page 2

DANGER

DANGER

cause property damage, injury, or death. Any alterations to this equipment will

WARNING

WARNING

WARNING

WARNING

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

SAFETY PRECAUTIONS

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

Improper installation, adjustment, alteration, service, or maintenance can

void the warranty and may cause a dangerous condition. NEVER make

alterations to this equipment. Read the Installation, Operating, and

Maintenance Instructions thoroughly before installing, servicing, or operating

this equipment.

008_051514

014_051514

To avoid burns, DO NOT touch the kettle or any heated surface.

DO NOT place or leave objects in contact with heated surfaces.

013_092414

ALWAYS wear safety glasses when servicing this equipment.

010_010914

No user serviceable parts inside. Refer servicing to qualified service

personnel.

011_051514

Read and understand operator’s manual and all other safety instructions

before using this equipment. To order copies of the operator’s manual go to

gmpopcorn.com or write to Gold Medal Products Co., 10700 Medallion Drive,

Cincinnati, OH 45241 USA 1-(800)-543-0862

022_060215

Page 2

gmpopcorn.com

Page 3

WARNING

WARNING

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

SAFETY PRECAUTIONS (continued)

DO NOT allow direct contact of this equipment by the public when used in

food service locations. Only personnel trained and experienced in the

equipment operation may operate this equipment.

Carefully read all instructions before operation.

This machine is NOT to be operated by minors.

Note: Improvements are always being made to Gold Medal’s equipment. This

information may not be the latest available for your purposes. It is critical that

you call Gold Medal’s Technical Service Department at 1-800-543-0862 for any

questions about your machine operations, replacement parts, or any service

questions. (Gold Medal Products Co. does not assume any liability for injury due

to careless handling and/or reckless operation of this equipment.)

012_010914

007_010914

Page 3

gmpopcorn.com

Page 4

2 Cup Acrylic

(2) Aluminum

1 qt. Measure

5 Gallon Measure

Bowl Scraper

20A Receptacle

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

INSTALLATION INSTRUCTIONS

Inspection of Shipment

After unpacking, check thoroughly for any damage which may have occurred in transit. Claims

should be filed immediately with the transportation company. The warranty does not cover

damage that occurs in transit, or damage caused by abuse, or consequential damage due to the

operation of this machine, since it is beyond our control (reference warranty in back of manual).

Manual

Read and understand the operator’s manual and all other safety instructions before using this

equipment. To order copies of the operator’s manual go to gmpopcorn.com or write to Gold

Medal Products Co., 10700 Medallion Drive, Cincinnati, OH 45241 USA 1-(800)-543-0862.

Model Description

The Digital Mark 5 Corn Treat Unit has a 5 gallon capacity and is available with either right hand

or left hand dump capability (see below for unit description). For electrical specifications, refer

to the Electrical Requirements section of this manual.

2174DEL: 120 Volt Corn Treat Junior with Digital Heat Control, Left Hand Dump

2174DER: 120 Volt Corn Treat Junior with Digital Heat Control, Right Hand Dump

2175DEL: 120/208 or 120/240 Volt Mark 5 with Digital Heat Control, Left Hand Dump

2175DER: 120/208 or 120/240 Volt Mark 5 with Digital Heat Control, Right Hand Dump

2175DEL: 120/208 or 120/240 Volt Mark 5 with Digital Heat Control, Left Hand Dump

2175DER: 120/208 or 120/240 Volt Mark 5 with Digital Heat Control, Right Hand Dump

Items Included with this Unit

Measure

Scoops

Page 4

(for popped corn)

(for 2175 Models only)

gmpopcorn.com

Page 5

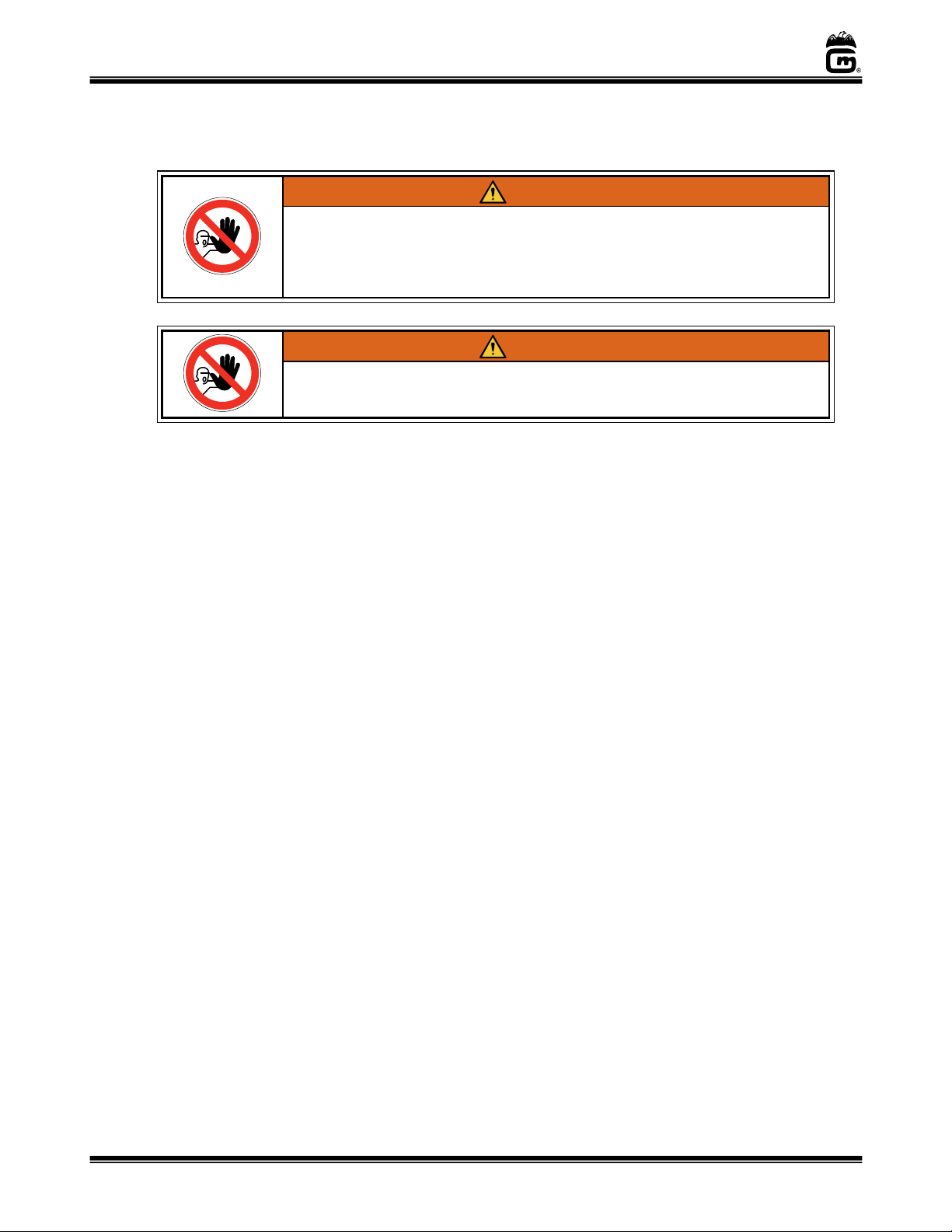

Counter Mounting Requirements

3” Minimum Clearance

18” Dia.

4 Holes for

6 1/2”

2 3/16”

12 3/8”

14 1/2”

10 1/2”

2”

Dia. X 1/8” Thick

3/4” Minimum

5/16

-18

3/16” Minimum

6” Recommended

26” 15 1/4”

5/16

-18

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Setup

1. Remove all packaging and tape before starting operation.

2. This unit must be properly fastened to a sturdy counter, see illustration below for counter

mounting requirements.

Between Kettle and Wall

5/16” Dia. Bolts

29”

Fender Washer

for Wood or

Wood Plastic

Products

Grade 5 Bolt

Thickness for

Stainless Steel

Grade 5 Nut

Over Wood

(Corn Treat Unit shown)

Minimum Clearance

Between Wall and

Control Box for Service.

Page 5

gmpopcorn.com

Page 6

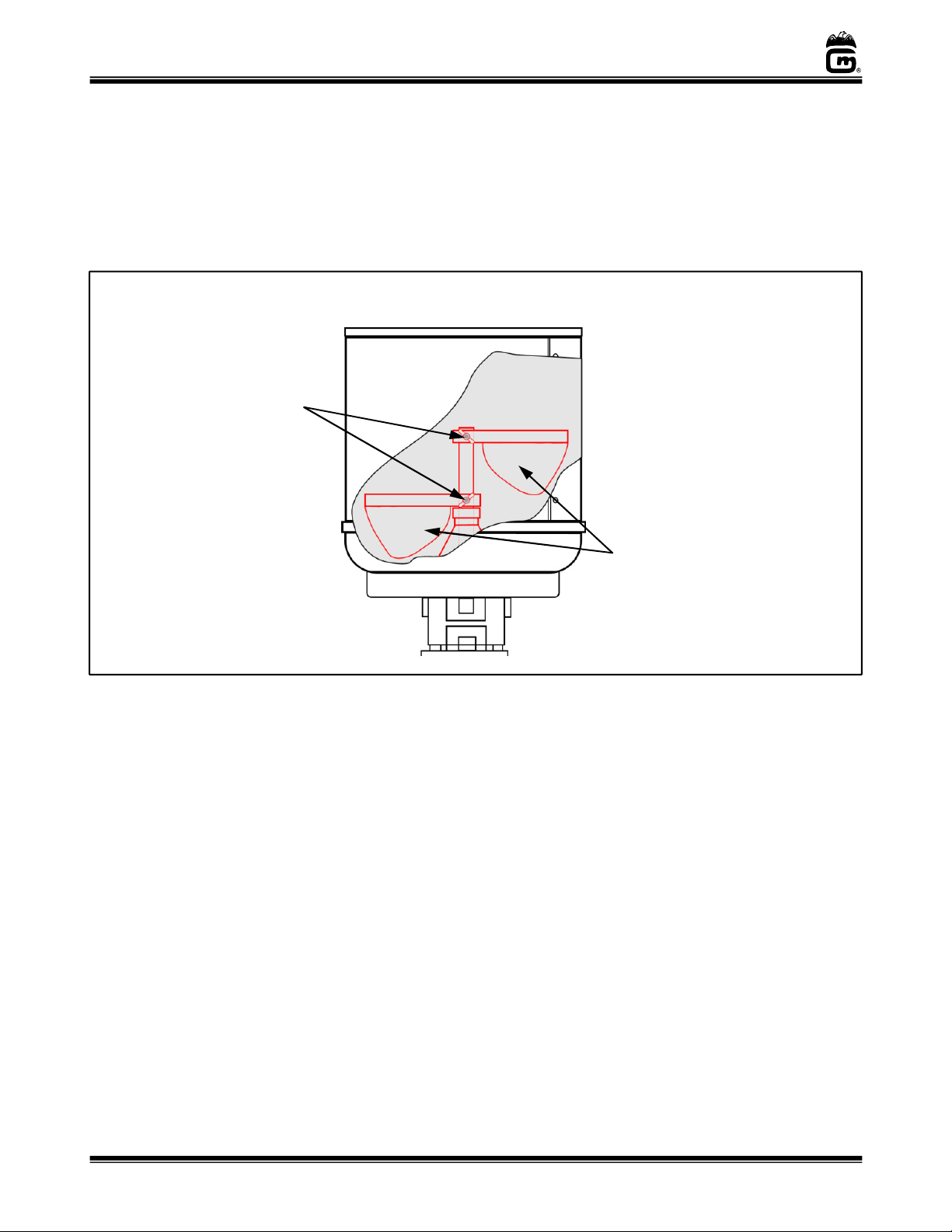

Paddles sh

own in

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

3. Prior to operation, rotate the top paddle from the shipping position into the mixing

position and fix into place with the wing bolt provided (see illustration below).

Make sure the wing bolt is securely set into the hole provided in the shaft, then finger

tighten to secure paddle in place.

4. After setup, the unit should be cleaned prior to use (see Care and Cleaning section of this

manual).

Paddle Assembly

Wing Bolts

Correct Mixing Position

Page 6

gmpopcorn.com

Page 7

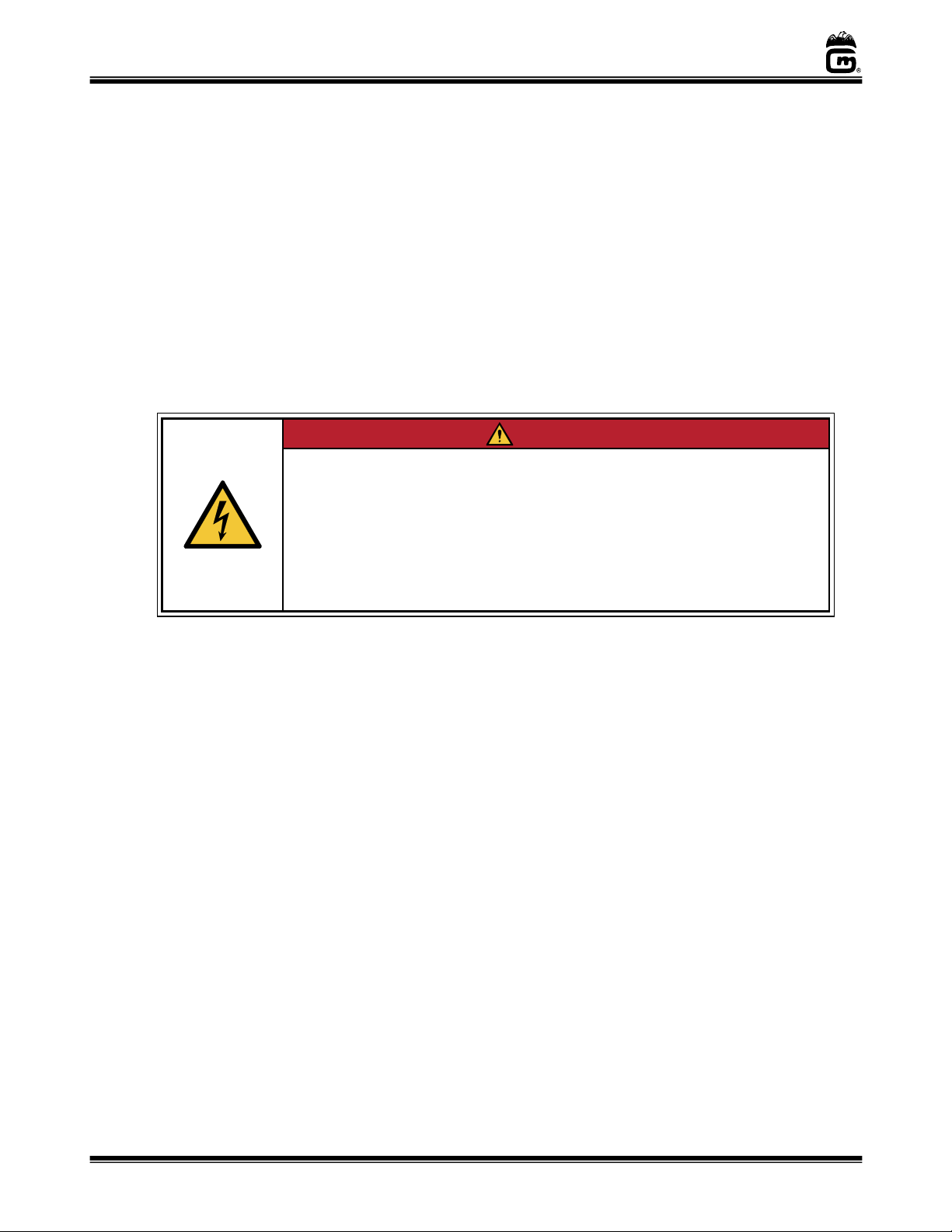

DANGER

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Electrical Requirements

The following power supply must be provided:

2174DEL and 2174DER: 120 V~, 3408 W, 60 Hz

This unit requires a NEMA 5-20R receptacle. A certified electrician must supply and

install the required wall receptacle.

2175DEL and 2175DER: 120/208 or 120/240 V~, 3408 W, 60 Hz

This unit is designed to operate on single phase, 20 AMP, 4 wire supply, 120/208 or

120/240 V~ (2 Hot, 1 Neutral, 1 Ground). All electrical components in this machine are

120 V (motors, heat elements, lights, etc.) and therefore require “Hot to Neutral”

connection (NOT “Hot to Hot”). A wall receptacle is supplied with the machine. This

receptacle will accept the attachment plug on the machine and must be used.

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

008_051514

A certified electrician must furnish sufficient power for proper machine operation and install any

supplied receptacle. We recommend this equipment be on a dedicated and protected circuit.

Failure to wire properly will void the warranty and may result in damage to the machine. It is Gold

Medal Products Co.’s recommendation that this machine be plugged directly into a wall outlet. The

use of extension cords is not recommended due to safety concerns, and may cause sacrificed

and/or reduced performance. Make sure cord is located to prevent a trip hazard or unit upset.

Page 7

gmpopcorn.com

Page 8

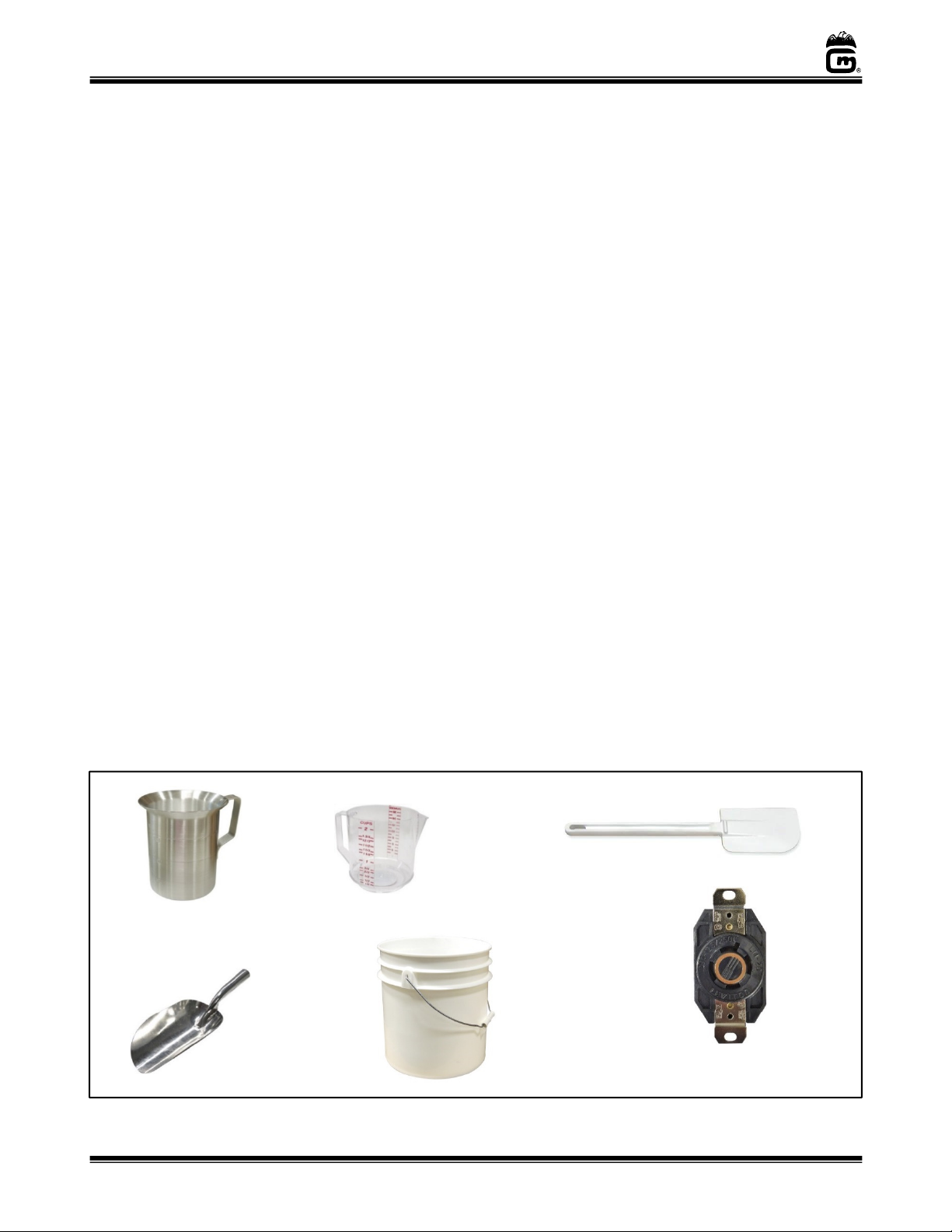

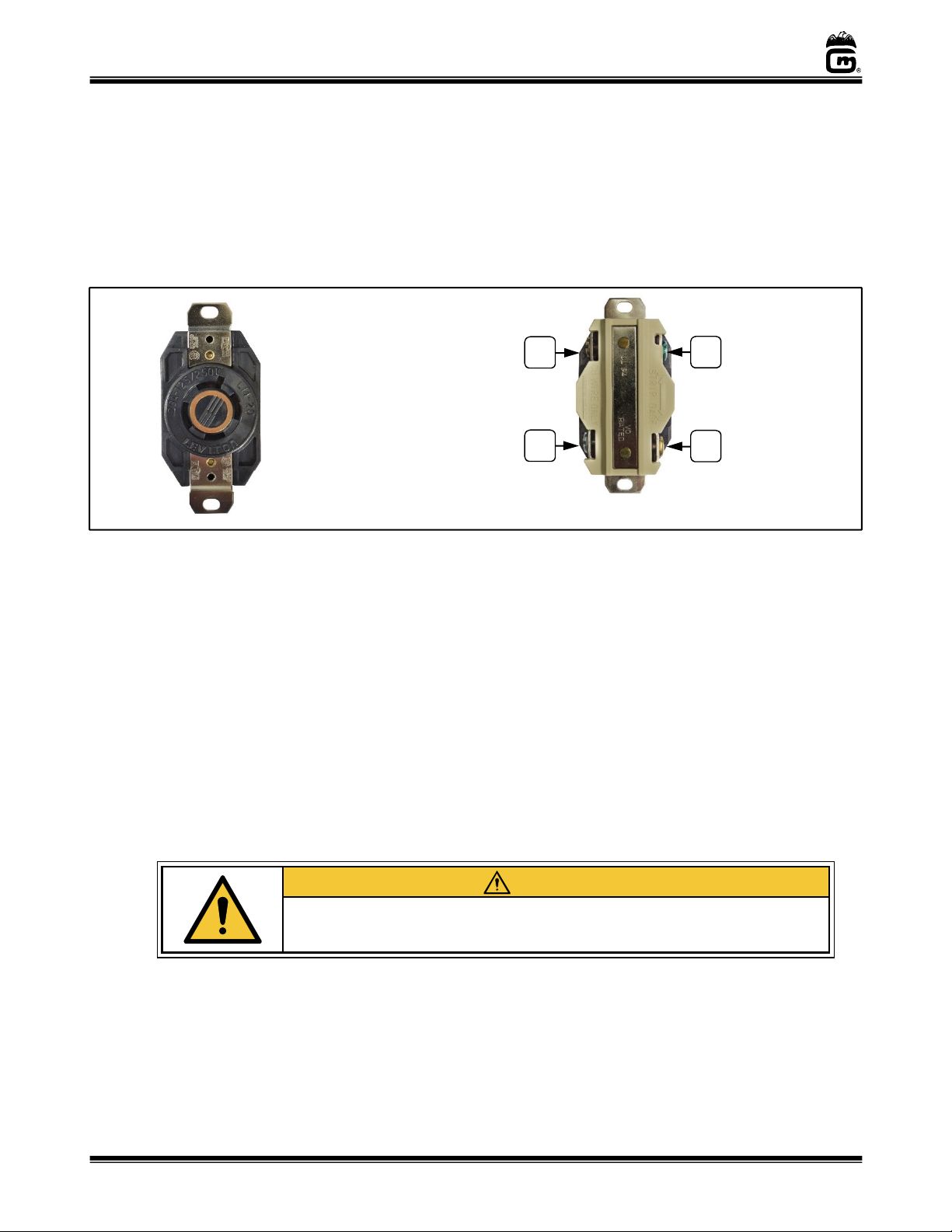

CAUTION

L14-20 Back View

Green Terminal

Brass

Terminal

Brass

Terminal

Black

Silver

Terminal

L14-20

Receptacle for

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Receptacle Installation (2175 Series ONLY)

A certified electrician must follow the IMPORTANT instructions below for installation of the

L14-20 Receptacle (Gold Medal Item No. 41254) provided with Model 2175 Series units.

If the receptacle is wired incorrectly, the heat elements/kettle and other electrical components

could be at 208 or 240 V potential instead of the needed 120 V, resulting in excessive temperatures

in the heat elements (i.e.: kettle) and possible fire, and/or damage to electrical components.

Model 2175

Series ONLY

Front View

Connect to

Connect to White

Before You Plug In Machine

1. Make sure all machine switches are in the OFF position before plugging the equipment

into the receptacle.

2. Make sure the wall outlet can accept the grounded plugs (where applicable) on the

power supply cord.

3. The wall outlet must have the proper polarity. If in doubt, have a competent

electrician inspect the outlet and correct if necessary.

4. DO NOT use a grounded to un-grounded receptacle adapter (where applicable).

(Hot) Wire

(Neutral) Wire

X

W

Connect to Green

G

(Ground) Wire

Connect to Red

Y

(Hot) Wire

5. Install the unit in a level position.

If the supply cord is damaged, it must be replaced by Gold Medal Products Co.,

its service agent or similarly qualified persons in order to avoid a hazard.

Page 8

039_080614

gmpopcorn.com

Page 9

Control Panel View

Kettle Dump Handle

Heat/Motor

Motor Only

Digital Heat

Control

Hole Plug

2 Position Bracket

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

OPERATING INSTRUCTIONS

Controls and Their Functions

HEAT/MOTOR SWITCH

Two position, ON/OFF lighted rocker switch – provides power to the heating elements in

the bottom of the kettle, and powers the agitator motor to turn for 30 seconds of every

minute. The green switch light ON indicates there is power to these features.

Note: It is normal for the motor to stop for 30 seconds of every minute (when the Motor

Only Switch is OFF).

MOTOR ONLY SWITCH

Two position, ON/OFF lighted rocker switch – provides power to the agitator motor to

run continuously.

Note: The main function of this switch is for mixing the product/popcorn at the

end of the cooking cycle with the kettle in the tilt position, and it is used for

“cleaning mode”.

CIRCUIT BREAKER

The Circuit Breaker protects the Motor and Heat Control from an overload condition.

KETTLE DUMP HANDLE

The Kettle Dump Handle tilts the kettle from the upright, cook position, to the mix

position or the dump position.

Switch

(used to hold kettle

in mix position)

Switch

Circuit Breaker

Page 9

gmpopcorn.com

Page 10

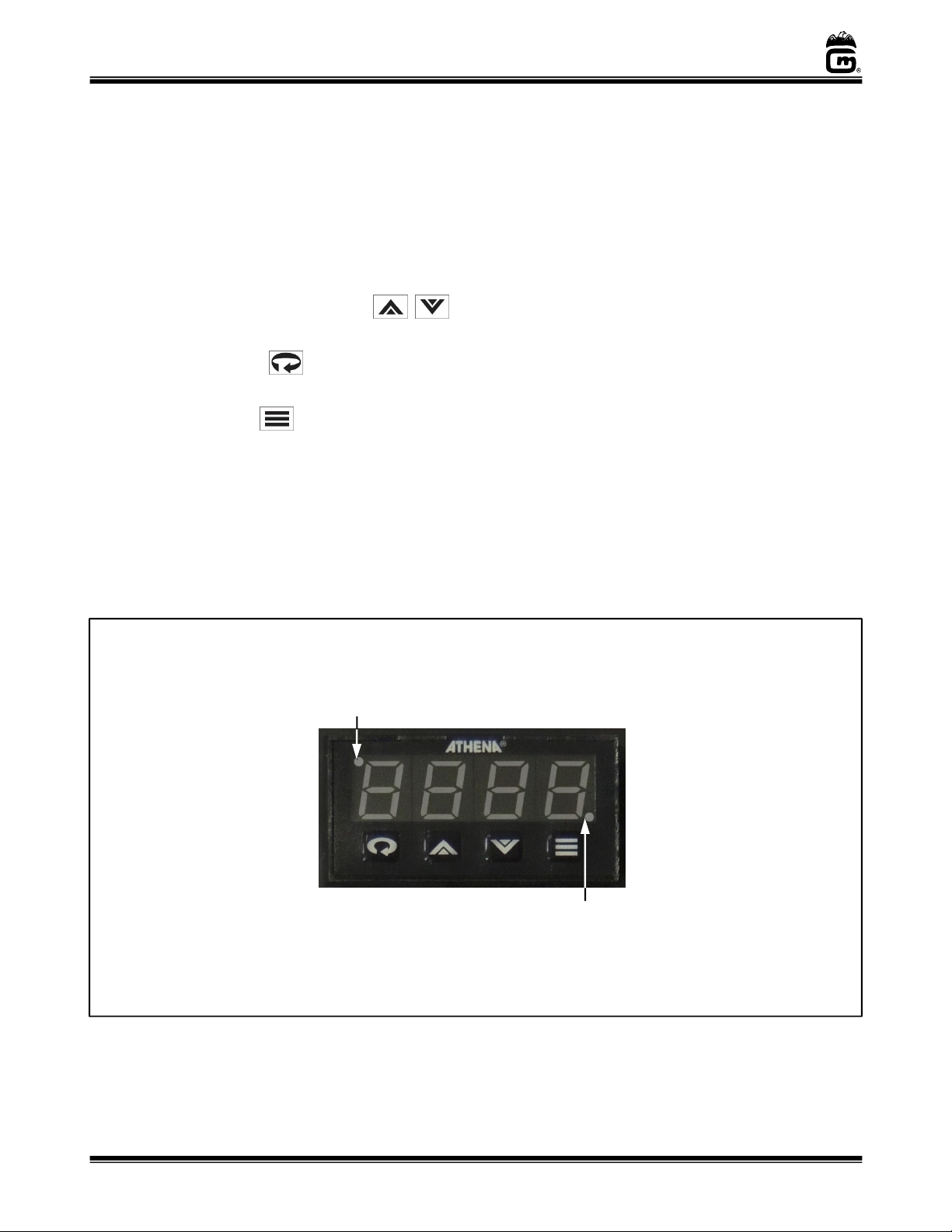

Digital Heat Control

Heat Indicator Light

Buzzer Indicator Light

ON when the buzzer

off).

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

DIGITAL HEAT CONTROL

The Digital Heat Control adjusts the Set Point Temperature of the unit. The machine comes

from the factory preset to achieve a Product Cook Temperature of 280°F. See Heat Control

Adjustment/Calibration section for adjusting the Product Cook Temperature.

Note: The sound of the buzzer signals kettle heat shut-off. The buzzer will continue to

sound until the unit is turned off or until the unit temperature falls below set point.

Buttons/Indicator Light Descriptions

UP Button / DOWN Button

– adjusts the Set point Temperature UP or DN

when in programming mode.

Access Button

– accesses programming mode to change Set Point Temperature, see

Heat Control Adjustment section.

Mode Button

– exits programming mode and locks in adjustments, see Heat Control

Adjustment section.

Digital Display – display shows temperature of the kettle; this is not the same as the product

temperature. (Reference the Digital Heat Control Adjustment/Calibration section.)

Heat Indicator Light – light is ON when the unit is heating. See image below for indicator

descriptions.

Buzzer Indicator Light – See image below for indicator light description.

Light is ON when the unit is heating. It goes

OFF when the buzzer sounds (signaling heat

shut-off).

Light comes

sounds (signaling heat shut-

Page 10

gmpopcorn.com

Page 11

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Digital Heat Control Adjustment/Calibration

Product Cook Temperature is the actual temperature of the PRODUCT (Caramel Corn Mix); this

is measured with an accurate candy thermometer. Infrared temperature readers are NOT

recommended.

Set Point Temperature is the temperature setting of the KETTLE; this is the temperature

needed to get the Carmel Corn Mix up to the finished Product Cook Temperature of 280°F. The

digital display shows the kettle temperature, NOT the product temperature.

Note: The Set Point Temperature will be higher than the product temperature.

Refer to the candy thermometer for accurate product temperature.

Digital Heat Control Adjustment

The machine comes from the factory preset to achieve a Product Cook Temperature of 280°F.

Small adjustments may need to be made for mix used or cooking conditions. If the product is

ready, either before or after the buzzer sounds, then follow the steps listed to increase or

decrease the Set Point Temperature of the kettle:

Note: The sound of the buzzer signals kettle heat shut-off.

1. To change the Set Point Temperature, press the key. The display shows SP

followed by a temperature number flashing. Use the arrow keys to set the desired

temperature.

2. Once the temperature is set, press the key to lock in the new temperature.

Digital Heat Control Calibration (Performed at the Factory)

This unit has been calibrated at the factory. Other than small adjustments made for mix used or

cooking conditions (see above Digital Heat Control Adjustments), the unit is ready for use and

should not need calibration.

To reset the Digital Heat Control back to factory settings follow the procedure shown below.

Note: For calibration purposes only, corn oil is used to determine the Digital Heat Control

temperature setting which will produce an accurate finished product temperature

of 280°F.

1. Start with a clean unit, which is cool before attempting to calibrate.

2. Fill the mixing bowl with a one inch depth of corn oil.

3. Turn the Heat/Motor Switch ON.

4. Use an accurate candy thermometer to measure the temperature of the oil in the

mixing bowl. (Infrared temperature readers are NOT recommended.)

5. Set the digital control set point temperature to 350°F.

Page 11

gmpopcorn.com

Page 12

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

6. Turn the Motor Only Switch ON to stir the oil while it heats.

7. When the oil reaches 325°F, note the temperature displayed on the digital control and

make that the Set Point Temperature.

Note: The Set Point Temperature will be higher than the product temperature.

Refer to the candy thermometer for accurate product temperature.

8. Allow oil to cool below 300°F, then repeat Step 5 to check the buzzer sounds at 325°F.

9. The unit is now calibrated for the heat control buzzer to sound at a finished product

temperature of 280°F.

Caution: Allow hot oil to cool below 140°F before attempting to drain.

Page 12

gmpopcorn.com

Page 13

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Making Carmel Corn

Instructions for Making Carmel Corn (Mark 5)

Always remember, leave the lid on the kettle during the first part of the batch. Once steam starts

to “roll-up” from underneath the lid, then carefully remove lid for remainder of the cooking cycle.

CAUTION: Beware of rising steam; keep face and hands clear of rising steam.

1. Turn Heat/Motor Switch ON (DO NOT turn on the Motor Only Switch).

2. Add (1) 22 ounce package of Gold Medal Caramel Corn Mix (Item No. 2094), 4 cups of

granulated sugar (brown or white), and 8-12 ounces of water (add water last).

Note: When using Gold Medal “One Step” Carmel Corn Mix, DO NOT add granulated

sugar.

3. Turn Motor Only Switch ON and mix for approximately one minute, then turn Motor

Only Switch OFF. (With the Heat/Motor Switch ON, the motor will run for 30 seconds

of every minute.)

4. Add 1 stick (4 ounces) of coconut oil or vegetable oil. Put on the lid.

Note: Once steam starts to “roll-up” from underneath the lid, then carefully remove

lid for remainder of the cooking cycle.

5. Allow mix to cook until the buzzer sounds at 280°F product temperature.

Note: Product temperature is measured with an accurate candy thermometer.

(Reference the Heat Control Adjustment section.)

6. Turn Heat/Motor Switch OFF.

7. Turn Motor Only Switch ON.

8. Add 5 gallons of pre-popped corn.

9. Allow corn to mix for approximately 10 seconds with the kettle in the upright position.

10. Move kettle to the mix position and spray 10-12 “squirts” of GOLD Medal Free-N-Easy

(Item No. 2250) for proper corn separation; mix popcorn until thoroughly coated.

11. Dump the caramel corn into the cooling pan, and mix/separate the caramel corn using

two popcorn scoops.

12. After dumping caramel corn, turn Motor Only Switch OFF.

13. Allow the finished product to cool before packaging.

During normal operation, sugar build-up will occur in the kettle. The build-up must be removed

by steaming out the kettle every 3-4 batches, and especially before the machine is turned off for

the day. If making single batches, with the unit turned off between batches, the kettle must be

steamed out after each batch has been completed. Follow the Proper Kettle Cleaning Procedure

in the Care and Cleaning section of this manual.

Page 13

gmpopcorn.com

Page 14

DANGER

WARNING

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Care and Cleaning

Machine must be properly grounded to prevent electrical shock to personnel.

DO NOT immerse in water.

Always unplug the equipment before cleaning or servicing.

To avoid serious burns, DO NOT touch the kettle while it is hot!

Good sanitation practice demands that all food preparation equipment be cleaned regularly (only

use non-toxic, food grade cleaners). A clean looking, well-kept machine is one of the best ways of

advertising your product.

025_020314

028_082715

Corn Treat Cleaning Instructions

Note: It is extremely important to follow all of the cleaning procedures, otherwise parts

damage and equipment failure will result. The warranty does not cover parts that

are damaged due to improper cleaning.

Proper Kettle Cleaning Procedure

Follow the procedure below to steam the sugar build-up out of the kettle every 3-4 batches

during regular operation and before the machine is turned off for the day. The kettle must also be

steamed out after making single batches, if the machine is turned off between batches.

1. After all product has been removed, and the kettle has cooled for 15-20 minutes,

carefully pour 24 oz. of water into the kettle.

CAUTION: Beware of rising steam; keep face and hands clear of rising steam.

2. Place the lid on the kettle, and turn the Heat/Motor Switch ON.

3. When water starts to boil, turn Heat/Motor Switch OFF.

4. Turn the Motor Only Switch ON; allow the machine to cool, then remove the lid and

carefully pour the contents of the kettle into a pan or bucket. Steam the kettle twice to

remove all traces of product.

5. Turn the Motor Only Switch OFF.

6. With all switches OFF, wipe out any excess sugar build-up from the kettle using a

damp rag, then the kettle is ready to begin another batch.

7. Do not leave water in the pans overnight.

Page 14

gmpopcorn.com

Page 15

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Daily Unit Cleaning Procedure

Follow the directions below to clean and sanitize the unit each day after use.

1. With the machine OFF, unplug the unit and allow it to cool before attempting to clean.

2. Make sure to clean all pans/accessories in order to sanitize them before each use.

3. Release the draw latch to easily remove the mixing drum, then remove paddles. The

mixing drum and paddles can be taken to the sink to clean.

4. Wipe the kettle lead cord with a clean SLIGHTLY damp cloth. DO NOT get moisture into

the kettle lead-in cord, severe damage will result.

5. The cabinet of your machine should be wiped clean daily (or more, depending on

usage) with a clean soft cloth, SLIGHTLY dampened with soap and hot water.

6. Wipe the stainless steel parts with a clean cloth and cleaner designed for stainless

steel, such as Gold Medal Watchdog Stainless Cleaner (Item No. 2088).

DO NOT use oven cleaners or abrasive materials as they will damage parts of the

machine.

Proper Hub Seal Assembly Cleaning Procedure

Follow the steps below weekly to ensure proper machine performance:

Important: For proper machine performance, keep the hub seal and o-rings clean.

1. With the machine OFF, unplug the unit from the power source and allow it to cool

before attempting to clean the Hub Seal Assembly.

2. Loosen the wing bolt(s) (Mixing Paddle Lock Studs) and remove the mix paddles.

3. Remove any burrs on the shaft using a fine grit emery paper to lightly sand the

surface. If the burrs are not removed, damage may occur to the o-ring/oil seal during

removal/installation.

4. Remove the hub seal assembly and soak it in hot water to clean.

5. Clean the area around the center hub. Remove any product residue. (See Kettle Shaft

Maintenance for note on lubricating the kettle bushings.)

6. Lightly lubricate the center hub of the kettle with a small amount of vegetable oil to

allow for easy re-installation of the hub seal assembly.

7. Slide the clean hub seal assembly down the agitator shaft. Apply pressure to ease the

assembly over the center hub of the kettle until it seats properly (reference image

shown.)

8. After the hub seal assembly has been properly installed, re-install the mix paddles

onto the agitator shaft.

9. Finger tighten the wing bolt(s) to secure mixing paddles in place.

Page 15

gmpopcorn.com

Page 16

(2) Wing Bolts

(Mixing Paddle

(2) Mixing

Hub Seal Assembly

Oil Seal

Hub Body

O-Ring

Agitator Shaft

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Hub Seal and Paddle Assembly

Lock Studs)

Paddles

(Includes Oil Seal, O-Ring,

and Hub Body)

Page 16

gmpopcorn.com

Page 17

Issue

Possible Cause

Solution

Kettle Does Not Heat

A. Power to Unit

A. Make sure the lead

-

in cord is plugged in.

B. Circuit

Breaker

B. Check the

condition of

the circuit breaker. The

C. Kettle Heat

/Motor

Switch

C. Have qualified service

personnel c

h

eck the

D. Control

D. A defective RTD lead will cause the kettle not

Indicator Lights

ON or OFF

A. Control Indicator Lights

A. The Heat Indicator Light and the Buzzer

Error Code on Digital

A. Digital display error code

A. Have qualified service personnel check the

Kettle Agitator Does Not

A. Kettle Agitator

A. If the kettle agitator shaft is not rotating,

Long

Cooking

Cycles

A. Heating Element

A. One of the heating elements in the kettle may

B. Low Voltage

B. Unit is designed to make approximately 3

C. Inadequate Supply Lines

C. Inadequately sized electrical supply lines, in

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Troubleshooting

breaker may trip during transit, if it is reset

and trips again; contact qualified service

personnel for inspection/repair before going

any further.

voltage to and from the Heat/Motor Switch,

and if the switch is defective replace it.

to heat. Check for good connections from the

kettle to the control.

at incorrect time.

Display

Turn

(Reference Controls and

Their Functions section

for indicator light

descriptions.)

or

Shaft/Motor Shaft

Indicator Light should NOT be on at the same

time. Contact qualified service personnel for

inspection/repair.

RTD resistance value (should read approx.

110 ohms at room temperature); also check

for shorts or opens.

If RTD resistance value is OK and there are

no shorts or opens, then replace digital

temperature control.

DO NOT use. Have qualified service personnel

inspect/repair as needed.

be burned out. This would result in the kettle

never reaching the proper operating

temperature.

batches per hour when operated at full voltage

(approx. 2 batches per hour for Model 2174

Series). To get unit warmed up, the first batch

usually takes about 5 minutes longer. If

machine is operated on low voltage, kettle will

not to reach the proper operating temperature

causing longer cooking cycles.

Page 17

120 V units need a 105 V minimum.

addition to being a fire hazard, would also

prevent the kettle from reaching the proper

operating temperature. Check with a qualified

electrician.

gmpopcorn.com

Page 18

DANGER

DANGER

cause property damage, injury, or death. Any alterations to this equipment will

WARNING

CAUTION

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

MAINTENANCE INSTRUCTIONS

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

Improper installation, adjustment, alteration, service, or maintenance can

void the warranty and may cause a dangerous condition. NEVER make

alterations to this equipment. Read the Installation, Operating, and

Maintenance Instructions thoroughly before installing, servicing, or operating

this equipment.

008_051514

014_051514

No user serviceable parts inside. Refer servicing to qualified service

personnel.

THE FOLLOWING SECTIONS OF THIS MANUAL ARE INTENDED ONLY

FOR QUALIFIED SERVICE PERSONNEL WHO ARE FAMILIAR WITH

ELECTRICAL EQUIPMENT. THESE ARE NOT INTENDED FOR THE

OPERATOR.

011_051514

027_010914

Page 18

gmpopcorn.com

Page 19

Kettle Bushing

(2) Mixing

Jaw Coupling

(2) Wing

Bolts

Agitator Shaft

Hub Seal Assembly

Oil Seal

Hub Body

O-Ring

Agitator Shaft

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

New Paddle/Hub Seal Kit Installation

Kettle Shaft Maintenance

1. With the machine OFF, unplug unit from the power source and allow it to cool.

2. Loosen the wing bolts (Mixing Paddle Lock Studs) and remove the mix paddles.

3. Remove any burrs on the shaft using a fine grit emery paper to lightly sand the

surface. If the burrs are not removed, damage may occur to the new o-ring/oil seal

during installation.

4. Remove the old hub seal assembly.

5. Clean the area around the center hub. Remove any product residue.

Note: The kettle shaft should be removed monthly and the bushings lubricated with

Never Seez® (use White Food Grade ONLY). To do this, loosen the (2) set

screws in the jaw coupling and remove the shaft. DO NOT lose the shaft key;

this must be reset into place when reassembling.

6. Lightly lubricate the center hub of the kettle with a small amount of vegetable oil to

allow for easy installation of the hub seal assembly.

7. Slide the new hub seal assembly down the agitator shaft. Apply pressure to ease the

assembly over the center hub of the kettle until it seats properly (see image below.)

8. After the hub seal assembly has been properly installed, re-install the mix paddles

onto the agitator shaft.

9. Finger tighten the wing bolts to secure mixing paddles in place.

10. Rotate shaft by hand to ensure paddle does not touch the kettle bottom; re-adjust

shaft as needed.

(Includes Oil Seal, O-Ring,

and Hub Body)

Paddles

w/(2) Set Screws

Page 19

gmpopcorn.com

Page 20

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

ORDERING SPARE PARTS

1. Identify the needed part by checking it against the photos, illustrations, and/or

parts list.

2. Use only approved replacement parts when servicing this unit.

3. When ordering, please include part number, part name, and quantity needed.

4. Please include your model number, serial number, and date of manufacture (located

on the machine nameplate/data plate) with your order.

5. Address all parts orders to:

Parts Department

Gold Medal Products Co.

10700 Medallion Drive

Cincinnati, Ohio 45241-4807

Or, place orders by phone or online:

Phone: (800) 543-0862

(513) 769-7676

Fax: (800) 542-1496

(513) 769-8500

E-mail: info@gmpopcorn.com

Web Page: gmpopcorn.com

Page 20

gmpopcorn.com

Page 21

All

Model

s

1 LID ASSEMBLY (includes handle)

67216

2 HANDLE BRACKET

67182

3 PLASTIC HANDLE

76075

4 2 POSITION BRACKET

46153

5 1/4-20 X 3/4 GRADE 5 BOLT

74520

6 1/4-20 SERRATED LOCK NUT

46311

7 CONTROL BOX COVER

55453

8 8-32 X 1/4 PHIL PAN

M/S 87314

See Kettle sections

See

Control Panel

section for parts

Data Plate

See

Safety Labels

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Cabinet Exterior – Parts Breakdown

1

for parts breakdown.

2

3

section.

8

4

7

5, 6

breakdown.

Item

Part Description

Part No.

Page 21

gmpopcorn.com

Page 22

**

CAUTION: If supply cord is damaged, it must be replaced by Gold Medal Products Co.,

NOTE: Concave side of *Large Spacer fits up

21 22

25

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Cabinet Exterior/Spring Assembly – Parts Breakdown

4, 5

1

19

2**

20

3

8, 9 7

14 15

11

16

17, 5

23*

4, 5

12 13

6

18

24

10, 11

against bracket weld on Dump Bar Shaft.

its service agent, or similarly qualified persons in order to avoid a hazard.

Page 22

gmpopcorn.com

Page 23

2174DEL

2174DER

2175DEL

2175DER

1 KETTLE LEAD IN ASSY (includes connectors)

48769

48769

48769

48769

2** LEAD

-

IN CORD ASSY.

47580

47580

41034

41034

3 STRAIN RELIEF T&B 3304

82227

82227

82227

82227

4 1/4-20x3/4 BUTTON HD SC

67927

67927

67927

67927

5 HEX NUT 1/4

-

20 ESLOK

42361

42361

42361

42361

6 KETTLE MTNG BRKT MACHINED

106060

106060

106060

106060

7 SPRING RETAINER ROD

82551

82551

82551

82551

8 SET COLLAR 1/2ID X 7/8OD

47326

47326

47326

47326

9 SET SCREW 1/4

-

20 X 3/16 (1 req’d. per collar)

47751

47751

47751

47751

10 GRIP, HANDLE BAR

46028

46028

46028

46028

11 TILT LEVER 1/2X3/4 CD BAR

46006

46006

46006

46006

1/4-20 SERRATED LOCK NUT

(top side of

13 1/4-20X1/2 BUTN HD SCREW

79242

79242

79242

79242

14 KEY (

.187 X .187 X

3/4) 12509

12509

12509

12509

15 SET SCREW 1/4

-

20 X 3/8

74125

74125

74125

74125

16 HUB 16707

16707

16707

16707

17 SOCKET HEAD 1/4

-

20 SCREW

77893

77893

77893

77893

LEFT SPRING & DUMP BAR ASS

EMBL

Y

R

IGH

T SPRING & DUMP BAR ASS

EMBL

Y

19 COLLAR

74661

74661

74661

74661

20 SET SCREW, 5/16

-

18 X 5/8 (3 req’d. per collar)

74662

74662

74662

74662

21 TORSION SPRING

74660

74660

74660

74660

22 SPACER

74658

74658

74658

74658

SPACER,LARGE

(DUMP

SIDE)

-

Concave side

R

IGH

T DUMP BAR WELDMENT

16705

16705

LEFT DUMP SHAFT WELDMENT

16706

16706

25 SPACER,LARGE

(CUSTOMER

SIDE)

74690

74690

74690

74690

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Cabinet Exterior/Spring Assembly – Parts List

Item

12

bracket use a 1/4-20 ESLOK Hex Nut)

(assembly includes items listed below)

18

(assembly includes items listed below)

Part Description

Part No.

46311 46311 46311 46311

16710 16710

16709 16709

23*

fits up against bracket weld on Dump Bar Shaft

24

74659 74659 74659 74659

Page 23

gmpopcorn.com

Page 24

* Hub Seal Assembly

For Key, see Kettle Bottom/

Motor

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Kettle and Drum – Parts Breakdown

2

1

3

13

(Includes Oil Seal, Hub

4

5

6*

10

11

12

Mount Parts Breakdown section)

14

Body, and O-Ring)

7

8

9

Page 24

gmpopcorn.com

Page 25

2174DEL

2175DEL

1 WING NUT, #8

-32

89126

89126

2 BLENDING STRIP

46532

46532

3 MIXING DRUM

46288

46288

4 MIXER PADDLE

46286

46286

5 MIX PADDLE LOCK STUD ASSY

46203

46203

HUB SEAL ASSY (includes Oil

Seal, Hub Body, and

7 O-RING 1 3/4ID X 2OD

46631

46631

8 HUB SEAL

46630

46630

9 HUB SEAL BODY

46629

46629

10 AGITATOR SHAFT

46143

46143

11 RETAIN RING

ASSY 46651

46651

12 DRUM SEAL

46701

46701

13 O-RING BUSHING SEAL

46119

46119

KETTLE ASSY (includes Shaft, Hub Seal Assy,

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Kettle and Drum – Parts List

Part No.

Item

Part Description

2174DER

2175DER

6

O-Ring)

Retaining Ring and Drum Seal; also see Kettle

14

Bottom and Kettle Element View sections for

itemized parts breakdown).

46632 46632

68007F 68015F

Page 25

gmpopcorn.com

Page 26

Strain R

elief

(not shown)

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Kettle Bottom Plate/Motor Mount – Parts Breakdown

1

6

7

8

11

12 13, 14

15

2

3

4, 5

9

10

7

19

20

16, 5, 17

18

21

on cord end to Control Box.

Page 26

gmpopcorn.com

Page 27

2174DEL

2175DEL

KETTLE ASSY (includes Shaft, Hub Seal Assy,

2 KETTLE REST BUMPER

83111

83111

3 KETTLE REST (metal rest/holds bumper)

8311

3 8311

3

4 1/4-20 X 1/2 P/H PHIL

(fastens Kettle Rest)

12471

12471

5 WASHER 1/4 INTERNAL TOOTH

12383

12383

6 13/16"ID 2"OD FLAT WASHER

77892

77892

KEY (

.187 X .187 X 3/4

) (one used for agitator

8 3/4 BORE

COUPLING BODY (includes set screws)

46145

46145

9 FLEXIBLE SPIDER

12141

12141

10 5/8 BORE

COUPLING BODY(includes set screws)

46144

46144

11 KETTLE LEAD IN ASSY

48769

48769

12 BOTTOM COVER

67995

67995

13 1/4-20 X 3/4 GRADE 5 BOLT

74520

74520

14 1/4 FLAT WASHER

STAINLESS

87261

87261

15 MOTOR MOUNT (bracket)

16708

16708

16 1/4-20 x 1 1/4 HEX CAP

(fastens motor)

48571

48571

17 MOTOR SPACER

67207

67207

18 DRIVE MOTOR

82085B

82085B

19 8-32 X 3/8 SLT. HWH M/S

42044

42044

20 CABLE CLAMP

87219

87219

STRAIN RELIEF (Plastic Strain Relief o

n cord end

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Kettle Bottom Plate/Motor Mount – Parts Breakdown

Part No.

Item

Retaining Ring and Drum Seal; also see Kettle

1

Bottom and Kettle Element View sections for

itemized parts breakdown).

Part Description

2174DER

68007F 68015F

2175DER

7

shaft, one used for motor shaft)

21

to Control Box)

12509 12509

76026 76026

Page 27

gmpopcorn.com

Page 28

2174DEL

KETTLE, CORN T

REAT CENTER (includes

2 BUSHING, MIX BOWL (bottom

bushing shown

) 46065PMO

BUSHING, MIX BOWL (

top bushing not shown;

4 O-RING BUSHING SEAL

46119

5 SHAFT COVER

12581

6 ELEMENT RETAINER BRKT

67174

7 STANDOFF 11/16 IN

12889

8 SET SCREW 10

-

24 X 1

46627

9 10-24 SERRATED LOCK NUT

49363

10 L-510

THERMOSTAT KETTLE

(2 required)

82219

11 RTD HEAT SENSOR

46299

12 TUBULAR ELEMENT, 1500W

48800

13 TUBULAR ELEMENT, 275

W 46439

* Bottom Bushing

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Kettle Element View – 2174 Series

Shown

2*, 3, 4

1

7

8, 9

6

5

10

11

12

13

Part No.

Item

1

bushings shown below)

3

bushing is machined to fit o-ring listed below )

Part Description

2174DER

46280

46065

Page 28

gmpopcorn.com

Page 29

2175DER

KETTLE, CORN T

REAT CENTER (includes

2 BUSHING, MIX BOWL (bottom

bushing shown

) 46065PMO

BUSHING, MIX BOWL (

top bushing not shown;

4 O-RING BUSHING SEAL

46119

5 SHAFT COVER

12581

6 ELEMENT RETAINER BRKT

67174

7 STANDOFF 11/16 IN

12889

8 SET SCREW 10

-

24 X 1

46627

9 10-24

SERRATED LOCK NUT

49363

10 L-510

THERMOSTAT KETTLE

(2 required)

82219

11 RTD HEAT SENSOR

46299

12 TUBULAR ELEMENT, 720W

55279

13 TUBULAR ELEMENT, 1500W

48800

14 HEAT ELEMENT 120V 1000W

41536

* Bottom Bushing

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Kettle Element View – 2175 Series

Shown

2*, 3, 4

1

7

8, 9

6

5

10

11

12

13

14

Part No.

Item

1

bushings shown below)

3

bushing is machined to fit o-ring listed below )

Part Description

2175DER

46280

46065

Page 29

gmpopcorn.com

Page 30

Digital Control Panel Interior

Digital Control Panel

9 7

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Digital Control Panel – Parts Breakdown

8

1

2

3

4

10

11

5

6

(Model 2175DER shown)

2

3

12

4

13

Exterior View

Page 30

gmpopcorn.com

Page 31

All

Model

s

DIGITAL CONTRL BOX ASSY (includes support

2 TEMPERATURE CONTROL 32C

48720

3 SWITCH, ROCKER DPDT LGHT

48616

4 CIRCUIT BREAKER 15 AMP

47364

5 BUZZER SIGNAL

46118

6 RESISTOR, 5K 8 WATT

48612

7 RELAY, 30A DPST 120V

55219

8 RESISTOR, 500K 1 WATT

(2 required)

55009

9 TIMER, PERCENTAGE 60 SEC

48688

10 7.5 MFD CAPACITOR

46107

11 CAPACITOR STRAP

48301

12 NAMEPLATE

48668

13 HOLE PLUG, ROCKER SWITCH

42743

All

Model

s

1 COOKER LABEL

111031

2 CAUTION HOT LABEL

38201

3 MINIMUM CLEARANCE LABEL

88720

4 MAIN GROUND LABEL

42375

5 WARNING LABEL CORD

68720

Unit

Labels

Power Cord Label

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Digital Control Panel – Parts Breakdown

Safety Labels

Item

1

and cover)

Part Description

Part No.

48681

2

4

Item

1

Part Description

3

5

Part No.

Page 31

gmpopcorn.com

Page 32

2174DEL

2175DEL

1 ONE QUART MEASURE

46466

46466

2 2 CUP ACRYLIC MEASURE

62807

62807

3 BOWL SCRAPER

46210

46210

4 STAMPED ALUM SCOOP

2071

2071

5 5GAL WHITE STORAGE BUCKET

46125

46125

6 RECPT, 20A

-

125/250 VOLT

41254

2

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Accessories

1

3

6

4

5

Part No.

Item

Part Description

2174DER

2175DER

Page 32

gmpopcorn.com

Page 33

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Wiring Diagram

Model No. 2174DEL, 2174DER

Page 33

gmpopcorn.com

Page 34

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

Model No. 2175DEL, 2175DER

Page 34

gmpopcorn.com

Page 35

10700 Medallion Drive, Cincinnati, Ohio 45241

-

4807 USA

Corn Treat - Digital Model No. 2174DER, 2175DEL, 2175DEL, 2175DER

WARRANTY

WARRANTY

Gold Medal Products Co. warrants to the original purchaser each item of its manufacture to

be free of defects in workmanship and material under normal use and service. Gold Medal

Products Co.’s obligation under this warranty is limited solely to repairing or replacing parts,

f.o.b. Cincinnati, Ohio, which in its judgment are defective in workmanship or material and

which are returned, freight prepaid, to its Cincinnati, Ohio factory or other designated point.

Except for “Perishable Parts” on specific machines, the above warranty applies for a period

of two (2) years from the date of original sale to the original purchaser of equipment when

recommended operating instructions and maintenance procedures have been followed. These

are packed with the machine. Parts warranty is two (2) years, labor is six (6) months.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR

IMPLIED, AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON OUR PART,

INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY. THERE ARE

NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

HEREOF. In no event shall Gold Medal Products Co. be liable for special, incidental or

consequential damages. No claim under this warranty will be honored if the equipment covered

has been misused, neglected, damaged in transit, or has been tampered with or changed in any

way. No claim under this warranty shall be honored in the event that components in the unit at

the time of the claim were not supplied or approved by Gold Medal Products Co. This warranty

is effective only when electrical items have been properly attached to city utility lines only at

proper voltages. This warranty is not transferable without the written consent of Gold Medal

Products Co.

The term “Original Purchaser” as used in this warranty shall be deemed to mean that person,

firm, association, or corporation who was billed by the GOLD MEDAL PRODUCTS CO.,

or their authorized distributor for the equipment.

THIS WARRANTY HAS NO EFFECT AND IS VOID UNLESS THE ORIGINAL

PURCHASER FIRST CALLS GOLD MEDAL PRODUCTS CO. AT 1-800-543-0862 TO

DISCUSS WITH OUR SERVICE REPRESENTATIVE THE EQUIPMENT PROBLEM,

AND, IF NECESSARY, FOR INSTRUCTIONS CONCERNING THE REPAIR OR

REPLACEMENT OF PARTS.

NOTE: This equipment is manufactured and sold for commercial use only.

Phone: (800) 543-0862 Fax: (800) 542-1496

(513) 769-7676 (513) 769-8500

© 2015 – The text, descriptions, graphics, layout, and other material in this publication are the exclusive property of

Gold Medal Products Co. and shall not be used, copied, reproduced, or published in any fashion, including website

display, without its express written consent.

gmpopcorn.com

Page 35

gmpopcorn.com

Loading...

Loading...