Page 1

Part No. 67861

Revised: February 2009

Citation

Models #2001, 2001ST, 2001BN

Instruction Manual

Cincinnati, OH 45241-4807 USA

Page 2

SAFETY PRECAUTIONS

Citation

2

Models 2001, 2001BN, 2001ST

Page 3

Citation

Forward

This manual covers the 16oz. Citation Popcorn Machine, model number 2001, 2001BN, and 2001ST.

Installation Instructions

Inspection of Shipment:

Unpack all cartons and check thoroughly for any damage that may have occurred during transit.

Damage claims should be filed immediately with the transportation company. Gold Medal is not

responsible for damage that occurs in transit.

Setup:

Your new Citation Popcorn Machine is completely assembled and tested at the factory.

Remove all packing material and tape before starting operation.

Electrical Requirements:

The following power supply must be provided:

Model No. 2001 – 2001BN – 2001ST: 1920 Watts, 120 VAC, 16 Amps, 60 Hz.

Your electrician must furnish sufficient current for proper machine operation. We recommend this

popper be connected to a dedicated 20 amp circuit protected line. Failure to wire properly will void

the warranty and can result in damage to the heat elements, light, motor and etc.

It is Gold Medal Products Company’s recommendation that this machine be plugged directly into a

wall outlet. The use of extension cords is not recommended due to safety reasons and the popper’s

performance will be sacrificed/reduced.

Before You Plug In Machine:

1. Make sure that the wall outlet can accept the three (3) prong grounded plug on the power supply

cord.

2. The wall outlet must have the proper polarity. If in doubt, have a competent electrician inspect the

outlet and correct if necessary.

3. DO NOT use a three (3) prong grounded to two (2) prong un-grounded adapter.

3

Models 2001, 2001BN, 2001ST

Page 4

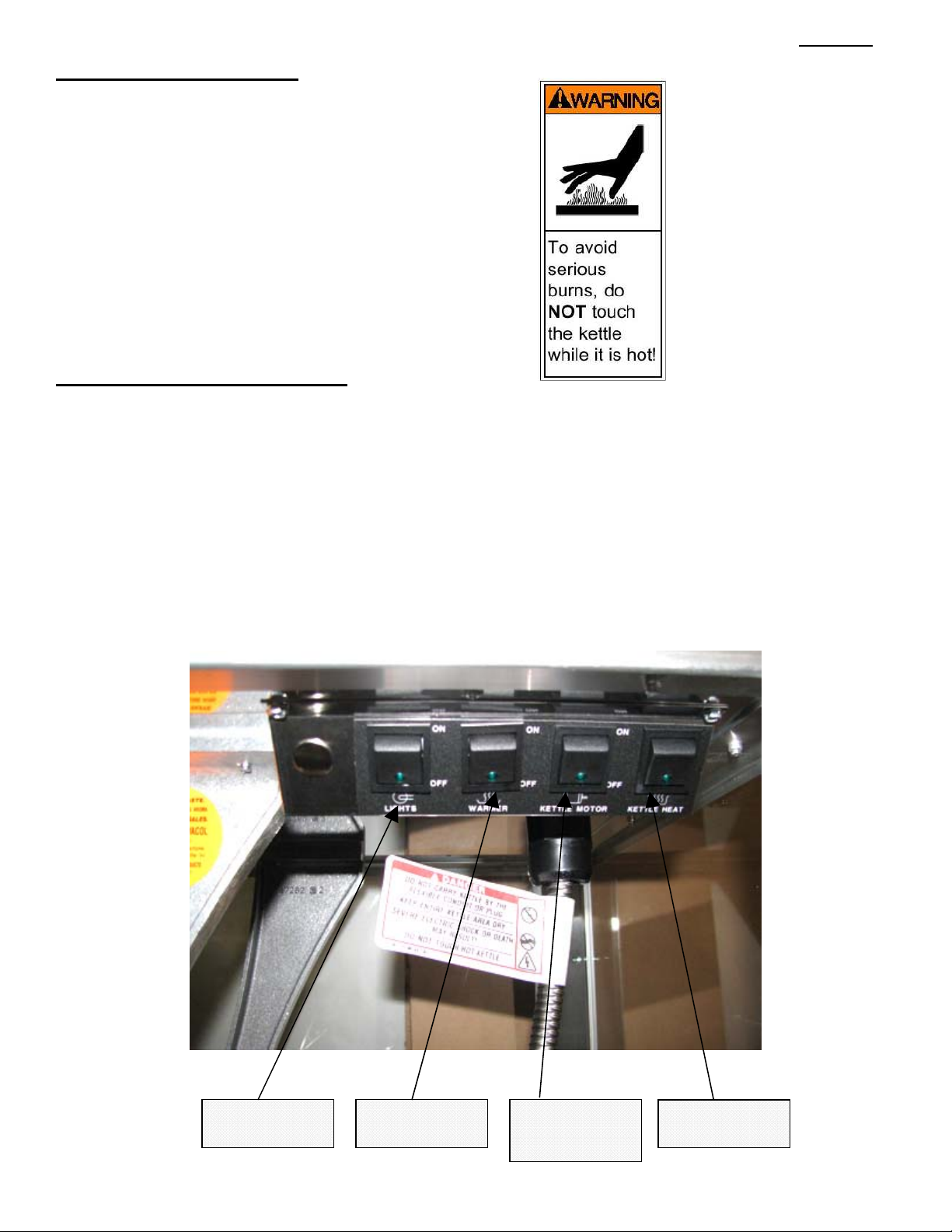

FINAL PREPARATIONS

The popcorn machine was adjusted, inspected, and

tested before it left the factory. After removing machine

from shipping box, remove all tape and packing material

in or on the machine before beginning operation.

OPERATING INSTRUCTIONS

Controls and their functions

LIGHT SWITCH

Turns on all of the lights, interior, and dome on your popcorn machine.

WARMER SWITCH

Operates the forced air popcorn crisping system.

KETTLE HEAT SWITCH

Operates the heating elements in the popping kettle.

KETTLE MOTOR SWITCH

Operates the kettle agitator motor, as well as the exhaust blower in the roof of the machine.

Light Switch

p/n 42798

WarmerSwitch

p/n 42798

Kettle Motor

Switch

p/n 42798

Citation

Kettle Heat Switch

p/n 42798

4

Models 2001, 2001BN, 2001ST

Page 5

Citation

Amount of Popcorn and Oil:

The Citation popper is equipped with a sixteen ounce corn measure cup. Gold Medal Products

Company recommends the use of flavored and colored coconut oil. Coconut oil does not leave

black deposits in the kettle like other oils.

Corn Charge: 16 Oz. (473 ml)

Oil Charge: 4-5 ounces

Flavacol (Salt): 1 ½ Tablespoon (20 cc) (Use the supplied Salt Scoop)

Popping Instructions:

1. Turn both the KETTLE HEAT and KETTLE MOTOR switches ON.

2. Test pop three (3) kernels of corn and one ounce (1 Oz.) of popping oil. When the kernels pop,

the kettle is ready for use.

3. Load both a full corn/oil charge and Flavacol Seasoning Salt into the kettle. Close the lids.

4. When the corn has finished popping, gently dump the kettle.

5. Repeat the cycle, starting with step number 3, until the desired amount of popcorn has been

achieved. Always pop 3 to 5 consecutive batches for the best popcorn.

On the final kettle of corn, it is a good idea to turn the KETTLE HEAT switch OFF just as the lids are

forced open by the popping corn. This procedure saves electricity, and reduces smoke/odor from

any oil residue that remains after you have finished popping.

5

Models 2001, 2001BN, 2001ST

Page 6

CLEANING INSTRUCTIONS

DAILY:

Clean the Kettle

1. CAUTION: The hot kettle will cause burns if you touch it with your hand. Allow the kettle

to cool for at least 1 hour before attempting to clean. Wipe the kettle with a clean cloth.

2. After ending extended use, mix a gallon of Heat’n Kleen solution (2 tablespoons per

gallon of water). Add 16 oz. of this solution into the kettle. Turn on the kettle heat. When

the water starts to boil, turn off the kettle heat and allow the solution to work over-night.

3. Before next use, dump the solution into a bucket and wipe the inside of the kettle with a

clean cloth. Make sure all of the solution goes into the bucket, and that you do not spill

any into the interior cabinet of the machine.

Clean the Exhaust Filter (Shown on Page 12 of this manual)

Clean the Exhaust Filter at least once a week by following these simple instructions:

1. Pull the filter out.

2. Wash in warm soap and water.

3. Allow filter to air dry, then re-install.

Clean the Popcorn Machine

1. Wipe the stainless steel parts with a clean cloth and cleaner designed for stainless steel. Do not

use oven cleaners, as they will damage parts of the machine.

2. Ammonia cleaners will damage the plastic doors. Use only non-ammonia cleaners, such as

Gold Medal’s – Watchdog Glass Cleaner – item number 2588.

Citation

6

Models 2001, 2001BN, 2001ST

Page 7

MAINTENANCE INSTRUCTIONS

Citation

7

Models 2001, 2001BN, 2001ST

Page 8

Citation

TROUBLESHOOTING

Below are some common issues you may encounter, along with basic trouble shooting

steps to resolve them.

EXPERIENCING LONG POPPING CYCLES

If your pop cycle is longer than 4 minutes, it can be the result of several things:

A. LOW VOLTAGE - If the machine is operated on low voltage, this could cause the kettle

not to reach the proper operating temperature. Voltage must be at least 110v.

B. INADEQUATE SUPPLY LINES - Inadequately sized electrical supply lines, in addition to

being a fire hazard, would also prevent the kettle from reaching the proper operating

temperature. Check with a qualified electrician.

C. INFERIOR CORN - Inferior quality corn would result in longer popping cycles. Use only

top quality fresh hybrid popcorn from reputable suppliers. Even then, if you let your corn

pick up moisture or dry out, your popping cycles will be slow.

THE KETTLE DOES NOT HEAT

Before you go any further, make sure the kettle lead-in cord is plugged in.

A. KETTLE HEAT SWITCH - Check the voltage to and from the “KETTLE HEAT” switch,

and if the switch is defective, replace it. (Repair should only be performed by qualified

service personnel.)

THE MOTOR WILL NOT TURN AGITATOR

WARNING!

between the kettle bottom and the stir blade to 1/32” (use a dime). Loosen the set screw in the

collars above and below the crossbar and adjust the agitator shaft as necessary. Then re-tighten the

set screws in the collars.

If the kettle agitator shaft is not rotating, DO NOT pop corn. Adjust the clearance

8

Models 2001, 2001BN, 2001ST

Page 9

ORDERING SPARE PARTS

1. Identify the needed part by checking it against the photos, illustrations, and/or the parts list.

2. When ordering, please include part number, part name, and quantity needed.

3. Please include the machine’s model name, serial number, and date of manufacture (located on the

machine nameplate) with your order.

4. Address all parts orders to:

Parts Department

Gold Medal Products Co.

10700 Medallion Drive

Cincinnati, Ohio 45241-4807

(800) 543-0862

(513) 769-7676

Fax: (513) 769-8500

or, place orders at:

E-mail: info@gmpopcorn.com

Web Page: www.gmpopcorn.com

Citation

9

Models 2001, 2001BN, 2001ST

Page 10

Cabinet Breakdown

p

p

p

p

Citation

Magnetic Catch

Bracket p/n 47559

Switch Box

p/n 48543

Switch Box Label

/n 48543

Magnetic Catch

p/n 47561

Kettle Receptacle

20A Twist Lock

p/n 47327

16 oz Unimaxx

Kettle Complete

/n 56100

Kettle Plug 20A

Twist Lock

/n 47363

Kettle Lead Assy.

p/n 62308

16 oz Unimaxx Kettle

Complete

p/n 56100

Hardware Kits for

Doors (See p. 11)

p/n 47054 (LH)

p/n 47055 (RH)

Glide (4)

/n 47328

20 Amp Power

Supply Cord

p/n 47580

Bottom Corn Pan

p/n 47736

10

Drop Panel

p/n 41017

Old Maid Pan

p/n 61181

Models 2001, 2001BN, 2001ST

Plexiglas Door (2)

p/n 47600

Page 11

Citation

Complete Hardware

Kit for LH Door

p/n 47054

{

Individual Hardware Components

Door Knob 41013

Tee Bolt 75267

LH Male Hinge 41349

8-32 X 3/8” Screws 74141

LH Female Hinge 41352

8-32 Acorn Nut 47702

8-32 X ½” Screws 47124

RH Female Hinge 41351

RH Male Hinge 41350

Door Hardware Kits

Complete Hardware

}

Kit for RH Door

p/n 47055

Cabinet Interior – Ceiling Components

Spur Gear (2)

p/n 47060

10-32 x 3/16 Set

Screw for Spur

Gear (2) p/n 41742

Hanger Arm Front

p/n 47262

Gear Block Assy.

p/n 67194

Hanger Arm

Rear, Assy.

p/n 47228

11

Models 2001, 2001BN, 2001ST

Page 12

Citation

r

Filte

p/n 47043

Heater Blower Components (Assembly p/n 50102L)

Thermostat Mount

p/n 61186

Heater Clamps

p/n 61133

Blower

p/n 48018

Thermostat

p/n 47385

Heat Element (2)

190 W Tubular

p/n 55437

Blower Plug And

Cord

p/n 47199

12

Models 2001, 2001BN, 2001ST

Page 13

Citation

p

r

p

p

Kettle Breakdown Kettle Complete – P/N 55199

Dump Handle Knob

p/n 47110

Junction Box (On

Bottom of Kettle)

p/n 47393

Junction Box Cover

p/n 56108

Dump Handle Assy

p/n 47102

Kettle Shell Assy.

p/n 41081

Lead-in Cord Assy.

Complete

p/n 62308

Element Clamp

/n 67894

Element – 1550W

/n 67014

Kettle

/n 67892

Kettle Gasket

p/n 41598

13

Twist Lock Plug (Plug Only)

p/n 47363

Thermostat 550F

p/n 77108

Themostat Shunt Ba

p/n 47193

Thermostat 510F

p/n 77107

Models 2001, 2001BN, 2001ST

Page 14

Citation

p

Bearing Hub (Included

with 41093 shaft assy.)

p/n 43434

Spur Gear

p/n 47060

Set Screw for Spur

Gear

p/n 41742

Set Collar (2)

p/n 47326

Set Screws for Set

Collars (2)

p/n 47751

Front Kettle Lid

p/n 41123

Crossbar Assy.

p/n 41180

Threaded Blocks

p/n 61167

Lid and Agitator Assembly available complete as P/N 41181

Lid and Agitator Assembly

Needle Bearing

p/n 47106

Agitator Shaft Assy.

(Includes 43434

Bearing Hub)

/n 41093

Crossbar Bushing (2)

p/n 47097

Rear Kettle Lid

p/n 41120

10-32X ½” Screw

p/n 40717

14

Models 2001, 2001BN, 2001ST

Page 15

Top - Motor Plate Assy.

p

p

p

Lamp Holder

p/n 47047

Light Shield

p/n 49480

Light Tube

Holder For

Starter

p/n 41021

Starter

p/n 41023

Exhaust Blower

p/n 47343

Model 2001BN Only:

75 Watt Coated

Flood Light

p/n 47176

Citation

Fluorescent Bulb

(2001)

p/n 16264

(2001ST)

/n 39016

Switch, Lighted

Rocker Gr (4)

/n 42798

Kettle Drive Motor,

120V p/n 47038

Kettle Receptacle

20A Twist Lock

/n 47327

Light Tube

Holder

p/n 41020

Light Ballast

p/n 41022

Power Supply,

12VDC

p/n 55231

LED Sign Assy,

24 Inch

p/n 45003

Molded Plug,

p/n 47726

15

Models 2001, 2001BN, 2001ST

Page 16

Electrical Schematic – 2001, 2001BN, 2001ST

Citation

16

Models 2001, 2001BN, 2001ST

Page 17

Citation

WARRANTY

WE WARRANT to the original purchaser the Gold Medal equipment sold by us to

be free from defects in material or workmanship under normal use and service. Our

obligation under this warranty shall be limited to the repair or replacement of any

defective part for a period of six (6) months from the date of sale to the Original

Purchaser with regard to labor and two (2) years with regard to parts and does not

cover damage to the equipment caused by accident, alteration, improper use, voltage,

abuse, or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED

OR IMPLIED, AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON OUR

PART, INCLUDING THE IMPLIED WARRANTY OF MERCHANTIBILITY.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION

ON THE FACE HEREOF. We neither assume, nor authorize any other person

to assume for us, any other obligation or liability in connection with the sale of said

GOLD MEDAL equipment or any part thereof.

The term “Original Purchaser” as used in this warranty shall be deemed to mean that

person, firm, association, or corporation who was billed by the GOLD MEDAL

PRODUCTS COMPANY, or their authorized distributor for the equipment.

THIS WARRANTY HAS NO EFFECT AND IS VOID UNLESS THE ORIGINAL

PURCHASER FIRST CALLS GOLD MEDAL PRODUCTS COMPANY AT 1-800543-0862 TO DISCUSS WITH OUR SERVICE REPRESENTATIVE THE

EQUIPMENT PROBLEM, AND, IF NECESSARY, FOR INSTRUCTIONS

CONCERNING THE REPAIR OR REPLACEMENT OF PARTS.

NOTE: This equipment is manufactured and sold for commercial use only.

© The text, descriptions, graphics and other material in this publication are the proprietary

and exclusive property of Gold Medal Products Company and shall not be used, copied,

reproduced, reprinted or published in any fashion, including website display, without its

express written consent.

GOLD MEDAL PRODUCTS COMPANY

10700 Medallion Drive

Cincinnati, Ohi o 45241-4807 USA

www.gmpopcorn.com

Phone: 1-800-543-0862

Fax: 1-800- 542- 14 96

17

Models 2001, 2001BN, 2001ST

Loading...

Loading...