Good Water Warehouse Inc.

1700 E Walnut Ave

Fullerton CA 92831

(714) 441-2893

(714) 441-0525 FAX

Reverse Osmosis System

Installation & Service Guide

Model # GOLDLINE-50

Please read this manual carefully

before attempting installation.

(1)

GoldLine Manual Introduction

The Goldline reverse osmosis drinking water system is designed for easy installation and maintenance. You will insure a successful installation

as well as reliable operation by carefully reading this manual and following the operational guidelines. Please note that routine maintenance is

essential to the longevity and performance of the system. Filters should be changed every six months (see below) depending on the quality of the

feed water supply. The Goldline RO installation should comply with all state and local laws and regulations. Manufacturer recommends

a TDS test every six months by your authorized dealer. Manufacturer recommends a Nitrate/Nitrite test every six months by your

authorized dealer. This reverse osmosis system contains a replaceable component critical to the efciency of the system. Replacement of the

reverse osmosis component should be with one of identical specications, as dened by the manufacturer, to assure the same efciency and

contaminant reduction performance.

Necessary Installation Tools

Recommended Filter & Membrane

Replacement Schedule

• Variable speed drill • Teon tape

• Relton Drill • Small knife

• 1" hole saw • Phillips screw driver

Filter/Membrane Part # Frequency

Sediment 93023 6 months

Carbon Block Prelter 32-250-125-975 6 months

Carbon Postlter CL10ROT40-B 6 months

* RO Membrane 555694-00 2-5 years

Conditions for Operation of TFC - Thin Film Composite Membrane

Used in the Goldline-50

Source Water Supply - TFC

Community / Private Bacteriologically Safe

System Pressure min/max 30 / 100 psi

Temperature 4º / 38ºC (40º / 100º F)

pH Range 3.0 to 11.0

Maximum supply TDS

level

Turbidity < 1.0 net turbidity (NTU)

1

Efciency rating means the percentage of the inuent water to the

system that is available to the user as reverse osmosis treated water

under operating conditions that approximate typical daily usage

1800 mg/L

Test parameters: 25º± 1ºC, 50 psi and pH of 7.5

2

Recovery rating means the percentage of the inuent water to the

membrane portion of the system that is available to the user as reverse

osmosis treated water when the system is operated without a storage

tank or when the storage tank is bypassed.

Chemical Parameters - TFC

Hardness (CaCo3)

Iron (Fe) < 0.1 mg/L

Manganese (Mn) < 0.05 mg/L

Hydrogen Sulde (H2S) 0.00 mg/L

< 170 mg/L (< 10 gpg)

Production Rate

1

Efciency Rate 8.67%

2

Recovery Rate 23.87 %

Daily Production Rate 10.22 gpd

Caution: Do not use with water that is microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system.

(2)

Starting Your Installation

(4)

Preparation

Check the following list of components to ensure that all

parts are packed with your system.

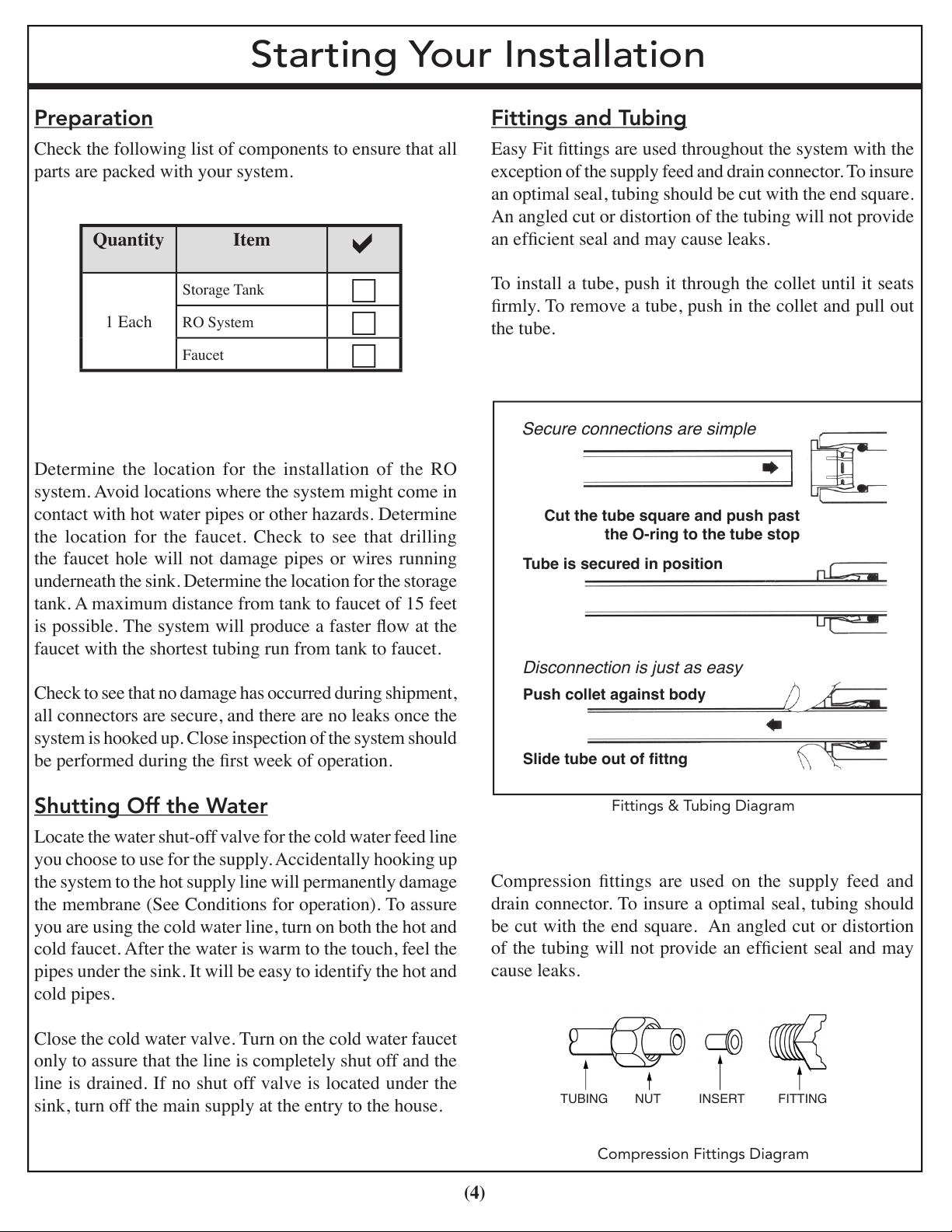

Compression ttings are used on the supply feed and

drain connector. To insure a optimal seal, tubing should

be cut with the end square. An angled cut or distortion

of the tubing will not provide an efcient seal and may

cause leaks.

Starting Your Installation

Determine the location for the installation of the RO

system. Avoid locations where the system might come in

contact with hot water pipes or other hazards. Determine

the location for the faucet. Check to see that drilling

the faucet hole will not damage pipes or wires running

underneath the sink. Determine the location for the storage

tank. A maximum distance from tank to faucet of 15 feet

is possible. The system will produce a faster ow at the

faucet with the shortest tubing run from tank to faucet.

Check to see that no damage has occurred during shipment,

all connectors are secure, and there are no leaks once the

system is hooked up. Close inspection of the system should

be performed during the rst week of operation.

Shutting Off the Water

Locate the water shut-off valve for the cold water feed line

you choose to use for the supply. Accidentally hooking up

the system to the hot supply line will permanently damage

the membrane (See Conditions for operation). To assure

you are using the cold water line, turn on both the hot and

cold faucet. After the water is warm to the touch, feel the

pipes under the sink. It will be easy to identify the hot and

cold pipes.

Close the cold water valve. Turn on the cold water faucet

only to assure that the line is completely shut off and the

line is drained. If no shut off valve is located under the

sink, turn off the main supply at the entry to the house.

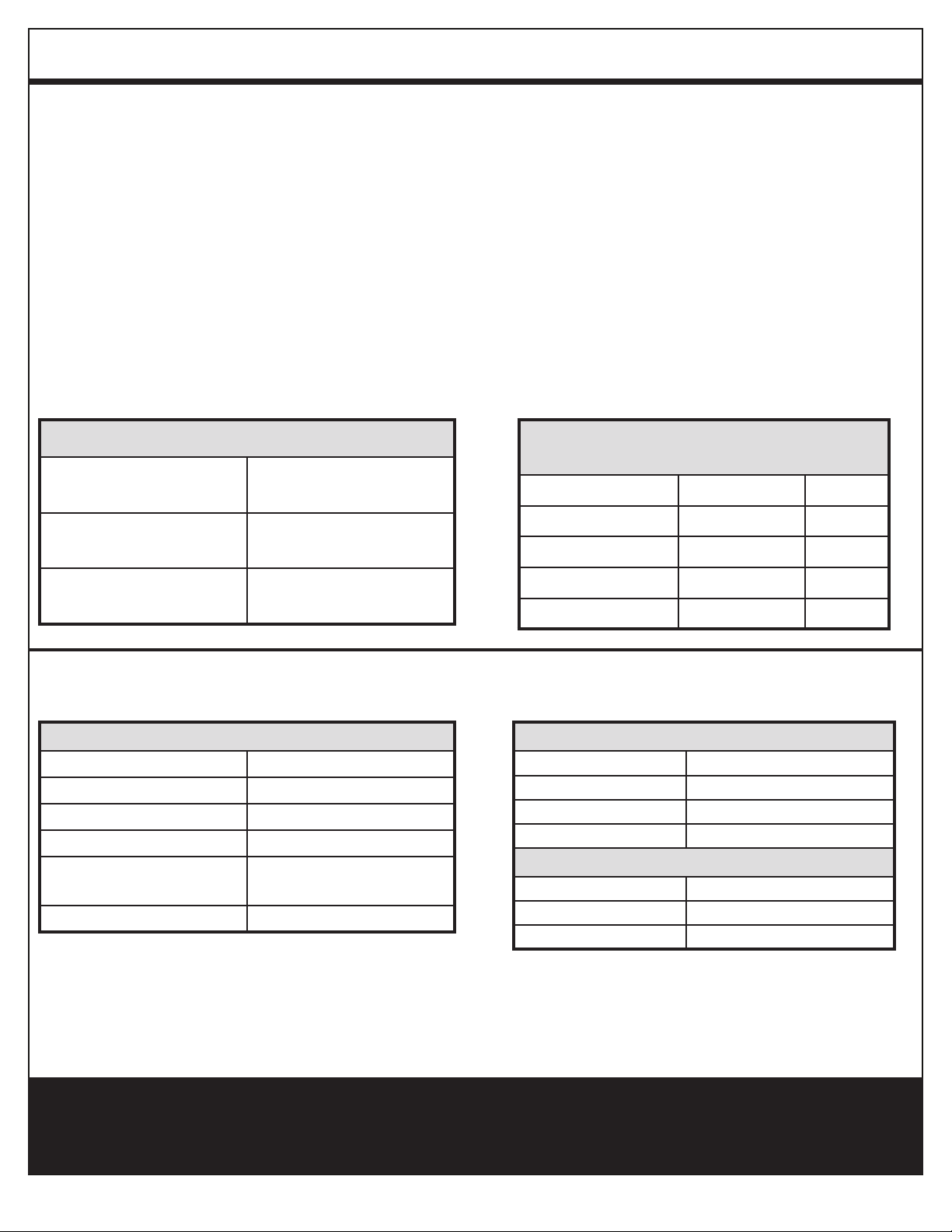

Fittings and Tubing

Easy Fit ttings are used throughout the system with the

exception of the supply feed and drain connector. To insure

an optimal seal, tubing should be cut with the end square.

An angled cut or distortion of the tubing will not provide

an efcient seal and may cause leaks.

To install a tube, push it through the collet until it seats

rmly. To remove a tube, push in the collet and pull out

the tube.

Compression Fittings Diagram

Fittings & Tubing Diagram

Quantity Item

a

1 Each

Storage Tank

c

RO System

c

Faucet

c

TUBING NUT INSERT FITTING

Cut the tube square and push past

the O-ring to the tube stop

Tube is secured in position

Push collet against body

Slide tube out of ttng

Disconnection is just as easy

Secure connections are simple

Preparation

Check the following list of components to ensure that all

parts are packed with your system.

Quantity Item

Storage Tank

1 Each

Determine the location for the installation of the RO

system. Avoid locations where the system might come in

contact with hot water pipes or other hazards. Determine

the location for the faucet. Check to see that drilling

the faucet hole will not damage pipes or wires running

underneath the sink. Determine the location for the storage

tank. A maximum distance from tank to faucet of 15 feet

is possible. The system will produce a faster ow at the

faucet with the shortest tubing run from tank to faucet.

Check to see that no damage has occurred during shipment,

all connectors are secure, and there are no leaks once the

system is hooked up. Close inspection of the system should

be performed during the rst week of operation.

RO System

Faucet

a

c

c

c

Shutting Off the Water

Locate the water shut-off valve for the cold water feed line

you choose to use for the supply. Accidentally hooking up

the system to the hot supply line will permanently damage

the membrane (See Conditions for operation). To assure

you are using the cold water line, turn on both the hot and

cold faucet. After the water is warm to the touch, feel the

pipes under the sink. It will be easy to identify the hot and

cold pipes.

Close the cold water valve. Turn on the cold water faucet

only to assure that the line is completely shut off and the

line is drained. If no shut off valve is located under the

sink, turn off the main supply at the entry to the house.

Fittings and Tubing

Easy Fit ttings are used throughout the system with the

exception of the supply feed and drain connector. To insure

an optimal seal, tubing should be cut with the end square.

An angled cut or distortion of the tubing will not provide

an efcient seal and may cause leaks.

To install a tube, push it through the collet until it seats

rmly. To remove a tube, push in the collet and pull out

the tube.

Fittings & Tubing Diagram

Compression ttings are used on the supply feed and

drain connector. To insure a optimal seal, tubing should

be cut with the end square. An angled cut or distortion

of the tubing will not provide an efcient seal and may

cause leaks.

Compression Fittings Diagram

(3)

Loading...

Loading...