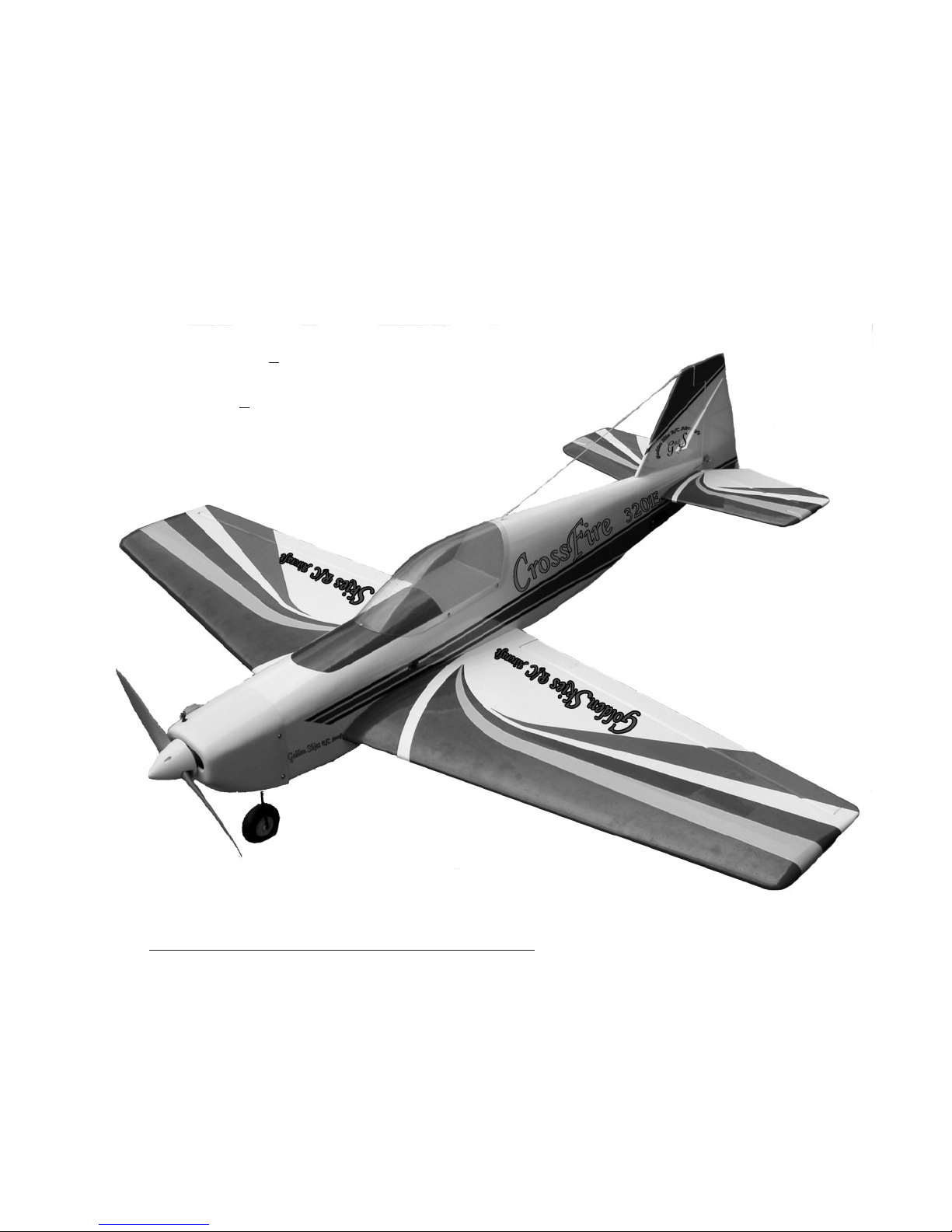

Golden Skies CROSSFIRE 320E Final Assembly Manual

CrossFire 320E

Unlimited Sport-Aerobatics

Professional Quality ARFs for Sport-Pilots

Final Assembly Manual

(refer to http://www.goldenskiesrc.com for complete, updated assembly manual)

Specifications:

Wing Span: 64 + 1/4 in, Area: 779 sq-in;

Wing Loading: 22-23 oz/sqft

Length: 60

Weight: 7 to 8-1/2 pounds (Depends upon equip. used)

Engine: 60 - 90 2/s, 90 - 120 4/s

Radio: 4 ch min, 5 servos

+ 3/8 in;

For Your Ultimate Enjoyment and Safety:

If this is your first ARF or RC model, Golden Skies R/C Aircraft, Inc. (GSRC) recommends that

you seek the knowledge and help of a long time, experienced modeler to assist you in the assembly

of this kit and to assist you in the preflight safety checks and first flights, during which you will be

trimming the plane for safety and performance. Your local hobby shop or the AMA association

(http:www.modelaircraft.org ) can assist you in finding a club, local expertise and a local flying

field. Seek a flying field with an AMA authorized club charter and one that has qualified flying

instructors. This is absolutely mandatory for your safety and the safety of others.

949-429-2910; http://www.goldenskiesrc.com Rev. 1.1 (8-6-04)

60-Size

Almost Ready to Fly

Golden Skies R/C Aircraft, Inc.

30882 Rivera Place, Laguna Niguel, CA 92677

1

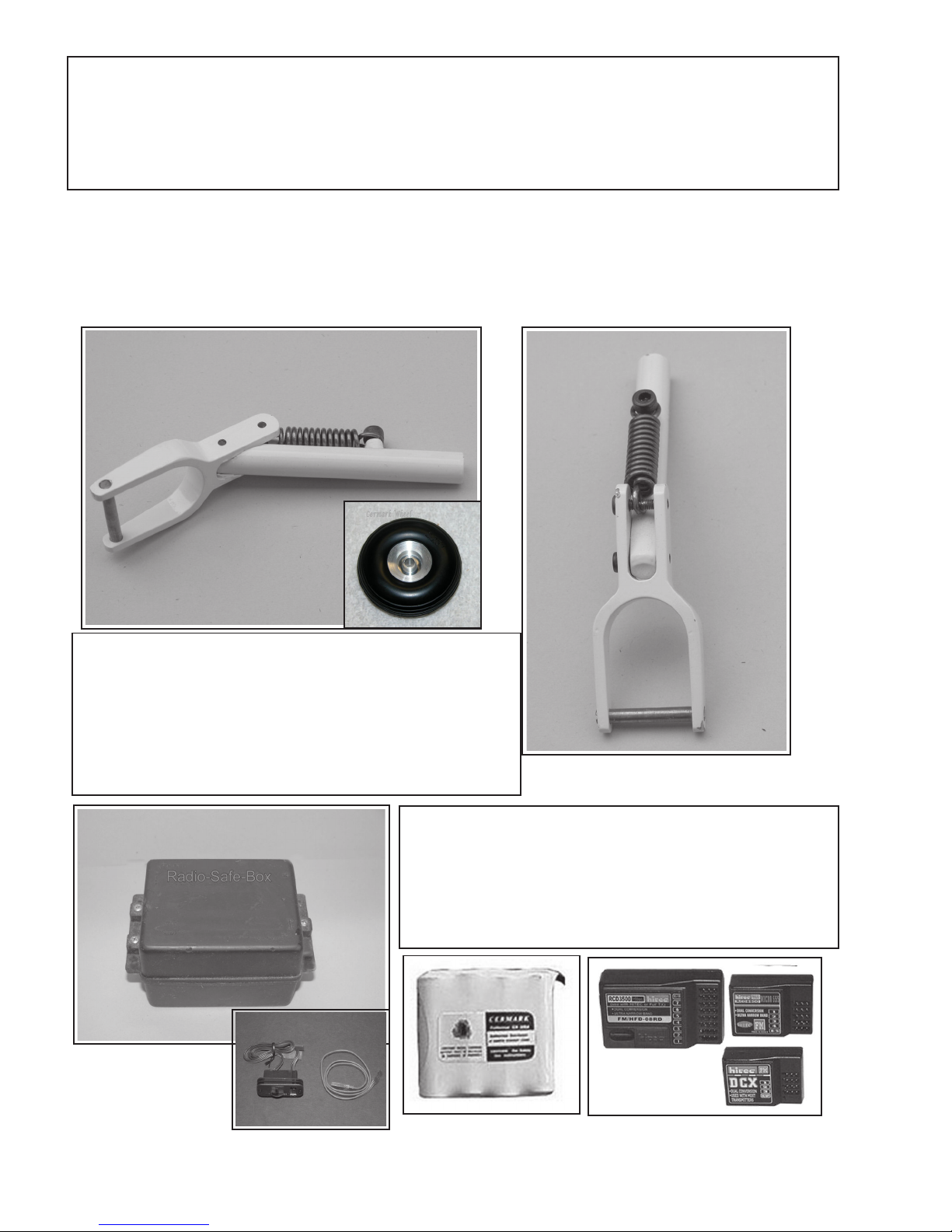

Optional Equipment and

Accessories

Through out this assembly manual, Golden Skies R/C Aircraft, Inc. (GSRC) will mention

optional installation and assembly procedures along with optional accessories that will enhance the performance, structural integrity, appearance, or safety of your aircraft. Listed and

pictured below are the accessories that are available directly from GSRC:

Spring Loaded, Caster Landing Gear: Add this

gear for the smoothest landings possible. Make a rough

landing and the spring gear smooths it out. Cut off the

torsion wire gear, slip on the spring-gear, tighten two

setscrews and you are ready to go. You still retain the

torsion wire capability and gain spring “shocks”.

Radio Safe-Box:

Add a light weight, Radio-Safe-Box ® to protect

your valuable radio receiver and battery from traumatic

crash damage and make the receiver & battery installation the easiest it has ever been.

Order these optional parts through: http://www.goldenskiesrc.com

Optional Equipment - Accessories ............................................................. 2

Table of Contents ...................................................................................... 3

Introduction ............................................................................................. 4

SAFETY WARNING & DISCLAIMER ................................................... 5 - 7

Warranty Statement ................................................................................... 8

Recommendations ..................................................................................... 9 - 10

Tools and Materials Needed ...................................................................... 11

English to Metric Conversion Table .......................................................... 12

Quick Build Process (for experienced builders) ........................................ 12

Assembly Steps: ........................................................................... 13-36

Rapid Assembly Step Order .............................................................................. 12

Step 1: Control Surface Hinge Installation .................................................... 13

Step 2: Wing Servo Construction ................................................................. 14

Step 3: Engine Mount Installation................................................................. 15

Step 4: Wing Panel Joining............................................................................ 16 -17

Step 5: Tail Surfaces, Installation.................................................................. 17 - 18

Step 6: Fuel Tank Assembly.......................................................................... 18 - 19

Step 7: Control Surfaces, Installation (Ailerons, Rudder, Elevator)................ 19 - 20

Step 8: Nose Wheel Assembly....................................................................... 20 - 21

Step 9: Push-rod, Pull-Pull Assembly............................................................ 22 - 24

Step 10: Belly Pan Installation........................................................................ 24 - 25

Step 11: Fuel Tank Installation....................................................................... 25 - 26

Step 12: Engine Installation............................................................................ 26 - 27

Step 13: Cowl Installation.............................................................................. 28 - 29

Step 14: Wheels............................................................................................. 30

Step 15: Radio, Battery, Switch...................................................................... 21 - 32

Spinner .......................................................................................................... 32

Decals ............................................................................................................ 33

Optional Assembly Steps: .................................................................................. 34 - 36

Balancing (Pitch-Roll-Yaw) ............................................................................... 37 - 38

Control Throws ................................................................................................. 38 - 39

Preflight Safety Checking .................................................................................. 39 - 40

Radio Controls .................................................................................................. 41

At the Field ....................................................................................................... 42

Flying ............................................................................................................... 42

Flight Trimming & Performance Chart ............................................................... 43

Supplemental Drawings and Figures ................................................................... 44

Engine Mount (rail separation) & Screw-Bolt Sizes and Drill-Tap Sizes ............. 45

Engine Drawings ............................................................................................... 46

Evaluation Sheet and Mailer .............................................................................. 47

Disclaimer ........................................................................................................ 48-50

3

Introduction

We are sincerely pleased that you have purchased the Golden Skies R/C Aircraft (GSRC),

CrossFire 320E ARF and we are sure you will thoroughly enjoy the CrossFire’s ease of assembly

and flight performance. The final assembly manual is written in two sections:

1) For the very experienced builder of ARF type R/C models

2) For the relatively new builder.

For the experienced builder (one who has successfully assembled several ARF kits) we have

a fast build scenario listing the major building steps in a multiplexing order to facilitate a very rapid

build (5-6) hours. For the less experienced builder, we present you with a traditional, step-by-step

building process. For both experienced and less-experienced builders, GSRC recommends you

read the entire manual to get a feel for the building process and the instruction manual. This will

assist you in the building process. If you have any questions about how to build the CrossFire

320E, please either call or email GSRC.

Updated Assembly Manuals are available in Adobe © *.pdf format on our website. Enlarged

and extra assembly pictures are also available, use “CrossFireAM” as a password to access this

website page.

Golden Skies R/C Aircraft, Inc.

Laguna Niguel, CA 92677

949-429-2910

email: service@goldenskiesrc.com

http://www.goldenskiesrc.com

(page 12); and,

GSRC, CrossFire 320E Features ......and benefits:

o Computer Aided Design (CAD) ...... ensures accurate, producible parts

o Strong, light weight design and construction ... High power to weight ratio

o Balsa and lite-ply construction ...... repairable with locally available materials

o OraCover ©, Heat Shrinkable Covering .... re-shrink, repairable

o After-Market Quality Hardware ...... The best available, a $35.00 retail value

o Pre-cut and Installed Canopy ...... A clean/accurate installation, time savings

o Pre-cut and drilled Cowl ......... For fast build and easy installation

o Pre-colored Cowl ....... long lasting color, fast build

o Heavy Duty landing gear ...... withstands rough landings

o Pull-Pull Rudder ........ Most positive control, easy adjustments.

o Dual, wing-aileron Servos ..... Low servo loads, quick control, reduced fluttering

o Fully symmetrical Airfoil Tail ..... More positive rudder control, no flat stab seeking

o Fully symmetrical Airfoil Wing ..... Predictable, smooth, stable in any position

o Secondary wing Spars, lite-ply ribs in wing gear area ....... Strength, durability

o Fast build Assembly manual ........ Fast build

o Warranted Firewall Strength ........ Reliability, peace of mind.

(See Optional “Spring-Gear”)

4

Safety Warning, Disclaimer and

ASSUMPTION OF RISK

Golden Skies R/C Aircraft, Inc.

Legal Agreements

Warning

The Radio Controlled (R/C), Almost Ready to Fly Aircraft (“ARF”) is NOT A TOY and is

potentially dangerous to property and individuals within several miles of your flying area. It

is capable of causing property damage, serious bodily harm,and possibly death if it strikes

personal property or an individual.

Consumer’s Responsibility

1) Assembly and Use

IT IS YOUR RESPONSIBILITY AND YOURS ALONE to assemble the ARF correctly and to properly install

all additional componentry, both included in the ARF kit and/or acquired by the purchaser of

this ARF; to preflight test the model; and to fly ONLY in an American Model Aeronautics

Association (AMA) approved flying site with the supervision and/or assistance of a fully

qualified flying site instructor. The pilot of this ARF must comply with all of the AMA’s

Safety Codes. The employment of common sense for safety of yourself and others is otherwise

mandatory. The ARF has a radio range of 500 (or less) feet and the pilot is directed not to

exceed this distance when flying the ARF. In the event the range is exceeded, the pilot will

lose control of the ARF which could cause injury and damages to objects which the ARF may come

into contact with upon an uncontrolled landing. Do not attempt to fly this ARF if you have not

been qualified as a solo pilot by the instructor at the AMA approved flying site. It is

recommended that on any first flight of a new R/C aircraft that you attain the assistance or

instruction of a highly experienced R/C pilot to verify the ARF’s construction from a safety

and flight perspective. If you are just starting to fly R/C Model Aircraft of any type, consult

your local Hobby Shop or write to the Academy of model Aeronautics to find an experienced

instructor in your area.

2) Assumption of the Risk

Participation in the operation of remote controlled aircraft is voluntary. I understand that

the operation of remote controlled aircraft is a dangerous sport which can result in bodily

injury, death, and/or damage to property for many reasons, including but not limited to

airplane accidents involving third parties known and unknown to the user; equipment failure,

malfunction, or misuse; weather conditions such as storms and lightning; the training, acts,

omissions, recommendations or advice given by your local Hobby Shop or the Academy of model

Aeronautics concerning the operation of remote controlled aircraft and related activities such

as transportation to and from the site; and first-aid, emergency treatment or other services

rendered to me as a user or others. I understand and acknowledge that the above list of reasons

is not complete or exhaustive. I accept and hereby assume all risks of injury, death, illness

5

or disease, or other damage to myself, to others, or to my property which arise from participation

in the referenced activities.

3) Release

I hereby voluntarily release, and forever discharge GOLDEN SKIES R/C AIRCRAFT, INC., a California

Corporation, on its behalf and on the behalf of its successors and assigns, and each of them

(“Golden Skies”) and its subcontractors, and all other persons or entities associated with

it, including other participants, (hereafter collectively the released parties) from all

liability, claims, demands, actions or causes of action for bodily injury, death, illness,

disease or damage to myself, to any participating minor child of mine, or to my property which

are related to, arise out of, or are in any way connected with participation in the above

referenced activities, including but not limited to those arising from any negligent or

reckless acts or omissions or breach of contract of the released parties, or hidden defects in

the equipment used. This release is intended to be as broad and inclusive as is permitted by

California law, and shall be construed and interpreted under California law. If any portion,

clause or sub clause is held invalid, I agree that the balance shall continue in full force and

effect.

4) Maintain Proper Insurance Coverage

It is also mandatory that all R/C airplane pilots obtain adequate insurance through their own

homeowner policy or a separate policy to cover liability in the event of property damage or

injury to individuals or personal property. Additionally, all R/C airplane pilots must join

the AMA to become secondarily insured.

Academy of Model Aeronautics http://www.modelaircraft.org … .

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, Indiana 47302-9252

800-435-9262

5) Indemnification.

The user of this product agrees to indemnify and defend Golden Skies R/C Aircraft, Inc., a

California Corporation, as well as all employees, shareholders, directors, officers and agents

thereof ( “Golden Skies”) , against any claims, lawsuits or actions arising as a result of the

use of the radio controlled aircraft, and shall pay for all legal expenses incurred by Golden

Skies in connection with the defense of such matters, whether or not such claims are resolved

without trial or other final decision and whether or not such expenses are incurred in the

defense of litigation or simply incurred prior to litigation in connection with an informal

claim. The obligation of the user to indemnify Golden Skies is express and unequivocal. The user

is expressly obligated to indemnify Golden Skies for Golden Skies’ own negligence if any,

which may give rise to any claim arising in connection with the use or misuse of the aircraft

or components thereof

6) No reliance

I acknowledge that I am not relying on any oral, written, or visual representations or

statements made by the released parties, including those made in released parties catalogs or

other promotional material.

6

7) Venue

he Venue of any dispute that may arise out of this agreement or otherwise between the parties

T

to which Golden Skies or its agents is a party shall be Superior Court for the State of

California located in the County of Orange.

Return Policy

If you are not prepared to: 1) obtain adequate insurance to operate the ARF; 2)

accept all responsibility for personal property damage and /or bodily injury,

including possible death; and 3) to indemnify the ARF designer, manufacturer,

distributor and retailer for any liability resulting from your actions, return

the complete ARF kit to the point of purchase for a refund. In order to return

the ARF Kit, the following steps must be undertaken: ARF kit must be presented

in its original carton, undamaged and un-assembled. ARF must be in the original

OEM condition and suitable for resale. Purchaser must show valid purchase

receipt. ARF kit must be return to point of purchase with sixty (6) days of

original purchase. A restocking fee may be charged by the retailer. All

shipping and handling cost shall be born by the consumer/purchaser

Governing Law

Any legal action stemming from the purchase or use of this product will be governed by the laws

of the State of California and decided by a court of law in the State of California.

7

Warranty Statement:

Warranty

Golden Skies R/C Aircraft (GSR/C) warrants the ARF to be free from defect in both

materials and ARF assembly workmanship for six (6) months from the date of purchase

or the first flight, which ever comes first. GSR/C warranty does not cover the whole or

any component parts thereof damaged by use, misuse, modification, or crash of the

ARF plane. In no case shall Golden Skies R/C Aircraft be liable for the effect(s) of

incidental, consequential or indirect damages as the result of the use or flight of the

ARF product. The warranty is limited to the original ARF purchase amount and shall

not exceed that cost and explicitly excludes the cost of additional ARF and R/C components either installed in or used to construct the ARF that are not included in the original ARF kit. The GRR/C warranty is not transferable under any circumstances.

Governing Law:

Any legal action stemming from the purchase or use of this product will be governed by the laws of

the State of California and decided by a court of law in the State of California in the County of Orange.

Spare and Replacement Parts:

Golden Skies R/C Aircraft stocks a complete line of Spare and/or replacement parts for your

CrossFire 320E ARF. We are trying to keep the replacement costs as low as possible, because we want

you to enjoy your CrossFire with genuine, good looking, factory parts. So, please do not hesitate to

replace broken or worn parts and keep your CrossFire in pristine condition. Consult your local hobby

dealer and ask them to order for you or order directly form Golden Skies R/C Aircraft at the address listed

on the front cover.

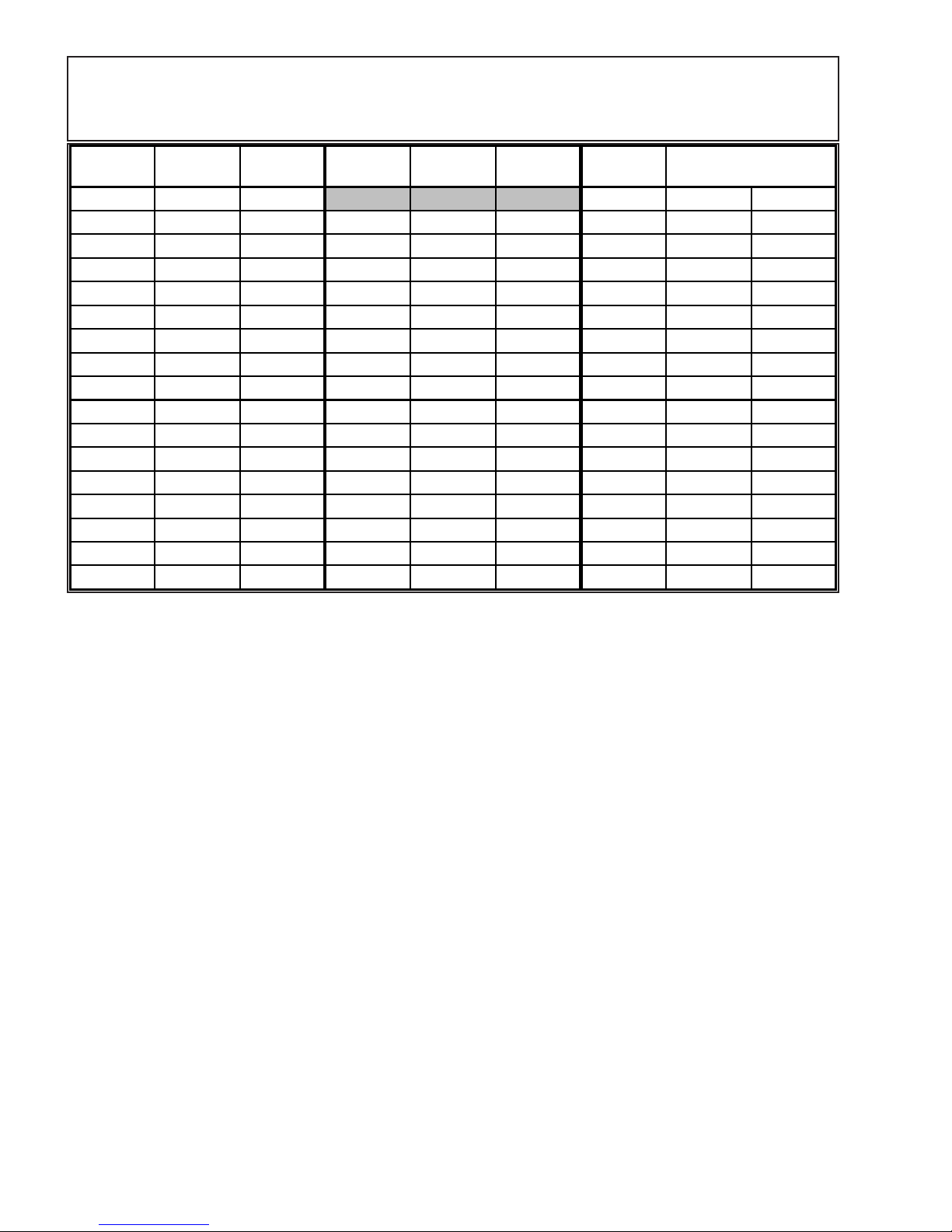

CrossFire 320E CrossFIre - II 320E

Ite m Part Number Ite m Part Number

Canopy 10056-00001 Canopy 10056-00031

Cowl 10056-00002 Cowl 10056-00032

Wing (Set) 10056-00003 Wing (S et) 10056-00033

Wing (Left) 10056-00004 Wing (Left) 10056-00034

Wing (Right) 10056-00005 Wing (Right) 10056-00035

Fuselage 10056-00006 Fuselage 10056-00036

Wing Gear (Set) 10056-00007 Wing Gear (Set) 10056-00037

Nose Gear 10056-00008 Nose Gear 10056-00038

Decals 10056-00040 Decals 10056-00040

Spring-Gear 10056-00039 Spring-Gear 10056-00039

Metal Clevis (5) 10056-00041 Metal Clevis(5) 10056-00041

Push-Rods (set) 10056-00042 Push-Rods (set) 10056-00042

Engine Mount 10056-00043 Engine Mount 10056-00043

Wheels (2.25") 10056-00044 Wheels (2.25") 10056-00044

Fuel Tank 10056-00045 Fuel Tank 10056-00045

Battery Switch 10056-00046 Battery Switch 10056-00046

8

GSRC GENERAL RECOMMENDATIONS

- Work Area: Keep the work area clean and free of debris and unused tools. This will help

prevent damage to your model. If you set the kit components on tools or debris you can damage the parts.

Cover the work area with a soft cloth (bath towels work well) to prevent unwanted marring or damage to your

model.

- Step-by-step Assembly: If you choose to follow the step-by-step assembly process, check

off the boxes as you complete each assembly step. This will help you remember what is completed and

what remains to be done. Read each assembly step thoroughly and completely to be sure you understand

the assembly process prior to doing the actual assembly.

- Organization: Open the hardware bags as they are needed for assembly per the assembly

manual instructions. Once the hardware bags have been opened, place the parts in a small box or bowl to

prevent loss. You may need several small boxes to keep parts separate.

- Dry-Fittings: Always “dry-fit” all parts in each assembly step to check fit, alignment, and ease

of assembly. This will prevent any surprises when racing against a glue setting-time.

- Take Your Time: In the anticipation of flying your new GSRC model, do not be tempted to

rush the assembly process and put your plane or others at risk.

- Choice of Engines: The CrossFire 320E was designed to fly with a strong “60-Size”, 2-Stroke

engine such as an OS-61FX ®. It will do all “sport-aerobatics” with great authority using the 60-size engine.

You may elect to install a 90-size, 2-stroke; however, it is more power than necessary to fly the CrossFire.

However, if you want to “stick-n-rudder” (SnR) the airplane, the 90-size will add to the “3-D” and “freestyle”

capability typical of SnR flying styles.

You may also choose to use a 90-size 4-stroke engine, such as an OS-91FS ® or equivalent. The 904/s is roughly equivalent to the 60-2/s but has more torque and can accommodate a larger prop. A 120-4/

s is, again, more power than necessary, but a lot of SnR fun. Take care to balance your props and perform

other routine vibration dampening procedures. Vibration in the fuselage, wing and other structural parts will,

in time, weaken your airplane to the point of failure.

- Balance your Props: Always, balance your props. Follow the engine manufacturers recom-

mendations for prop size, and balance the prop. Vibration is your models enemy and will eventually cause

structural failure. The worse and more prolonged the vibration, the sooner the failure will occur. This is true

of all aircraft, whether they be full-size or models.

- Servos: GSRC recommends high quality, ball-bearing servos with either metal gears or high

reliability, resin-composite gears. Metal gears will add weight to the plane, so the resin composites are a

good alternative. Use this type of servo on all control surfaces; however, a “standard” servo is suitable for

the throttle control. GSRC recommends 80-100 in-oz. torque for elevator and rudder whereas you can use

60-80 in-oz (minimum) servos for each wing-aileron servo. As a minimum, the Hitec © HS-545BB is a good

servo and can be used for all control surfaces, and the HS-325HB is suitable for the throttle. Hitec servos

may be ordered through the GSRC website ...... http://www.goldenskiesrc.com.

9

Recommendations Continued

- Batteries: 4.8 V, 600 mAh batteries are typical in sport model aircraft, however, GSRC prefers

to use 6.0 V, 1100 mAh batteries for higher torque and greater servo actuation speed. The 6.0 V battery is

heavier by one “cell” (5- vs 4-cells), but GSRC believes in highly aerobatic aircraft such as the CrossFire,

you will be more satisfied with the 6.0 V performance. Also the higher voltage “tends” to provide for better

noise immunity in the receiver, and the 1100 mAh tend to provide for more flying time than a 600 mAh.

- OraCover © Heat-Shrink Covering: OraCover is absolutely the best heat-shrink

covering available of its type. It is durable, repairable, replaceable and re-shrinkable as needed.

normal for the covering to show wrinkling from time to time. As temperature and humidity changes, the

balsa will expand and contract. This is natural and the covering may wrinkle. Simply re-shrink the covering

using a covering heat gun. Heat guns are available from your local hobby dealer.

- Radios (Tx & Rx): All of the name brand radios are good, and GSRC prefers you use the radio

you are most accustomed to and comfortable with. The CrossFire will require four Channels minimum and

possibly a 5-channels if you split your ailerons for flaperon capability. It is a good practice to keep the

Transmitter and Receiver to the same brand; however, servos of a different brand are a generally accepted

practice and should cause no problems. Always check your radio manufacturer’s recommendations. Be

aware that different radio receivers may require a specific servo plug-type to be both mechanically and

electrically compatible.

It is

- Conventions: When the manual refers to left and right, it is in reference to your left or right as

viewed from the fuselage tail looking forward or as if you were sitting in the cockpit. Generally, when

“Increasing a Function” of any entity (such as battery switch, a servo, etc.), the following conventions should

be observed:

- Forward

- Clockwise

- To the right

- Up

Doing the opposite of the above, is considered “Decreasing the Function”

- What you need to complete the CrossFire 320E

- Two 18” Servo Extensions,

- One “Y-harness” servo cable

- One 24” Servo Extension

- One Engine, glow-plug, muffler and suitable propeller

- Five Servos

- Fuel Tubing, 16-20 inches

- “Fuel Stopper” or fuel fulling valves (optional)

- Foam Rudder to pad fuel tank, as desired

- Receiver

- Battery

- Battery Switch

10

Tools and Supplies Needed:

The following items will be needed to complete the final assembly of the CrossFire 320E

ARF. The assembler should acquire all needed supplies prior to starting assembly and become

familiar with each item by thoroughly reading the manufacturer’s directions.

Materials:

- C/A medium viscosity adhesive, any brand

- C/A thin viscosity adhesive, any brand

- Epoxy, both 5-minute and 30-minute (2000 pound shear), 2-part epoxy

- C/A Debonder, 1-0z

- Acetone, pint or quart

- Denatured alcohol, pint or quart

- Mixing cups, 1-0z

- Silicon Caulking, white (optional)

- Fiberglass (2-0z) and polyester resin (Optional)

- Clear, polyurethane spray, fuel proof

Tools:

- # 0, # 1 and # 2 Phillips head screw drivers

- # 1 & # 2 Flat blade screw driver

- Adjustable Wrench

- Needle Nose Pliers

- Modeling knife, # 11 blade

- Single edge razor blades

- Electric drill, 1/16” to 1/4” bits in 1/32” increments

- Modeling T-pins

- Sandpaper, 180 to 220 grit

- Dremel © “Moto-Tool” ®, wheel cutter, drum-sander, coarse and fine

- Paper towels and/or soft rags

- Pencil and/or felt tip pens (Sharpie ®)

- Ruler, scale

- Toothpicks

- Center Punch

- Hex driver set, Metric and English

- Nut driver set,

- Clamps, variety (see assembly pictures)

- Epoxy brushes, (Solder flux brush)

- T-square or triangle square

- Incidence Meter, Robart ® Model # 404 Incidence Meter

- Rubber bands, # 64 or stronger

- Covering/sealing iron and/or covering heat gun

11

Table 1: English to Metric Conversion Chart

English

(in)

1/64 0.4 0.04 1 25.4 2.54

1/32 0.8 0.08 17/32 13.5 1.35 1.5 38.1 3.81

1/16 1.6 0.16 9/16 14.3 1.43 2 50.8 5.08

3/32 2.4 0.24 19/32 15.1 1.51 2.5 63.5 6.35

1/8 3.2 0.32 5/8 15.9 1.59 3 76.2 7.62

5/32 4.0 0.40 21/32 16.7 1.67 3.5 88.9 8.89

3/16 4.8 0.48 11/16 17.5 1.75 6 152.4 15.24

7/32 5.6 0.56 23/32 18.3 1.83 9 228.6 22.86

1/4 6.4 0.64 3/4 19.1 1.91 12 304.8 30.48

9/32 7.1 0.71 25/32 19.8 1.98 18 457.2 45.72

5/16 7.9 0.79 13/16 20.6 2.06 21 533.4 53.34

11/32 8.7 0.87 27/32 21.4 2.14 24 609.6 60.96

3/8 9.5 0.95 7/8 22.2 2.22 30 762.0 76.20

13/32 10.3 1.03 29/32 23.0 2.30 36 914.4 91.44

7/16 11.1 1.11 15/16 23.8 2.38 40 1016.0 101.60

15/32 11.9 1.19 31/32 24.6 2.46 48 1219.2 121.92

1/2 12.7 1.27 1.00 25.4 2.54 62 1574.8 157.48

Metric

(mm)

Metric

(cm)

English

(in)

Metric

(mm)

Metric

(cm)

English

(in)

Metric

(mm)

Metric

(cm)

Quick Build Step Sequence:

For very experienced builder, follow the building sequence below and refer to the

appropriate pictures or narrative as needed for assistance.

1. Epoxy hinges into all control surfaces

2. Construct the aileron wing servos

3. Install the engine mount

4. Join the wing panels together

5. Install tail surfaces

6. Assembly the fuel tank

7. Attach control surfaces

8. Install nose wheel

9. Install all servos, push-rods, pull-pull rudder system

10. Attach belly pan

11. Install fuel tank

12. Install engine.

13. Install cowl

14. Attach wheels

15. Install Radio Gear

16. Attach Spinner

17. Attach Decals

18. Perform preflight checks

Following this sequence, one should be able assemble the CrossFire 320E in 4-6 hours.

12

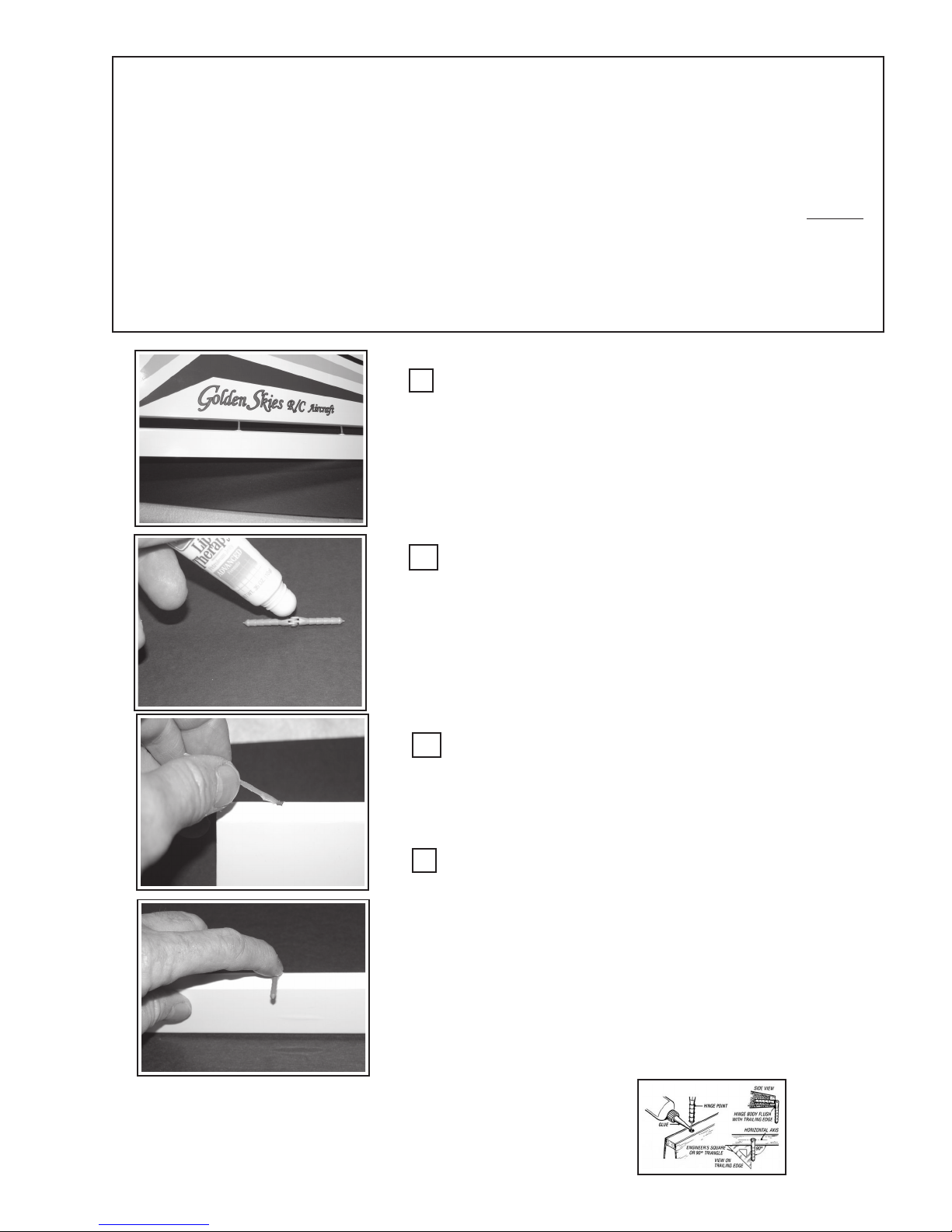

Step 1: Hinge Installation for all Control Surfaces:

In this step, you will install all the hinges into the Ailerons (2), Elevator (2-halves), and

the Rudder. There should be seventeen (17) hinges in all. Three (3) for each elevator

half, three (3) for the Rudder, four (4) for each aileron. You will need a light grease, the 17

hinges, and each control surface. Epoxy the hinges only into the control surfaces, do not

attach control surfaces to its corresponding mating part (i.e. elevator to horizontal stabilizer) at this time.

While the epoxy is curing, move on to Step 2.

Dry Fit Control Surfaces:

Place the hinges into the control surface hinge-holes and slip the

assembly into the corresponding, mating part (i.e. Aileron to wing, elevator to Horz. Stab, etc.) Check for fit and alignment. There should

be no appreciable gap at the hinge line. The hinges’ metal pins should

be at the control surface’s hinge line or pivot point. When satisfied,

continue. Mark the ailerons to know which wing panel they go on.

Grease Hinge Area:

Using a light grease such as Vaseline, lightly cover the entire hinge

area to prevent the epoxy from entering the hinge joint. Take care not

to get grease on the ribbed hinge shank area where it will be glued

into the control surface.

CAUTION: Do not use Oil !

Apply Epoxy to Hinge Hole:

Mix an ample amount of 2-part, 30-minute epoxy following

the epoxy manufacturer’s directions. Apply a sufficient amount, using

a toothpick to the hinge hole and allow to settle into the hole. Wipe off

any excess epoxy from the surface.

Insert the Hinge:

Insert the Hinges into the control surface’s hinge hole. Press the

hinge sufficiently into the hole so that the metal hinge pin is in-line

with the control surface’s hinge point or line. Bend the hinge as shown

in the picture (left) so that the free hinge arm is perpendicular to the

control surface’s hinge line. This will assure that the hinge axis is inline with the control surface’s hinge line.

Repeat this process for all hinge locations on all

control surface. (2-Elevators, Rudder, 2-Ailerons)

13

Courtesy of Robart, Inc

Step 2: Wing Servos & Servo-Wire Extensions:

In this step you will be installing the wing-servos onto the wing-servo access covers and placing the

wing and elevator servo-extension cables in the wings and fuselage respectively.

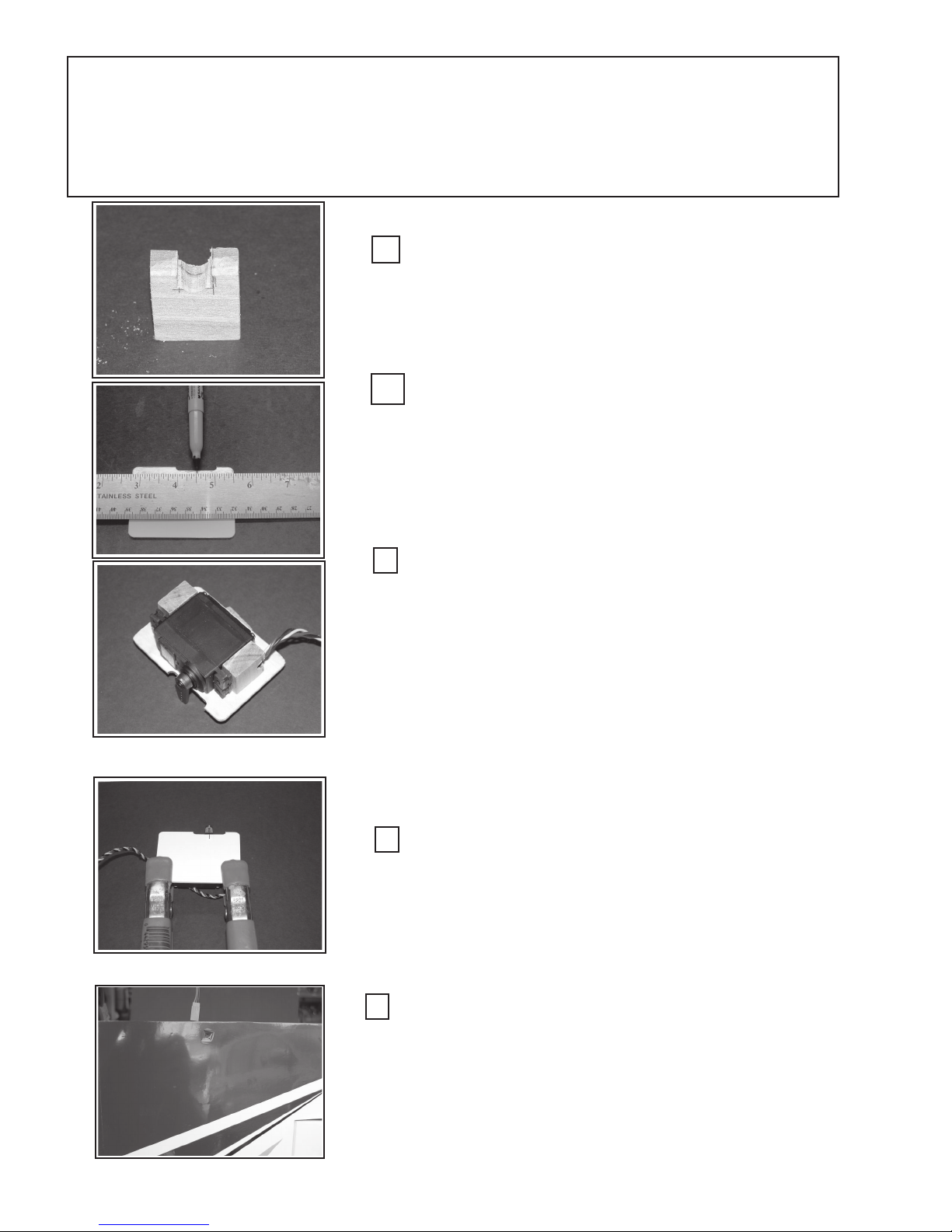

Hardwood Mounting Blocks: Locate the four hard-

wood servo-mounting blocks. On two of the blocks, cut a

notch ~ 1/4” x 1/4” to accommodate the servo wire. A 1/4” rattail file

works well for this job. Round the edges of the cut to prevent abrading or cutting the servo wire. Make sure the cut is oriented such that

the servo screws will go in the block’s cross-grain.

Prepare the wing-servo Access Covers: On both

wing servo covers, measure the width of the opening-notch

and mark the center of the opening. You will be aligning the servo

arm with this mark. Marking both sides will make it easier to align the

servo. The servo-cover only goes on one way. Please observe that

the notches face toward the wing tips; therefore, the servo-arms in

each wing panel face in opposite directions; i.e.; toward the wing tip.

Mount Servo to Hardwood Blocks: Place the wood

servo blocks against the servo mounting tabs as shown left. Place 2

- 3 pieces of 20 pound paper beneath the servo to raise it off the

surface slightly. While holding the blocks against the servo mark the

mounting holes with a pencil or a punch. Predrill the blocks with a 1/

16” drill bit and mount the servo to the blocks using the servo

manufacturer’s supplied screws.

Now is a good time to mechanically center the servo arms.

Connect the servo to the receiver’s aileron port and turn on your receiver and transmitter. With the aileron controls (stick, trim, subtrims, centering) set to neutral, mechanically mount the servo arm on

the servo shaft, such that it is perpendicular or square with the cover

surface. Repeat this process for both wing servos.

Epoxy Servo Blocks to Cover Plate:

Remove the paper spacer from under the servo and place a

piece of wax paper between the servo, the blocks and the cover plate

to prevent epoxy from getting on the servo. Realign the servo and

mark its position. Mix the two-part, 30-minute epoxy and apply to the

block, reposition the servo on the cover and clamp. Set aside and

repeat process on the other wing servo. Remove wax-paper when

cured.

Install Servo Extension Cables:

Locate the servo extension cable-hole on the top of the wing

near the root rib. Cut an “X” in the covering over the hole. Hold the

wing vertically, with the tip down and feed the 18” extension wire through

the wing and into the servo box. Dress the cable through the hole and

tape-off both ends so that you do not lose the wire. Be sure to note the

“sex” of the connectors so it will mate with the servo connector. (The

Female cable-end goes into the servo box.)

14

Step 3: Assemble the Engine Mount:

Although GSRC had intended to have the engine mount blind-nuts pre-mounted, but in order

to provide the assembler with the most engine mounting flexibility we allow the assembler to

decide the engine mount orientation. We will show how to side-mount an engine. We will be

showing an OS-91FS®; however, the procedure will be similar for other engines. Take note and

pre-plan for the mounting and thoroughly consider the implications of the muffler and needle

valve locations.

There is ~ 2° right thrust offset built into the fuselage, make reference there.

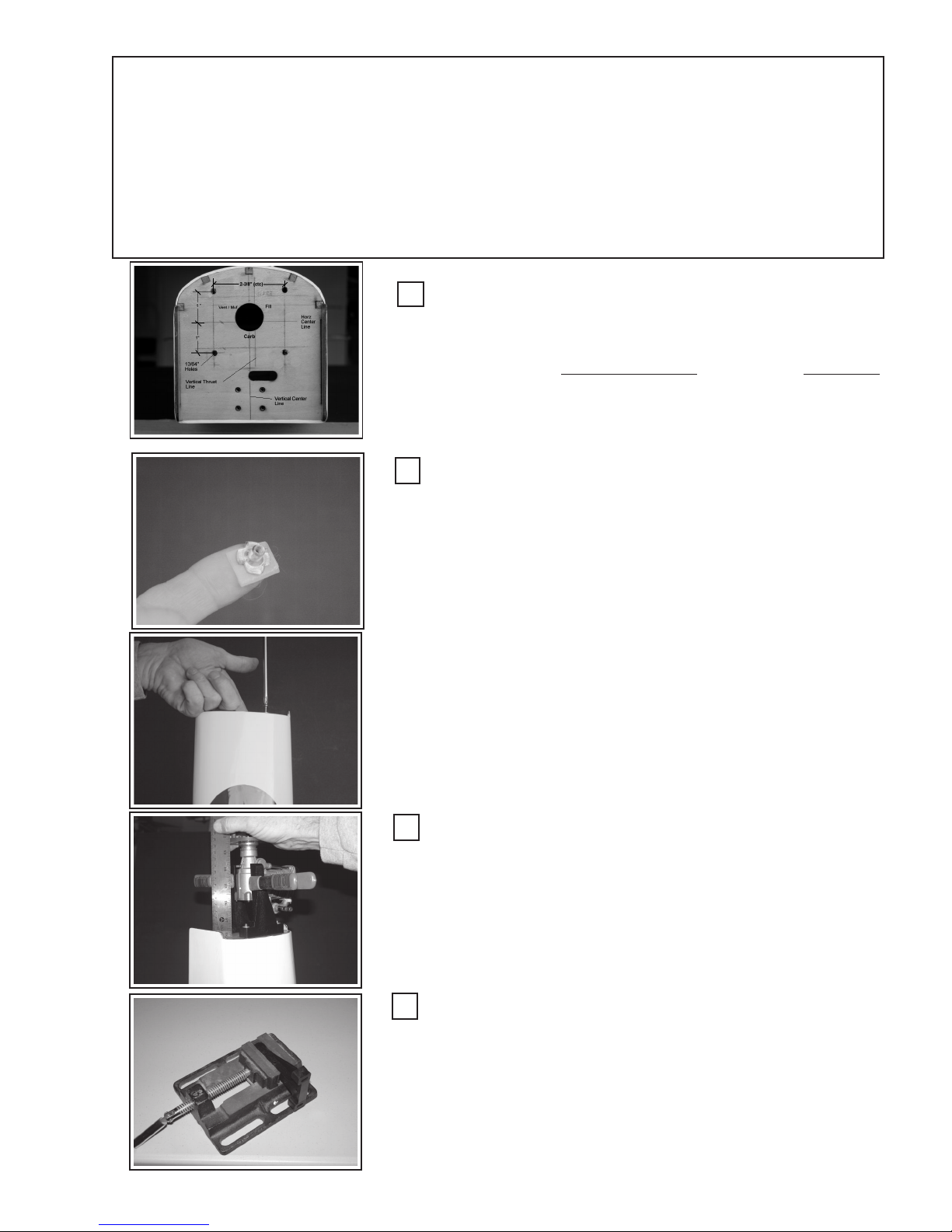

Locate the Engine Mounting Holes:

Locate the Vertical and Horizontal center lines. If they are not visible, measure and draw them in. The horizontal center line is 3-13/32”

up from the fuselage bottom. Draw two (2) parallel lines, 1-3/16”, one to

the right and left of the vertical thrust line which is 3/32” left* of Vc/l.

Add 0.05” (~3/64”) to the engine-rail separation required by your engine,

(See Table 2), divide this number by two and draw two parallel lines, above

and below, Hc/l. Where the four lines cross, center punch and drill 13/

64” diameter holes for the blind nuts. (*Right if facing the Firewall)

Install Engine Mount Blind-nuts:

Place a washer on one of the engine-mount bolts and have it and a

# 2 phillips screwdriver at hand. Using a piece of tape, make a loop and

stick it to the end of your index finger. Place a blind-nut on the tape as

shown, left. Orient the blind-nut through the fuel tank hole and under

one of the firewall bolt holes. Using the engine-bolt & washer, thread

the bolt into the blind-nut. Tighten with the phillips-head screwdriver to

draw the blind-nut into the back side of the firewall. Repeat this process

for the remaining three engine-mount holes.

Note that the firewall has been marked with the fuel-tank tubing

information. Refer to the fuel tank assembly step for fuel-tank tubing

(port) orientation. The markings refer to: 1) Muffler or Vent port, 2)

Carburetor port, 3) Fill port (the 3rd filling port is optional)

Temporarily attach the engine mounts using the four engine mounting bolts and washers. Snug it down tight; however, it will be removed

later to drill the engine mounting holes in the engine mount rails.

Locate Engine Position:

With the spinner’s backplate on the engine shaft, clamp the

engine to the mount-rails, as shown. Position the engine so that the

rear edge of the spinner backplate is 5-1/2” from the firewall front

surface. Be sure to measure all the way around the backplate to be

sure the backplate is parallel with the firewall and everything is centered and “squared-up). With the engine securely fastened, mark the

engine mounting hole on the mount-rails, using a pencil or center

punch.

Drill Engine Mounting Holes:

Center punch the engine mounting hole locations that you marked

above and place in a drill-press vise or bench vise. Drill the engine

mounting holes for the size of bolt recommended by the engine manu facturer. Attach the engine mount to the firewall. Do not mount the

engine at this time (For 60 - 120 size engines, use # 6-32 steel bolts

(minimum), and locking nuts on each engine bolt.)

15

Step 4: Join Wing Panels:

Gather together the following items: Wing panels (2); dihedral brace; 2-part, 30minute epoxy; epoxy brush; mixing cup, clamps (4); rubber bands #64; 2 pieces of scrap

lite plywood (~ 1” x 8”). Be sure you have placed the wing servo-extension cables in the

wing as described in step 2.

Gather and Layout Wing Panel & Materials:

Assemble the materials as described above on a flat surface at least

60” long. You will need at least six (6) each # 64 or stronger rubber bands.

Also have handy the wing bolt backing strip (~ 1/8” thick lite-ply with two 1/

4” holes in it) and the 1/4” nylon wing mounting bolts.

Dry Fit to Check Fit & Alignment:

Measure and mark the center of the dihedral brace. Dry fit the

Dihedral Wing-Brace into the wing-box and push the two wing panels

together to check for proper fit and alignment. The beveled edges of

the wing-brace face forward. The top, bottom and wing edges should

align evenly and the root rib of each wing panel should fit perfectly flush

to each other. When you are satisfied with the fit, proceed to next step.

Apply Epoxy and Assemble:

Mix a generous amount of 30-minute epoxy and using the epoxy

brush, apply a liberal amount of epoxy into the wing-box, one-half of

the dihedral brace and fit the brace into the wing box up to the center

mark. Apply epoxy to the surface of the root rib. Repeat for the other

wing panel..... be sure to epoxy both rib roots. Slide the two wing

panels together

Check Fit and Secure Wing Panels:

Place at least six (6) rubber bands over the wing dowel pins to

draw the wing’s leading edge together. Check to make sure the fit is

correct and all surfaces align and match. Wipe off any squeezed out

epoxy using a rag and denatured alcohol as necessary.

Secure Trailing Edge:

Using the wing-bolt plate, insert the two wing-bolts through the

plate and then through the holes in the wing. This will bring the trailing

edge together. It may be necessary to push the panels together by

bracing one wing-tip against a solid object and applying pressure to the

opposite wing tip to push them together. Using the two scrap pieces of

lite-ply, place one on the top and one on the bottom of the wing at the

trailing edge. Clamp in place. (See Optional Assembly Step:

“Fiberglass Wing Bottom” ... “WPFG-1”, on page 34)

16

Loading...

Loading...