Golden engineering XR150 Operator's Manual

OPERATOR'S MANUAL

MARCH 2018

- Golden Engineering

�- Portable X-ray Technology

TABLE OF CONTENTS

PAGE

1.0 INTRODUCTION 2

2.0 WARNINGS 2

DUTY CYCLE 2

3.0 PHYSICAL DESCRIPTION 3

HIGH VOLTAGE PULSER/TUBEHEAD 3

HOUSING 3

HANDLE 3

BATTERY PACK 3

BATTERY CHARGER 3

REAR VIEW 3

CONTROLS 4

CABLE CONNECTOR DIAGRAM 5

4.0 DESCRIPTION OF OPERATION 6

BLOCK DIAGRAM 6

5.0 OPERATING INSTRUCTIONS 7

OPERATING PRECAUTIONS 8

EXCLUSION ZONE 8

NAVIGATING THE MENU 9

MAIN MENU 10

SET COUNTS/PULSES 11

PULSE COUNT EXCEED DUTY CYCLE 12

SET DELAY TIME 14

SET MULTIPLE PULSE TRAINS 15

MULTIPLE PULSE TRAINS EXCEED DUTY CYCLE 16

PULSE COUNTER/LIFETIME PULSE COUNT 17

BACKLIGHT ON/OFF 18

PULSE/COUNTS MODE CHANGE 19

VOID WARRANTY INDICATOR 20

GENERATOR IDENTIFICATION NUMBERS 21

ERROR MESSAGES 22

SUGGESTED PULSE SETTINGS 23

6.0 MAINTENANCE 23

7.0 TROUBLE-SHOOTING 23

8.0 INSTRUCTIONS FOR REPAIR 24

STORAGE, TRANSPORT, DISPOSAL 24

9.0 WARRANTY 24

MANUFACTURER 24

10.0 CE CERTIFICATE 25

11.0 SPECIFICATIONS 26

PHYSICAL DIMENSIONS 26

X-RAY OUTPUT 26

ELECTRICAL & THERMAL CHARACTERISTICS 26

12.0 SPARE PARTS 26

1

1.0 INTRODUCTION

The XR150 produces high levels of radiation and must be operated by quali ed personnel who have read the

WARNINGS and OPERATING INSTRUCTIONS sections of the manual before operating the device.

The XR150 is an industrial type open beam x-ray generator intended to radiograph inanimate objects. The XR150

is a pulsed x-ray device that produces x-ray pulses of very short duration (30 nanoseconds). The energy produced

by the XR150 is up to 150kVp, which makes it possible to radiograph up to one half (0.5) inch (1.27 cm) of steel.

XR150 standard accessories are two keys, two 12V (or 10.8V) battery packs, and one battery charger. Remote

cable, carrying case are also common accessories.

2.0 WARNINGS

The XR150 is a pulsed X-ray generator that emits hazardous ionizing radiation when pulsing. The XR150 should

only be operated by authorized personnel who are properly trained to safely operate the generator. The XR150

must be registered with proper authorities prior to use and should not be used to intentionally expose humans.

Develop and closely follow a safe operating system for using the XR150. The safe operating system must ensure

that no one is exposed to radiation above the permissible limits which are 2 mR (0.02 mSv) per hour for a member

of the public. The safe operating system must ensure the XR150 is used within federal and state guidelines.

All operators and users of the XR150 x-ray machine must wear a personal radiation monitoring device, such as

a TLD (thermoluminescent dosimeter), lm badge, and/or a pocket dosimeter consistent with the appropriate

federal, territorial or provincial standards (note: an electronic dosimeter will not detect the XR150 radiation

pulses). If an operator or bystander is exposed to an unacceptable level of radiation contact your Radiation

Safety Of cer and/or appropriate health care provider.

Due to the short pulse width of the XR150, survey meters of the Geiger-Mueller and scintillator type do not

accurately detect the radiation emitted from the x-ray source.

Survey meters should be of the ionization type and should be used in the integration mode. Survey meters must not

be used in the rate mode because the XR150 does not produce constant radiation. The XR150 produces very high

rates of radiation for very short periods of time resulting in either unrealistically high readings or no readings for

a survey meter in rate mode.

The XR150 has no explosion proof rating and should not be used in an explosive atmosphere. The Spark Gap

is vented to the air and could be a source of ignition.

DUTY CYCLE WARNING

The XR150 is a light duty machine that is not made to pulse continuously. The maximum duty cycle for the XR150

is 100 counts (300 pulses) every four minutes (1500 counts/4500 pulses per hour). Exceeding the duty cycle

will shorten the life of the tube and head. In temperatures above 90 °F (32.22 °C) or continual use, rest 30

seconds after every 50 pulses and 4 minutes after every 200 pulses.

2

3.0 PHYSICAL DESCRIPTION

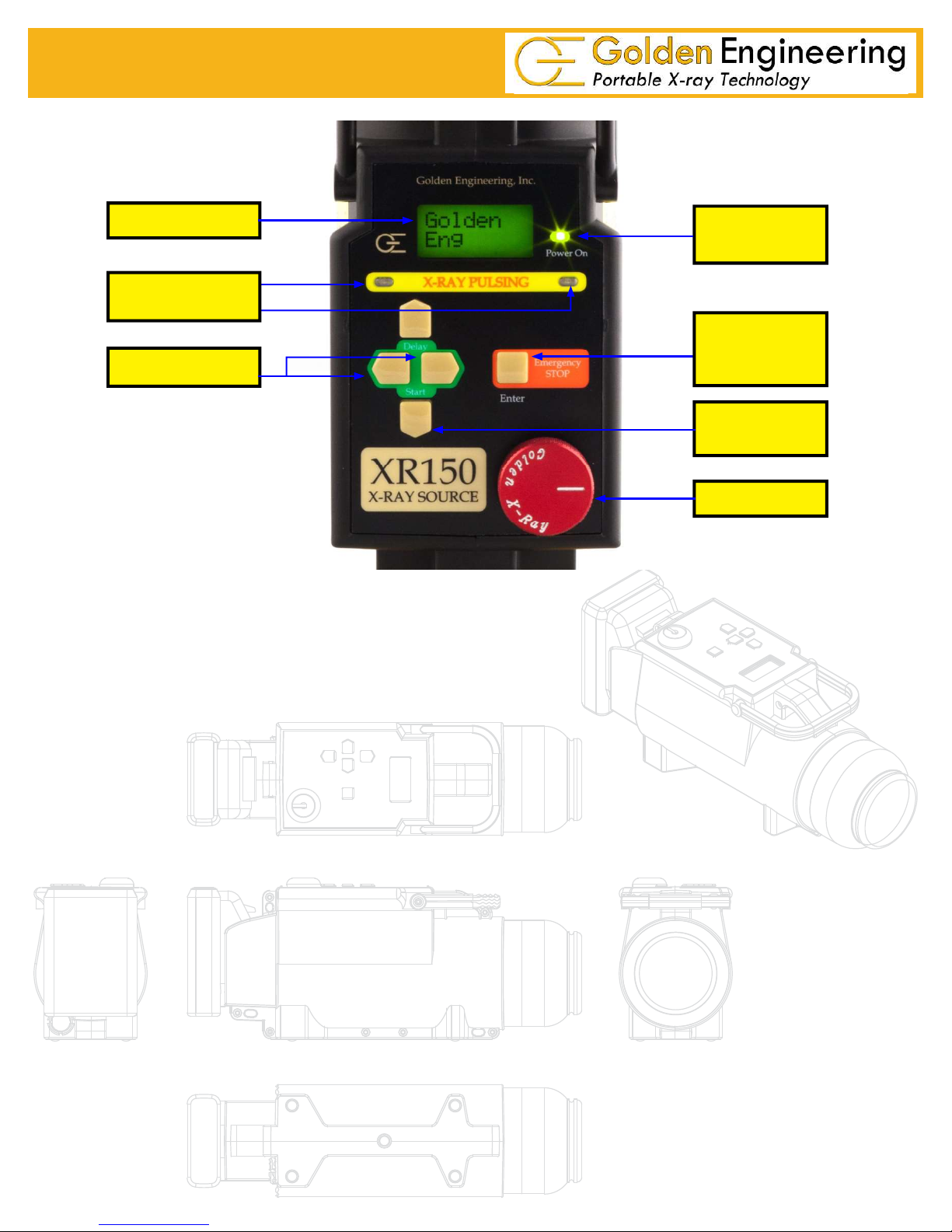

HANDLETOUCH PADKEY

BATTERY

RADIATION

WARNING LABEL HOUSING

HIGH VOLTAGE PULSER/TUBEHEAD The XR150 high voltage head which contains the cold cathode type X-ray

tube, spark gap, high voltage capacitor, transformer, and 40 degree collimator.

HOUSING The XR150 housing encloses the electronics and most of the high voltage head. The housing includes the

touchpad interface, key switch, battery terminal block, cable connector, ¼-20 threaded tripod insert, and several

tie off points that accommodate a variety of fasteners.

BEAM ANGLE

LABEL

HEAD

HANDLE Handle is attached to the left and right side of the housing adjacent to the LCD. The handle can be

removed using a T10 Torx driver.

BATTERY PACK The standard battery pack is a DeWalt® DCB127 Lithium Ion battery pack. In the USA

the DCB127 battery is rated as a 12V battery. Outside the USA the DCB127 battery maybe rated as a 10.8V

or 12V battery pack.

BATTERY CHARGER The standard battery charger is the DeWalt® DCB107 charger. DCB115

fast charger or DCB109 Car Charger are optional. Battery charge time is less than one hour with the standard

charger. See battery charger manual for additional instructions and warnings.

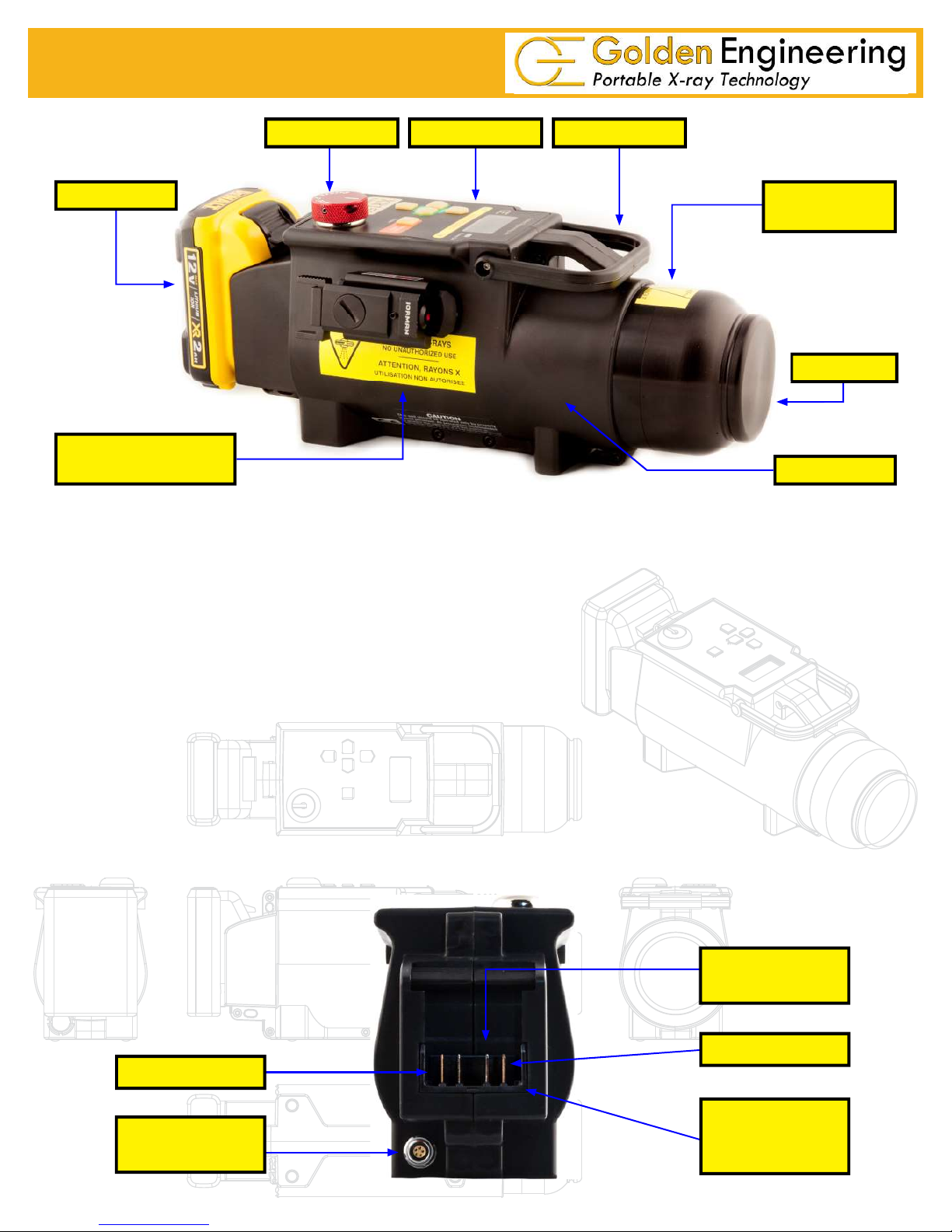

REAR VIEW

TEMPERATURE

SENSOR

POSITIVE +

NEGATIVE -

BATTERY

REMOTE CABLE

CONNECTOR

TERMINAL

BLOCK

3

CONTROLS

LCD

POWER ON

LIGHT

X-RAY PULSING

LIGHTS

ENTER /

EMERGENCY

DELAY SWITCH

STOP

DIRECTIONAL

ARROWS

KEY

X-RAY PULSING LIGHTS:

Blink after time delay button or remote cable button is pressed AND between multiple pulse trains.

Stay on continuously while the XR150 pulses.

Blink at a slower rate between multiple pulse trains.

LIQUID CRYSTAL DISPLAY (LCD): 16-character LCD. Home screen displays counts/pulses (C or P), number of

pulse trains (if multiple pulse trains are entered), safety time delay (D), and time delay between pulse trains (if

multiple pulse trains are entered). See NAVIGATING THE MENU section for menu options.

DELAY SWITCH: Initiates time delay mode count down when left and right arrows pressed simultaneously.

POWER ON LIGHT: Illuminates when battery voltage is applied to control module.

ENTER/ EMERGENCY STOP SWITCH: ENTER used when menu options are selected.

EMERGENCY STOP stops the unit during delay count down mode or between multiple pulse trains.

DIRECTIONAL ARROWS: Left, Right, Up, Down used to navigate through LCD and menu options.

4

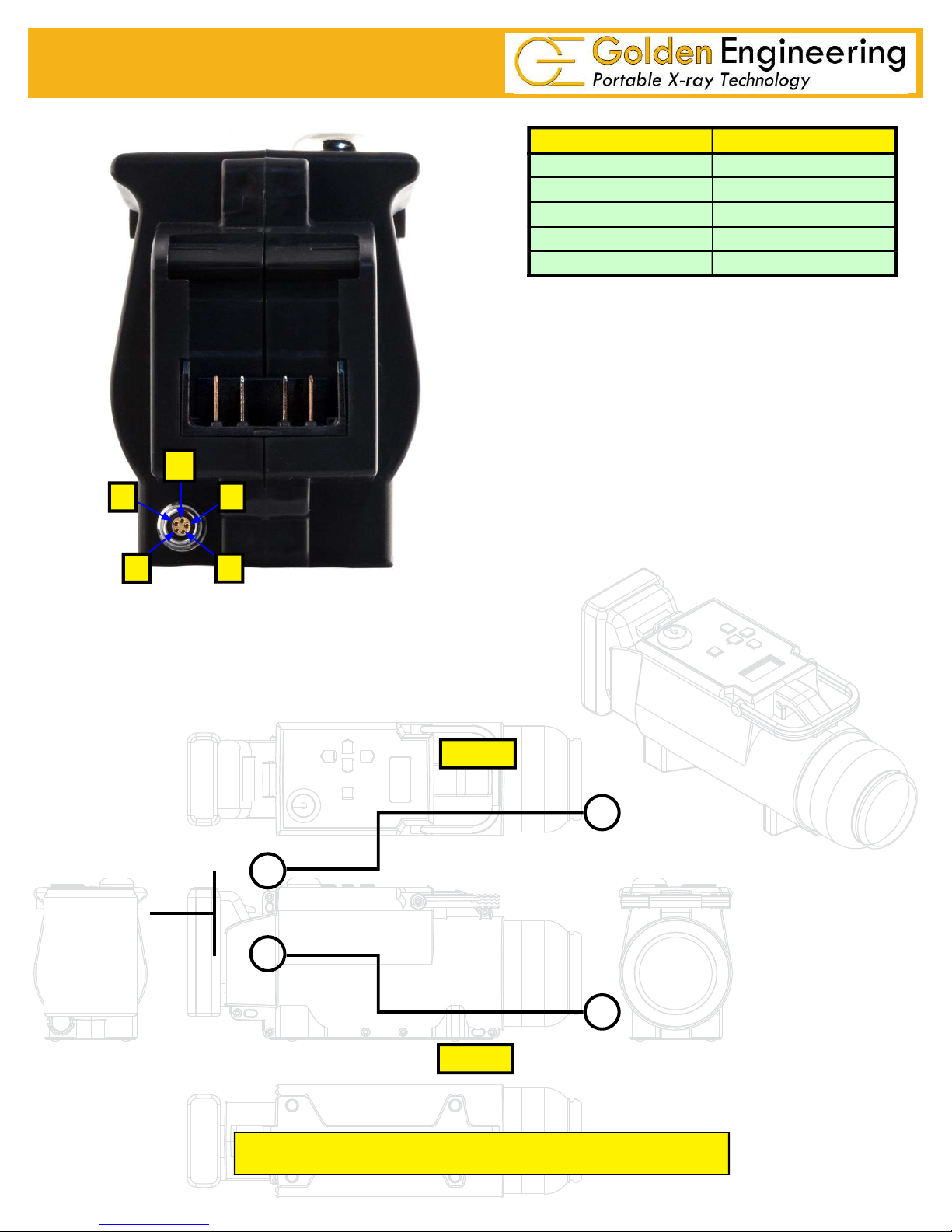

XR150 REAR VIEW/CABLE CONNECTOR

1

52

PIN # DESCRIPTION

1 +5 VOLTS 100 ma MAXIMUM

2 REMOTE SWITCH

3 REMOTE SWITCH - NO DELAY

4 X-RAY ON SIGNAL

5 COMMON 0 VOLTS

3 4

REMOTE CONNECTOR: LEMO EPG.0B.305.HLN

MATING CABLE PLUG: LEMO FGG.0B.305.CLAD 56Z

PIN 2

Remote switch inputs are activated when grounded.

5

PIN 5

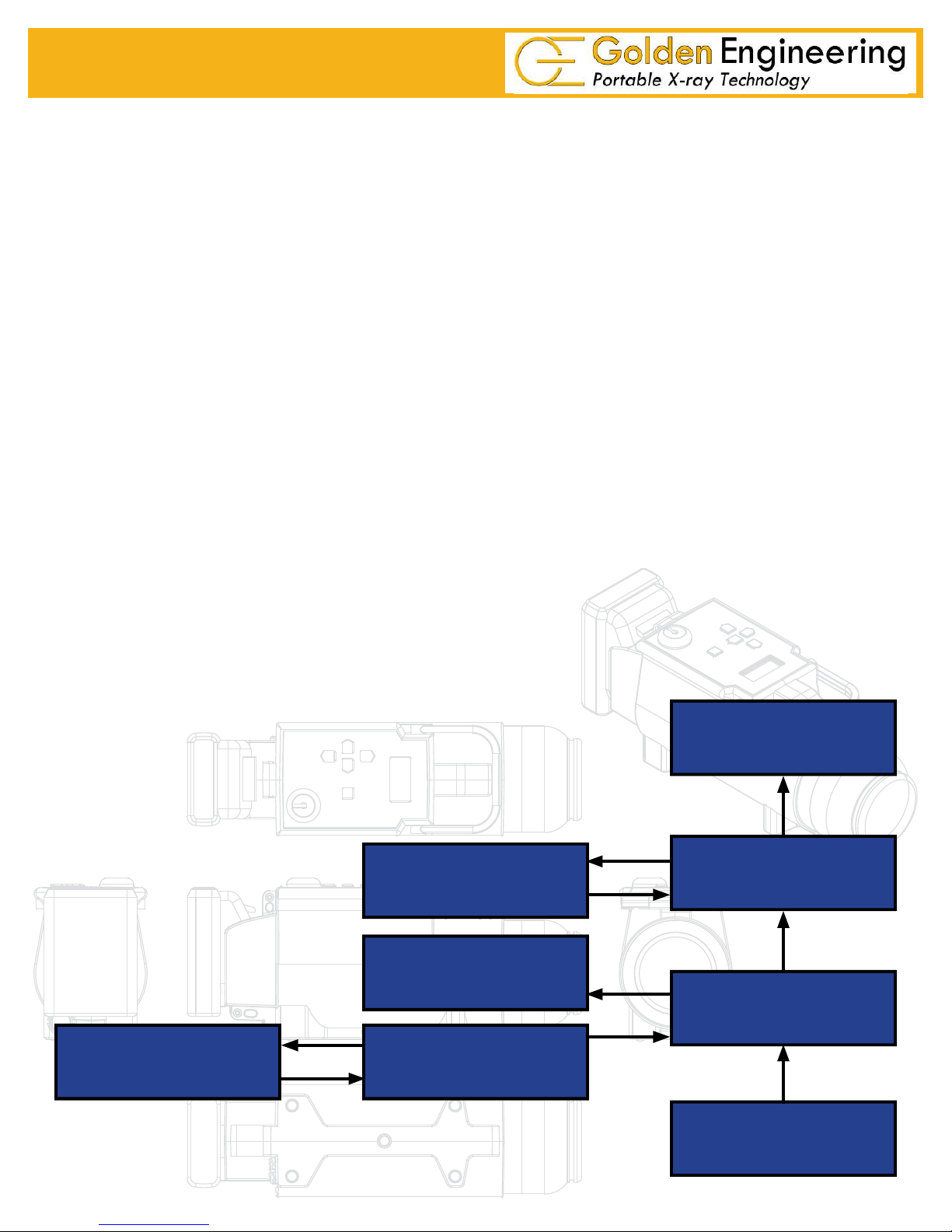

4.0 DESCRIPTION OF OPERATION

The block diagram below illustrates how the XR150 functions. The following sequence of events

takes place each time the XR150 is fi red:

1. User initiates operation of the machine.

2. The control section sends a signal to the converter section to begin oscillating.

3. Once oscillating, the converter section changes the 12 volts DC to 22Khz AC.

4. The transformer charges the High Voltage Capacitor to about 8000 volts.

5. The spark gap arcs after the High Voltage Capacitor reaches proper voltage.

6. The pulse detector signals the control block that the unit has pulsed.

7. As the High Voltage Switch is closed, a high voltage transient of approximately 150,000 volts

and 30 nanoseconds in duration is applied across the x-ray tube generating x-rays.

The closing of the High Voltage Switch produces an audible pulsing sound. The XR150 cannot

produce x-rays without the pulsing sound so it serves as an additional warning the XR150 is

functioning.

This unit generates x-rays through high voltage bombardment of a tungsten target. The XR150 does

not contain radioactive materials. All the high voltage is contained within the aluminum canister

and as long as the canister is not punctured the operator is not exposed to dangerous voltages.

USER INTERFACE

BLOCK DIAGRAM

SPARK GAP

PULSE DETECTOR

CONTROLLER

X-RAY TUBE

HIGH VOLTAGE

CAPACITOR

CONVERTER

BATTERY

6

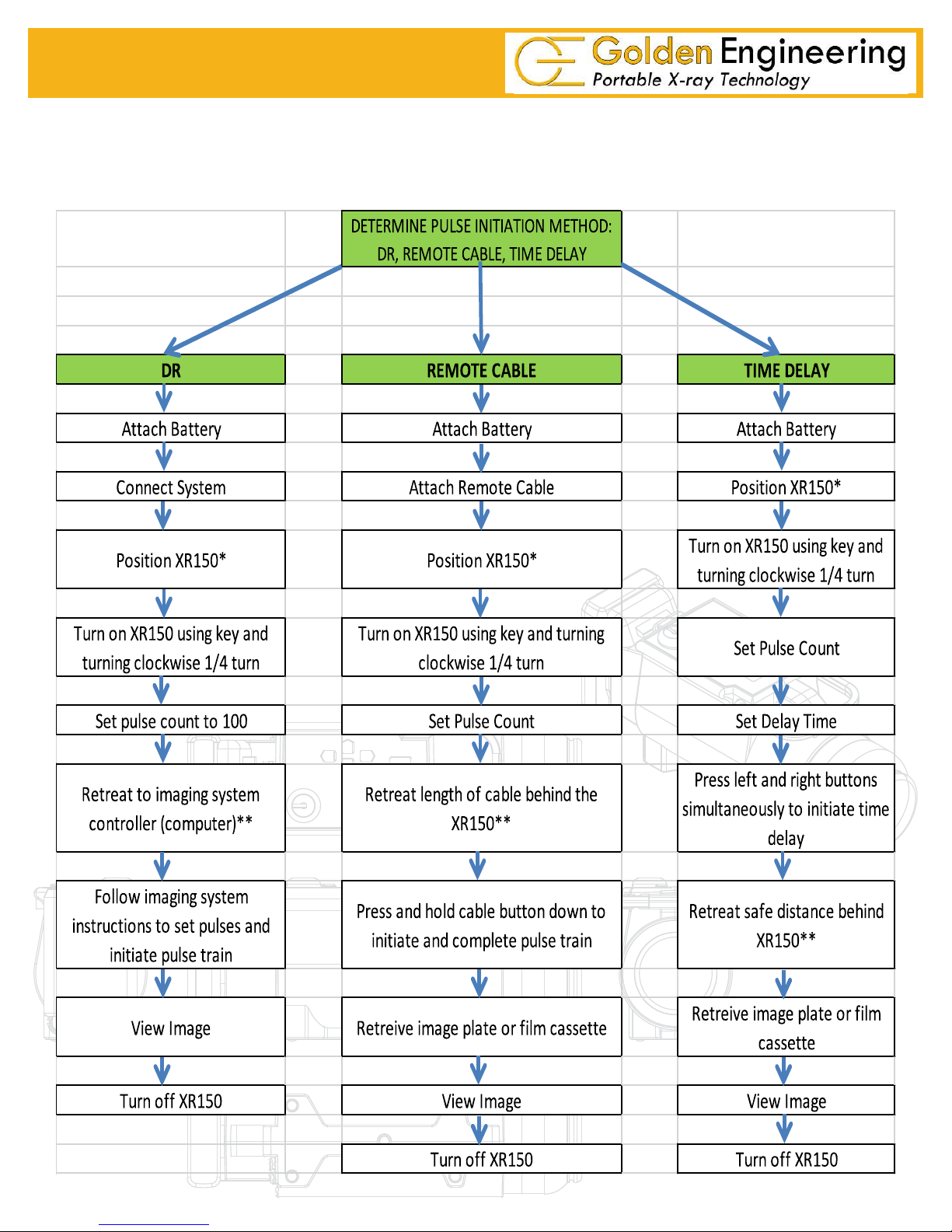

5.0 OPERATING INSTRUCTIONS

The following are basic operation instructions to take an X-ray image using the XR150. Certain applications may

require modi cations to these basic procedures.

7

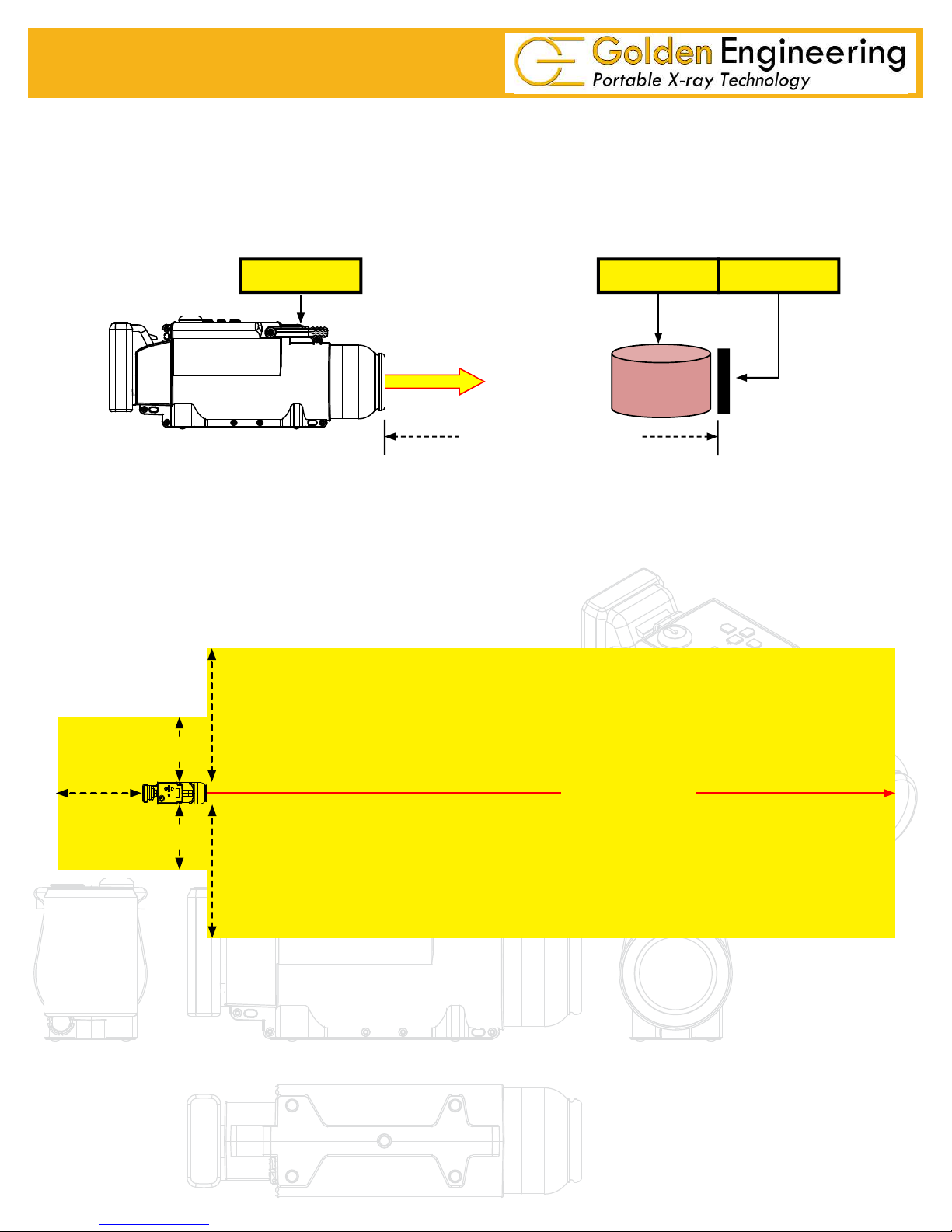

*XR150 should be positioned directly in front of the object to be X-rayed and the imager placed directly behind

the object to be X-rayed. Imager should be placed as close to the object as possible. Distance between XR150

and imager is usually 24 to 72 inches (30 to 180 cm). During operation XR150 should be stabilized on a at

surface, a tripod, or a custom xture suitable for holding the 5 pound (2.2 Kg) XR150.

XR150 OBJECT IMAGER

24 to 72 inches (30 to 180 cm)

**OPERATING PRECAUTIONS: The operator should always stand at least 10 feet (3m) behind the X-ray

unit and clear all personnel at least 10 feet (3m) behind the unit or at least 100 feet (30m) from the front of the unit

before pulsing. The exclusion zone (below) should be a controlled area free of all personnel while

X-ray pulses.

10’(3m)

20’ (6m)

10’(3m)

100’ (30m)

X-ray Beam

10’(3m)

20’ (6m)

Figure 4: Exclusion Zone

8

Loading...

Loading...