Golden Eagle Cam Gear User Manual

Golden Eagle Mfg.

Cam Gear Install

Thank you for your purchase of Golden Eagle Mfg. products for your high

performance needs. You now own one of the best products on the market, all 100%

made in the USA! We are very confident you will be more than pleased with your

purchase. If you ever experience any problems, have any concerns or just want to

give some advice, we would love to hear from you.

(909) 592 – 4311 or e-mail

Cam Gear Bolts Are NOT Tight!!!!!

! WARNING !

gear install. Do not attempt to perform this installation procedure if you are not

very familiar with how the timing belt system works. Incorrect disassembly or reassembly of the timing belt system could lead to extensive engine damage! Always

have a shop manual on hand for reference when performing the cam gear install.

Items this box should contain:

• 12 point 5/16” socket for the cam gear bolts

• 10 – 12 – 14 – 17 – 19 mm socket set w/ ratchet and extension

• 10 – 12 – 14 mm open end wrenches

• Flat head screw driver

Some of our cam gears come with a key and some do not. If you need to find out

which gears require a key, if not supplied, please give us a call at (909) 592 – 4311

or e-mail at sales@goldeneaglemfg.com

1. First, take off the spark plug wire cover, the spark plug wires and the valve

cover. Before you remove the valve cover, be sure to gather up all the nuts

and washers to prevent them from falling into the engine. Carefully remove

the valve cover and set in a clean place up-side down.

2. You will need to remove all of the spark plugs so that the engine can be

rotated easily by hand.

Once the valve cover is removed, the upper timing belt cover can be removed.

3.

4. Next, use a 19 mm (sometimes a 17mm) socket and ratchet to rotate the

engine so that the number one cylinder is at Top Dead Center (TDC) in the

intake stroke. Simply turn the crank counter clockwise until the whit mark on

the crank pulley lines up with the timing mark on the lower timing belt cover.

5. Mark the timing belt at TDC. Take the stock gears off using a 14 mm socket

and an impact wrench. Loosen the belt tensioner (14 mm) and slip the belt

off of the stock gears. Carefully remove the stock gears taking caution not to

lose the key (s).

6. Install the new cam gears along with the keys and replace the cam shaft bolts

using a 14 mm socket and a torque wrench to 27 ft-lbs. (38 N-m) Be sure to

tighten the 12 point bolts that fix the cam gear timing, as they do not come

tightened from the factory. To tighten the belt, rotate the engine over twice

counter clockwise then tighten the belt tensioner bolt 14 mm to 33 ft-lbs (45

N-m) Make sure that when the crank is at TDC, the cam gears line up with

the inscribed alignment marks (dotted lines on the gear outers ) Tighten the

cam gear bolts to a torque of 18 ft-lbs to prevent the gears from slipping

during vehicle operation ( recheck the bolts periodically. Use Loctite

whenever possible)

Replace the valve cover and spark plug wires accordingly.

7.

Rotate the motor by hand using a wrench on the crank pulley bolt, rotating it

8.

counter clockwise at least two full rotations to be sure there are no

interference issues with the valves and pistons.

Once everything check out, start the motor and check for leaks and make sure

9.

everything is in order. Remember, we always suggest having a shop manual

on hand for reference on removal and replacement of the cam gears.

Optional: cut the valve cover and belt cover to allow easy access to make gear

adjustments.

Again, we thank you for your purchase and we are always here for your input.

Golden Eagle Mfg.

414 Borrego Ct.

San Dimas, CA 91773

Ph. (909) 592 – 4311

Web www.GoldenEagleMfg.com

Sales@goldeneaglemfg.com

Be sure to tighten the bolts before engine start-up.

We strongly suggest having a trained technician perform the cam

sales@goldeneaglemfg.com

®

Golden Eagle Mfg.

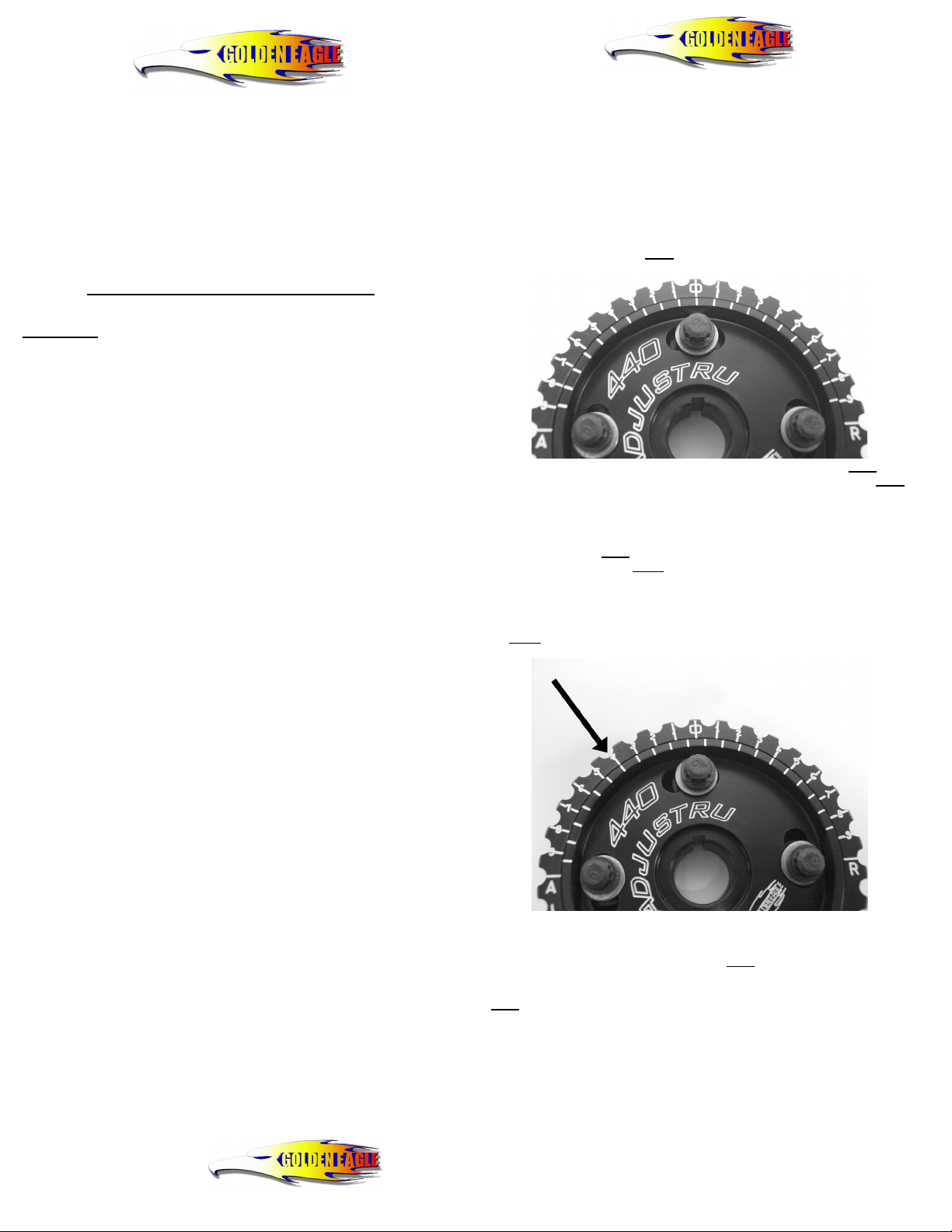

Reading the Amplified Scale

Timing Marks on ADJUSTRU Cam Gear

This is one of the easiest ways to line up the correct degree on any cam gear. It is as

easy as 1 – 2 – 3. No more squinting and trying to get the lines that you “think” are

the correct degrees to line up.

The following will help you get your bearings on how to use this scale.

First, you need to set the gear at 0° ( degrees ) by lining up the “ 0 ” line on the

outer with the “ 0 ” line on the inner

the slots. ( see photo below )

Notice how the “ 0 “ line on the outer lines up with the “ 0 “ line on the inner and

the bolts are centered in the slots. Also note that the further most lines on the inner

are both under the 9° mark in both the Advanced and Retard section. This helps in

finding true 0°.

Next, the “ A “ and the “ R “ indicate the Advanced and Retard section of the cam

gear. If you rotate the inner

section and if you rotate the inner

the advanced section. There is also an arrow that shows the rotation of the gear

while the motor is running.

Lets say you want to set the gear at 4° Advanced. All you will need to do is rotate

the inner

mark on the outer. ( see photo below )

This rule applies to any degree adjustment you will need to make when using these

cam gears.

Rule of thumb, 0° is always when a line on the inner

the outer and the bolts are centered in the slots. When adjusting to a certain degree,

focus your eye on the degree you desire, either in Advance or Retard, and rotate the

inner

to the left ( counter-clockwise ) until a line matches up with the “ 4° “

until a line matches up with your desired outer degree mark.

Always remember to tighten up the cam gear bolts

after you get them set to your desired degrees!

If you have any question regarding this Amplified Scale, please give us a call at

(909) 592 – 4311 or e-mail us at sales@goldeneaglemfg.com.

. This is easily done by centering the bolts in

to the right ( clockwise ) you will be in the Retard

to the left ( counter-clockwise ) you will be in

lines up with the “ 0 “ line on

Loading...

Loading...