Goldacres Super Cruiser G8 Operator's Manual

Super Cruiser G8

Operator’s Manual MY19

GA8700989 REV 0

APR 2019

FROM SERIAL #202114

For further information about any of the products

shown please visit - www.goldacres.com.au.

© Goldacres Trading 2019

This publication and all designs are copyright.

No part, products or designs may be reproduced

by any process except in accordance with the

Copyright act 1968.

All information in this operator’s manual is based

on the latest product information available at the

time of printing. The policy of Goldacres is one of

continuous improvement and as such, Goldacres

reserve the right to alter any specications and

designs without notice and without incurring any

obligation regarding such changes.

No part of this manual may be reproduced without

written permission from Goldacres. All photographs

and technical information remain the property of

Goldacres.

Goldacres Trading Pty Ltd

3 Morang Crescent

Mitchell Park Vic 3355

Ph: 03 5342 6399

Fax: 03 5342 6308

Contents

1 INTRODUCTION 1

Welcome . . . . . . . . . . . . . . . . . . . . . . . . .

2 SAFETY 3

Safety Information . . . . . . . . . . . . . . . . . . . .

3 GENERAL INFORMATION &

SPECIFICATIONS 9

Machine Orientation . . . . . . . . . . . . . . . . . . .

General. . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dimensions. . . . . . . . . . . . . . . . . . . . . . . 12

Wheels & Tyres. . . . . . . . . . . . . . . . . . . . . 13

Identication & Parts Ordering . . . . . . . . . . . . 13

4 CABIN 15

Key Features . . . . . . . . . . . . . . . . . . . . . .

Armrest Controls - Raven Controller - 36-42m. . . . 16

Armrest Controls - Raven Controller - 48m . . . . . 17

Joystick Controls - Raven Controller. . . . . . . . . . 18

Operator Seat . . . . . . . . . . . . . . . . . . . . . 19

Steering Column . . . . . . . . . . . . . . . . . . . . 20

Multifunction Switch . . . . . . . . . . . . . . . . . . 21

Vehicle Information Unit . . . . . . . . . . . . . . . . 21

Overhead Components . . . . . . . . . . . . . . . . 22

Air Conditioning . . . . . . . . . . . . . . . . . . . . 23

AM/FM Radio . . . . . . . . . . . . . . . . . . . . . 25

UHF Two Way Radio . . . . . . . . . . . . . . . . . . 25

Map Light. . . . . . . . . . . . . . . . . . . . . . . . 25

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rear Corner Console . . . . . . . . . . . . . . . . . 28

Power Distribution Box . . . . . . . . . . . . . . . . 29

Power Distribution Box - Fuse Box Layouts . . . . . . 30

Autosteer System - Connectors . . . . . . . . . . . . 31

Pressure Gauges . . . . . . . . . . . . . . . . . . . . 32

CANtrak System. . . . . . . . . . . . . . . . . . . . 33

CANtrak System - Parameters Monitored . . . . . . 37

CANtrak System - Alarms . . . . . . . . . . . . . . . 40

CANtrak System - Engine Fault Codes . . . . . . . . 41

CANtrak System - Conguration . . . . . . . . . . . 49

GEM Diagnostics . . . . . . . . . . . . . . . . . . . . 52

15

Glossary . . . . . . . . . . . . . . . . . . . . . . . . 53

1

5 DRIVETRAIN 55

Key Features . . . . . . . . . . . . . . . . . . . . . .

Engine . . . . . . . . . . . . . . . . . . . . . . . . . 56

3

Axles . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Transmission . . . . . . . . . . . . . . . . . . . . . . 58

Braking System . . . . . . . . . . . . . . . . . . . . . 59

Steering System . . . . . . . . . . . . . . . . . . . . 60

9

Suspension System . . . . . . . . . . . . . . . . . . . 61

Transfer Case. . . . . . . . . . . . . . . . . . . . . . 62

6 CALIBRATION 63

General. . . . . . . . . . . . . . . . . . . . . . . . .

Flow Meter & Pressure Transducer Location . . . . . 64

Flow Control Valve . . . . . . . . . . . . . . . . . . . 64

Rate Control Module (RCM) . . . . . . . . . . . . . 64

Flow Meter . . . . . . . . . . . . . . . . . . . . . . . 64

Nozzles. . . . . . . . . . . . . . . . . . . . . . . . . 65

3 Tier System (3TS) . . . . . . . . . . . . . . . . . . 66

Speed Sensors . . . . . . . . . . . . . . . . . . . . . 66

7 PRE-OPERATION 67

Preparing Sprayer For Use . . . . . . . . . . . . . . .

Spray Calibration . . . . . . . . . . . . . . . . . . . . 68

Maintenance . . . . . . . . . . . . . . . . . . . . . . 68

Starting . . . . . . . . . . . . . . . . . . . . . . . . . 69

Shut Down . . . . . . . . . . . . . . . . . . . . . . . 69

8 OPERATION 71

Machine Key Features . . . . . . . . . . . . . . . . .

EZ Control Station . . . . . . . . . . . . . . . . . . . 72

EZ Control Station - Key Functions . . . . . . . . . . 73

Suction Filter . . . . . . . . . . . . . . . . . . . . . . 74

Chemical Induction Hopper . . . . . . . . . . . . . . 75

Joystick Control . . . . . . . . . . . . . . . . . . . . 78

Side Console Switches - General . . . . . . . . . . . 80

Side Console Switches - Boom 36-42 m . . . . . . . 81

Side Console Switches - Boom 48 m . . . . . . . . . 82

Tank Source Control . . . . . . . . . . . . . . . . . . 83

Controller - Raven Rate Control Module . . . . . . . 84

55

63

67

71

ISOBUS System . . . . . . . . . . . . . . . . . . . . 85

Transmission . . . . . . . . . . . . . . . . . . . . . . 86

Tank Filling . . . . . . . . . . . . . . . . . . . . . . . 88

Agitation . . . . . . . . . . . . . . . . . . . . . . . . 90

Spray Application. . . . . . . . . . . . . . . . . . . . 90

RapidFire . . . . . . . . . . . . . . . . . . . . . . . . 91

RapidFlow . . . . . . . . . . . . . . . . . . . . . . . 94

RapidFlow - Pressure Delivery Schematic . . . . . . . 95

RapidFlow - Rinsing Schematic. . . . . . . . . . . . . 96

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . 97

Pressure Filter Cleaning . . . . . . . . . . . . . . . . 98

Decontamination. . . . . . . . . . . . . . . . . . . . 98

End of Day . . . . . . . . . . . . . . . . . . . . . . . 99

End of Program . . . . . . . . . . . . . . . . . . . . 99

9 BOOM 101

General. . . . . . . . . . . . . . . . . . . . . . . .

Boom Overview - 36-42 m . . . . . . . . . . . . . 102

Boom Overview - 48 m . . . . . . . . . . . . . . . 104

Boom Features . . . . . . . . . . . . . . . . . . . . 106

Boom Options . . . . . . . . . . . . . . . . . . . . 108

Boom Adjustment - 36-42 m . . . . . . . . . . . . 110

Boom Adjustment - 48 m . . . . . . . . . . . . . . 122

Three Dimensional Breakaway - 36-48 m . . . . . . 127

Centre Level Adjustment 36-48m . . . . . . . . . . 128

10 LUBRICATION & MAINTENANCE 129

Headlights . . . . . . . . . . . . . . . . . . . . . .

Engine . . . . . . . . . . . . . . . . . . . . . . . . 130

Cabin Air Cleaner . . . . . . . . . . . . . . . . . . 132

Transmission . . . . . . . . . . . . . . . . . . . . . 133

Driveline . . . . . . . . . . . . . . . . . . . . . . . 133

Transfer Case. . . . . . . . . . . . . . . . . . . . . 135

Suspension . . . . . . . . . . . . . . . . . . . . . . 136

Steering. . . . . . . . . . . . . . . . . . . . . . . . 138

Braking System . . . . . . . . . . . . . . . . . . . . 139

Wheels . . . . . . . . . . . . . . . . . . . . . . . . 141

Hydraulics - General . . . . . . . . . . . . . . . . . 142

Hydraulics - 36-42m . . . . . . . . . . . . . . . . . 146

Hydraulics - 48m . . . . . . . . . . . . . . . . . . . 149

Pneumatic System . . . . . . . . . . . . . . . . . . 151

Electrical System . . . . . . . . . . . . . . . . . . . 152

Air Conditioning System . . . . . . . . . . . . . . . 153

First Service - 50 Hours . . . . . . . . . . . . . . . 154

101

129

Service Parts - Lubricants . . . . . . . . . . . . . . 155

Service Parts - Filters. . . . . . . . . . . . . . . . . 156

Service Parts - Headlights . . . . . . . . . . . . . . 156

Service Parts - Belts . . . . . . . . . . . . . . . . . 156

Maintenance Schedules . . . . . . . . . . . . . . . 157

11 TROUBLESHOOTING 163

Spray Pump . . . . . . . . . . . . . . . . . . . . .

Flow Meter & Controller. . . . . . . . . . . . . . . 165

Chemical Probe . . . . . . . . . . . . . . . . . . . 167

Spray Nozzles . . . . . . . . . . . . . . . . . . . . 167

TriTech Boom . . . . . . . . . . . . . . . . . . . . 168

Plumbing . . . . . . . . . . . . . . . . . . . . . . . 169

Induction Hopper . . . . . . . . . . . . . . . . . . 169

Brakes . . . . . . . . . . . . . . . . . . . . . . . . 169

Air Conditioning . . . . . . . . . . . . . . . . . . . 169

Hydraulic & Pneumatic . . . . . . . . . . . . . . . . 170

12 OPTIONAL ACCESSORIES 171

General Information . . . . . . . . . . . . . . . . .

Chemical Induction Probe . . . . . . . . . . . . . . 172

Chemical Transfer Pump . . . . . . . . . . . . . . . 174

Flow Meter - FM-1100 . . . . . . . . . . . . . . . . 175

Flow Meter & Pump - Troubleshooting . . . . . . . 178

Hydraulic Fill Pump. . . . . . . . . . . . . . . . . . 179

Fill Flow Meter - 70 Series . . . . . . . . . . . . . . 180

Groeneveld Auto Greaser . . . . . . . . . . . . . . 184

Groeneveld Auto Greaser - Overview I . . . . . . . 185

Groeneveld Auto Greaser - Overview II . . . . . . 186

Groeneveld Auto Greaser - Components . . . . . . 187

Groeneveld Auto Greaser - Pump Unit . . . . . . . 194

Groeneveld Auto Greaser - Meter Units . . . . . . 196

Groeneveld Auto Greaser - Meter Unit Operation . 197

Groeneveld Auto Greaser - Electronic Timer . . . . 199

Groeneveld Auto Greaser - Maintenance & Testing . 200

Groeneveld Auto Greaser - Warnings Summary . . 202

Groeneveld Auto Greaser - Technical Data . . . . . 203

Groeneveld Auto Greaser - Troubleshooting . . . . 204

Groeneveld Auto Greaser - Dealer Contacts . . . . 205

163

171

INTRODUCTION

Welcome

Congratulations on your purchase of a Goldacres

sprayer. For more than a quarter of a century

Goldacres has supplied Australian farmers with quality,

innovative and technologically advanced spraying

solutions - equipment designed in Australia for

Australian conditions.

Goldacres not only produce Australia’s nest range of

spraying equipment - we also keenly value the unique

relationship we enjoy with owners of our equipment.

We are pleased to welcome you as a Goldacres owner

and look forward to making your spray applications as

efcient as possible.

Chapter 1

Please use this comprehensive resource to gain a full

understanding of your equipment, and don’t hesitate to

contact your Goldacres Dealer or Goldacres for further

information.

Roger Richards

General Manager

Chapter 1 - Introduction - 1G8 Super Cruiser Operator’s Manual MY19 - REV 0

GOLDACRES - RESELLER TERMS AND CONDITIONS OF SALE

Interpretation

1. In terms and conditions:

(1) “Goldacres” means Goldacres Trading Pty. Ltd. A.C.N. 061 306 732 trading as Goldacres Agricultural Equipment (its successors and

assigns) which is the seller of the Goods;

(2) “Purchaser” means the purchaser of the Goods;

(3) “Goods” means the products and, if any, the services sold or provided by Goldacres to the Purchaser ;

(4) “GST Act” and “GST” are given the meanings referred to in a New Tax System (Goods and Services Tax) Act 1999.

(5) “PPSA” means the Personal Property Securities Act 2009 (Clth) (as amended);

(6) Nothing in these terms and conditions shall be read or applied so as to exclude, restrict or modify or have the effect of excluding,

restricting or modifying, any condition, warranty, guarantee, right or remedy implied by law (including the Competition and Consumer

Act 2010) and which by law cannot be excluded, restricted or modied.

General

2. (1) The Goods and all other products or services provided by Goldacres are provided subject to these terms and conditions. These

terms and conditions and any terms and conditions incorporated herein by virtue of clause 3 hereto shall prevail over all other terms

and conditions of the Purchaser or otherwise to the extent of any inconsistency.

(2) These terms and conditions may not be modied or amended without the expressed written consent of Goldacres endorsed by the

Managing Director of Goldacres Trading P/L.

Additional Terms and Conditions

3. From time to time Goldacres may provide additional or extended warranties in respect of certain goods and/or services. Where such

additional or extended warranties are provided to a Purchaser in writing they will be incorporated into these terms and conditions

provided that in the event of any inconsistency between these terms and conditions and the terms of any additional or extended

warranty, the provisions of the additional or extended warranty shall prevail.

Goldacres quotations.

4. Unless previously withdrawn, Goldacres quotations are open for acceptance within the period stated therein or, when no period is

stated, with 14 days only of the quotation date. Goldacres reserves the right to refuse any order based on any quotation within 7 days of

receipt of the order.

Packing

5. The cost of any special packing and packing materials used in relation to the Goods shall be at the Purchaser’s expense notwithstanding

that such cost may have been omitted from any quotation.

Shortage

6. The Purchaser waives any claim for shortage of any Goods delivered if a claim in respect thereof has not been lodged with Goldacres

within (7) seven days from the date of receipt of the Goods by the Purchaser.

Specications, etc: Catalogues, etc: Quantities

7. All specications, (including but not limited to: drawings, particulars of weights, volumes, capacities, dimensions, load factors) are

approximate only and any deviation shall not be taken to vitiate any contract with Goldacres or form any claim against Goldacres. The

descriptions, illustrations, and performances contained in catalogues, price lists and other advertising matter do not form part of the

contract of sale of the Goods. Where specications, drawings or other particulars are supplied by the Purchaser, Goldacres’ price is

made on estimates of quantities required. Should there be any adjustments in quantities above or below the quantities estimated by

Goldacres and set out in a quotation, then any such increase or decrease shall be adjusted on a unit rate basis according to unit prices

set out in the quotation.

Performance, Capacities, Chemicals, Liquids, Application Methods, Environmental Effects

8. Any performance, volumes, and/or capacity gures given by Goldacres are estimates only. Goldacres shall be under no liability for

damages for failure to obtain such gures unless specically guaranteed in writing and any such written guarantee shall be subject to

the recognised tolerances applicable to such gures. The suitability of chemicals and other liquids for any application and the application

methods and the environmental effects shall be the sole decision and responsibility of the Purchaser and the user of the Goods.

Goldacres gives no warranty as to the suitability of any chemicals or other liquids for any application, nor the application methods

nor the environmental effects, which may result from the use of the Goods. Goldacres shall be under no liability for damages arising

out of the use of any chemicals, liquids, or mixtures in the Goods nor for any application, nor for the application methods nor for the

environmental effects, which may result from the use of the Goods.

Delivery/Service Times

9. The delivery times and service times made known to the Purchaser are estimates only and Goldacres shall not be liable for late delivery,

non-delivery or delay and under no circumstances shall Goldacres be liable for any loss, damage or delay occasioned by the Purchaser

or its customers arising from the late or non-delivery or late installation of the Goods.

Loss or damage in transit

10. Goldacres is not responsible for any loss or damage to Goods in transit. Goldacres shall render the Purchaser such assistance as may be

necessary to press claims on carriers provided that the Purchaser shall have notied Goldacres and the carriers immediately the loss or

damage is discovered on receipt of Goods and shall lodge a claim on the carrier within three days of the date of receipt of the Goods.

Insurance of Goods in transit is the responsibility of the Purchaser.

Limit of Liability

11. (1) Goldacres liability for Goods manufactured by it is limited to:

(a) where the law implies consumer guarantees into these terms and conditions pursuant to Part 3.2 Division 1 of Schedule 2 to the

Competition and Consumer Act 2010 (C’th”) (“consumer guarantees”) which cannot be excluded and Goldacres breaches a consumer

guarantee, the loss and damage the Purchaser is entitled to at law which cannot be excluded by these terms and conditions;

and, in all other cases

(b) making good any defects by repairing the same or at Goldacres option by replacement within a period not exceeding either 1000 hours

or twelve calendar months, whichever comes rst, after the Goods have been dispatched provided that:

(i) the defects have arisen solely from faulty materials or workmanship;

(ii) the Goods have not received maltreatment inattention or interference;

(iii) accessories of any kind used by the Purchaser are manufactured or approved by Goldacres;

(iv) where applicable, the seals on the Goods remain unbroken;

(v) there has been no improper adjustment, calibration or operation;

(vi) the use of accessories including consumables, hardware or software (not manufactured by Goldacres) has been approved in writing by

Goldacres;

(vii) no contamination or leakage has been caused or induced;

(viii) any modication to the Goods have been authorised in writing by Goldacres;

(ix) there has been no inadequate or incorrect use, storage, handling or application of the Goods;

(x) there has been no use or operation of the Goods outside of the physical, electrical or environmental specications of the Goods;

(xi) there has been no inadequate or incorrect site preparations;

(xii) there has been no inadequate or improper maintenance of the Goods;

(xiii) it has not been caused by fair wear and tear; and

(xiv) rstly the Goods have been thoroughly inspected and any damage (from whatever cause) to the Goods (and in particular – the

structure, welding, seams, bolts, booms) has been repaired prior to the Goods being operated, used driven or moved and on each

occasion the tanks are lled; and

(xv) there has been no failure to comply with the requirements of all present or future laws or regulations relating to the Goods and/or the

use and/or the operation of the Goods; and

(xvi) there has been no failure to maintain a record of hours of operation (which record shall contain full details of all inspections, repairs and

maintenance) and produce same to Goldacres at the time of the claim;

(xvii) the defective Goods or any damaged part of the Goods are promptly returned free of cost to Goldacres or a representative of

Goldacres;

(xviii) all warranty related repairs have been carried out with the prior authorisation of Goldacres;

(2) If Goods or any part thereof are not manufactured by Goldacres, in particular engines, engine accessories, transmissions, transfer cases,

differentials, tyres, tubes, batteries, radios and UHFs, the guarantee of the manufacturer thereof shall be accepted by the Purchaser and

is the only guarantee given to the Purchaser in respect of the Goods or that part provided always that this clause does not seek to

exclude the consumer guarantees;

(3) In the case of hydraulic systems, Goldacres shall replace defective parts in accordance with clause 11(1) of these conditions, provided

that the failure of the part was not related to contamination within the system, Goldacres shall not be liable for labour in the case of

repairing hydraulic system defects;

(4) Goldacres will not accept liability for damage attributed to fair wear and tear including but not limited to fair wear and tear to nozzles,

chains, belts, lters, brake pads, polyethylene bushes and liquid pump valves, valve O-rings, diaphragms and seals;

(5) Goldacres shall not be liable for and the Purchaser releases Goldacres from any claims in respect of faulty or defective design of any

Goods supplied unless such a design has been wholly prepared by Goldacres and the responsibility for any claim has been specically

accepted by Goldacres in writing and in any event Goldacres liability hereunder shall be strictly limited to the replacement of defective

parts in accordance with paragraph 11(1) of these conditions provided always that this clause does not seek to exclude the consumer

guarantees;

(6) Except as provided herein, all express and implied warranties, guarantees and conditions under statute or general law as to the

merchantability, description, quality, suitability or tness of the Goods for any purpose or as to design, assembly, installation, materials

or workmanship or otherwise are hereby expressly excluded and Goldacres shall not be liable for physical or nancial injury, loss or

damage or for consequential loss or damage of any kind arising out of the supply, layout, assembly, installation or operation of the Goods

or arising out of Goldacres negligence or in any other way whatsoever;

(7) The benet of any warranty provided under these terms and conditions shall only be available to the Purchaser and shall not be

transferable by the Purchaser;

(8) The warranties provided under these terms and conditions do not extend to second hand or used Goods that may be sold by

Goldacres.

12. Goldacres liability for breach of a consumer guarantee is hereby limited (in the case of goods and services not used for personal,

domestic or household purposes) to:

(1) in the case of Goods, any one or more of the following:

(a) the replacement of the Goods or the supply of equivalent Goods;

(b) the repair of the Goods;

(c) the payment of the cost of replacing the Goods or acquiring the equivalent Goods;

(d) the payment of having the Goods repaired; or

(2) in the case of services;

(a) the supplying of the services again; or

(b) the payment of the cost of having the services supplied again.

Prices

13. (1) Unless otherwise stated in writing by Goldacres, all prices quoted by Goldacres are inclusive of GST for supplies within Australia

and exclusive of GST for exports outside of Australia. Prices quoted are those ruling at the time of quotation or the date the price

is given and are based on rates of freight, insurance, customs, duties, taxes, exchange, shipping expenses, sorting and stacking charges,

cartage, cost of materials and other charges affecting the cost of production ruling on that date and any alterations thereto either before

acceptance of or during currency of the contract shall be to the Purchaser’s account.

(2) For the purpose of 38-185 of the GST Act, the day upon which the seller gives the invoice for the supply shall be the date of the invoice.

Payment

14. (1) The purchase price in relation to the Goods and the cost of the service shall be payable without deduction and or set off and

payment thereof shall be made on or before the thirteenth day of the month following the delivery of the Goods or performance of the

Goldacres Goods are only available for purchase upon the terms and conditions set out below.

services unless other terms of payment are expressly stated in writing.

(2) A decreasing or increasing adjustment and or the issuing of an adjustment note, pursuant to Division 21 and Division 29-C of the GST

Act, shall not, in any way, constitute a release, waiver, and or forgiveness of the debt incurred by the Purchaser.

Interest on overdue payments

15. If Goldacres is not paid for any Goods or services on the due date specied in this agreement without prejudice to any other right or

remedy, all outstanding money shall bear interest at the rate set, pursuant to the Penalty Interest Rates Act, Victoria, 1986, as such money,

together with interest shall be recoverable forthwith from the Purchaser.

Rights in relation to Goods.

16. (1) Title to the Goods supplied by Goldacres to the Purchaser shall remain with Goldacres until the total amount due in respect of

the Goods and all monies owing to Goldacres have been paid in full (the “Debts”). Risk in the Goods shall pass to the Purchaser upon

delivery.

(2) The Purchaser shall have the right to resell Goods but only as duciary agent and trustee for Goldacres by way of bona de sale at full

market value and in the ordinary course of its business.

(3) Until all the Debts have been paid in full:

(a) the Purchaser shall take custody of the Goods as trustee, duciary agent and bailee for Goldacres;

(b) the Purchaser shall keep the Goods separate from any other goods and properly marked, stored, protected and insured;

(c) the Purchaser must hold all of the money it receives (“Proceeds”):

(i) from the sale of any property into which Goods supplied have been incorporated; and

(ii) from the sale of Goods or provision of services including the Goods supplied by the Goldacres as bailee, duciar y agent and trustee for

Goldacres, but the Purchaser need not hold on trust any money exceeding the amount of the Debts at the time the money is received.

(d) The Purchaser expressly acknowledges that it is bound by the duciary obligation created in the preceding paragraph and acknowledges

that:

(i) it must hold the Proceeds on trust for Goldacres;

(ii) it must place the whole of the Proceeds in an account separate from its own moneys (the “Proceeds Account”);

(iii) it must maintain the Proceeds Account separate from its own moneys at all times.

(iv) it must maintain proper records for the Proceeds Account.

(v) it must not assign or encumber any book debts arising from sales made in circumstances set out in clauses 16(c)(i) and (ii) or do any

other act in derogation of Goldacres’ legal or benecial interests; and

(vi) it must account to Goldacres on demand for all moneys standing to the credit of such account.

(e) For the purposes of identication of different consignments of Goods purchased from Goldacres and receipt of Proceeds, the Purchaser

agrees that the principle of “Last In, First Out” shall be applied to any items that cannot be distinguished.

(f) Goldacres may trace the Proceeds in equity.

(4) Goldacres may at any time, without notice to the Purchaser and without prejudice to any other rights which it may have against the

Purchaser, terminate any contract connected with the Goods and the bailment referred to in clause 16(3) and enter upon any premises

owned or occupied by the Purchaser where Goldacres reasonably believes the Goods may be stored, and repossess the Goods without

liability for any damaged caused, and subsequently dispose of the Goods at Goldacres’ discretion if:

(a) the Debts are not paid in accordance with these terms and conditions or any other contract or arrangement between Goldacres and

the Purchaser; or

(b) Goldacres receives notice of or reasonably believes that:

(i) a third person may attempt to levy execution against the Goods; or

(ii) the Purchaser is insolvent (within the meaning of the Corporations Act 2001) or bankrupt; or

(iii) the Purchaser has entered into any arrangement or composition with its creditors, gone into liquidation, or has appointed a receiver, a

receiver and manager or administrator.

(5) If after repossession under clause 16(4) Goldacres sells the Goods, Goldacres shall account to the Purchaser for any proceeds of sale

(less expenses of repossession and sale) that exceeds the amount of the outstanding Debts.

(6) If any Goods belonging to Goldacres are disposed of by the Purchaser or an insurance claim is made in respect of them, Goldacres shall

be entitled to trace the sale or insurance proceeds, which proceeds shall be held by the Purchaser in a separate bank account on trust

for Goldacres.

(7) The Purchaser agrees and acknowledges that in the event it sells Goods to a third party on account, it will include in its terms and

conditions of sale a provision under which the Purchaser retains title to the Goods until such time that the total amount due in respect

of the Goods and all monies owing to the Purchaser have been paid in full by that third party debtor. The Purchaser also agrees and

acknowledges that in these instances, it will register its PMSI in accordance with the PPSA in respect of its security interest in the

Goods.

PPSA provisions

17. (1) The Purchaser acknowledges that these terms and conditions constitute a security agreement for the purposes of section 20 of the

PPSA and that a security interest exists in all Goods (and any associated Proceeds from their sale) previously supplied by Goldacres to

the Purchaser (if any) and in all in future Goods (and any associated Proceeds from their sale) that may be supplied to the Purchaser by

Goldacres.

(2) The Purchaser acknowledges that Goldacres has a rst ranking purchase money security interest (“PMSI”) (as dened in section 14 of

the PPSA) in the Goods and the Purchaser must not jeopardise such ranking (whether by act or omission).

(3) The Purchaser acknowledges that it has received value as at the date of rst delivery of the Goods and has not agreed to postpone the

time for attachment of the security interest (as dened in the PPSA) granted to Goldacres under these terms and conditions.

(4) The Purchaser will execute documents and do such further acts as may be required by Goldacres to register the security interest

granted to Goldacres under these terms and conditions under the PPSA.

(5) Until ownership of the Goods passes, the Purchaser must not give to Goldacres a written demand or allow any other person to give

Goldacres a written demand requiring Goldacres to register a nancing change statement under the PPSA in respect of Goldacres’

interest in the Goods.

(6) The Purchaser must indemnify Goldacres and on demand reimburse Goldacres for all costs and expenses incurred by Goldacres in

respect of these terms and conditions including but not limited to Goldacres registering its security interest in the Goods, lodging,

discharging or amending any nancing statement or nancing change statement, or otherwise complying with the PPSA.

(7) The Purchaser agrees (other than as provided in these terms and conditions) not to sell, lease, mortgage, deal with, dispose of or create

or attempt to create any other security interest in or affecting the Goods unless and until the Purchaser’s Debts have been satised.

(8) The Purchaser waives its rights under the following provisions of Chapter 4 of the PPSA:

(a) to receive a notice on enforcement action against liquid assets (section 121(4),

(b) to receive a notice to seize collateral (section 123);

(c) to receive a notice of disposal of Goods by Goldacres purchasing the Goods (section 129);

(d) to receive a notice to dispose of Goods (section 130);

(e) to receive a statement of account following disposal of Goods (section 132(2));

(f) to receive a statement of account if no disposal of Goods for each 6 month period (section 132(4));

(g) to receive notice of any proposal of Goldacres to retain Goods (section 135(2));

(h) to object to any proposal of Goldacres to either retain or dispose of Goods (section 137(2));

(i) to redeem the Goods (section 142);

(j) to reinstate the security agreement (section 143);

(k) to receive a notice of any verication statement (section 157(1) and section 157(3);

(9) The rights Goldacres may have under the PPSA are supplementary and in addition to those set out in these terms and conditions and

do not derogate from the rights and remedies of Goldacres under these terms and conditions or under any other statute or under

general law.

(10) The Purchaser must give 10 business days prior written notice of any proposed change in the Purchaser’s name or other identifying

characteristics and details.

Purchasers property

18. Any property of the Purchaser under Goldacres’ custody or control shall be entirely at the Purchaser’s risk as regards loss or damage

caused to the property or by it.

Storage

19. Goldacres reserves the right to make a reasonable charge for storage if delivery instructions are not provided by the Purchaser within

(14) fourteen days of a request by Goldacres for such information.

Returned Goods

20. Goldacres shall not be under any obligation to accept Goods returned by the Purchaser and will do so only on terms to be agreed in

writing in each individual case.

Goods sold

21. All Goods to be supplied by Goldacres shall be described on the purchase order agreed by Goldacres and the Purchaser and the

description on such purchase order modied as so agreed shall prevail over other descriptions including any Purchaser’s specication or

enquiry.

Cancellation

22. No order may be cancelled except with the consent in writing and on terms, which will indemnify Goldacres against all losses.

No waiver

23. The failure of any party to enforce the provisions of these terms and conditions or to exercise any rights expressed in these terms and

conditions shall not be a waiver of such provisions or rights and shall not affect the enforcement of this agreement. The exercise by any

party of any of its rights expressed in this agreement shall not preclude or prejudice such party from exercising the same or any other

rights it may have irrespective of any previous action taken by that party.

Force Majeure

24. If by reason of any fact, circumstance, matter or thing beyond the reasonable control of Goldacres is unable to perform in whole or

in part any obligation under these terms and conditions then Goldacres shall be relieved of that obligation under these terms and

conditions to the extent and for the period that it is so unable to perform and shall not be liable to the Purchaser in respect of such

inability.

Passing of risk

25. Risk in the Goods shall pass to the Purchaser upon delivery of the Goods to the Purchaser or collection of the Goods by the

Purchaser’s agent or carrier as the case may be.

Exclusion of liability

26. To the extent permitted by law Goldacres shall not be liable to the Purchaser in contract or in tort arising out of, or in connection

with, or relating to, the performance of the Goods or any breach of these conditions or any fact, matter or thing relating to the Goods

or error (whether or not it is negligent or a breach of contract) in information supplied to the Purchaser or a user before or after the

date of the Purchaser’s or user’s use of the Goods and Goldacres shall be under no liability for damages arising out of the use of any

chemicals, liquids, or mixtures in the Goods, nor for any application, not for the application methods nor for the environmental effects,

which may result therefrom or from the use of the Goods.

Exclusion of representations and arrangements

27. To the extent permitted by law the terms and conditions supersede and exclude all prior and other discussions, representations

(contractual or otherwise) and arrangements relating to the supply of the Goods or any part thereof including, but without limiting the

generality of the foregoing, those relating to the performance of the Goods or any part thereof or the results that ought to be expected

from using the Goods.

Place of contract

28. The contract for sale of the Goods and the provision of the services is made in the State of Victoria and the Purchaser agrees to submit

all disputes arising with Goldacres to the courts of such State and any court competent to hear appeals therefrom.

SAFETY

Safety Information

Chapter 2

General

The following pages outline important safety

information. At Goldacres safety is a high priority.

These safety and warning instructions MUST be

followed to ensure the safe operation of your

Goldacres equipment.

Explanation of key terms used in this operator’s

manual are:

DANGER - You will be killed or seriously hurt if you

don’t follow instructions

WARNING - You can be seriously hurt if you don’t

follow instructions

CAUTION - You can be hurt if you don’t follow

instructions

NOTE - Is used to notify people of installation,

operation or maintenance information that is

important but not hazard related.

The Operator

All operators of this equipment should be adequately

trained in the safe operation of this equipment. It

is important that all operators have read and fully

understand the operator’s manual prior to using this

equipment.

All new operators should be trained in an area

without bystanders or obstructions and become

familiar with the sprayer prior to operation.

The machine is tted with a roll-over protection

structure incorporated into the frame of the cabin. To

minimize the risk of injury in the event of an accident,

the operator and anyone in the training seat must

wear seat belts at all times.

Passengers

The machine is equipped with one training seat with

a seatbelt. To minimize the risk of injury in the event

of an accident, the operator and anyone in the training

seat must wear seat belts at all times.

Any further passengers will not be protected by the

roll-over protection system and must be kept off the

machine.

Do not stand on or carry passengers on the steps or

platform when the sprayer is in motion or when the

booms are being folded or unfolded.

Warnings

• Always read and understand the operator’s manual

prior to operation of this equipment.

• It is the responsibility of the operator to ensure

that there are no damaged or missing decals on the

equipment and that any damaged or missing decals

are replaced prior to operation.

• Goldacres equipment either ordered or

operated outside the guideline limitations may

not be warranted by Goldacres for successful

performance. Operators working outside these

limitations do so at their own risk, unless specic

advice has been sought from, and provided by,

Goldacres in writing.

• Inspect the equipment thoroughly for damage and

wear before operation.

• Always read and follow the chemical

manufacturer’s guidelines for safe application as per

the chemical label. Particular attention should be

given to the recommended target application rate

of the chemical being applied as per the chemical

label.

• Goldacres equipment uses several materials

that may be harmful to the environment.

Potentially harmful waste used with Goldacres

equipment includes such items as oil, fuel, coolant

and batteries. If these items are disposed of

incorrectly the waste can threaten the surrounding

environment and ecology. The waste products

can leech into surrounding water sources and

contaminate the area.

• Certain chemicals may be unsuitable for use with

Goldacres standard plumbing designs. Consult your

Goldacres dealer if in doubt.

• Do not operate the equipment while under the

inuence of any drugs, alcohol or if excessively

tired.

• Lubricate the equipment as per recommended

requirements before operating.

• Make sure that the equipment complies with all

relevant road regulations when transporting.

• Flush chemicals from equipment immediately after

use.

Continued over page

Chapter 2 - Safety - 3G8 Super Cruiser Operator’s Manual MY19 - REV 0

Safety Information

• When draining uids from the equipment use

appropriate, leak proof containers. Do not use

food or beverage containers because someone

may consume the contents by mistake.

• Any unauthorised modications to this equipment

may affect its function and create a serious safety

risk.

• Keep clear of overhead obstructions – especially

power lines as contact can be fatal.

• Never attempt to clean parts, or nozzles, by

blowing with mouth.

• Never attempt to siphon chemicals, or substances,

by sucking.

• It is imperative that the vehicle manufacturer’s

specications be checked and all instructions for

use when transporting, or towing, be adhered to at

all times.

• Care should be taken when transferring liquid

into the tank to ensure that the gross weight of

the equipment does not exceed the braking and

carrying capacity of the vehicle as specied by the

vehicle manufacturer.

NOTE: 1 Litre water = 1 Kg.

• Water weighs 1kg per litre, however conversion

factors must be used when spraying liquids

that are heavier or lighter than water. Example:

liquid nitrogen has a density of 1.28 kg/L and will

therefore be signicantly heavier than water if the

tank is lled completely. The total weight of a tank

full of chemical, should not exceed that of a full

tank of water. Machine damage can result if the

machine is over weight. See lling instructions in

Chapter 8 ‘Operation’ for more information.

• Suitable care should be taken when driving the

vehicle. Consideration should be given to both the

carrying capacity of the vehicle and the gradient of

the terrain when determining the speed at which

the vehicle can be driven safely.

• Ensure that the maximum speed of the vehicle,

when loaded, is within the vehicle manufacturer’s

limitations.

• Ensure equipment is securely fastened or attached

to vehicle at all times.

• Never stand within the radius of the boom wings.

• Never work under any hydraulically raised boom.

Cautions

• When leaving the sprayer always isolate the

batteries by turning the isolator key off and

removing it.

• A supply of fresh water should be with the

equipment at all times.

• Water tanks are not designed for use with diesel

fuel or any ammable liquid.

• Do not use this machine in ambient temperatures

exceeding 40 degrees Celsius.

• Ensure that all bolts are tightened and secured

before operation.

• Always ensure that the boom is securely suppor ted

when travelling.

• Standard centrifugal spray pump: Running the

pump dry will cause failure. Care should be not to

operate at speeds exceeding 4200 rpm.

• Optional diaphragm spray pump: Care should be

taken to never overll with oil or operate at speeds

exceeding 540 rpm.

• Do not exceed the maximum spraying pressure of

8 Bar.

Dangers

• Check area to be sprayed for overhead powerlines.

Contact between the machine and powerlines

can result in serious injury or death. If there are

powerlines in the spray area, exercise extreme

caution when tilting boom wings.

• Do NOT walk on machine platform when near

power lines.

• NEVER start the engine when standing on the

ground. Only star t the engine from the operator’s

seat, with the transmission in neutral. Possible injury

or death can occur by starting the machine through

other methods.

• Never exit the cabin while the machine is in

motion.

• Diesel engine exhaust fumes are harmful and can

cause severe sickness or death. If it is necessary to

run the engine in an enclosed area use an exhaust

pipe extension. If an exhaust pipe extension is

unavailable ensure that all doors are fully open and

the room is well ventilated.

Personal Protective Equipment

(PPE)

Always wear close tting clothing and appropriate

safety equipment designed for the job at hand.

• Exposure to loud noise over an extended period

can cause permanent hearing impairment or loss.

Be active in the conservation of your hearing and

wear appropriate hearing protection at all times.

• Chemicals can be harmful to humans, appropriate

PPE should be used when handling chemicals.

Continued over page

4 - Chapter 2 - Safety G8 Super Cruiser Operator’s Manual MY19 - REV 0

Safety Information

CAUTION: Always refer to the chemical

manufacturers label for guidelines on the appropriate

PPE to use with the chemical/s you are using.

Goldacres also suggests that you read and understand

the following Australian standards:

• Australian Standard for Chemical

protective clothing AS3765.

• Australian Standard for Respiratory

protection devices AS1715.

Poisons Information Centres - Call 131 126 (AU)

Cuts, Stabs & Punctures

When Servicing machine, be mindful of sharp edges

on parts such as trimmed cable ties, hose clamps, cut

reinforced hose and the edges of plates and brackets

as they could cause cut, stab or puncture injuries.

Crush Hazard

Never attempt to maintain axles, wheels or

components within the vicinity of the wheels with the

engine running.

Pinch Hazard

When operating moving components such as the

boom, access ladder, bonnet or other components,

keep ngers and hands away from potential pinch

points.

Burn Hazard

• Avoid contact around the entire exhaust system of

the sprayer when at operating temperature

• Avoid contact around the hydraulic tank and all

hydraulic lines when at operating temperature

Entanglement Hazard

Rotating drives can cause serious injury or even death

when entanglement occurs. Keep hands, feet, hair and

clothing away from all moving parts to prevent injury.

Never operate this machine with covers, shrouds, or

guards removed.

Stored Energy Hazard

Even when the machine is not running, energy can be

stored in components such as hydraulic accumulators,

air tanks, tyres, A/C hoses, springs and boom cables.

Hydraulically supported components such as the

boom center are also a source of stored energy.

Before working on the machine, ensure that these

parts are relieved of their energy in a safe manner.

Overhead Hazard

BOOM LIFT OR TILT AND RADIO ANTENNA

COULD STRIKE POWER LINES. Keep clear of

overhead obstructions – especially power lines as

contact can be fatal.

Do NOT walk on machine platform when near

power lines.

Airborne Particles

• Always stand well clear of equipment during

operation.

• Any spray drift is dangerous and may be hazardous

to humans and other animals.

• When heating and welding components, ensure

that all paint and other such materials are removed.

Often hazardous airborne particles and fumes are

generated from welding and heating.

Fluids Under Pressure

Fluids escaping from high pressure lines can cause

serious injury to skin. Hydraulic oil can easily penetrate

human skin. This hazard can be avoided by relieving

the pressure in the system.

Do not disconnect any hoses, nozzles or lters

while equipment is operating. Disconnecting these

components while under pressure may result in

uncontrolled uid discharge which may be hazardous.

Be mindful of the location of pressurised lines in the

vicinity of the work area when using equipment such

as grinders, oxy torches and welders. The two main

risks are that this equipment may easily cut through

the lines or the local heat generated near the lines

may cause them to rupture.

Ensure that all ttings and lines are fully/tightly secured

before re-pressurizing after repairs.

Boom Height Control System

If boom height control system is tted, keep clear of

the boom as it could potentially move without notice.

Cooling System

• At operating temperature the uids in the cooling

system are under pressure. Only remove the

radiator cap when the engine is turned off and has

cooled down.

• Loosen the radiator cap slowly to relieve the

pressure before removing the cap completely.

• Coolant can be added when the engine is cool and

turned off.

Batteries

The machine is supplied with sealed, non-ser viceable

batteries. The battery electrolyte contains sulfuric acid;

this is a highly dangerous liquid and should be handled

with the greatest degree of care.

Continued over page

Chapter 2 - Safety - 5G8 Super Cruiser Operator’s Manual MY19 - REV 0

Safety Information

The acid can cause blindness, burn skin and dissolve

clothing. Batteries also produce ammable hydrogen

gas (especially when charging), so keep them

separated from any sources of sparks and ames.

A vigilant operator can avoid these hazards by:

1. Wearing the correct personal protective

equipment.

2. Avoid spilling or dripping electrolyte.

3. Place into a plastic collection tray ready for disposal

if the case is found to be damaged.

EMERGENCY MEASURES

• If the electrolyte gets in your eyes, ush your eyes

with clean water for at least 15 minutes, then get

immediate medical assistance.

• Also thoroughly wash all other affected areas on

your body with water and remove all clothing.

• If you swallow any electrolyte seek medical

attention immediately.

Lifting Machine

Before raising the machine off the ground:

Ensure that the boom is in its closed position.

Park on a at level, rm area and engage the park

brake.

Empty the spray tank where possible.

Chock all wheels that remain on the ground.

Securely lift the machine using a jack and support

the machine on work stands.

Do not work under the machine when supported

solely by a jack.

Do not support the sprayer using materials that

may crumble.

Changing Wheels & Tyres

An experienced person with the correct equipment

should mount the wheels on the sprayer.

When changing a wheel on the sprayer ensure that

the sprayer is on rm level ground and the wheels are

chocked.

Tyre Maintenance

Maintain correct tyre pressure at all times. Ination

of tyres above or below the recommended pressure

exerts additional pressure on the tyre, which may

result in tyre damage.

Extreme caution is required during the ination of

tyres. If the tyre is inated at a rapid rate separation

and/or explosion of the rim can occur. This event can

inict serious or fatal injuries to the operator.

Always use a tyre ination gauge.

Be proactive and continually check the condition of

your tyres.

Do not weld, heat or modify the rim.

Machine Operation

• High speed turning places severe stresses on

the wheels and axles and should be avoided. It

is essential to observe the effects of turning on

the open spray boom. Excessive turning speeds

transmit great stresses to the spray boom and

WILL CAUSE boom damage.

• Modication of the machine to increase maximum

speed is STRICTLY PROHIBITED. This machine

is designed for a maximum speed of 50 km/h.

This speed must only be used on suitable terrain

conditions. All components i.e. tyres, brakes,

suspension, steering and chassis are designed and

built to this maximum speed.

• MAXIMUM SPEED WHEN CORNERING,

TURNING AT AN ANGLE GREATER THAN

45º OR DRIVING ON A SLOPE OR UNEVEN

TERRAIN IS 5KM/H. When tted with narrow

wheel track and with high centre of gravity, the

self-propelled sprayer may become unstable when

turning at excessive speed or when operating on

excessively steep terrain.

• Before leaving the sprayer the engine must be

shut off, the transmission placed in neutral and

the park brake engaged. NEVER ENGAGE THE

PARK BRAKE WHILE THE SPRAYER IS MOVING.

DAMAGE TO THE TRANSMISSION MAY RESULT.

Refuelling

• Handle fuel with extreme caution. Do not refuel

the machine while smoking or near open ames or

sparks.

• Always stop the engine before refueling the

machine.

• To prevent res always keep the machine clean of

grease, debris and dirt.

• Do not use current emitting devices when refuelling.

Collision Prevention & Warning

Lights

• Before operating the machine check with the

relevant road management authorities for

information regarding safe and legal transport on

public roads in the state where the machine is

being operated.

• To assist in the prevention of collisions with other

road users the Goldacres sprayers are tted with

warning lights and signs in accordance with national

road regulations.

Continued over page

6 - Chapter 2 - Safety G8 Super Cruiser Operator’s Manual MY19 - REV 0

Safety Information

• The machine is tted with a reverse warning

beeper when the machine is put into reverse.

• The machine can only be driven on public roads

during daylight hours.

• Keep lighting and signs in good order and replace

any damaged or faulty xtures.

Working at Heights

Please contact your local government on the

restrictions and safety requirements needed to

operate at heights.

• There is a risk a falling if a person has “climbed”

onto the machine.

• Do not “climb” on machine to get access.

• Use ladder or work platform to get access

to parts or areas of the machine above local

government restrictions.

Slippery Surfaces

• The surface of the platform has raised portions

to stop slipping.

• The platform surface needs to be kept clean of

mud and other material to help stop slipping.

Main Tank

• Danger - Conned space do not enter.

• Do not enter the tank for any purpose.

Safe Chemical Usage

The safe use of Agricultural (Ag) chemicals with

this equipment is the responsibility of the owner/

operators. All operators should be trained in the safe

use of Ag chemicals. Goldacres suggest that a relevant

course is completed by owners/operators prior to

operation of this equipment as a spray unit.

Safety Decals

Understanding safety decals and their purpose assists

in the safe operation of your sprayer. Safety decals are

there for your protection and it is the responsibility

of the owner operator to replace damaged and/or

missing safety decals.

Regularly review safety decals with operators. It

is very impor tant to ensure that all new machine

components and replacement parts include current

hazard identication decals.

Replacement safety decals can be ordered from your

Goldacres dealer. Part numbers and descriptions of

the decals on this machine can be found in the parts

manual supplied.

First Aid Kit

It is recommended that a rst aid kit be added to

your machine.

Fire Extinguisher

A re extinguisher is tted under the training seat in

the cabin of your machine.

It is a dry chemical ABE type re extinguisher

approved for wood, paper, ammable liquid and live

electrical equipment res.

Machine Recovery

• The mechanical drive system delivers efcient,

positive power to the ground for superior traction.

However, should your machine become bogged

and the wheels subsequently locked, do not engage

rst gear and maximise engine revs.

With the wheel ‘locked’ in a bog situation,

transmitting full power WILL DAMAGE the

driveline.

• Goldacres recommends that bog situations are

addressed prudently by using the assistance of a

tow vehicle. Doing otherwise can cause signicant

driveline damage and VOID WARRANTY.

Towing & Transporting Sprayer

• A disabled sprayer is best transported on a drop

deck trailer. Use chains to secure the sprayer via

the tie down attachment point located under the

front and rear axles.

• The machine must not be towed unless the engine

is running (as the steering and brakes require

engine power to operate). Before towing, the front

& rear tail shaft should be disconnected due to the

risk of damage to the transmission. While towing

do not travel at a speed greater than 10 Km/h.

• An operator must steer and brake the sprayer

under tow.

• The park brake needs to be manually released if

engine is not able to run.

• Check the wheel nut tension on a regular basis. The

torque and inspection frequency is outlined in the

maintenance section.

• Brake performance should be checked regularly.

The inspection frequency is outlined in the

maintenance section.

Chapter 2 - Safety - 7G8 Super Cruiser Operator’s Manual MY19 - REV 0

8 - Chapter 2 - Safety G8 Super Cruiser Operator’s Manual MY19 - REV 0

GENERAL INFORMATION &

SPECIFICATIONS

Machine Orientation

FRONT

LEFT RIGHT

REAR

Chapter 3

General

Chassis

The chassis is an all steel construction, that is fully

welded for superior strength. The chassis is grit

blasted, primed and then protected by the Goldacres

paint process for excellent chemical resistance and

durability.

Paint Codes

Wheels: N23 Neutral Grey

Steel work: G13 Dark Green

Steel work: N61 Black

Australian Standards AS2700

Tank

All tanks are constructed from UV resistant

polyethylene. Polyethylene tanks have a very high

chemical resistance. Due to the rotational moulding

process, there can be variance in the overall

dimensions of the tank which in turn results in

5-10% variation in the tank capacity. For this reason,

calibration markings should be used as a guide only.

Cabin

The cabin features panoramic views surrounding

the sprayer and is customised to suit spraying

applications. The rate controller and all key spraying

functions are within easy reach of the operator

Further information on the cabin can be found in

Chapter 4 ‘Cabin’.

Agitation

The Supermix agitator is located at the back of the

tank and is used to generate increased agitation

within the tank. The pressure line to the Supermix

agitator from the control manifold passes through a

nozzle and then through the barrel into the tank. This

causes extra agitation as ow around the agitator is

sucked into the barrel and is then passed back into

the tank. To increase this venturi effect, the bypass

ow from the electric regulating valve also passes

through the barrel, multiplying the agitation effect.

The Supermix agitator has an approximate capacity

of 300 - 1300 L/min depending of the pump size and

operating pressure. For further information refer to

Chapter 10 ‘Lubrication & Maintenance’.

Rate Controller

These sprayers are tted with a Raven Rate Control

Module (RCM). This is an automatic rate controller

that will maintain a user dened application rate

automatically as the vehicle speed changes. In order

to function, the automatic rate controller relies on

a ow meter, speed sensor and control valve. For

specic information on the Raven controller please

refer to Raven operator’s manual supplied and

Chapter 6 ‘Calibration’ of this manual.

Continued over page

Chapter 3 - General Information & Specs - 9G8 Super Cruiser Operator’s Manual MY19 - REV 0

General

Boom Nozzle Control

Nozzle control is achieved using the Rapid Fire with

Rapid Flow system tted as standard equipment.

Electrically activated air-solenoids control individual

boom nozzles and boom section on/off functions.

The nozzles have a standard spacing of 500 mm, but

250 mm distances can also be optioned.

3 Tier System (3TS)

The 3 Tier System (3TS) aims to give a wider

range of exibility around application rate and

spraying speed. The 3TS effectively gives the driver

a much wider operating band whilst still maintaining

optimum droplet size.

The 3TS can be thought of as a three step gearbox,

or in the case of the 3TS Pro, a seven step gearbox.

Each nozzle type has an operating pressure band for

a given droplet size. As the rst nozzle set, or tier,

reaches the top of its pressure band, the next larger

size nozzle tier is activated.

When the second tier reaches the top of its

pressure band, the rst tier will be reactivated to

spray at the same time. This effectively gives three

operating bands.

The 3TS Pro option is an extension of this idea

using three different nozzle sizes and gives seven

effective bands of operation for even greater

application control. It requires an unlock code for the

Raven RCM which is provided when the feature is

optioned.

The Raven RCM controls the 3TS system. For

specic calibration and operating instructions, see

Raven RCM operation manual supplied.

Filtration

Filtration is a critical par t of the sprayer’s

performance.

As standard, these sprayers are tted with:

1 x Suction lter (32 mesh)

2 x Pressure lters (1 x 80 & 1 x 100 mesh)

Nozzle strainers (50 mesh)

Spray Pump

A centrifugal 400 L/min at 8 Bar spray pump is tted

as standard. Positive displacement and oil backed

diaphragm pumps capable of 260 L/min can also

be tted optionally. The normal operating range is

from 1 - 8 bar which is sufcient for efcient nozzle

performance.

• The maximum combined ow of all boom

sections is limited to 140 litres per minute, or 50%

of the pump ow, whichever is the lesser amount

with clean lters.

• Standard centrifugal spray pump: Running the

pump dry will cause failure. Care should be not to

operate at speeds exceeding 4200 rpm.

• Optional diaphragm spray pump: Care should

be taken to never overll with oil or operate at

speeds exceeding 540 rpm.

• Do not exceed the maximum spraying pressure

of 8 Bar.

Chemical Induction

The method of chemical induction into your sprayer

is dependent on the optional chemical induction

equipment tted to your sprayer.

Goldacres chemical induction equipment available

includes:

• Chemical Probe

• Chemical Induction Hopper

• 12 V Chemical Transfer Pumps

Booms

This machine can be tted with a variety of boom

widths ranging from 36 to 48 metres. They feature

hydraulic lift, fold and individual wing tilt controllable

from the cabin. Goldacres TriTech booms feature

pitch, roll and yaw suspension in order to provide

a superior boom ride and assist in the efcient

application of chemical to your target.

Nozzles

As information regarding nozzles is specic to those

being used in your application, no specic reference

is made to nozzle application rates or nozzle types in

this operator’s manual. Goldacres suggest the use of

a current TeeJet or Lechler nozzle selection catalogue

for reference to nozzle sizes, outputs, spray patterns

and general spraying information. For more technical

information on the function of spray nozzles and

factors affecting their performance you can also use

the TeeJet ‘User’s guide to spray nozzles’.

The TeeJet & Lechler nozzle selection catalogue and

Users guides to spray nozzles are available from your

Goldacres dealer, or as a free download from the

TeeJet web site: www.teejet.com

Lechler web site: www.lechler.de

Continued over page

10 - Chapter 3 - General Information & Specs G8 Super Cruiser Operator’s Manual MY19 - REV 0

General

Machine Limitations

All Goldacres equipment is subject to operating

limitations, it is the operator’s responsibility to

ensure that this equipment is being operated within

these limitations and appropriately to the operating

conditions at hand.

Goldacres do not endorse use of this machine for

spraying at speeds greater than 20 km/hr and should

not be used in ambient temperatures exceeding 40

degrees Celsius or below 5 degrees Celsius.

Do not travel at excessive speeds over rough terrain.

The superior ride characteristics of this machine can

disguise the impact of rough terrain on the driveline

and suspension system of the machine. Stop the

machine and inspect for damage after impact with

gutters, sinkholes, rocks etc.

Violent speed change WILL CAUSE boom damage.

The high power to weight ratio and braking

capacity (especially when empty) enables very high

acceleration and decelerations of the machine. It is

important during accelerating and braking that the

effect on the spray boom in the open position is

taken into account.

The mechanical drive system delivers efcient,

positive power to the ground for superior traction.

However, should your machine become bogged and

the wheels subsequently locked, do not engage rst

gear and maximise engine revs.

With the wheel ‘locked’ in a bog situation,

transmitting full power WILL DAMAGE the driveline.

Goldacres recommends that bog situations are

addressed prudently by using the assistance of a

tow vehicle. Doing otherwise can cause signicant

driveline damage and VOID WARRANTY.

Hydraulics

Electric over hydraulic valves are standard on these

machines. The hydraulic functions are then controlled

from electric switches in the cabin. The valve block

is mounted on the boom centre section which is

located at the rear of the sprayer.

Hand Wash Tank

A fresh water hand wash tank is located on the left

hand side of the machine under the left hand access

ladder. It has a bottle with a hand pump that can be

lled with a liquid hand cleaner. The main tank can be

lled with fresh water for operator use.

Ladder

The Ladder is to be used to access to the platform

and cabin by the operator. Always face the ladder

and retain three points of contact with the ladder

at all times when ascending and descending. The

ladder is only lifted to the raised position when

the key is turned on and the handbrake is released.

The operator must take care when operating the

handbrake to ensure that no person is standing on

or near the ladder at the time. In an emergency, the

ladder can be lowered by either applying the park

brake or turning off the ignition, or removing the air

supply hose from the air cylinder.

Air Conditioning

The cabin is climate controlled and a carbon lter is

installed to ensure operator safety.

Further information can be found in Chapter 4

‘Cabin’.

Custom Built Equipment

Where the owner of this sprayer has requested that

custom built equipment or options be tted to this

sprayer it is necessary to understand that custom

fabrication and engineering is subject to many

variables. Goldacres cannot fully eld test all custom

built options prior to despatch, and owners of new

sprayers tted with custom built equipment or

options need to understand that the functionality of

these items may require rening in order to operate

as desired.

Suspension

The machine is tted with 5 link airbag axle

suspension to provide excellent ride and comfort.

Further information on the suspension can be found

in Chapter 10 ‘Lubrication & Maintenance’.

Chapter 3 - General Information & Specs - 11G8 Super Cruiser Operator’s Manual MY19 - REV 0

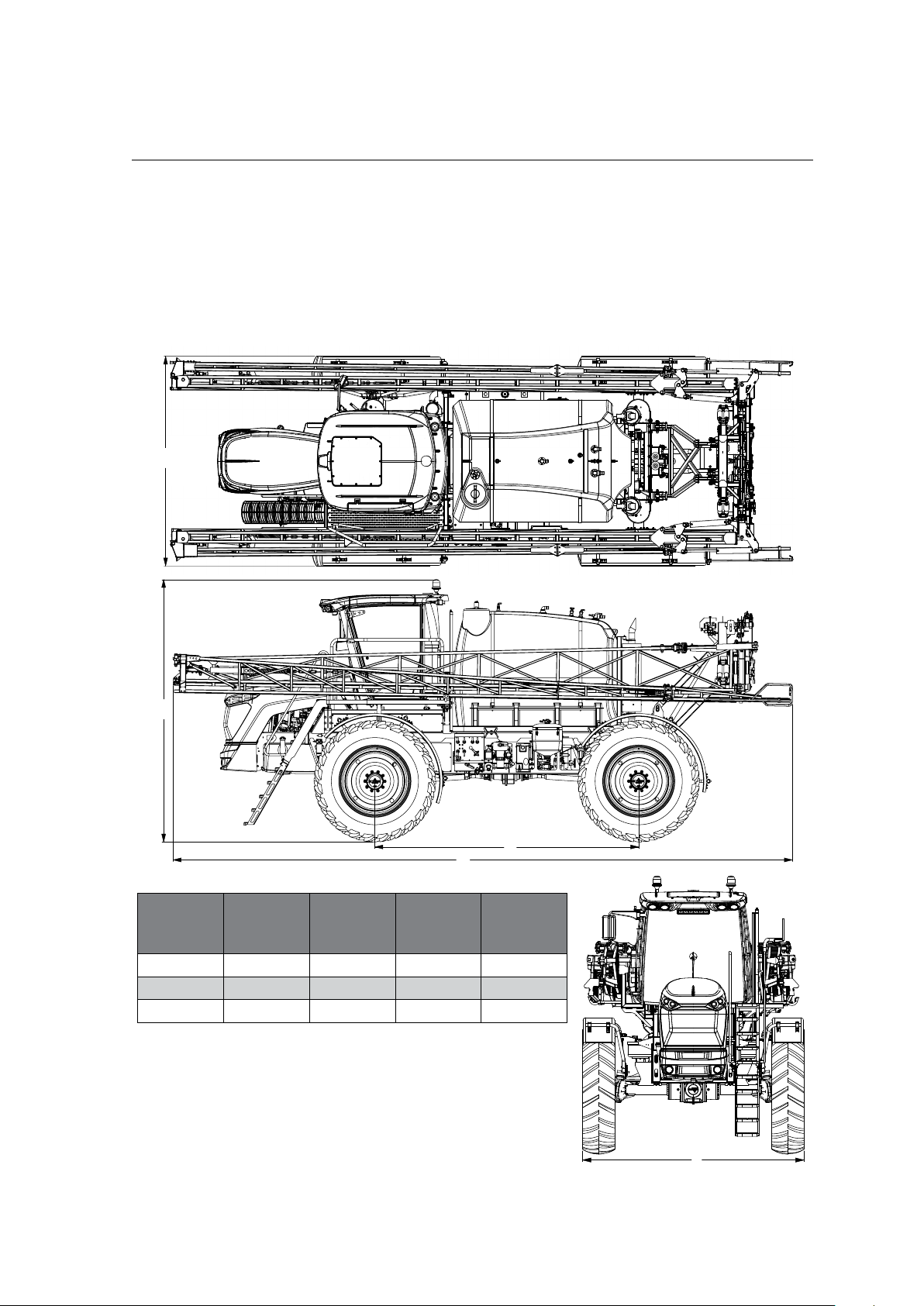

Dimensions

B

5

C

D

4

6

7

8

A

B

The following information is provided as a guide only.

Variations in dimensions may occur without

notication. To ensure that the dimensions are

accurate for your sprayer it is recommended that

you measure your sprayer individually.

NOTE: This sprayer is approximately 4.3 metres in

height and with aerials on the roof, can be much

B

higher. Check the regulations in your state for

maximum vehicle height restrictions. When driving

on roads it may be necessary to remove aerials to

meet the required height restrictions.

Aerials on the roof may also need to be removed to

meet clearance requirements for over head power

lines, while on the road and also in some paddocks.

A

D

C

BOOM

SIZE

A

FRONT

HEIGHT

36 m 4.30 m 3.50 m 9.85 m 4.45 m

42 m 4.30 m 3.50 m 10.40 m 4.45 m

48m 4.30 m 4.20 m 9.35 m 4.45 m

NOTE: Sprayer height is based on 520/85 R46 tyres tted and with

air bags deated.

B

WIDTH

C

TOTAL

LENGTH

D

WHEEL-

BASE

12 - Chapter 3 - General Information & Specs G8 Super Cruiser Operator’s Manual MY19 - REV 0

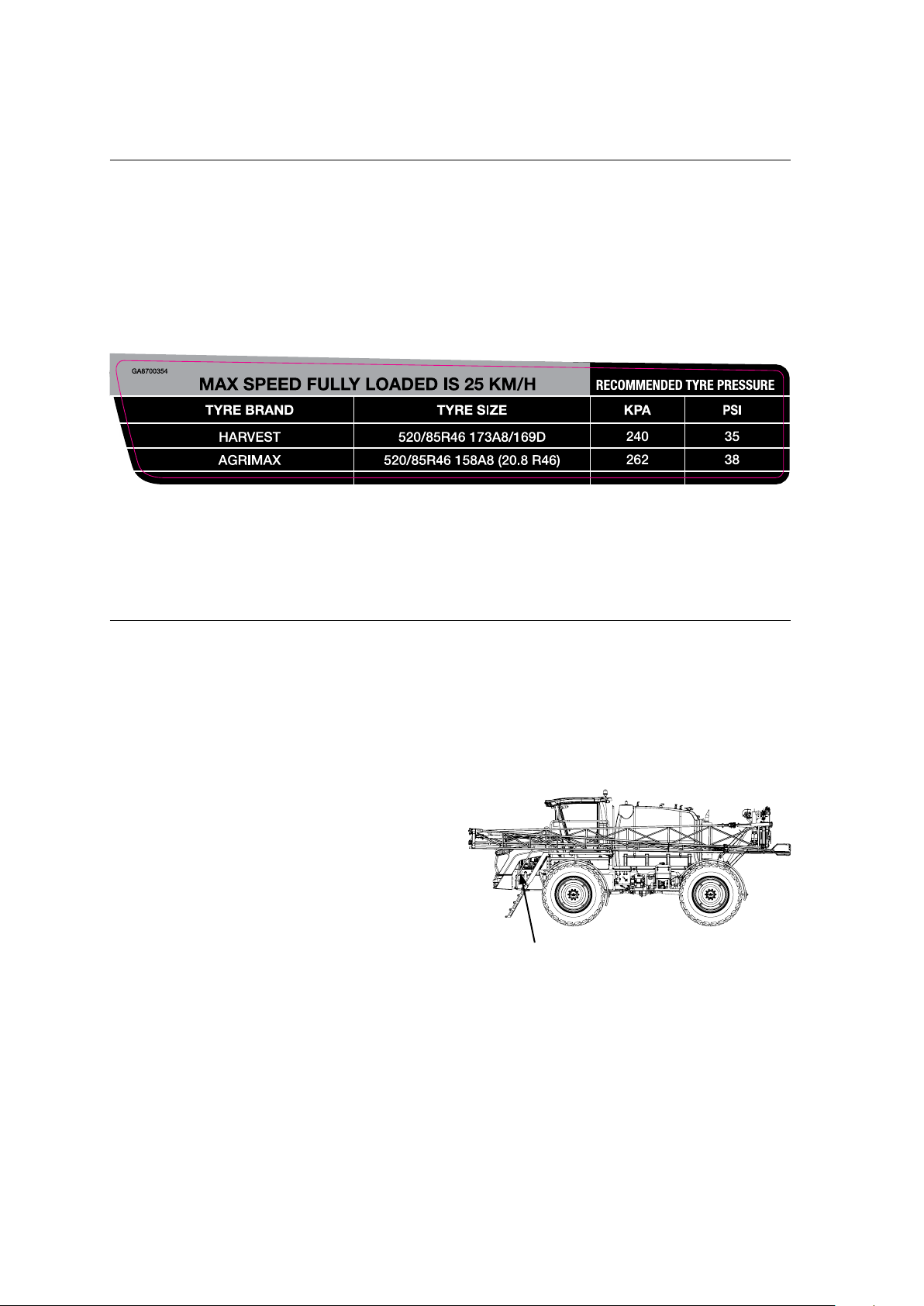

Wheels & Tyres

Tyre pressures need to be checked regularly - check

every 8 to 12 hours of operation.

There are many factors concerning the appropriate

tyre pressure for a particular tyre and load. For

example, the tyre size, rim type, tyre status (driven

or free rolling), load, speed, haul length and ply rating

all need to be considered when determining the tyre

pressure.

NOTE: PSI = Kpa x 0.145

EXAMPLE: 240 Kpa x 0.145 = 34.8 PSI

NOTE: If a tyre is replaced with a different brand

or size, please contact the supplier for correct air

pressures to suit the load carrying capacity of this

machine.

For further information on wheels and tyres please

refer to Chapter 10 ‘Lubrication & Maintenance’.

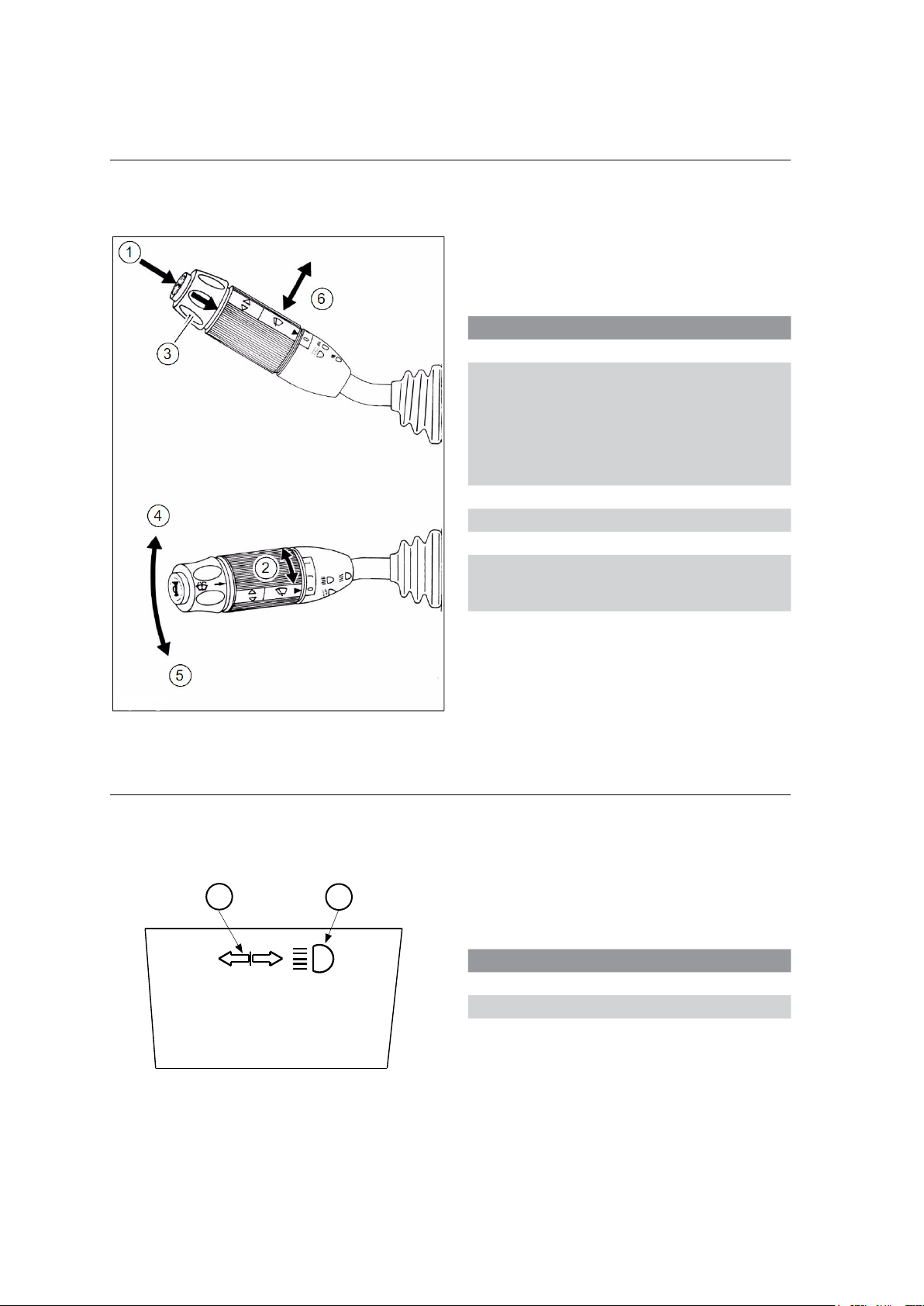

Identication & Parts Ordering

When ordering parts or requesting service

information for your sprayer it is important to quote

the serial number of your machine, and the purchase

date, in order to receive accurate information. The

location of the serial number plate on your machine

is shown in the picture.

NOTE: To identify the exact options tted to your

particular machine, refer to the original quotation

and/or build sheet. If needed, a copy of the build

sheet may be obtained by contacting your dealer

and quoting your machine serial number as

described above.

When ordering parts from your Goldacres dealer,

please quote:

• Machine serial number

• Part number required

• Part description

• Quantity required

The parts manual supplied with this machine

includes all the relevant information that you need

when ordering parts from your dealer. When

returning parts to a Goldacres dealer for service or

repair, all parts MUST be cleaned thoroughly before

sending them. Dealers cannot expose technicians

to the many potentially hazardous pesticides and

substances that are in use.

NOTE: Please ensure that all par ts are clearly

labelled with the owner’s details, and a brief

description of the fault. Dealers are not liable for

the return of any goods to a Goldacres Dealer. The

goods must be returned to the point of sale.

Genuine Goldacres parts only should be used on

Goldacres equipment.

ID plate located on the left

hand chassis rail near steps.

Chapter 3 - General Information & Specs - 13G8 Super Cruiser Operator’s Manual MY19 - REV 0

14 - Chapter 3 - General Information & Specs G8 Super Cruiser Operator’s Manual MY19 - REV 0

CABIN

Key Features

16

Chapter 4

1

15

10

9

5

11

12

NO. FEATURE

1. Over Head Console

2. Side Arm Rest Console

3. Rear Corner Console

4. Operators Seat

5. Steering Wheel & Controls

6. Training Seat

7. Fire Extinguisher (Under Training Seat)

8. Storage Area/Fridge - when optioned (Under Training Seat)

9. Power Distribution Box

10. Engine Monitor CAN

11. Spray pressure gauge - other positions not used

12. Storage Area (Under Operator’s Seat)

13. Operator Seat Belt

14. Fridge Switch (When Fridge Optioned)

15. Fold Out Cup Holder

16. Fuel Gauge

3

2

4

13

6

7

14

8

NOTE: Training seat

shown folded up.

Chapter 4 - Cabin - 15G8 Super Cruiser Operator’s Manual MY19 - REV 0

Armrest Controls - Raven Controller - 36-42m

2

3

8

7

6

1

5

4

9

10

11

16

NO. FEATURE

1. Joystick control

2. Raven CR7 universal terminal (Optional)

3. Engine monitor CAN

4. Transmission shifter

5. Boom rest IN/OUT

6. Boom fold IN/OUT

7. Boom bi-fold IN/OUT

8. Rinse tank/Main tank

9. Cruise ON/OFF - RPM Raise ON

10. Boom recirculation ON/OFF

11. Spray pump ON/OFF

12. GPS ON/OFF (if wired in)

13. Diff lock - Centre ON/OFF

14. Diff lock - Rear ON/OFF

15. Park brake

16. Fence line jet indicator

12

13

14

15

16 - Chapter 4 - Cabin G8 Super Cruiser Operator’s Manual MY19 - REV 0

Armrest Controls - Raven Controller - 48m

2

3

8

7

6

1

5

4

9

10

11

16

NO. FEATURE

1. Joystick control

2. Raven CR7 universal terminal (Optional)

3. Engine monitor CAN

4. Transmission shifter

5. Boom fold 3 IN/OUT

6. Boom fold 2 IN/OUT

7. Boom fold 1 IN/OUT

8. Boom catch CLOSE/OPEN

9. Cruise ON/OFF - RPM Raise ON

10. Boom recirculation ON/OFF

11. Spray pump ON/OFF

12. GPS ON/OFF (if wired in)

13. Diff lock - Centre ON/OFF

14. Diff lock - Rear ON/OFF

15. Park brake

16. Fence line jet indicator

12

13

14

15

Chapter 4 - Cabin - 17G8 Super Cruiser Operator’s Manual MY19 - REV 0

Joystick Controls - Raven Controller

6

4

5

7

9

NO. FEATURE

1. Boom lift/lower - Fenceline Nozzle Left/Right

2. GPS - Autosteer

3. Boom tilt left/right

4. Cruise cancel

5. Cruise resume/increase

6. Cruise set/decrease

7. Dual tilt UP/DOWN (On reverse side, not shown)

8. Spray master

3

1

2

18 - Chapter 4 - Cabin G8 Super Cruiser Operator’s Manual MY19 - REV 0

Operator Seat

7

6

9

3 4

1

2

5

NO. FEATURE INSTRUCTIONS

1. Fore / Aft Adjustment

2. Fore / Aft Locking lever

3. Seat Depth Adjustment

Seat Pan Angle

4.

Adjustment

5. Height Adjustment

6. Tilt

7. Arm Rest Adjust By turning this knob the arm rest can be lowered or raised to suit.

8. Lumbar

9. Seat Belt

By lifting this lever the seat can be slid backwards or forward to the

desired position.

Release this lever to enable the Fore & Aft adjustment of the seat, and

engage to lock the seat to the desired position.

To adjust the depth of the seat cushion, pull the handle upwards. By

moving the seat cushion backwards the desired seating position can be

reached.

To adjust the angle of the seat pan, pull the handle upwards. By exerting

pressure on or off the front or rear part of the seat pan it can be

moved to the desired position.

By lifting this lever air will be pumped in to the airbag suspension. By

lowering this lever air is exhausted from the air bag.

The lever on the right hand side of the seat allows the back rest to be

tilted forward or rearward. Pulling the lever forward releases the back

rest so it can be repositioned.

By turning this handle the lumbar in the back of the seat will increase or

decrease the pressure on the operators back.

Operator lap seat belt must be tted when ever the operator is seated