Goldacres Pro-Reel Operator's & Parts Manual

1

Pro-Reel

Operator’s & Parts Manual

50m - GA4904585

100m - GA4904584

150m - GA4906985

GA8700158 REV 6 MAY 17

2

General Information

and Specs ............................3

Specications ........................3

Pro-Reel Dimentions ...................3

Key Features .........................4

Set up ...............................5

Connecting to a power source ............5

Connecting to a water source ...........5

Connecting the ENGINE OFF ............5

Operation

Prepare for use .......................5

Instructions ..........................6

Goldacres Pro-Reel

®

Single Reel Controller

Conguration .........................7

Supplying Power to the Remote Unit and

the Pro-Reel

®

Control Box. ..............8

Pro-Reel

®

Control Box Conguration .....8

Restoring a Control Box to factory default

settings ..............................9

Troubleshooting. .....................10

Maintenance ........................11

Troubleshooting ......................12

Pro-Reel Assembly ...................13

Hose Guide Assembly .................14

Control Box, Antenna & Gun Mount .....15

100m Electric Motor & Guard Mounting ..16

Hose Reel 100m ......................17

150m Electric Motor & Guard Mounting ..18

Hose Reel 150m ......................19

Electrical Schematic ..................20

Turbo 400 spray gun ..................21

Safety Decals ........................22

Safety ..............................23

The Operator ........................23

Safety Precautions ...................23

Personal Protective Equipment (PPE) ....24

Warranty ............................24

Goldacres Warranty Statement .........25

Terms and Conditions .................26

NOTE: Front Page, Spray gun is shown, but is

an option only.

Contact

Goldacres

1-3 Morang Crescent,

Mitchell Park Vic 3355

P: 03 5342 6399

F: 03 5342 6308

info@goldacres.com.au

Please note: All information in this operator’s manual is based on the latest product information available at the time of printing.

The policy of Goldacres is one of continuous improvement and as such, Goldacres reserve the right to alter any specications and

designs without notice and without incurring any obligation regarding such changes. No part of this manual may be reproduced

without written permission from Goldacres. All photographs and technical information remain the property of Goldacres.

3

General Information

and Specs

General

The Pro-Reel hose reel is electrically driven

with 12V from the vehicle battery. Up to

150 metres of hose can be tted and a

gunjet provides for even and accurate spray

application.

Single or multiple units can be linked to an

appropriate tank and pump conguration.

Chassis:

The chassis is an all steel construction, that is

fully welded for superior strength. The chassis

is shot blasted, primed and then protected

by the Goldacres paint process for excellent

chemical resistance and durability.

Paint Colours:

Steel work:

G13 Dark Green

Specications

Dimensions

See page 11

Hose size

10mm

Hose length

50,100,150 metres

Pump

requirements

Min 20 l/min

Connections

50 Amp Anderson plug

(supplied)

Control type

Remote

Drive

12V electric

448

671

901

445

352

84

239

9

12

3

2

5

C

D

4

6

7

8

A

B

2015 100m Pro Reel Assembly

1-3 MORANG CR

MITCHELL PARK 3352

PH: 03 53426399

FAX: 03 53426308

GOLDACRES

TITLE:

671

901

5

C

D

4

6

7

8

A

B

2015 100m Pro Reel Assembly

1-3 MORANG CR

MITCHELL PARK 3352

PH: 03 53426399

FAX: 03 53426308

GOLDACRES

TITLE:

445

352

84

239

9

12

C

B

A

2

1

446

721

969

239 445

85

10.5

9.0

352

721

969

239 445

85

10.5

9.0

352

Pro-Reel 50

Pro-Reel 100

Pro-Reel 150

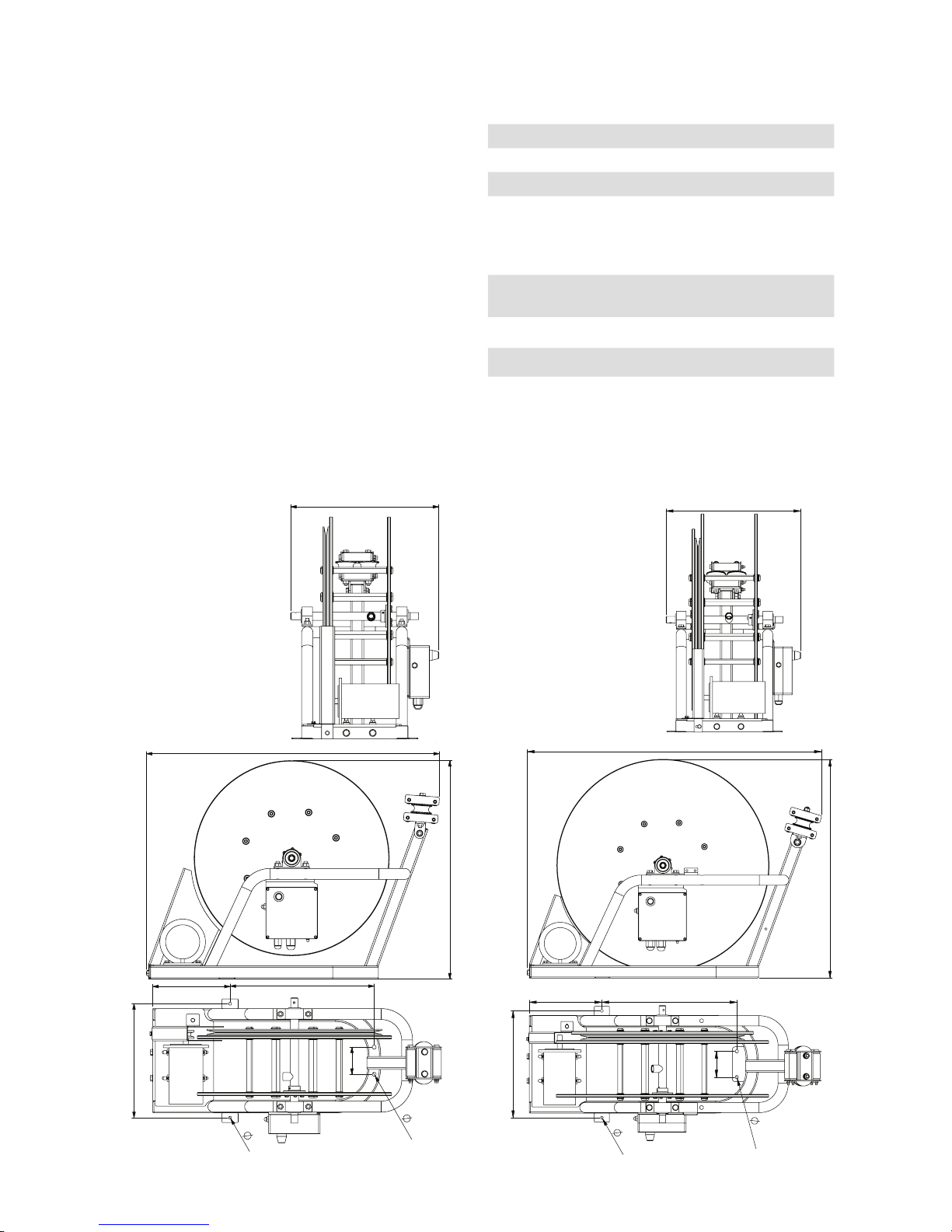

Pro-Reel

Dimentions

4

Key Features

No Part No Function

1 Hose Feeder

2 GA5063500 Electrical Control Box, Antenna, Remote and loom (complete assly)

3 GA5052970 Electrical motor

4 GA5023475 Spray Gun

5 V Belt Adjusters

6 GA5061710 Remote Aerial

7

Anderson Plug

8 GA 5061715 Remote Control Black

9 GA5061720 Remote Control Grey

10 GA5072390 PCB Board (457PN3-1000)

11 GA5072380 Switch Circuit Breaker

12 GA5053245 50amp Anderson Plug

13 GA5072541 Con guration Cable, 2.5mm Jack

14 GA5072545 Switch, Manaul over-ride

2

3

4

1

6

5

14

7

13

8

9

5

Connecting to a power

source

The following steps should be followed when

connecting to a power source:

1 Ensure that the battery is 12V DC and that

a 40amp, circuit breaker is tted to the

positive lead at the battery.

2. Using the Anderson plug supplied,

connect the red connector to the positive

(+) terminal and the black connector to the

negative (-) terminal. It is recommended to

get an electrician to wire this unit.

WARNING: Do not use the nominally 1.5V

Lithium cells in the remote unit as these

are in fact above 1.8V when new, and may

result in damage to the remote unit. Use

only high quality 1.5V alkaline cells for good

performance and product reliability.

Connecting to a water

source

The following steps should be followed when

connecting to a water source:

1 The ½” supply hose must have a pressure

rating that exceeds the pump pressure,

needs to be connected up to the hose reel.

2. Slide the supplied nut onto the hose, then

slide the olive on so there is about 4-5mm

of hose coming through the olive.

3. Fit the hose and tighten the nut to the ProReel.

Connecting the Engine

Remote Shutdown

WARNING: Do not have any power connected

for this operation.

1. Disconnect the 6 pin plug from the control

box.

2. Open the female plug that is on the electric

motor side. Remove the seal from the “E”

port

3. With a 3mm blue wire, t the supplied

green seal and crimp on the terminal pin.

4. Fit wire into the “E” port on the 6 pin plug

and press home until you feel a click. The

pin is seated. Close the cover on the plug.

5. Fit the two plugs together and ensure they

seat correctly.

6. Feed the blue wire to the pump motor ON

switch making sure that it is out of the way

of moving parts and will not get hot from

any parts of the engine.

7. Fit the wire to the earth wire on the engine

ON/OFF switch.

Operation

Prepare for use

1. Inspect the unit to ensure there is no

damage or wear which could lead to injury,

further damage or reduce its performance.

2. Check all hoses and ttings, including

spray gun, for leaks or damage.

3. Check all bolts and nuts to make sure they

are tight and secure.

4. The Pro-Reel hose reel is operated by

remote control and when tted should be

in a location which is easily accessible

with clearance between the reel and all

other items.

PROREEL CABLE SIZE CHART @ 12vdc / 30 amps

30 amp overload protection

Distance from battery to Anderson plug (mts) 1 2 5 7.5 10

Cable in mm

x2 2.5 6 16 25 25

AWG 13 10 6 4 3

Set up

6

Instructions

CAUTION: Keep hands, feet,hair and clothing

away from all moving parts to prevent injury.

NOTE: Hose will un-wind with a small amount

of restriction when pulled out by hand

Operation

1. While connected to a power source, the

unit is always powered.

2. Remove the linch pin and check the spray

gun.

3. Test the remote and manual rewind

functions. The manual “REWIND” button

is located on the control box.

4. Unwind the hose (taking care to not overrun the hose)

5. The hose can then be wound in by

pressing the “REWIND” button on the

remote control.

6. If the reel stops turning due to a hose jam

DO NOT continue to push the button or

damage may occur. Clear the cause of the

jam prior to further operation. If the remote

does not work after the jam, the control

box overload may need to be reset. Press

to reset.

7. When nished, rinse the line out with fresh

water.

8. Retract all the hose and remount the spray

gun.

9. When complete, disconnect the power at

the anderson plug.

Current overload reset button

7

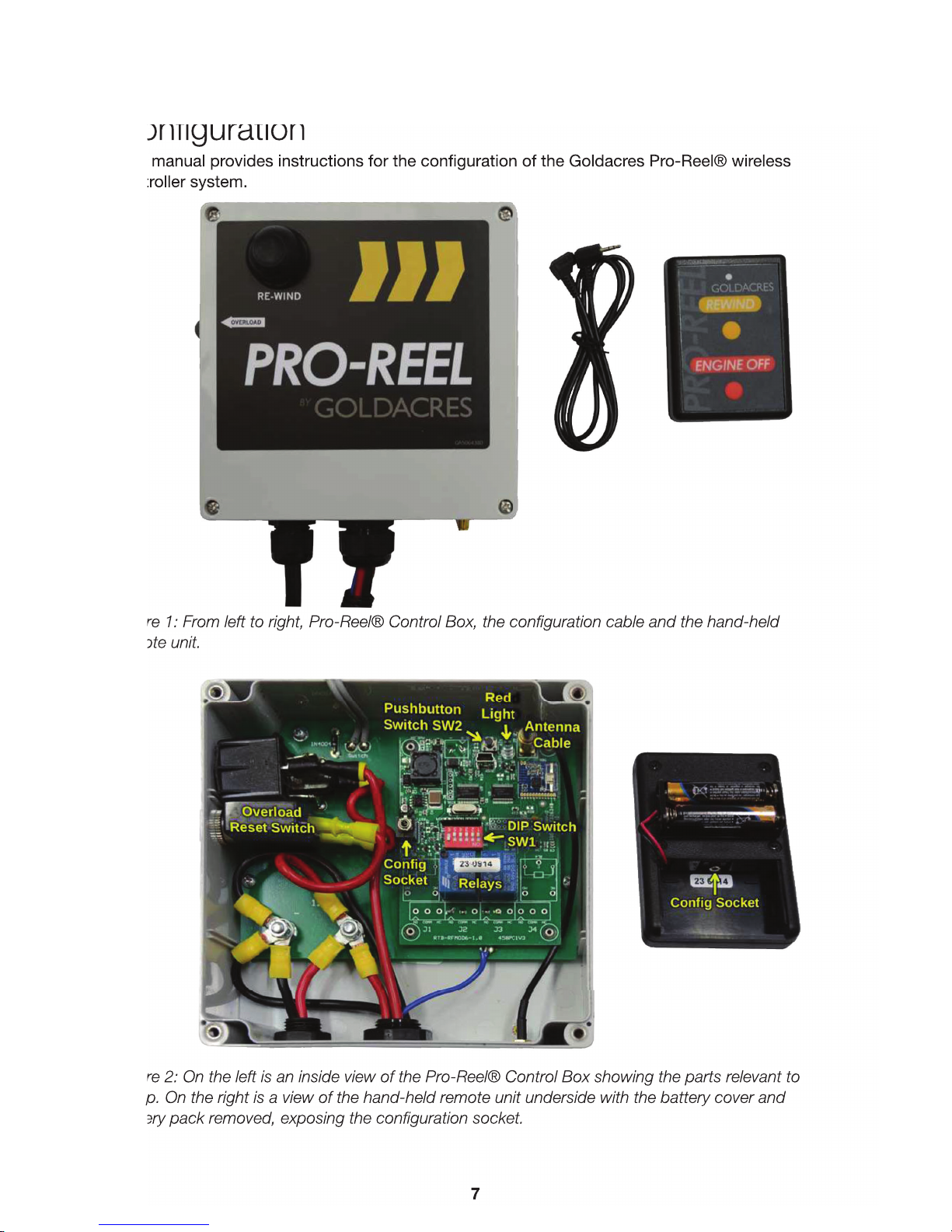

Goldacres Pro-Reel® Single Reel Controller

Con guration

This manual provides instructions for the con guration of the Goldacres Pro-Reel® wireless

controller system.

Figure 1: From left to right, Pro-Reel® Control Box, the configuration cable and the hand-held

remote unit.

Figure 2: On the left is an inside view of the Pro-Reel® Control Box showing the parts relevant to

setup. On the right is a view of the hand-held remote unit underside with the battery cover and

battery pack removed, exposing the configuration socket.

8

Supplying Power to the

Remote Unit and the

Pro-Reel® Control Box.

Refer to gure 2 on page 1 for information on

the locations of the various parts.

CAUTION: Ensure that battery polarity is

correct when inserting batteries into the

remote unit battery

compartment.

WARNING: Do NOT use the nominally 1.5V

Lithium cells in the remote unit as these are in

fact above

1.8V when new and may result in damage to

the remote unit. Use only high quality 1.5V

alkaline cells for

good performance and product reliability.

For the remote unit, ensure that a suitable pair

of 1.5V cells are inserted correctly into the unit.

The battery cover

is on the rear of the unit at the base. Two size

‘AAA’ cells will be required. Spring contacts in

the battery holder

always connect to the negative ends of the

cells. Also under the battery cover can be

found the con guration

socket (see gure 2 on page 1) which is a

2.5mm socket. This is used to connect the

remote unit and the control

box together with the supplied con guration

cable to enable programming of remote unit

buttons to control box

relays. The battery holder must be removed in

order to access the con guration socket of the

remote unit, but the

batteries should be left in the holder to ensure

that the remote unit is still powered.

The Pro-Reel® control box should already

be suitably con gured with 12V DC vehicle

battery power.

Pro-Reel® Control Box

Con guration.

Con guration of the system is required if

replacing a damaged or lost remote (hand held

transmitter) unit, since

each transmitter and receiver are paired using

unique identi er codes.

2.1 Con guring a Remote Unit to control a

Control Box’s relays.

In the event that a remote unit must

be replaced or a new one added to an

existing con guration, the following steps

will enable a new remote unit to be used

with an existing control box. The location

of relevant parts can be identi ed using

gure 2 on page 1.

CAUTION: Do not touch any component in the

control box except those parts referred to

in the following procedure.

1. Check that the DIP switch (SW1 in the

control box) is set as follows:

Figure 3: DIP Switch (SW1) setting. Note that

all switches are in the OFF position except

switch 6.

2. Connect the con guration cable between

the remote unit and the control box via the

con guration sockets. If done successfully,

the red light of each unit will light up

continuously. If both lights do not ensuring

that neither light is lit and then reconnect

the cable. (If, after several attempts to

establish the con guration connection, the

lights do not both remain lit, then consult

the troubleshooting section, section 3, of

this manual.)

3. Once the red lights of both the remote unit

and the control box remain lit while the

con guration cable is connected, press

and hold push-button switch, SW2, in the

control box until the control box’s red light

turns o , then release the push-button

switch. The control box’s red light should

remain o but the remote unit’s red light

should still be on.

4. On the remote unit, depress the Rewind

button. The light on the remote unit

should turn o and the light in the control

box should very brie y turn on and then

9

immediately o again.

5. Now depress the Engine O button on

the remote unit. The light on the remote

unit will turn back on and the light in

the control box should also switch on

and remain on. This indicates that the

conguration is complete.

6. Disconnect the conguration cable and

test the system by pressing each of the

two remote unit buttons in succession to

observe whether or not they perform as

required.

This completes the setup and test of a hand-

held remote unit with a Pro-Reel® control box.

If there are problems

with operation of the system, the control box

can be restored to factory settings as follows:

Restoring a Control

Box to factory default

settings.

Do not connect the conguration cable since

this operation is done to the control box alone.

1. Press and hold down the control box

push-button switch, SW2, for at least 12

seconds. Time this by counting slowly

to 12, during which time the red light will

switch on and o various times and for

various durations. When the required time

has elapsed, the light will blink on and o

continuously at a fast rate (ashing about

twice per second). This means that 12

seconds has elapsed.

2. Release the push-button switch. The

control box’s factory settings have now

been fully restored.

3. Perform the conguration process again,

as described in section 2.1, if required.

The control box factory restore process will

always restore settings back to their factory

defaults. If any settings

have been altered for an alternative mode of

operation, these will have to be congured

again.

Troubleshooting.

The following list of items may be used to

aid in fault nding if the control box fails to

respond to remote unit transmissions. Use

this when the control box is opened for

conguration of a new or replacement remote

unit if the equipment fails to perform correctly

upon conguration.

NOTE: Do not attempt repairs to the control

box internal circuitry or associated wiring

looms, connectors and external associated

equipment. This list is only intended as a basic

guide to resolve any minor issues or to simply

locate potentially major issues that may result

from wear of the equipment. Refer all servicing

to the product supplier.

CAUTION: Do not make physical contact

with any of the components in the control box

except to connect the conguration cable

to the conguration socket, to set the DIP

switch (SW1) as described in section 2.1 (if

it has been altered) and to press the pushbutton switch (SW2) as described in section

2.1. Contamination of circuitry or electrostatic

discharge into the circuit may result in

permanent damage to the control box.

1 Check control box power as described in

section 1. Ensure that adequate vehicle

battery power is available to the Pro-

Reel® control box and that it is correctly

connected. The system is designed for

12V DC automotive power supplies.

2. Press and release the Pro-Reel® control

box current overload reset button (on the

left side of the control box exterior) in case

an overload has occurred. If the unit now

works, it is advisable to inspect the system

to discover, if possible, what caused the

overload and rectify the problem.

3. Check that the hand-held remote unit

batteries are correctly oriented and that

they are serviceable. Replace them if

uncertain about their age. Never mix old

and new batteries or batteries of dierent

types. When replacing batteries, always

replace both with a pair of the same type

of batteries. Mixing batteries can result in

damage to the remote unit if either battery

leaks. Refer to section 1 regarding the

correct selection of battery types.

Loading...

Loading...