Goldacres Batchmate Operator's & Parts Manual

1

Batchmate

Operator’s & Parts Manual

GA4914520

GA8700153 REV 4 OCT 16

2

Contact

Goldacres

1-3 Morang Crescent,

Mitchell Park Vic 3355

P: 03 5342 6399

F: 03 5342 6308

info@goldacres.com.au

Disclaimer

Any advice or recommendations given by Goldacres, Goldacres’ dealers, or employees is given in good faith and provided based

on the best information available to us. No liability or responsibility is accepted or implied as a result of any information or advice

tendered in this operating manual or by Goldacres its agents or employees. The end user accepts all responsibility arising from

that advice. No part of this manual may be reproduced without written permission from Goldacres. All photographs and technical

information remain the property of Goldacres.

Operator’s Manual Part Number: GA8700153

General Information and Specs ..........3

Dimensions ..........................3

Key Features .........................4

Operation ............................5

Prepare for use .......................5

Instructions ..........................5

Add Granular chemical to main tank ......5

Add chemical from Chem Probe

- Empty tank ..........................5

Add chemical from Chem Probe

- Full tank ............................6

Transfer to Sprayer ....................6

Tank Cleaning ........................7

End of day tasks ......................7

Drain the main tank ....................7

Engine & Pump

Safety Alert ...........................8

Start Up & Installation ..................8

Engine & Pump - Troubleshooting ........9

Engine & Pump Warranty ..............10

Maintenance ........................11

Honda Engine .......................11

Air Cleaner ..........................12

Fuel ................................12

Starting the Engine ...................12

Operation ...........................13

Stopping the Engine ..................13

Maintenance ........................13

Maintenance Schedule ................15

Transport / Storage ...................15

Troubleshooting ......................16

Specications .......................16

Wiring Diagram ......................17

Main Tank & Frame ...................18

Washdown Gun ......................19

Hand Wash Tank .....................20

Tank inlet & Drain. . . . . . . . . . . . . . . . . . . . .21

Pre-assembled Rinse Valve Station ......22

Pump Plumbing Mounting .............23

Pump Plumbing Assembly .............24

Venturi,Chem Probe Assembly ..........25

Tank Rinse Elbow ....................26

Drain Elbow Assembly ................27

Main Tank Drain ......................28

Large Lid, Drum Rinse Assembly ........29

Small Lid, Drumbuster Assembly ........30

Safety Decals ........................30

Safety ..............................31

The Operator ........................31

Safety Precautions ...................31

Personal Protective Equipment (PPE) ....32

Goldacres Warranty Statement .........33

Terms and Conditions .................34

3

General Information

and Specs

General

The Batchmate allows you to mix and agitate

chemical in preparation for loading into your

sprayer – taking the work out of loading

powders or granules and speeding up your

sprayer ll cycle.

Fitted with a high capacity 3” poly pump and

powerful twin agitation system, the Batchmate

delivers maximum chemical agitation and high

tank ll rates to add speed and eciency to

sprayer loading tasks.

Chassis:

The chassis is an all steel construction, that is

fully welded for superior strength. The chassis

is shot blasted, primed and then protected

by the Goldacres paint process for excellent

chemical resistance and durability.

Paint Colours:

Steel work: G13 Dark Green

Tank:

All tanks are constructed from UV resistant

polyethylene. Polyethylene tanks have a very

high chemical resistance.

Due to the rotomoulding process, there can be

a variance in the overall dimensions of the tank

which in turn results in variations to the tank

capacity. For this reason, calibration markings

should be used as a guide only.

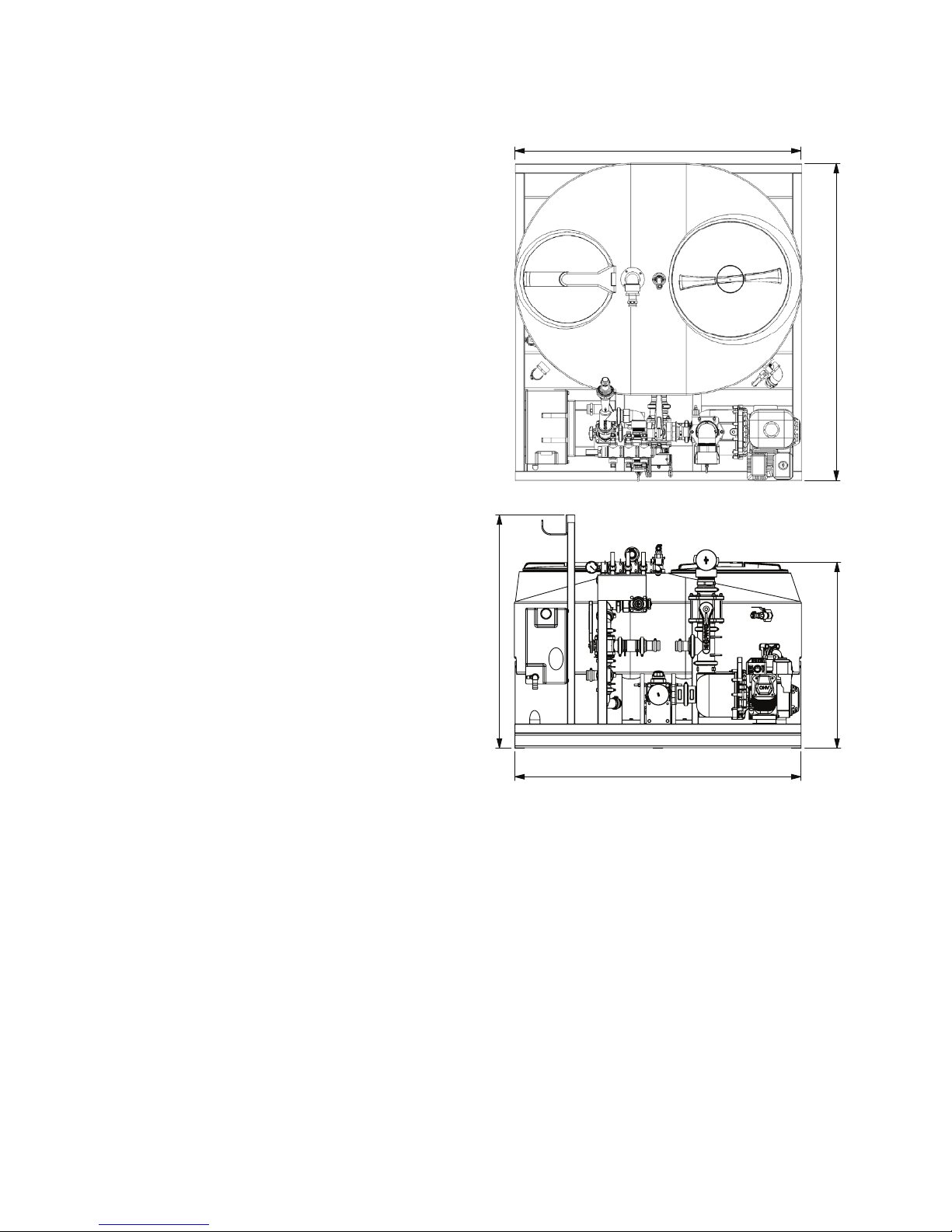

Dimensions

4

1229

1507

981

1670

1507

5

4

6

7

8

4

Key Features

Ref No Function

1 Suction Valve

2 Suction Valve Inlet

3 Chem Probe Coupling

4 Agitator, Venturi, O Valve

5 Fresh water hand wash

6 Main Tank Drain (not Shown)

7 Pressure Gauge

8 Rinse Valve Station

9 Drumbuster

10 Tank Rinse

Ref No Function

11 Drum Rinse

12 Drum Rinse Tap

13 Sprayer Fill outlet

14 Sprayer Fill Valve

15 Honda Engine

16 Aussie Pump

17 Wash down hose

1

3

4

8

9

10

11

12

13

14

15

17

7

5

2

16

5

Operation

Prepare for use

1. Inspect the unit to ensure there is no

damage or wear which could lead to

injury, further damage or reduce its

performance.

2. Check all hoses and ttings, including

rinse gun, for leaks or damage.

3. Check all bolts and nuts to make sure they

are tight and secure.

4. Check all ball valves and taps are easy to

move.

5. Check engine as per included

manufacturer’s operator manual.

6. Check pump as per included

manufacturer’s operator manual.

Instructions

CAUTION: Do not run pump dry as this may

cause damage to the pump.

CAUTION: Never leave the “AGITATOR

VENTURI OFF VALVE” in the OFF position

when the pump is running

NOTE: Ensure you operate the unit on level

ground to prevent oil alert being activated.

NOTE: Only clean fresh water FROM WATER

SOURCE should be used for rinsing drums in

the DRUM RINSE.

If the chemical is to be added through the

Chemical Probe connection, this can be done

during the tank lling process or after the tank

has the required amount of water.

Add Granular chemical

to main tank

1. Follow steps in “Prepare for use”

instructions as above.

WARNING: PPE must be on during this

procedure.

2. Remove quick release coupling cap from

the Suction Valve inlet

3. Connect suction hose to the Tank Fill Inlet.

4. Turn the SUCTION VALVE to the FROM

WATER SOURCE position. Lever cross

ways.

5. Ensure the SPRAYER FILL ball valve is in

the OFF position, horizontal.

6. Ensure the ball valve on the left is in the

AGITATOR ON position.

7. Follow instructions for use of the pump

for lling as per pump manufacturers

operators manual included.

8. Start the engine.

9. Fill the tank with approx 300L of fresh

water, or to just above the agitator ll

ports.

10. Turn the SUCTION VALVE to FROM

BATCHMATE so the water is cycling

through the tank.

WARNING: PPE Cut and Puncture

resistant gloves to Level 4 should be worn.

11. Open the smaller lid on the main tank and

add the chemical required by tipping in or

use the Drumbuster implement to empty

the drums.

12. Close the lid of the tank.

13. Turn the SUCTION VALVE to the FROM

WATER SOURCE position. Lever cross

ways.

14. To rinse the drums, if required, open the

red ip valve DRUM RINSE, then open

the large lid of the tank, cover the nozzle

with the drum then turn on the Drum Rinse

Tap to rinse, when nished turn the tap o

before removing the drum. When drums

are rinsed, replace the lid on the tank and

turn o the DRUM RINSE ip valve.

15. When the water level is reached,turn the

SUCTION VALVE to FROM BATCHMATE.

This will keep the chemical mixed and

ready to be transferred to a sprayer tank.

Add chemical from Chem

Probe - Empty tank

1. Follow steps in “Prepare for use”

instructions as above.

WARNING: PPE must be on during this

procedure.

2. Remove quick release coupling cap from

6

the Suction Valve inlet.

3. Connect suction hose to the Suction Fill

Inlet.

4. Turn the SUCTION VALVE to the FROM

WATER SOURCE position. Lever cross

ways.

5. Ensure the SPRAYER FILL ball valve is in

the OFF position, horizontal.

6. Ensure the ball valve on the left is in the

VENTURI ON position.

7. Attach the Chem Probe hose to the

camlock coupling on the front of the

BATCHMATE.

8. Follow instructions for use of the pump

for lling as per pump manufacturers

operators manual included.

9. Start the engine.

10. When the water is owing through, open

the ball valve CHEMICAL PROBE and

empty the drums. Close the valve when

drums are empty.

11. To rinse the drums, open the red ip valve

DRUM RINSE, then open the large lid of

the tank, cover the nozzle with the drum

then turn on the Drum Rinse Tap to rinse,

when nished turn the tap o before

removing the drum. When drums are

rinsed, replace the lid on the tank and turn

o the DRUM RINSE ip valve.

12. When the required amount of water has

been reached, turn the SUCTION VALVE

to FROM BATCHMATE.

13. Turn the left valve to AGITATOR ON. This

will keep the chemical mixed and ready to

be transferred to a sprayer tank.

Add chemical from

Chem Probe - Full tank

1. Follow steps in “Prepare for use”

instructions as above.

WARNING: PPE must be on during this

procedure.

2. Remove quick release coupling cap from

the Suction Valve inlet.

3. Connect suction hose to the Suction Valve

Inlet.

4. Turn the SUCTION VALVE to the FROM

WATER SOURCE position. Lever cross

ways.

5. Ensure the SPRAYER FILL ball valve is in

the OFF position, horizontal.

6. Ensure the ball valve on the left is in the

AGITATOR ON position.

7. Follow instructions for use of the pump

for lling as per pump manufacturers

operators manual included.

8. Start the engine.

9. When the required amount of water has

been reached, turn the SUCTION VALVE

to FROM BATCHMATE.

10. Move the ball valve on the left to VENTURI

ON position.

11. Attach the Chem Probe hose to the

camlock coupling on the front of the

BATCHMATE.

12. When the water is owing through, open

the ball valve CHEMICAL PROBE and

empty the drums. Close the valve when

drums are empty.

13. To rinse the drums, open the red ip valve

DRUM RINSE, then open the large lid of

the tank, cover the nozzle with the drum

then turn on the Drum Rinse Tap to rinse,

when nished turn the tap o before

removing the drum. When drums are

rinsed, replace the lid on the tank and turn

o the DRUM RINSE ip valve.

14. Turn the left valve to AGITATOR ON. This

will keep the chemical mixed and ready to

be transferred to a sprayer tank.

Transfer to Sprayer

1. Follow steps in “Prepare for use”

instructions as above.

2. Remove quick release coupling cap from

the Sprayer Fill outlet

3. Connect pressure hose to the SPRAYER

FILL outlet point and t the other end to

the sprayer inlet point.

4. Turn the SUCTION VALVE to the FROM

BATCHMATE position.

5. Ensure the SPRAYER FILL ball valve is in

the ON position, vertical.

7

6. Ensure the ball valve on the left is in the

OFF position.

7. Start the engine.

8. Chemical will start to be transfered to the

sprayer tank. When tank is empty, stop

the engine, close all valves.

Tank Cleaning

1. Follow steps in “Prepare for use”

instructions as above.

2. Remove quick release coupling cap from

the Suction Valve inlet.

3. Connect the fresh water suction hose to

the Suction Valve Inlet.

4. Turn the SUCTION VALVE to the FROM

WATER SOURCE position. Lever cross

ways.

5. Ensure the SPRAYER FILL ball valve is in

the closed position, horizontal.

6. Ensure the ball valve on the left is in the

AGITATOR ON position.

7. Follow instructions for use of the pump

for lling as per pump manufacturers

operators manual included.

8. Start the engine.

9. Turn on the Tank Rinse Valve to clean the

main tank. Run for at least 5 minutes.

10. After about 2 minutes, move the ball valve

on the left to VENTURI position.

11. Attach the Chem Probe hose to the

camlock coupling on the front of the

BATCHMATE.

12. Have a drum with clean water, place the

Chem Probe into the drum, open the ball

valve CHEMICAL PROBE and empty the

drums. Close the valve when drum is

empty.

13. Turn o the Tank Rinse valve

14. Turn on the valve for the Rinse Gun and

the Drum Rinse. Use the Rinse Gun to

dilute any chemical on the outside of the

tank and turn on the tap to run fresh water

through the drum rinse nozzle. Close o

all valves.

15. Turn the left valve from VENTURI to OFF.

16. Open the SPRAYER FILL valve and

turn the SUCTION VALVE to FROM

BATCHAMTE. This will put the rinsate into

the sprayer main tank.

17. Run the pump intil near empty, and turn

the engine OFF.

18. Open the Main Tank Drain to empty the

feed lines to the pump. Be careful where

the drainage from the tank is being

deposited as it may contain chemical

residue. Close ball valve when nished

draining.

End of day tasks

NOTE: Store the equipment in a suitable

location to prevent freezing. If the equipment

is to be left where freezing may occur, cover

the pump with a material bag and empty

pump of all water by removing the bung in the

bottom of the pump. Make sure any ice has

thawed before using. Open all ball valves to

prevent cracking of the ball valve housing by

ice.

Drain the main tank

CAUTION:

• The main tank-drain is to be used solely

for draining. Do not ll through the main

tank-drain line.

• If this unit has been used with chemicals

be careful where the drainage from the

tank is being deposited as it may contain

chemical residue.

The main tank should be drained through the

main tank-drain ball valve. This line drains

from the bottom elbow in the tank and almost

all the tank liquid will drain through this line.

To drain, open the main tank-drain ball valve.

When nished draining, make sure the main

tank-drain ball valve is closed.

The batchmate has two drain valves, the rst

one will drain the majority of the liquid from

the tank and plumbing, the other drain valve

is located at the base of the poly pump. Note

when the pump is drained it will need to be

re-primed before use.

Please ensure both drain taps are turned o

and system is primed before operating the

batchmate.

8

Engine & Pump

Safety Alert

To get the best out of your Aussie Pump these

important warning notices need to observed.

1 Four stroke petrol engines supplied with

Aussie Pump products use unleaded

gasoline.

2 Pump must be primed before starting.Fill

pump body with liquid. Pump must not

be allowed to run without liquid passing

through the casing. DO NOT run pump

either dry or with insucient water supply.

Pump supply or delivery lines must not be

shut o.

3 Do not use the pump in a gaseous

or hazardous environment or near

combustible material.

4 Do not use the pump in an enclosed area,

engine exhaust could build up and cause

asphyxiation.

5 Do not refuel engine while operating.Shut

engine down before refueling.

6 Do not run pump dry.

7 Some engine components will get hot

during operation. Do not touch engine

components while engine is running or

immediately after operation. For details

check engine operator’s manual.

8 Do not let children operate the pump.

9 Familiarise yourself with the pump’s

controls with emphasis on how to stop the

pump quickly.

10 Always refuel in a well ventilated area, do

not smoke or allow ames or sparks in the

refuelling area or where gasoline is stored.

11 Do not over ll the fuel tank, as spilled fuel

can ignite if it comes into contact with hot

engine parts or sparks. After refueling,

make sure tank cap is closed properly and

is secure.

12 Protect your pump from pressure spikes

by installing a by-pass or pressure relief

valve if sudden shut o of the water ow is

likely to occur.

13 If your pump is supplied with an Absorbed

Glass Mat dry cell battery gel battery, the

battery must be recharged using a Trickle

Charge battery charger.Contact a battery

specialist for further assistance.

14 Do not pump hydrocarbons with this

pump.

For maximum performance, eciency

and life, operate the pump at the best

eciency point … 85% of total pump

head.

Start Up & Installation

When installing an Aussie self priming pump,

always remember that the closer the pump is

placed to the source of supply the better the

performance will be.

To ensure maximum capacity select a site that

will permit the shortest and most direct suction

piping and smallest vertical lift.

Connecting the Suction Hose

Use commercially available hose, hose

connector and hose bands. The suction

hose must be of reinforced non collapsible

construction. Suction hose length should not

be longer than necessary as the longer the

suction hose, the less delivery performance

of the pump. Self priming time is also

proportional to suction hose length!

A strainer should always be used on the end

of the suction hose to keep solids out of the

pump.

Check carefully to make sure there are no air

leaks in the suction line and that the rubber

gaskets are in good condition.

Priming

Remove the priming cap at the top of the

delivery port. Fill pump body with water and

ret priming cap tightly.

Open gate valve on delivery line if tted, turn

on engine and run at full speed during priming.

Allow up to 3 minutes to prime.

Never attempt to operate pump without

priming rst. Extended dry operation will

destroy pump seal.

If unit has been run dry, stop the engine

immediately, allow the pump to cool before

adding priming water.

9

Hydraulic Shock

If the water ow is suddenly terminated by

closing a valve, without stopping the pump

rst, it can cause hydraulic shock. This can

travel back to the pump causing serious

damage. To prevent pump damage install a

by-pass or safety relief valve.

Cavitation

Your pump is cavitating if knocking noises and

vibrations can be heard when it is operating. If

you continue to operate your pump when it is

cavitating, it will be damaged.

How to avoid cavitation

• Minimise the number of valves and bends

in suction line

• Suction length should be as short as

possible

• Suction pipe should be at least the same

diameter as the pump inlet connection

• Use long radius bends

• Do not allow air into the suction line

• Ensure adequate submergence, at least

5.3 times the suction hose diameter

Handy service hints

1. To maximize pump life, drain pump after

use and ush out with clean, fresh water.

2. Read engine manufacturer’s owner’s

manual thoroughly and service as

recommended.

3. Store pump in a dry, safe location when

not in use.

4. If storing for long periods, drain fuel from

engine and tank.

5. Aussie Quik Prime pumps are specically

designed to pump water. Pumping other

liquids may shorten life and impact on

warranty.

6. Pumping water containing solids will

prematurely wear pump components, and

may impact warranty.

7. Ensure that the correct size strainer is

installed on the suction hose at all times,

even on trash pumps.

Engine & Pump - Troubleshooting

SYMPTOM POSSIBLE PROBLEM SOLUTION

Pump does not take

on water.

Not enough priming water in the

housing?

Add water

Engine speed too low? Increase throttle

Strainer plugged? Clean strainer

Suction hose damaged? Replace or repair hose & clamps

Air leak at suction port? Check that ttings are tight & sealed

Pump is located too high above

water line?

Move pump closer to water

Debris collecting in pump

housing?

Clean pump housing

Too much distance between

impeller and volute.

Adjust clearance by adding shims or

replace impeller. Min. .010" -Max. .020

Water leaking out weep hole

between pump and engine?

Check condition of mechanical seal

& gaskets, between pump end and

engine housing

Suction lift or discharge head too

high.

Check hose/pipe installation

10

Engine & Pump

Warranty

Aussie QP 5 year warranty

Australian Pump warrants all Aussie QP self

priming centrifugal pumps, whether used for

domestic or commercial applications, to be

free of faulty workmanship or material for a

period of 5 years from the date of supply to

the end user.

Aussie will replace or repair, at our discretion,

any faulty pump free of charge subject to the

following conditions.

Engine Warranty

Warranty for engines tted to Aussie Pump

products is the responsibility of the engine

manufacturer or his representative and subject

to their terms and conditions, and operating

instructions included with the product.

The Aussie Pump 5 year warranty naturally

does not cover the following:-

1. Normal wear and tear, misuse, improper

installation, negligent handling, failure to

follow operating instructions or to carry

out maintenance.

2. Pumping of chemicals, salt or corrosive

uids.

3. Unauthorised repair or attempted repair

(i.e. not authorised by Australian Pump)

4. Shipping or transit damage

5. Use of non-genuine parts.

The warranty is valid only for the original

consumer purchaser and non transferable.

NOTE:- This warranty is limited to the cost of

the product and does not include third party

costs including pump installers, plumbers

etc. unless expressly authorised by Australian

Pump Industries in writing.

Contact your Goldacres Dealer to arrange a

warranty claim

SYMPTOM POSSIBLE PROBLEM SOLUTION

Pump takes in

water, little or no

discharge.

Engine speed too low? Increase throttle speed

Suction strainer partially plugged? Clean strainer

Impeller/volute worn? Adjust clearance by adding shims or

replace impeller/volute

Suction hose leaks

at inlet

Fittings/clamps are not sealed

properly?

Tighten, replace or add clamp. (Keep

extra seals on pump)

Hose diameter is too large? Use smaller diameter hose or replace

hose

Discharge hose

does not stay on

coupling.

Pressure too high? Check pressure, add additional clamp

Hose kinked or end blocked? Check hose

Impeller does not

turn, pump is hard

to start.

Impeller jammed or blocked? Open pump cover and clean dirt and

debris from inside housing

Impeller and volute binding? Adjust clearance by removing shim

from behind impeller

11

Maintenance

To ensure that you get the most from your

Batchmate, it is important to regularly maintain

and service.

Service Interval Daily Weekly Monthly Yearly

Nuts and bolts Inspect Inspect Inspect Inspect

Hoses and ttings Inspect Inspect Inspect Inspect

Tank (empty) Inspect Inspect Inspect Inspect

Ball valves Open & inspect Open & inspect Open & inspect Open & inspect

Honda Engine

Engine Oil

• Engine oil is a major factor a ecting

engine performance and service life.Nondetergent oils and vegetable oils are not

recommended.

• Be sure to check the engine on a level

surface with the engine stopped.

Use Honda 4-stroke oil or an equivalent

high-detergent, premium quality motor oil

certi ed to meet or exceed U.S. automobile

manufacturer's requirements for Service

Classi cation SG.SF/CC.CD. Motor oils

classi ed SG.SF/CC.CD. will show this

designation on the container. SAE IOW-30 is

recommended for general, all-temperature

use. Ambient temperature use. Other

viscosities may be used when the average

temperature in your area is above the

recommended range for SAE 10W-30.

NOTE: Running the engine with insu cient oil

can cause serious damage.

Loading...

Loading...