Goldacres ATV75 Operator's & Parts Manual

ATV75

Operator’s & Parts Manual

GA8700277 REV 1.0 SEP 16

ATV75 - GA4905985

2

Revision number: 1.0

12-109-2016

Operator’s Manual Part Number: GA8700277

Contact

Goldacres

1-3 Morang Crescent,

Mitchell Park Vic 3355

P: 03 5342 6399

F: 03 5342 6308

info@goldacres.com.au

Please note: All information in this operator’s manual is based on the latest product information available at the time of printing.

The policy of Goldacres is one of continuous improvement and as such, Goldacres reserve the right to alter any specications and

designs without notice and without incurring any obligation regarding such changes. No part of this manual may be reproduced

without written permission from Goldacres. All photographs and technical information remain the property of Goldacres.

General Information & Specs ............3

Identication .........................3

Dimensions ..........................4

Operation ............................4

Calibration ...........................4

Spray Application .....................5

Storage ..............................5

Key parts ............................6

Pressure regulator - parts ..............6

Suction lter - parts ...................6

Maintenance & Troubleshooting .........6

Spraylance gun .......................7

12v pump wiring diagram ...............7

12v Shuro 8000 Pump 6.8 l/min 107 psi ...7

Safety Decals .........................8

Important Safety Message for Owners &

Operators ............................9

Safety ..............................10

The Operator ........................10

Safety Precautions ...................10

Safe use of chemicals .................11

Personal Protective Equipment (PPE) ....11

Warranty ............................12

Goldacres Warranty Statement .........13

Terms and Conditions .................14

DFO, Pressure regulator kit, ATV 75 .....16

3

General Information

& Specs

Tank:

All tanks are constructed from UV resistant

polyethylene. Polyethylene tanks have a very

high chemical resistance.

Due to the rotomoulding process, there can

be a variance in the overall dimensions of the

tank which in turn results in variations to the

tank capacity. For this reason, any calibration

markings should be used as a guide only.

Filtration:

Filtration is a critical part of the sprayer’s

performance.

ATV75 is tted with an inline suction strainer.

It is important that the strainer is cleaned out

regularly.

Pump:

The pump is critical to any sprayer

performance. Correct operation and

maintenance of the pump will ensure the

sprayer is able to perform to its capabilities.

Make sure the pump wires are connected up

to the correct terminals (red to positive, black

to negative).

Always ush pump with clean water after every

use. Prolonged chemical contact can severely

damage valves, diaphragms and seals.

Do not leave water in pump if sprayer is to

be left in a cold environment. The water may

freeze and cause damage to pump. Empty

pump of all water and cover the pump to

ensure this situation does not arise. If this has

not been done, and there is a possibility there

may be frozen water in the pump, wait until

any ice has thawed before using the pump.

The 12 volt pumps are positive displacement

diaphragm pumps which provide delivery upon

demand.

They are self-priming and some models are

tted with a pressure switch which senses

the outlet pressure of the pump. The pressure

switch turns the electrical power o to the

pump at a pre-determined high pressure point.

As the outlet side of the pump is opened,

the pressure starts to drop and at a predetermined point (typically 40-75 psi) contacts

in the switch will lose causing the pump

to start automatically. The pump will then

pump until the pressure reaches the shut-o

pressure point.

CAUTION:

Do not adjust the pressure switch out so that

the pumping pressure exceeds the maximum

pressure for the pump.

If the ow demand is very low, the pump may

reach this high pressure point and cause

“cycling” (pump turns on and o rapidly).

This is not a problem unless the pump is

subject to continuous cycling within two

second intervals for long periods of time.

Altering the setting of the pressure switch, or

adjusting the agitation ball valve so that there

is some bypass back to the tank and altering

the adjustable conejet nozzle on the gunjet will

all remedy this situation, depending on what is

most suitable.

Chemical Induction:

Chemical should be put into the main tank

through the main tank lid. It is important to

ensure that chemical is thoroughly mixed prior

to spray application.

Nozzles:

As information regarding nozzles is specic

to those being used in your application,

no specic reference is made to nozzle

application rates or nozzle types in this

operator’s manual. Goldacres suggest the

use of a current nozzle selection catalogue

for reference to nozzle sizes, outputs, spray

patterns and general spraying information.

Goldacres recommends Lechler nozzles.

Identication

When ordering parts or requesting service

information for your sprayer it is important to

quote the serial number of your machine, and

the purchase date, in order to receive accurate

information. The location of the serial number

is shown in the picture.This number is located

on the warning decal as indicated below.

4

Operation

Connections

The following steps should be followed when

connecting to a power source:

1. Ensure that the battery is 12V DC

2. Connect the red connector to the positive

(+) terminal and the black connector to the

negative (-)terminal.

Filling

When lling the sprayer it is necessary to

use an external water source and wear the

appropriate PPE.

The following steps should be followed when

lling the tank:

1. Turn the pump o

2. Remove the tank lid

3. Add chemical as required. When lling

with water, after adding the chemical,

some agitation will take place.

4. Use external water source to ll main tank

(Do not exceed the tank capacity)

5. Replace the tank lid and ensure that it is

secure prior to switching on pump. You are

now ready to use the sprayer.

Calibration

All sprayers need to be calibrated and kept

in good condition. This will ensure that the

correct rate of chemical is applied to the

target.

Follow these steps to calibrate the sprayer:

1. Measure the spray width of the nozzle on a

dry surface (in metres)

2. Spray a test area at the intended pressure

and speed. Record distance (in metres)

covered in one minute (minute)

3. Measure the nozzle output in litres over

one minute in a measuring jug (l/min)

The spray volume can be calculated by the

following formula:

Application Nozzle output (l/min) x 10,000

rate (L/Ha) = Spray width (m) x speed (m/min)

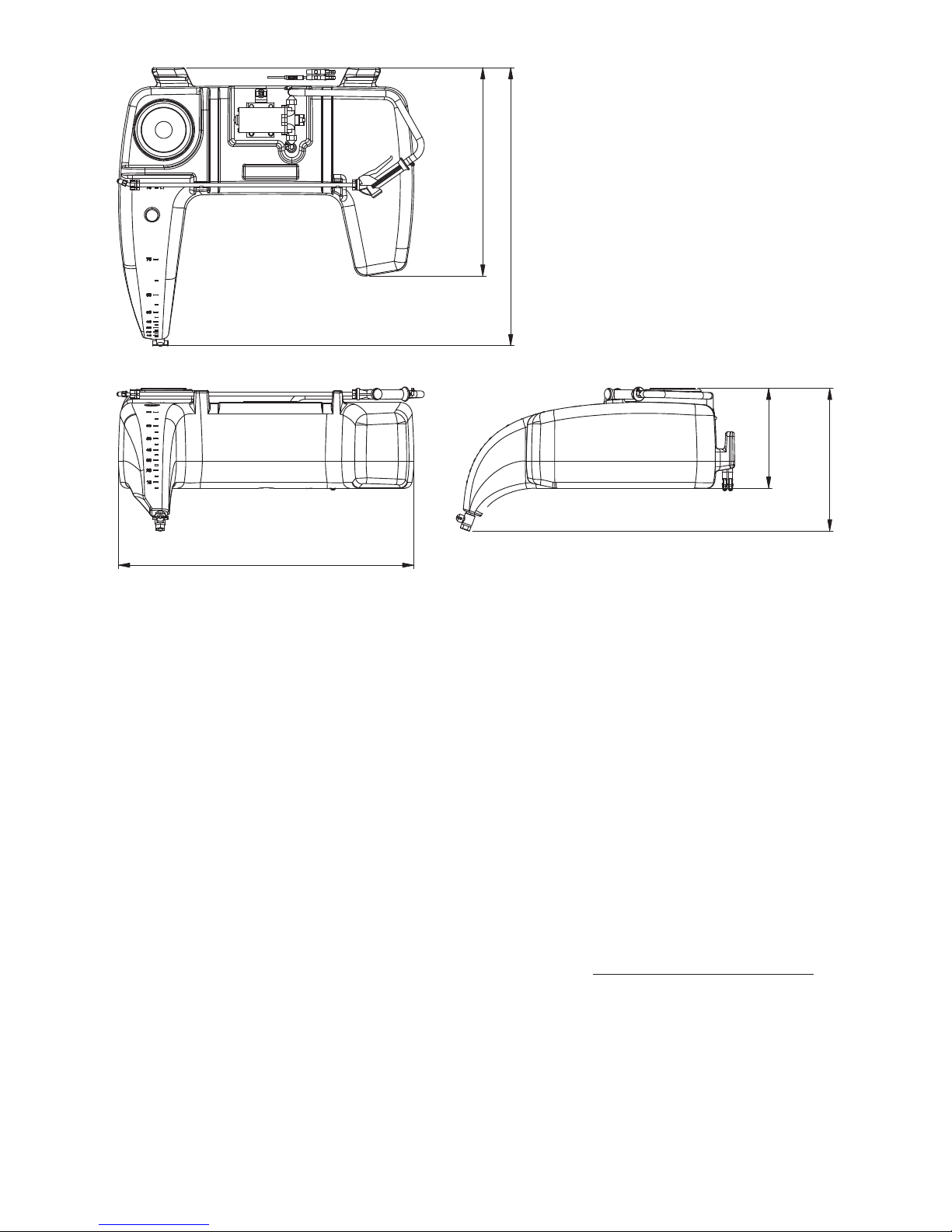

Dimensions

614mm

294mm

420mm

870mm

819mm

5

Key parts

Spray Application

After completing the lling process, you are

now ready to start spraying.

NOTE: It is the responsibility of the operator

to ensure that the chemical mix is suciently

agitated and that the conditions are right

to start spraying. Operators must wear the

appropriate PPE.

1. Switch “On” pump

2. Allow pump to build pressure

3. Engage the trigger on the spray lance to

start spraying

4. Adjust the nozzle pattern as required

by rotating the nozzle in the appropriate

direction

5. Use a consistent speed or swath pattern

to ensure even coverage of the target, or

adjust the method of application according

to your target

Agitation

Agitation should take place when lling or

through another method as deemed suitable

by the operator.

Flushing

The following information is provided as a

general guide for ushing your sprayer after a

spray application

For more specic information regarding

ushing, and decontamination, specic

to the products that you are applying, it is

recommended that you consult the chemical

label or your chemical supplier.

1. Turn pump o

2. Add a quantity of fresh water to main tank

and then drain.

3. Add a quantity of fresh water, and

decontaminating agents if required, to

main tank.

4. Turn on pump, and spray fresh water

through the lance / gun. This will ensure

that fresh water has circulated through the

pump and lance.

5. Drain remaining contents of fresh water.

The sprayer is now ready for storage.

Storage

If the sprayer is to be stored for a long period

of time without use, there are several tasks

that need to be performed.

1. Clean the sprayer thoroughly as described

under “ushing”

2. Store the sprayer out of direct sunlight and

where it will not be aected by frosts

3. Ensure that the main tank is empty

4. Protect hoses and electrical connections

Pos Part No Description Qty

1 GA5071300

75 Ltr Atv

tank with lid

1

2 GA5023400

Shuro 8000

pump

1

3 GA5022255

Wiring Loom

with in line

fuse

1

4 GA1100003

CT Trigger

gun CP500

1

5 38720-PPB Nozzle 12

6 HOS10P

10mm

Pressure hose

1

7 GA4523505

Serial Number

Plate

1

1

5

6

4

3

2

7

6

Problem Possible Cause Possible Remedy

Pump not priming Valves damaged

Restriction in suction line

Restriction in delivery line

Diaphragm damaged

Check, clean and/ or replace valve

kit

Check suction line

Check delivery line

Replace diaphragm

Pulsating liquid ow Pump switching on and o due

to pressure switch

Pump sucking air

Alter settings of the pressure switch

Alter the adjustable conejet nozzle

Restricted pump delivery

Check suction line

Pump pressure lower

than expected

Suction lter screen blocked

Restriction in suction line

Valves damaged

Diaphragm damaged

Pump sucking air

Insucient voltage

Clean screen

Check hoses, ttings and tank outlet

Check/or replace valve kit

Check/or replace diaphragm

Check suction line

Check power supply

Pump stopping and

starting when not in

use

Valves damaged

Insucient voltage

Damaged diaphragm

Check valves

Check power supply

Check/or replace diaphragm

Maintenance &

Troubleshooting

The troubleshooting information is provided

as a reference when your sprayer is not

functioning correctly. To ensure that you

receive the best possible service, it is

recommended that you exhaust all applicable

troubleshooting solutions shown prior to

calling your dealer for service advice.

Suction lter - parts

Pos Part No Description Qty

1 305010 Filter 1

2 GA5012199 Grommet 1

3 GA5015187 Elbow ½” to ⅜” 1

*Fitted as option

Pressure regulator* - parts

Pos Part No Description Qty

1 23120-1/2-PP Regulator Valve 1

2 GA4948470

Small face 160

psi Gauge

1

3 TEE050 ½” Female Tee 1

4 HB050038

½” to ⅜” straight

hose tail

1

5 NIP050 ½” Nipple 1

6 GA5071400

½” through tank

tting

1

7 GA5020615

½” Male/Female

ball valve

1

1

1

5

6

4

3

3

2

7

2

7

Spraylance gun

The model CP500 spraylance is a lightweight

lance designed for use with low pressure

spraying systems. The Spraylance is made of

moulded polypropylene and stainless steel for

excellent chemical resistance and durability.

Features:

• 600mm spraylance

• Locking valve in open position for

continuous ow

Repair Kit for CP500 - GA5071440

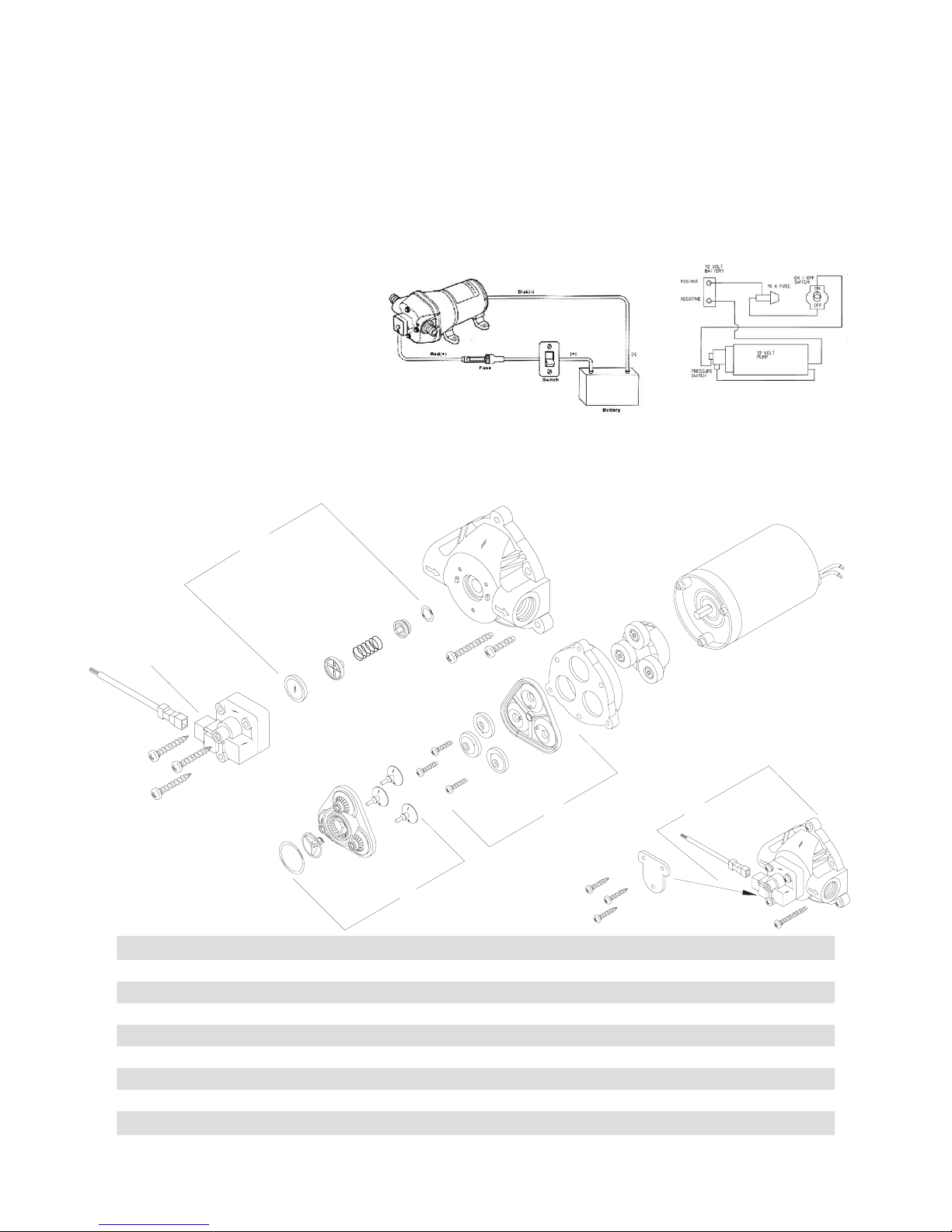

12v pump wiring

diagram

Important: Use 14 gauge stranded wire up to 6

metres from power source and 12 gauge up to

18 metres from power source.

Connect Red to Positive (+) terminal and Black

to Negative (-) terminal.

Service Kits

Kits are readily available to repair standard

8000 series pumps. Repair kits include

simple illustrated instructions allowing easy

installation. To insure that the correct kit is

received the model number and all name

plate data must be included with the order.

12v Shuro 8000

Pump 6.8 l/min 107 psi

1

7

3

2

5

Pos Part No Description Qty

1 Complete assembled pump head 1

2 GA5071545 Pressure switch assembly 1

3 GA5071560 Check valve components 1

4 Upper housing 1

5 GA5071550 Bypass valve and discharge valve assembly 1

6 Valve plate assembly 1

7 GA5071555 Diaphragm and piston components 1

8 Drive assembly 1

9 Motor assembly (less base plate) 1

8

Safety Decals

Understanding safety decals and their purpose

assists in the safe operation of your sprayer.

Safety decals are there for your protection and

it is the responsibility of the owner operator

to replace damaged and/or missing safety

decals.

Regularly review safety decals with operators.

It is very important to ensure that all new

machine components and replacement parts

include current hazard identication decals.

Replacement safety decals can be ordered

from all Goldacres dealers.

GA8700409 ATV75 – Tank decal kit – Left & Right hand sides

GA5060617 Warning Label and Serial No.

GA8700410 ATV75 – Complete decal kit includes

Left & Right hand side tank decals and all warning label

Loading...

Loading...