Page 1

SPRAY

OPERATOR´S

MANUAL

to ensure

the correct usage

of the IK Vector

Control sprayer

VECTOR CONTROL

BY EXPERTS FOR EXPERTS

Page 2

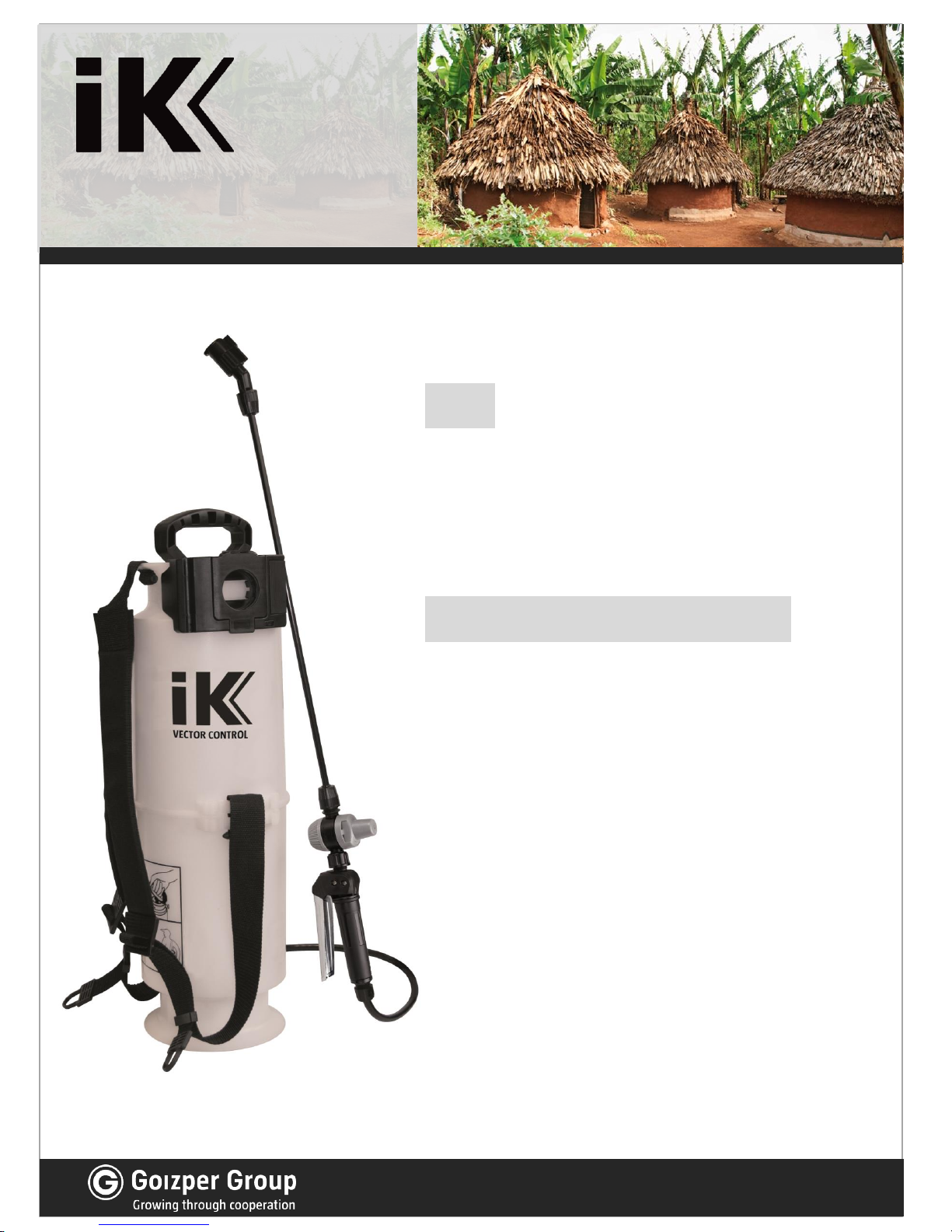

PUBLIC HEALTH

BY EXPERTS FOR EXPERTS

USE

IK VECTOR CONTROL

PUBLIC HEALTH applications, especially for

control of Malaria, Dengue and Chagas disease

vectors . In compliance with the most demanding

International Standards for Vector Control

spraying equipment.

TECHNICAL CHARACTERISTICS

• Efficient, Light, robust and safe

• Spray able wall surface: 250 m2

• Useful capacity of the tank 7,5 ltr. equipped

with Control Flow Valve

• Double filtering system

• Nozzle protector to avoid nozzle blockages

• Equipped with long life nozzles with excellent

erosion resistance properties: 3 even fan

nozzles for IRS and 1 nozzle for larviciding

• Storage box for carrying spare nozzles & filters

• Pressure, Corrosion and U.V. resistant

translucent tank (easy reading of liquid volume)

• Equipped with Security valve

• Extremely light pump (net weight less than 2

Kg.)

• Equipped with double adjustable strap system

• Reinforced hose

• Easy to clean and maintain. 100% tool free

• Service Kit available

www.goizper.com

T.: +34 943 786 000

Page 3

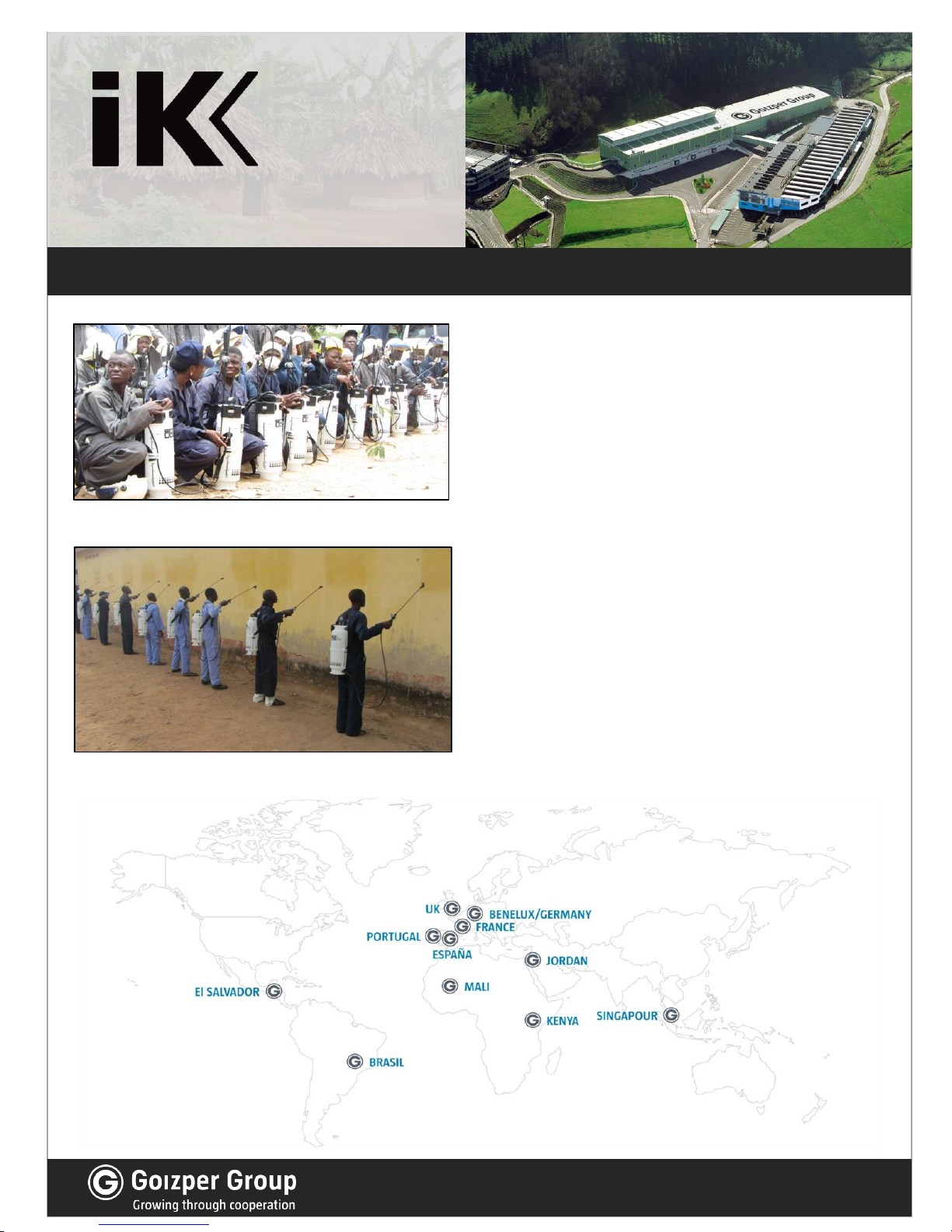

GOIZPER VECTOR

CONTROL

IK Vector Control professional sprayer

Training Services

Goizper S.Coop., with its headquarters in

Spain is a leading manufacturer

worldwide specialised on Spraying

Solutions.

For more than 50 years Goizper has

developd an extensive network of

distributors backed up by its own 10

delegations (4 in Europe, 1 in South East

Asia, 1 Middle East, 2 in Africa, 2 in

America)

Goizper develops its own brands (Matabi,

Osatu, Inter, IK) for different applications

in Vector Control, Agriculture, Public

Health, Construction, Automotive or

Industrial Sprayers.

PUBLIC HEALTH

www.goizper.com

T.: +34 943 786 000

Page 4

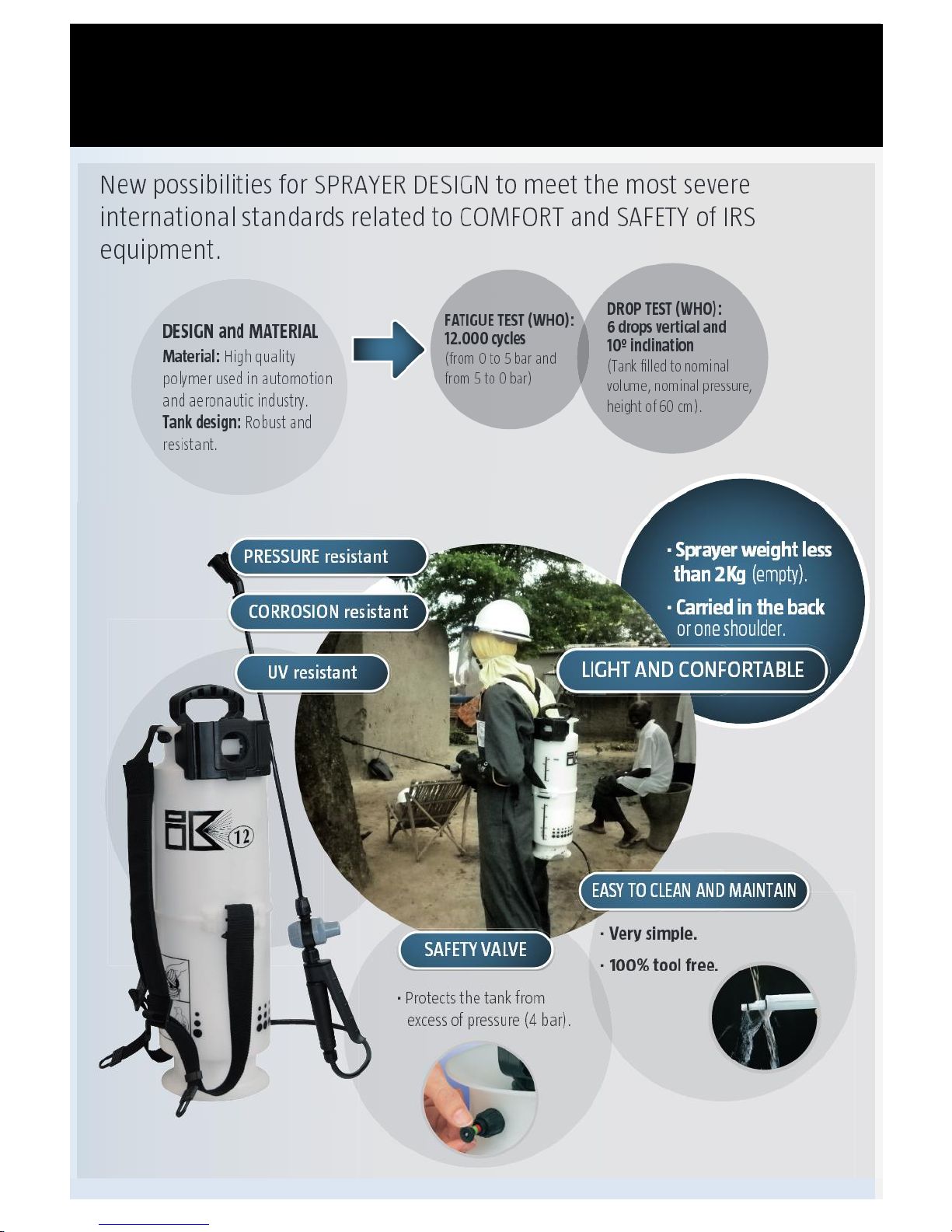

NEW ADVANCED MATERIALS and

New MANUFACTURING PROCESS

Page 5

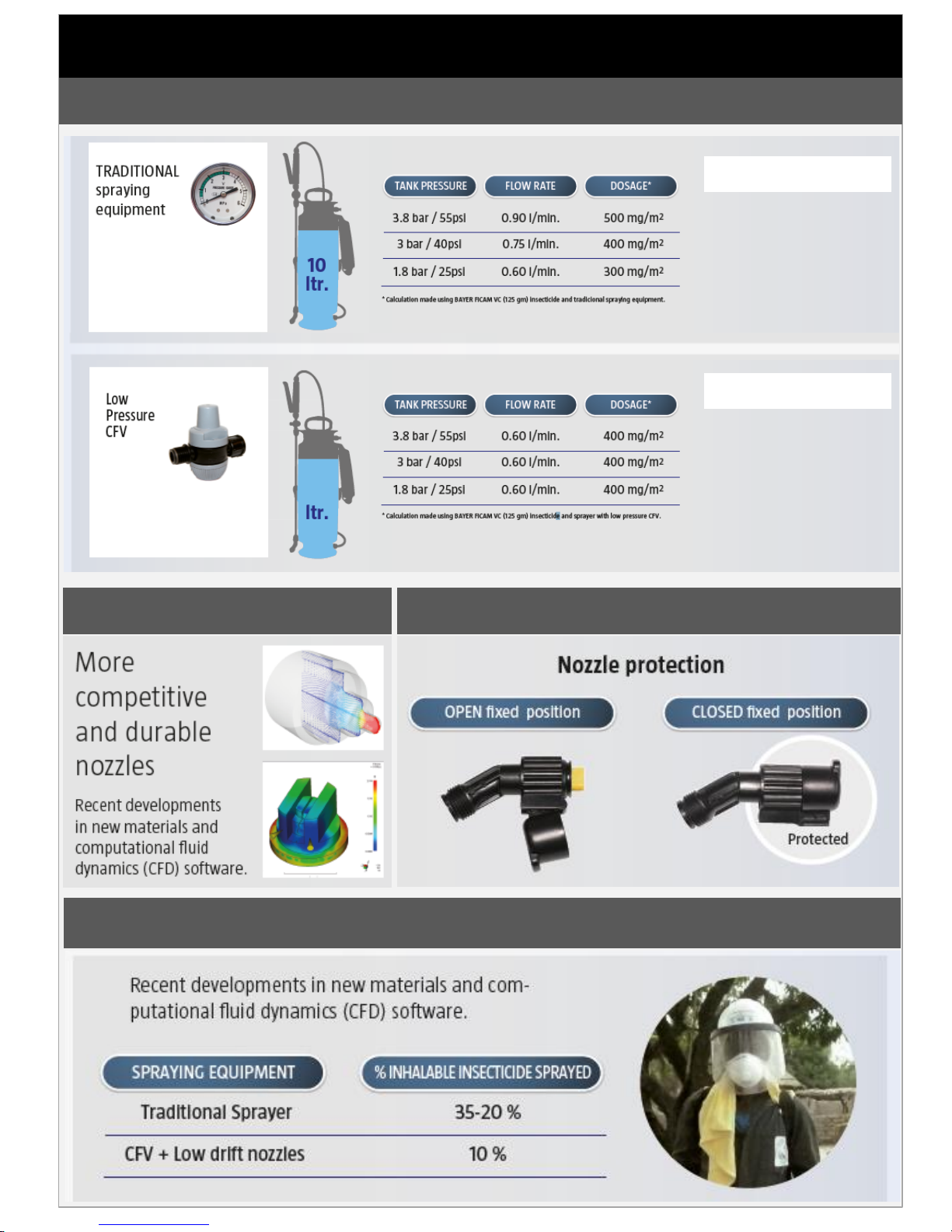

NEW Advanced Nozzles Nozzle Protector to avoid BLOCKAGES

Reducing Operators Contamination Risk

NEW TOOLS TO IMPROVE IRS

APPLICATIONS

Low Pressure Control Flow Valve (CFV): Uniform Insecticide Dosage

Considerable variation in

the DOSAGE of insecticide

(aprox. ±25%) measured

on wall surfaces.

Conclusions:

1.BETTER EFFICIENCY:

uniform dosage of

insecticide is sprayed

during all the operation.

2.SAVING WATER: 25 %

less water is used (7,5 ltr

instead of 10 ltr.)

Conclusions:

7,5

Pressure gauge.

Tank pressure and nozzle

flow varies condierably

Operator has to decide

when to STOP

Nozzle flow rate constant

Automatic STOP

.

.

.

.

.

Page 6

A

B

B

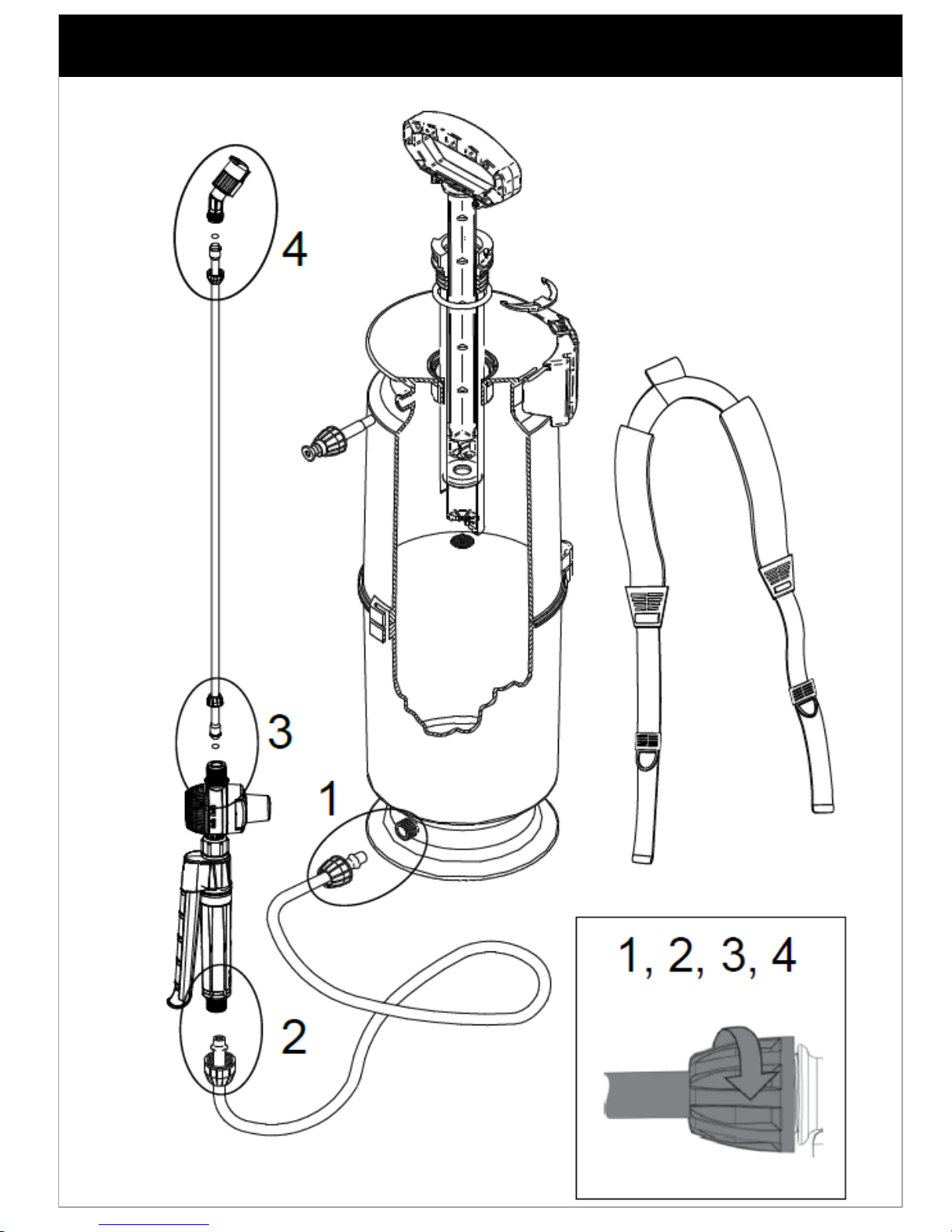

1. ASSEMBLY

Page 7

1. ASSEMBLY

1.1. Straps

1.2. Hose

Page 8

1. ASSEMBLY

1.3. Tie all nuts tightly

1.4. Nozzle Orientation

Page 9

1. ASSEMBLY

1.5. Nozzle Protector

1.6. Parking Lance

OPEN

CLOSE

Page 10

1. ASSEMBLY

1.7. Hose Parking

1.8. Nozzle storage box

Page 11

2. CARRYING

2.1. BACK or ONE Shoulder

2.2. Strap length rregulation

In the BACK One Shoulder

Page 12

3. FILLING AND PRESSURIZING

3.1. Release pressure before opening the tank

3.2. Pump parking

Page 13

3. FILLING AND PRESSURIZING

3.3. Correct insecticide mixing

3.4. Pressurizing

7,5 ltr.

4 ltr.

MAX

(3-4 ltr.)

50

Page 14

4. CALIBRATION AND SPRAYING

4.1. Nozzle Protector

4.2. Calibration

Page 15

4. CALIBRATION AND SPRAYING

4.4. Control Flow Valve (CFV)

7,5

AUTOMATIC FLOW RATE REGULATION

Sprayable wall surface area: 250 m

2

AUTOMATIC SPRAYING CUT OFF

when the minimum recommended

pressure has reached in the tank

Page 16

5. SPRAYING TECHNIQUE

Page 17

6. CLEANING AND MAINTENANCE

9. Open the lid of the

Control Flow Valve and

clean it thoroughly with

water

Page 18

6. CLEANING AND MAINTENANCE

Nozzle cleaning

MAINTENANCE: OIL or GREASE

Page 19

6. CLEANING AND MAINTENANCE

Spare parts and service kit

- Handle filter w/joints.

- Elbow with nozzle.

- Viton Collar seal.

- Viton Closing valve.

- Safety valve.

- Viton Round gaskets.

Available with the

most frequently

requested spares.

Page 20

Loading...

Loading...