GoGaS Goch KMI 20 - 1, KMI 40 - 1, KMI 60 - 1, KMI 90 - 1, KMI 120 - 1 Installation, Operation And Service Instructions

...

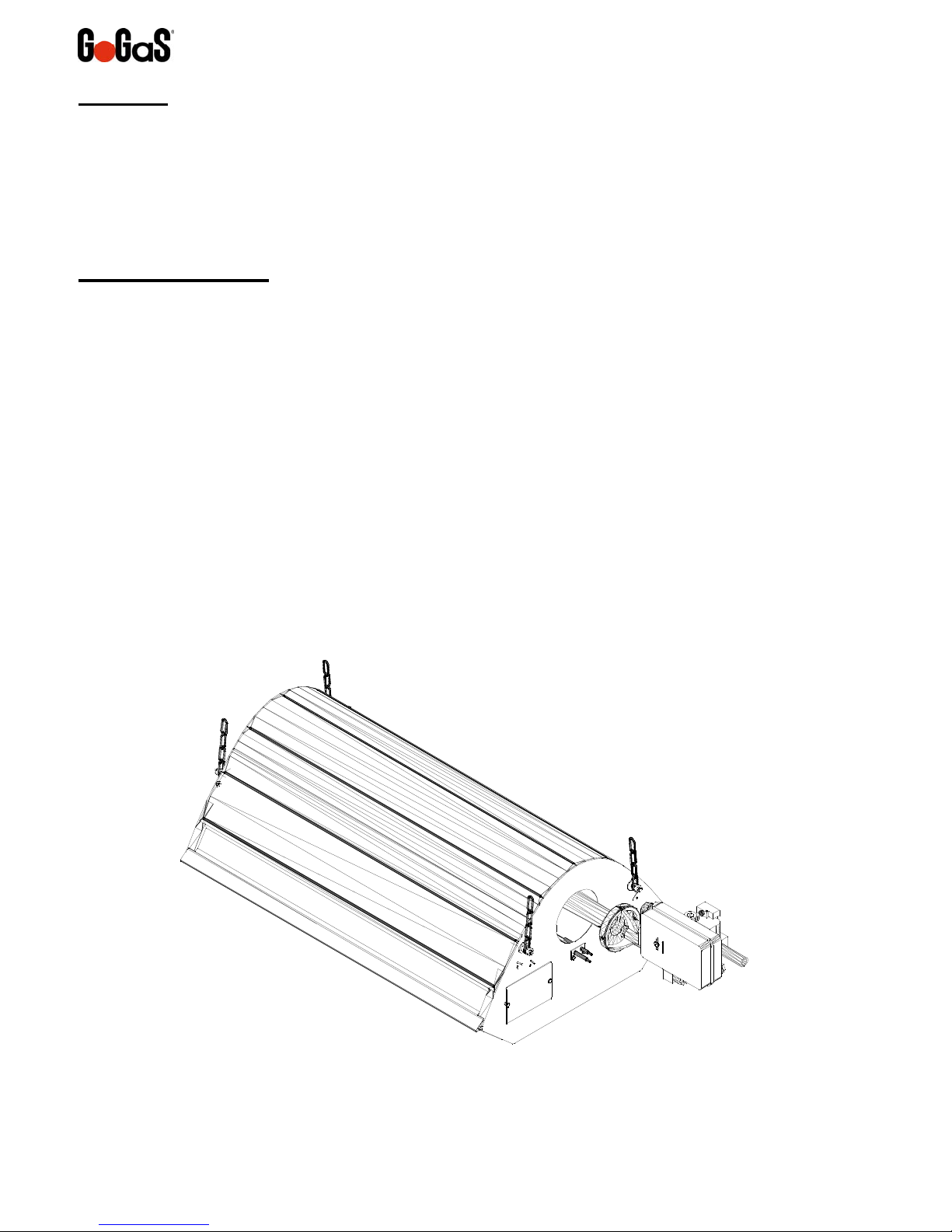

Series KMI High Intensity Heater

Installation, Operation and Service Instructions

KMI 20 - 1

KMI 40 - 1

KMI 60 - 1

KMI 90 - 1

KMI 120 - 1

GoGaS Goch GmbH & CO. KG

Zum Ihnedieck 18

44265 Dortmund - Germany

Phone +49 231 46505-0

Fax +49 231 46505-88

FOR YOUR SAFETY

If you smell gas:

1. Open windows

2. Don´t touch electrical switches

3. Extinguish any open flame

4. Immediately call your gas supplier

CONSIGNES DE SECURITE

Si vous sentez une odeur de gaz:

1. Ouvrez les fenêtres

2. Ne touchez pas aux interrupteurs

électriques

3. Éteignez tout flamme nue

4. Contactez immédiatement votre

fournisseur de gaz

Read and thoroughly understand these instructions before attempting any installation.

Retain this manual for reference.

Installer

Owner

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

CONSIGNES DE SECURITE

Il est interdit d’utiliser des liquides

inflammables ou dégageant des

vapeurs inflammables, a proximités

de tout appareil fonctionnent au gaz.

Goch GmbH & Co. KG

Improper installation, adjustment, alteration, service or maintenance can cause injury, death

or property damage. Read the installation, operation and service instructions thoroughly

before installing or servicing this equipment.

WARNING

Superior Radiant Products

www.superiorradiant.com

LT152 November 4, 2013

CAUTION: FIRE OR EXPLOSION HAZARD

Maintain clearance to combustible constructions as further specified in this manual.

Failure to do so could result in a serious fire hazard. Heaters should not be located in

hazardous atmospheres containing flammable vapours or combustible dusts. Signs

should be provided in storage areas specifying maximum safe stacking height.

CAUTION: MECHANICAL HAZARD

This equipment is designed and approved for indoor use only. This product is not

intended to be installed indoors in residential applications.

CAUTION: FIRE OR EXPLOSION HAZARD

This heater equipped with an automatic ignition device. Do not attempt to light the

burner by hand. Failure to comply could result in a serious fire and personal injury

hazard.

CAUTION: MECHANICAL HAZARD

Do not use high pressure (above ½ psi) to the test gas supply system with the burners

connected. Failure to do so could results in damage to the burner and its control

components requiring replacement.

CAUTION: SERVICE LIFE RISK

Do not install equipment in atmospheres containing halogenated hydrocarbons or other

corrosive chemicals. High intensity heaters are not recommended for installation in

enclosed swimming pool areas. Failure to do so may lead to premature equipment

failure and will in-validate the warranty.

Serires KMI - 2 - November 4, 2013

Goch GmbH & Co. KG

TableofContents

PREFACE.......................................................................................................................................4

THETECHNOLOGY........................................................................................................................4

IMPORTANT.................................................................................................................................5

GENERALINFORMATION..............................................................................................................5

NSTALLATIONCODES.........................................................................................................................................5

I

G

ENERALINSTALLATIONANDGASCODES/ELECTRICALCODES...................................................................................5

A

IRCRAFTHANGARINSTALLATION........................................................................................................................5

P

UBLICGARAGES...............................................................................................................................................5

P

ARKINGSTRUCTURES........................................................................................................................................5

ARNING:........................................................................................................................................................5

W

LAYOUTCONSIDERATIONS...........................................................................................................6

S

POTHEATING..................................................................................................................................................6

S

UGGESTEDHEATLOADINGFORINDOORSPOTHEATINGUNDERSTATEDCONDITIONS:...................................................7

F

ULLBUILDINGHEAT..........................................................................................................................................7

ENGINEERINGSPECIFICATIONS.....................................................................................................8

E

NERGYSUPPLY.................................................................................................................................................8

M

INIMUMCLEARANCESTOCOMBUSTIBLES...........................................................................................................9

INSTALLATIONSINSTRUCTIONS..................................................................................................10

H

IGHINTENSITYMOUNTINGINSTRUCTIONS/CONFIGURATIONS.............................................................................10

HorizontallyMountedHighIntensityHeater...........................................................................................................10

Angledhighintensityheater....................................................................................................................................12

A

IRPLATEINSTALLATIONINSTRUCTIONS..............................................................................................................13

Procedure:................................................................................................................................................................13

ASCONNECTIONS..........................................................................................................................................14

G

LECTRICALCONNECTIONS................................................................................................................................15

E

Single‐stageelectricalconnection/WiringDiagram..............................................................................................16

ENTILATION...................................................................................................................................................17

V

ONDENSATION............................................................................................................................... ................17

C

OPERATION................................................................................................................................18

S

INGLE‐STAGEHIGHINTENSITYHEATER...............................................................................................................18

ControlOperatingSequence....................................................................................................................................18

Controlling/CheckingManifoldPressure...............................................................................................................18

NNUALMAINTENANCE...................................................................................................................................19

A

TROUBLESHOOTING...................................................................................................................20

REPLACEMENTPARTSECTION....................................................................................................21

WARRANTY................................................................................................................................22

Serires KMI - 3 - November 4, 2013

Preface

GoGaS high intensity heaters represent an efficient and comfortable alternative to conventional

heating systems. The infrared gas fired heater is an atmospherically operated infrared heater

which converts most of the energy applied (natural gas or LPG) into thermal radiation. The

sensible radiation component within the vicinity of persons allows a reduction in the air

temperature, thus leading to energy savings.

The Technology

The GoGaS KMI Novus high intensity heater from the KMI series is a high-quality product with

ratings from 6 kW (21,000 BTU/h) to 36 kW (125,000 BTU/h). The modern injector burner allows

almost pollution-free operation, from the smallest to the largest heater unit, with only one

combustion chamber. The stainless steel combustion chamber is integrated in an insulated

hood. The hot waste gases collect under the hood and pre-heat the gas-air mixture in the

combustion chamber, leading to a maximum degree of radiation. The reflector is made of highly

reflecting material and directs the captured radiation towards the vicinity of persons.

Serires KMI - 4 - November 4, 2013

Goch GmbH & Co. KG

Important

This appliance must be installed in accordance with current connection and installation

regulations and may only be used in adequately ventilated rooms. The installation and operating

instructions must be inspected and understood before installation and before start-up.

Before installation it must be checked whether local gas distributions, gas types and gas

pressures as well as the settings of the appliance are compatible.

Important

These instructions, the layout drawing, local codes and ordinances, and applicable

standards such as apply to gas piping and electrical wiring comprise the basic information

needed to complete the installation, and must be thoroughly understood along with general

building codes before proceeding.

Only personnel who have been trained and understand all applicable codes should

undertake the installation. SRP Representatives are Factory Certified in the service and

application of this equipment and can be called on for helpful suggestions about installation.

General information

GoGaS infrared heaters are manufactured in accordance with ANSI Z83.19-2009/CSA 2.35-

2009. Each appliance is subjected to a function test before it leaves the factory and is preset to

the relevant gas type. For setting up and operating radiation equipment, the following

regulations and guidelines must be complied with.

This heater maybe approved for either indoor or outdoor installation. Not for use in

residential dwellings, refer to Rating plate.

Installation Codes

The installation must conform with local building codes or, in the absence of local codes, with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1.

General Installation and Gas Codes/Electrical Codes

If an external electrical source is utilized, the heater, when installed, must be electrically

grounded in accordance with the National Electrical Code, ANSI/NFPA 70, or current Canadian

Electrical Code, CSA C22.1.

Aircraft Hangar Installation

Installation in aircraft hangars must conform to the Standard for Aircraft Hangars, NSI/NFPA 409

in the US and CAN/CGA B149.1 and B149.2 Installation Codes in Canada

Public Garages

Installation in public garages must conform to the Standard for Parking Structures, NFPA 88A or

the Standard for Repair Garages, NFPA 88B, in the US and CAN/CGA B149.1 and B149.2

Installation Codes in Canada.

Parking Structures

Technical requirements are outlined in ANSI/NFPA 88A (USA)

Warning: Heaters should be installed so that the minimum clearances marked on the heater will

be maintained from vehicles parked below the heater.

Serires KMI - 5 - November 4, 2013

Layout Considerations

1. Because high intensity heaters are un-vented, ensure that adequate ventilation will be

available; most codes require a minimum of 4 cfm per 1000 BTUH of installed heat

capacity in natural gas, 4.5 cfm per 1000 BTUH for propane. Also see section on

Ventilation.

2. Check local codes for mounting requirements and the requirement for flexible gas

connectors or rigid mounting.

3. Do not locate heaters near windy locations such as door openings.

4. Do not locate heaters in very dusty environments

5. Avoid placing heaters below sprinkler heads or provide more than adequate clearance.

Spot Heating

High intensity heaters are ideal for spot heating applications. The following are key

considerations to the success of the application:

1. Minimize any wind in order to maximize the effect of the radiant heat.

2. Placing two smaller heaters opposing each other will be more c omfortable than placing

one large heater.

3. Hang the heaters back and at an oblique angle (rather than directly overhead) in order to

maximize the exposure of the peoples’ bodies to radiant heat.

The following charts are intended for guidance only. Specific applications may require other

parameters.

Suggested Minimum Mounting Heights

Heater Input

Mounting Angle

Rate

0° – 10° 30°

BTU/hr

ft m ft m

20,000 10 – 15 3 – 4.6 9 – 13 2.7 – 4

40,000 12 – 19 3.7 – 5.9 11 – 17 3.4 – 5.2

60,000 14 – 22 4.3 – 6.7 13 – 19 4 – 5.9

90,000 15 – 24 4.6 – 7.3 14 – 22 4.3 – 6.7

120,000 17 – 29 5.2 – 8.8 16 – 25 4.9 – 7.6

Serires KMI - 6 - November 4, 2013

Suggested heat loading for indoor spot heating under stated conditions:

BTU/hr per sq. ft of

Ambient Air

Temperature

At 50 ft/min of wind

(15.2 m/min)

Floor Area to be Heated

At 100 ft/min of wind

(30.5 m/min)

40°F / 4°C 150—165 165—180

55°F / 13°C 75—88 85—100

Example:

Work counter for light assembly, space is 15 ft x 25 ft. (4.5 m x 7.6 m),

ambient air temperature 40°F / 4C, located near shipping doors.

Approximately 170 BTUH/sq.ft x (15x25) sq.ft = 63,750 BTUH

Two heaters at opposing locations would be preferred

Goch GmbH & Co. KG

Full Building Heat

Calculate the total heat input required, ensuring the inclusion of any unheated make-up air due

to exhaust fans. Use the following chart as guidance to heater placement.

Model/BTUH KMI-20 KMI-40 KMI-60 KMI-90 KMI-120

Heater

Mounting

Height,

ft (m)

Mounting

Angle 0°-10°

Mounting

Angle 30°

Distance of first heater

row

from outside wall, ft (m)

Distance between heaters

along outside wall*, ft (m)

Distance between rows –

out-side wall row to next

interior row, ft (m)

10-15

9-13

6

(1.9)

8-20

(2.5 – 6.1)

30-60

(9.2 – 18.3)

12-19

11-17

10

(3.1)

15-30

(4.6 – 9.2)

50-80

(15.2 – 24.4)

14-22

13-19

12

(3.7)

20-40

(6.1 – 12.2)

75-110

(22.9 – 33.5)

15-24

14-22

14

(4.3)

30-50

(9.2 – 15.2)

90-115

(27.5 – 35.0)

17-29

16-25

16

(4.9)

40-60

(12.2 – 18.3)

100-125

(30.5 – 38.1)

* Distance between heaters along interior rows should be up to twice the indicated number

Serires KMI - 7 - November 4, 2013

Loading...

Loading...