Page 1

DIN EN ISO 9001

Documentation Rev. 08

SR-Module HG 76360 ZA

Operational Description, Block Diagrams and Users Manual

Revision - History Documentation

Rev. Author Date Reason fo Modification

01 TN 27.05.2009 Reissued

02 TN/TG/TK 21.07.2009 Adapted to firmware V0.17

03 TN/TG 26.10.2009 Adapted to firmware V0.22 (page.5 and page.8)

04 TN/TG 03.09.2010 V0.24-V0.28 updated and commissioning

05 TN/TG 09.12.2010 V0.29 updated

06 TN/TG 24.03.2011 P. 18, Table 8, Bit 3 and 4, Rx, Tx changed

07 TN 12.05.2011 Block diagram included

08 TN 01.06.2011 Labels for type approvals added, page 27

09 TN 11.07.2011 minor changes

Revision - History Software

Rev. Date Reason for Modification

V0.20 10.08.2009 Module doesn’t start before Host configuration

V0.21 11.09.2009 Debug version for log- analysis

V0.22 13.10.2009 Different bug fixes

Master of last connection is stored on slaves

Packets have to be received successfully on both channels if slave

looks for a master

The configuration memory will be regularly written with meaningful

values before each interrupt calling for configuration

V0.24 29.01.2010 Detection and signalisation of burst errors

V0.26 28.04.2010 Reading bus- test and debug information

V0.28 11.08.2010 Quicker activation of radio chips (Warning: unstable)

V0.29 16.08.2010 The “Lost-Sync” interrupt (BIT 5) is now redefined to a “Lost- Reg”

interrupt, as already defined before.

If text debugdata are provided, a SetDebugAvailable is set now,

otherwise 0 (see GRFExternInterface, i.e. after SerDebug).

So far only values from 1- 10 were correctly processed for the

Master ID. From now on the Master ID can be set up to a value

of 255 (as usual, only more options). The automatic search

function only scans the first 10 options. Thus a conflict in an

environment with a lot of operational systems can be avoided.

Created: TN, 21.02.2011 Page 1 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 2

DIN EN ISO 9001

Table of Contents

SR-Module HG 76360 ZA......................................................................................................1

Revision - History Documentation.......................................................................................1

Revision - History Software.................................................................................................1

Table of Contents ...............................................................................................................2

Documentation.....................................................................................................................4

Short-range transmission module (SR module for Transmodule)........................................4

General points ....................................................................................................................4

Block diagrams...................................................................................................................5

Timing.................................................................................................................................6

Signal integrity....................................................................................................................6

Registering a new vehicle, solving slave to master allocation problems..............................7

Allocating time slot to a sledge number and slave ID ..........................................................7

Sledge malfunction.............................................................................................................8

Commissioning new machine / new facility.........................................................................8

Commissioning, service (controlled by host).......................................................................9

Standard operation.............................................................................................................9

Memory configuration / structure.........................................................................................9

Configuration....................................................................................................................10

Start- Configuration register from offset 0x0400 (RXDPRAM):..........................................11

Frequency Hopping...........................................................................................................11

Data Memory....................................................................................................................12

Telegram Memory Configuration (received from offset 0x400)..........................................12

Telegram memory configuration (transmitting from offset 0x0000)....................................12

Status Information.............................................................................................................13

Control- and Status register (CTRL register from offset 0x800).........................................14

CRC Checksum................................................................................................................15

Initialising Process............................................................................................................16

Communication Cycle.......................................................................................................17

Timing...............................................................................................................................17

Time Slots.........................................................................................................................17

LED Status Signalling.......................................................................................................18

Module is configured as slave.......................................................................................18

Module is configured as master.....................................................................................18

Interrupts ..........................................................................................................................19

Write access..................................................................................................................19

Error analysis....................................................................................................................20

Bus test.............................................................................................................................20

Debug Log.......................................................................................................................20

Firmware Update- Serial...................................................................................................21

Cable Allocation................................................................................................................22

Firmwareupdate................................................................................................................22

Commands for the firmware update..................................................................................22

hCStartUpgrade............................................................................................................22

hcStartUpgradeDistribution ...........................................................................................22

hcExecuteLocalUpgrade...............................................................................................22

Assembly diagram, position of solder bridges in relation to IRQ setting ............................23

Commissioning for wireless measurements......................................................................24

Starting data transmission.............................................................................................25

Sending a continuous carrier:........................................................................................26

Setting up a wireless link...............................................................................................26

Labelling...........................................................................................................................27

Labelling of host device:................................................................................................27

Created: TN, 21.02.2011 Page 2 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 3

DIN EN ISO 9001

RF Exposure information:..............................................................................................27

Antenna:........................................................................................................................27

Specifications....................................................................................................................28

Glossary ...........................................................................................................................29

References:......................................................................................................................29

Structure of configuration data (Source code excerpt) ......................................................30

Structure of status information (Source code excerpt).......................................................31

FCC ID: NUDHG76360

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired

operation.

Modifications not expressly approved by this company

could void the user's authority to operate the equipment.

The SR-radio module HG 76360 meets the requirements according to R&TTE Directive

1999/5/EC:

Safety/Health: EN 60950-1:2006

EN 50371:2002

EMC: EN 301 489-1 V1.8.1:2008-04

EN 301 489-3 V1.4.1:2002-08

Radio: EN 301 440-2 V1.2.1:2008-05

For more information according labelling see on page 27.

Created: TN, 21.02.2011 Page 3 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 4

DIN EN ISO 9001

Documentation

Short-range transmission module (SR module for Transmodule)

General points

The SR module offers reliable, contact- free data transmission with real-time capability of

data transmission within a set time frame between a Transmodule master control / master

host, referred to in the following as a base station and up to 32 mobile, rail- mounted

carriage controls / slave hosts, referred to in the following as mobile station.

The SR modules communicate with the hosts using a PC / 104 structure. Data access is in

16-bit mode. External access is provided via the ISA bus and via a Dual- Ported RAM

(DPRAM). There is an interrupt for events that can be configured with solder bridges.

The structure of the SR modules for the base station and mobile station are identical.

A configuration parameter tells the module whether it is being used as master, slave or is

inactive. The SR modules have two separate wireless modules that operate in the ISM

frequency band between 2400 MHz and 2483.5 MHz. These can be operated in full, semiduplex or fully redundant mode with the Simplex procedure (alternating duplex). Currently

the system is operated in Simplex-redundant mode. Data is either sent or received at the

same time on both channels. High levels of availability are more important to the application

than speed. In redundant mode, the same data is transmitted simultaneously on different

frequencies, so that the likelihood of interrupting the entire transmission is almost zero. The

channel spacing is 40 MHz, so that narrow band interferences can be concealed.

The wireless transmission procedure is handled via an ARM7 derivate in conjunction with an

FPGA.

The high- frequency transmission is carried out on the stationary side via a radiating cable,

which the SR master module’s two wireless channels are connected to directly using a 3 dB

coupler / splitter. The SR mobile modules link their signal using a double coupler to the

Radiating cable. The couplers are working bi-directionally.

Depending on each time frame, the frequencies change (adaptive frequency hopping) to

allow other ISM band users interruption- free communication. Channels that are occupied or

experiencing interference are identified by CRC faults and passed over.

The mobile SR modules do not only give the slave- host their according telegram, but

telegrams for all vehicles. As a result, the slave- hosts are informed about the target status

of all other vehicles. After receiving the data and transmitting it into the DPRAM, an interrupt

is triggered that tells the vehicle’s computer that up-to-date data is available. The vehicle

computer must only read off the data within a certain data frame, so that the buffer for the

next transmission is free. Direct communication between the slave- hosts with one another is

not envisaged.

Each SR module has an RS- 232 interface, not used in normal mode, for directly debugging

and for text and diagnosis purposes, as well as software updates. There is a special terminal

program for this.

Created: TN, 21.02.2011 Page 4 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 5

DIN EN ISO 9001

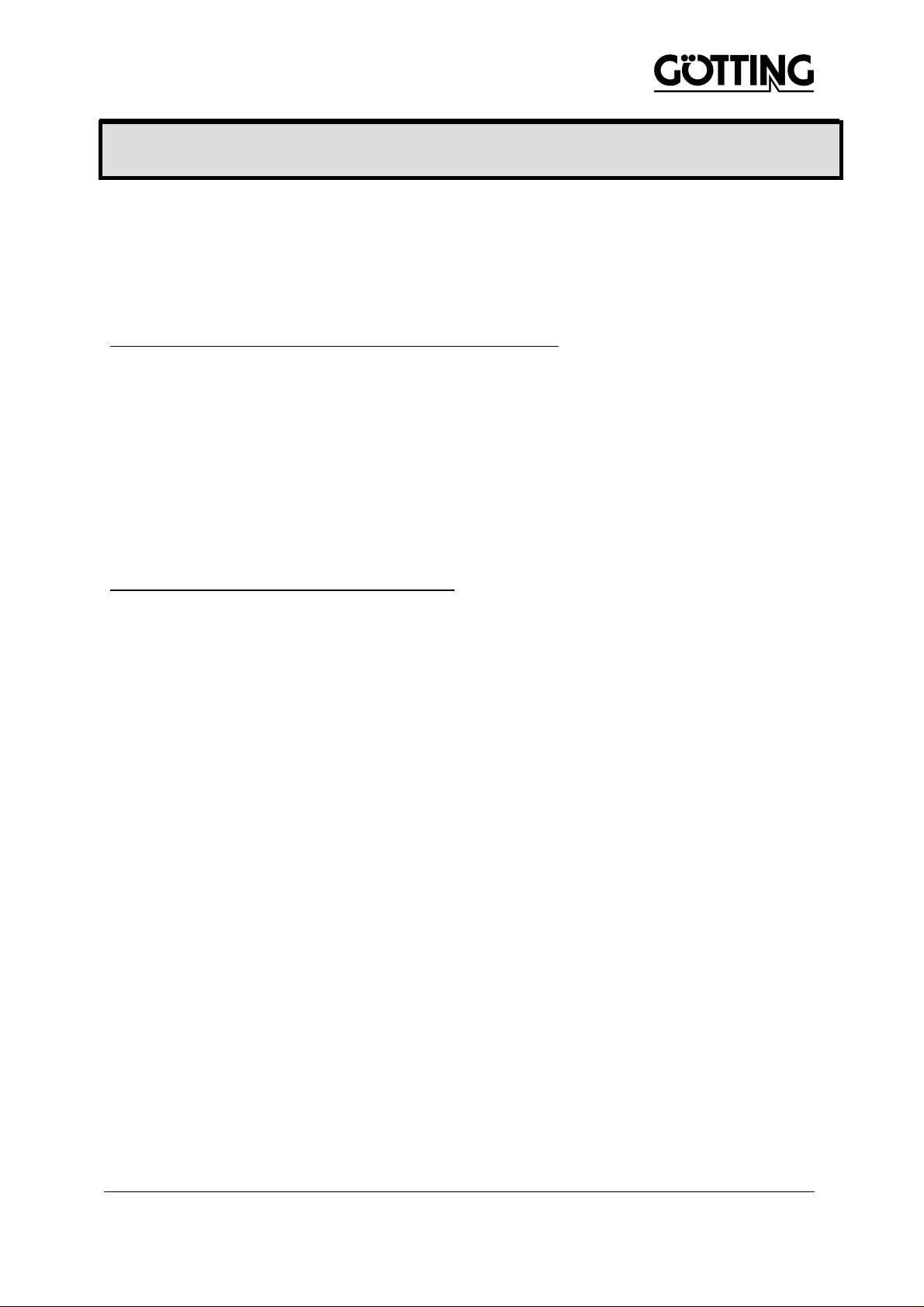

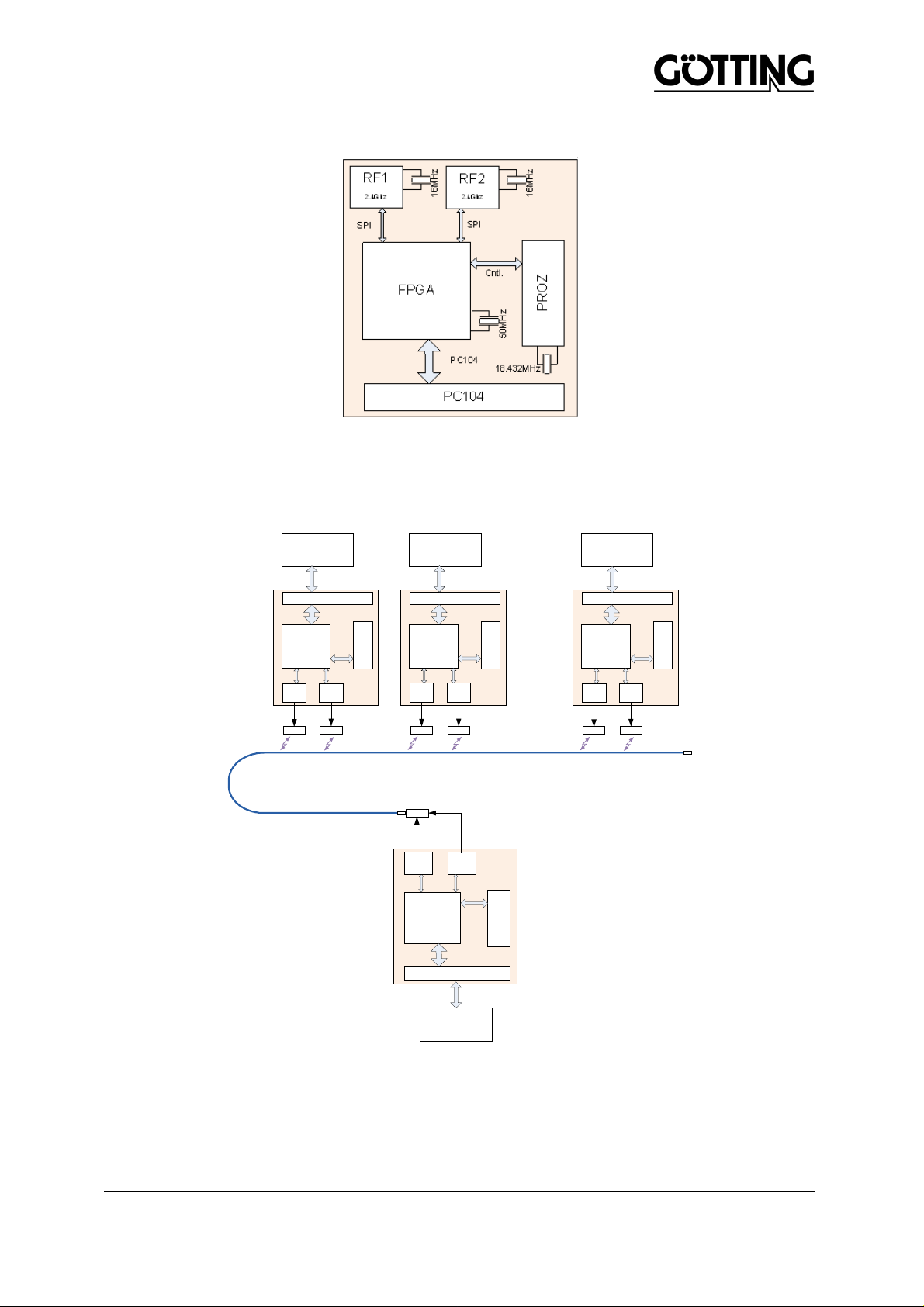

Block diagrams

Figure 1

Figure 1 shows the block diagram of one SR-module. One pcb includes two radio-modules,

a controlling FPGA and an arm processor. Figure 2 shows one complete system, including

the master-module, the radiating cable and up to 32 slave modules. The two antenna ports

of the master module are connected to a power combiner, connected to the radiating cable.

SLAVE 1

SLAVE 2

SLAVE 32

SPI

RF1

2.4Ghz

FPGA

PC104

PC104

RF2

2.4Ghz

PC104

PC104

RF2

2.4Ghz

RF2

SPI

Cntl.

SPI

2.4Ghz

MASTER

Cntl.

Processor

………...

SL2

Processor

RF1

SPI

SPI

2.4Ghz

RF1

2.4Ghz

FPGA

Cntl.

SPI

SL1

FPGA

SPI

RF1

2.4Ghz

FPGA

PC104

PC104

RF2

2.4Ghz

Processor

Cntl.

SPI

SL32

50R

Processor

PC104

PC104

HOST

Figure 2

Created: TN, 21.02.2011 Page 5 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 6

DIN EN ISO 9001

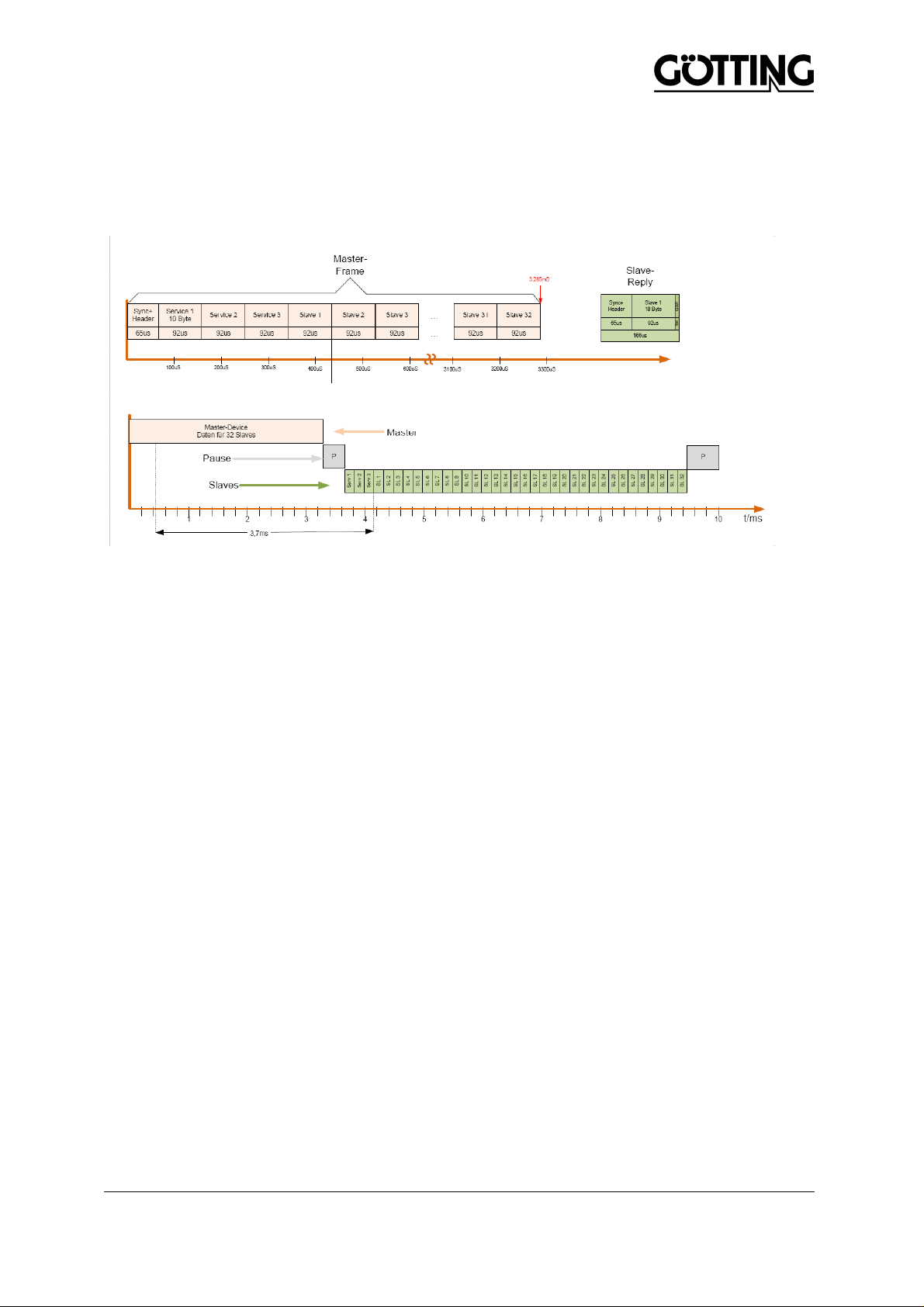

Timing

Because transmission takes some time, the master SR module controls the overall timing. It

should be assumed that the master- host is in the position to send on or pick up data at

adequate speed. There are differences in the timing (Figure 3) between the master and the

slave- module.

Figure 3

Signal integrity

Errors in the data are identified by using addresses and creating a CRC check sum.

Incorrect data is rejected, there is no FEC (forward error correction). The transmission is not

repeated, as this would take just as long as transmitting new, up-to-date data. When

transmission is carried out on two different frequencies at the same time, there may be

interference in one of the two data sets, but the correct data set is displayed. If errors

accumulate on one channel, a new channel can be selected. In each master frame, the next

bottom channel to be used is coded. The top channel is 40 MHz above the bottom one. The

information is available to both channels so that switching works reliably, even if there is

interference on another channel. A new subscriber scans all 40 available channels for 10 ms

each and is then up to date very quickly. As the cycle is 10 milliseconds, this procedure

takes a maximum of 400 ms.

The block error rate determines the signal integrity.

Created: TN, 21.02.2011 Page 6 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 7

DIN EN ISO 9001

Registering a new vehicle, solving slave to master allocation problems

As the module has no clear allocation from the configuration, the slave has to automatically

identify its appropriate master.

A clear identification by the master host (1-10) is issued on the stationary SR module. Where

neighbouring Transmodules are concerned, this must be different so that a slave does not

receive a master nearby that has the same ID.

When changing the slaves to another machine, the voltage supply to the wireless module is

interrupted and therefore only has to find the allocation to its master when switched on.

With these conditions in mind, the problem is solved as follows:

• The slave starts and looks for a master on the frequencies and addresses possible

• Once a master is found, the slave tries to synchronise to it

• The slave now waits until it has received 10,000 packages from the master. If until

that point fewer than 20 CRC errors have occurred, standard communication

operation is triggered. If more than 20 CRC errors have occurred, the search for a

master is started again.

From V0.22 on: After successfully connecting, the slave ID (1..32) and the master that has

been found (1..10) are saved. These settings are used during a reboot, so that contact to the

master can be made more quickly. Strict conditions are used to test whether the master is

the correct one. If the master last used is not considered good, the search for the master is

started once more.

Absolute reliability that the slaves contact the correct master is not guaranteed. If successful,

the whole procedure takes approx. 30 seconds until communication starts. When a sledge is

added to a Transmodule and communication is experiencing interference, the master will not

use the new sledge if the identification process can not be completed. This can for example

occur at the turning position that is affected frequently by CRC errors because of poor

coupling.

Allocating time slot to a sledge number and slave ID

A customer’s sledge pool can include up to 999 vehicles (sledges). A plate showing the

sledge number is applied to the outside of the sledge so that the user can read it. To begin

with, the sledge number is not available in the sledge. The user does not need to issue the

time- slot number, as the SR slave module reports to the SR master module which allocates

the next free time slot. The master host identifies a new sledge as soon as in a previously

unused receiving- data range data is transmitted from a slave host.

The offset of the received- data memory range is calculated from the (slave ID-1) x 32. The

base address is 0x400. A slave ID can be allocated to the SR slave module by the slave

host, which can however lead to collisions if a slave ID is allocated twice. Therefore, the

system usually allocates these slave IDs automatically. Via a wireless connection, the

master host will then ask for the MAC address of the slave host. The master host will then

link the MAC address with the carriage number that the operator has to enter. As only one

transmission data address range exists on the slave, the slave host does not need to know

the slave ID. The slave ID can be obtained at any time by looking at the status information.

Created: TN, 21.02.2011 Page 7 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 8

DIN EN ISO 9001

Sledge malfunction

If a wireless slave / carriage fails, no login is carried out. If login lapses, the master host

must always check the slave host by asking for the MAC address and reacting accordingly.

This is the only way of guaranteeing that the master host has an up-to-date overview of its

sledges.

Commissioning new machine / new facility

For the wireless modules commissioning new machinery / facility is no different to an

interruption in the electricity supply. When switching on, a search for a master will always be

carried out. The slave contains no configuration data on a particular master and therefore no

machinery number either. It always logs into the master to which the transmission is better

than the defined quality criterion. This means of course that after a reboot the master host

has to request all MAC addresses to learn which is the current carriage.

Actually the sledges contain a memory card (SD-card) which holds the configuration of the

machine. Therefore no master search is necessary.

Created: TN, 21.02.2011 Page 8 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 9

DIN EN ISO 9001

Commissioning, service (controlled by host)

The block error rates on both channels are constantly captured and can be read out. The

transmission capacity of the master module can now slowly and gradually be reduced in

three increments. The increments decrease in units of 6 dB each (0 dBm, - 6 dBm, - 12dBm

and – 18 dBm), so that finally a transmission is carried out at an output power of – 18 dBm

(0,016 mW). The block error rate is identified for each transmission level. The data is

entered in the DPRAM and is available to the host for analysis. Reducing the transmission

capacity to –18 dBm must not lead to an significant increase in the block error rate.

Standard operation

The maximum transmitter power is used during standard operation. In the standard

transmission mode, the block error rates for each radio channel used are constantly

identified, in order to be able to recognize previously unpredictable ageing effects and

failures at an early state.

Memory configuration / structure

An ISA bus structure is used, which is implemented via a PC/104 interface for the SR

module to communicate with the host. The external control computer (controller) can access

the SR module’s memory via memory I/O access. The quantity of payload data to be

transmitted is 16 bytes per slave. Some 16 bytes of status information is reserved per frame.

A maximum of 32 vehicles can communicate with the master. This results in 32 blocks of 16

bytes each = 512 TX bytes and 32 blocks of 32 bytes each = 1024 RX bytes that have to be

made available by the SR module. Additional memory area with control registers is planned

from 0x800 for control and monitoring.

The memory blocks are clearly allocated to the slave ID:

Address = I/O-offset + (Slave-ID-1) x sizeof(block).

Via the configuration blocks to be transmitted by the master, the slaves can be put into other

definable operating modes, such as software update, commissioning. Table 1 shows the

memory structure for transmitting data from the SR module to the host.

For data transmission addresses 0x0000-0x01FF, for data receiving addresses 0x04000x07FF is provided. 0x200 to 0x3FF is for status information. From 0x800 onwards control

registers will follow.

I/O-Offset

0xXX0000

CTRL Register

0xXX0800

0xXX07FF

DPRAM RX

0xXX0400

0xXX03FF

STATUS

0xXX0200

0xXX01FF

DPRAM TX

0xXX0000

Table 1

Created: TN, 21.02.2011 Page 9 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 10

DIN EN ISO 9001

Configuration

The maximum number of mobile subscribers can be configured during booting. The

appropriate parameter is entered when commissioning the system and as a result defines

the maximum number of addresses occurring. Therefore, automatic registering (see above)

is guaranteed and the frame time optimised.

The number of bytes per subscriber to be transmitted is currently compiled in the source text

for controller and FPGA. Consequently the duration of the transmission can be enhanced.

The value is currently set to 16 bytes. This value cannot be configured.

Wireless software upload is implemented. The configuration is stipulated by the host

controller and cannot be read back. A configuration tool for the RS- 232 interface was

created. During real operations the configuration and firmware uploads are carried out via

the ISA bus.

All subscribers to the system must have the same parameters. The set of parameters is

retransmitted in each cycle as a broadcast message in the service blocks. Therefore,

configuration is done on the master and radio- transmitted to the slaves. In the module itself,

the serial number and the I/O offset address is stored for access to the ISA bus.

Configuration is carried out via the memory for receiving data (RXDPRAM). Notification that

configuration has been completed is shown when the first data word is nonzero (0x000).

After booting the modules, an interrupt is triggered that is initially actively masked.

This configuration range is pre- initialised by the wireless module with meaningful values. In

the testing phase the module boots with the pre-set default values if the host computer has

not written any other configuration for three seconds. From version V0.20 the module does

not boot until the host has given it a configuration.

From V0.22 the memory for the initial configuration is now written with meaningful default

values before each interrupt that calls for configuration. Parameters that are not of interest

should not be changed. Bytes that exceed the length of the configuration may not be

changed as they should contain settings for the new firmware versions which for downwards

compatibility reasons are yet not processed.

After writing the configuration the memory area must not be written for at least 150 ms.

Normally this should not happen, as the memory area concerns the receiving memory that is

only read during operation. Please must be regarded during a memory test: The

configuration range is written on every 100 ms with the default configuration.

Only the master / slave configuration (Word [1]) is required for all subscribers and clear

identification of the Transmodule (Word [28]) at the master. The rest, which is shown as

optional in the table, can be ignored at the moment and is only displayed for reference

purposes should there be any unpredictable changes.

Created: TN, 21.02.2011 Page 10 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 11

DIN EN ISO 9001

Start- Configuration register from offset 0x0400 (RXDPRAM):

WORD[i]

Range Opt. Definition

0 0xXXXX Configuration completely written

1 1-32 opt Unique identification of radio module within the facility /

machinery

2 0/1/2 must 1 = module is slave

2 = module is master

otherwise = module inacitve

3 0xXXXX opt Clear address of facility / machinery

4-23 0-40 opt Frequency-hopping sequence. Only relevant for the

master.

0 = turns off hopping channel

1-40 = hopping channel f with frequency:

2.4 GHz + f x 1 MHz (f = 10: freq. = 2410 / 2450 MHz)

24 1-4 opt Transmission power of both channels

1 = -18dBm

2 = -12dBm

3 = -6dBm

4 = 0dBm

25 1-32 opt if operation as master function:

Maximum numbers of slave modules supported

26 1-32 opt if operation as master function:

Number of packages to be sent from the master to the

slaves

27 1-999 opt if operation as slave function:

Carriage number

28 1-10 must if operation as master function:

Clear identification of the transmodule

29-31 opt MAC address of the slave host

Table 2

The definition of this strucure is given in the appendix of the source code excerpts under

HostCnfData_s or HostCnfData_t.

Frequency Hopping

If the hopping sequence comprises one channel only frequency hopping is implicitly turned

off. The channels apply for the first radio chip. The second radio chip works 40 MHz parallel

above the first one. The hopping sequence is pre- defined by the master and can be

configured there. The slave automatically synchronises to the master’s hopping sequence.

This ensures that the system remains synchronised even after experiencing an interference.

Should interferences accumulate the hopping sequence will be automatically adjusted by a

bit error rate evaluation of the single channels. Subsequently these channels will be blocked.

Created: TN, 21.02.2011 Page 11 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 12

DIN EN ISO 9001

Data Memory

A memory area of 1536 bytes total is available for the reception and transmission of user

data. The maximum length of one user's data is 16 bytes. The memory configuration is

determined to 32 bytes, independent from the length of the user data. Thus a memory area

of 2048 bytes is defined.

Telegram Memory Configuration (received from offset 0x400)

Byte Offset Length Description

0 1 Received frames counter, Number of packages with correct CRC

1 1 This counter indicates the unreceived data (CRC errors or not

received, if slave is registered)

2 20 User data: Type (1) + address (1) + data (10-16) + CRC (2) +

Padding

22 4 Padding

26 1 Counter for reception

27 1 Master: Firmware Version of Slave

Slave: Padding

28 1 Master: Counter of slave registrations

Slave: Padding

29 1 Master: Slave registration status

1 = registered at master

0 = not registered

Slave: padding

30 1 Burst Error Detection

The number of consecutive packages not received will be stored in a

bit field. Thus burst errors with 1 – 8 consecutive incorrect packages

are identifiable.

Comand “12” resets this bit field.

31 1 Padding

Table 3, Received Data

The reception byte counter will be stored at two positions (byte offset 0 and 26). During data

receipt both counters will be increased. Thus when the data is read it can in its entirety be

verified that there was a no overlapping access on the DPRAM by first reading counter 1,

then reading the data, subsequently reading counter 2. If both counters match, the criteria

for data consistency is fulfilled.

Telegram memory configuration (transmitting from offset 0x0000)

Area 0x0000-0x01FF (32*16=512 bytes at master and 16 bytes at slave) is provided for data

transmission. Data from slave to master always have to be written to offset 0.

Byte Offset Length Description

0 16 Userdata: Data + Padding

Table 4, Transmitted Data

Created: TN, 21.02.2011 Page 12 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 13

DIN EN ISO 9001

Status Information

Area 0x0200-0x03FF provides information on the operating status. Source code excerpts in

the appendix illustrate the structure and give information on the status information available:

GRFStats_t.

Information interpreted by the radio module will be supplied by EventCode, EventData and

EventConter. For further details please consult the source text (GRFExternInterface.h).

The host will be provided with error counters for each frequency and each radio module for

long- term monitoring of interferences on the radio frequencies. These counters have to be

read periodically and a counter overflow has to be monitored by the host controller.

CurrentRegMap enables a compact readout of the current registration status at the master

module.

Created: TN, 21.02.2011 Page 13 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 14

DIN EN ISO 9001

Control- and Status register (CTRL register from offset 0x800)

Register Offset Attributes Default

Values

0x00: FPGAID R 0x55AA FPGA- ID register for recognition if FPGA is ready for

0x01: TEST1 RW 0x0015 Test register can be applied for radio module monitoring.

0x02: INT R 0x0000 Unconfirmed interrupts

0x03: INTMASK RW 0x0100 Mask for selecting those events for which an interrupt

0x04:

INTCLEAR

0x05: TOGGLE R 0x0000 Toggles every second between 0 and 1. The change is

0x06: RXFCLO R 0x0000 Counter for the number of correctly received telegrams

0x07: RXFCHI R 0x0000 Counter for the number of correctly received telegrams

0x08: CRCERR R 0x0000 Counter for the number of received telegrams with CRC

0x09: CMD RW 0x0000 Command Register (command is 8 bit)

W 0xXXXX Bit mask for those events that shall be resetted.

Description

operation

For this purpose the host sets a value which will be reset

to a default value upon reboot.

shall be generated

caused by the micro controller and can be considered as

a crash indicator.

(Bit 0 – 15)

(Bit 16 – 31)

error occuring on both radio chips simultaneously

0: No command

1: Carry out a reset (Module subsequently answers

with a configuration interrupt)

2: Stop communication (proceeds only after reset)

3: Change to firmware transfer mode

4: Wireless transmission of uploaded firmware

and programming

5: Local programming of uploaded firmware

(3 - 5 For the firmware’s upgrade via ISA bus (see

source code examples)

6: Set transmission power in operation to 0dBm

7: Set transmission power in operation to –6dBm

8: Set transmission power in operation to –12 dBM

9: Set transmission power in operation to –18dBM

10: Start of Debug Dumps

11: End of Debug Dumps

12: Reset fields for burst error detection

13: Polling of Debug Information during operation

14: Carry out bus tests

Table 5

For further information status please refer to status register from 0x0200 onwards.

Created: TN, 21.02.2011 Page 14 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 15

DIN EN ISO 9001

CRC Checksum

All telegrams are protected by a 16- bit CRC. 0x1021 (CCITT CRC16) is used as the

GeneratorPolynom. The CRC is initalised with 0xFFFF. Thus transmission errors of leading

zeros can be detected as well.

Created: TN, 21.02.2011 Page 15 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 16

DIN EN ISO 9001

Initialising Process

(after power supply was turned on or after command 1 via CMD register, see configuration)

• The ARM processor starts.

• FPGA configuration will be loaded by the ARM processor.

• From now on FPGA answers on ISA bus access.

• The ARM processor triggers the Start- interrupt, invoking the host controller

configuration (interrupt bit 8).

• Now the ARM processor waits for the host controller (only during test phase this

process will be started with default values after a short timeout!).

• At this point the default values are also readable via host controller. Thus e.g. the

hopping sequence does not necessarily have to be adjusted.

• Now the host controller writes the configuration into RXDPRAM as documented. It is

essential that a uniquely defined vehicle ID will be set. As last point the first word will

be written with a value unequal to zero (RXDPRAM[0]) informing the ARM controller

that a valid confirmation is predefined.

• The ARM controller reads the first data word in an infinite loop (still with timeout, as

described above) until it receives a non-zero value.

• Now the ARM controller reads the valid confirmation from the memory and applies it.

• The radio modules will be initialised and the regular communication process begins.

• The master starts transmitting its master block, the slaves search for an appropriate

master and log in.

Created: TN, 21.02.2011 Page 16 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 17

DIN EN ISO 9001

Communication Cycle

1. Start of communication cycle (resolution accurate to 1µs)

2. SR-master transmits service telegrams (always exactly 3)

3. SR-master transmits the user data frames (max. 32) to the SR-slaves

4. Intermission

5. SR-master changes to receive mode and SR-slaves to transmission mode

6. Intermission

7. A SR-slave can connect to the SR-master during reserved time slots

8. SR-slaves transmit their data frames to the SR-master in the time slots allocated

9. Intermission

10. Frequency hopping

11. SR-master returns to transmission mode the SR-slaves to receive mode

Timing

Cycle time with 32 users and 10 user data bytes: 10 ms.

Each additional byte of the user data bytes (>10) extends the cycle by 300 µs. This results in

a cycle time of 11.8ms per cycle, if 16 bytes user data shall be exchanged. The number of

frames transmitted for the SR-master to the SR-slaves or vice versa will be configured

during start up by the host and thus determines the cycle time.

Time Slots

During a login of a previously unknown SR-slave it is allocated to the next free time slot.

An already known SR slave will be assigned to the time slots last used upon login.

Created: TN, 21.02.2011 Page 17 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 18

DIN EN ISO 9001

LED Status Signalling

Module is configured as slave

LED 1 Toggels upon Data reception

LED 2 Login Status

On: Slave cycle is synchronized and logged into the master

Out: Slave cycle will be re-synchronised and logged into the master

LED 3 Toggels upon data reception error or reception error on both channels

LED 4 Second tick

All Toggling of all LEDs as long as the module waits for the configuration from the

host controller

LED 1+2 Simultaneous blinking: Slave looks for a master module

Table 6

Module is configured as master

LED 1 Toggels upon data reception

LED 2 Login Status:

On: At least one Slave is logged in

Off: No Slave is logged in

LED 3 Toggels upon data reception error or reception error on both channels

LED 4 Second tick

All Toggling of all LEDs as long as the module waits for a configuration from the

host controller

Table 7

Created: TN, 21.02.2011 Page 18 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 19

DIN EN ISO 9001

Interrupts

A 16 bit register (INT) is available for the interrupts. The events that might trigger an interrupt

can be masked individually (INTMASK). For the reset of an interrupt the corresponding bit

will be written into the INTCLEAR register. The IRQ number is specified only once via solder

bridge (see Figure 5).

The significance of all bits is indicated in Table 8. INT 6 is pre-setted by the corresponding

solder bridge in Figure 5.

Bit 0 Sign of life once a second

Bit 1 Reception of synchronisation frame (once in a cycle time)

Bit 2 Channel switching (once in a cycle time)

Bit 3 Switch to Tx- mode (once in a cycle time)

Bit 4 Switch to Rx- mode (once in a cycle time)

Bit 5 Loss of master synchronization

Bit 6 Firmware transmission was started

Bit 7 Firmware update is carried out (Flash will be written)

Bit 8 Waits for host controller configuration

Bit 9 RX- DPRAM Handshake signal:

Received data on DPRAM ready for data readout (once in a cycle time!). Only one

slave data interrupt is triggered for those data destined for the slave itself.

Bit 10 TX- DPRAM Handshake signal

Write transmission data into the DPRAM (once in a cycle time!)

Bit 11 TX- DPRAM Handshake signal:

No more data writing to DPRAM! (once in a cycle time)

Bit 12 RX-DPRAM Handshake signal:

No more reading from DPRAM! (once in a cycle time

Bit 13 Wireless transmission of firmware is completed

Bit 14 Wireless transmission of firmware was cancelled: Incorrect firmware or timeout

Bit 15 Error conditions or time when debug data shall be stored.

Table 8

Write access

Write access, if implemented at a maximum bus- speed, can be carried out with the interrupt

by the end of the write access time and enables to use the last available write access. Ca.

100µ are left, before a collision occurs.

Created: TN, 21.02.2011 Page 19 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 20

DIN EN ISO 9001

Error analysis

For a more detailed error analysis conditions for bus test and debug information of the radio

are provided via ISA bus.

Bus test

Start the memory test with command hcCheckDPRAM. Here the first 20 bytes in TXDPRAM

are used. The first 16 bytes will be checked. The test result will be stored at byte offset 16.

Once the test has been passed, the confirmation value 0x001 will be written at byte offset

18. Depending on the value written in byte offset 16 the following different test will be carried

out:

Test Types (Value at byte

offset 16)

0x0001 Calculation of CRC

0x002 Test of the 16 bytes for 0xFF 0x001, if all bytes are 0xFF,

0x003 Test of the 16 bytes for 0x00 0x001, if all bytes are 0x00,

Test function Result

CRC data checksum

checksum as described in

chapter CRC checksum.

otherwise 0x0000

otherwise 0x0000

Table 9

Debug Log

Data retrieval operating over a serial console can alternatively be queried via the ISA bus.

The buffer can obtain data volumes of up to 8kbytes, providing detailed information in text

form.

For data retrieval the status information area will be applied (GRFStats_t). Issuing command

hcGetSerDebugInformation (13) will copy debug data to the status area.

SerDebugIndex (byte-offset 380) will be increased for each copying process.

Subsequently (in SerDebug) data information with a maximum of 53 bytes is

available as a zero terminated string. This retrieval should be repeated as long as no

more data will be supplied, i.e. a zero- length string.

An interrupt signal serves as a reasonable time signal when the debug log is to be

retrieved. It can be retrieved at any other time as well

The debug information can also be retrieved during normal communication operation.

Created: TN, 21.02.2011 Page 20 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 21

DIN EN ISO 9001

Firmware Update- Serial

With program “HG 76360 ZA management” a firmware update can be carried out using the

red contact on the circuit board via a serial interface.

Figure 4, serial RS-232 connection

Created: TN, 21.02.2011 Page 21 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 22

DIN EN ISO 9001

Cable Allocation

Colour Signal Serial (Sub-D 9-pol. female) Radio module

Brown RX Pin 3 Pin 2

Green TX Pin 2 Pin 3

Yellow Ground Pin 5 Pin 4

Table 10

A simple serial cable is used as a connection to the PC (No null modem serial cable!)

Firmwareupdate

A firmware update can be downloaded onto the modules via the serial interface or the ISA

bus (PC / 104).

Wireless transmission sends the firmware update from the master to the slave modules. The

firmware is distributed to all slaves simultaneously that are logged on to the master at that

time. When the new firmware with a valid MD5 check sum has reached all slave modules,

the actual flashing process is started. The firmware also includes configuration of the FPGA.

A source text excerpt on the firmware update is available through the ISA bus. In order to

make use of this firmware update mechanism, there are special commands that can be

carried out with the command register (0x09: CMD).

First of all a “3” is entered into the command register and the module will then switch to

transfer mode in which the firmware is now transmitted to the module. During transfer mode,

wireless communication is interrupted and the RX- DPRAM is used for communication.

Once the new firmware has been transferred, it can be programmed locally (Cmd 5) or

distributed wirelessly (Cmd4).

The firmware has an MD5 check sum. If errors occur during transmission, the update aborts

and the old firmware continues to be active.

Commands for the firmware update

hCStartUpgrade

Change to the firmware transfer mode. The RX- DPRAM area is used for communication

purposes. The memory structure is GRFIsaUpgData_t. As soon as a command has been

read, it is returned to zero. The ARM controller reports its status back on the commands.

The source code shows an example of the procedure for transferring firmware. The firmware

transfer mode is ended at the latest when a timeout of 2 minute occurs.

hcStartUpgradeDistribution

This command starts wireless distribution of the firmware. In this case it is important to note

that only the slaves that are logged onto the master at that point will receive the new

firmware. Only the master can distribute the firmware. Successful or unsuccessful results

are notified by the interrupts.

hcExecuteLocalUpgrade

Executes upgrades of the firmware previously transmitted.

Created: TN, 21.02.2011 Page 22 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 23

DIN EN ISO 9001

Assembly diagram, position of solder bridges in relation to IRQ setting

IRQ 7 6 5 4 3

Figure 5

The solder bridges are in the yellow marked area. It is not allowed to set more than one

solder bridge once. Only lead-free soldering is allowed. IRQ6 is factory default set.

Created: TN, 21.02.2011 Page 23 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 24

DIN EN ISO 9001

Commissioning for wireless measurements

The modules are usually configured via the PC104 interface. If necessary, they can also be

started and served via the serial interface with a default configuration. To do so, use the

adapter included to connect them with the serial interface of a PC under Windows:

Use a standard, straight lead / not a null modem cable:

• Start the “HG76360Mgm.exe” configuration program

• The COM port is selected and opened in the configuration program

• The adapter cable is used to connect the module with a serial interface of the PC

(see picture on the right)

• The angled cable included (do not twist) is used to connect the module with voltage

of +5VDC / 150 mA (see picture on the left), the green LEDs will flash (module is

waiting for configuration)

• Messages from the module can then be seen in the terminal tab in the terminal

window

Supply voltage connection

Tab "Terminal"

Serial interface and antenna cable

Created: TN, 21.02.2011 Page 24 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 25

DIN EN ISO 9001

Starting data transmission

Use the mouse click in the terminal window and enter “9” in the terminal window and the

module will start (see LEDs). This must be done for both modules; afterwards they will

connect automatically and in the “Device Status / Statistics” tab you will see the green RX

counter which counts the telegrams sent correctly. Next to it on the right, the faults statistics

are shown, separately for each of the RF modules and for faults on both RF modules at the

same time (only for each SR module connected, an SR module includes two, fully redundant

RF modules). If there is a loss of voltage or after a reset (red button on the panel) the

procedure mast be repeated.

The following commands can be carried out by entering them in the serial terminal

(“Terminal” tab):

‘5’: similar to ‘9’, but without a master search

‘6’: display debug information

‘9’: start default settings

‘d’: distribute the firmware to the slave logged on (in the master)

‘e’: upgrade after uploading the firmware

‘R’ or’1’: reboot

Tab "Device Status / Statistics

Tab "Commands"

Created: TN, 21.02.2011 Page 25 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 26

DIN EN ISO 9001

Sending a continuous carrier:

In the “Commands” tab unmodulated continuous carriers can be activated. To do this, the

module is selected under “SetTxCarrier” (1 or 2), the channel concerned

(2400 MHz + n x 1 MHz), the transmission capacity and then activated via “Set”. Both RF

modules in an SR module can be configured independently of one another and operated at

the same time.

Setting up a wireless link

The two connecting cables on the antenna coupler (aluminium plate with coupler elements)

link it with the one SR-module; the radiating cable is connected via the power splitter with

the two cables to the other SR-module. At the other end, the radiating cable must be

connected with a 50 ohm terminating resistor. The nominal distance between the antenna

coupler plate and the radiating cable's surface is 15 mm. One of the two flattened parts of

the cable must be directed to the coupler.

Figure 6, Measuring setup

Created: TN, 21.02.2011 Page 26 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 27

DIN EN ISO 9001

Labelling

Labelling of host device:

The modular transmitter is labelled with its own FCC identification number, and, if the FCC

identification number is not visible when the module is installed inside another device, then

the outside of the device into which the module is installed must also display a label referring

to the enclosed module. This exterior label shall use wording as the following:

“Contains FCC ID: NUDHG76360”

RF Exposure information:

The internal / external antennas used for this mobile transmitter must provide a separation

distance of at least 20 cm from all persons. OEM integrators and end users must be

provided with transmitter operating conditions for satisfying RF exposure compliance.

Antenna:

The module has been tested and approved for use with the antenna listed below:

- HG G-97601ZA (2.45 GHz)

- Radiating Cable HW CAB00058

Created: TN, 21.02.2011 Page 27 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 28

DIN EN ISO 9001

Specifications

PC/104-Bus Interface

• Power supply: 4.75..5.25 VDC via PC / 104bus

• Current consumption: less than 130 mA

• Onboard conversion to 3,3V, 1,2V and 1,8V

• IRQ 3....7 adjustable via solder bridges, IRQ 6 default setting

AT91SAM7X256 Microcontroller with ARM7TDMI core

• 64KByte SRAM

• 256KByte Flash

• System clock: 50MHz

XC3S50A(N) FPGA, Xilinx Spartan-3A(N)

• Sync. source: 50MHz oscillator

2 SRD- Radio modules nRF24L01+ Company Nordic

• Data rate: 2Mbit/s

• Bandwidth for radio transmission: 2MHz

• Maximum output power 0dBm

• 2,4GHz ISM frequency band

JTAG-interface with Flash programmer

UART debugger and firmwareupdate

Operating temperature range

• -20°C...+60°C

Storage temperature range

• -20°C...+80°C

Shock

• TBD

Vibration

• TBD

Created: TN, 21.02.2011 Page 28 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 29

DIN EN ISO 9001

Glossary

SR-module PC / 104 Short Range radio module with 2 radio chips, controller and FPGA

RF-module Each SR module has two different RF modules which are able to transmit

data on different frequencies.

Slave- / Master Host Controller with PC / 104 interface, to which the SR module is attached to

Sledge Controller see Slave host

Vehicle Controller see Slave host

Host Controller see Master host

References:

PC/104 Specification, Version 2.5, November 2003 / www.PC104.org /

ISA-Plug&Play c't 13/97, S.284: http://www.heise.de/ct/97/13/284/

AT-Bus, Die Busspezifikation des PC/AT gemäß IEEE P996, A. Stiller, c't 11/91, HeiseVerlag

Created: TN, 21.02.2011 Page 29 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 30

DIN EN ISO 9001

Structure of configuration data (Source code excerpt)

typedef struct HostCnfData_s

{

/*

* A non zero value confirms initialization of configuration by host and radio module shall start

* now

* Attention: During development the module starts automatically after some seconds with

.* default configuration

*/

u_short ConfigReady;

// Unique device-ID (values 1..32) - Will be adjusted automatically in case of conflicts.

u_short DeviceID;

/*

* Function of radio module:

* 1 -> Slave

* 2 -> Master

* otherwise -> deactivated

*/

u_short ModulFunction;

// Unique address for each transmodule (will be automatically determined in future releases)

u_short SystemRFAddress;

u_short HopSeq[20];

/*

* Transmit power of radio modules:

* 1 -> -18dBm

* 2 -> -12dBm

* 3 -> -6dBm

* 4 -> 0dBm

*/

u_short TxPower;

// Maximum Number of slaves, that can log onto Master. (1..32)

u_short MaxSlaves;

// Number of data packages, the master shall send to the slaves. (1..32)

u_short MasterFrames;

// The sledge's number (1..999)

u_short UniqueSystemID;

/* Unique ID for the master (1..10)

* A slave must not receive more than one master with the same ID!!

*/

u_short MasterID;

// MAC-address of Host

u_char SystemMAC[6];

} __attribute__ ((packed)) HostCnfData_t;

Created: TN, 21.02.2011 Page 30 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 31

DIN EN ISO 9001

Structure of status information (Source code excerpt)

typedef struct

{

u_long StatusCount1; // == StatusCount2

struct

{

// Text based information of Version

u_char VersionInformation[28];

// Version of status information (-> fixed value: CURRENT_VERSION_STATUS)

u_short VersionStatus;

// Registered event

u_short EventCode;

// Event related data

u_long EventData;

// Counter of the event – will be incremented by one for each event

u_short EventCounter;

// Length of current hopping sequence

u_char HopSeqLen;

u_char DummyByte;

// Current hopping sequence

u_char HopSeq[20];

// Uptime of the module in seconds

u_long Uptime;

// Number of received packages

u_long RxCounter;

// Number of transmitted packages

u_long TxCounter;

// For each channel a counter for packages, where a CRC error was detected.

u_short RxErrorRF1[MAX_CHANNELS_COUNT];

// For each channel a counter for packages, where a CRC error was detected.

u_short RxErrorRF2[MAX_CHANNELS_COUNT];

// Number of lost packages (CRC, Timeout)

u_long RxLostFrames;

u_char Reserved[120];

} __attribute__ ((packed)) General;

continued on next page!

Created: TN, 21.02.2011 Page 31 of 32 S_01125-

A1_E_Documentation_R09.doc

Page 32

DIN EN ISO 9001

union

{

struct

{

// Registration status of the slave -> '1' = registrated at master

u_char bIsConnected;

//

u_char Reserved1;

//

u_char Reserved2[6];

// Time slot, given by the master (1..32)

u_char LocalTimeSlot;

// Slave-ID (Allocation of data at the master!!!) (1..32)

u_char LocalSlaveID;

} __attribute__ ((packed)) Slave;

struct

{

// Bitmap of actually registered slaves (32 Bit -> 1 Bit for each slave)

u_long CurrentRegMap;

// Used Timeout, after wh the slaves loose their registration

(in 50ms steps)

u_short SlaveTimeout50MS;

} __attribute__ ((packed)) Master;

} Data;

u_char Dummy[128];

u_long StatusCount2; // == StatusCount1

} __attribute__ ((packed)) GRFStats_t;

Further information in GRFExternInterface.h and GRFIsaFWUpgrade.c

END

Created: TN, 21.02.2011 Page 32 of 32 S_01125-

A1_E_Documentation_R09.doc

Loading...

Loading...