Goetti Air Conditioning Heat Pump User Manual

Installation & Operating Instructions

For

Heat Pump Units

Manufactured By

GOETTL AIR CONDITIONING, INC.

P.O. Box 52029, Phoenix, Arizona 85072-2029

_TABLE OF CONTENTS

PAGE

II1.

IV.

VI.

VII

Vo

II.

Io

INTRODUCTION .................................................................................... 1

DIMENSIONS ......................................................................................... 2

POWER SUPPLY & WIRING ................................................................. 2

INSTALLATION ...................................................................................... 3

START UP/CHECK-OUT PROCEDURE ............................................... 5

ELECTRICAL OPERATION ................................................................... 8

_IE_tS'T-AN CE HEATE RS ...................................................................... _8

VIII,

_:[:-ION' AND MAINTENANCE ....................................................... 9

IX. WIRING DIAGRAMS .............................. 11

INSTALLATION AND OPERATING INSTRUCTION MANUAL

HEAT PUMP - HP MODELS 1 1/2 - 5 1/2 TONS

1. INTRODUCTION

Please take a few minutes to read our instructions before you install and use yonheat pump. This will

help you obtain the full value from your unit. It will also help you avoid any needless service costs that

result from causes we cannot control and cannot cover in our guarantee.

RULES FOR INSTALLATION AND SAFE OPERATION

1. Read these rules and the instructions carefully.

Failure to follow the rules and the instructions

could cause a malfunction of the heat pump unit

resultingin injury,death and/or propertydamage.

2. Check your local codes and utilitystandards.

The installation must comply with their rules.

3. Shut off the electric oower before makino

connections on the unit or removing 0anels for

servicing. (There may be more than one

di_;connect!.

4. Referto Section VIII for maintenance procedures.

5. Do not operate this unit at outdoor temperatures

below 60"F on cooling nor above 75° on heating.

6. The components of a heat pumpmay have sharp

edges or protrusions which can cut you. The

tubing and compressor contain high pressure

refrigerant. They must not be exposed to high

temperature or be punctured. When installingor

servicing the heat pump, be extremely careful to

avoid injury.

7. The refrigerant circuitis in a closed, pressurized

system. If for any reason, the system needs to

be opened for servicing, it is imperative that both

high and low sides of the system be purged

completelyintoa recoverytank before anysection

of the tubing is cut or unbrazed.

The importance of proper installation cannot be overemphasized. The best designed unit wll appear

to operate poorly if installed improperly. Unlike the small appliance where quality of operation can

usually be determined as it leaves the factory, the performance of a heat pump depends, to a large

extent, on its installation.

Problems always occur if the installerdoes not take precautions in the following areas:

Wire Size

Duct Size

Duct Openings

Duct Insulation

Refrigerant Charge

- Inadequate wire sizes can cause an excessive voltage drop, causing the compressor

and fan motors to operate at undesirably low voltage levels.

- Inadequate duct size, elbows, distributorsor registers can restdctair flow.

- Improperly sealed ductsections can cause considerable loss in coolingcapacity due

to air leakages.

- Inadequate duct installationin attic space will cause heat gain in the system.

- Unit is precharged, but should a charge be necessary, it should be verified against

the operating system pressures, temperatures, and current draws as specified in the

catalog.

These heat pumps have proven their reliability over several decades. Years of research, engineering

and only the highest quality component partsand workmanship have gone intothese heat pumps to"

make them the mostreliable inthe industry. Before a model is released for production,it undergoesa

battery of testsin environmental test rooms withtemperatures rangingfrom sub-freezing 0°F to 120°F

desert temperatures.

-1 -

II. DIMENSIONS

• k

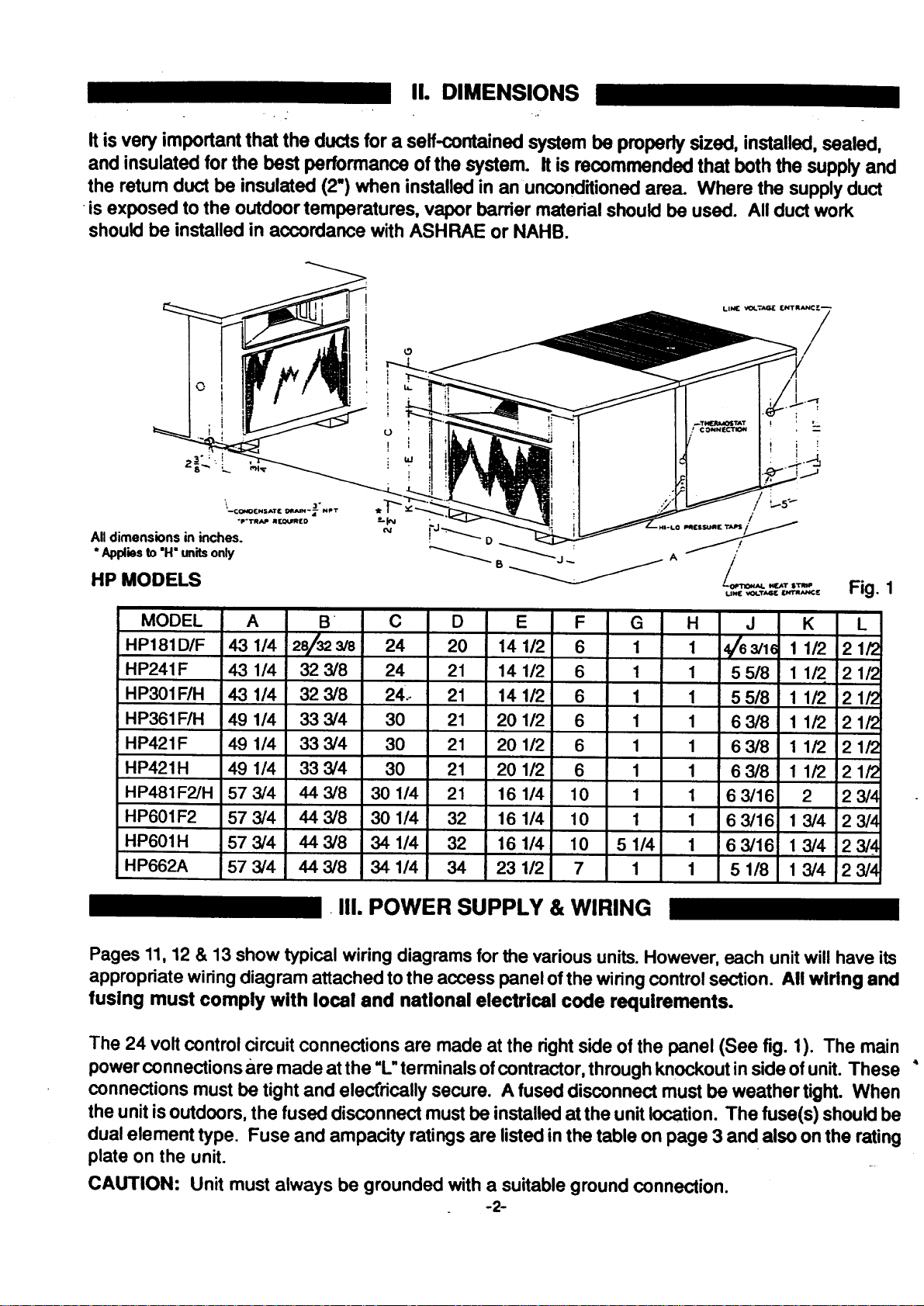

It is very important that the ducts for a serf-contained system be properly sized, installed,sealed,

and insulated for the best performance of the system. It is recommended that boththe supplyand

the retum duct be insulated (2") when installed in an unconditionedarea. Where the supplyduct

is exposed to the outdoor temperatures, vapor barrier material should be used. All duct work

shouldbe installed in accordance with ASHRAE or NAHB.

I

I

/

HP MODELS

MODEL A B C D E

HP181D/F 43 1/4 28/323/8 24 20 14 1/2

HP241F 43 1/4 32 3/8 24 21 14 1/2

HP301F/H 43 114 32 3/8 24.- 21 14 112

HP361F/H 49 1/4 33 3/4 30 21 20 1/2

HP421F 49 1/4 33 3/4 30 21 20 1/2

HP421H 49 1/4 33 3/4 30 21 20 1/2

HP481F2/H 57 3/4 44 3/8 30 1/4 21 16 1/4

HP601F2 57 3/4 44 3/8 30 1/4 32 16 1/4

HP601H 57 3/4 44 3/8 34 1/4 32 16 1/4

HP662A 57 3/4 44 3/8 34 114 34 23 112

F G H J K L

6 1 1 4/63/1( 1 112

6 1 1 55/8 11/2 !21/2

6 1 1 55/8 11/2 21/2

6 1 1 63/8 11/2 21/2

6 1 1 63/8 11/2 21/2

6 1 1 63/8 11/2 21/?

10 1 1 63/16 2 23/4

10 1 1 63/16 13/4 23/4

10 51/4 1 63/16 1 3/4 23/4

7 1 1 51/8 13/4 23/4

Fig. 1

2 1/2

i

_lJ. III. POWER SUPPLY & WIRING

Pages 11, 12 & 13 show typical wiring diagrams for the various units. However, each unit will have its

appropriate wiring diagram attached to the access panel of the wiring control section. All wiring and

fusing must comply with local and national electrical code requirernents.

The 24 volt control circuit connections are made at the rightside of the panel (See fig. 1). The main

powerconnections are made at the "L"terminals ofcontractor, through knockoutinside ofunit. These

connections must be tightand elect'ricallysecure. A fused disconnect must be weather tight. When

the unit isoutdoors,the fused disconnect mustbe installedat the unit location. The fuse(s) shouldbe

dual element type. Fuse and ampacity ratingsare listedinthe table on page 3 and also on the rating

plate on the unit.

CAUTION: Unit must always be grounded with a suitable ground connection.

-2-

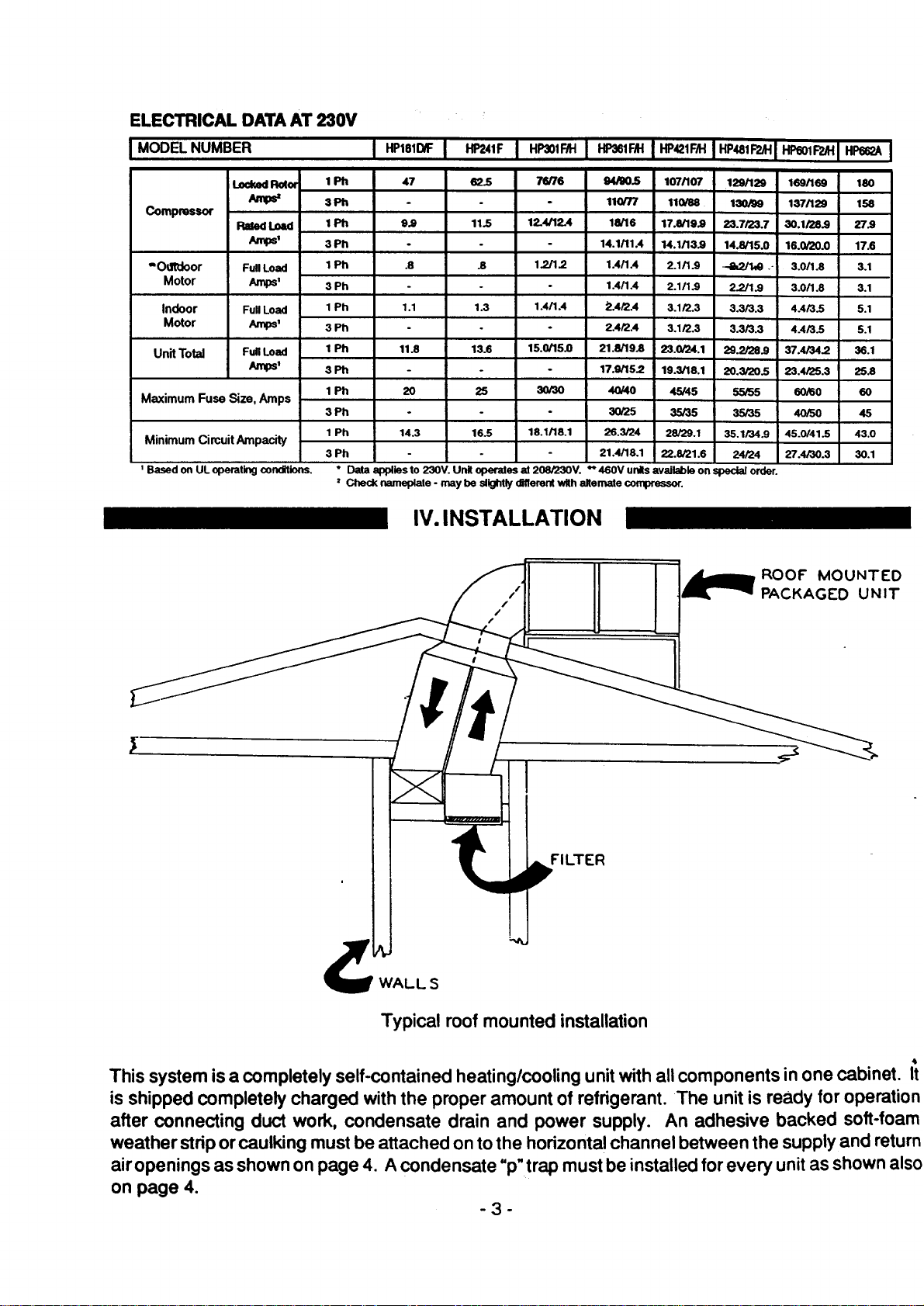

ELECTRICAL DATA AT 230V

MODELNUMBER I I I H O,F I I I I

Compressor

-OL1tdoor

Motor

Indoor

Motor

Full Load

J_ps'

Full Load

,a_ps,

UnitTotaJ

MaximumFuseSize,Amps

MinimumCircuitAmpacity

i Based on UL operating conditions.

1Ph

3Ph

1Ph

3 Ph

1 Ph

3 Ph

1 Ph

3 Ph

1Ph

3Ph

1Ph

3 Ph

1 Ph

3 Ph

° Data appliesto230V.Unit operatesat 208/230V. "* 460V unitsavailableon specialorder.

= Check nameplate- maybe sllghUydifierer_withalternatecompressor.

47

9.9

.8

1.1

11.8

20

14.3

62.5 76/76

11.5 12.4/12.4

.8 1.2/1.2

1.3 1.4/1.4

13.6 15.0/15.9

. .

25 30/30

. o

16.5 18.1/18.1

°

IV. INSTALLATION

94/00.5 107/107 129/129 169/169 180

.

.

110/T/ 110/88 130/99 137/129 158

18/16 17.8/19.9 23.7/23.7 30.1/28.9 27.9

14.1/11.4 14.1/13.9 14.8/15.0 16.0/20.0 17.6

1.4/1.4 2.1/1.9 _ --1 3.0/1.8 3.1

1.4/1.4 2.1/1.9 2.2/1.9 3.0/1.8 3.1

2.4/2.4 3.1/2.3 3.3/3.3 4.4/3.5 5.1

2.4/2.4 3.1/2.3 3.3/3.3 4.4/3.5 5.1

21.8/19.8 25.0/24.1 25.2/28.9 37.4/34.2 36.1

17.9/15.2 19.3/18.1 20.3120.5 23.4/25.3 25.8

40/40 45/45 55/55 60/60 60

30/25 35/35 35/35 40/50 45

26.3/24 28/29.1 35.1/34.9 45.0/41.5 43.0

21.4/18.1 22.8/21.6 24124 27.4/30.3 30.1

/

/

FILTER

WALL S

Typical roof mounted installation

ROOF MOUNTED

PACKAGED UNIT

This system is a completely self-contained heating/cooling unit with all components in one cabinet. It

isshipped completely charged with the proper amount of refrigerant. The unitis ready for operation

after connecting duct work, condensate drain and power supply. An adhesive backed soft-foam

weather strip or caulking must be attached on to the horizontal channel between the supply and return

air openings as shown on page 4. A condensate "p"trap must be installed for every unit as shown also

on page 4.

-3-

Loading...

Loading...