GOEBEL GO-39 Instruction Manual

14

1)

2)

3)

4)

Position Rack Bearing Plate (9) through the rear of Aluminum Body (1) into the slot, then push Gear Rack (8)

forward into the front of Aluminum Body (1).

Position the first tooth of Gear Sector (10) engaged with the first tooth of Gear Rack (8) <NOTE: Can use a

screwdriver to adjust Gear Sector (10) position.>, the hole of Gear Sector (10) should align with the front Pivot

Pin hole, install the first Pivot Pin (17) with Pivot Pin Washer (16) and Snap Ring (15) to the front Pivot Pin hole

of Aluminum Body (1). When assembled correctly, the wider section (W) of Gear Sector (10) should face down to

Lower Handle (12) position.

Swing Upper Handle (11) to the front and to position the first tooth of Driving Gear (11) engaged with the first

tooth of Gear Sector (10) <NOTE: Can use a screwdriver to adjust Gear Sector (10) position.>, the hole of

Driving Gear (11) should align with the rear Pivot Pin hole, install the second Pivot Pin (17) with Pivot Pin

Washer (16) and Snap Ring (15) to the rear Pivot Pin hole of Aluminum Body (1).

Reassemble Head (3) back to Aluminum Body (1) firmly.

B

REASSEMBLY:

NOTE: ALWAYS CHECK Fig. E CAREFULLY TO REASSEMBLE.

E.

1)

2)

PROBLEM - Rivet Mandrel can not be inserted into Working Nosepiece (2) or Spent Mandrel can not be ejected

after setting.

CAUSE 1 - Handles (11, 12) are not fully opened.

CORRECTION 1 - Open Handles (11, 12) fully.

CAUSE 2 - Working Nosepiece (2) is loose.

CORRECTION 2 - Tighten Working Nosepiece (2) with service Wrench (18).

PROBLEM - Rivet Mandrel is not gripped or Tool requires more operations than normal to set Rivet.

CAUSE 1 - Jaws (5) are dirty, worn or broken.

CORRECTION 1 - Clean or replace Jaws (5).

CAUSE 2 - Working Nosepiece (2) is loose.

CORRECTION 2 - Tighten Working Nosepiece (2) with service Wrench (18).

F. TROUBLE SHOOTING GUIDE:

When operating, ALWAYS WEAR SAFFTY

GOGGLES TO PROTECT YOUR EYES.

Tool must clear off and eject the Spent

Mandrel from Tool before setting next Rivet.

2017 GOEBEL

C

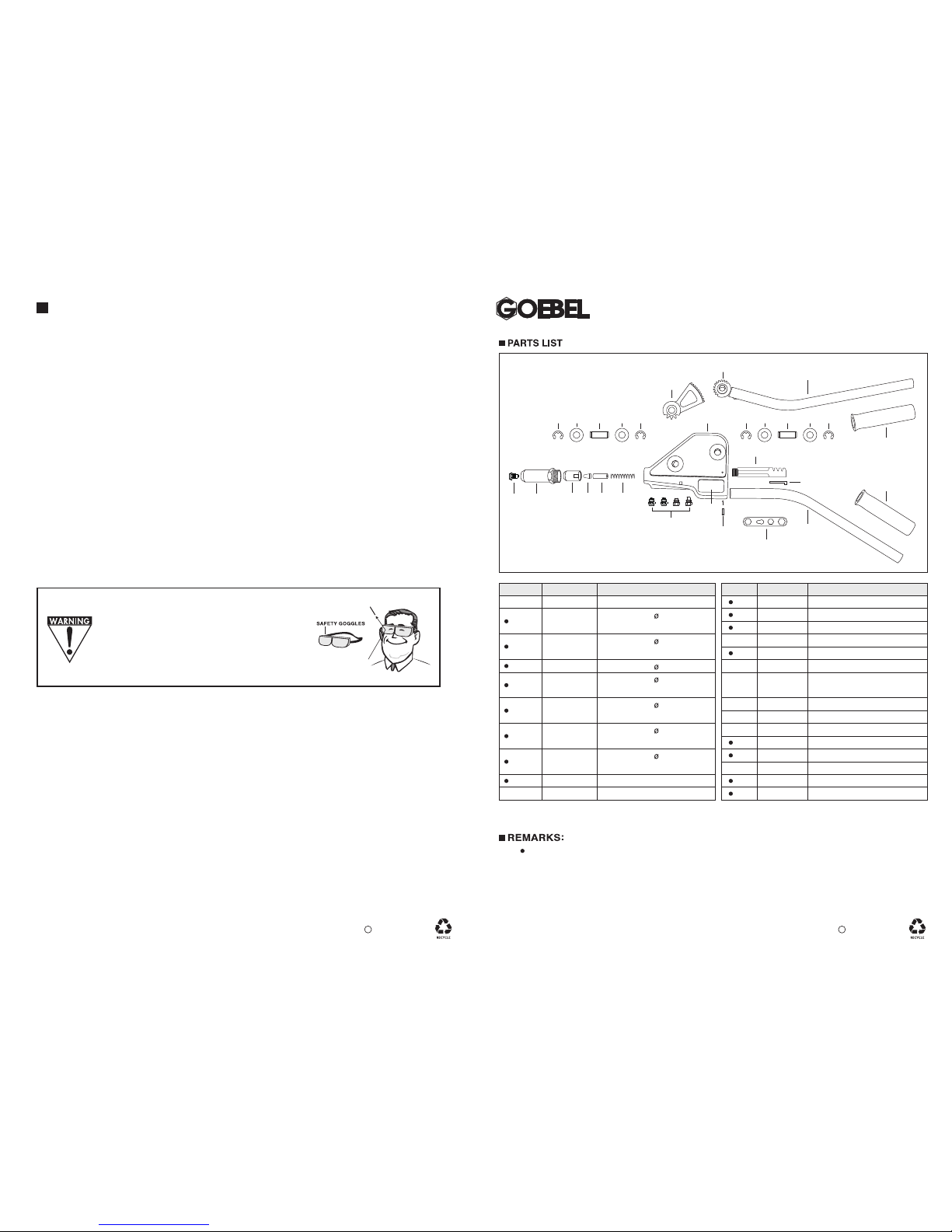

No. Part No. Part Name

1

2-40

2-48

2-64

2-48M

2-64M

2-64T

GO-39-0240

GO-39-0248

GO-39-0264

GO-39-01 Aluminum Body

Nosepiece, for 4.0 mm or

5/32” Rivet

Nosepiece, for 4.8/5.0 mm or

3/16” Rivet

Nosepiece, for 6.0 mm

Nosepiece, for 6.4 mm or

1/4” Rivet

Nosepiece, for 4.8/5.0 mm or

3/16” *Monobolt Rivet

Nosepiece, for 6.4 mm or

1/4” *Monobolt Rivet

Nosepiece, for 6.4 mm or

1/4” *T Rivet

Head, Standard

Jaw Case

No. Part No. Part Name

5

6

7

8

9

10

12

13

14

15

16

17

18

19

11 GO-39-11

GO-39-05

GO-39-06

GO-39-07

GO-39-08

GO-39-09

GO-39-10

GO-39-12

GO-39-13

GO-39-14

GO-39-15

GO-39-16

GO-39-17

GO-39-18

GO-39-19

1

4 5 6 7

18

14

19

19

13

8

15 16 17 16 1515 16 17 16 15

32

10

11

Driving Gear

12

2

9

2017 GOEBEL

C

Jaws, 3-pc Type

Jaw Pusher

Jaw Pusher Spring

Gear Rack

Rack Bearing Plate

Gear Sector

Driving Gear & Upper

Handle Assembly

Lower Handle

Name Plate

Drive Pin

Snap Ring

Pivot Pin Washer

Pivot Pin

Wrench

Grip

1) means Wearing Parts or Possible Missing Parts.

2) GO-39 Rivet Tool can set Ø4.8 mm (3/16") & Ø6.4 mm (1/4") *Monobolt Rivets and Ø6.4 mm (1/4") *T Rivet.

3) GO-39 Rivet Tool may install various Nosepieces for different applications on request.

4) GO-39 Rivet Tool can be packed in a Plastic Carry Case or Steel Carry Case on request.

5) *Monobolt Rivet and *T Rivet are the registered trademark of Avdel.

Gear Type Hand Rivet Tool GO-39

Industrial

Heavy Duty

GO-39-0260

GO-39-03

GO-39-04

GO-39-0248M

GO-39-0264M

GO-39-0264T

2-60

3

4

Lorem ipsum

A. FEATURES:

GOEBEL Big Shark GO-39 Heavy-Duty Rivet Tool has advanced Gear & Lever Dual System offering powerful

riveting capacity, 3-Jaw System provides not only stronger riveting power but also Rivet Mandrel easy loading and

Spent Mandrel easy ejection. Powerful riveting capacity can set 4.0, 4.8/5.0, 6.0, 6.4 mm or 5/32", 3/16", 1/4"

diameter Blind Rivets in all materials (Aluminum, Steel, Copper, Stainless Steel/Inox), also can set 4.8/5.0 & 6.4 mm

or 3/16" & 1/4" diameter *Monobolt rivets and set 6.4 mm or 1/4" diameter *T-Rivet. Quick-Maintain Head is easy to

clean or replace Jaws, Jaw Pusher and Jaw Pusher Spring. No adjustment is required after reassembling the parts.

C. HOW TO SELECT AND CHANGE NOSEPIECES (2):

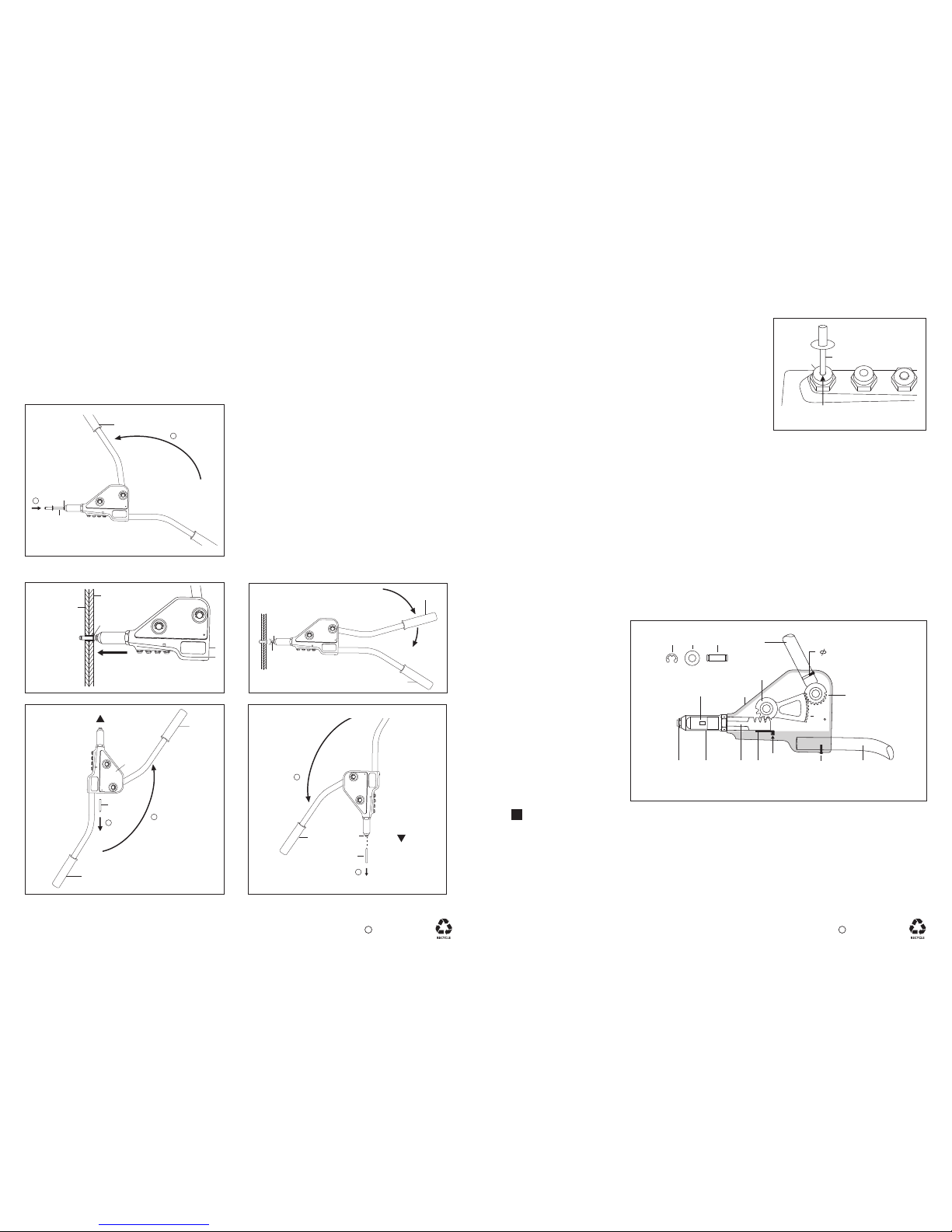

B. HOW TO OPERATE GO-39 TOOL TO SET BLIND RIVET:

1)

2)

3)

4)

Open Upper Handle (11) fully and insert Rivet Mandrel all

the way into Working Nosepiece (2) (Fig. 1).

Hold Rivet Mandrel in the Tool, insert Rivet Body into the

prepared hole of work pieces to be fastened, and press

Blind Rivet firmly to assure the Rivet Head is in contact

with the work piece (Fig. 2).

Squeeze Upper Handle (11) toward Lower Handle (12)

until Rivet Mandrel breaks off (Fig. 3). If more than one

squeeze is required to break off Rivet Mandrel, open

Upper Handle (11) fully, push Working Nosepiece (2) to

contact Rivet Head and squeeze Upper Handle (11)

again.

Open Upper Handle (11) fully and tilt Tool up to eject

the Spent Mandrel from the rear of Aluminum Body (1)

(Fig. 4), or open Upper Handle (11) fully and tilt Tool down

to eject the Spent Mandrel from the Working Nosepiece

(2) (Fig. 5).

2

1)

2)

3)

4)

Use the Mandrel of Blind Rivet to be applied as a Gauge, select the

Working Nosepiece (2) with the smallest hole that Mandrel can insert

into easily (Fig. C).

Close Tool Handles (11, 12) completely. CAUTION: If Tool Handles

(11, 12) are not completely closed before loosening the Working

Nosepiece (2) installed in Head (3), the Working Nosepiece (2) may

be forcibly ejected by the Jaw Pusher Spring (7). Do Not point Tool

at anyone when changing Nosepieces!

Remove Working Nosepiece (2) from Head (3) and store it into

Aluminum Body (1) with service Wrench (18).

Install and tighten the selected Working Nosepiece (2) to Head (3)

with service Wrench (18).

D. HOW TO CLEAN AND REPLACE JAWS (5), JAW PUSHER (6) AND JAW

PUSHER SPRING (7):

1)

2)

3)

4)

NOTE: If Jaws (5) can not bite or slip on the Rivet Mandrel, it is suggested to clean teeth of Jaws or replace new

Jaws (5). When Tool Handles (11, 12) are fully opened, but Jaws (5) are still not open completely, it is suggested

to check and replace new Jaw Pusher (6), Jaw Pusher Spring (7) and Nosepiece (2).

Close Tool Handles (11, 12) completely.

Remove Head (3) from Aluminum Body (1).

Remove Jaw Case (4), take out Jaws (5), Jaw Pusher (6) and Jaw Pusher Spring (7) from Jaw Case (4) and

Gear Rack (8). Clean teeth of Jaws with a wire brush, inspect Jaws for worn or broken teeth. Replace new

Jaws (5), Jaw Pusher (6) and Jaw Pusher Spring (7) if needed.

Lubricate outside surface of Jaws (5) and inside surface of Jaw Case (4) with a film of light machine oil.

Reverse above steps to reassemble, making sure Jaw Case (4) and Head (3) are tightened firmly.

3

E.E.HOW TO REPLACE GEAR RACK (8), RACK BEARING PLATE (9), GEAR SECTOR (10),

AND DRIVING GEAR & UPPER HANDLE ASSEMBLY (11):

NOTE:

Carefully check the Fig. E

and follow instructions,

otherwise damage might be

caused to the Tool.

1)

2)

3)

4)

Remove Head (3).

Remove Jaw Case (4), take out Jaws (5), Jaw Pusher (6) and Jaw Pusher Spring (7).

Remove the rear Snap Ring (15) and rear Pivot Pin Washer (16) from one side of Aluminum Body (1), then

press out rear Pivot Pin (17). Now the Driving Gear & Upper Handle Assembly (11) can be removed.

Remove front Snap Ring (15) and front Pivot Pin Washer (16) from one side of Aluminum Body (1), then press

out front Pivot Pin (17). Now the Gear Sector (10), Gear Rack (8) and Rack Bearing Plate (9) can be removed

from the rear of Aluminum Body (1). Replace the worn or broken Part(s).

A

DISASSEMBLY:

Fig. E

2017 GOEBEL

C

2017 GOEBEL

C

Fig. 1

Fig. 4

1

11

1

12

Spent

Mandrel

2

TOOL UP

Fig. 5

1

2

11

Spent

Mandrel

TOOL

DOWN

2

11

12

Fig. 3

2

Rivet Mandrel

Fig. 2

3.2

W

832

4

10

1

11

9

12

SLOT

14

Driving Gear

or 1/8”

Rivet

Fixed by a

15 16 17

Fig. C

Mandrel ( =Gauge)

Smallest Hole

2

2

11

Rivet Mandrel

2

1

Work Piece 1

Rivet Head

Work Piece 2

Loading...

Loading...