― INSTRUCTIONS ―

Operation and

Service Manual

May 2018

GO-DEVIL® Manufacturing Company of Louisiana LLC

(225) 752-0167 • Toll Free 1-888-490-3254 • Fax (225) 752-0175

18649 Womack Road • Baton Rouge, LA 70817

Please visit our website at www.godevil.com

SURFACE DRIVE SAFETY

• GASOLINE IS EXTREMELY FLAMMABLE! Always handle in properly approved containers.

Spilled fuel could ignite if it comes in contact with a hot engine or sparks!

• DO NOT LEAVE ANY FUEL TANK CONNECTED WHEN THE BOAT IS NOT IN USE.

TANKS SOLD AFTER JULY 2011 DO NOT HAVE A STANDARD VENT! Heat from the

suns radiation will build pressure inside the fuel tank and will force fuel through the carburetor

and into the crankcase. At this point the crankcase will become over full and will blow oil into

the air cleaner from the breather. After the air cleaner becomes saturated with oil, the fuel

mixture will become too rich and will foul the spark plugs.

• KEEP HANDS, FEET, HAIR, AND CLOTHING AWAY FROM ANY MOVING PARTS to

prevent accidents while engine is running both in the water and, most importantly, while on

land!

• WARNING!! – The trim knob is angled outward and away from a pinch point between the

engine and transom bracket. DO NOT PLACE HANDS BETWEEN ENGINE AND

TRANSOM BRACKET WHILE ENGINE IS RUNNING!!! If the skeg or prop strikes an

obstruction while underway, the engine may tilt violently and cause injury.

• NEVER TOUCH ENGINE COMPONENTS DURING OR IMMEDIATELY AFTER

OPERATION. Components can become extremely hot which could result in severe burns!

• NEVER RUN YOUR SURFACE DRIVE IN AN ENCLOSED AREA! Exhaust gases contain

poisonous carbon monoxide! Always test run in a well-ventilated area.

• ALWAYS OPERATE YOUR SURFACE DRIVE WITH THE SAFETY KILL SWITCH

LANYARD ATTACHED TO YOUR WRIST OR BELT LOOP! After warm up, always test your

safety kill switch to make sure it is operating properly!

• OPERATE YOUR SURFACE DRIVE FROM A SITTING POSITION, unless you install a grab

bar in your boat to operate while standing!

• BE ALERT FOR HAZARDS AT ALL TIMES! Shallow water areas in particular can present

a variety of challenges. Continually read the terrain for unexpected obstructions, turns, or

changes in water depth.

• KEEP YOUR SURFACE DRIVE IN A SAFE CONDITION. It is important to keep your engine

properly maintained. Having a breakdown can be difficult, especially if you are far away from

help or land. To help avoid problems, inspect your engine before each use and perform all

recommended maintenance.

TABLE OF CONTENTS

SURFACE DRIVE SAFETY

ASSEMBLY AND BOAT SETUP................................................................................. 1-4

• Crate Removal.................................................................................................... 1-2

• Boat Setup....................................................................................................... 3-4

• Bolting Engine to Transom................................................................................. 3

OPERATION INSTRUCTIONS.................................................................................... 5-9

• Surface Drive Features........................................................................................ 5

• Launching, Engine Starting.................................................................................. 6

• Low Speed Operation.......................................................................................... 7

• High Speed Operation, Trim Adjustment........................................................... 7-8

• Reverse Operation on Go-Devil Surface Drive FNR…………………………….... 9

LUBRICATION......................................................................................................... 10-12

• Engine Lubrication............................................................................................. 10

• External Grease Fittings.................................................................................... 10

• Pressure Lubrication.......................................................................................... 11

• Internal Drive Lubrication................................................................................... 12

BELT TENSION AND INSTALLATION.................................................................... 13-15

• Tension Tester...How it Works!.......................................................................... 13

• Checking Belt Tension....................................................................................... 14

• Adjusting Belt Tension, Replacing belt................................................................ 15

SPECIAL TOOLS TO SERVICE SURFACE DRIVES………………………………….... 16

CHANGING TRANSMISSION OIL……………….…………………………………….…… 17

CLUTCH AND TRANSMISSION REMOVAL………………………………………..… 18-19

CLUTCH AND TRANSMISSION INSTALLATION………………………………...….. 19-21

LOWER SEAL REPLACEMENT…………………………………………………………… 22

INSTALLING THE LOWER SEAL HOUSING……………………………………………. 23

PROPELLER REMOVAL/INSTALLATION……………………………………………….. 23

SHAFT REMOVAL/INSTALLATION………………………………………………………. 24

BUSHING REMOVAL AND INSTALLATION…………………………………………….. 25

SURFACE DRIVE FNR LOWER DRIVE ASSEMBLY…………………………………... 26

SERVICE MEMOS………………………….………………………………………………... 21

WARRANTY

1

TO THE NEW OWNER

Dear Customer,

You have just purchased one of the toughest pieces of marine equipment ever built. The

GO-DEVIL Surface Drive will give you many years of service with very little maintenance.

Of the few problems that occur, most are due to dirty fuel or not running the engine out of

fuel at the end of the season. We have found that unleaded gasoline will gum the

carburetor in a few months if your engine is not in use. We recommend adding a fuel

stabilizer such as Briggs & Stratton part number 100117(4oz) 100119A(32oz) to the fuel

in your last full tank of the season. Always disconnect the fuel hose from the tank and

run the engine completely out of fuel before storage if your engine has a carburetor!

Fuel injected engines do not need to be run out of gas but add stabilizer and

disconnect the battery and fuel tank. Fuel tanks should also be checked periodically

for water which may appear from condensation. We recommend using a transom

mounted water separating fuel filter (Sierra part # 18-7852-1 or equivalent) to collect water

before it reaches the engine.

ASSEMBLY AND BOAT SETUP

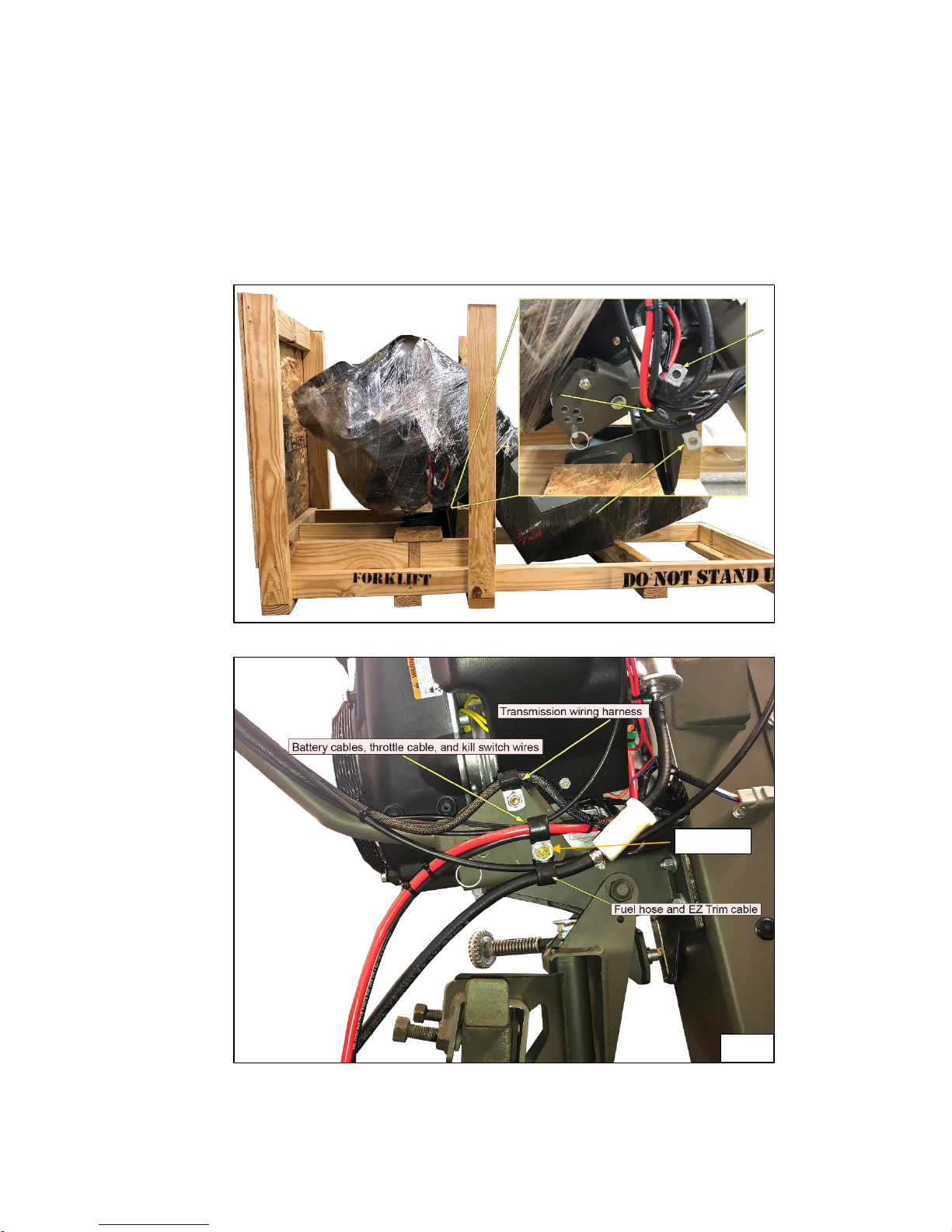

1. Lay the crated engine flat with the engine in a normal upright position.

2. Remove the plywood and 2x4’s surrounding the engine.

3. Locate the metal band holding down the prop end of the Surface Drive frame and

cut it with a pair of tin snips or remove the nails with a claw hammer.

4. Remove the plastic wrapping from the engine.

5. Inspect the engine for freight damage and contact our office immediately if

anything seems damaged. Note that the tail end of the skeg just in front of the

propeller is factory bent. This bend is designed to compensate for torque created

by the surfacing propeller.

6. Loosen the transom clamping studs located under the engine.

7. Locate the lifting eyes on the frame just below the muffler. Using the lifting eyes,

hoist the engine vertically from the crate and place it onto the transom of your boat.

8. Center the engine on the transom measuring from the outside gunnel rails of the

boat to the edges of the transom bracket. Tighten the clamping studs using a

crescent wrench or 1-1/16” wrench or socket (15/16” wrench for galvanized

models).

9. Remove the tiller handle from the frame by cutting all plastic tie-wraps that have

not been trimmed.

2

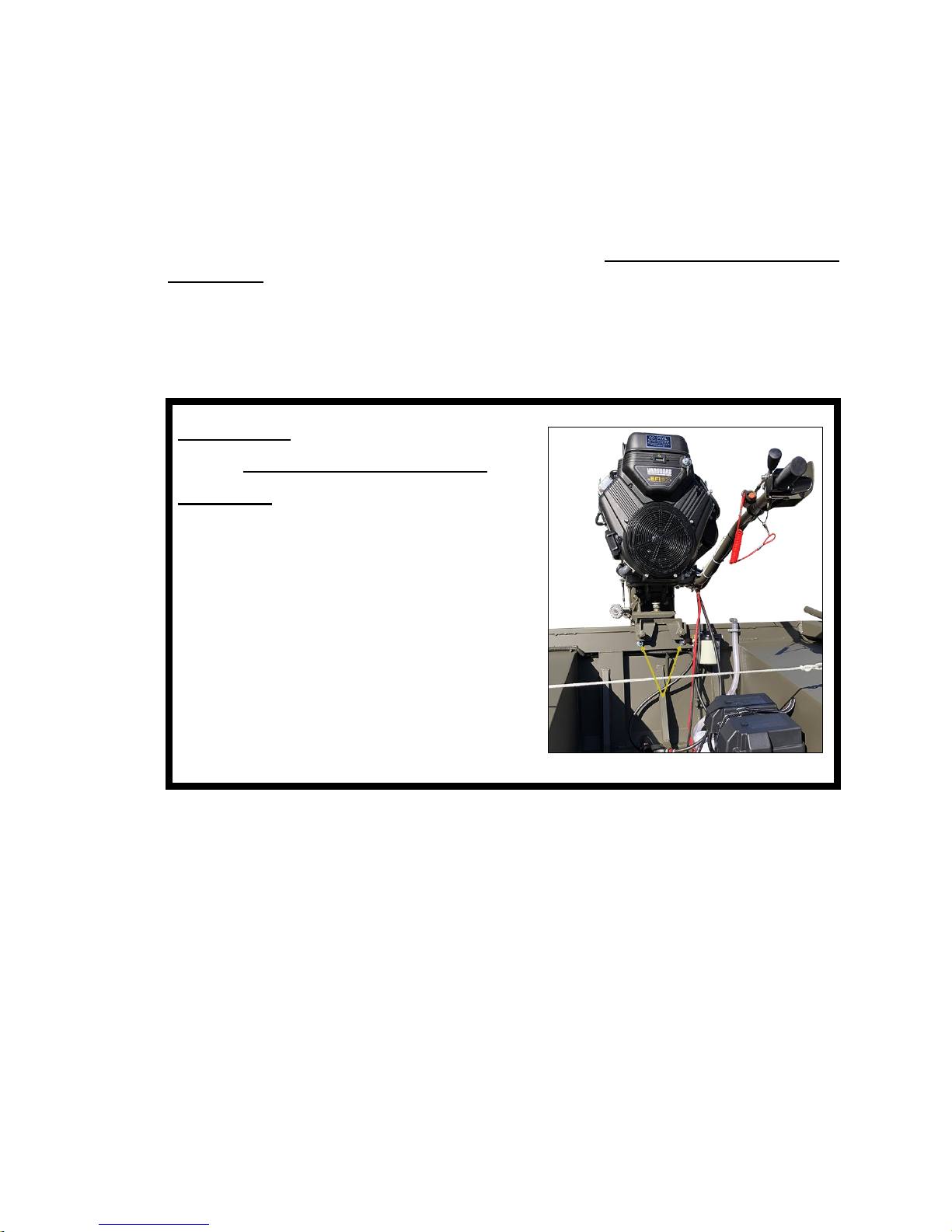

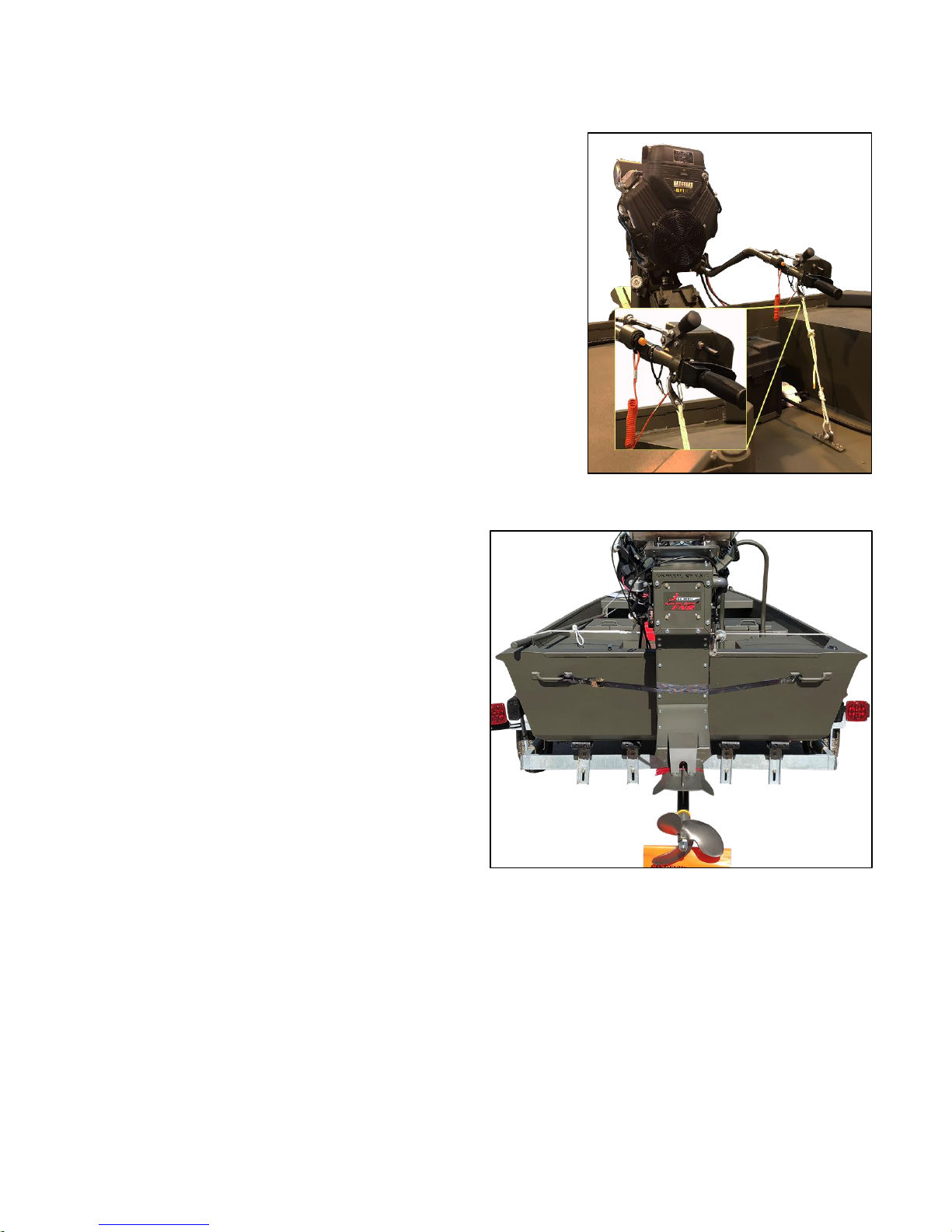

10. The 3/8”x 2-1/2” pivot bolt indicated by the arrow in (Fig. 1) is the pivot point for

the Adjustable/Floating handle. Remove the bolt and insert the handle into the

engine-mounted handle bracket. Reinstall the bolt into the bracket, passing it

through the hole at the end of the handle. Be sure to include the wire loom to

secure the cables as it was shipped. Install the washer and nut and tighten the nut

firmly or until a slight amount of drag can be felt while pivoting the handle up and

down from the grip.

37 hp Vanguard Shown

Check to ensure that the throttle linkage on the engine moves throughout its full

range when the throttle lever is depressed and that it returns to the idle position

when released.

Fig. 1

Pivot Bolt

3

For added safety, a stainless-steel throttle return spring has been installed on

engines with a carburetor during factory assembly. This spring returns the throttle

linkage to idle position when the squeeze lever is released. To ensure that the

throttle operates smoothly on engines with a carburetor, periodically lubricate the

throttle linkages with a WD-40 type spray lubricant. This is not necessary for an

EFI engine. For freezing temperatures, stand the handle in a vertical position and

inject antifreeze into the throttle cable with a hypodermic needle and work the

throttle back and forth. This will keep any moisture from freezing your throttle.

12. Bolt the engine to the transom as described below.

Looking from the rear of the engine, notice that the transom clamp has two

horizontal rows of holes. Either the two upper or two lower holes need to be used

to secure the engine to the transom. Four holes are provided to accommodate

various transom designs.

Using a 3/8” drill bit, drill through the lowest hole pattern on the bracket which

would allow the bolts to pass through a structural cross-member of the transom.

Install the two supplied 3/8” x 3” bolts, washers and nylon insert nuts. For GoDevil boats, the engine should be bolted to the transom using the two top holes.

ATTENTION: The Go-Devil Surface Drive

engine MUST BE BOLTED TO THE

TRANSOM!!!!! Failing to do so will cause

the transom clamp to loosen while

trailering, allowing the engine to possibly

fall off of the transom!!!!

BOLTS MUST PASS THROUGH A

STRUCTURAL CROSS-MEMBER OF THE

TRANSOM!!! (channel, tube, rib, etc.)

4

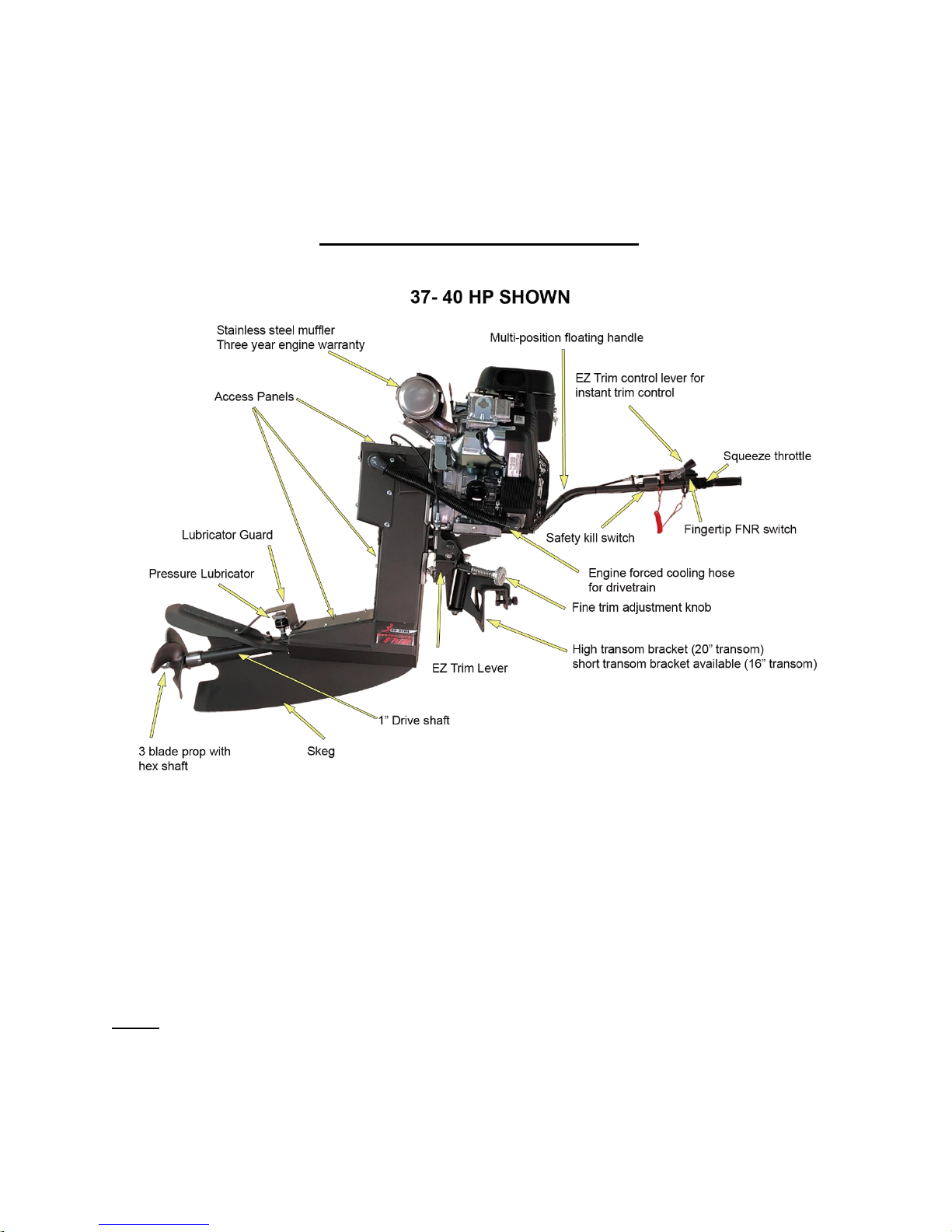

13. Tie a rope to the rib in your boat under the loop

welded on the underside of the Surface Drive

handle. Attach the clip provided with the engine to

the rope and use it to hold the Surface Drive

handle as shown in the picture to the right. This

clip should be used for launching your boat or any

time you need to hold the prop out of the water.

(It MUST not be used when the boat is being

trailered.)

14. Connect the battery cables to the battery. Attach

the red cable to the positive (+) side of the battery

and attach the black cable to the negative (-) side

of the battery. Make sure to tighten the battery

cables with a wrench and not just hand tight.

The battery should be kept in a covered battery

box secured to the floor of the boat and away from

gasoline vapors.

15. We recommend using a good nylon

rope to tie your boat instead of a boat

strap. Tie the rope to the trailer frame

on one side of the boat even with the

hand grip. Bring the rope over the

boat, then tie a loop in the rope before

the rope comes down the side of the

boat. Bring the rope around the trailer

frame and back up to the loop, cinch

the rope tight and tie it off.

This procedure will hold your boat as

tight as any boat strap so it will not

bounce when trailering. We also

recommend that you tie a red flag or

the Go-Devil Flag included with your purchase to the tail end of the Surface Drive

when towing your boat down the highway.

16. To tie down the engine for trailering use a ratchet strap attached to one boat handle

then make a wrap around the frame as shown above making sure not to wrap the

strap on top of the cover bolts and then attach the strap to the other boat handle

on the other side of the boat. Do not tie the Surface Drive FNR engine handle

down for any reason while trailering!

5

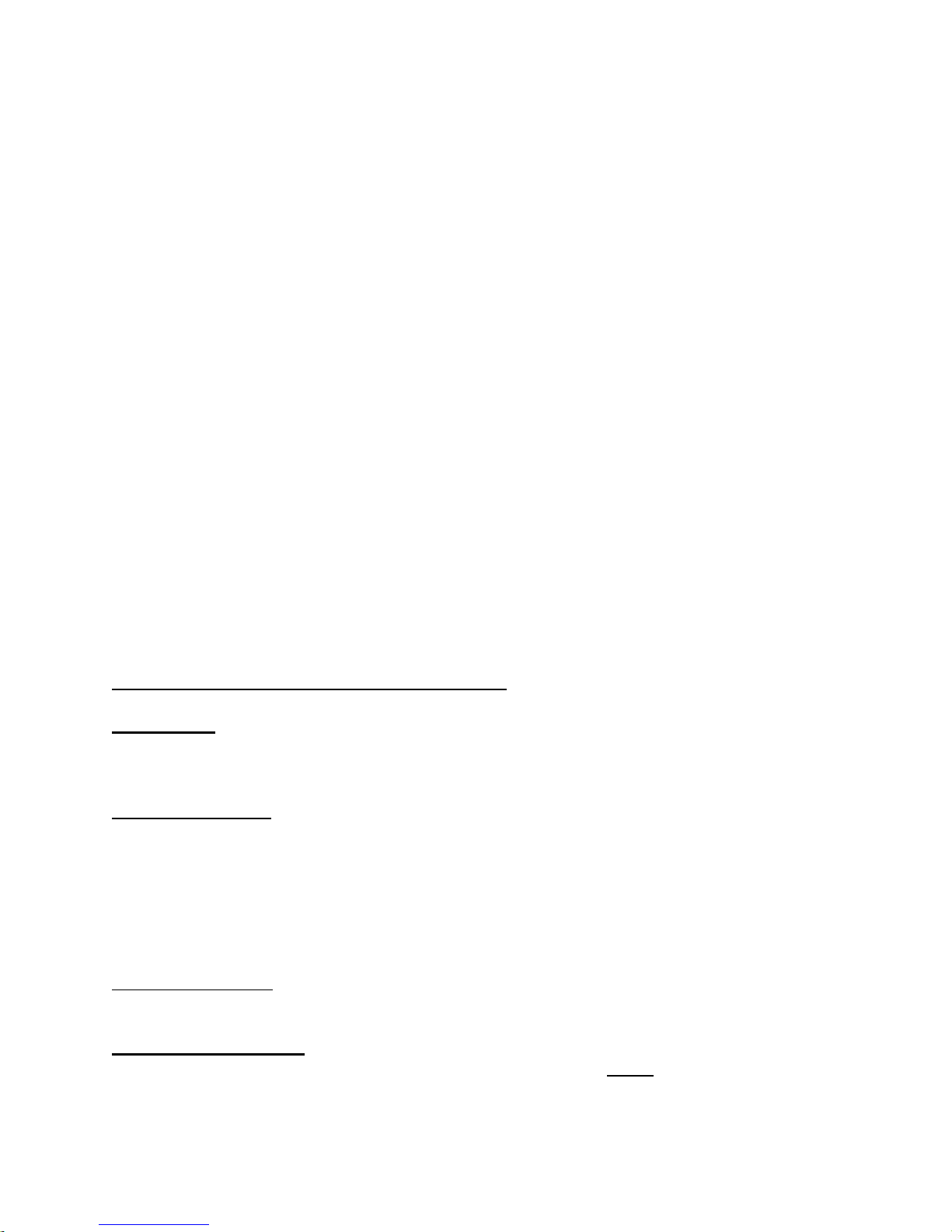

Surface Drive Features

SURFACE DRIVE FNR

OPERATION INSTRUCTIONS

ENGINE OIL

Fill the engine crankcase with the recommended amount and type of oil. With the engine

held perfectly level, check the oil level with the dip stick. Use a high detergent motor oil

of the same viscosity you are using in your car or truck for that time of the year. In warm

temperatures we recommend to use straight 30 weight oil. This will reduce oil

consumption.

Notice: For 23 Vanguard models it is important that the crankcase is not over filled with oil. Over

filling the crankcase will cause a decrease in vacuum at high speed, preventing the carburetor from

supplying an adequate amount of fuel to the engine. When this happens, the engine will starve for

fuel and temporarily lose performance. Ensure that the engine oil level does not exceed the full

level line on the dipstick.

6

FUEL

Fill the fuel tank with clean, fresh gasoline from a clean fuel can. Connect the fuel line

from the engine to the fuel tank and squeeze the primer bulb until firm. If the tank has a

vent (tanks sold before July 2011), the vent must stay open during operation. If you

purchased your tank July 2011 or after, disconnect your tank anytime it is not in use

because the tank does not have an open vent.

BASIC OPERATION

Launching

When launching your boat always leave the handle rope clipped with the shaft in a

horizontal position.

Before starting the engine on the water, always put on your life vest as you would in any

boat with any engine.

Attach the safety kill switch lanyard to your belt loop or wrist.

Starting the Engine

ALWAYS check engine oil level before starting!!

WARNING!!

Never run the engine in an enclosed area! Exhaust contains poisonous carbon

monoxide gas that may cause a loss of consciousness and/or death!

To Start the engine, FNR switch must be in the neutral (center position) to start. Pull the

choke rod to the choke position if your engine is a carbureted model. If you have an EFI

engine wait 5 seconds before starting. You will hear the fuel pump stop priming. Turn the

key to the start position. It may be necessary to run the engine on choke for a few seconds

until the engine warms up. You should run the engine for a few minutes to ensure that it

runs properly. If the engine runs rough after warm up, the carburetor may need

adjustment. (Refer to the engine Manual.)

To Stop the engine, release the throttle and allow the engine to idle for a few seconds.

Turn the key switch to the OFF position.

EMERGENCY STOP! The engine may be stopped at any time by pulling and detaching

the emergency kill switch lanyard from the kill switch. Note: It is the operator’s

responsibility to ensure that the kill switch operates properly before each use.

7

CAUTION! – Lowering the propeller into the water or shifting into forward at a high engine

rpm may cause a standing operator or passenger to lose balance or be ejected from the

boat. ALWAYS ALLOW THE ENGINE TO COME TO IDLE OR SHIFT INTO NEUTRAL

BEFORE LOWERING THE PROPELLER INTO THE WATER!

NOTE: AFTER YOUR FIRST TEST RUN ON THE WATER IT IS NECESSARY TO

REMOVE THE DRAIN PLUG (SHOWN ON PAGE 10) AT THE REAR OF THE DRIVE

HOUSING TO CHECK FOR WATER LEAKING IN. THIS BOX MUST RUN

COMPLETELY DRY. IF WATER COMES OUT OF THE DRAIN PLUG THE COVER

PLATES MUST BE REMOVED AND RE-SEALED WITH A GOOD GRADE SILICONE.

PERFORM THIS CHECK ANY TIME THE COVERS ARE REMOVED AND REPLACED.

Low Speed Operation

As described before, let the engine warm up for a few minutes. Holding the handle

carefully, remove the handle rope and get a feel for the balance of the engine.

For the first time operating your new Surface Drive engine, turn the trim adjustment knob

counterclockwise until the prop and cavitation plate can be fully submerged while the boat

is floating at rest. Under normal conditions the trim can be adjusted for high speed

performance and does not need to be changed while idling or getting back up on plane.

Steer the engine slowly to avoid getting water into or overturning the boat. The

Go-Devil Surface Drive engine is better suited for wider bottomed boats (48” or wider).

Use extreme caution- even while idling -when making sharp turns on narrow boats.

To turn the boat around in a tight situation, allow the boat to nearly come to a complete

stop. While the engine is idling and in neutral, turn the engine all the way to one side and

shift into forward. Most boats will turn in their own length when this is done.

TIP! - Turning left at low speed requires less reach due to the handle being on the left

side of the engine. When reversing direction from rest or idle speed, set up to turn left

whenever possible. This will become instinctive with time.

High Speed Operation

As its name implies, the Go-Devil “Surface Drive”, uses a surface piercing propeller. The

surface propeller is designed to be run primarily with a fraction of each blade breaking the

surface of the water with each revolution. To get maximum performance from the engine,

propeller depth can be fine tuned using the manual trim.

The manual trim mechanism is a standard feature on all SD models. The trim is simply

a bottom stop on the tilt axis of the engine which allows the engine to tilt upward freely

when an underwater obstacle is struck.

8

Manual Trim Adjustment

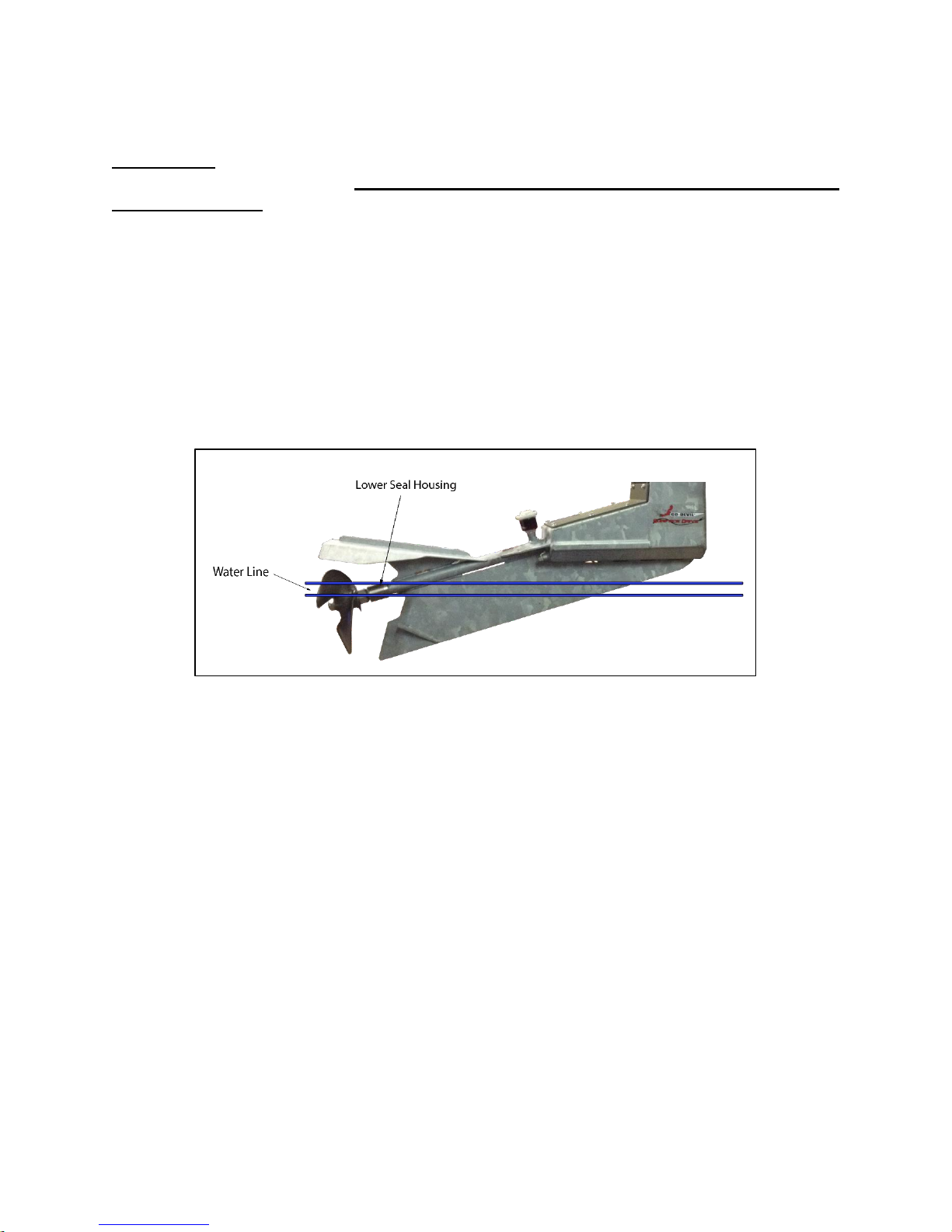

WARNING!! – The trim knob is angled outward and away from a pinch point between the

engine and transom bracket. DO NOT PLACE HANDS BENEATH THE ENGINE WHILE

IT IS RUNNING!!! If the skeg or prop strikes an obstruction while underway, the engine

may tilt violently and cause injury. With the boat floating at rest, set the trim low enough

to fully submerge the propeller and cavitation plate below the waters surface. After getting

up on plane and to full throttle, take notice of the propeller depth.

Trim the engine up until maximum performance and comfort is achieved. For the average

boat and engine combination, the prop should be run with approximately 1/3 of its

diameter above the surface. (Shown below) Different hull designs and horsepower to

weight ratios will affect optimum propeller depth and performance while on plane. If

necessary, the drive ratio may be reduced to accommodate extremely large hulls and

loads.

Starting on May 15th, 2008 all Surface Drive Engines are equipped with an EZ Trim Lever.

The EZ Trim Lever allows the prop height to be dropped approximately 9” without

adjusting the manual trim knob. This allows a smooth and efficient transition between

your trim height for running on plane and “digging” out of a situation where you are stuck

or in extremely shallow water. Simply push down on the Surface Drive handle and flip

down the EZ Trim Lever to drop your prop height. After getting on plane and you are in a

sufficient water depth, push down on the Surface Drive handle again and flip the EZ Trim

Lever back up to come back to your normal trim height.

An engine mounted tachometer/hour meter is a highly recommended accessory since it

allows you to view both engine rpm and total run time. Maximum performance will

generally be achieved between 3400-3800 RPM since the engines make maximum

horsepower within this range. Idle RPM should be 1100-1200 out of the water and 900

RPMs in the water at idle.

9

Reverse Operation on Go-Devil Surface Drive FNR

After the engine warms up, shift the engine into reverse by pushing the FNR switch away

from you to power the electric brake and put the drive unit in reverse. The engine will back

up while the EZ Trim Lever is in the forward run position but you will have more power in

reverse when the E-Z Trim Lever is lowered. To lower the E-Z Trim Lever put the engine

in reverse and start to back up. Now depress the Surface Drive handle downward and

push the E-Z Trim Lever near the throttle backwards to let the prop down to the lower

position. This will allow the prop to drop about 9” to give you more power in reverse. When

you are ready to go forward, depress the handle downward and flip the E-Z Trim Lever

forward and flip the FNR switch back to the forward position. It is not necessary to shift

into reverse before depressing the Surface Drive handle but it will make it a little easier

to depress the Surface Drive handle while in reverse. It is preferred to bring the engine to

idle when shifting. (Illustrations below.) Operating the engine in reverse for an extended

period of time can generate a high heat situation and shorten the transmission’s oil life.

EZ Trim Control Lever Forward Position EZ Trim Control Lever Reverse Position

In the event of an electrical failure, you can use the emergency power supply to bypass

a failed electrical component and place the engine in a “direct drive” state that will allow

you to send 12 volts directly to the clutch and operate the engine in forward or to the

electric brake and operate in reverse. You must unplug both the electric brake

harness and clutch wiring harness if the emergency power supply is being used.

You will not have the option of neutral until you can repair the failed component and will

have to rely on raising the prop out of the water for “neutral”.

1. Remove the connector cover and

cut the tyraps holding all three

connectors together.

2. Remove the cap in the

emergency power supply and

unplug both of the other plugs.

Plug the emergency power

supply into the clutch wiring

harness plug and you can now

operate the engine in forward.

You must unplug both the electric brake harness and clutch

wiring harness if the emergency power supply is being used

10

LUBRICATION

ENGINE LUBRICATION

CHECK ENGINE OIL BEFORE EACH USE. We recommend changing engine oil after the first

10 hours on a new engine and every 50 hours or yearly after that. When changing oil, run the

engine to heat the oil before draining. When changing the oil filter always fill the filter with oil

before installing. Fill crankcase and then prime the oil pump by spinning the engine with the

electric starter for about 10 seconds with the safety kill switch in the kill position. Start the engine

and let it idle for a few minutes before speeding up.

Lubricate the engine’s throttle linkage on carbureted engines as needed with a WD-40 type spray

lubricant. This may or may not be necessary depending on environmental conditions. An

occasional spray will help keep the throttle functioning smoothly. EFI engines do not have any

linkage to lubricate.

EXTERNAL GREASE FITTINGS

The Surface Drive unit has 3 external grease fittings which require periodic lubrication. One fitting

is located on the drive tube and the other two are located on the tilt axis and steering axis (see

photos below). We recommend using a #1 or #2 marine grade waterproof grease such as AQUALUBE to lubricate all fittings.

Grease the steering and tilt axes after every 10-20 hours of run time. Any more often will be

excessive and messy. In addition to lubricating the fittings, apply a small amount of grease to the

transom clamp bolts yearly or as needed.

The fitting shown in the figure on the right below is used for lubricating the prop shaft and lower

bushing and seal system. A pressure lubricator shown to the left of the fitting feeds grease to

the system as needed and allows for heat expansion inside the drive tube. See the following

section on PRESSURE LUBRICATION on page 11 for proper lubrication and maintenance.

The drain plug shown is used to check for water leakage inside the frame housing. This should

be checked after your first test run on the water and again each time the panels are removed

and reinstalled. While the engine is out of the water, remove the plug and tilt the engine back

so that any water inside the housing will drain out of the drain hole. If water comes out when

checked, the panels should be resealed with a good grade silicone.

Grease Fittings

Drain Plug

Pressure

Lubricator

Serial

Number

Location

11

PRESSURE LUBRICATION

A pressure lubricator shown on the previous page is mounted on the upper end of the

drive tube and features a spring loaded piston which creates a small amount of grease

pressure inside the drive tube. This grease volume lubricates the prop shaft, lower bronze

bushing, and lower seals. During assembly the lubricator is intentionally oriented so that

the factory grease fitting is inaccessible. Lubricate ONLY the grease fitting mounted

adjacent to the lubricator to ensure that grease is fed into the drive tube and not just into

the lubricator. Pumping grease through this fitting will fill both the drive tube and the

lubricator.

• Visually inspect the position of the lubricator piston before and after each use.

• The lubricator should be kept about ¾ full so that grease consumption can be easily

monitored. The lower drive system should use up very little or no grease at all when

functioning properly.

• If the grease level does not seem to change after several hours of run time, pump grease into

the drive tube until the piston starts to rise. This ensures that the lubricator piston is not “stuck”

and giving a false impression that the tube is full. If the lubricator and drive tube are properly

filled, the piston should move upward after only a few pumps of grease.

• The lubricator cannot be damaged by over-lubricating the drive unit. The lubricator is

designed so that grease will expel from under the cap if over-filled.

• ATTENTION: The lubricator piston will not reach the bottom of the cup. When the piston

is at its lowest position, the visual grease column will be approximately 3/8” high. When the

piston reaches this level it will no longer supply grease to the tube. In order to insure proper

lubrication, the piston must be kept above this level at all times.

• IT IS THE CUSTOMER’S RESPONSIBILITY TO CHECK AND INSURE THAT THE

LUBRICATOR IS WORKING PROPERLY!! Remove and clean the lubricator yearly to ensure

that it is working properly and the piston is not stuck. If working properly, it should expel

grease from the bottom hole when removed.

• Do not clean the lubricator with a petroleum solvent such as gasoline, varsol, kerosene,

thinner, or carburetor cleaner. Petroleum solvents will destroy the plastic components. Wipe

excess grease with paper towels and clean components with mild dishwashing liquid.

SEAL AND BUSHING WEAR

As the lower and/or upper seals start to wear, the unit may start to consume more grease.

It may be time to replace the seals if the lubricator ever becomes empty after a normal

operation period or requires 10 pumps or more from the grease gun to fill on two

occasions. DO NOT DELAY THIS PROCEDURE!!! If the drive unit is run without grease,

premature wear on the prop shaft and lower bushing will occur and will elevate the cost

of repair. The life of the lower seals is determined by how the shaft is lubricated and how

abrasive the material is that the engine is run in, such as mud, sand, and silt. Under

extensive or commercial use, especially in brackish or salt water, the lower seals should

be replaced annually.

12

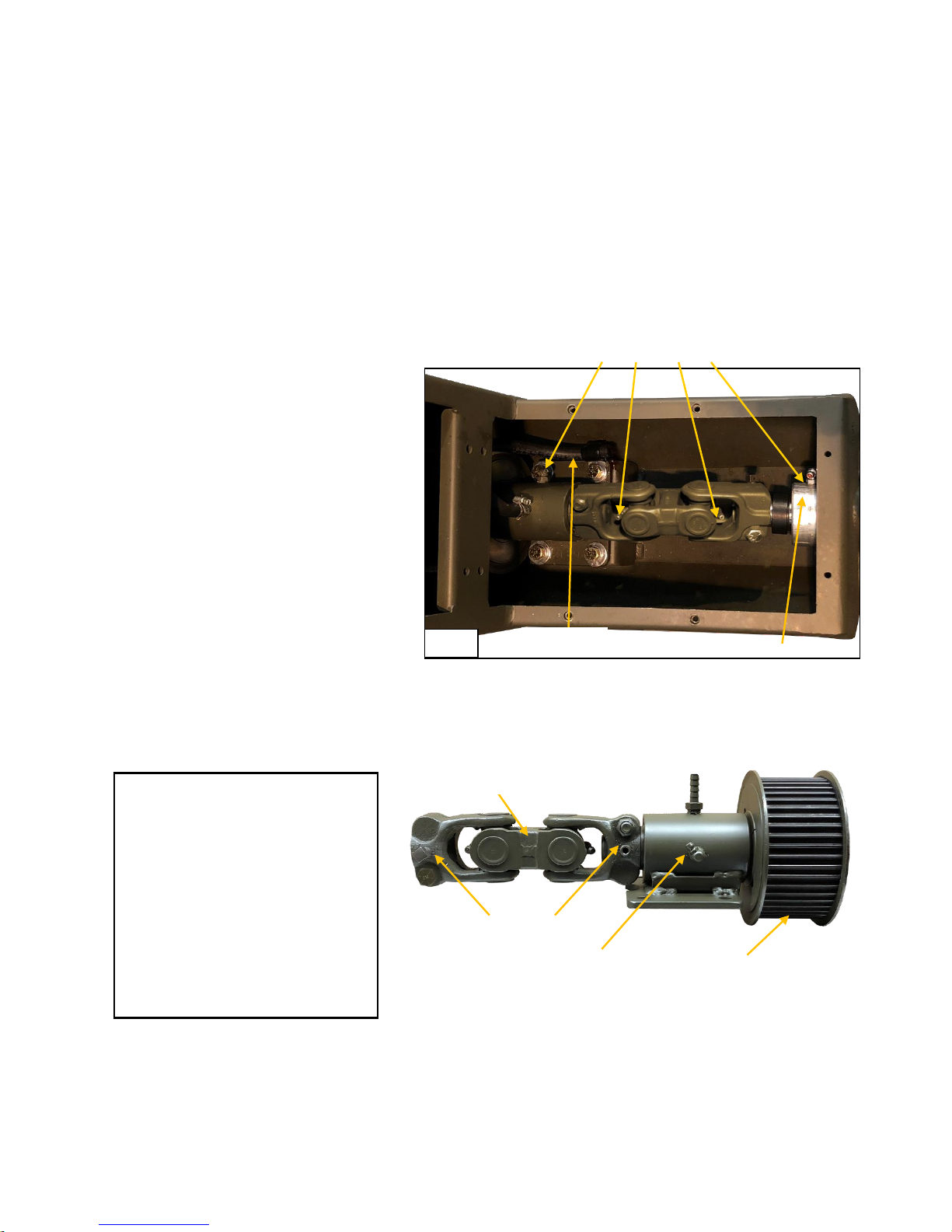

INTERNAL DRIVE LUBRICATION

The Surface Drive unit has 4 internal grease fittings located within the frame housing.

One fitting is located on each of the two universal joints and also on both the upper

bearing housing supporting the prop shaft and on the sprocket shaft bearing housing

shown in the photo below.

After every 75-100 hours of use, lubricate the upper bearing housing and the

universal joint fittings shown below with 2-3 pumps from a grease gun.

The Sprocket Shaft Bearing

Housing shown contains a set of

Tapered Roller Bearings. This

Housing is sealed and grease

lubricated.

After every 75-100 hours of use,

remove the clamp holding the vent

tube connected to the barb fitting

(Fig. 1) and pump grease into the

grease fitting until grease starts to

exit the top of the housing through

the vent hose. Collect excess

grease with a paper towel and

continue pumping grease into the

housing until clean grease starts to expel through the vent hose. Run the engine a few

minutes to mix the old grease with the new grease and kill the engine and pump with

grease again until new grease comes out of the vent tube. Repeat this process three

times and replace the vent tube clamp when finished.

Grease Fittings

Upper Bearing Housing

Grease Fitting

Sprocket

Replace the lower access

panel following the same

instructions as for the upper

panel described on the bottom

of page 15. Add an additional

amount of Silicone to the

corner areas where the bend in

the lower access panel mates

to the frame. Panels must be

sealed properly to keep water

out of the frame housing.

Set Screws

Vent hose

Fig. 1

Double U-Joint

13

BELT TENSION AND INSTALLATION

Gates Tension Testers

(Part# 7401-0076) are available

directly from Go-Devil or any

local Gates Dealer. (See page

14 for Instructions)

Gates Tension Tester...How it works!

The tension tester is pushed against the center of the belt width through the inspection

hole. Pencil type tension testers like this one measures belt tension by showing the force

required to deflect the belt a predetermined distance. Force and deflection on Surface

Drive Engines should be kept within the tolerance listed below. Belts that are run too loose

will cause an increase in driveline vibration resulting in reduced belt life. When

tensioning a new belt, adjust to the high end of the given tolerance to allow for belt

stretch. Never tension the belt more than specified! Over-tensioning the belt may

cause premature wear or damage to the engine and drive unit bearings. If checking

the tension on an existing motor target 17 lbs. for belt tension.

All FNR Models

Force = 13 - 21 lbs. (Target 17 lbs.) Deflection = 1/4”

TOOLS REQUIRED

Torque Wrench (to 250 Lbs.-In.)

3/8” Socket

9/16” Socket

6” long Socket Extension

3/8” Drive Ratchet

9/16” Wrench

11/16” Crowfoot or open end wrench

3/8” Drive universal joint

Gates Tension Tester

Gates Tension Tester

(Product No. 7401-0076)

- Up to 30 lbs. -

Deflection FORCE Scale

Deflection DISTANCE Scale

Sliding Rubber

“O” Ring

14

CHECKING BELT TENSION

Checking Belt Tension on the Surface Drive does not require removal of the rear access

panels. An inspection hole on the side of the frame is provided to inspect and check belt

tension from outside of the frame.

Belt tension should be checked every 30-50 hours of run time as described below and

readjusted if necessary.

1. Locate the black hole plug on the side of the frame behind the engine.

2. Carefully slip a knife blade behind the plug flange and pry it out of the hole.

3. Use a flashlight to look inside the hole and locate the belt. When using the tension

tester, force must be applied to the belt by pushing the tester in the center of the

belt width. The inspection hole may or may not be centered on the belt width.

4. Insert tension gauge (Gates # 7401-0076) through the

hole in drive housing and set large O-ring ¼” from the

frame. Be sure to use the inch scale and not the

metric scale on the tester. (Fig. 1)

5. Slide small O-ring against the large part of the gauge.

Make sure the tension gauge is in the middle of the belt.

Push the gauge in until the large O-ring touches the

housing. Remove the tester from the hole and view the

small sliding “O” ring location on the force scale. The

force applied to deflect the belt is indicated by the

location of the bottom of the “O” ring on the force scale.

(Fig. 2)

6. Repeat steps 4-5 at least three times or until you

achieve the same result for each measurement.

7. The desired tension is 13-21 pounds with a target of

17 pounds with 1/4” deflection on an existing belt

using Gates belt gauge # 7401-0076. If the belt

tension is less than 13 pounds it will be necessary

to adjust belt. Tension a new belt to 21 lbs. to allow

for stretching. A new belt will stretch over night without running the engine.

If the measured force falls below specs shown below, re-tension the belt as

described on the following page (15).

All FNR Models

Force = 13-21 lbs.

Deflection = 1/4”

Fig. 2

15

ADJUSTING BELT TENSION

1. To adjust the belt, remove the top panel and two

lower panels shown in Fig. 1. The lower panels are

sealed with Loctite 598 High Performance RTV

Silicone Gasket Maker. The panel will need to be pried

from the frame with a large screwdriver. (Fig. 1)

2. Loosen all eight frame housing bolts. (Fig. 2 has the

brake plate removed so you can see the bolts easier. It

is not necessary to remove the brake for belt

adjustment.) The top set of 3 bolts go into the back of

the engine. Loosen the two top bolts with the universal

joint, 6” extension, and 5/8” socket. (Fig. 3) The bottom

four hold the engine plate onto the frame. The lower

right of that set is a stud with a nut welded on it. It is a

lot easier to use an 11/16” crowfoot wrench on this bolt

but an open-end wrench can be used. Adjust the nuts

on the vertical 3/8” x 6” bolt to tighten the belt. Move

about 1/2 turn on the nut and recheck tension. Repeat

until desired tension is reached. When tension is

reached tighten all eight frame bolts to 250 in.-lbs. (21

ft.- lbs.) and recheck tension again. If it is too tight or

too loose adjust again.

3. NEW BELT ONLY - If installing a new belt, loosen the

lower adjustment nut and turn the Upper adjustment

nut clockwise to loosen the belt. Remove all four of the

3/8” bolts securing the sprocket shaft bearing housing

shown on page 12. The sprocket unit can then be lifted

enough to change the belt. Reinstall them with the new

belt in place around the sprocket. Torque all four bolts

to 250 In.-Lbs. (21 Ft.-Lbs.)

4. Remove all existing RTV Silicone from frame and

access panel and insure that mating surfaces are clean.

Apply a continuous 1/8” bead of silicone to the frame

surface and inside the bolt holes. Ensure that the bead is

continuous around the perimeter to prevent water leakage.

(Fig. 4)

5. Install the Access Panel and lightly tighten the 1/4” bolts.

Allow Silicone to cure for several hours and then torque all

bolts to 125 In.Lbs. (10Ft.- Lbs.)

6. After running your engine for the first time after sealing the

lower cover plates, remove the frame drain plug next to the

shaft housing to check for any water leakage. If any water

come out of the drain plug, you need to remove the lower

cover plates and re-seal it.

Remove

panels

Remove top

panel

Fig. 1

Fig. 2

Fig. 3

Fig. 4

11/16”

5/8”

16

SPECIAL TOOLS TO SERVICE SURFACE DRIVES

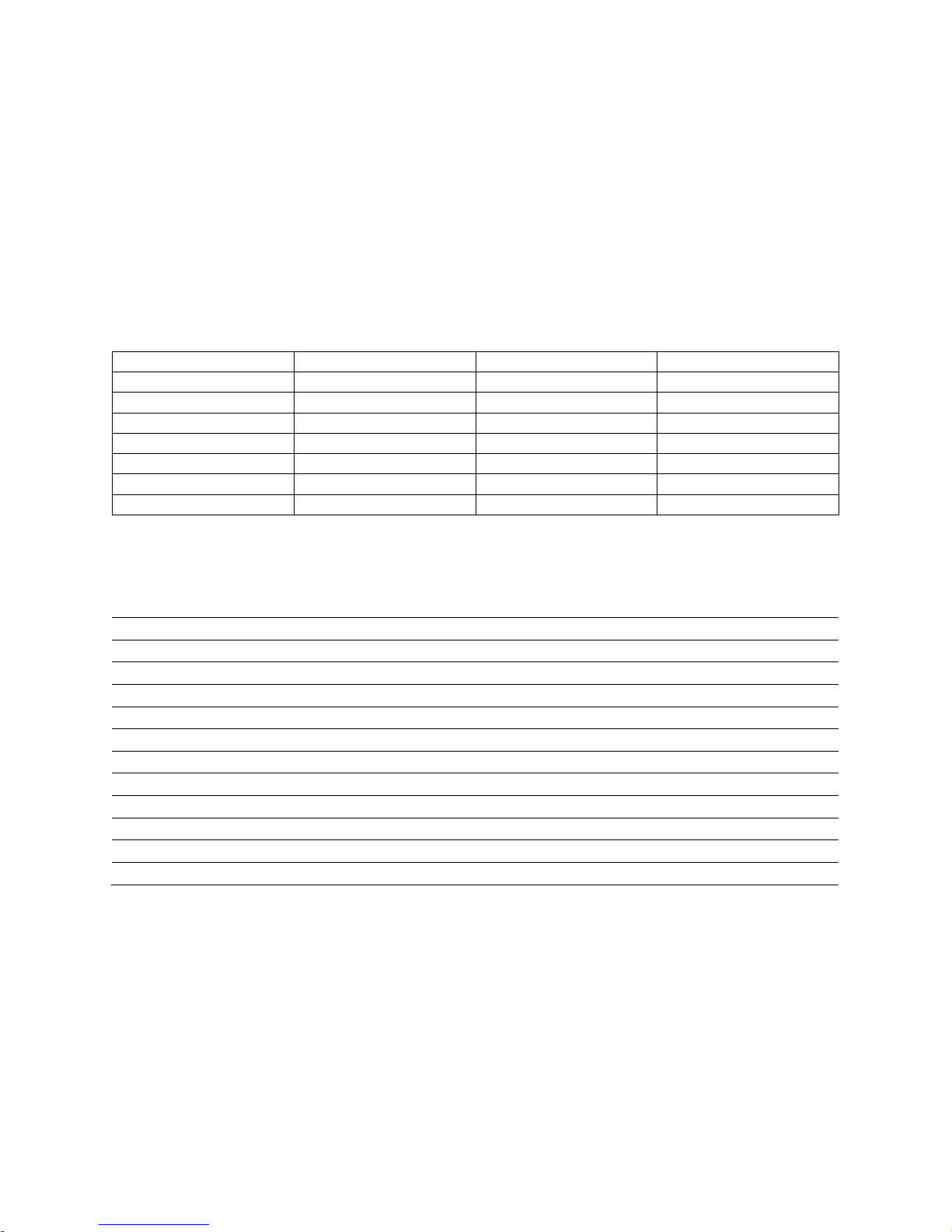

TOTAL $325.00

These tools can be rented for $20.00 plus shipping with a $325.00 deposit.

OTHER TOOLS NEEDED TO SERVICE FNR

SURFACE DRIVES

18” PIPE WRENCH

1/2” DRILL

8” OR 10” CRESCENT WRENCH

1-1/16” SOCKET OR COMBINATION WRENCH

1-1/8” DEEP SOCKET OR COMBINATION WRENCH

PAIR OF CHANNEL LOCK PLIERS

4 TO 5 LB HAMMER

5/16” DRILL BIT

1-1/4” X 6-1/2” LONG PVC PIPE (to install lower seals)

11/16” CROWFOOT (to loosen and tighten engine housing to frame)

½” x ¾” ADAPTER FOR SLIDE HAMMER (to remove transmission)

¾” SHAFT SLIDE HAMMER

2- ½” BOLTS 2 -1/2” long (to lock transmission when torqueing bolts)

3/16” HEX SOCKET DRIVER (to tighten brake disc bolts)

1/8” HEX SOCKET DRIVER (for transmission drain plug)

5/32” HEX SOCKET DRIVER (for installing transmission housing to sprocket)

TWO STRIPS OF .063” MATERIAL (for setting brake shoes)

NEVER SIEZE

BLUE LOCTITE

SYRINGE TO FILL GEARBOX

PART #

DESCRIPTION

USED FOR

PRICE

DIE114X1

1-1/4” HEX DIE

HEX DIE (TO REPAIR SHAFT TUBE THREADS)

$100

SHBUPU

PULLER FOR

SHAFT & BUSHINGS

(SLIDE HAMMER)

USED WITH:

SHAFT ADAPTER TO REMOVE SHAFT

BUSHING PULLER- TO REMOVE BUSHING-

(MUST USE 1-1/8” TAP TO THREAD INNER

BUSHING FOR BUSHING PULLER INSERTION.)

$50

SHAD

SHAFT ADAPTER

USED WITH PULLER TO REMOVE SHAFT

$15

BUPU1

BUSHING PULLER

USED WITH PULLER TO REMOVE BUSHING

$20

BUIN1

BUSHING INSTALLER

TO INSTALL BUSHINGS

$10

T118

1-1/8” TAP

USED TO THREAD INNER BUSHING FOR

INSERTION OF BUSHING PULLER FOR

REMOVAL OF BUSHING.

$60

R1

1” REAMER

AFTER BUSHING INSTALLATION, USED TO

REAM THE BUSHING FOR PROPER SHAFT

PLACEMENT/FIT.

$70

17

CHANGING TRANSMISSION OIL

1. Remove the top and rear cover

plates on drive housing. It is

not necessary to remove the

bottom cover plate that attaches

to the lubricator

guard. (Fig.1)

2. Place clean rags or paper towels

between the belt and

transmission to catch any oil you

may spill.

(Fig 2.)

3. Locate a fill/drain plug and rotate

that plug to 12 o’clock and remove

it using a 1/8” hex bit socket.

Remove the second plug which

will be at the six o’clock position to

drain the oil. Both plugs have to

be removed for the oil to drain.

(Fig 3.)

4. Using a cut off water bottle, drain

the oil. Reinstall one of the drain

plugs. (Fig. 4.)

5. Fill the transmission with the

supplied syringe and 1.5 oz of

Mobil 1 4T 10W-40 Racing Oil

and install the second drain plug.

Change the oil every 100 hours

when you service the sprocket

shaft bearings and u-joints.

(Fig. 5)

6. Reinstall the covers using a good

grade RTV silicone on the back

cover. (Fig. 6)

7. After running your engine for the

first time after sealing the lower cover plates, remove the frame drain

plug next to the shaft housing to

check for any water leakage. If any

water come out of the drain plug, you

need to remove the lower cover plates

and re-seal it.

100 hours is the recommended oil change interval for the transmission under

normal conditions. If your engine is being used excessively in reverse you

should change the oil every 50 hours.

Seal with RTV

Fig. 3

Fig. 1

Fig. 4

Fig. 5

Fig. 6

Fig. 2

18

CLUTCH AND TRANSMISSION REMOVAL

1. Remove the top, back covers,

wiring harness cover and brake

plate assembly. You can remove

the side covers and brake plate in

one piece. (Fig.1)Hang the brake

plate assembly from the lift eye

on the frame. (Fig. 2 and 2a)

2. Refer to steps 2-4 of “Changing

Oil in FNR Gearbox” to drain the

oil from the gearbox before

proceeding.

3. Remove the 4 bolts in the bearing

unit using a 9/16” socket to

relieve the belt tension. Doing this

will allow you to reinstall the belt

without needing to tension it

again (Fig. 3)

4. Insert two ½” bolts through the

brake plate into the machined

stops on the transmission to lock

the transmission in place. Insert a

large screwdriver between the

bolts. (Fig. 4)

5. Loosen the center bolt on the

transmission with a 5/8” socket

but do not remove the bolt.

6. Remove the four socket head

screws attaching the brake plate

with a 3/16” hex bit socket by

holding the ½” bolts with a large

screwdriver and remove the

brake plate and 5/8” bolt you

loosened in step 5. (Fig. 5)

7. Screw the ½” x ¾” adapter into

the center of the crankshaft

extension and pull the

transmission out with the slide

hammer. (Fig. 6)

8. Slide the transmission housing

off of the crankshaft. (Fig. 7)

Fig. 3

Fig. 4

Fig. 6

Fig. 7

Fig. 1

Fig. 2

Fig. 5

Fig.2a

19

9. Slide the rotor assembly off of the

crankshaft. (Fig. 8)

10. Disconnect the rubber coated

clamps holding the clutch wire.

(Fig. 9)

11. Slide the Field Assembly off of

the crankshaft. (Fig 10) Make sure

not to lose the clutch spacer

behind the Field Assembly marked

with an arrow in (Fig. 11)

CLUTCH AND TRANSMISSION INSTALLATION

1. Install the clutch spacer with the

bevel towards the engine. Add a

light coat of never seize to the

full length of the crankshaft.

(Fig.1)

2. Slide on the clutch field

assembly first, then the rotor

assembly. (Fig.2)

Fig. 8

Fig. 9

Fig.10

Fig. 1

Fig. 2

Fig.11

20

3. Apply a light film of oil (oil for

Transmission is Mobil 1 4T Racing

Oil) on the two seals in the

transmission housing. Slide the

sprocket/transmission housing

onto the crankshaft. (Fig.3)

4. Install the key with the square side

in the crankshaft by holding it with

a needle nose pliers and tapping it

in with a hammer. The key will be

tight. Do not file the key for a

loose fit! The key can be partially

installed when installing the shaft

extension. With the sun gear it will

slide the key all the way in. (Fig. 4)

5. Slide the shaft extension onto the

crankshaft with the key lined up

with the slot and tap in with a

rawhide or rubber hammer until it

bottoms out. (Fig. 5)

6. Add a film of oil on the seal in the

planet gear assembly. Now slide in

the planet gear assembly onto the

crankshaft. You will need to rotate

it for the gears to line up. After it is

pushed in, it will have a cushion of

air inside holding it from bottoming

out. This is not a problem. You

could remove the fill/drain plug

from the outer housing to relieve

this cushion. (Fig. 6)

7. Install the 5/8” center bolt with the

heavy machined washer and lock

washer as shown with Blue

Loctite. Tighten snug with a

wrench and you will torque it after

disc installation. (Fig. 7)

8. Install the belt over the

transmission assembly and onto

the bottom sprocket. It will be

necessary to remove the four bolts

in the bearing unit to enable you to

install the belt onto the bottom

sprocket and to tighten the eightframe mounting bolts after adjusting the drive belt. If the belt becomes tight when

tightening the bearing unit down loosen the 8 bolts that secure the engine and

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

21

engine mount to the frame and

adjust tension bolt to give the belt

slack. Do not tension the belt

until the crankshaft bolt is

torqued to the proper torque!

(Fig.8)

9. Install the brake disc with two of the

socket head screws installed. Do

not use Blue Loctite yet because

this part of assembly is temporary.

Insert two ½” bolts into the through

holes in the disc and into the slots

machined into the outer

transmission housing. Using a large

screwdriver as shown in

(Fig. 9) torque the center bolt to 78foot lbs.

10. Remove the brake disc and adjust

the drive belt until it becomes tight.

Refer to Page 14 and 15 “Checking

the belt tension” and “adjusting the

belt tension” and follow the steps to

properly tension the belt.

11. Remove a fill/drain plug from the

transmission and rotate the hole to

12 o’clock. (Fig. 10) Fill the

transmission with 1-1/2 oz of Mobil

1 4T 10W-40 Racing Oil using a

syringe with a hose. (Fig. 11)

(syringe is provided with each

engine when shipped) Reinstall the

fill/drain plug. Install the brake disc

using the four 5/16” socket head

screws using a 3/16” hex socket with Blue Loctite and the two ½’ bolts and large

screwdriver to hold disc. Torque the socket head bolts to 200-inch lbs. or 16.6-foot

lbs. (Fig. 12)

12. Reinstall the brake assembly. (Fig. 13) Check the clearance of the brake shoes to

the brake plate. The required clearance is .063”. We use two strips of .063”

material long enough to check the clearance on all four brakes at once. To adjust

the clearance, you must loosen the 4 cap screws using a ½” socket. Then you

screw in the socket set screws until the brake shoes push the .063” strips against

the brake plate. (Fig.14-15) Now torque the four cap screws to 200 In. Lbs. to

secure the adjustment. If you do not have these strips you can loosen the four cap

screws with a ½” socket and screw the socket set screws in until the brake pads

touch the brake plate. Now unscrew the set screws one full turn on each screw and

torque the cap screws to 200 In. Lbs. The set screw is 3/8” x 16 threads per inch.

One full turn = .063”

13. Refer to PAGE 17 steps 6-7 to re-seal the cover plates on the frame.

Fig. 10

Fig.11

Fig.12

Fig.13

Fig.14

Fig.15

22

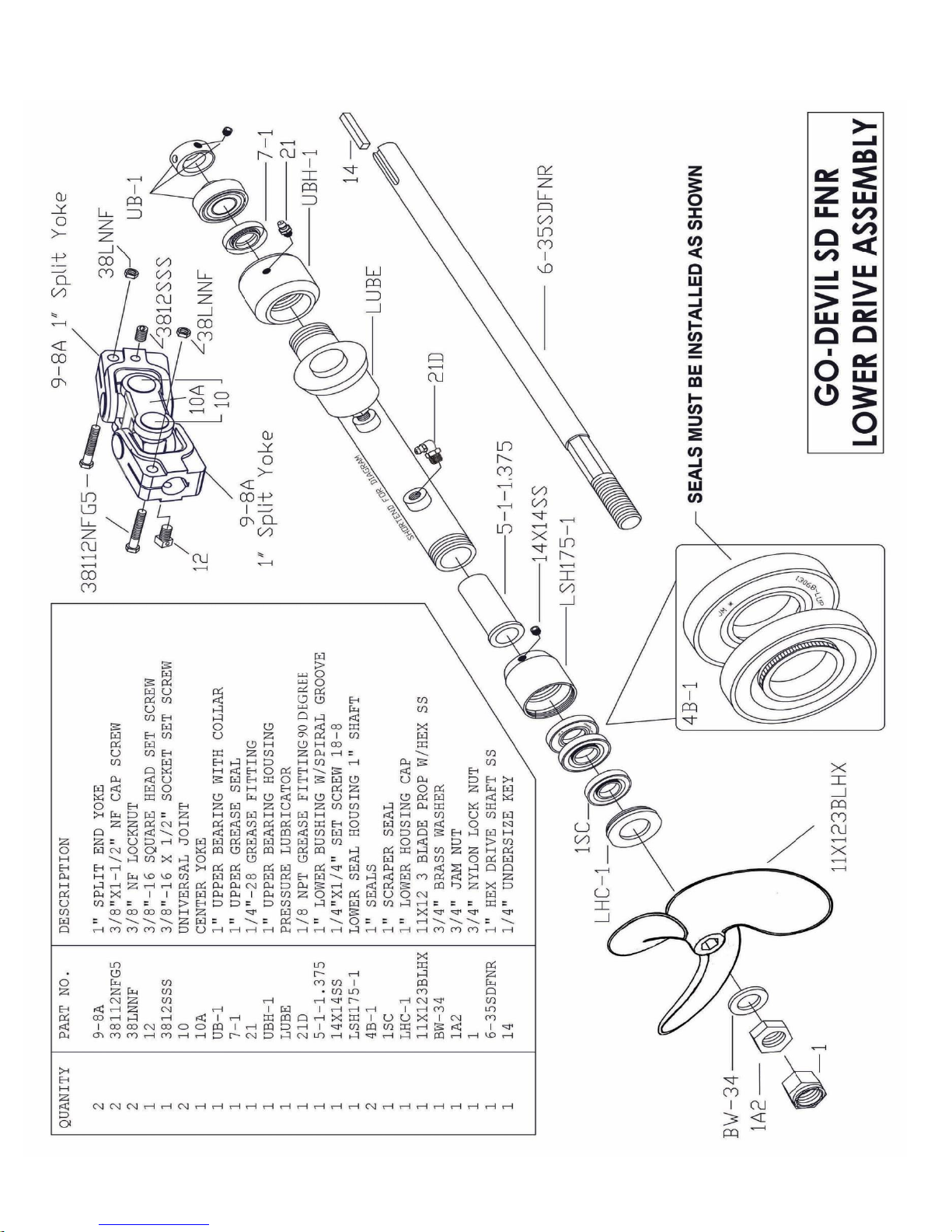

LOWER SEAL REPLACEMENT

1. Determine if the lower bushing should also be

changed by holding the cavitation plate with one

hand and moving the propeller up and down then

left to right with the other hand. If no movement is

felt, there is no wear in the bushing. Once the

movement becomes 1/16” or more, it will be

necessary to replace the bushing.

2. Remove the propeller and unscrew the lower seal

housing cap (LHC1) (Refer to PAGE 23 Propeller

Removal)

3. Remove the lower housing cap (LHC1 which has

left hand threads). (It must be turned clockwise to

remove it.) Clean thoroughly of any grease or

Loctite.

4. Pick old seals out with a tool such as an ice pick

with a 90-degree bend on the end. We prefer not to

remove the seal housing from the shaft outer

housing. (See note at the bottom of the page if the

lower seal housing is removed.)

5. Pack the first seal with grease and insert it into the

housing with the spring-side facing the engine and

screw the seal on over the threads on the shaft.

(Fig. 1) These seals can be pushed in with a 1-1/4”

schedule 40 PVC pipe cut 6-1/2” long. This

procedure may shave a small amount of material

off of the outside diameter of the seal. (Fig. 2) Insert

the next seal with the spring facing the prop. Pack

the area between the two seals with a small amount

of grease and use the same PVC pipe to push the

seal in completely.

6. Install the new scraper seal (1SC) into the lower

housing cap (LHC-1) and install onto the lower seal

housing (LSH175-1) with blue Loctite on the

threads by turning it counter-clockwise (left-hand

threads). (Fig. 3)

7. Pump the grease fitting on the shaft housing until

the lubricator is about ¾ full.

8. Apply never seize to the hex shaft and slide the

propeller on. You may need to tap it with a hammer

to seat completely.

9. Install a ¾” brass washer on the shaft and then

screw the jam nut tight. Screw on the nylon insert

nut and tighten.

Fig. 1

Fig. 2

Fig. 3

23

INSTALLING THE LOWER SEAL HOUSING

1. Remove any excess silicone from the shaft housing and inside the lower seal

housing.

2. Add a good grade of silicone to the bore in the front of the lower seal housing and a

small amount on the threads of the drive shaft housing.

3. Screw the housing on by hand until it bottoms out. Now tighten it with a large pipe

wrench extremely tight.

4. After tightening apply blue Loctite to the 14x14SS set screw and tighten it into the

front edge of the edge of the lower seal housing.

5. Remove all excess silicone inside the housing. Any excess silicone can plug the

return groove on the lower bronze bushing return groove on the lower bronze

bushing and cause the lower seals to leak.

PROPELLER REMOVAL

1. Remove first nut with a 1-1/16” socket or wrench.

2. Remove the second nut with a 1-1/8” wrench or deep socket.

3. Slide off the ¾” brass washer

4. Tap the prop off of the shaft with a rawhide or rubber hammer. You can also use a

block of wood between the prop and a metal hammer if necessary.

PROPELLER INSTALLATION

1. Lubricate the hex and threads with a thin coat of never seize.

2. Slide the prop onto the shaft. It may be necessary to bump the prop onto the shaft to

seat the prop over the 1” diameter part of the shaft.

3. Slide the ¾” brass washer over the threads.

4. Screw the 1-1/8” nut onto the threads and tighten.

5. Screw on the 1-1/16” nylon lock nut and tighten.

24

SHAFT REMOVAL

1. Leave the engine mounted on your boat in the trailering position or clamped to a solid

saw horse. Remove propeller, all nuts, and washers. (Refer to PAGE Propeller

Removal.)

2. Remove the lower cover plate to access the shaft and yoke.

3. Remove the set screw in the yoke clamped to the prop shaft. DO NOT REMOVE THE

SET SCREW FROM THE FRONT YOKE!

4. Loosen the bolt in the split yoke with two 9/16” wrenches. Drive a flat-head screwdriver

into the split yoke as parallel to the shaft as possible. DO NOT DRIVE IN

PERPINDICULAR OR AT A RIGHT ANGLE TO THE SHAFT!

5. Loosen the set screw on the eccentric collar on the upper bearing. Now rotate the

eccentric collar clockwise (standing from rear of engine) using a 1/8” pin punch or

center punch. (The collar can tighten in either direction.)

6. Install the propeller and nut and bump shaft out with a rubber mallet or rawhide

hammer by tapping on the propeller.

SHAFT INSTALLATION

1. Slide the shaft through the housing slowly until it comes out of the upper bearing

housing. Slip the eccentric collar over the shaft and leave it loose.

2. Install the shaft key ¾ of the way into the yoke and slide the shaft to the yoke with a

pair of channel locks. Now tap the shaft in about ¾” with a ¾” coupling nut or our shaft

puller. At this point, remove the lubricator and fill the tube with grease until grease

comes out at the grease fitting. Now install a 1/8” pipe plug and finish filling the tube

slowly until grease starts coming out of the lower bushing. At this time we recommend

removing the pressure lubricator and taking it apart and cleaning it thoroughly. Use

paper towels or soap and water, no solvents. Stretch the spring to insure proper

pressure.

3. Now install the lower seal housing by applying silicone inside the lower seal housing,

in front of the threads. Tighten the lower seal housing with a pipe wrench and install

the set screw with blue Loctite. Install the lower seals as described on PAGE 22. Install

the prop using steps 1-5 in “PROPELLER INSTALLATION” on PAGE 23. Now drive

the shaft in until you have 1/8” to 3/16” air gap between the prop and the LHC1.

4. Countersink the set screw hole in the split yoke with a 5/16” drill bit. Tighten the bolt

on the yoke at this time using two 9/16” wrenches extremely tight. Install the set screw.

Install the lower seal housing cap and fill the pressure lubricator until it is ¾ full. You

are now ready to install the propeller.

25

BUSHING REMOVAL AND INSTALLATION

WITH OUR TOOLS

1. Remove the shaft and lower housing.

2. Using the 1-1/8” tap, screw it into the bushing. This will cut threads in the bushing

to fit the bushing puller (#BUPU1).

3. Screw the bushing puller (#BUPU1) into the bushing. Screw the shaft puller

(#SHBUPU) into the bushing puller.

4. Using the slide hammer on the shaft puller, remove the bushing.

5. Drive the new bushing in with our bushing installer (BUIN1) and a four to five-

pound hammer.

6. The bushing will need to be reamed with a 1” reamer or 1” drill bit to allow the shaft

to spin freely. The goal is to have a .001 to .002 tolerance between the shaft and

the bushing.

BUSHING REMOVAL AND INSTALLATION

WITHOUT OUR TOOLS

SPECIAL ITEMS NEEDED

1 sabre saw or sawzall with blade to cut bronze

1 7/8” bolt (any length)

1. Remove the shaft and lower housing.

2. Using a saw, split the bushing at two locations. Be careful not to cut the shaft

housing. After the bushing is split, pull out the two pieces with a pair of pliers.

3. Insert a 7/8” bolt into the bushing using it as a bushing installer. Drive the bushing

in with a four or five-pound hammer.

4. The bushing will need to be reamed with a 1” reamer or 1” drill bit to allow the shaft

to spin freely. The goal is to have a .001 to .002 tolerance between the shaft and

the bushing.

26

27

SERVICE MEMOS

Engine handle pulling while on plane.

If you are having problems with the handle pulling to one side while operating the engine

it is an easy fix. You may have to fine tune the offset bend in the skeg to correct this issue.

If the handle is pulling to the starboard side (right) of the boat, the skeg needs to be bent

more to the port (left) side. Use a 12” crescent wrench to perform this procedure. Testrun the boat with the load level and no cross wind until the boat tracks straight without

pulling. Do not move the engine on the transom to try and correct handle torque!

Throttle freezing issues.

Surface Drive throttles have been found to have issues with freezing and not operating in

very cold temperatures. Moisture enters the cable by rain or condensation etc. and

freezes when the ambient temperature is below freezing.

To remedy this:

1. Raise the handle to a vertical position.

2. Remove the black plastic cap at the top of the throttle cable.

3. Using a hypodermic needle, inject antifreeze down the side of the inner

throttle cable.

4. Squeeze throttle to move the cable back and forth and work in the antifreeze.

This will prevent the cable from freezing anymore.

5. Repeat this procedure multiple times until you can no longer inject any

antifreeze into the throttle cable.

ENGINE OIL CAPACITIES

Engine Model

Capacity

23hp Briggs & Stratton Vanguard

Model #: 386447

46-48 ounces or 1.43-1.5 quarts with filter

25hp Kohler Command

Model#: CH740S

54-61 ounces or 1.7-1.9 quarts Kohler oil

35hp, 37hp, and 40hp Briggs & Stratton

Vanguard

Model#: 613477, 61E477, 61G477

78-80 ounces or 2.43-2.53 quarts

NOTE: THESE OIL CAPACITIES ARE LISTED IN THE ENGINE MANUFACTURER’S

MANUAL. DO NOT RELY ON THESE MEASUREMENTS ALONE. ALWAYS HOLD

THE ENGINE PERFECTLY LEVEL AND CHECK THE OIL LEVEL ON THE DIPSTICK

MAKING SURE IT IS NOT OVER-FILLED OR UNDER-FILLED.

ALL 23HP ENGINES WILL NOT RUN IF THEY ARE OVER-FILLED WITH OIL.

28

SERVICE RECORD

ENGINE MAKE ____________________ VALVE CLEARANCE:

ENGINE MODEL # _________________ INTAKE ____________________

OIL FILTER # _____________________ EXHAUST___________________

FUEL FILTER # ____________________ SPARK PLUG # ______________

OIL CHANGE OIL CHANGE

DATE

HOURS

DATE

HOURS

SERVICE WORK PERFORMED

War r an t y

This warranty replaces any warranties before May 1, 2018

Go-Devil Manufacturing Company of Louisiana LLC. will repair or replace

any components on the Go-Devil FNR drive unit that we manufacture at no charge

for a period of one year that is defective in materials or workmanship.

Transportation charges on parts submitted for repair or replacement under this

warranty must be borne by the owner of the unit. This warranty does not cover

normal wear, abuse, neglect, or failure due to the elements of nature, such as salt

water corrosion. Wear on the shaft and/or bushing due to the lack of lubrication

will not be covered by this warranty! See your Service Manual for the proper

lubrication instructions.

Engines on our products have a three-year engine warranty and a lifetime

ignition warranty as long as the original purchaser owns the unit. The lifetime

ignition warranty does not cover electrical items such as ignition switches, starters,

solenoids, or wiring. These items are covered by the three-year engine warranty.

An engine warranty can be handled through any small engine dealer in your

area that is an authorized warranty service dealer for the brand of engine that you

have on your unit. Go-Devil Manufacturing Company of Louisiana LLC. is

authorized to warranty all the engines that we sell on our products. In many cases,

we can expedite a repair by sending the part to you because most warranty repairs

are as simple as replacing a simple part. You will however, be required to return

the defective part to us. At that point, we will file the warranty claim directly to

the engine manufacturer at no charge to you.

Loading...

Loading...