Underwater remotely

operated vehicle for inspections

GNOM PRO

Operators manual

2017

2

TABLE OF CONTENTS

Warning !!!

Hi voltage on cable!

Do not touch the cable in a water during operation!

If any damages happen on a shield of cable it must be repaired or

changed !

Attention! AC power maximum 240V !

1. Description 3

1.1 Purpose 3

1.2 Technical specifications 4

1.3 Basic complete set 5

2. User’s manual for operation with GNOM 6

2.1 Surface control module 6

2.2 Deployment 8

2.3 Operation 10

2.4 Keys and Buttons at the control panel 12

2.5 Screen modes 13

3. Maintenance operation 14

4. Safety requirements 15

5. Warranty statement 16

6. Appendix 17

3

1. DESCRIPTION

1.1 PURPOSE

LIST OF ABBREVIATIONS:

Underwater module

Surface control module

Protection polypropylene frame

Hand reel

Joystick

Digital video recorder

Computer

Monitor

Waterproof case

Grabber

sector sonar

USBL positioning system

Remotely operated underwater vehicle GNOM is intended for inspection of underwater wrecks

and other objects by video camera.

The modern computer and telecommunication technologies are used in the device, and made it easy

in handling, compact, light and inexpensive.

These solutions allowed to use flexible communication cable for transmission data, power and video

signals to/from vehicle. The special Kevlar threads have been used to improve the cable's tensile

strength. Because of this fact, the device keeps the highest degree of stabilization what is very

important for inspections. The vehicle has a good maneuverability and can easily turn on the spot.

High-effective electric motors with magnetic couplings and hi-tech electronics are used in the vehicle,

provide the fast speed of the GNOM with low power consumption.

One of the most important features of this device is a possibility to operate it from PC and via

Lan/Internet.

The GNOM, in essence, an underwater helicopter with the video-camera which moves in any direction

according to the operator's instructions.

Thrusters are DC motors which are put into the aluminium halls. The rotation transmision to the screw propeller is

realized with aid of magnetic coupling disks.

One disk is fastened at the motor's shaft in the body, and the other one – at the screw propeller's shaft inside the

cone-shaped head, which is filled up with water. The cone-shaped head may be removed by operator for cleaning

( see manual).

The vehicle is connected with the operators console via thin cable, which transmits power voltage, operation

instructions, data and video signal from the vehicle.

4

The cable with diameter 6mm is stregthened by Kevlar threads (breaking effort is 200kg) and by additional

polyehylene shield. The cable length is max up to 400m. To compensate the weight of vehicle and give neutral

buoyancy to it, the float made of foam polysyren is used, and it is put in front part of vehicle. Similar floats can be

put on the cable to change the neutral buoyancy to little positive buoyancy. Maximum operating depth of vehicle

is 150m.

Using the control pads and joystick the operator can move GNOM forward-backward, turn to the right – left, up –

down; adjust the thruster speed and the lights brightness. All data is displayed on the monitor in "TV-text" mode.

By pressing one of the buttons on the joystick the operator can pass to the menu of tuning up some vehicle's

functions – calibrating of the depth sensor and the compass as well as some other functions.

1.2 TECHNICAL SPECIFICATION

Speed:

horizontal motion, up to 1,5 m/s

vertical motion, up to 0.5 m/s

laterial motion, up to 0.5 m/s

(above numbers depend on a length of pooling cable)

Max operating depth 150 m

Power voltage 100-230VAC 2000 Watts

Operating temperature range from -5…+45°C

Operating environment humidity, up to 100%

Weight of the vehicle 25 kg

Full weight of the system 100 kg

Dimensions of vehicle 600х380х400 mm

Tether:

diameter 10 mm

length up to 400m

5

1.3 BASIC COMPLETE SET

Underwater module

Surface control

module

Hand reel with

tether

6

2. USER’S MANUAL FOR OPERATION

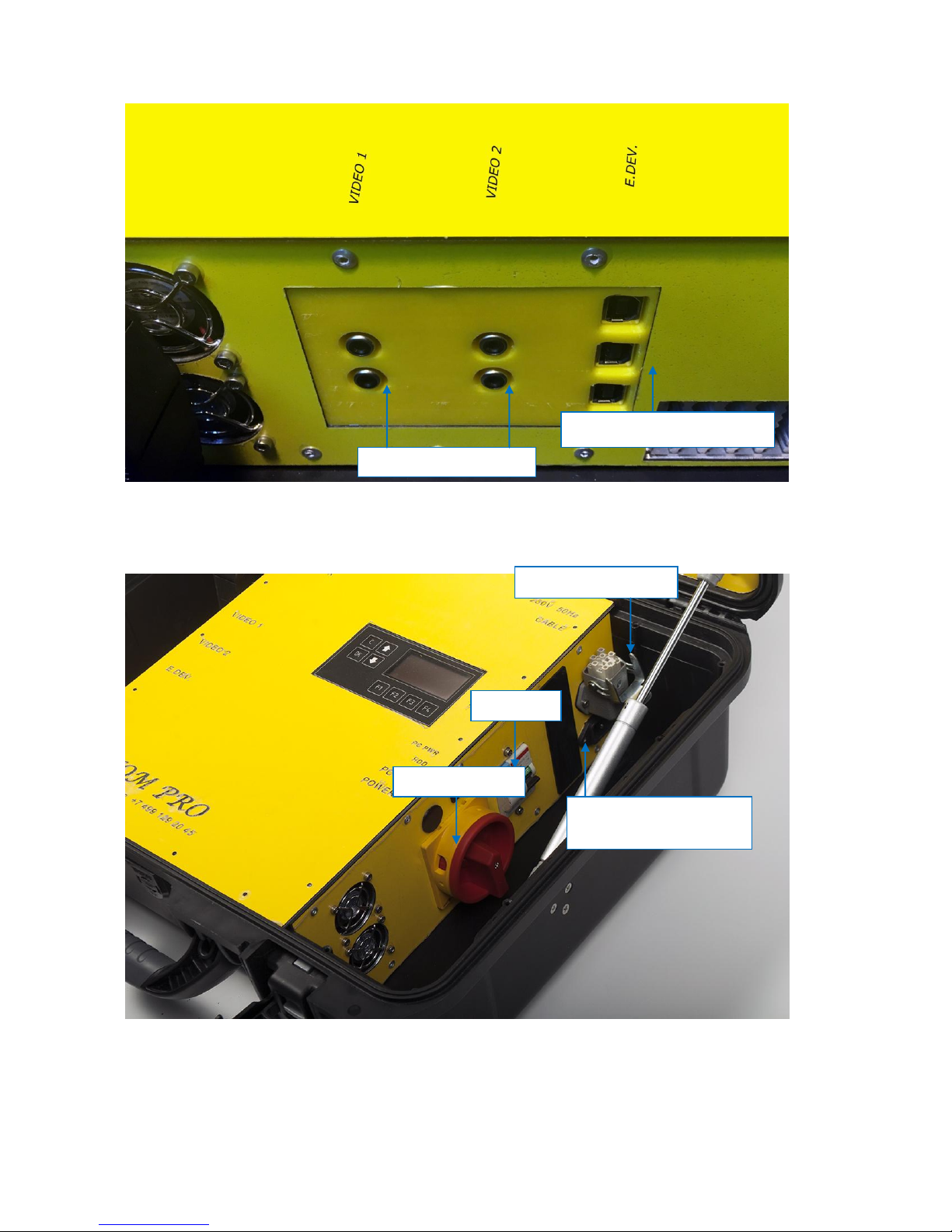

2.1 Surface control module

Front panel of module

Settings and

diagnostics menu

Joystick socket

7

Left side of module

Right side of module

Additional videoout

Sonar communication

Tether plug

230VAC

(transformer)socket

RCBO

Power on/off

8

2.2 Deployment

Before using, please, check up all parts of vehicle especially propellers, cable and dome. Clean it if it is

necessary. Check propellers rotation by finger.

Connect underwater module. Plug in tether connector to underwater module.

Connect hand reel and Surface control module by cable.

Plug in voltage transformer to 230VAC socket and AC power cable to transformer.

Do not use ROV without transformer !

Do not rotate thrusters on air!

Do not switch lights on a full power on air!

Be very careful with cable, do not:

- stand on it

- press it

- twist it.

voltage on a cable is 360VDC! If any damages happen you must repair or change

the cable.

You can not connect to the GNOM and other devices (accessory) to the

mains with the following problems:

Wrong - incorrect wire connections L and N conductors in the appropriate

slot.

Without protective earthing conductor.

Without voltage transformer

Note. Checking the correct wiring connections (phase conductor - L)

inspects the operator. (E.g. by phase tester)

Power ON control box.

Press HOME or MODE or Central buttom (depend on model) on joystick.

9

Joystick is connected and LED is light.

After power ON you see message WELCOME. GNOM is ready for operation.

If you use GNOM in a salt water (sea) you should add weights (included in spare parts) on the

frame to change buoyancy. ROV should have neutral buoyancy for correct works.

Additional weight

Place for the weight

10

2.3 Operation.

Do not rotate thrusters on air! Do not switch lights on a full power on air!

Put the vehicle into the water.

# To move vehicle Forward/Back and turn Right/Left use

# Slow mode (SLOW). Press and adjust power gradually

(30% or 75% or 100%).

The direction and speed are indicated on an overlay.

# To move vehicle Up/Down and Laterial use

# Use arrows Up/Down to select active lights

# Simultaneously press ③ + to change the intensity of the active lights ( LOOP : 0%...100%,

100%........0%. If press ③ + + simultaneously all lights turns on/off.

# Control the GRABBER (if this is part of device) by keys /

# Control the GRABBER TURN (if available) : by arrows Left/Right

# To tilt cam Up/Down press / pads. If press + simultaneously camera goes to the

median position.

# By keys ③ + switch-on/switch off laser

# By key switch - active forward/back camera

# Autodepth mode. Press key ① to fix the vehicle at the depth you need To change the depth use

left joystick. Autodepth mode and depth are indicated on an overlay.

# Autoheading controls ON/OFF from the key (version: left joystick to left – ON, to right OFF ).

You should select forward speed then switch ON autoheading. Autoheading mode holds the speed

and direction.

# Press key ④ to select SCREEN MODES :

Mode1 or Mode2 or Mode3 (see below)

right joystick

right joystick

left joystick

R 1

R 1

R 2

R 1

R 2

L 1

L 2

L 1

L 2

SELECT

SELECT

Start

11

# Finishing the operation

To finish the operation switch power OFF then disconnect cables and pull into the reel.

Try to avoid nods and twisting of the cable.

After operation please clean propellers and shafts of motors and wash the vehicle in fresh water.

Special Functions

Sleeping mode (Power Saving Mode)

In order to save power and lengthen the using life of batteries, a power saving system is designed in

the wireless joystick. The joystick turns into sleeping mode (power saving mode) under the following

conditions:

A. If there is no operation within 30 seconds since the connection between the controller and the

receiver, the controller will turn into sleeping mode (power saving mode).

B. There is operation since the connection between the controller and receiver. If there is no operation

for 5 minutes, the controller will turn into sleeping mode (power saving mode).

Press【 or or 】 or Central button can stop this sleeping

mode (power saving mode).

ANALOG

HOME

MODE

12

2.4. KEYS AND BUTTONS AT THE JOYSTICK

L1, L2 - Camera Up/down.

L1+L2 - Camera center.

R1+R2+X - on/off all lights

R1/R2 + X –intensity of the active lights

R1, R2 – grabber control

1 ▲ - Autodepth

2 O - fixing

hor. speed

4 - Screen overlays

START - Autoheading

Up/Down – forward/reverse

Left/Right - turn

Click – slow mode

Up/Down movement

Left/Right - laterial movement

SELECT - change

active camera

Up/Down change active lights

Left/Right -

grabber rotate

HOME or ANALOG or MODE

control activation

13

2.5 SCREEN MODES / OVERELAYS

Screen 1: Full overlays.

Screen 2: depth and compass overlays only.

Screen 3: no overlays.

Current depth

Front

camera

position

Current bightness

of lights

Time

Date

Required depth

Real

direction

Rear

camera

position

Required

direction

Link status

Laser status

Active cam.

Power % and directions

of thrusters

10

10

10

10

14

3. MAITENANCE OPERATION

To maintain the vehicle it is necessary:

to clean the propellers

to rinse the vehicle in the fresh water after using in the sea

to inspect the cable after the operation. In case of any damages the cable must be

repaired or changed

to check the magnetic disk coupling regularly

Avoid nods and twisting of cable.

Within the certificate of warranty the bond (joint) mainenance manual is included.

Use it only in case of emergency, if standard maintenance is insufficient.

Before this service consult technical problems in our company on email addresses:

info@gnomrov.com

Attention:

In case of non-professional action and damage of any part, the consecutive service in our

company will be charged.

15

4. SAFETY REQUIREMENT

1. Device belongs to CLASS 1 . For this reason the power adapter must have connection

to protective earth.

2. Swith-on and swith-off the machine by main 230V switch, which is placed over the

power cord to the external control unit.

3. Do not use the system with the damaged cable.

4. Do not touch underwater vehicle and the cable if you are in water and the power is

turned ON.

5. Keep the control module and the cable reel dry.

6. When recharging the battery disconnect the vehicle and the cable reel.

16

5. WARRANTY STATEMENT

Manufacturer warrants that at the time of shipment all products shall be free from defects in material

and workmanship and suitable for the purpose specified in the product literature.

The unit/system warranty commences immediately from the date of customer acceptance and runs for

a period of 1 year. Customer acceptance will always be deemed to have occurred within 72 hours of

delivery.

Note: Any customer acceptance testing (if applicable) must be performed at either NORD SLOVAKIA

premises or at one of their approved distributors unless mutually agreed in writing prior to despatch.

Conditions:

These include, but are not limited to, the following:

1. The warranty is only deemed to be valid if the equipment was sold through NORD SLOVAKIA or

one of its approved distributors.

2. The equipment must have been installed and commissioned in strict accordance with approved

technical standards and specifications and for the purpose that the system was designed.

3. The warranty is not transferable, except or as applies to Purchaser first then to client.

4. NORD SLOVAKIA must be notified immediately (in writing) of any suspected defect and if advised

by NORD SLOVAKIA , the equipment subject to the defect shall be returned by the customer to NORD

SLOVAKIA , via a suitable mode of transportation and shall be freight paid.

5. The warranty does not apply to defects that have been caused by failure to follow the recommended

installation or maintenance procedures. Or defects resulting from normal wear & tear, incorrect

operation, fire, water ingress, lightning damage or fluctuations in vehicles supply voltages, or from any

other circumstances that may arise after delivery that is without the control of NORD SLOVAKIA. (Note:

The warranty does not apply in the event where a defect has been caused by isolation

incompatibilities.)

6. The warranty does not cover the transportation of personnel and per diem allowances relating to any

repair or replacement.

7. The warranty does not cover any direct, indirect, punitive, special consequential damages or any

damages whatsoever arising out of or connected with misuse of this product.

8. Any equipment or parts returned under warranty provisions will be returned to the customer freight

prepaid by NORD SLOVAKIA

9. The warranty shall become invalid if the customer attempts to repair or modify the equipment without

appropriate written authority being first received from NORD SLOVAKIA .

10. NORD SLOVAKIA retains the sole right to accept or reject any warranty claim.

11. Each product is carefully examined and checked before it is shipped. It

should therefore be visually and operationally checked as soon as it is

received. If it is damaged in anyway, a claim should be filed with the courier

and NORD SLOVAKIA notified of the damage.

Note: NORD SLOVAKIA reserve the right to change specifications at any time without notice and

without any obligation to incorporate new features in instruments previously sold.

Note: If the instrument is not covered by warranty, or if it is determined that the fault is caused

by misuse, repair will be billed to the customer, and an estimate submitted for customer

approval before the commencement of repairs.

17

11. ANNEX

PROBLEMS SOLUTION

Alight LED on control

unit

Check that control unit is connected to a power supply

Check that control unit is switch on

If previous conditions are met but LED is still alight, check network fuse of

control unit

Underwater unit does

not respond to

JOYSTICK

Check that control unit is switch on – LED must illuminate

Check that joystick is switch on

Check batteries in joystick

Underwater unit

does not swim

directly

Check horizontal thrusters – propellers have turn easy– check by finger

In case that some propeller turns hard, clean slide bearing of coupling axis of

propeller and check setting of coupling

Underwater unit does

not respond correctly

to Joystick

You have probably switch on function MAKRO on joystick ( some of models).

Resolve problem in according to the procedure in chapter JOYSTICK

DESCRIPTION

The screen displays

incorrect value of

navigation depth

Make calibration of depth sensor in according to this manual

Underwater module

does not respond

to joystick

Joystick is in sleep mode (power saving).

See chapter USER’S MANUAL FOR OPERATION

The monitor screen is

black. There is no

picture

Check the connection between the monitor and the control unit. See images in

the manual.

When connection is OK, check setting of the monitor – THE CHOICE OF INPUT

SIGNALS – see the manual for the monitor

18

11. ANNEX

SERVICE COUPON

Coupon No.1

Date of sale

SERIAL NUMBER

DATE OF INSPECTION

TRUE

FALSE

DESCRIPTION OF REPARATION

HORIZONTAL THRUSTER L

HORIZONTAL THRUSTER

R

VERTICAL THRUSTER F

VERTICAL THRUSTER B

LIGHTS

SERVO COMPASS

DEPTH SENSOR

JOYSTICK CONTROL UNIT

MOTOR COUPLING

STAMP AND SIGNATURE

Coupon N.2

Date of sale

SERIAL NUMBER

DATE OF INSPECTION

TRUE

FALSE

DESCRIPTION OF REPARATION

HORIZONTAL THRUSTER L

HORIZONTAL THRUSTER R

VERTICAL THRUSTER F

VERTICAL THRUSTER B

LIGHTS SERVO

COMPASS

DEPTH SENSOR

JOYSTICK

CONTROL UNIT

MOTOR COUPLING

STAMP AND SIGNATURE

Coupon No.3

Date of sale

SERIAL NUMBER

DATE OF INSPECTION

TRUE

FALSE

DESCRIPTION OF REPARATION

HORIZONTAL THRUSTER L

HORIZONTAL THRUSTER R

VERTICAL THRUSTER F

VERTICAL THRUSTER B

LIGHTS

SERVO COMPASS

DEPTH SENSOR

JOYSTICK CONTROL UNIT

MOTOR COUPLING

STAMP AND SIGNATURE

Coupon No.4

Date of sale

SERIAL NUMBER

DATE OF INSPECTION

TRUE

FALSE

DESCRIPTION OF REPARATION

HORIZONTAL THRUSTER L

HORIZONTAL THRUSTER R

VERTICAL THRUSTER F

VERTICAL THRUSTER B

LIGHTS SERVO

COMPASS

DEPTH SENSOR

JOYSTICK

CONTROL UNIT

MOTOR COUPLING

STAMP AND SIGNATURE

19

11. ANNEX

Year of purchase:

TABLE № 1. Registration of working time

Start and end date of

executed works

Place of works

Underwater unit working

time (hours)

Operator name and

signature

20

11. ANNEX

Table No. 2 Statistics of damaged and replaced fuses in control unit

Date / time of fuse

seasoning and her

replacements

Type and

parameter of

network fuse

Type and parameter

of power cable fuse

+180V

Operator name and

work position

Signature

1.

2.

3.

4.

5.

Table No. 3 Inspection of coaxial cable intact

Date

Type of cable

Result

Name

Signature

1.

2.

3.

4.

5.

Table No. 4 Inspection of grounding cable clamp resistance

Date

Type of cable

Result

Name

Signature

1.

2.

3.

4.

5.

21

11. ANNEX

Protocol of perform warranty repairs

Client

Address

Client’s agent name

Name of employee taking complaint

Date of taking complaint

Date of product sale

Type of product + serial number

Description of defect by client

Description of defect by service

operator

Used material

Legitimate complaint

Yes

No

If no legitimate - reason

Date of repaired good expedition to

client

Loading...

Loading...