Underwater

remotely operated vehicle

GNOM BABY

Operators manual

VFTECH s.r.o.

Vapenicka 24, 971 01 Prievidza, Slovakia

Tel/Fax +421 46 54264 56

odbyt@vftech.sk

http://www.vftech.sk

2015

v05/2016

2

TABLE OF CONTENTS

1. Description 3

1.1 Purpose 3

1.2 Design 4

1.3 Technical specifications 6

2. User’s manual for operation with GNOM 7

3. Keys and Buttons at the control panel 12

4. Screen modes 15

5. Calibration 16

6. Maintenance operation 17

7. Safety requirements 18

8. Warranty statement 19

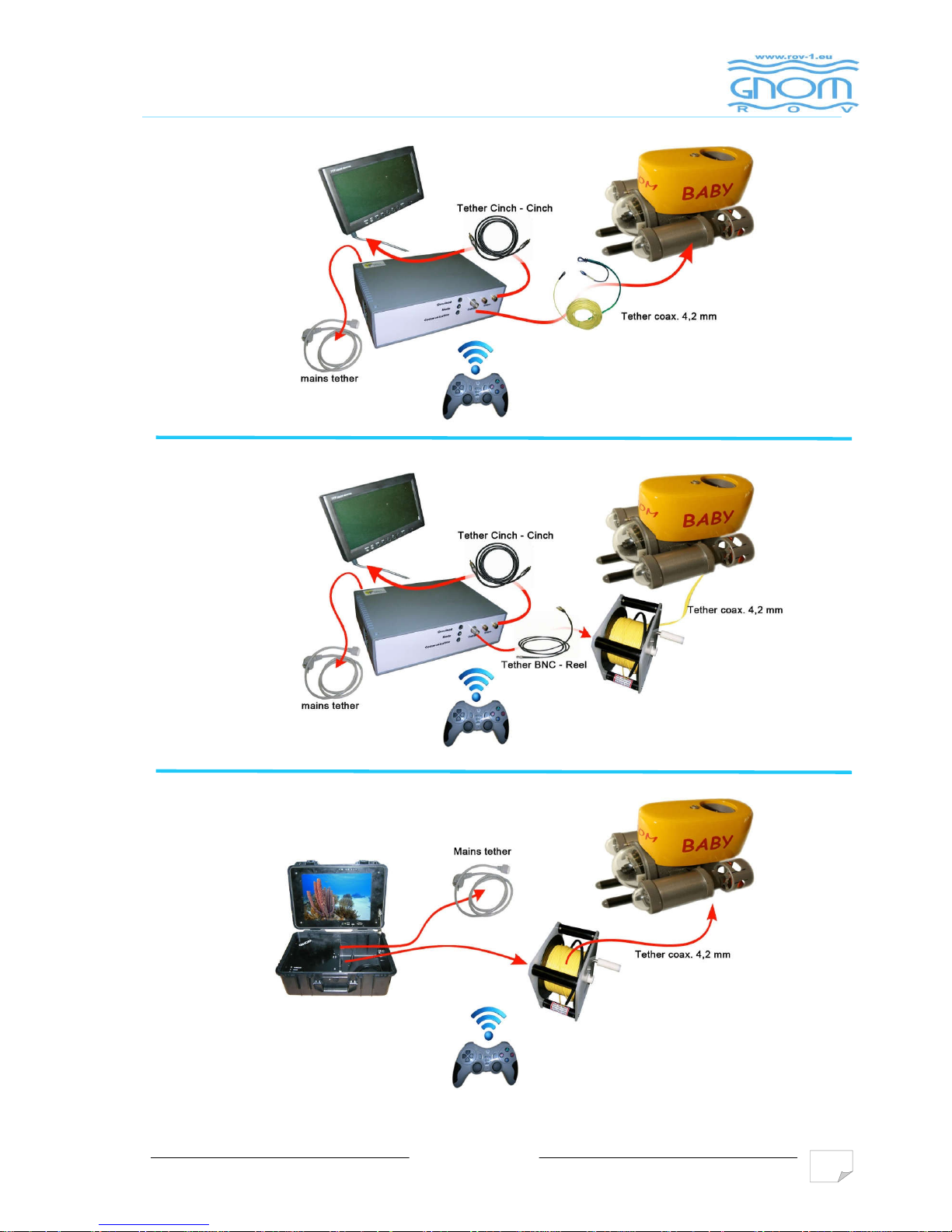

9. Examples of linking modules 20

10. Appendix 21

11. Annex 26

v05/2016

3

1. DESCRIPTION

1.1 PURPOSE

LIST OF ABBREVIATIONS:

Underwater module

Surface control module

Hand reel

Coaxial cable

Joystick

Digital video recorder

Computer

Monitor

Waterproof case

ROV Gnom Baby is intended for inspection of underwater objects such as wrecks, ship

underwater parts, propellers and different underwater constructions.

ROV Gnom Baby has a small color camera with tilt function. Two clusters of ultra-bright

LEDs are installed at both sides of the underwater module. The module has horizontal and

vertical thrusters which allow the movement of underwater module in all directions. The

underwater module is operated from the surface control module and is linked with it by

umbilical cable . The operator controls the underwater module by joystick according

to video and data from sensors on the TV screen . Maximum operation depth is 50 m.

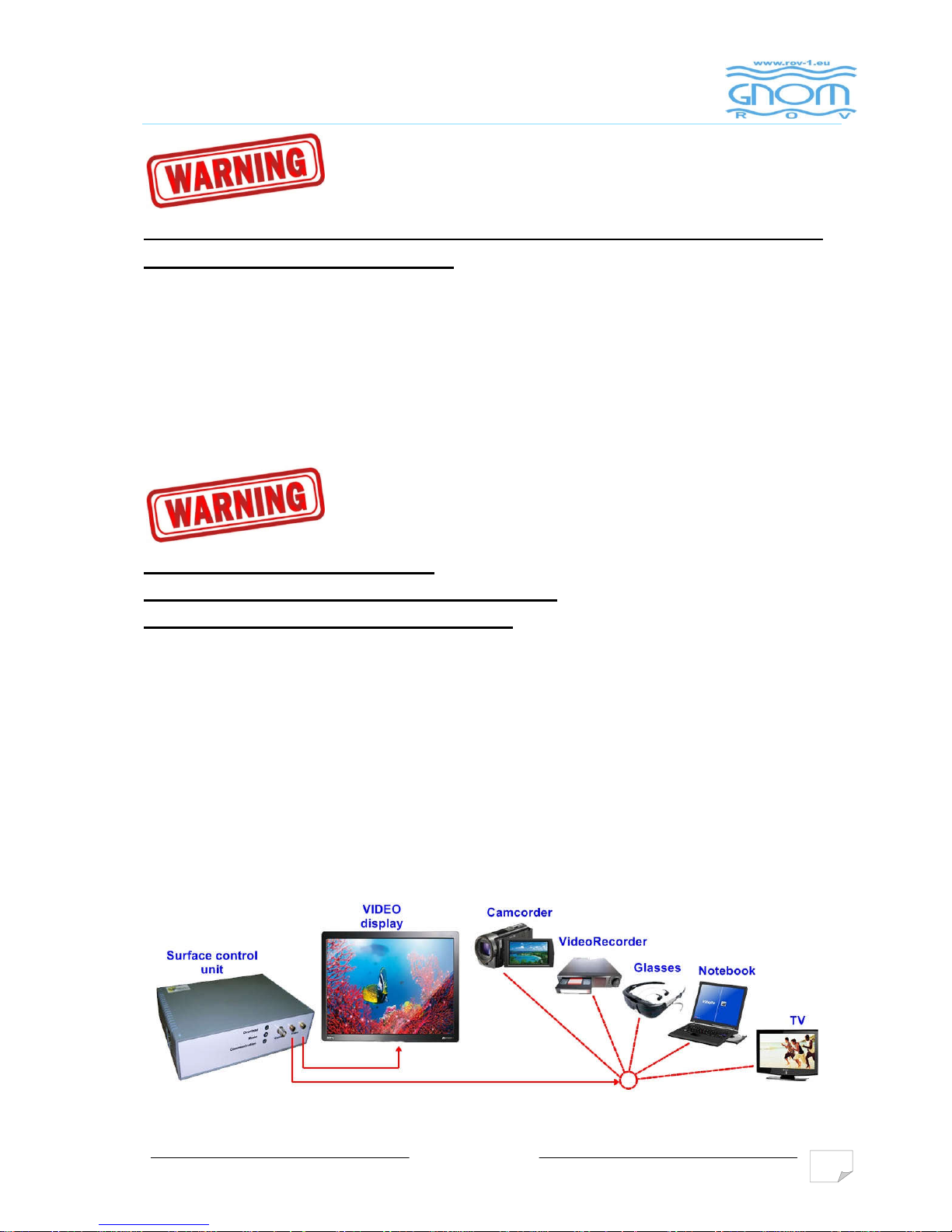

The video signal from surface control module can be connected to monitor , TV receiver

or video recorder (if delivered) via standard AV cable. At surface controle module there

are two output connectors with video signal, what allows connect at the same time two display

units, or one display unit and a video recorder.

The power supply of surface control module is 110-230VAC 50Hz or 12-24VDC from battery with

inverter 12VDC/230VAC can be used. Maximum power consumption is 200 Watt. Battery

operation time (12 Ah) is more than 1 hour.

The complete system can be integrated into two plastic cases. One case contains the underwater

module and cable reel with cable , the other contains control module , joystick

and accessory equipment (monitor, video recorder - if delivered).

The size of operating area is limited by cable length (35 m in basic set). It is possible to increase

the cable length up to 75 m. The video camera together with lights provides 15-20 m daylight

visibility in transparent water. Maximum 3-4 m visibility can be reached during the night.

LCD display ot videorecorder can be installed upon request.

For update info please visit our web site www.vftech.sk

v05/2016

4

1. DESCRIPTION

1.2 DESING

Recommended configurations

Hand reel +

Coax. cable

Underwater module

Power supply/control module

Joystick

Transportation waterprof cases

LCD

The system consists of underwater vehicle, cable and

contains aluminum waterproof cylindrical hull

thruster

.

A glass dome

front part of the vehicle. Two

hull. The plastic

floatation block

the end of thrusters’ axis. All the electronic parts (the power supply converter, electronic m

and depth sensor) are installed into main cylindrical hull. Communication tether is placed at the

back roof of the hull together with depth sensor membrane.

There are protective plastic feet

of the vehicle using additional metal weights.

Thrusters are DC motors and located inside waterproof hulls. The rotation transmission to

the screw propeller performed with an aid of disk magnetic coupling. One disk is fastened at the

motor’s

shaft inside the thruster’s hull and another one at the screw propeller’s shaft inside the

cone-

shaped cap filled up with water. The cone

user for cleaning.

v05/2016

1. DESCRIPTION

–

with a side wall

with a color camera based on a 1/3” CCD matrix locates at the

horizontal thrusters

with lighters

are fastened to the main

fastened by nut and screw

.

Screw propellers are installed at

under the vehicle that are used to adjust for the

-

shaped cap can twisted off (with an effort) by a

5

with a fastened vertical

odule

buoyancy

v05/2016

6

1. DESCRIPTION

The vehicle is connected with the operator’s module via thin coaxial cable which transmits power

voltage (48V), operation commands, data from all sensors and video-signal.

The plastic cable reel with a moving lift point allows to reel in/out the cable during the

operation. The cable is strengthened by the Kevlar threads and the additional polyethylene shield.

The central cable core has 48V voltage. The power supply module has the short circuit

protection.

Surface module is mounted in a separate case and consists of power supply module,

control module and joystick. LCD display and battery 12V/7(12Ah) can be added to the basic set

of equipment upon request. Module has standard RCA jack for connecting to TV or audio/video

recorder.

Using the control pads and joystick the operator can move GNOM forward-backward, turn

to the right-left, up-down; adjust the thruster’s speed and the lighters’ brightness. All the data are

displayed in TV-text mode. By pressing one of the bottoms on the joystick the operator can pass

to the menu of tuning up some vehicle’s functions such as calibrating of the depth sensor.

1.2 TECHNICAL SPECIFICATION

3 magnetically coupled thrusters

Operation time - 500 h

Speed: - horizontal – up to 1 m/sec

vertical - up 0,3 m/sec

Operation depth – 50 m, ( can be modified up to maximum depth – 100 m)

Cable length max. – 75 m

Cable is strengthened by the Kevlar threads and the additional polyethylene shield,

negatively buoyant

Cable diameter –4.2 mm, breaking effort – 90 kg

Two clusters of ultra-bright LEDs

Color camera PAL CCD 1/3", 720 TV Lines, 0.1 lux

Power supply and surface control unit

Power supply – 230VAC or 12-24VDC battery 12V/7(12Ah)

Voltage value is displayed on a screen

Operating environment humidity – up to 100%

Operating temperature range – -5 …+ 45º. С.

Complete system is packed in two high-performance waterproof STORMCASE

ROV weight – 1.7 kg, full weight of system – 8 kg

Vehicle dimensions 210х185х150 mm

Depth sensor (sensibility 10 – 20 cm) with TV-text overlay on a screen, autodepth mode

Compass with TV-text overlay on a screen, autoheading mode

Vehicle has slight positive buoyancy, adjusting by adding metal weights

v05/2016

7

2. USER’S MANUAL FOR OPERATION

The central cable wire has 48V voltage! If any damages happened you

must repair or change the cable

2.1. Before using, please, check up all parts of vehicle especially propellers, cable and dome.

Clean the vehicle if necessary, check propeller rotation.

2.2. Adjust the buoyancy of the vehicle if necessary adding additional weights on the plastic feet

(Note that cable weight in water is approximately 2 g/m)

2.3. Plug in 3-sockets connector to reel and video cable to monitor video input. If you work from

230 VAC, connect AC power cable.

Do not rotate thrusters on air!

Do not switch lights on a full power on air!

Be very careful with the cable, do not:

Stand on it

Press on it

Twist it

2.4. If use any additional display or audio/video recorder, please, connect video cable to RCA

jack of additional video device

v05/2016

8

2. USER’S MANUAL FOR OPERATION

2.4.1 - You can not connect to the GNOM and other devices (accessory) to the

mains with the following problems:

• Wrong - incorrect wire connections L and N conductors in the appropriate slot.

• without protective earthing conductor.

Note. Checking the correct wiring connections (phase conductor - L) inspects the

operator. (E.g. by phase tester)

2.4.2 Checking the RCD

Carry out before any underwater operation at the new location as follows:

• If the requirements of paragraph 2.4.1 are met and connect to the power supply

only power module

• Switch on mains voltage button on the control panel

• After 5 seconds press the "TEST" button on the residual current device. It would

immediately lead to a safe shutdown of module

• Switch off the mains voltage button on the control panel. Switch on the current

circuit breaker

• Again switch on the power supply button on the control panel. Residual current

device must remain switched on.

2. USER’S MANUAL FOR O

2.5. Power supply from 2

3

Set switch 230V ON

(UP position)

2.6.

If use LCD display switch on its power supply separately. Brightness,

contrast and color saturation can be adjusted manually (see the user’s

manual LCD display).

For monitor operation (TV) follow manual to the

appropriate monitor.

2.7. After switch power ON “

WELCOME

After

finish operation set switch 230V in

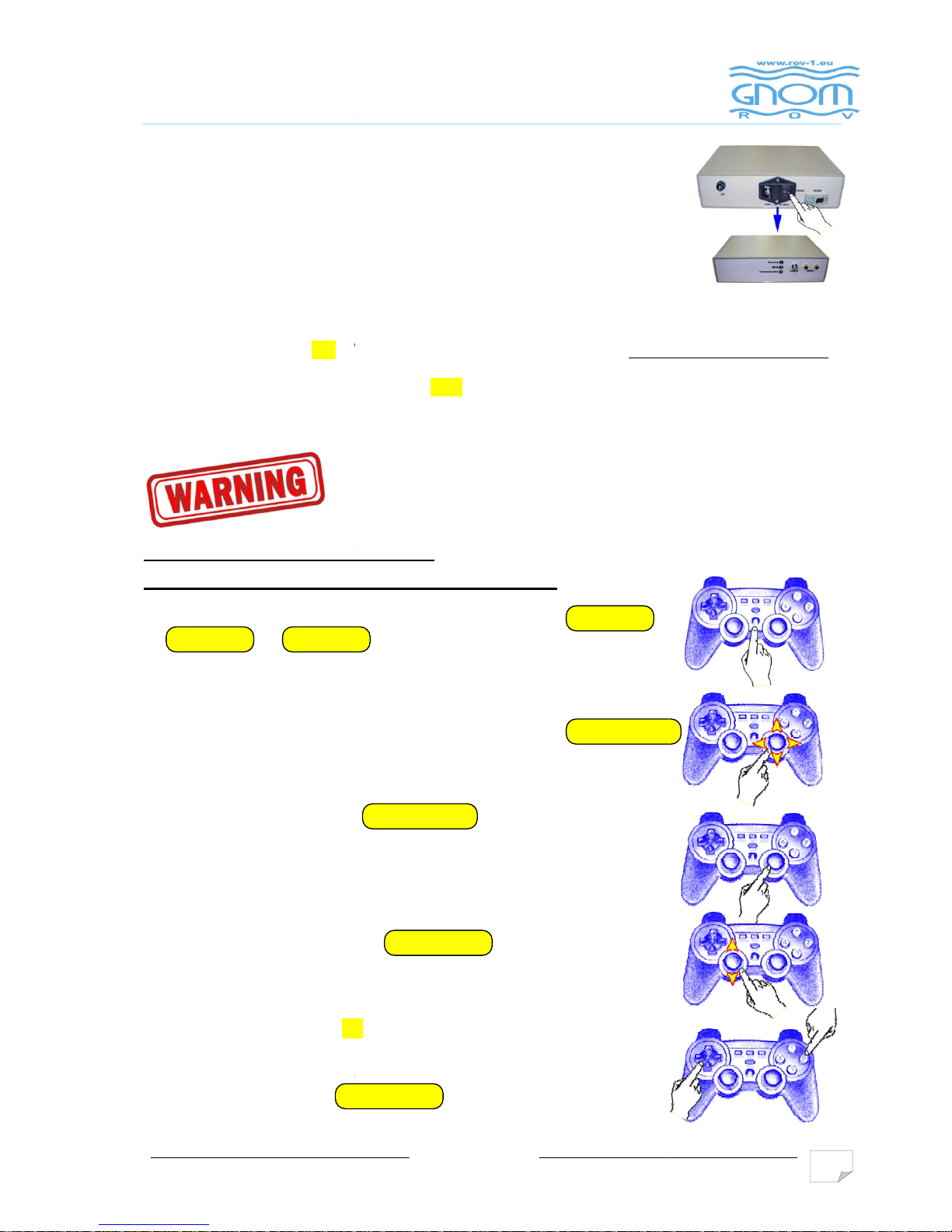

2.8. Operation

Do

not rotate thrusters on air!

Do not switch lights on a full power on air!

Put the vehicle into the water. To start operation press key

or on a joystick

All control functions are

displayed on a console draw (see below).

# To move vehicle

Forward/Back

# Slow mode (SLOW).

Press

(25%, 50%, 75%, 100%)

You can adjust

speed gradually (128 grades) pressing the joystick. The

direction and speed are indicated on an overlay.

# To move vehicle Up/Down

use

# Jump mode - Also press

②

A

llows to push vehicle slightly for a distance 30

chose the jump direction press arrows (

adjust the jump power use

left joystick

HOME

MODE

v05/2016

0V

WELCOME

” is displayed on monitor.

Gnom is ready for operation

OFF position

or

and turn Right/Left use

and adjust power gradually

.

to adjust the Jump mode.

– 50 cm them stop. To

Left/Right, Up/Down). To

.

left joystick

right joystick

right

joystick

ANALOG

9

.

2. USER’S MANUAL FOR O

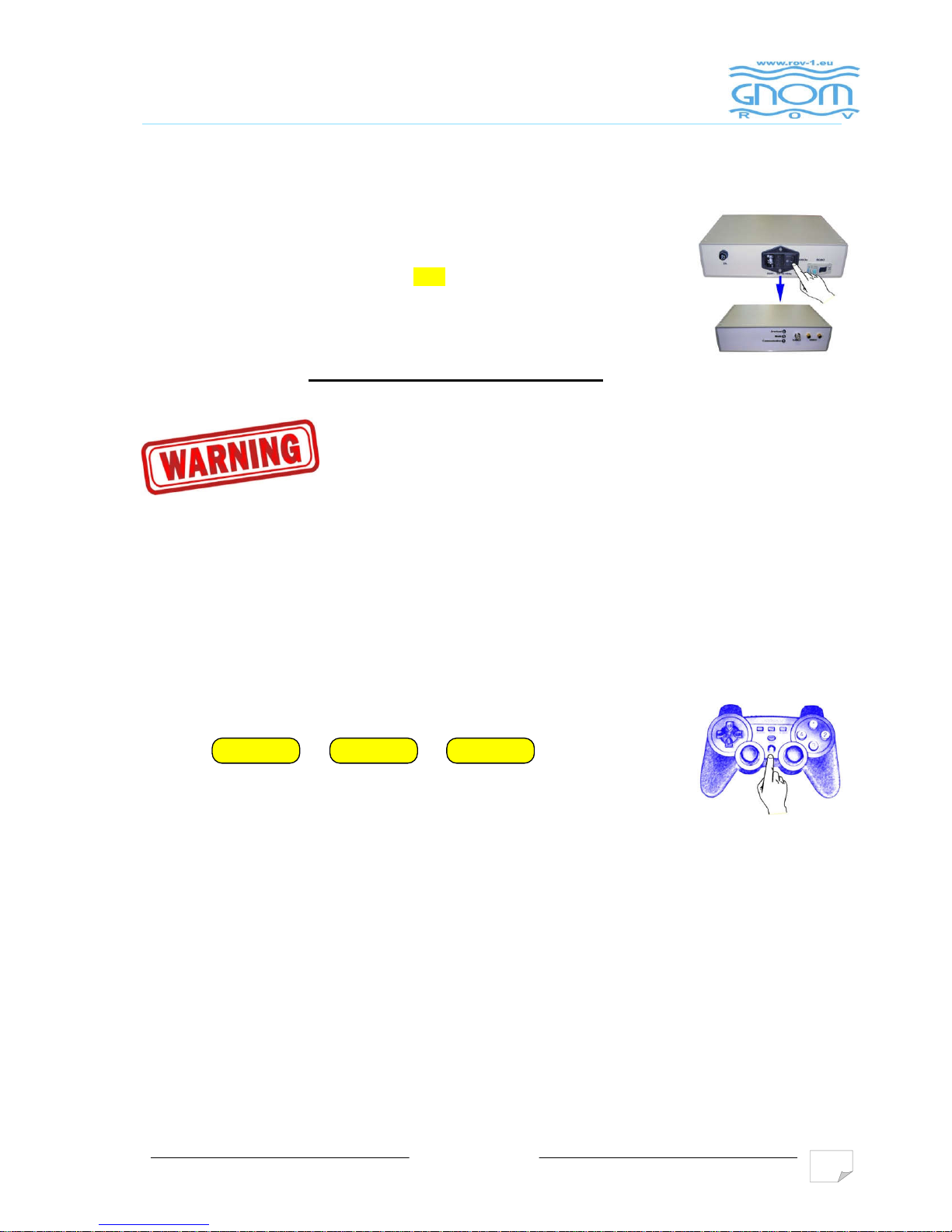

# Simultaneously press ③+

lights ( LOOP : 0%

100%, 100%

simultaneously 100% brightness turns on

( Simultaneously press ③+

mounted )

# Control

the GRABBER (if this is part of device)

by keys /

# To tilt cam Up/Down press

If press +

simultaneously camera goes to the

position.

# By keys ③ +

switch

# Autodepth mode.

Press key

actual depth you need.

To change the depth use left joystick.

Autodepth

mode and depth are indicated on an overlay.

# Autoheading

controls ON/OFF from the

joystick to left –

ON, to right OFF ). You should select forward speed

then switch ON autoheading. Autoheading

and direction.

# Press key ④ to

select SCREEN MODES :

Mode1 or Mode2 or Mode3

(see below)

SELECT

L 1

L 2

R 1

R 2

v05/2016

to change the intensity of the front

. If press ③+ +

/off.

adjust rear lighters – if it is

/ pads.

median

-on/switch off laser

① ON/OFF to fix the vehicle at the

key (version: left

mode holds the speed

Start

L 1

L 2

R 1

R 1

R 2

R 2

10

v05/2016

11

2. USER’S MANUAL FOR OPERATION

# You can choose the menu language (Russian/English)

2.9. Finishing the operation

To finish the operation switch power OFF then disconnect cables and pull

into the reel.

Try to avoid nods and twisting of the cable.

After operation please clean propellers and shafts of motors and wash the vehicle in fresh

water.

Special Functions

Sleeping mode (Power Saving Mode)

In order to save power and lengthen the using life of batteries, a power saving system is designed

in the wireless joystick. The joystick turns into sleeping mode (power saving mode) under the

following conditions:

A. If there is no operation within 30 seconds since the connection between the controller and the

receiver, the controller will turn into sleeping mode (power saving mode).

B. There is operation since the connection between the controller and

receiver. If there is no operation for 5 minutes, the controller will turn into

sleeping mode (power saving mode).

Press【 or or 】button can

stop this sleeping mode (power saving mode).

ANALOG

HOME

MODE

v05/2016

12

3. KEYS AND BUTTONS AT THE CONTROL PANEL

v05/2016

13

3. KEYS AND BUTTONS AT THE CONTROL PANEL

v05/2016

14

3. KEYS AND BUTTONS AT THE CONTROL PANEL

v05/2016

15

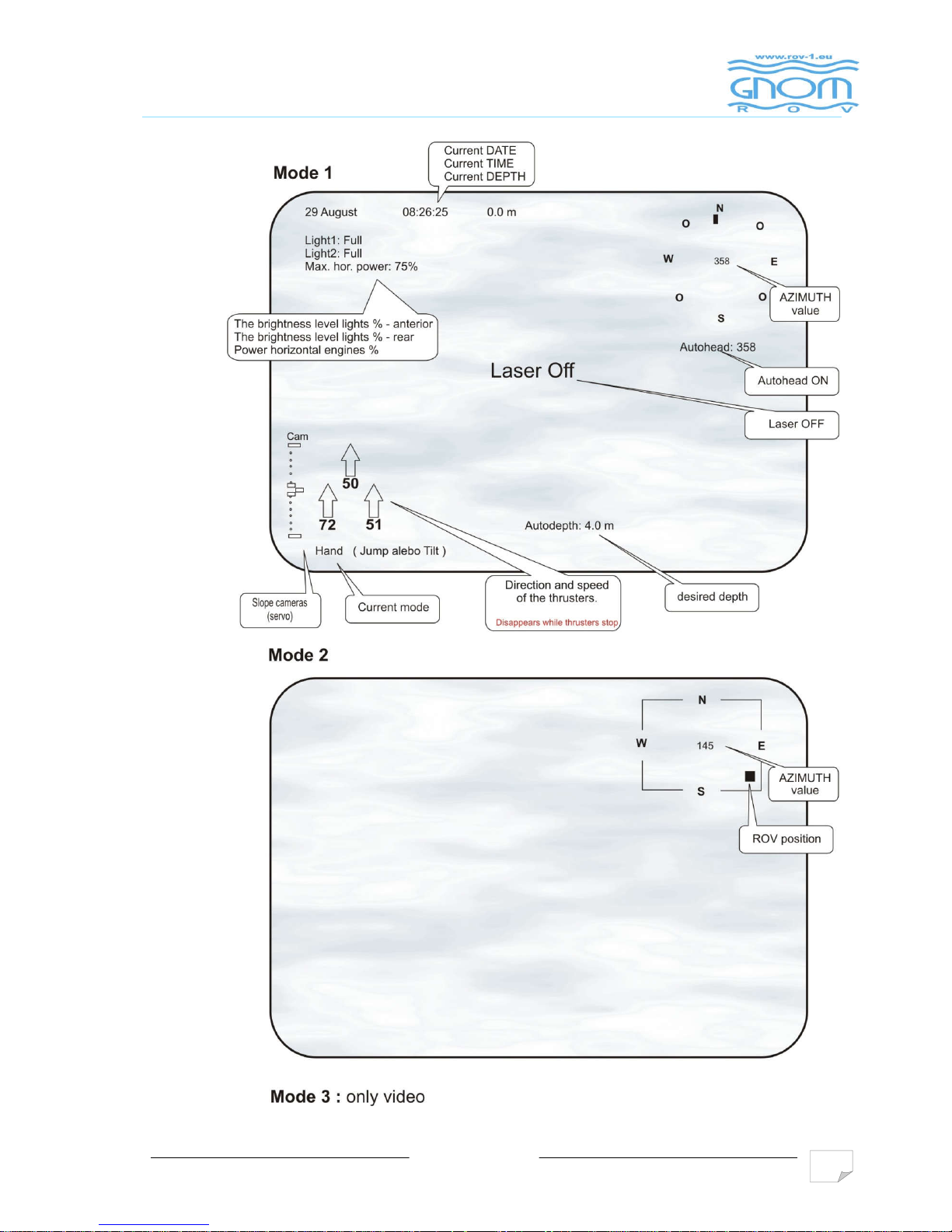

4. SCREEN MODES

v05/2016

16

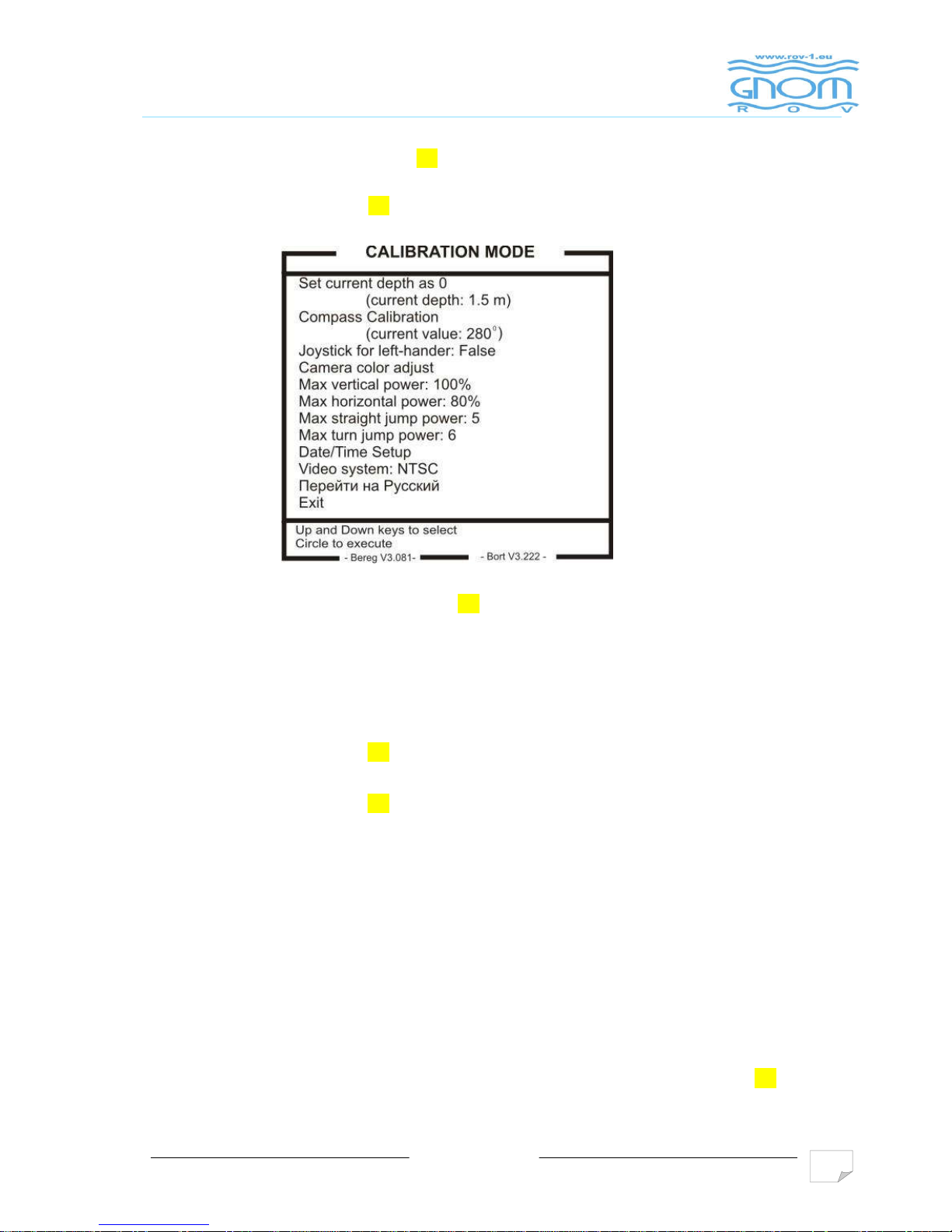

5. CALIBRATION

To enter this mode you should be in start mode (message WELCOME is indicated). To calibrate depth

sensor and compass you should press key ③ and hold it for 7-8 sec only while message WELCOME is

indicated. Message "Calibration mode" appears. To select function you should use left arrows. To enter

functions you should use right key ②

- “Set current depth as 0”. To calibrate depth sensor you should set 0m when GNOM is on a surface.

To finish calibration press Enter (right key ②). We recommend to set depth 0 in 5 minutes after

power ON.

- “Compass Calibration”. Preinstalled. Please, use only in a case of incorrect work. To calibrate

compass you should do:

Calibration procedure

:

1. Put the GNOM on flat surface far from metal things to North directions

2. Press circle (right key ②) to start calibration

3. Slowly turn the GNOM, clockwise, around own axis and not less than two turns

4. Press circle (right key ②) to finish calibration

- “Joystick for left-handler”. Do not use.

-

“Camera color adjust” . Do not use.

-

“Max vertical power”. Set up maximal power of vertical thrusters in %.

-

“Max horizontal power” Set up maximal power of horizontal thrusters in %.

-

“Max straight jump power” . Set up length of straight jump

-

“Date/Time Setup” . Set up date and time.

-

“Video systems” . Select PAL or NTSC.

-

“Перейти на Русский”. Select language (Russian or English).

-

“- Bereg Vx.xxx -” and “- Bort Vx.xxx -” indicates version of software.

- To return from calibration menu set the cursor to word Exit and press Enter (right key ②).

v05/2016

17

6. MAITENANCE OPERATION

To maintain the vehicle it is necessary:

to clean the propellers from alge, sand and mud

to rinse the vehicle in the fresh water after using in the sea

to inspect the cable after the operation. In case of any damages the cable must be

repaired or changed

to check the magnetic disk coupling regularly

Use silicon oil spray for lubrication shafts of props every time after diving. Oil must

penetrate inside of conus heads of motors. See appendix position 96, 147, 217 of

thrusters assembly.

Avoid nods and twisting of cable.

Within the certificate of warranty the bond (joint) mainenance manual is included.

Use it only in case of emergency, if standard maintenance is insufficient.

Before this service consult technical problems in our company on email addresses:

odbyt@vftech.sk

or

vladoo@vftech.sk

Attention:

In case of non-professional action and damage of any part, the consecutive service in our

company will be charged.

v05/2016

18

7. SAFETY REQUIREMENT

1. Device belongs to CLASS 1 . For this reason the power adapter must have

connection to protective earth.

2. Swith-on and swith-off the machine by main 230V switch, which is placed over the

power cord to the external control unit.

3. Do not use the system with the damaged cable.

4. Do not touch underwater vehicle and the cable if you are in water and the power is

turned ON.

5. Keep the control module and the cable reel dry.

6. When recharging the battery disconnect the vehicle and the cable reel.

v05/2016

19

8. WARRANTY STATEMENT

VFTECH warrants that at the time of shipment all products shall be free from defects in material and

workmanship and suitable for the purpose specified in the product literature.

The unit/system warranty commences immediately from the date of customer acceptance and runs for a

period of 1 year ( except for thrusters ). Warranty for thrusters is to 6 months from the date of purchase.

Customer acceptance will always be deemed to have occurred within 72 hours of delivery.

Note: Any customer acceptance testing (if applicable) must be performed at either VFTECH premises or at

one of their approved distributors unless mutually agreed in writing prior to despatch.

Warranty service can only apply observance of inspection at intervals of 3 months from the receipt of the module.

When unrealized maintenance checks is not applicable warranty. You can apply warranty only in case if regular 3-

months service inspections of product are performed. In other case warranty can not be applied to product.

Conditions:

These include, but are not limited to, the following:

1. The warranty is only deemed to be valid if the equipment was sold through VFTECH or one of its approved

distributors.

2. The equipment must have been installed and commissioned in strict accordance with approved technical standards

and specifications and for the purpose that the system was designed.

3. The warranty is not transferable, except or as applies to Purchaser first then to client.

4. VFTECH must be notified immediately (in writing) of any suspected defect and if advised by VFTECH , the

equipment subject to the defect shall be returned by the customer to VFTECH , via a suitable mode of transportation

and shall be freight paid.

5. The warranty does not apply to defects that have been caused by failure to follow the recommended installation or

maintenance procedures. Or defects resulting from normal wear & tear, incorrect operation, fire, water ingress,

lightning damage or fluctuations in vehicles supply voltages, or from any other circumstances that may arise after

delivery that is without the control of VFTECH. (Note: The warranty does not apply in the event where a defect has

been caused by isolation incompatibilities.)

6. The warranty does not cover the transportation of personnel and per diem allowances relating to any repair or

replacement.

7. The warranty does not cover any direct, indirect, punitive, special consequential damages or any damages

whatsoever arising out of or connected with misuse of this product.

8. Any equipment or parts returned under warranty provisions will be returned to the customer freight prepaid by

VFTECH

9. The warranty shall become invalid if the customer attempts to repair or modify the equipment without appropriate

written authority being first received from VFTECH .

10. VFTECH retains the sole right to accept or reject any warranty claim.

11. Each product is carefully examined and checked before it is shipped. It should therefore

be visually and operationally checked as soon as it is received. If it is damaged in anyway, a

claim should be filed with the courier and VFTECH notified of the damage.

Note: VFTECH reserve the right to change specifications at any time without notice and without any obligation to

incorporate new features in instruments previously sold.

Note: If the instrument is not covered by warranty, or if it is determined that the fault is

caused by misuse, repair will be billed to the customer, and an estimate submitted for

customer approval before the commencement of repairs.

v05/2016

20

9. EXAMPLES OF LINKING MODULES

v05/2016

21

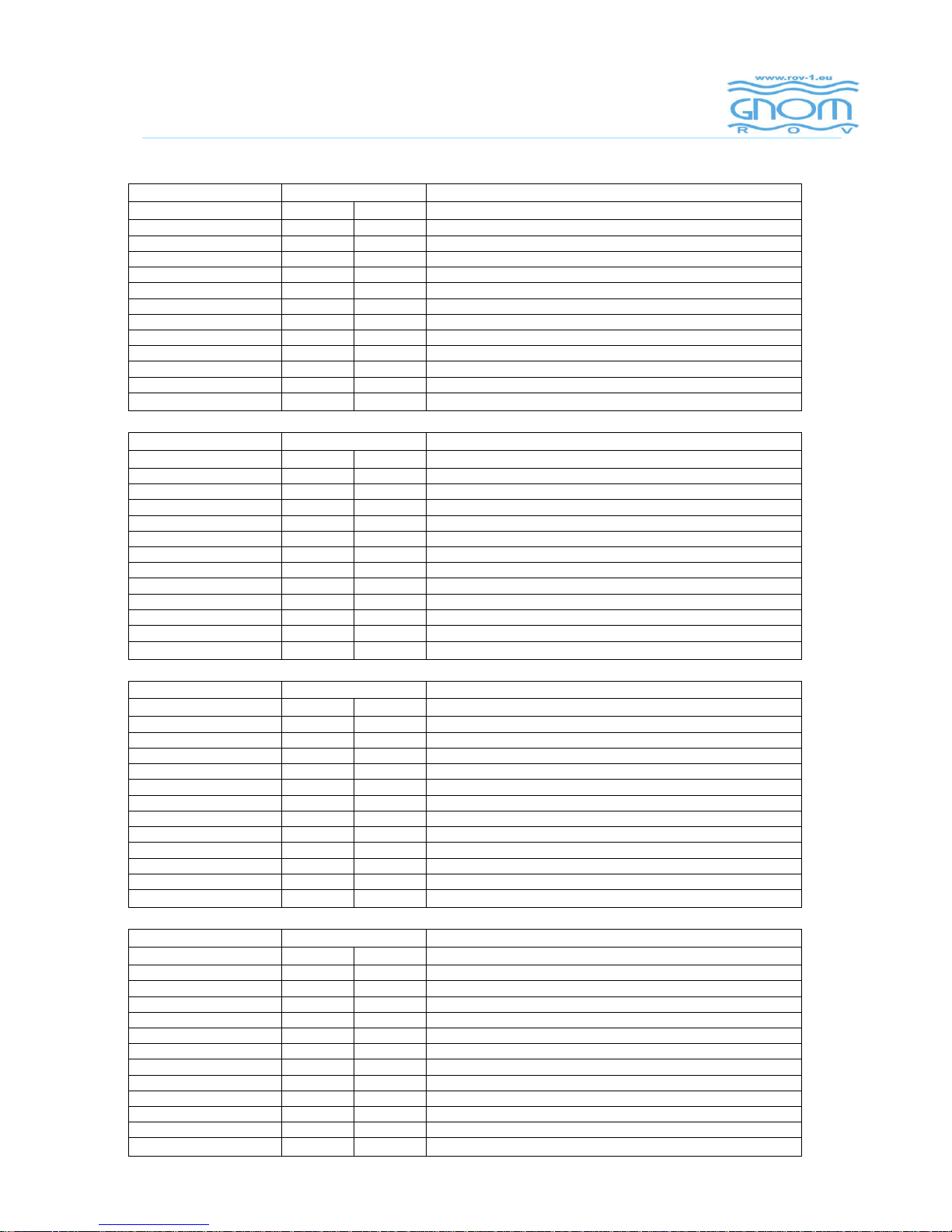

10. APPENDIX

5 PAGES

For use GNOM in fresh water you need install additional floatation [pos.1]

You should do the next:

1. To unscrew screws [pos.3] of skids [pos.2]

2. To remove skids [pos.2]

3. To install the additional block of floatation [pos.1] (enters into the equipment complete

set)

4. To install skids back

Power supply~230V,

50-60 Hz

power cable: max 20 m.

3G х 1.0 mm?

L, N, PE - wires

L, N, PE - wires

power cable: max 5 m.

3G х 0.75 mm?

plug

L

N

PE

L

N

F1

L

N

RF filter RCBO

TEST

~230V 50-60 Hz

Main board

+48V

Control

Video

F2

connection cable

Joystick

Power, video and control cable +48V

monitor

Hand

reel

RCBO - Residual Current Circuit Breaker

with Overcurrent Protection 16A/10iA

F1 - fuse 3A/250V

F2 - fuse 2A/250V

ROV

Tether, 50м.

Video out 1

Video out 2

Connection diagramm

+48V

AC\DC

additional monitor or

record device

Input power – max. 125W

wirelles

Сборочный чертеж малогабаритного подводного телеуправляемого осмотрового аппарата

Micro ROV assembly

Сборка корпуса Main hull assembly

1 Заглушка полозьев skid closing plug

2 Кольцо уплотнительное sealing ring

3 Полозья опорные skid

4 Крепление блистера blister fixing ring

5 Иллюминатор forward-viewing window

6 Корпус блистера front hull insertion

7 Корпус камеры camera fixing body

8

Кольцо крепления

PCB fixing ring

9

Сборка двигателя

horizontal thruster

10 Сборка задней крышки assembled closure backwall

11

Шпилька крепления

flotation fastering stud

12 Хомут крепления кабеля cable clip

13

Сборка двигателя

vertical thruster

14

Сборка двигателя

horizontal thruster

15 Болт screw

16 Крепление движителя thruster mounting

17 Шпилька stud

18 Плата электроники PCB

19 Крепление электроники PCB mounting

20

Кронштейн крепления

tilt camera fixing body

21 Болт screw

22 Кольцо уплотнительное sealing ring

23 Втулка опорных полозьев bush

24 Кольцо уплотнительное sealing ring

25 Гайка nut

26 Болт screw

Сборочный чертеж задней крышки

Backwall asembly

30 Болт screw

31 Шайба washer

32 Плата электроники PCB

33 Датчик глубины depth sensor

34 RS-разъем RS-connector

35 Крышка задняя backwall

36

Кольцо крепления задней

backwall mounting

37 Кольцо уплотнительное sealing ring

38

Крепление двигателя

thruster mounting

39 Кольцо уплотнительное sealing ring

40 Гермоввод cable pressure seal

41

Кольцо крепления

fit ring

42 Втулка гермоввода

cable pressure seal

43 Шайба washer

44 Болт screw

45 Гайка гермоввода кабеля

cable pressure seal

46 Хомут крепления кабеля cable clip

47 Кольцо уплотнительное sealing ring

48 Болт screw

50 Шайба washer

Сборка горизонтального

Horizontal thruster

55 Ограждение гребного винта propeller guard

56 Гайка крепления гребного

propeller cap nut

57 Гребной винт propeller

58 Кольцо крепления

propeller guard mounting

59 Втулка фильтра filter bushing

60 Оголовье thruster cone

61 Гайка крепления оголовья thruster cone n ut

62 Гайка корпуса thruster cap nut

63 Передняя часть корпуса thruster cap

64 Кольцо уплотнительное sealing ring

65 Шпилька thruster rod

66 Электродвигатель thruster

67 Шайба крепления двигателя motor mounting washer

68 Сегмент крепления

thruster mounting washer

69 Труба thruster tube

70 Кольцо уплотнительное sealing ring

71 Задняя часть корпуса thruster closure backwall

72 Кольцо уплотнительное sealing ring

73 Стекло осветителя light port

74 Прокладка sealing ring

75 Гайка задника closure backwall nut

76 Кольцо уплотнительное sealing ring

77 Проставка hull spacer

78 Гайка nut

79 Шайба washer

80 Винт screw

81 Муфта внутренняя inside magnetic coupling

82 Муфта наружняя outside magnetic coupling

83 Винт Screw

84 Втулка thruster bushing

85 Фильтр filter

86 Ось propeller shaft

Сборочный чертеж движителя

Horizontal thruster assembly

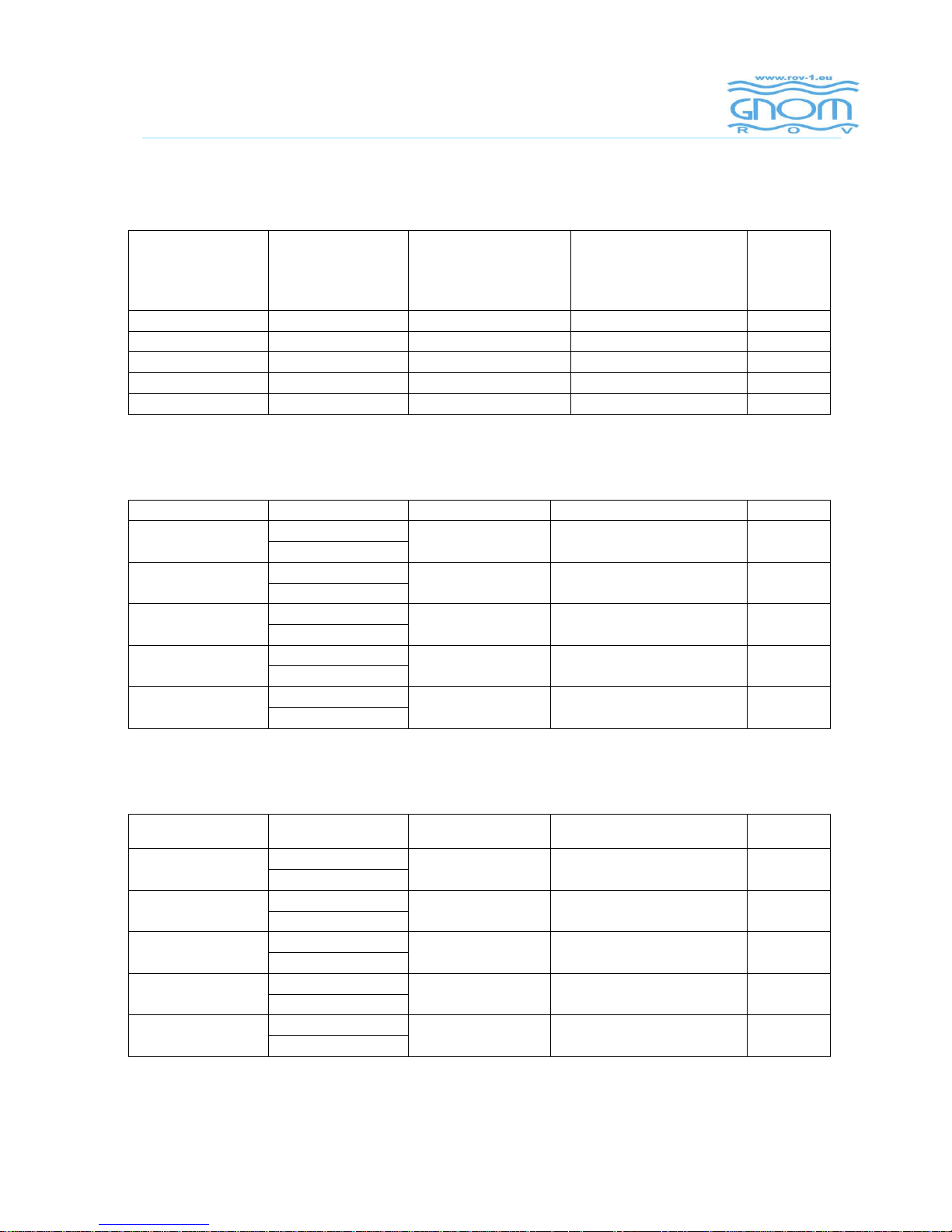

11. ANNEX

PROBLEMS SOLUTION

Alight LED on control

unit

Check that control unit is connected to a power supply

Check that control unit is switch on

If previous conditions are met but LED is still alight, check network fuse of control unit

Underwater unit does

not respond to JOYSTICK

Check that control unit is switch on – LED must illuminate

Check that joystick is switch on

Check batteries in joystick

Underwater unit does

not swim directly

Check horizontal thrusters – propellers have turn easy– check by finger

In case that some propeller turns hard, clean slide bearing of coupling axis of propeller

and check setting of coupling

Underwater unit does

not respond correctly to

Joystick

You have probably switch on function MAKRO on joystick ( some of models). Resolve

problem in according to the procedure in chapter JOYSTICK DESCRIPTION

The screen displays

incorrect value of

navigation depth

Make calibration of depth sensor in according to this manual

Underwater

module

does not respond to

joystick

Joystick is in sleep mode (power saving).

See chapter USER’S MANUAL FOR OPERATION

11. ANNEX

SERVICE COUPON

Coupon No.1

Date of sale

SERIAL NUMBER

DATE OF INSPECTION

TRUE

FALSE

DESCRIPTION OF REPARATION

HORIZONTAL THRUSTER L

HORIZONTAL THRUSTER R

VERTICAL THRUSTER F

VERTICAL THRUSTER B

LIGHTS

SERVO

COMPASS

DEPTH SENSOR

JOYSTICK

CONTROL UNIT

MOTOR COUPLING

STAMP AND SIGNATURE

Coupon N.2

Date of sale

SERIAL NUMBER

DATE OF INSPECTION

TRUE

FALSE

DESCRIPTION OF REPARATION

HORIZONTAL THRUSTER L

HORIZONTAL THRUSTER R

VERTICAL THRUSTER F

VERTICAL THRUSTER B

LIGHTS

SERVO

COMPASS

DEPTH SENSOR

JOYSTICK

CONTROL UNIT

MOTOR COUPLING

STAMP AND SIGNATURE

Coupon No.3

Date of sale

SERIAL NUMBER

DATE OF INSPECTION

TRUE

FALSE

DESCRIPTION OF REPARATION

HORIZONTAL THRUSTER L

HORIZONTAL THRUSTER R

VERTICAL THRUSTER F

VERTICAL THRUSTER B

LIGHTS

SERVO

COMPASS

DEPTH SENSOR

JOYSTICK

CONTROL UNIT

MOTOR COUPLING

STAMP AND SIGNATURE

Coupon No.4

Date of sale

SERIAL NUMBER

DATE OF INSPECTION

TRUE

FALSE

DESCRIPTION OF REPARATION

HORIZONTAL THRUSTER L

HORIZONTAL THRUSTER R

VERTICAL THRUSTER F

VERTICAL THRUSTER B

LIGHTS

SERVO

COMPASS

DEPTH SENSOR

JOYSTICK

CONTROL UNIT

MOTOR COUPLING

STAMP AND SIGNATURE

11. ANNEX

Year of purchase:

TABLE № 1. Registration of working time

Start and end date of

executed works

Place of works

Underwater unit working

time (hours)

Operator name and

signature

11. ANNEX

Table No. 2 Statistics of damaged and replaced fuses in control unit

Date / time of fuse

seasoning and her

replacements

Type and parameter

of network fuse

Type and parameter of

power cable fuse +180V

Operator name and work

position

Signature

1.

2.

3.

4.

5.

Table No. 3 Inspection of coaxial cable intact

Date Type of cable Result Name Signature

1.

2.

3.

4.

5.

Table No. 4 Inspection of grounding cable clamp resistance

Date Type of cable Result Name Signature

1.

2.

3.

4.

5.

11. ANNEX

Protocol of perform warranty repairs

Client

Address

Client’s agent name

Name of employee taking complaint

Date of taking complaint

Date of product sale

Type of product + serial number

Description of defect by client

Description of defect by service operator

Used material

Legitimate complaint Yes No

If no legitimate - reason

Date of repaired good expedition to client

Loading...

Loading...