PRESENTATION OF MANUAL

INSTRUCTIONS FOR USE

Technical Name: Odontological cuspidor

Brand: Gnatus

Trade Name: Water Unit Syncrus G4

Models: G4 / G4 A

Manufacturer / Distribuitor:

GNATUS - EQUIPAMENTOS MÉDICO ODONTOLÓGICOS S/A.

Rod. Abrão Assed , Km 53+450m - Cx. Postal 782 CEP 14097-500

Ribeirão Preto - S.P. - Brasil

Fone +55 (16) 2102-5000 - Fax +55 (16) 2102-5001

C.N.P.J. 48.015.119/0001-64 - Insc. Est. 582.329.957.115

www.gnatus.com.br - gnatus@gnatus.com.br

Technical Duties: Ricardo J. Ravaneli

CREA-SP: 5060714523

Registration ANVISA nº: 10229030067

ATTENTION

For greater safety:

Read and understand all the instructions contained in these

instructions for use before installing or operating this equipment.

Note: These instructions for use must be read by all the operators

of this equipment.

2

INDEX

PRESENTATION OF MANUAL ........................................................................02

IDENTIFICATION OF EQUIPMENT .................................................................05

Indication of Equipment ...................................................................................05

Principles and fundamentals applied to the product functioning ..............................05

Equipment Description .....................................................................................06

MODULES, ACCESSORIES, OPTIONALS AND CONSUMPTION MATERIALS .......08

TECHNICAL SPECIFICATIONS .......................................................................14

- Technical features of the Delivery Unit and its accessories ...................................14

- Electromagnetic Emissions ..............................................................................16

- List of pieces and circuit scheme .....................................................................19

- Standards applied .........................................................................................19

- Dimensions ..................................................................................................20

- Packing symbols ...........................................................................................22

- Product symbols ...........................................................................................22

- Content of accessible and non-accessible demarcations .....................................23

INSTALLATION OF EQUIPMENT ....................................................................23

EQUIPMENT OPERATION ..............................................................................24

- Control panel ................................................................................................24

- Terminal Triggering .......................................................................................22

- Adjustment of Spray of “TB/TM high and low rotation terminals” .........................25

- Ejectors operation .........................................................................................25

- Use of 3-Way Syringe ...................................................................................25

- Replacement of the standard of cannula coupling ..............................................26

- Curing Light Activation ...................................................................................27

- Activation of the “Laser Hand” .........................................................................28

- Water ow adjustment ...................................................................................29

- Regulation of the water selecting valve .............................................................29

- Master Valve .................................................................................................29

- How to provision the reservoirs .......................................................................29

PRECAUTIONS, RESTRICTIONS AND WARNINGS ..........................................30

- Transportation, storage and operation ..............................................................30

- Sensitivity to environmental conditions in normal situations of use .......................30

- Precautions and warnings “during the installation” of equipment ..........................30

- Recommendations for the dental equipment maintenance. ..................................31

- Precautions and warnings “during the use” of equipment ....................................31

- Precautions and warnings “after” the use of equipment ......................................31

- Precautions and warnings during the “cleaning and disinfection” of equipment .......32

- Precautions in case of alteration in the functioning of equipment ..........................32

- Precautions to be adopted against foreseeable or uncommon risks,

related to the deactivation and abandoning of equipment ......................................32

CORRECTIVE AND PREVENTIVE MAINTENANCE AND PRESERVATION............33

- Additional procedures for reuse .......................................................................33

- Cleaning and Disinfection ...............................................................................33

Cleaning:

- Triple syringe ................................................................................................35

- Reservoirs ....................................................................................................35

33

INDEX

- Cleaning of the drain .....................................................................................35

- Basin cleaning ..............................................................................................36

- Bio-System ..................................................................................................36

- Curring Light ................................................................................................37

- Laser Hand ...................................................................................................37

- Bicarbonate Jet "Jet Hand" .............................................................................37

- Preventive Maintenance .................................................................................37

- Corrective Maintenance ..................................................................................37

UNFORESEEN EVENTS – SOLUTION OF PROBLEMS ........................................37

WARRANTY OF EQUIPMENT ..........................................................................40

FINAL CONSIDERATIONS ..............................................................................40

4

IDENTIFICATION OF EQUIPMENT

Dear Customer

Congratulations. You have made a good choice when you decided to buy a GNATUS

QUALITY product comparable to the best products available in the World. This manual is a

general presentation of your product and it will give you important details to help you to

solve possible problems.

Please, read it and keep this with you.

Indication of Equipment

This equipment is for dental use use only. It must be operated and utilized by specialized

professional (certied professional, according to the legislation of the country) and following

the instructions of the manual. The operation of the equipment required, for the professional,

the utilization of correct instruments and it should to be in perfect conditions of the use,

and to protect the professional, the patients and others, in the eventual danger situation.

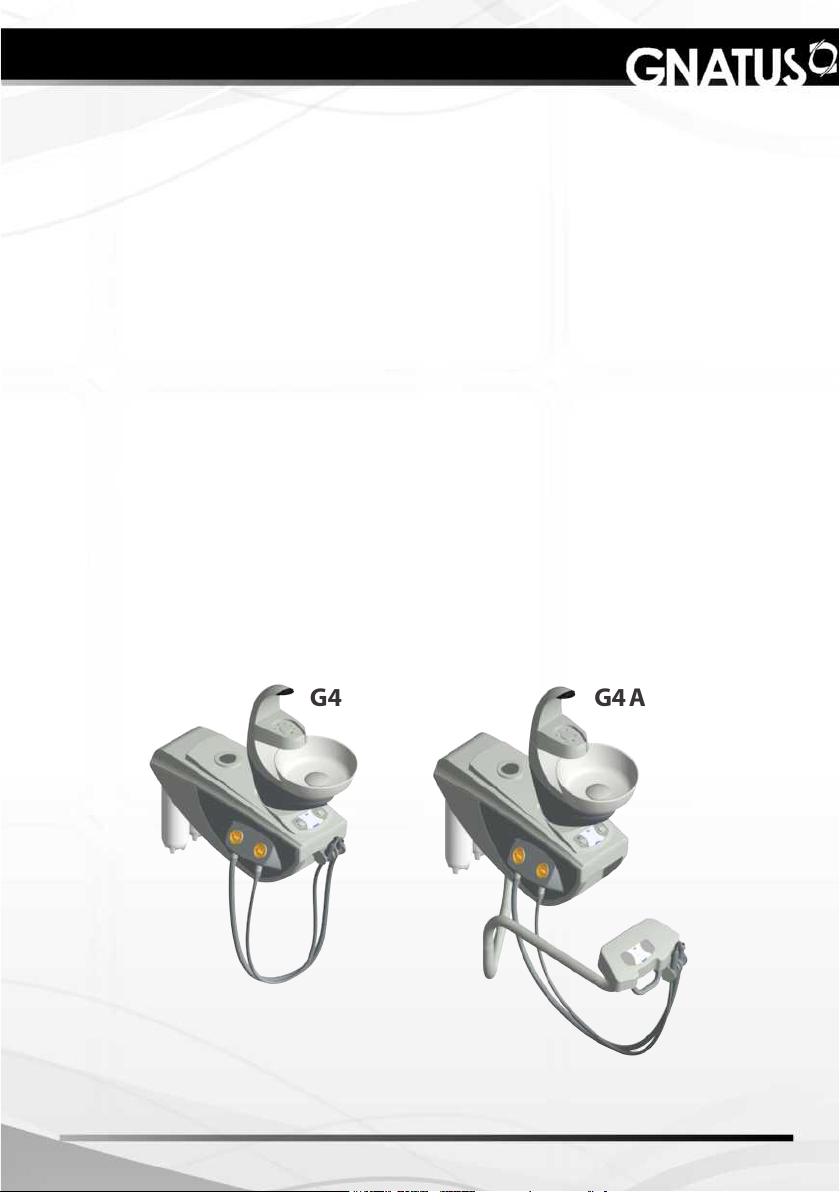

Principles and fundamentals applied to the product functioning

Auxiliary waste collector unit, has suctors which suction is caused by venturi system or

vacuum pump with compressed air.

Identication

Technical Name: Odontological cuspidor

Trade Name: Water Unit Syncrus G4

Brand: GNATUS

Models: G4/G4A

G4 G4 A

55

IDENTIFICATION OF EQUIPMENT

Equipment Description

Water unit for odontological use, for auxiliary work such as water supply for waste

collection and spitting and sucking activation; ambidextrous (for right- and left-handed).

Attached to the chair, with electronic control panel which activates the following functions:

water in the bowl, water in the cup holder and *water heating of the triple syringe.

Programmable timer for water trigging in the cup holder and in the spitting bowl by a

time interval set by the professional, providing bigger water savings at the ofce.

The frame is manufactured with steel structure, ABS injected body with anti-UV protection.

Smooth high glossy paint, epoxy-based, cured in an oven at 250° C, with phosphate treatment

resistant to rust, corrosion and cleaning chemicals.

Upper part of the unit with suitable location for the best spitting position, 180° foldable

bowl providing total patient comfort.

Ceramic bowl spittoon, deep and easily removable for hygiene and asepsis, supplied

with strainer drain for solids retention.

Water ux regulating system allowing ne-tuning in the bowl and the cup holder water

ux.

Smooth, rounded, light and exible hoses and with quick release that is easily connected,

without the need of tools.

Has a debris lter easy to clean and disinfection.

Ejectors with automatic drive easy to use, they provide an excellent operating

performance, allow professionals to work with better visualization of the operative eld and

reduce the risk of contamination by aerosol and greater patient comfort.

*High power electric Ejectors with individual low voltage drive, provide lightness and

accuracy in the drive.

*Triple syringe swivel spout, removable and autoclavable.

*Double system for water supply (network/reservoir).

*Master valve (key for water cut).

Arm Reach with Front Handle: terminal support with wide horizontal movement that

enables optimal approach to the surgical eld and excellent accessibility to the various

resources available. Optimizes work prioritizing the ergonomics and biosafety.

Automatic selection of tips through individual pneumatic valves, allowing light handling.

Translucent water tanks for syringe and spray tips and chlorinated water Bio- System.

*

Bio-System: disinfection system, which provides the internal hose and terminals cleaning

through liquid bactericide, preventing risk of cross contamination.

EN ISO 9001/2000 and EN ISO 13485/2003 Quality System, assuryng the products

are manufactured under standart procedures.

Products manufactured in agreement with RDC 59/00 - ANVISA - (Sanitary Surveillance

National Agency).

Laser Hand Kit (optional item) – Features of the product:

See the Owner’s Manual - Laser Hand

Bicarbonate jet (optional item) – Features of the product:

See the Owner’s Manual - Jet Hand

* Optional item

6

IDENTIFICATION OF EQUIPMENT

Curing light (optional item) – Features of the product:

The Curing Light belongs to the newest generation of LED photo-activation devices. This

abbreviation stands for Light Emitting Diode, a totally different type of light emission, if

compared to conventional halogen equipment.

Unlike traditional devices, which generate wide-spectrum light and heat, this technology

uses a cold light of the precise wave length needed to activate various dental products.

LED technology, which was recently introduced in Dentistry, brought about several useful

features to those light-curing devices used in composite resin restoration. Besides being

more durable, LED technology turned devices more compact, ergonomic and easier to install

and transport. The emission of cold light within a precise wave length range ensures the

safe cure of camphorquinone-activated composites, preventing dental heating, pulp damage

or discomfort for both patient and dentist. Although being relatively new, this technology

is nowadays in its second generation. LED safety and efciency, now allied to high-energy

emission, are available to all clinic procedures which require light-curing power, including

bleaching treatments.

The light of 440nm-460nm wave length, allied to the high energy emitted by Curing

Light, makes possible the multi-functionality of this device:

- Direct restoration procedures: composite resins, ionomers and adhesives.

- Indirect restorations: adhesive cementation of laminates, inlays, esthetic pins and

metal-free crowns.

- Dental Bleaching: activation of bleaching gel and polymerization of gingival barriers.

Compatible with 35% hydrogen peroxide-based bleaching gels.

- Attachment of braces and orthodontic accessories.

- Activation of light-cure materials, such as sealants, surgical cements and covering

bases.

Designed and built with cutting-edge technology, it meets the highest standards specied

by world’s dental authorities.

Operation control display in handpiece, sound alarm with beep every 10 seconds and 4

beeps at the end of the cycle.

Advantages offered by Curing Light:

- More spectrally-selective light than conventional lamps.

- Cold light, it doesn’t heat up the resin nor the tooth.

• Light compact equipment that provides handling comfort.

• Low power consumption.

• Longer useful life of the light emitting diode (equivalent to 36.000.000 cycles of 10

seconds).

• It does not use optical lter.

• It does not require forced ventilation, thus avoiding noise emission.

We noted that the light emitted by the Curing Light is completely contained within the

absorption interval of the photo starter, therefore it’s 100% used, whereas the conventional

equipment running on halogen lamps has non-used wave-length regions.

The Curing Light doesn’t generate heat since it uses light emitting diodes.

The light conductor is removable, made out of high resistance polymer and of easy

maintenance.

* Optional item

77

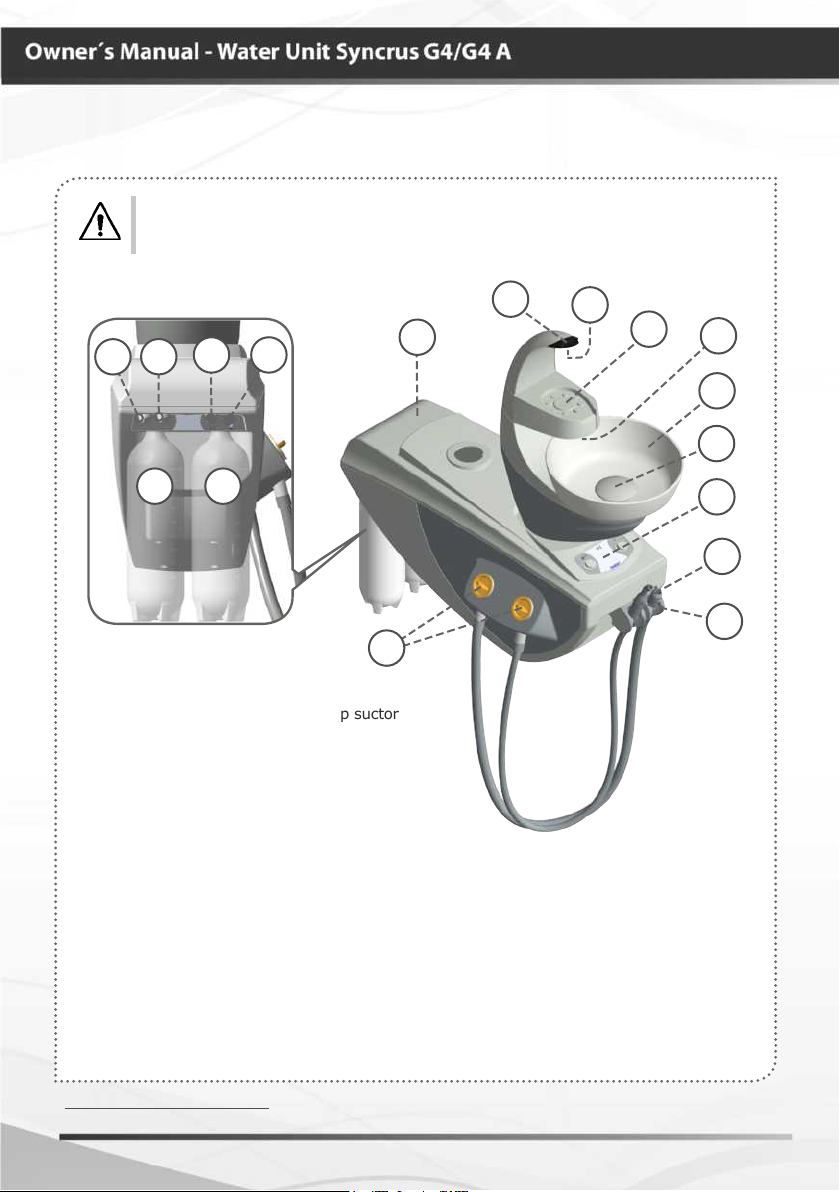

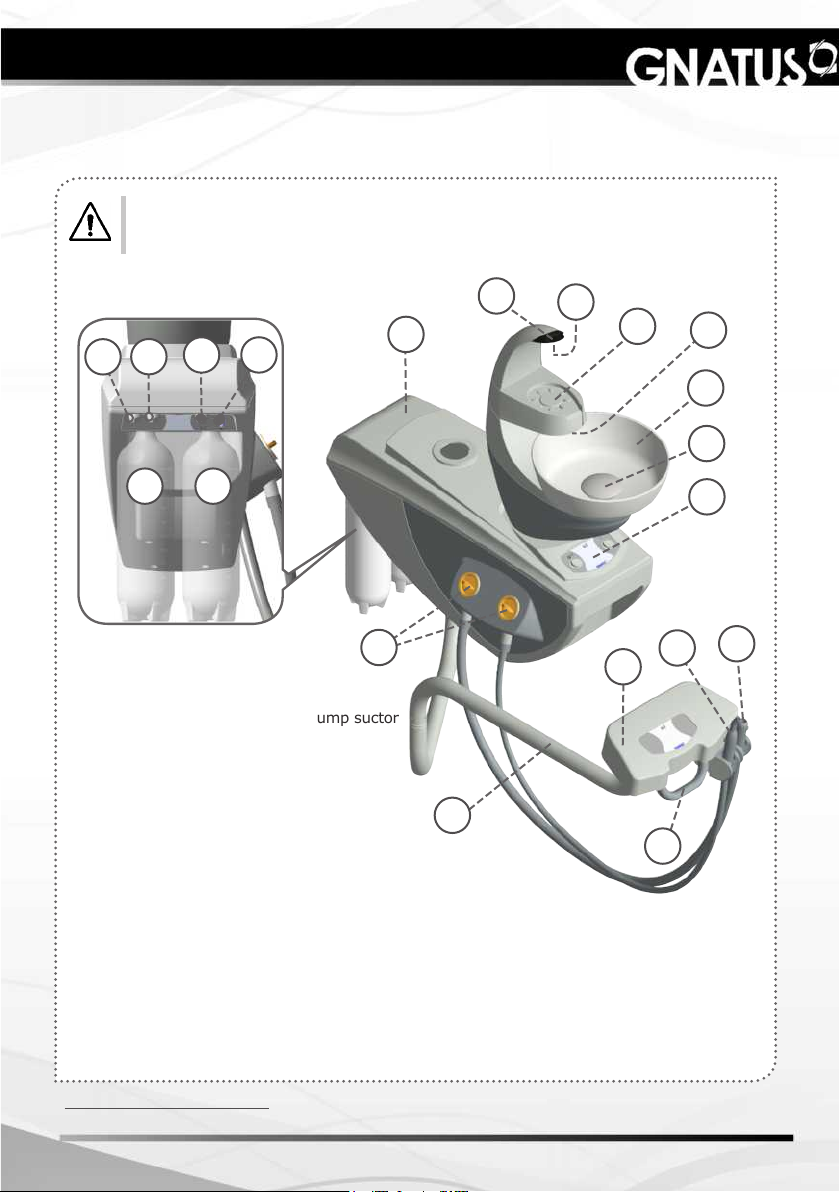

MODULES, ACCESSORIES, OPTIONALS AND CONSUMP

TION MATERIALS G4

The content on this page is informative; the equipment can be different from those

illustrated. Therefore, when purchasing the product check the technical compatibility

between equipment, coupling and accessories.

15 16

14

13

1211

09

Basic product conguration:

1 Venturi type suctor, 1 Vacuum pump suctor

01 - Water conductor cup holder

02 - Cup holder

03 - Water conductor bowl

04 - Bowl

05 - Drain cover

06 - Control Panel

*

07 - Vacuum pump suctor

*

08 - Venturi type suctor

09 - Suctor Filters

10 - Cabinet body

11 - Bio-System Reservoir

12 - Water Reservoir

13 - Water ux regulating cup holders

14 - Water ux Regulating bowl

*

15 - Master valve - releases/block water input

*

16 - Water selector valve - reservoir/network

*

17 - Optical Sensor

10

17

01

02

03

04

05

06

07

08

* Optional item

8

MODULES, ACCESSORIES, OPTIONALS AND CONSUMP

TION MATERIALS G4A

The content on this page is informative; the equipment can be different from those illustrated.

Therefore, when purchasing the product check the technical compatibility between

equipment, coupling and accessories.

15 16

14

13

1211

09

Basic product conguration:

1 Venturi type suctor, 1 Vacuum pump suctor

10

18

20

01

17

02

19

08

03

04

05

06

07

01 - Water conductor cup holder

02 - Cup holder

03 - Water conductor bowl

04 - Bowl

05 - Drain cover

06 - Control Panel

*

07 - Vacuum pump suctor

*

08 - Venturi type suctor

09 - Suctor Filters

10 - Cabinet body

* Optional item

11 - Bio-System Reservoir

12 - Water Reservoir

13 - Water ux regulating cup holders

14 - Water ux Regulating bowl

*

15 - Master valve - releases/block water input

*

16 - Water selector valve - reservoir/network

17 - Cover reach

*

18 - Arm reach

19 - Central Catcher

*

20 - Optical Sensor

99

MODULES, ACCESSORIES, OPTIONALS AND CONSUMP

TION MATERIALS

01

04

10

02

05 06

0807

11

09

12

03

13

14

15

10

MODULES, ACCESSORIES, OPTIONALS AND CONSUMP

TION MATERIALS

16

* 01.Terminals:

- Borden terminal (TB)

- Midwest Terminal (TM)

- Fiber Optic Terminal (FO)

- Electric micro motor Terminal (MME)

* 02. Curing Light + 3 teeth tip

* 03. Intra oral Camera set

* 04. Bicarbonate spray set (Hand jet)

* 05. Coupling arm reach for up to 5 tips

* 06. Coupling arm reach for up to 3 tips

* 07. Triple syringe with fully metal body or injected thermoplastic handle

* 08. Triple syringe with fully injected thermoplastic body

* 09. Ejectors with fully metal body or injected thermoplastic:

- Venturi ejector

- High performance Venturi type ejector

- Large ejector for Vacuum Pump

- Small ejector for Vacuum Pump

- Cleaning brush ejector

- Cannula ejector

17

*Aspirators’ hoses available

in smooth and corrugated

versions.

* 10. Water bowl manufactured with injected material

* 11. Water selector valve - tank / network

* 12. Master Valve (system that allows cutting the ow of water and air

to the ofce.)

* Optional item

1111

MODULES, ACCESSORIES, OPTIONALS AND CONSUMP

TION MATERIALS

* 13. Optical sensor to actuate the water supply to the bowl

* 14. Integrated paddle "Chip Blower"

* 15. Progressive paddle

* 16. Progressive paddle with water activation/cut

* 17. Heating kit for triple syringe

*Items (5) and (6) available in

versions with or without articulation.

WARNING

- The drawing illustrates all optional items (page 10 and 11). Therefore,

your equipment will consist only of the chosen items selected during

your purchase option.

- The use of any part, accessory or material not specied or provided

in these instructions is of entire responsibility of the user.

* Optional item

12

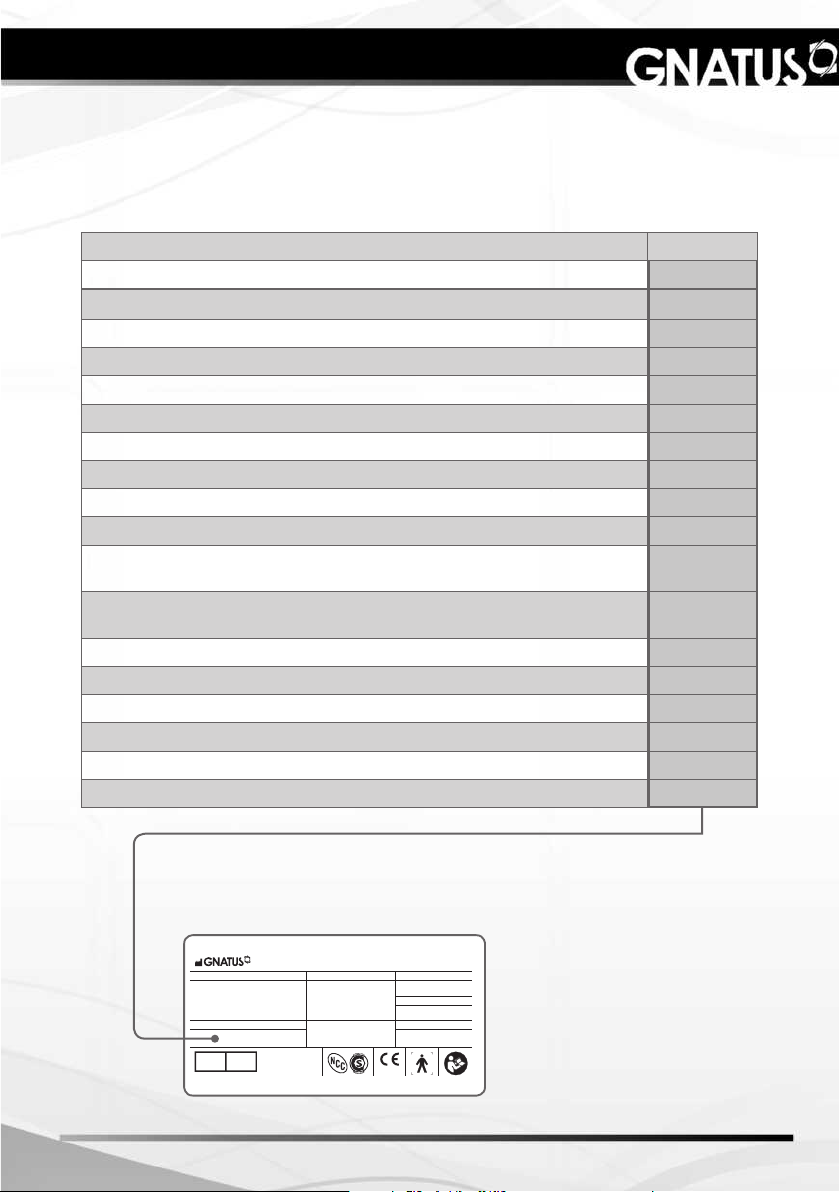

MODULES, ACCESSORIES, OPTIONALS AND CONSUMP

0499

CONFIGURAÇÃO CONFIGURATIONCONFIGURACIÓN

GNATUS EQUIPAMENTOS MÉDICO-ODONTOLÓGICOS S/A.

Rod. AbrãoAssed, Km 53+450m - Ribeirão Preto - SP - Brasil

EQUIPAMENTO DE CLASSE l

CLASS l EQUIPMENT

EQUIPAMIENTO DE CLASSE l

Contínuo, com carga intermitente

Continuous, with intermittent load

Continuo, con carga intermitente

FREQUÊNCIA FREQUENCY

FRECUENCIA

12/24 V~

50/60 Hz

NUM. REG. ANVISA

UNIDADE DE ÁGUA SYNCRUS G4A

APARELHO

EQUIPMENT

APARATO

OPERAÇÃO

OPERATION

OPERACIÓN

TENSÃO

TENSIONTENSIÓN

Wellkang Ltd

LONDON, W1G 9QR, U.K.

Suite B, 29 Harley Street

EC REP

TION MATERIALS

Units may be made composed by:

Optional Acronyms

1 BV ejector

1 Venturi ejector

1 Venturi ejector + 1 BV ejector

2 Venturi ejectors

2 BV ejectors

1 Syringe + 1 Venturi ejector

1 Syringe + 1 BV ejector

1 Syringe + 1 Venturi ejector +1 BV ejector

1 Syringe + 2 Venturi ejector

1 Syringe + 2 BV ejector

1 Syringe + 1 Photo +1 Terminal High Speed + 1 Terminal micro motor

+ 1 Venturi ejector

1 Syringe +1 Photo + 1 Terminal High Speed + Terminal micro motor +

1 BV ejector

Curing Light

Cup holder

Intra Oral Camera

Arm reach

Activation by electronic panel

Complete equipment

TBV

TV

2T

2 TV

2T BV

S TV

S TBV

3T

3T V

3T BV

5T

5T BV

OPTI

E

CAM

ALC

P

FULL

Identication label "responsible

eld to identify the product

conguration."

1313

TECHNICAL SPECIFICATIONS

Technical features of the Delivery Unit and its accessories

General

Model

Water Unit Syncrus G4/G4A

Classication of Equipment as per ANVISA:

Class II

Classication of Equipment as per standard IEC 60601-1:

Protection against Electric Shock - Type B and Class I Equipment (IEC 60601-1)

Degree of safety of application in presence:

Equipment not suited to an anesthetic mixture inammable with air, oxygen or nitrous

oxide.

Mode of Operation

Continuous operation with intermittent load

Power Supply

Inlet air pressure

80 PSI (5,52 BAR)

Voltage in equipment (coming from dental chair)

12V~ and 24 V~

Other specications

Capacity of water reservoir

1000ml

High rotation air consumption

9 l/min

High rotation water consumption

0,02 l/min

Inlet air pressure - Syringe

40 PSI (2,76 BAR)

Syringe air consumption

17 l/min

Syringe water consumption

0,1 l/min

Net weight (complete version)

15 Kg

14

TECHNICAL SPECIFICATIONS

Gross weight (complete version)

21 Kg

Venturi suction system – Maximum vacuum

220 mm/Hg

Venturi suction system – Volumetric displacement

30 l/min

“Bio Vac II Vacuum Pump” suction system – Maximum vacuum

400 mm/Hg

“Bio Vac II Vacuum Pump” suction system – Volumetric displacement

120 l/min

“Bio Vac IV Vacuum Pump” suction system – Maximum vacuum

550 mm/Hg

“Bio Vac IV Vacuum Pump” suction system – Volumetric displacement

350 l/min

Specications of Curring Light

Power

5,2VA

Light source

1 LED

Active medium

Semicondutor Led (InGaN)

Wavelength

440nm - 460nm

Timer

90 seconds

Timer alarm

sound alarm with beep every 10 seconds and 4 beeps at the end of the cycle

Activation

Through the hand-piece button

Light conductor

Made out of special polymer, rotational, removable and reuse sable.

Hand-piece body

ABS injected

1515

TECHNICAL SPECIFICATIONS

The materials used to produce the equipment are Biocompatible.

Electromagnetic Emissions

Use of different cables, transducers and accessories from those specied may result

in increased emissions or decreased immunity of the equipment.

16

TECHNICAL SPECIFICATIONS

Electromagnetic Emissions

1717

TECHNICAL SPECIFICATIONS

Electromagnetic Emissions

18

TECHNICAL SPECIFICATIONS

Electromagnetic Emissions

List of pieces and circuit scheme

Gnatus Company declares that the supply of the circuit scheme, list of pieces or any

other information that propitiate technical attendance for the user, can be request if there

is an agreement between the user and Gnatus Company.

Standards applied:

NBR 60601-1:1997 - Equipamento Eletromédico- Parte 1: Prescrições gerais para segurança;

NBR ISO 14971:2004- Medical devices - application of risk management medical devices;

NBR ISO 9687: 2005 - Dental equipment - graphical symbols;

EN ISO 13485-2003 - Quality systems - medical devices;

IEC 60601-1-2:2007 - Compatibilidade Eletromagnética.

1919

TECHNICAL SPECIFICATIONS

Dimensions (mm)

Equipment with coupling "reach arm" G4 A

20

TECHNICAL SPECIFICATIONS

Dimensions (mm)

Equipment without coupling "reach arm " G4

2121

TECHNICAL SPECIFICATIONS

Packing symbols

It determines the maximum

quantity of boxes which can be

stacked during transportation

and storage “as per packaging”.

Packing to be transported and / or

stored with the harrows up.

Packing to be transported and /

or stored with care (should not

suffer drop and neither receive

impact).

Product symbols

Careful : It indi cates an important

instruction for the operation of the

product. Not following it can cause

dangerous malfunctioning.

Note: It indi cates useful

information for operation of the

product.

Packing to be transported and

/ or stored avoiding humidity,

rains and wet oor.

The packing must be stored and

transported away from direct

sun light exposure.

Temperature limit for the

packing to be stored or

transported.

High-speed with FO

Curring Light

Triple syringe

Important: It indicates an

instruction of safety for operation

of the product. Not following it,

can lead to serious danger to the

patient.

Landing (in many parts of the

equipment) indicates the condition

of being landed.

B type equipment

Laser Hand

BV ejector

Ejector type Venturi

Bicarbonate Jet

Water heating activation

22

TECHNICAL SPECIFICATIONS

Product symbols

Bowl’s water ow

Bowl water ux regulation

Key switch water supply

Cup lling

Cup holder water ux regulation

Master valve (key for water cut)

network/reservoir

Warning - Consult the manual

Authorized representative in

the European Community

Content of accessible and non-accessible demarcations

GNATUS EQUIPAMENTOS MÉDICO ODONTOLÓGICOS S/A.

Rod. Abrão Assed, Km 53+450m - Ribeirão Preto - SP - Brasil

UNIDADE DE ÁGUA SYNCRUS G4

CONFIGURAÇÃO CONFIGURATIONCONFIGURACIÓN

APARELHO EQUIPMENT APARATO

Wellkang Ltd

EC REP

Suite B, 29 Harley Street

LONDON, W1G 9QR, U.K.

EQUIPAMENTO DE CLASSE l

EQUIPAMIENTO DE CLASSE l

CLASS l EQUIPMENT

TENSÃO TENSION

12/24 V~

FREQUÊNCIA

50/60 Hz

NUM. REG. ANVISA

0499

TENSIÓN

FREQUENCY

FRECUENCIA

INSTALLATION OF EQUIPMENT

The installation of this equipment requires specialized technical

assistance (Gnatus).

OBS: These information also make part of the Manual of Installation

and Maintenance of the equipment that can be found with the

authorized Gnatus technician.

2323

INSTALLATION OF EQUIPMENT

- This equipment shall only be able to be unpacked and installed by a Gnatus authorized

technician, under penalty of losing the warranty, as only (s)he has the information, suitable

tools and training required to execute this task.

- Gnatus bears no responsibility for damages or accidents caused by poor installation

executed by a technician not authorized by Gnatus.

- Only after the equipment has been installed and duly tested by the authorized technician

representing Gnatus, will it be ready to start work operations.

EQUIPMENT OPERATION

Control Panel

01

A

03

02

01 – Water triggering in the Bowl

02 – Water triggering in the cup holder

03 – Water triggering heating syringe

*

(optional)

WARNING:

To set the time of water ux in the cup

holder, press the "water in the cup holder"

button (02) for 3 seconds (it will produce a

long beep and the LED will ash).

Upon reaching the desired time, press

again the button "Water in the cup holder" (02). The ux time is recorded. To set the time

of the water ux in the bowl, press the "Water in the bowl" button (01) for 3 seconds (it

will produce one long beep and the LED will ash). Upon reaching the desired time, press

again "Water in the Bowl" (01). The ux time is recorded.

The settings "Water in cup holder" and "Water in the bowl" have a water ux timeout, 1

minute for the water in the cup holder and 4 minutes for the water in the bowl.

When turning the key "triggering heating water syringe" (03), the LED will turn on (A)

starting the heating of syringe water. The temperature must remain around 40º C. To turn

off the "trigger water heating", press (03) again.

Terminal Triggering

For the functioning of the rotating

instruments remove from the support the

instrument to be used, trigger the control

pedal moving the lever (A) with the feet.

B

The power (air supply) can be controlled

by the operator with higher or lower pressure

on the pedal lever (A).

Chip Blower System:

The "chip-blower" system allows the

release of the airow with the stopped turbine

(air function). Pressing the (B) key downward, air will trigger on the tips.

Pressing the key (B) downward and moving the lever to the right (A) together, it will

trigger the high speed air turbine and water (spray).

24

A

EQUIPMENT OPERATION

Adjustment of Spray of “TB/TM high

and low rotation terminals”

- The adjustment is made via a valve

positioned in the terminal. Turn it in a clockwise

direction to reduce the spray and in a counterclockwise direction to increase it.

Note: As the “TB” double terminal does not

have a spray this adjustment is not required.

Ejectors operation

The ejectors (both BV and Venturi) start

working automatically when retired from the

tips support the BV ejectors feature suction ow

adjustment , and its regulated moving the lever

located at the ejector up or down.

Use of 3-Way Syringe

- Press button (A) for water to come out, (B) for air to come out or both simultaneously

to obtain a spray.

B

C

03

A

Water Heating:

When you turn on the key "hot water activation" (03), LED will light (C), starting to heat

water from the syringe. Temperature should remain about 40 °C. To turn off the "water

heating activation" function, press key (03) again.

2525

EQUIPMENT OPERATION

Water supply to the bowl is driven by the "optical sensor *"

Water supply is done automatically through the optical sensor by simply approaching

the patient, providing greater convenience in operation.

Optical sensor positioning for right or

lefthanded.

The water unit is designed in order to meet the

left or right hand users, with ease of installation

of the "optical sensor set" on both sides, without

loss of functionality in any case. At the time of

installation by authorized technician from Gnatus,

inform desired position (right or left handed). He

will make necessary adjustments.

Replacement of the standard of

cannula coupling

If there is the necessity of using the 6.5mm (A)

cannula in the BV suctor, make the replacement

of the cannula coupling, as the procedure below:

• Remove the coupling of 11 mm (B) by

unscrewing it from.

• Screw the coupling of 6.5 mm (C) in the

aspirator BV set and attach the coupling tube.

Coupling of tube of 6.5 mm

The curve of the coupling of the cannula was

designed for better handling, but can also be cut

at the location indicated with the aid of a knife.

A

C

B

* Optional item

26

EQUIPMENT OPERATION

Curing Light Activation

- Select application time, press time

selection button (01), which values are: 10s

(standard mode), 20s, 60s, 80s and 90s.

- To initiate a polymerization cycle, press

the timer trigger (02), which generates a

short beep every 10 seconds and a 4 beeps

at the end of cycle.

- To interrupt a polymerization cycle just

activate the timer trigger again (02).

IMPORTANT:

- Keep the light conductor tip (03) at least 2mm away from the restoration.

- Keep the light conductor (03) always protected by an expendable PVC lm, which must

be changed for every patient. This procedure protects the light conductor from scratches

and other residues.

- Use the polymerization time recommended by the compound resin manufacturer and

always perform restorations in incremental layers with a maximum thickness of 2mm.

WARNING

- Never aim the blue light beam towards the eyes

- Use the eyesight protection (04)

- In order to protect the eyes, the eyesight protection (04) lters only the blue light

used for the resins polimerization, and it allows ambient light to pass through.

03

04

06

02

01

2727

EQUIPMENT OPERATION

Laser Hand

The “Laser Hand Kit” is low intensity (780nm) and provides relief of acute and chronic

pain, and speeds repair of damaged tissue by means of biostimulation effects of radiation.

Eminently analgesic, anti-inammatory and biomodulation effect.

Applications:

• Inammations;

• Oral mucous lesions;

• Dental hypersensitivity;

• Analgesia;

• Paresthesia;

• Alveolitis and pericoronitis;

• Acceleration of post surgical and

injury cicatrisation;

Activation of the “Laser Hand”

Turn on the main unit power switch, which will

automatically turn on the laser.

To select application time, press the time selection

button (01) with variations of: 01s to 90s. Maintain

pressure on the key until desired time selection,

which can be at 1-second intervals (1s, 2s, 3s, 4s,

5s, 6s, 7s...) or 10-second intervals (10s, 20s, 30s,

40s, 50s..).

To start, press timer activation button (01). A

single beep will be heard, followed by 5 beeps at each

conclusion.

The laser will remain active with a 10-minute

program. After 10 minutes, a beep will inform that

the laser is in standby mode.

To restart the cycle, press the key (02) which will

sound 2 beeps and the last programmed selection will

appear on the screen. To interrupt the cycle, press

button (02).

• Decrease of edemas, bruising and

scabbing;

• Distension, muscular spraining and

articular pain;

• Acupuncture (optional).

02

01

Note: For a new program, in case desired time is less than the previous program,

press (01) until the start of time “00”.

WARNING: Never direct the red light towards eyes.

28

EQUIPMENT OPERATION

Water ow adjustment

01 - Cup ller adjustment

02 - Bowl ush adjustment

To regulate the bowl ush and cup lling water

ow, use the bowl ush adjustment (02) and the cup

ller ow adjustment (01), to increase ow, turn it

anticlockwise, to decrease, turn in clockwise.

Regulation of the water selecting

valve

To regulate this kind of water feeding, please use

the selecting valve (04) to select the feeding through

the reservoir and turn around in the clockwise sense.

To select the feedign through the net, turn around

counter clockwise sense.

Master Valve

The master valve is a safety device that aims

to block / release the entry of water to the dental

set. It is of utmost importance to have interrupted

the water supply to the dental set in the end of the

working day, which can be done through the key

(ON/OFF - 03)

01 0402 03

A B

How to provision the reservoirs

Water - Syringe/Handpieces

Remove the reservoir (B) uncoiling it on clockwise and make the replacement of water.

After the replacement put it back coiling on anticlockwise. Always use ltered water or

aseptic products.

Bio-System

Remove the reservoir (A) uncoiling it on clockwise and make the replacement. Use a

chlorinated water solution 1:500

Preparing the solution:

From a solution of hypochlorite of sodium at 1%, a solution of chlorine at 500 p.p.m.

is prepared.

How to prepare the solution: Take 25ml of hypochlorite of sodium at 1% and dilute it in

500 ml of water (1 to 20). Such solution should be prepared daily.

IMPORTANT: Follow this proportion strictly to avoid damages in the equipment and to

have an efcient result in the disinfection.

Bicarbonate Jet "Jet Hand"

For further information, please see the Jet Hand manual which comes with the product.

2929

PRECAUTIONS, RESTRICTIONS AND WARNINGS

Transportation, storage and operation

This equipment must be transported and stored observing the following directions:

- Avoid falls and impacts;

- Keep it dry, do not expose it to rain, water drops or wet oor;

- Keep it away from water and direct sunlight, and in it original wrapping;

- Don’t move it over irregular surfaces, protect it from rain and observe the maximum

stack quantity specied in the packaging;

- Transportation and storage temperature range: -12°C to 50°C.

- Ambient temperature range recommended by Gnatus +10 ° C to +35 ° C.

The Equipment maintains its condition of safety and efcacy, provided that it is

maintained (stored) as mentioned in this instruction of use. Thus, the equipment

will not lose or alter its physical and dimensional features.

Sensitivity to environmental conditions in normal situations of use

The equipment has been planned not to be sensitive to interference such as magnetic

elds, external electrical factors, electrostatic discharge, pressure or variance of pressure,

provided that the equipment is installed, maintained, clean, preserved, transported and

operated as per this instruction for use.

Precautions and warnings “during the installation” of equipment

- The equipment should only be installed by Gnatus authorized technical assistance or

technicians.

- Position the unit in a place where it will not get wet.

- Install the unit in a place where it will not be damaged by the pressure, temperature,

humidity, direct sunlight, dust, salts, or sulfur compounds.

- The unit should not be submitted to inclination, excessive vibrations, or blows (including

during transportation and handling).

- This equipment was not planned for use in an environment where vapors, anesthetic

mixtures inammable with air, or oxygen and nitrous oxide can be detected.

- Before the rst use and/or after long interruptions from work such as vacations, clean

and disinfect the equipment; eliminate air and water deposited in the internal hoses.

These information also make part of the Manual of Installation and

Maintenance of the equipment that can be found with the authorized

Gnatus technician.

30

PRECAUTIONS, RESTRICTIONS AND WARNINGS

Recommendations for the dental equipment maintenance

Your Gnatus equipment has been designed and developed according to the standards

of modern techology. Similarly to other kinds of equipment, it requires special care, which

is many times neglected due to several reasons and circunstances.

Therefore, here are some important reminders for your daily routine. Try to follow these

simple rules, which will save you a lot of time and will avoid unnecessary expenses once

they start making part of your working procedure.

Precautions and warnings “during the use” of equipment

- The equipment should only be operated by duly enabled and trained technicians (Dental

Surgeons, Capacitated Professionals)

- If any maintenance should be required, only use services of the Gnatus Authorized

Technical Assistance.

- The equipment has been manufactured to handle both continuous and intermittent

operation; so follow the cycles described in these Instructions for Use.

- Although this equipment has been planned in accordance with the standards of

electromagnetic compatibility, it can, in very extreme conditions, cause interference with

other equipment. Do not use this equipment together with other devices very sensitive to

interference or with devices which create high electromagnetic disturbance.

- Do not expose the plastic parts to contact with chemical substances, use in the routines

of dental treatment, such as: acids, mercury, acrylic liquids, amalgams, etc.

Bicarbonate Jet:

- It is not advisable to use this equipment in patients who have serious renal or respiratory

alterations, or who undergo hemodialysis. These cases should be followed be followed by

a doctor.

- We recommend the use of a mask and goggles for applying the bicarbonate jet.

- Avoid leaving sodium bicarbonate in the container for long periods without use.

The effect of residual humidity in the air may alter the properties of the powder and

cause blocking.

Gnatus shall not be responsible for:

- Use of the equipment differing from that for which it is intended.

- Damages caused to the equipment, the professional and/or the patient by the incorrect

installation and erroneous procedures of maintenance, differing from those described in

these Instructions for use which come with the equipment or by the incorrect operation of it.

Precautions and warnings “after” the use of equipment

- Turn off the main switch of the dental set when it is not in use for an extended period

of time.

- Always maintain the equipment clean for the next operation.

- Do not modify any part of the equipment. Do not disconnect the cable or other

connections without need.

- After using the equipment, clean and disinfect all the parts which may be in contact

with the patient.

- Upon noticing irremovable stains, splits or cracks in the light conductor or in the eye

protector, replace the damaged components.

3131

PRECAUTIONS, RESTRICTIONS AND WARNINGS

Precautions and warnings during the “cleaning and disinfection”

of equipment

Unidad:

- Before cleaning the equipment, turn off the main switch.

- Avoid spilling water, even accidentally, or other liquids inside the equipment, which

could cause short circuits.

- Do not use microabrasive material or steel wool when cleaning, or employ organic

solvents or detergents which contain solvents such as ether, stain remover, gasoline etc.

Amalgam collecting vessel, lters and drains:

- To prevent infection risks, use protective gloves during amalgam collecting vessel

replacement and when handling lters and drains. Dispose wastes and contaminated

products in biological waste.

Curring Light:

- The equipment and the light conductor cannot be placed in the oven or autoclaves.

- The conductor can’t be immersed in solvents or substances that contain acetone in its

composition.

- Avoid the light conductor to terminal to touch the resin to be polymerized.

- When using the Curring Light check if the light conductor output doesn’t have residues

that might obstruct the light beam.

Bicarbonate Jet:

For further information, please see the Jet Hand manual which comes with the product.

Laser Hand:

For further information, please see the Laser Hand manual which comes with the product.

Precautions in case of alteration in the functioning of equipment

- If the equipment has any abnormality, check if the problem is related to any item

listed in the topic of unforeseen events (failures, causes and solutions). If it is not possible

to resolve the problem, turn off the equipment, remove the power supply cable from the

socket and contact your representative (Gnatus).

Precautions to be adopted against foreseeable or uncommon

risks, related to the deactivation and abandoning of equipment

In order to avoid environmental contamination or undue use of the Equipment after it

has become useless, it should be discarded in the suitable place (as per the local legislation

of the country).

- Pay attention to the local legislation of the country for the conditions of installation

and disposal of residue.

32

CORRECTIVE AND PREVENTIVE MAINTENANCE AND

PRESERVATION

Additional procedures for reuse

The equipment can be reused in undetermined, i.e. unlimited, quantities, only needing

to be cleaned and disinfected.

Cleaning and Disinfection

Important: In order to execute cleaning or any type of maintenance, ensure that the

equipment is disconnected from the electrical network.

The cleaning procedure below should be executed at the start of the

working day and after each patient.

Always turn off the main switch before executing the procedures of

daily maintenance.

To clean the equipment, we recommend the use of “BactSpray

(Reg nº MS: 3.2079.0041.001-5) or any other similar product:

Active component: Benzalkonium chloride (tri-quaternary

ammonium)

Solution 50%................................................. 0.329%

Chemical composition: Butyl Glycol, Decyl polyglucose, Sodium

Benzoate, Sodium Nitrate, Essence, Deodorized Propane / Butane,

demineralized Water.

For more information concerning cleaning procedures, see

manufacturer’s instructions.

WARNING:

- In order to prevent risks and damages to equipment, make sure

that the liquid does not enter into the unit.

- The application of other solvent-based cleaning products or

sodium hypochloride isn’t recommended, because they may damage

the equipment.

NOTE: The registration at the Ministry of Health of the

“BactSpray” is executed separately from the product described in this manual, as the

“BactSpray” is not manufactured by Gnatus.

Disinfection

Use clean and soft cloth dampened in alcohol 70% to disinfection of the equipment.

Never use corrosive disinfectants or solvents.

Note: Use gloves and other

systems of protection,

during the disinfection.

3333

CORRECTIVE AND PREVENTIVE MAINTENANCE AND

PRESERVATION

Clearing the suction system

Using Vacuum Pump (BioVac II or IV):

Gnatus suggests performing a daily suction of the clearance and

disinfectant solution, avoiding the risk of cross contamination and

increasing equipment service life. To perform the disinfection of your

equipment we recommend the use of the “Sugclean” (MS Reg. No.:

31.080.003-2) product.

• Indication: It is indicated for clearance of Ejector and hose

suction system. It is important to perform the suction solution in all

suction terminals, which it is also important to be open. Then, remove

Ejectors from hose for asepsis.

• Preparing the Solution: Add “Sugclean” 30mL in 1 liter of water.

Aspirate the solution with maximum power of the Ejectors, and also

put the liquid in the water unit bowl.

In the rst use of “Sugclean” product, we suggest adding

60mL of concentrated product in 1 liter of water during the rst

5 days in order to remove accumulated residues.

• Composition:

• Active Drug: Phosphoric Acid 13.6%

• Excipients: Isopropyl Alcohol, Acidulant, Dye and Thickener.

Warning: do not use foaming product.

NOTE: The registration at the Ministry of Health of the

“Sugclean” is executed separately from the product described in

this manual, as the “Sugclean” is not manufactured by Gnatus.

Fig.A

Using Vacuum Pump (BioVac Sec):

CAUTION: For internal cleaning of Suction pipelines of the Pump Vacuum BioVac Sec, the

use of "Sugclean" product or any similar product is not allowed; use only the recommended

mixture below:

• After each patient leaves, perform the suction of 250 ml of clean water in each totally

open suctor;

• At the end of the working Day, perform the suction of the 250 ml mixture of bleach

mixed with 250 ml of clean water (proportionally divided in each used suctor); Then, remove

Ejectors from hose for asepsis.

WARNING:

• Never use foamy products in the suction (deep cleaner, detergents, oaters, etc), this

procedure may damage the internal parts of the dry vacuum pump’s engine;

• Never use the bleach solution for external cleaning of any equipment, because this

mixture is highly corrosive and may damage metal parts.

34

CORRECTIVE AND PREVENTIVE MAINTENANCE AND

PRESERVATION

Triple syringe

Only the syringe tip is autoclavable (01). The other pieces must

be cleaned using a piece of cotton wool and alcohol 70% vol. Never

use a hot air sterilizer.

Reservoirs

It’s highly recommended the cleaning of the water reservoirs,

using chlorinated water solution 1:500 (as described previously).

Cleaning of the Ejector and lters

After the suction of the solution through the

suctor, take the lid (01) and the lter (02) and

wash them in running water.

01

0201

03

Cleaning of the drain

Pull the drain (03) with a tweezer, clean

and disinfect it.

Warning: Always use protection gloves

when manipulating lters and drainages.

Discard waste and contaminated products

in biological waste containers.

3535

CORRECTIVE AND PREVENTIVE MAINTENANCE AND

PRESERVATION

Basin cleaning

In order to obtain better results in the clean the

bowl in your water unit, we strong recommedn the

use of the product “Easy-Off Bang” or similar, nº

Reg. MS: 3.00227-0.

Chemical composition: Glycolic Acid, Maleic

Anhydride, Citric Acid, Ethoxyled Fatty Alcohol,

Essence and Water.

Apply the “Easy-Off Bang” in the water unit bowl

along with a smooth cloth up to clean it.

If you want additional information regarding

cleaness, please look at the instructions from the

product.

Bio-System

Remove the terminal hand parts. Take the hand parts of

terminals to the sink or tank of water unit.

Completely open the spray register of the terminals.

Press the Bio-System triggering button for some seconds,

located under the coupling panel reaching arm of the water

unit, to perform the disinfection of internal components

with bactericidal liquid. Then, trigger the control pedal for a

few seconds to perform rinsing in order to remove chemical

residues of bactericidal liquid internally retained in the

components of water unit.

Important: This procedure should be done in the

beginning of the workday and after each patient.

36

CORRECTIVE AND PREVENTIVE MAINTENANCE AND

PRESERVATION

Curring Light

The light conductor cleaning and the optical protector must be done using only neutral

soap and cotton. To the exterior of the pen use neutral soap or alcohol 70% vol.

Never use any other chemical based product than previous mentioned, because along

the time these products attack the surface of the instrument.

Never immerse the instrument in disinfection baths.

Laser Hand

For further information, please see the Laser Hand manual which comes with the product.

Bicarbonate Jet "Jet Hand"

For further information, please see the Jet Hand manual which comes with the product.

Preventive Maintenance

The equipment should be calibrated routinely, as per the legislation in force in the country.

But never with a period exceeding 3 years.

In order to protect your equipment, seek Gnatus technical assistance for periodic revisions

of preventive maintenance.

Corrective Maintenance

If the equipment has any abnormality, check if the problem is related to any of the items

listed in the item Unforeseen Events (situation, cause and solution).

If it is not possible to solve the problem, turn off the equipment, and request Gnatus

technical assistance.

UNFORESEEN EVENTS SOLUTION OF PROBLEMS

Upon coming across any problem in operation, follow the instructions below to check

and repair the problem, and/or get in touch with your representative.

Problem Probable cause Solution

Water Unit

- Ejector without suction.

-Handpiece with low speed. -Inlet pressure below speci-

- Insufficient air pressure

from compressor.

- Filter clogged with particles.

- Filter lid misplaced.

ed (80 PSI).

-Adjust air ow.

-Remove and clean lter.

-Remove lid and place it

correctly.

-Adjust inlet pressure (80

PSI).

3737

UNFORESEEN EVENTS SOLUTION OF PROBLEMS

Problem Probable cause

-No water from handpiece

spray.

-Handpiece is not working. - Compressor disconnected. -Plug the compressor in.

-No water from syringe. -Reservoir run out of water.

- Bowl’s water ow and cup

lling are not operating.

- There is no water ow in the

tank when the patient gets

closer (optical sensor).

- Insufficient air pressure

from compressor.

-Reservoir run out of water.

-Closed terminal.

-Compressor disconnected.

- Lack of water

- Water valve is closed

- Power cut

- Chair fuse burned.

-Chair’s main switch is off or

terminal box is disconnected.

- Damaged-sensor.

- Distance between the patient to the upper sensor

larger than 300mm.

- Dirt on the lens sensor.

- Chair fuse is burnt.

-Adjust air ow.

- Put ltered water in reser-

voir.

- Open terminal.

-Put ltered water in reservoir.

-Plug compressor in.

- Check the water supply

- Open the water valve

- Check the energy supply

- Turn off the chair from

mains power and request a

Technician presence.

- Switch the main switch on

or connect the terminal box.

- Request assistance by GNATUS Technician.

- Get closer to the sensor

(less than 300 mm).

- Clean the sensor lens.

- Turn off the power supply

to the chair and request

asistance by the Technician.

Solution

-When Bio-system is operated no disinfectant come

from handpiece terminals.

Curring Light

-Equipment’s not working.

-Bio-system reservoir run

out of water.

- Chair fuse burned.

-Main or chair switch is off.

-Power cut.

-Chair’s fuse burned.

38

-Put disinfectant in the reservoir.

-Turn off the chair from

mains power and request a

Technician presence.

-Switch main/chair switch

on.

-Check power supply.

-Turn off the chair from mains

power and request a Technician presence.

UNFORESEEN EVENTS SOLUTION OF PROBLEMS

-Equipment is not polymerizing resins.

Bicarbonate Jet - For further information, please see the Bicarbonate Jet

Laser Hand - For further information, please see the Laser Hand manual

-Resin is not appropriate

for LED’s photopolymerizer

wave length range.

"Jet Hand" manual which comes with the product.

which comes with the product.

-Get the indicated resin for

the photopolymerizer’s wave

length range, one with contains photoinitiators based

on camphorquinone.

3939

WARRANTY OF EQUIPMENT

This equipment is covered by the warranty terms and norms contained in the Warranty

Certicate that accompany the product.

FINAL CONSIDERATIONS

The most important aspect related to equipment care is that concerning spare parts.

To guarantee the life span of your equipment, use only original Gnatus spare parts.

They are sure to follow the technical specications and standards required by Gnatus.

We must also point out to you our chain of authorized dealers. Only dealers that make part

of this chain will be able to keep your equipment constantly new for they count on technical

assistants who have been trained and on spedic tools for the correct maintenance of your

equipment.

Doubts and information: GNATUS Call center (55-16) 2102-5000 / SAC: 0800-7015-054.

40

4141

42

4343

Loading...

Loading...