TG uni 1

Appliance tester for

testing safety measures in accordance

with DIN VDE 0701and 0702

Operating Manual

Version 1.07

Operating manual for the TG uni 1 appliance tester

Contents

Contents Page

1. Safety information ..........................................................4

2. Introduction .......................................................................4

2.1 Model and type designation / identification ...............................5

2.2 Product description ................................................................5

2.3 Other equipment features ...................................................5

2.4 Scope of delivery ....................................................................5

2.5 Optional accessories ...............................................................5

2.6 Transport and storage .............................................................5

3. Safety instructions ...............................................................6

4. Appropriate usage ..........................................................7

5. Operating elements ...............................................................8

5.1 Meaning of the signal tones .........................................................8

6. Commissioning ...............................................................9

6.1 Basic settings of the tester ...................................................9

6.2 Compensation of the measuring line ..........................................10

6.3 Setting the measuring method for

protective conductor current measurement ..................................10

6.4 Setting the date ............................................................11

6.5 Selection of the data memory ....................................................11

6.6 Changing the duration of a test stage ............................................12

6.7 Entering the name of the inspector ..............................................12

6.8 Customer-specific settings ...............................................12

7. Conducting tests:

General information on

DIN VDE 0701 and DIN VDE 0702 ...........................................13

7.1 Why ..................................................................................13

7.2 What ...............................................................................13

7.3 How ...............................................................................13

Contents Page

8. Conducting tests:

Explanation of terminology ....................................................14

8.1 Touch current (IT) ..................................................................14

8.2 Differential current (ID)............................................................14

8.3 Substitute leakage current (ISL) .....................................................14

8.4 Insulation resistance (R

8.5 Protection class I (PC I) ...............................................................15

) ..........................................................15

INS

8.6 Protection class II (PC II)..............................................................15

8.7 Protection class III (PC III) ............................................................15

8.8 Protective conductor current (IPE) ...................................................16

8.9 Protective conductor resistance (RPE) ............................................16

8.10 Visual inspection .......................................................................16

9. Conducting tests in accordance with

DIN VDE 0701 and DIN VDE 0702:

Definition of standards ...........................................................17

9.1 Visual inspection .......................................................................17

9.2 Measuring the protective conductor resistance ................................17

9.3 Measuring insulation resistance ............................................17

9.4a Measuring the protective conductor current ....................................18

9.4b Measuring touch current ................................................19

9.5 Inspecting the inscriptions ............................................................19

9.6 Function test ......................................................................19

9.7 Documentation ..........................................................................19

9.8 Diagram 1:

Test procedure for devices of protection class I ................................20

9.9 Diagram 2:

Test procedure for devices of protection classes II und III ...................21

2

Operating manual for the TG uni 1 appliance tester

Contents

Contents Page

10. Conducting tests with the appliance tester in accordance

with DIN VDE 0701 and DIN VDE 0702, PC I .........................22

10.1 Visual inspection .......................................................................23

10.2 Protective conductor resistance ....................................................23

10.3 Insulation resistance ..................................................................24

10.4a Protective conductor current (substitute leakage current) ...................25

10.4b Protective conductor current ........................................................25

10.5 Function test ......................................................................26

10.6 Inspecting the inscriptions ............................................................26

10.7 Documentation ..........................................................................27

11. Conducting tests with the appliance tester in accordance

with DIN VDE 0701 and DIN VDE 0702, PC II ........................29

11.1 Visual inspection .......................................................................30

11.2 Insulation resistance ..................................................................30

11.3a Touch current (substitute leakage current) .......................................31

11.3b Tou ch current ......................................................................31

11.4 Function test ......................................................................32

11.5 Inspecting the inscriptions ...........................................................32

11.6 Documentation ..........................................................................33

12. Conducting tests with the appliance tester in accordance

with DIN VDE 0701 and DIN VDE 0702, PC III .......................35

12.1 Visual inspection .......................................................................36

12.2 Insulation resistance ..................................................................36

12.3 Documentation ..........................................................................37

13. Conducting tests with the appliance tester in accordance

with DIN VDE 0702, all protection classes ...........................39

14. Conducting tests with the appliance tester in accordance

with DIN VDE 0701 and DIN VDE 0702 - special test procedure

according to customer-specific settings..............................40

Contents Page

15. Technical data ....................................................................42

15.1 Technical data for function tests ..........................................43

15.2 General technial data ........................................................43

16. Manifacturer’s guarantee conditions ........................................44

3

Operating manual for the TG uni 1 appliance tester

Safety information

1. Safety information

Tests on the electrical safety of electrical appliances may only be carried

out by qualified electricians or under their supervision. Carefully read the

following safety information before commissioning the TG uni 1 appliance

tester (referred to as appliance tester or tester in the following).

Symbols used in the operating manual and on the tester:

Warning:hazardous situation. Follow the operating manual.

Caution! Dangerous voltage, danger of electric shock.

Note. Make sure you follow the manual.

&&

&

&&

CE CE mark of conformity.

The operating manual contains information and notes which are

&&

&

&&

necessary for the safe operation and use of the tester. Before use

(commissioning / installation) of the tester the operating manual

should be carefully read through and followed in all points.

If the manual is not observed or if you fail to observe the warnings

&&

&

&&

and notes, serious injury to the user and damage to the tester can

occur.

All the technical data and quoted standards in this manual are up-

&&

&

&&

to-date at the time of going to press and have been determined to

the best of our knowledge, nevertheless this data may be subject

to errors and printing errors. Therefore no legal responsibility or

any other liability can be accepted for incorrect information or

the conseqences of this information.

The definitive document for carrying out tests is the

original version of the respective regulation or standard.

There is no intention to

other property rights with this publication.

2. Introduction

You have acquired a high-grade device from the company Gossen Müller &

Weigert (GMW), with which you can carry out repeatable measurements

over a very long period of time. The product was calibrated during the

manufacturing process in accordance with the specified operating

procedures. All quality-relevant activities and processes carried out in GMW

are permanently monitored as part of the quality management system in

accordance with DIN EN ISO 9001:2000.

infringe on any existing patents and

4

Operating manual for the TG uni 1 appliance tester

Introduction

2.1 Model and type designation / identification

A type plate and serial number sticker are situated on the inside of the

housing cover (behind the accessories bag).In the case of queries, always

give the product designation and serial number.

2.2 Product description

The appliance tester has been developed for carrying out the following

measurements for testing the safety of electrical appliances in accordance

with DIN VDE 0701 and 0702 (BGV A3):

– Measuring protective conductor resistance with compensation of the

measuring line

– Measuring insulation resistance

– Measuring substitute leakage current

– Measuring protective conductor current (direct method or as differential

current)

– Measuring touch current

– Function test with measurement of mains voltage, load current, active

power, apparent power and reactive power, power factor and

frequency

– Testing of non-heating devices and extension cables

2.3 Other equipment features

– Stable, dust-proof carrying case as housing

– Large, easy-to-read touch-screen for operating the tester (backlit)

– Good/bad display in plain text (suitable for technically trained persons)

– Connection for barcode scanner for reading-in the test object’s ID

numbers

– USB-interface

– MMC-card for saving and transporting measured data

– PC standard software for saving and printing measurement reports

2.4 Scope of delivery

1 TG uni 1 appliance tester

1 safety test line, length 100 cm

1 safety crocodile clip, clip width 30 mm

1 safety test tip

1 USB cable, length 150 cm

1 MMC memory card 128 MB

1 CD-ROM with Windows®-PC standard software

1 accessories bag with velcro fastener and quick guide

1 operating manual

2.5 Optionale accessories

(not included in delivery)

– Barcode scanner

– RS232 PC interface cable, length 200 cm

– Measuring adapter for testing devices with tree-phase connection (in

preparation for plug connectors CEE 3-pole, 16 A, 230 V; CEE

5-pole, 16 A, 400 V and CEE 5-pole, 32 A, 400 V)

– Adapter for checking extension cables

– PC software with database functions (customer master data, device

master data, test data, analysis function, data backup)

2.6 Transport and Storage

Please retain the original packaging for dispatch at a later date, e.g. for

calibration. Transport damage that occurs due to inadequate packaging is

not covered by the manufacturer’s guarantee.

The tester must be stored in a dry, closed room. If the device it transported

in extreme tenperatures, it requires at least 2 hours acclimatisation before

being switched on.

5

Operating manual for the TG uni 1 appliance tester

Safety instructions

3. Safety instructions

The appliance tester TG uni 1 was constructed and tested in accordance

with the applicable safety regulations and left the workshop in a faultless

safety condition. In order to maintain this condition and ensure safe

operation, the user must observe the instructions and warnings contained in

this operating manual.

With all work, the applicable accidend prevention regulations of the

&&

&

&&

trade associations for electrical systems and equipment must be

observed.

To avoid electric shock, the applicable safety regulations and DIN-

VDE regulations regarding high touch voltage

without fail when working with voltages greater than 120V (60 V)

DC or 50 V (25 V) eff. AC. The values in brackets apply for

restricted areas (e.g. medicine, agriculture).

Measuring at a dangerous proximity to electrical systems should only be

carried out under the instruction of a responsible electrician, and never

alone.

Check the tester and the connecting cables for external damage before

every new operation.

Make sure that the tester and the connecting cables are in faultless

condition. The tester may not be used if one or more functions fail or if

functional readiness is not evident.

must be observed

The measuring lines and the measuring accessories may only be

touched in the designated handling areas.

Touching measuring connections, e.g. test tips must be avoided

under all circumstances.

If the safety of the operator is no longer guaranteed, the tester must

&&

&

&&

be decommissioned and secured against unwanted use. This is

the case if the device:

– shows obvious signs of damage

– no longer carries out the required measurements

– has been stored in adverse conditions for too long

The tester may only be used in the operating and measuring ranges

specified under Technical Data.

Prevent overheating of the tester by exposure to direct sunlight.

Only this will guarantee faultless functioning and a long sevice life of the

device.

Never open the housing of the tester because of the danger of high

voltages. The tester contains no parts that can be replaced by the user.

Only let the tester be serviced by qualified personnel.

6

Operating manual for the TG uni 1 appliance tester

Appropriate usage

4. Appropriate usage

The tester may only be used under the conditions and for the purposes for

which it has beeen designed. It is particularly important to observe the

safety instructions and the technical data regarding ambient conditions and

usage in a dry environment.

The tester may not be used for measurement in electrical systems.

The tester may only be plugged into a properly connected earthed mains

socket. This may be protected with a maximum 16 A!

The tester is designed for operation with a rated voltage of 230 V AC 50 Hz,

it may never be connected to higher voltage.

The maximum output current of the mains socket is 16 A!

The tester may not be used for constant measuring.

Operational safety is no longer guaranteed in the case of modifications or

conversions that have not been carried out by the manufacturer.

Maintenance or calibration work may only be carried out by the

manufcturer.

If the tester has been exposed to an electromagnetic field, this can impair

the functionality of the tester.

The tester may not be used near to explosive gasses, steam or dust, or in

a damp environment.

In order to avoid damaging the testing device, the test socket and the

measurement connections may not be connected to an external voltage

source.

Only the supplied original measuring lines or equivalent safety measuring

accessories may be used!

7

Operating manual for the TG uni 1 appliance tester

Operating elements

5. Operating elements

Explanation of the tetster’s connections, operating elements and displays

Mains cable with mains plug

for connecting the T ester to

the mains power supply

230 V +/-15%, 50 Hz

Thermal fuse for the test

object and tetster F 16 A

ON / OFF switch

Card slot for an MMC memory

card

USB socket for connecting a

PC

RS232 socket for

connecting a barcode

scanner

Storage compartment for the

mains cable

Housing cover with 2 snap fasteners

Accessories bag with quick guide

Case housing

Fig. 2

Handle (fold-away)

Test / mains socket for connecting the test object with earted

plug , 230 V 16 A, 50 Hz

Front panel, Fig. 1

5.1 Meaning of the signal tones

– short single tone: confirmation of button press

– short double tone: end of a test stage with automatic

– long single tone,

continuous tone: fault

8

Optional connecting sockets (VDE 0751):

´L1´ (black)

´N´ (blue)

´I

´ (red)

EPA

Connecting socket ‘PE’ (yellow/green), parallel

connection of the protective conductor of the

test socket, for connecting the test object

without an earthed mains plug

connecting socket ´Probe´ (red), for the test line

when measuring RPE and R

T ouch-screen (LC display and control screen)

Symbols used in the LC display:

- internal memory

- MMC memory card

INS

procedure

Operating manual for the TG uni 1 appliance Tester

Commissioning

6. Commissioning

The tester is equipped with modern touch-screen technology. That means

that the LC display and the control buttons are in one control screen. The

control buttons are always edged.

After activating the mains switch a self-test is carried out. If everything is in

order, the following display appears on the touch-screen as a switch-on

message (Fig. 3):

Fig. 3

Type designation

Relevant standard

Firmware version

Manufacturer

Large button

Continue with large button (Fig. 3).

A display for entering the date appears (Fig. 3a).

Fig. 3a

As the tester does not have its own real-time clock, you are prompted to

confirm the displayed date or enter a new date.

Also see Point 6.4.

&&

&

&&

After confirmation with the [OK] button the Main menue appears (Fig. 4):

Fig. 4

Headline

Function buttons:

T ests according to standard

T esting of individual parameters

Basic settings of the tester

6.1 Basic settings of the tester

Press the [Configuration] button in the Main menue (Fig. 4).

The Configuration menue appears (Fig. 5):

Headline

Fig. 5

Symbol for the internal memory

or the MMC memory card

Measuring method for protective

conductor or touch current:

DIR. - direct Measurement

(test object insulated from earth)

DIF. - differential current method

(Test object not insulated from

earth)

Function buttons

9

Operating manual for the TG uni 1 appliance tester

Commissioning

6.2 Compensation of the measuring line

In order to achieve correct results when measuring the protective conductor

resistance, the resistance of the measuring line must be compensated (zero

balance).

Press the fuction button [Comp.] (Fig. 5).

The zero balance menu appears. Follow the instructions in the display

(Fig. 6):

Fig. 6

– Connect the test tip/test

clip with the measuring line

and insert the measuring

line plug in the ‚Probe’

socket (Fig. 1).

– Connect the test tip/test

clip with the protective

earthing contact of the test

socket.

If the following message appears in the display:

‚Fault: zero balance’

and a permanent warning signal sounds, the measuring line resistance is

greater than 2 Ω and cannot be compensated.

The protective conductor resistance test is locked.

In this case the measuring line should be checked or be replaced with a

low-impedance version.

If the measuring line has been successfully compensated – the following

message appears in the display

‚Zero balance OK’.

Press the [Next] button, only then disconnect the line!

6.3 Setting the measurement method for protective conductor

current measurement (also current touch measurement)

In the case of devices of protection class I, on which the insulation

resistance measurement cannot or may not be carried out, the protective

conductor current measurement is an alternative measurement for

determining the insulating capacity.

The protective conductor current can be determined either by the direct

measuring method, the differential current method or the substitute leakage

current method.

The direct measuring method or the differential current method should be

used with test objects that can only be switched on with mains voltage

(also see Point 9.8).

Caution! In this case the test object is supplied with mains

voltage during the test.

The differential current measurement determines the total leakage current of

the test object by measuring the total current of all avtive conductors (L-N).

The differential current measurement must be applied if the test object has

additional earthing connections or cannot be insulated.

Direct measurement can be applied if the test object has no additional

earthing connections or can be insulated.

In order to change the measuring method, press the [Measure] function

button in the configuration menu, see Fig. 5.

The symbol in the headline changes accordingly:

[DIR.] – direct measurement

[DIF.] – differential current method

10

Operating manual for the TG uni 1 appliance Tester

Commissioning

6.4 Setting the date

You can set the test date on the tester.

Press the function button [Date] to change to the input screen (Fig. 5). The

date is entered on the touch-sreen by means of the pictured 10-button

keypad (Fig. 7).

The date can be entered in the following formats:

|D.M.YY|, |DD.MM.YY| and |DD.MM.YYYY|.

The set date is safed along with the measuring results of every test and

also appears in the log prinout.

Fig. 7

once the date has been set, it remains unchanged in the tester’s

&&

&

&&

memory until it is reentered or deleted

- the tester is not equipped with a real-time clock!

6.5 Selection of the data memory

To save the measurement results, the tester has an internal memory (16

MB) and an MMC memory card (128 MB, supplied with the tester).

The MMC memory card can be used to backup or transfer the

measurement results.

MMC memory cards with a capacity of 128 to 256 MB can be used.

Inserting the MMC memory card:

Insert the memory card, with the label facing down, into the card slot and

slightly press until it engages.

To eject the memory card, press it down until it disengages and pull the

card upwards and out of the slot.

Caution!

Never force the memory card into the card slot of the tester.

The use of force can damage the memory card and the card

slot. If the card is not recognised by the tester, check if it

has been properly inserted.

Press the function button [Memory] in the configuration menu to switch

between the internal memory and the MMC memory card. The symbol in

the headline changes accordingly (Fig. 5):

– internal memory

– MMC memory card

The measurement results can be stored either in the internal

&&

&

&&

memory or on the MMC memory card.

Use a PC with a USB connection if you wish to completely delete or format

the MMC memory card. After the USB connection has been made the MMC

memory card appears as an external storage medium in the file manager.

From here the card can be deleted or formatted – the file system is

automatically adjusted.

Caution! Formatting a memory card deletes all the data on the

card.

To read out saved measurement results - see the operating manual of the

PC software

11

Operating manual for the TG uni 1 appliance tester

Commissioning

6.6 Changing the duration of a test stage

With automatic test procedures, the preset duration of every test stage is 5

seconds.

This setting can be changed, if for example the test object requires a longer

time to be switched on.

To do this press the function button [T.-time] in the configuration menu.

Using the 10-button keypad, you can enter a new test time in the next

screen (Fig. 8).

The possible setting range is 3 to 254 seconds.

The factory setting of the tester is 5 seconds per test stage.

Fig. 8

6.7 Entering the name of the inspector

To enter the name or designation of the inspector, press the function button

[Inspector] in the configuration menu.

The screen changes to an alphanumeric keypad, with which you can enter

the name or the designation of the inspector. The input field has 20

characters (Fig. 9).

You can switch between letter and numeric keys by using the buttons [123]

or [ABC].

The [C] button deletes the last entered character.

Press the [OK] button to confirm the entry.

The entered name is saved in the memory after the tester has been

switched off.

The entered name is assigned to every test carried out and also

&&

&

&&

appears in the log printout.

Fig. 9

6.8 Customer-specific settings

The scope of functions of the tester can be adapted to customer

specifications. This can simplify the operation of the tester.

These settings do not change the standard conformity of the tester!

You reach the setup menu by pressing the function button [Setup] in the

configuration menu (Fig. 5).

This input area is locked by a code key

&&

&

&&

(Fig. 10)

Please contact us for further information:

Tel. +49 (0)911 / 3502-0, Fax +49 (0)911 / 3502-307.

Fig. 10

12

Operating manual for the TG uni 1 appliance tester

General Information on DIN VDE 0701 and DIN VDE 0702

7. Conducting tests:

General information on DIN VDE 0701 and DIN VDE 0702

Why, What, How

7.1 Why?

Electrical systems and equipment must be safe. They have to be

manufactured and operated in such a way that they cannot endanger

people, animals and property.

The legal regulations are primarily anchored in:

– The German Ordinance on Industrial Safety and Health ( BetrSichV)

– The Accident Prevention Regulations (BGV A 3)

– The DIN-VDE standarts harmonised within the EU

The stipulation for transportable devices states:

„The manufacturer or the importer of technical equipment may only bring

this equipment onto the market if, in accordance with the generally

recognised rules of technology, the user or third parties are protected from

danger when using this equipment for its intended purpose, as far as the

form of appropriate usage allows.“

(from the German Ordinance on Industrial Safety and Health )

The operator has to ensure that the electrical systems and equipment are

operated in accordance with the rules pertaining to electrical equipment.

(from BGV A 3 Electrical systems and equipment)

Those who manufacture or modify transportable devices must comply with

the applicable standards, e.g.:

DIN VDE 0700 Part 1 „Household and similar electrical appliances - Safety“.

7.2 What?

Whoever operates, services and repairs transportable devices must

observe the following:

DIN VDE 0701 „Repair, modification and inspection of electrical appliances“

Part 1 as well as the special provisions of this standard

For those commissioned with regular tests, the applicable specifications are

contained in DIN VDE 0702 „Periodic inspection on electrical appliances“.

Requirements for the appliance tester from the VDE regulations:

Safety tests on transportable electrical equipment are based on

– DIN VDE 0701

„Repair, modification and inspection of electrical appliances“

– DIN VDE 0702

„Periodic inspection of electrical appliances“

7.3 How?

Measuring and testing devices must be constructed in accordance with DIN

VDE 0404 „Testing and measuring equipment for checking the electric

safety of electric devices - Part 1: General requirements“.

Insulation and protective conductor measurements are also subject to the

standards DIN VDE 0413 Part 1 and Part 4.

In addition:

DIN VDE 0404 „Testing and measuring equipment for checking the electric

safety of electric devices - Part 2“.

13

Operating manual for the TG uni 1 appliance tester

Explanation of terminology

8. Conducting tests:

Explanation of terminology

8.1 Touch current (IT)

Current that can flow to earth via the person handling the device (test

object).

The measurement is carried out between touchable conductive parts of the

test object and the earth.

The measurement can either be made directly or with the differential current

method.

Direct measurement is applicable if the test object can be insulated from

earth.

In all other cases the differential current method should be used.

The touch current measurement is carried out on test objects in protection

class II with touchable conductive parts, or on test objects in protection

class I, which have touchable conductive parts that are not connected to the

protective conductor.

The measurement is to be carried out in both positions of the mains

&&

&

&&

plug - the reversal of polarity is automatic with the tester extracting and reversing the mains plug is not necessary.

Also see measuring principle circuits on Page 19.

&&

&

&&

8.2 Differential current (ID)

In terms of the standards DIN VDE 0701/0702, this is the total instantaneous

values of all currents flowing through all active conductors on the mains

side connection of the device (test object).

The differential current method is a measuring method for determining

protective conductor current or touch current.

The total leakage current of a test object can be measured. This measuring

method must be applied if the test object cannot be insulated.

Also see measuring principle circuit M6 on Page 18.

&&

&

&&

Caution! The test object is supplied with mains voltage

during the test.

8.3 Substitute leakage current (I

Current that would flow through the interconnected active conductors of the

device (test object) and the protective conductor or the touchable conductive

parts at nominal voltage and nominal frequency of the device.

This measuring method determines the leakage current without mains

voltage. It is an alternative measuring method for determining protective

conductor current or touch current.

Also see measuring principle circuit M4a on Page 18.

&&

&

&&

)

SL

14

Operating manual for the TG uni 1 appliance tester

Explanation of terminology

8.4 Insulation resistance (R

Ohmic resistance between the conductive parts separated by insulation.

Measurements are taken between the active parts and the body as well as

touchable conductive parts that are not connected to the protective

conductor.

Also see measuring principle circuits on Page 17.

&&

&

&&

)

INS

8.5 Protection class I (PC I)

The active parts of the device are protected against direct touching by the

basic insulation. Through connection of the touchable conductive housing

parts to the protective conductor, these are included in the protective action

in the case of indirect touching (fault protection) with the system. The

device has a protective conductor connection (earthed plug).

8.6 Protection class II (PC II)

The active parts are separated by strengthened or double insulation (basic

insulation and additional insulation). This ensures protection against direct

contact.

Protection against indirect contact is also given, since an insulation fault is

practically impossible. Such devices can nevertheless have touchable

metallic housing parts. Devices of protection class II have a mains plug

without an earthing contact.

8.7 Protection class III (PC III)

Devices of protection class III are exclusively connected to protective extralow voltage electric circuits.

The protection against dangerous body currents is achieved by the low

voltage and the safe separation to other electric circuits.

15

Operating manual for the TG uni 1 appliance tester

Explanation of terminology

8.8 Protective conductor current (IPE)

Current that flows through the protective conductor from the devices (test

objects) of protection class I, when their bodies are insulated from earth.

A direct measurement is applicable if the test object can be insulated from

earth.

In all other cases the differential current method should be applied, see Point

6.3 (Basic settings of the tester, Page 10).

Also see measuring principle circuits on Page 18.

&&

&

&&

Caution! The test object is supplied with mains voltage

during the test.

8.9 Protective conductor resistance (RPE)

Resistance between any conductive touchable parts, connected to the

protective conductor for protective purposes, and the earthed contact of the

mains plug, the device plug or the protective conductor, which is constantly

connected to the mains power supply.

During the measurement of the protective conductor resistance, the

connecting cable should be moved, section by section, along its whole

length. This measuring method only applies for devices of protection class I.

Also see measuring principle circuit M1 on Page 17.

&&

&

&&

8.10 Visual inspection

Testing in accordance with DIN VDE 0701 or 0702 also involves visual

inspection of the device.

According to the standard the devices should be inspected for external

defects (without opening the device) and, as far as possible, for suitability to

the place of installation. In particular, attention should be paid to the

following:

– Damage to the housing

– Defects of the cord connector guard and strain relief fittings

– External damage of the connecting cables

– Unauthorised interference and changes

– Signs of overloading and improper use

– Orderly condition of the protective covers

– Safety impairing soiling and corrosion

– Unblocked cooling vents

– Existence of necessary air filters

– Leak tightness, pressure relief valve

– Legibility of safety-related inscriptions

– Fuse links in accordance with manufacturer’s specifications

Externally visible defects, which could lead to a mechanical or fire

&&

&

&&

hazard should be repaired immediately.

16

Conducting tests in accordance with VDE 0701 and 0702 - definition of standards

Operating manual for the TG uni 1 appliance tester

9. Conducting tests in accordance with DIN VDE 0701 and

DIN VDE 0702:

Definition of standards

The sequence of tests is specified in the standard:

9.1 Visual inspection

The test objects are inspected for externally visible defects.

9.2 Measuring the protective conductor resistance

(with devices of protection class I)

The limit value is:

ΩΩ

0.3

Ω for devices with connecting cables up to 5 m,

ΩΩ

plus 0.1 Ω for every 7.5 m, but a mximum of 1.0 Ω.

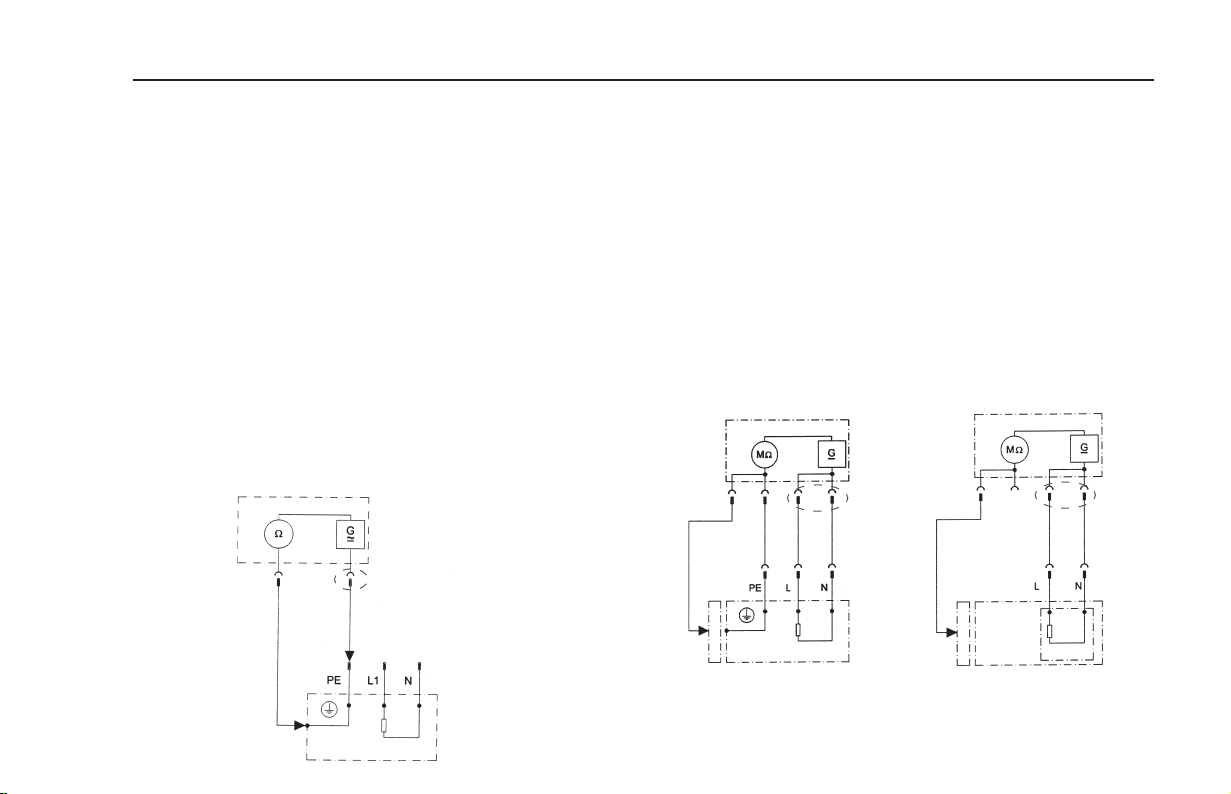

Measuring principle circuit

protective conductor resistance PC I, Diagram M1

T ester

´Probe´

socket

Test line

Test socket

T est object

9.3 Measuring insulation resistance

The limit value is:

ΩΩ

1 M

Ω for devices of protection class I

ΩΩ

ΩΩ

2 M

Ω ffor devices of protection class II

ΩΩ

ΩΩ

0.25 M

Ω for devices of protection class III

ΩΩ

ΩΩ

0.3 M

Ω for devices of protection class I

ΩΩ

with switched-on heating elements

1)

Also applies for touchable conductive parts of test objects in

protection class I that are not connected to the protective conductor.

2)

If the required insulation resistance is not achieved in the case of test objects in

protection class I with heating elements with a total capacity ≥ 3.5 kW, the test object

is nevertheless rated as faultless if the protective conductor current does not exceed

the limit values.

Measuring principle circuit

Insulation resistance PC I, Diagram M2 PC II and III, Diagram M3

T ester

´Probe´

socket

Test line

If the insulation measurement is technically impossible, then a

&&

&

&&

Test socket

Test

object

1)

2)

´Probe´

socket

Test line

protective conductor current measurement (direct or differential

current method) must be carried out on test objects in PC I and a

touch current measurement on test objects in PC II.

17

Test socket

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - definition of standards

9.4a Measuring the protective conductor current

(with devices of protection class I)

The limit value is 3.5 mA.

In the case of test objects with heating elements with a total capacity

greater than 3.5 kW, the protective conductor current may not be

greater than 1 mA/kW heat output. The protective conductor current can

either be measured directly with the substitute leakage current method

or with the differential current method.

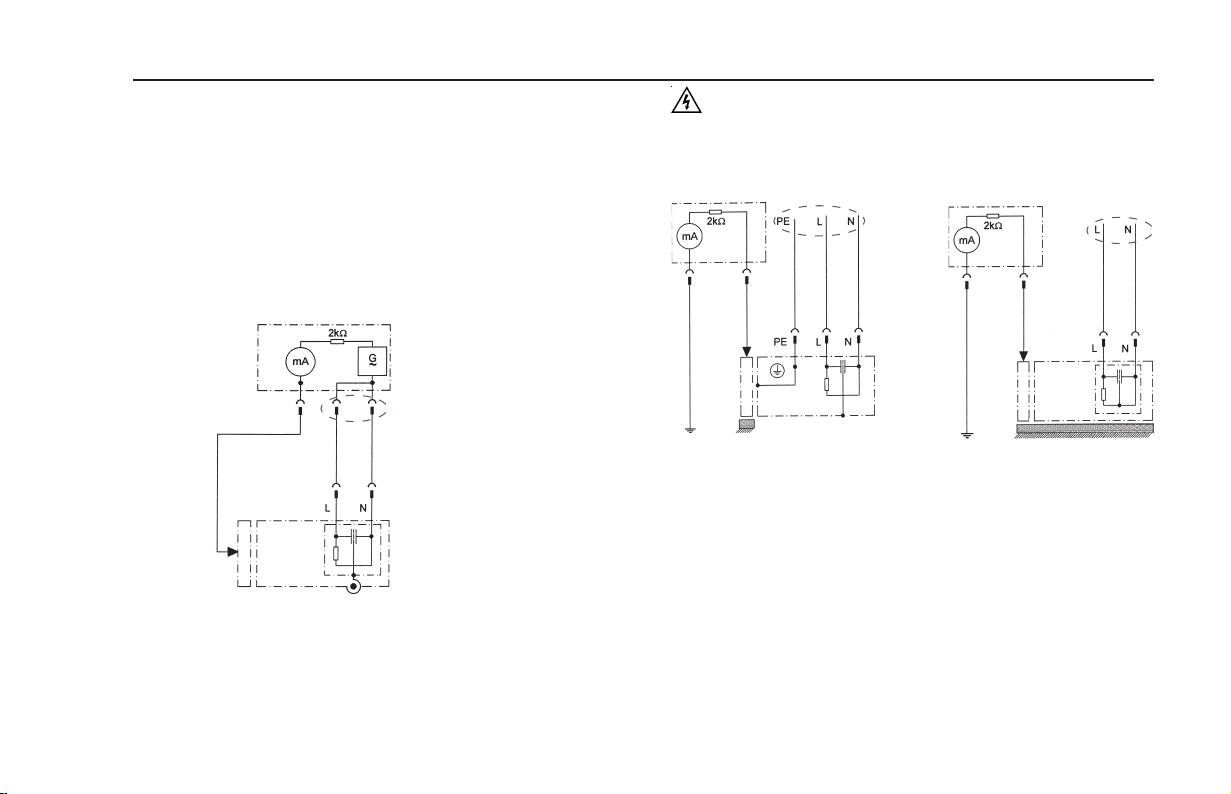

Measuring principle circuits

Protective conductor current – substitute leakage current method PC I, Diagram M4a

T ester

Test socket

T est object

Caution! The test object is supplied with mains voltage

during the test.

Protective conductor current - direct measurement PC I, Diagram M5

T ester

Test socket

T est object

Insulated installation

Protective conductor current – differential current method PC I, Diagram M6

T ester

Test socket

In case of test objects in PC I with touchable conductive parts that

&&

&

&&

are not connected to the protective conductor, an additional touch

current measurement must be carried out in line with PC II

(see Diagram 1 on Page 20)

T est object

18

Conducting tests in accordance with VDE 0701 and 0702 - definition of standards

Operating manual for the TG uni 1 appliance tester

9.4b Measuring touch current

(with devices of protection class II)

The limit value is 0.5 mA

The touch current can either be measured directly with the substitute

leakage current method or with the differential current method. This

measurement must also be carried out on devices of protection class I with

touchable conductive parts.

Measuring principle circuits

Touch current – substitute leakage current method PC II, Diagram M4b

T ester

´Probe´

socket

Test line

Test socket

Test

object

Caution! The test object is supplied with mains voltage

during the test.

Test socket

Touch current:

Test

object

T ester

Socket

´Probe´

Test line

Test

object

Insulated installation

Test socket

Direct measurement PC I, Diagram M8b Direct measurement PC II, Diagram M8a

T ester

Socket

´Probe´

Test line

Insulated installatio

Measurement of all touchable conductive parts of the test

object that are not connected to the protective conductor

9.5 Inspection the inscriptions

Safety-related inscriptions must be controlled and, where necessary,

renewed or supplemented in suitable form.

9.6 Function test (only required for DIN VDE 0701)

After completion of the electrical test, a function test shall be carried out on

the test object. A partial test can be sufficient.

9.7 Documentation

Once a test is passed, it should be documented in suitable form. If a test

object proves to be unsafe, this should be clearly indicated on the device

and the operator informed in writing. Recording the measured values and

the changes is recommended.

19

Operating manual for the TG uni 1 appliance tester

Test procedure in accordance with VDE 0701 and 0702

9.8 Diagram 1

Test procedure for devices of portection class I

Visual Inspection

Fig.15

Diagram M6

Measuring the

protective conductor

current, differential

current method

Diagram M1

Testing the protective

conductor resistance

Measuring the

insulation resistance

Yes

Diagram M5

Measuring the

protective conductor

current, direct

measurement

Can the test object be

insulated from earth?

Measuring the

protective conductor

current, substitute

leakage current

method

Function test, optional with VDE 0702, Fig.66

Diagram M4a

No

Yes

No

Diagram M6 Diagram M6 Diagram M5 Diagram M6

Measuring the

protective conductor

current, differential

current method

Function test and

inspection of

inscriptions

Test object with conductive

parts that are not connected

to the protective connector

Is measuring the insulation

resistance applicable?

Diagram M4a

Measuring the

protective conductor

current, substitute

leakage current

method

Fig.26

Fig.14

Test log, test report

(documentation)

Yes

No

Yes

Measuring the

protective conductor

current, differential

current method

Fig.27/28

As with ‘No’, but additional

measurements for these parts

in according with the test

procedure diagram for

protection class II

Can the test object be

insulated from earth?

Measuring the

protective conductor

current, direct

measurement

Fig.5Fig.5

20

No

Measuring the

protective conductor

current, differential

current method

End

9.9 Diagram 2

Test procedure for devices of protection class II and III

Protection class II and touchable

conductive parts of protection class I

that are not connected to the

protective conductor

Diagram M3

Measuring the

insulation resistance

Yes

Can the test object be

insulated from earth?

Yes

Operating manual for the TG uni 1 appliance tester

Test procedure in accordance with VDE 0701 and 0702

Visual Inspection

Protection class

II or III

Is measuring the insulation

resistance applicable?

No

Fig.36

Fig.35

Fig.35

Protection class II

Diagram 3

Measuring the insulation

resistance

No

Fig.5Fig.5

Yes

Can the test object be

insulated from earth?

No

Fig.41

Measuring the touch

current, differential

current method

Diagram M8a

Measuring the touch

current, direct

measurement

Function test, optional with VDE 0702, Fig.66

and not with PC III

Measuring the touch

current, substitute

leakage current

method

Diagram M4b

Fig.41 Fig.41 Diagram M8a

Measuring the touch

current, differential

current method

Function test and

inspection of

inscriptions

Diagram M4b

Measuring the touch

current, substitute

leakage current

method

Fig.45

Measuring the touch

current, differential

current method

Test log, test report

(documentation)

Fig.46/47

Measuring the touch

current, direct

measurement

21

Fig.41

Measuring the touch

current, differential

current method

End

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC I

10. Conducting tests with the TG uni 1appliance tester:

in accordance with DIN VDE 0701 and DIN VDE 0702, PC I

Connecting the test object

– Connect one end of the test line to the probe socket of the tester.

– Use the crocodile clip to connect the other end of the test line with a

metal part of the test object, which is connected to the protective

conductor.

Ensure that the crocodile clip makes a good contact with the metal part

of the test object.

– Connect the mains plug of the test object with the test socket of the

tester.

– Switch on the test object with the mains switch.

Switching on the appliance tester

Connect the mains plug of the tester to a properly connected and functional

earthed mains socket. Switch on the tester with the mains switch. Press the

large button in the Switch-on display (Fig. 12).

Entering the test date

The test date is entered or confirmed in the following display (Fig. 12a).

The tester is not equipped with a real-time clock!

&&

&

&&

Fig. 12 Fig. 13

Fig. 12a

Settings for measuring

Press the function button [Test procedure according to standard] in the ‘Main

menu’ (Fig. 13).

A display with the ‘Settings for measuring’ appears (Fig. 14). The standard

VDE 0701 is preset – change with the [Standard] button.

The protection class is set with the [PC] button (presetting: PC I). Selection

of the test procedure – with or without insulation resistance – is specified

with the [Ins y/n] button.

The headline shows the set measuring method for protective conductor

current [DIR.] or [DIF.] (see Point 6.3) and the setting for the manual [H] or

automatic [A] test procedure. The status line provides information about the

current settings throughout the test procedure. In the limit values line you

see the corresponding limit values.

Headline

Status line

Limit values line

Fig. 14

f

f

Test procedure:

- manual [H]

- automatic [A]

22

f

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 -PC I

The [PE -> 5.0 m] button determines the length of the test object’s

connecting cable. With every press on this button the value is increased by

a further 7.5 m. The resulting limit value for the maximum protective

conductor resistance (see below) is visible in the limit values line.

Lenght of the connecting Limit value for protective

cable (PE) up to conductor resistance (R

5.0 m 0.3

12.5 m 0.4 Ω

20 m 0.5 Ω

27.5 m 0.6 Ω

35 m 0.7 Ω

42.5 m 0.8 Ω

50 m 0.9 Ω

With the function button [Hand/Auto] you determine whether the test

procedure should be carried out manually (by hand) or automatically.

Manual test procedure means that you have to confirm every test

&&

&

&&

stage by pressing the [OK] button to get to the next test stage.

Automatic test procedure means that a test stage automatically

&&

&

&&

changes to the next after 5 seconds - except for confirmation of

connection to the mains voltage (see Point 6.6, basic settings of

the tester).

Fig. 15

Ω

PE

)

Fig. 16

f

f

The headline shows the setting for a manual [H] or automatic [A] test

procedure. The [Cancel] button takes you back to the ‘Main menu’. To

move to the next stage press the [Next] button (also see Diagram 1 in Point

9.8).

If in the ‘Configuration menu’, direct measurement is set as the

&&

&

&&

measuring method for the protective conductor current, the

following warning message appears in the display: ‘ATTENTION!

The test object must be insulated during the following test stages!’.

Please follow this instruction without fail; otherwise the protective

conductor current cannot be measured correctly.

10.1 Visual inspection

The [->Next] button takes you to the first stage of the test: the visual

inspection (Fig. 15). The housing, connecting cable, inscriptions and other

parts should be inspected in this test. You confirm positive results of the

visual inspection by pressing the appropriate buttons – the display changes

from ‘not OK’ to ‘OK’ (Fig. 16).

10.2 Protective conductor resistance

The limit value is:

0.3 Ω for devices with connecting cables up to 5 m,

plus 0.1 Ω for every 7.5 m, but only up to a maximum of 1.0 Ω

(see table on Page 22)

Fig. 17

f

f

23

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC I

The [->Next] button takes you to the first electrical test: the protective

conductor resistance (Fig. 17).

The measured value appears in the middle of the display in large figures.

The star sign on the left side of the display blinks when the

&&

&

&&

measuring process is running (the values are being measured).

The

[OK] button appears when the measured value is determined.

The corresponding limit value LV as well as the instantaneous test current

(+) is also displayed.

By pressing the [Help] button you change to the help display for the

protective conductor resistance measurement. A measuring principle circuit

corresponding to the figure in this operating manual and a short help text are

displayed.

After pressing the [End] button you return to the measuring display.

With the manual test procedure the measuring display remains until the [OK]

button is pressed. In the next stage the polarity of the test current (–) is

reversed and the protective conductor resistance remeasured.

During the measurement, the connecting cable of the test object

&&

&

&&

should be moved, section by section, along its whole length, in

order to find broken conductors or weak points.

Fig. 18

Fig. 19

f

10.3 Insulation resistance (compare with Point 10.4a)

The limit value is:

1.0 MΩ (PC I)

2.0 MΩ for touchable conductive parts that are not connected to the

protective conductor (PC I).

0.3 MΩ for devices of PC I with switched-on heating elements ≥ 3.5 kW *)

*) If the required insulation resistance is not achieved in the case of devices in protection class I

with heating elements with a total capacity of 3.5 kW, the device is nevertheless rated as faultless if

the protective conductor current does not exceed the limit values. (tester setting – PC: Ie).

If you have selected a test procedure with insulation resistance in the

‘Settings for measuring’, the measuring display for the insulation resistance

measurement (Fig. 19) appears after you press the [OK] button. Beside the

measured value, the level of the test voltage is also displayed (min. 500 V DC).

The star sign on the left side of the display blinks when the

&&

&

&&

measuring process is running (the values are being measured).

[OK] button appears when the measured value is determined.

The

A help display with a measuring principle circuit and a help text is also

available here.

Fig. 20

f

24

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 -PC I

10.4a Protective conductor current (substitute leakage current)

The limit value is:

3.5 mA (PC I)

In the case of devices with heating elements with a total capacity

greater than 3.5 kW, the protective conductor current may not be

greater than 1 mA/kW heat output.

The [OK] button takes you further to the measuring display ‘Protective

conductor current’ (according to the substitute leakage current principle).

Here, too, the related limit value is displayed beside the measured value

(Fig. 20).

Warning!

With the test procedure according to DIN VDE 0702 and a test with

insulation resistance, the protective conductor current is

always measured by the tester with connection to the mains

voltage (direct method or according to the differential current

principle).

Fig. 21

f

Fig. 22

f

10.4b Protective conductor current (compare with Point 10.4a)

The limit value is:

3.5 mA (PC I)

In the case of devices with heating elements with a total capacity

greater than 3.5 kW, the protective conductor current may not be

greater than 1 mA/kW heat output.

If you have selected a test procedure without insulation resistance in the

‘Settings for measuring’, the tester changes to measuring the protective

conductor current (Points 3. – Insulation resistance and 4a. – Substitute

leakage current, are omitted).

Caution! The test object is supplied with mains voltage

during the test.

After pressing the [OK] button you will see a warning about connection to

the mains current (Fig. 21).

Fig. 23

f

25

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC I

With your assent – by pressing the large button – the display changes to

measuring the protective conductor current and the mains voltage is

connected – the test object is put into operation!

You can see the measured value in the middle of the display, with the

related limit value to the right (Fig. 22).

The star sign on the left side of the display blinks when the

&&

&

&&

measuring process is running (the values are being measured).

[OK] button appears when the measured value is determined.

The

The symbol

With the [Help] button, you can also go to the help display from here.

Pressing the [OK] button automatically reverses the polarity of the mains

plug of the test object (Fig. 23).

A compulsory break of 8 seconds serves to halt any running motors.

Thereafter, you are again warned about connection to the mains voltage.

After confirmation with the [OK] button, the mains voltage is reconnected

and the measurement of the protective conductor current repeated (Fig. 21

and 22).

&&

&

&&

Fig. 24 Fig. 25

blinks to indicate the connection to the mains voltage.

Selecting the measuring method for protective conductor current -

see Point 6.3 Setting the measuring method for protective

conductor current measurement.

f

10.5 Function test (only required for DIN VDE 0701)

Press the [OK] button to go to the menu ‘Function test’ menu.

Here a function test of the test object is carried out in accordance with DIN

VDE 0701 (Fig. 24).

Caution! The test object is supplied with mains voltage

during the test.

Before connection is made to the mains voltage a warning message

appears in the display. The automatic test procedure is stopped; it only

proceeds when a button is pressed (Fig. 25).

After you have confirmed the connection of the mains voltage by pressing

the button, the tester changes to the function test display (Fig. 26).

The display shows the instantaneous mains voltage, the load current, the

active power, apparent power and reactive power, the power factor and

mains frequency.

10.6 Inspecting the inscriptions

At this point the values displayed in the function test should be compared

with the data on the type plate of the test object.

Fig. 26

f

26

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC I

10.7 Documentation

After pressing the [OK] button, the display changes to the ‘Test result’

screen (Fig. 27).

Here you can see all the measurement results with the related limit values.

If the measurement results of the electrical values, the visual inspection and

the function test were all in order, the following message appears:

‘Test OK’.

If the test was not successful the message says:

‘Test not OK!’.

At this point you can cancel the test with the [Cancel] button (the display

goes back to the ‘Settings for measuring’ screen) or switch to the ‘Memory

menu’ with the [->Next] button.

In the ‘Memory menu’ (Fig. 28) you can use the function button [Change

memory] to switch the storage location for measurement results between

the device-internal memory and the MMC memory card.

The current setting is shown in the menu headline.

Fig. 27 Fig. 28 Fig. 29

With the [Save] button the display changes to ‘Enter appliance identification’.

Here you can enter a max. 10-character test object ID number or read it in

from the barcode label with the optionally available barcode scanner (Fig. 29).

The barcode scanner is connected to the RS232 socket of the

&&

&

&&

tester

Symbols for memory settings:

- internal memory

- MMC memory card

f

f

f

f

27

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC I

Confirm the entry with the [OK] button – the display changes (Fig. 30) and

shows the ID number, the name of the inspector and the date (see Points

6.4 and 6.7 for entering the inspector’s name and the date). The data is

saved in the memory with the [Save] button.

A confirmation message appears (Fig. 31) – continue with the [End] button.

With the entry of an already used ID number, the data is „attached“ as a

new test to this ID number.

After the saving process, the display changes to the ‘Settings for measuring’

menu – the tester is ready for the next test (Fig. 32).

Fig. 30

Fig. 31 Fig. 32

f

The test results can be saved on a PC with the supplied PC programme or

printed from there in the form of a test log. To do this, make the USB

connection between the tester and the PC (USB cable supplied with the

tester) or transfer the saved data from the MMC memory card to the PC.

Procedure on the PC – see the operating instructions for the PC software.

General information

Every test stage during which the test object is supplied with mains voltage

is time limited for reasons of safety! The maximum duration of this test

stage is approx. 4 minutes. After this time has expired a message appears

in display. At this point you can continue the test with the [->Next] button or

cancel it with the [Cancel] button.

f

28

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC II

11. Conducting tests with the TG uni 1 appliance tester:

in accordance with DIN VDE 0701 and DIN VDE 0702, PC II

Connecting the test object

– Connect one end of the test line to the probe socket of the tester.

– Use the crocodile clip to connect the other end of the test line with a

touchable metal part of the housing of the test object.

Ensure that the crocodile clip makes a good contact with the metal part of

the test object.

– Connect the mains plug of the test object with the test socket of the tester.

– Switch on the test object with the mains switch.

Switching on the appliance tester

Connect the mains plug of the tester to a properly connected and functional

earthed mains socket. Switch on the tester with the mains switch.

Press the large button in the Switch-on display (Fig. 33).

Entering the test date

The test date is entered or confirmed in the following display (Fig. 33a).

The tester is not equipped with a real-time clock!

&&

&

&&

Fig. 33 Fig. 34

Fig. 33a

Settings for measuring

Press the function button [Test procedure according to standard] in the Main

menu (Fig. 34).

A display with the ‘Settings for measuring’ appears (Fig. 35).

The standard VDE 0701 is preset – change with the [Standard] button. The

protection class is set with the [PC] button (Presetting: PC I). Press the

[PC] button to change the setting to protection class II. Selection of the test

procedure – with or without insulation resistance – is specified with the [Ins

y/n] button.

The headline shows the set measuring method for touch current [DIR.] or

[DIF.] (see ‘Configuration menu’ Point 6.3) and the setting for the manual [H]

or automatic [A] test procedure.

The status line provides information about the current settings throughout the

test procedure.

Headline

Status line

Limit values line

Fig. 35

f

Test procedure:

- manual [H]

- automatic [A]

f

f

29

f

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC II

The corresponding limit values are given in the limit values line.

With the function button [Hand/Auto] you determine whether the test

procedure should be carried out manually (by hand) or automatically.

Manual test procedure means that you have to confirm every test

&&

&

&&

stage by pressing the [OK] button to get to the next test stage.

Automatic test procedure means that a test stage automatically

&&

&

&&

changes to the next after 5 seconds - except for confirmation of

connection to the mains voltage (see Point 6.6, basic settings of

the tester)

The [Cancel] button takes you back to the ‘Main menu’.

To move to the next stage press the [->Next] button (also see Diagram 2 in

Point 9.9).

If, in the Configuration menu, direct measurement is set as the

&&

&

&&

measuring method for the protective conductor current/ touch

current (Point 6.3), the following warning message appears in the

display:

‘ATTENTION! The test object must be insulated during the

following test stages!’

Please follow this instruction without fail; otherwise the touch

current cannot be measured correctly.

Fig. 36

f

11.1 Visual inspection

The [->Next] button takes you to the first stage of the test, the visual

inspection (Fig. 36).

The housing, connecting cable, inscriptions and other parts should be

inspected in this test. You confirm positive results of the visual inspection

by pressing the appropriate buttons – the display changes from ‘not OK’ to

‘OK’ (Fig. 37).

11.2 Insulation resistance (compare with Point 11.3b)

The limit value is:

2.0 MΩ (SK II) *)

*)

Also applies for touchable conductive parts of devices in protection class I that

are not connected to the protective conductor.

If you have selected a test procedure with insulation resistance in the

‘Settings for measuring’, the measuring display for insulation resistance

measurement (Fig. 38) appears after you press the [->Next] button. Beside

the measured value, the level of the test voltage is also displayed (min. 500

V DC).

The star sign on the left side of the display blinks when the

&&

&

&&

measuring process is running (the values are being measured).

The

[OK] button appears when the measured value is determined.

By pressing the [Help] button you go to a help display with the measuring

principle circuit and a help text.

Fig. 38Figb. 37

f

30

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC II

11.3a Touch current (substitute leakage current)

The limit value is:

0.5 mA

This measurement must also be carried out on devices of

protection class I with touchable conductive parts that are not

connected to the protective conductor.

Press the [OK] button to go to the ‘Touch current’ measuring display.

The measurement is made in accordance with the substitute leakage

current principle.

Here, too, the corresponding limit value is displayed beside the measured

value (Fig. 39).

The star sign on the left side of the display blinks when the

&&

&

&&

measuring process is running (the values are being measured).

The

[OK] button appears when the measured value is determined.

A help display is also available if you press the [Help] button.

Warning!

With the test procedure according to DIN VDE 0702 and a test with

insulation resistance, the touch current is always measured

by the tester with connection to the mains voltage (direct method

or according to the differential current principle).

Fig. 39 Fig. 40

f

f

11.3b Touch current (compare with Point 11.2)

The limit value is:

0.5 mA

This measurement must also be carried out on devices of

protection class I with touchable conductive parts that are not

connected to the protective conductor.

If you have selected a test procedure without insulation resistance in the

‘Settings for measuring’, the tester changes to measuring the touch current

(Points 11.2. Insulation resistance and 11.3a. Touch current / Substitute

leakage current, are omitted)

Caution! The test object is supplied with mains voltage

during the test.

After pressing the [->Next] button the display changes and you receive a

warning message about the connection to the mains current (Fig. 40).

With your assent – by pressing the large button – the display changes to

measuring the touch current and the mains voltage is connected – the test

object is put into operation!

You can see the measured value in the middle of the display, with the

related limit value to the right (Fig. 41).

Fig. 41

f

f

31

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC II

The star sign on the left side of the display blinks when the

&&

&

&&

measuring process is running (the values are being measured).

The [OK] button appears when the measured value is determined.

The symbol blinks to indicate the connection to the mains voltage.

With the [Help] button, you can also go to the help display from here.

Pressing the [OK] button automatically reverses the polarity of the mains

plug of the test object (Fig. 42).

A compulsory break of 8 seconds serves to halt any running motors.

Thereafter, you are again warned about the connection to the mains

voltage. After confirmation by pressing the button, the mains voltage is

reconnected and the measurement of the touch current repeated (Fig. 40

and 41).

Selecting the measuring method for touch current - see Point 6.3,

&&

&

&&

Setting the measuring process for protective conductor current

measurement.

Fig. 42

Fig. 43 Fig. 44

f

11.4 Function test (only required for DIN VDE 0701)

Press the [OK] button to go to the function test.

Here a function test of the test object is carried out in accordance with DIN

VDE 0701 (Fig. 43).

Caution! The test object is supplied with mains voltage

during the function test.

Before connection is made to the mains voltage a warning message

appears in the display. The automatic test procedure is stopped; it only

proceeds when a button is pressed (Fig. 44).

After you have confirmed the connection of the mains voltage by pressing

the button, the tester changes to the function test display (Fig. 45).

The display shows the instantaneous mains voltage, the load current, the

active power, apparent power and reactive power, the power factor and

mains frequency.

11.5 Inspecting the inscriptions

At this point the values displayed in the function test should be compared

with the data on the type plate of the test object.

f

32

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC II

11.6 Documentation

After pressing the [OK] button, the display changes to the ‘Test result’

screen. Here you can see all the measurement results with the related limit

values (Fig. 46).

If the measurement results of the electrical values, the visual inspection and

the function test were all in order, the following message appears: ‘Test OK’.

If the test was not successful the message says: ‘Test not OK!’.

At this point you can cancel the test with the [Cancel] button (the display

goes back to the ‘Settings for measuring’ screen) or switch to the ‘Memory

menu’ with the [->Next] button.

Fig. 45

Fig. 46

f

f

In the ‘Memory menu’ you can use the function button [Change memory] to

switch the storage location for measurement results between the deviceinternal memory and the MMC memory card. The current setting is shown

in the menu headline (Fig. 47).

With the [Save] button the display changes to ‘Enter appliance identification’.

Here you can enter a 10-character test object ID number or read it in from

the barcode label with the connected barcode scanner.

Connecting the barcode scanner – see Page 27.

&&

&

&&

Symbols for die memory settings:

- internal memory

- MMC memory card

Fig. 47

f

f

33

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC II

Confirm the entry with the [OK] button – the display changes (Fig. 49) and

shows the ID number, the name of the inspector and the date (see Points

6.4 and 6.7 for entering the inspector’s name and the date). The data is

saved in the memory with the [Save] button.

A confirmation message appears (Fig. 50) – continue with the [End] button.

With the entry of an already used ID number, the data is “attached“

&&

&

&&

as a new test to this ID number.

After the saving process, the display changes to the ‘Settings for measuring’

menu – the tester is ready for the next test.

Fig. 48

Fig. 49

f

The test results can be saved on a PC with the supplied PC programme or

printed from there in the form of a test log. To do this, make the USB

connection between the tester and the PC (USB cable supplied with the

tester) or transfer the saved data from the MMC memory card to the PC.

Procedure on the PC – see the operating instructions for the supplied PC

software.

General information

Every test stage during which the test object is supplied with mains voltage

is time limited for reasons of safety!

The maximum duration of this test stage is approx. 4 minutes. A warning

message then appears in display.

At this point you can continue the test with the [->Next] button or cancel it

with the [Cancel] button.

Fig. 50

f

34

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC III

12. Conducting tests with the TG uni 1 appliance tester: in

accordance with DIN VDE 0701 and DIN VDE 0702, PC III

Connecting the test object

– Connect one end of the test line to the probe socket of the tester.

– Use the crocodile clip to connect the other end of the test line with a

touchable metal part of the housing of the test object. Ensure that the

crocodile clip makes a good contact with the metal part of the test object.

– Connect the low voltage connection of the test object with the test socket

of the tester (see Diagram M3 on page 17).

– Switch the test object on.

Switching on the appliance tester

Connect the mains plug of the tester to a properly connected and functional

earthed mains socket. Switch on the tester with the mains switch.

Press the large button in the Switch-on display (Fig. 51).

Entering the test date

The test date is entered or confirmed in the following display (Fig. 51a).

The tester is not equipped with a real-time clock!

&&

&

&&

Fig. 51 Fig. 52

Fig. 51a

Settings for measuring

Press the function button [Test procedure according to standard] in the Main

menu (Fig. 52).

A display with the ‘Settings for measuring’ appears (Fig. 53).

The standard VDE 0701 is preset – change with the [Standard] button.

The protection class is set with the [PC] button. Press the [PC] button to

change the setting to protection class III. The headline shows the setting for

a manual [H] or automatic [A] test procedure.

The status line provides information about the current settings throughout the

test procedure. In the limit value line you now see the corresponding limit

value of the insulation resistance.

With the function button [Hand/Auto] you determine whether the test

procedure should be carried out manually (by hand)

or automatically.

Headline

Status line

Limit values line

Fig. 53

f

Test procedure:

- manual [H]

- automatic [A]

f

f

35

f

Operating manual for the TG uni 1 appliance tester

Conducting tests in accordance with VDE 0701 and 0702 - PC III

Manual test procedure means that you have to confirm every test

&&

&

&&

stage by pressing the [OK] button to get to the next test stage.

Automatic test procedure means that a test stage automatically

&&

&

&&

changes to the next after 5 seconds - except for confirmation of

connection to the mains voltage (see Point 6.6, basic settings of

the tester)

The [Cancel] button takes you back to the ‘Main menu’.

To move to the next stage - also see Diagram 2 in Point 9.9.

&&

&

&&

12.1 Visual inspection

The [->Next] button takes you to the first stage of the test, the visual

inspection (Fig. 54).

The housing, connecting cable, inscriptions and other parts should be

inspected in this test.

You confirm positive results of the visual inspection by pressing the

appropriate buttons – the display changes from ‘not OK’ to ‘OK’ (Fig. 55).

Fig. 54

Fig. 55 Fig. 56

f

12.2 Insulation resistance

The limit value is:

0.25 MΩ (PC III)

After pressing the [->Next] button, the display for the insulation resistance

measurement appears (Fig. 56).

Beside the measured value, the level of the test voltage is also displayed

(min. 500 V DC).

The star sign on the left side of the display blinks when the

&&

&

&&

measuring process is running (the values are being measured).