Page 1

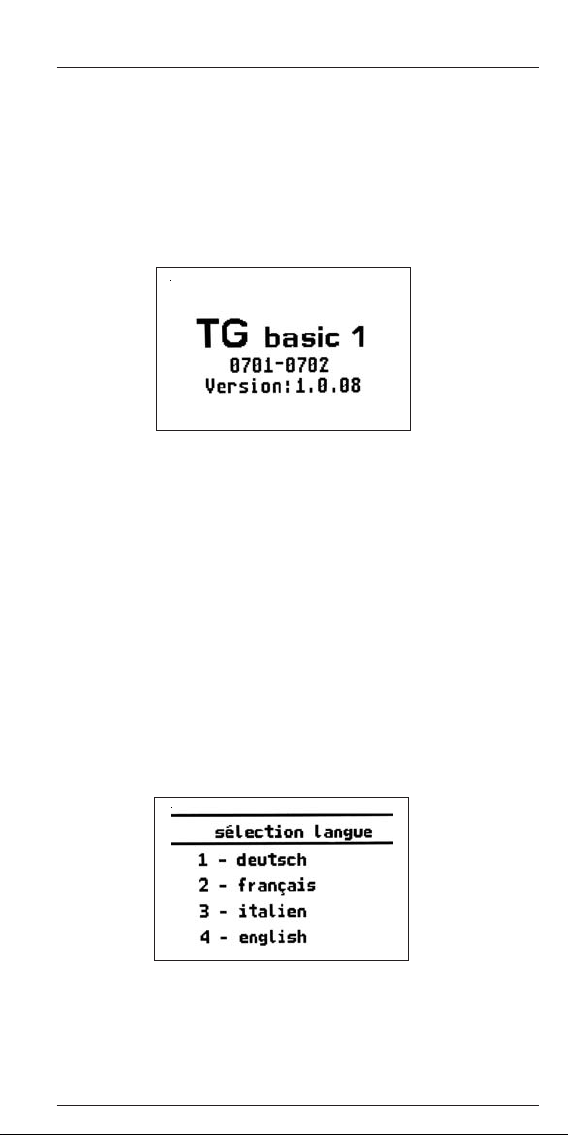

TG basic 1

Appliance tester for testing

protective measures

in accordance with DIN VDE 0701-0702

(DIN EN 62638)

Operating manual

(Version 1.00.8 or higher)

Page 2

Operating manual for the TG basic 1 appliance tester

Table of contents Page

1. Safety information 3

2. Introduction 4

3. Safety instructions 5

4. Appropriate usage 6

5. Operating elements 7

6. Starting up 8

6.1. Initial equipping or battery replacement 8

6.2. Switching the tester on and off

Selecting the measuring sequences 8

7. Explanation of terminology 11

7.1. Protection class I (PC I) 11

7.2. Protection class II (PC II) 11

7.3. Protection class III (PC III) 11

7.4. Protective conductor resistance (RPE)11

7.5. Insulation resistance (R

7.6. Substitute leakage current (IEA)12

)11

ISO

7.7. Visual inspection 12

8. Conducting tests in accordance with

DIN VDE 0701-0702; Definition of standards 13

8.1. Visual inspection 13

8.2. Measuring the protective conductor resistance 13

8.3. Measuring the insulation resistance 13

8.4. Measuring the substitute leakage current

for devices of protection class I 14

8.5. Measuring the substitute leakage current for devices

of protection class II 15

8.6. Inspecting the inscriptions 15

9. Test procedures 16

9.1. Testing devices of protection class I 16

9.1.1. Measuring the protective conductor resistance 16

9.1.2. Measuring the insulation resistance 18

9.1.3. Measuring the substitute leakage current 19

9.1.4. Test assessment 19

9.2. Testing devices of protection class II 20

9.2.1. Measuring the insulation resistance 20

9.2.2. Measuring the substitute leakage current 20

9.2.3. Test assessment 21

9.3. Cable test 21

9.3.1. Protective conductor resistance 22

9.3.2. Insulation resistance 22

9.3.3. Cable test 22

9.4. Measuring the voltage at an external earthed

mains socket 23

10. Checking the battery voltage 24

11. Technical data 24

12. Notes on cleaning 25

13. Calibrating the tester 25

14. Manufacturer’s guarantee conditions 26

GOSSEN Müller & Weigert

Page 3

Operating manual for the TG basic 1 appliance tester

1. Safety information

Tests on the electrical safety of electrical appliances may only be

carried out by qualified electricians or under their supervision.

Carefully read through the following safety information before

starting up the TG Basic appliance tester.

Symbols used in the operating manual and on the appliance

tester:

Warning of a hazardous situation. Follow the operating

manual.

Caution! Dangerous voltage, danger of electric shock.

Note: Please be sure to follow the manual!

&&

&

&&

CE mark of conformity

The operating manual contains information and notes

&&

&

&&

which are necessary for the safe operation and use of the

appliance tester. Before using (starting up) the appliance

tester, the operating manual should be carefully read

through and followed in all points.

If the manual is not observed or if you fail to observe the

&&

&

&&

warnings and notes, serious injury to the user and

damage to the appliance tester can occur.

All the technical data and quoted standards in this manual

&&

&

&&

are up-to-date at the time of going to press and have

been determined to the best of our knowledge,

nevertheless this data may be subject to errors and

printing errors. Therefore no legal responsibility or any

other liability can be accepted for incorrect information or

the consequences of this information.

The respective provisions, regulations and standards

are the authorities defining the procedures to be

followed when conducting tests.

There is no intention to infringe on any existing patents

and other property rights with this publication.

GOSSEN Müller & Weigert

3

Page 4

Operating manual for the TG basic 1 appliance tester

2. Introduction

You have acquired a high-grade device from the company Gossen

Müller & Weigert with which you can carry out repeatable

measurements over a very long period of time.

The product was calibrated during the manufacturing process in

accordance with the specified operating procedures.

The TG basic 1 appliance tester, hereafter referred to as the

tester, has been developed for carrying out the following

measurements for testing the safety of electrical appliances in

accordance with DIN VDE 0701-0702 (BGV A3):

- Measuring the protective conductor resistance

- Measuring the insulation resistance

- Measuring the substitute leakage current

- Testing of IEC and extension cables

- Measuring the power socket voltage

Scope of delivery

1 qty TG basic 1 appliance tester

1 qty set of measuring accessories with safety test line, safety

crocodile clip and safety test tip

6 qty batteries of type AA (Mignon)

1 qty IEC connection cable, 0.5 m

1 qty carrying bag

1 qty operating manual

Transport and storage

Please retain the original packaging for dispatch at a later date,

e.g. for calibration.

Transport damage that occurs due to inadequate packaging is not

covered by the manufacturer’s guarantee.

The appliance tester must be stored in a dry, closed room. If the

device is transported in extreme temperatures, it requires at least

2 hours acclimatisation before being switched on.

GOSSEN Müller & Weigert

4

Page 5

Operating manual for the TG basic 1 appliance tester

3. Safety instructions

The appliance tester was constructed and tested in accordance

with the applicable safety regulations and left the factory in a

faultless safety condition. In order to maintain this condition and

ensure safe operation, the user must observe the instructions and

warnings contained in this operating manual.

With all work, the applicable accident prevention

&&

&

&&

regulations of the trade associations for electrical systems

and equipment must be observed.

To avoid electric shock, the applicable safety regulations

and DIN-VDE regulations regarding high touch voltage

must be observed without fail when working with voltages

greater than 120 V DC or 50 V AC.

Measuring at a dangerous proximity to electrical systems should

only be carried out under the instruction of a responsible

electrician, and never alone.

Check the appliance tester and the connecting cables for external

damage before every new operation.

Make sure that the appliance tester and the cable connections

are in faultless condition.

The appliance tester may not be used if one or more functions fail

or if functional readiness is not evident.

The measuring lines and the measuring accessories may

only be touched in the designated handling areas.

Touching measuring connections, e.g. test tips, must be

avoided under all circumstances.

If the safety of the operator is no longer guaranteed the

&&

&

&&

appliance tester must be decommissioned and secured

against unwanted use. This is the case if the device:

– Shows obvious signs of damage

– No longer carries out the required measurements

– Has been stored under adverse conditions for too long

GOSSEN Müller & Weigert

5

Page 6

Operating manual for the TG basic 1 appliance tester

4. Appropriate usage

The tester may only be used under the conditions and for the

purposes for which it has been designed. It is particularly

important to observe the safety instructions and the technical data

regarding ambient conditions and usage in a dry environment.

The appliance tester may not be used for measuring in electrical

systems.

Operational safety is no longer guaranteed in the case of

modifications or conversions that have not been carried out by the

manufacturer.

Maintenance or calibration work may only be carried out by the

manufacturer.

Subject the appliance tester to an electromagnetic field can

impair the function of the appliance tester.

In order to avoid damaging the appliance tester, the test socket

and the test line may not be connected to an external voltage

source.

Only the supplied original measuring lines or equivalent safety

measuring accessories may be used!

GOSSEN Müller & Weigert

6

Page 7

Operating manual for the TG basic 1 appliance tester

5. Operating elements

Explanation of the appliance tester’s connections, operating

elements and displays.

In-case socket for IEC appliances, for

testing connection and extension cables/

measuring the mains voltage at a

protective earth mains socket.

T est socket for connecting test

objects

„Probe“ connection socket (red) for

the test line

LC display

Briefly pressing the „START“ button:

start measuring,

press and hold for 2 s: Help function

GOSSEN Müller & Weigert

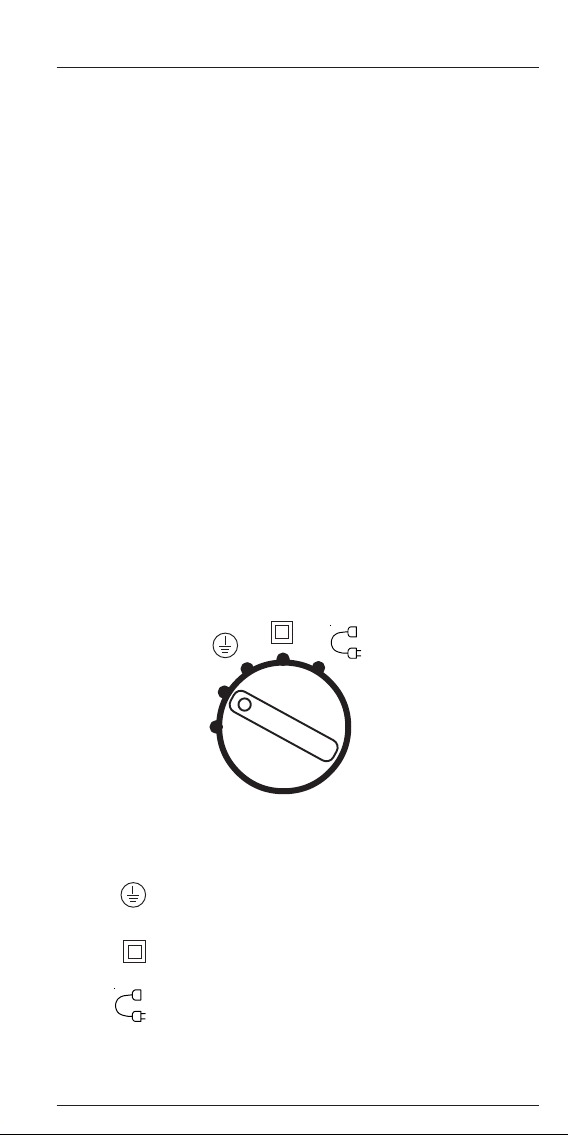

Rotary switch for selecting the type

of measurement

7

Page 8

Operating manual for the TG basic 1 appliance tester

6. Starting up

6.1. Initial equipping or battery replacement

The tester is operated using 6 x 1.5 V type AA batteries (IEC LR6)

or six type AA rechargeable batteries.

The six batteries supplied must be inserted into the tester before

starting the device.

Proceed as follows to insert the batteries:

- Switch off the device (rotary switch in the „OFF“ position)

- Release the screw from the battery cover

- Lift the cover from the lower part of the case

- Remove the old batteries if necessary

- Insert the batteries into the correct locations in the

battery compartment (taking care to ensure correct

polarity)

- Click the battery cover into place in the lower part of the

case and secure it by tightening the screw

6.2. Switching the tester on and off – Selecting the

measuring sequences

The tester is operated via a rotary switch and a „Start“ button.

EIN

ON

AUS

OFF

Measurements for devices with protective

conductor (PC I)

Measurements for devices without protective

conductor (PC II)

Measurements for testing the device connection

and extension cable (LPR)

GOSSEN Müller & Weigert

8

Page 9

Operating manual for the TG basic 1 appliance tester

„OFF“ switch position:

Turning the rotary switch to the „OFF“ position switches off the

device.

Turn the rotary switch to the „ON“ position to switch on the tester.

The device performs a self-test. If the device is OK, the following

switch-on message appears in the display:

Note that no other functions are available until the switch-

&&

&

&&

on message is displayed!

Selecting the menu language

To select the menu language, turn the rotary switch to the „ON“

position and press the „Start“ button.

The display shows the following menu.

The desired language is selected by briefly pressing the „Start“ button

(< 2 s). The respective number before the language designation

blinks to indicate the currently selected language. Pressing the „Start“

button for a longer time (> 2 s) confirms the currently selected

language and exits the language selection.

GOSSEN Müller & Weigert

9

Page 10

Operating manual for the TG basic 1 appliance tester

After the switch-on message has been displayed, the desired

operating mode PC I, PC II or cable test can be selected.

The „Measuring sequence“ window is displayed depending on the

setting of the rotary switch.

Briefly pressing the „START“ button starts the selected measuring

sequence.

Pressing the „START“ button for a longer time (> 2 s) calls up a

quick guide for the select measurement type.

Briefly pressing the „START“ button pages forwards through this

quick guide.

The scrollbar at the left provides an indication of how many

pages are available in the quick guide.

Help window (example)

Pressing the „START“ button for a longer period of time returns

you to the „Measuring sequence“ window.

If a measuring sequence is not started within a period of 3

minutes then the tester automatically switches off.

To switch the tester on again, the rotary switch must first be set to

the „OFF“ position and then back to the „ON“ position (normal

switch-on procedure).

GOSSEN Müller & Weigert

10

Page 11

Operating manual for the TG basic 1 appliance tester

7. Explanation of terminology

7.1. Protection class I (PC I)

The active parts of the device are protected against direct

touching by the basic insulation.

Through connection of the touchable conductive housing parts to

the protective conductor, these are included in the protective

measure in the case of direct touching (fault protection) with the

system.

The device has a protective conductor connection (earthed plug).

7.2. Protection class II (PC II)

The active parts are separated by strengthened or double

insulation (basic insulation and additional insulation). This

ensures protection against direct contact.

Protection against indirect contact also exists, since an insulation

fault is practically impossible. Such devices can nevertheless

have touchable metallic housing parts. Devices of protection class

II have a mains plug without an earth contact.

7.3. Protection class III (PC III)

Devices of protection class III are exclusively connected to

protective extra-low voltage electric circuits.

The protection against dangerous body currents is achieved by

the low voltage and the safe separation from other electric

circuits.

7.4. Protective conductor resistance (RPE)

Resistance between any conductive touchable parts, connected

to the protective conductor for protective purposes, and the

earthed contact of the mains plug, the device plug or the

protective conductor, which is constantly connected to the mains

power supply.

See also the measuring principle circuit under point 8.2.

&&

&

&&

7.5. Insulation resistance (R

This is the Ohmic resistance between conductive parts separated

by insulation.

Measurements are taken between the active parts and the body

as well as touchable conductive parts that are not connected to

the protective conductor.

See also the measuring principle circuit under point 8.3.

&&

&

&&

GOSSEN Müller & Weigert

)

ISO

11

Page 12

Operating manual for the TG basic 1 appliance tester

7.6. Substitute leakage current (IEA)

Current that would flow through the interconnected active

conductors of the device (test object) and the protective

conductor or the touchable conductive parts at rated voltage and

rated frequency of the device.

This measuring method determines the leakage current without

mains voltage.

It is an alternative measuring method for determining protective

conductor current or touch current.

See also the measuring principle circuit under point 8.4.

&&

&

&&

7.7. Visual inspection

Testing in accordance with DIN VDE 0701-0702 requires a visual

inspection of the device. According to the standard, the devices

should be inspected for external defects (without opening the

device) and, as far as possible, for suitability to the place of

installation.

(More details are provided in the DIN VDE 0701-0702 standard).

GOSSEN Müller & Weigert

12

Page 13

Operating manual for the TG basic 1 appliance tester

8. Conducting tests in accordance with

DIN VDE 0701-0702 Definition of standards

The sequence of tests is specified in the standard.

8.1. Visual inspection

The test objects are inspected for externally visible defects.

8.2. Measuring the protective conductor resistance

(for devices of protection class I)

The limit value is:

≤≤

Ω Ω

≤ 0.3

Ω for devices with connecting cables up to 5 m,

≤≤

Ω Ω

plus 0.1

1.0

Measuring principle circuit

Protective conductor resistance PC I

Ω Ω

Ω for every extra 7.5 m, up to a maximum of

Ω Ω

ΩΩ

Ω.

ΩΩ

Appliance tester

´Probe´

socket

Test line

Test socket

8.3 Measuring the insulation resistance

The limit value is:

ΩΩ

1 M

Ω for devices of protection class I

ΩΩ

ΩΩ

2 M

Ω for devices of protection class II

ΩΩ

ΩΩ

0.3 M

Ω for devices of protection class I (with switched-on

ΩΩ

heating elements)

1)

Also applies to touchable conductive parts of test objects

in protection class I that are not connected to the protective

conductor.

2)

If the required insulation resistance is not achieved in the

case of test objects in protection class I with heating

elements with a total capacity

nevertheless rated as faultless if the protective conductor

current does not exceed the limit values.

GOSSEN Müller & Weigert

2)

≥ 3.5 kW, the test object is

13

1)

Test object

Page 14

Operating manual for the TG basic 1 appliance tester

Measuring principle circuit

Insulation resistance PC I PC II

Appliance

tester

Test

object

´Probe´

socket

T est line

Test socket

´Probe´

socket

T est line

T est socket

8.4. Measuring the substitute leakage current for devices of

protection class I

The substitute leakage current procedure is an alternative method

for measuring the protective conductor current.

The limit value is 3.5 mA.

The substitute leakage current for test objects with heating

elements having a total connected power greater than 3.5

kW must not be greater than 1 mA/kW heating power, up to

a maximum value of 10 mA.

Measuring principle circuits

Substitute leakage current procedure PC I

GOSSEN Müller & Weigert

Appliance

tester

T est socket

T est object

14

Page 15

Operating manual for the TG basic 1 appliance tester

8.5. Measuring the substitute leakage current for devices of

protection class II

The substitute leakage current procedure is an alternative method

for measuring the touch current.

The limit value is 0.5 mA.

Measuring principle circuits

Substitute leakage current procedure PC II

Appliance tester

´Probe´

socket

T est line

Test socket

Test object

8.6. Inspecting the inscriptions

Safety-related inscriptions must be controlled and, where

necessary, renewed or supplemented in suitable form.

GOSSEN Müller & Weigert

15

Page 16

Operating manual for the TG basic 1 appliance tester

9. Test procedures

9.1. Testing devices of protection class I

Rotary switch position:

Test object connection:

The test procedure occurs automatically in the sequence

specified below:

- Protective conductor resistance

- Insulation resistance

- Substitute leakage current

Please note: The test object must be switched on.

&&

&

&&

The test sequence is started by pressing the „Start“ button

for < 2 s.

9.1.1. Measuring the protective conductor resistance

The protective conductor resistance is measured using a

measuring current > 200 mA DC. The direction of current is

automatically reversed by the tester.

The measuring sequence is indicated on the display as follows:

Exceeding of the limit value is indicated as follows:

- The momentary measurement value blinks

- An audio signal is emitted

33

A „

3“ is shown in the assessment field if the measurement does

33

not reach the limit value.

GOSSEN Müller & Weigert

16

Page 17

Operating manual for the TG basic 1 appliance tester

At the start of measuring, the tester checks to see if the

measuring current is greater than 200 mA. If this is not the case,

the test is aborted.

This can occur for the following reasons:

- The test object is not of protection class I

- The test object is not connected to the tester or the test

line is not connected

- The protective conductor has an open-circuit

This is indicated by a scrolling message in the status line.

The tester performs the following checks:

a)Check of the test wiring!

The measurement procedure is continued when the

missing connection to the test line or test object is

restored and the measuring current is > 200 mA.

b)Check that the appliance conforms to

protection class I!

If the tester detects that the appliance does not

conform to protection class I, then the test must be

aborted by pressing the „START“ button.

If the test wiring is „OK“ and the test object conforms to protection

class I, then the protective conductor connection has an opencircuit or high resistance. The test must be aborted by pressing

the „START“ button.

When the test is aborted, the assessment window is shown in the

display.

Measurement of the insulation resistance and substitute leakage

current is not performed.

This also applies when the measured protective conductor

resistance is > 1 Ω .

GOSSEN Müller & Weigert

17

Page 18

Operating manual for the TG basic 1 appliance tester

When performing the protective conductor resistance

measurement, the automatic test sequence can also be switched

to a permanent measurement (max. 3 min).

When the tester is in the normal measuring mode, pressing the

„START“ button switches the tester into the permanent

measurement mode.

The bar graph is then no longer shown in the display.

Pressing the button again continues the measurement with a

reversed test current polarity. Pressing the button again ends the

protective current measurement and continues with the next

measurement in the measuring sequence.

During permanent measurement, the connecting cable of the test

object should be moved, section by section, along its whole

length, in order to find broken conductors or weak points. The

momentary measurement values are continuously acquired and

displayed by the tester. The maximum measurement value is

stored and displayed in the assessment window at the end of the

measuring sequence.

9.1.2. Measuring the insulation resistance

The insulation resistance is measured automatically. Switching to

permanent measurement is not possible.

Failure to reach the limit value is indicated as follows:

- The momentary measurement value blinks

- An audio signal is emitted

33

A „

3“ is shown in the assessment field if the measurement

33

exceeds the limit value.

GOSSEN Müller & Weigert

18

Page 19

Operating manual for the TG basic 1 appliance tester

9.1.3. Measuring the substitute leakage current

The substitute leakage current is measured automatically.

Switching to permanent measurement is not possible.

Exceeding of the limit value is indicated as follows:

- The momentary measurement value blinks

- An audio signal is emitted

33

A „

3“ is shown in the assessment field if the measurement does

33

not reach the limit value.

9.1.4. Test assessment

When the automatic test sequence finishes, an assessment

window is displayed.

The measurements and their assessments („X“ or „

displayed here.

The status bar displays „Test OK“ or „Test n. OK“ depending on

the result.

Briefly pressing the „START“ button will repeat the test or perform

a new test if a new test object has been connected. Pressing the

„START“ button for longer than 2 s will display the quick guide

(see point 6.2.)

GOSSEN Müller & Weigert

19

33

3“) are

33

Page 20

Operating manual for the TG basic 1 appliance tester

9.2. Testing devices of protection class II

- Testing devices without a protective conductor and with

touchable conductive parts

- Testing devices with a protective conductor and with

touchable conductive parts that are not connected to the

protective conductor

Caution:

With these appliances, this test can only check the

&&

&

&&

insulation resistance and the substitute leakage current

between the touchable electrical components that are not

connected to the protective conductor and the L and N

connections.

Testing of the protective conductor resistance and the

substitute leakage current relating to the protective

conductor must first be performed after the measuring

sequence for protection class I appliances.

Rotary switch position:

Test object connection:

The test procedure occurs automatically in the sequence

specified below:

- Insulation resistance

- Substitute leakage current

The test object must be switched on (mains switch).

&&

&

&&

The test sequence is started by pressing the „Start“ button

for 2 s.

9.2.1. Measuring the insulation resistance

The same statements apply as in point 9.1.2.

9.2.2. Measuring the substitute leakage current

The same statements apply as in point 9.1.3.

GOSSEN Müller & Weigert

20

Page 21

Operating manual for the TG basic 1 appliance tester

9.2.3. Test assessment

The measurements and their assessments („X“ or „

displayed here.

The status bar displays „Test OK“ or „Test n. OK“ depending on

the result.

Briefly pressing the „START“ button will repeat the test or perform

a new test if a new test object has been connected.

Pressing the „START“ button for longer than 2 s will display the

quick guide.

9.3. Cable test

The cable test allows testing of IEC cables (appliance connection

cables with non-heating device connections), distribution boxes

and extension cables.

Rotary switch position:

33

3“) are

33

The IEC connection line

The test procedure occurs automatically in the sequence

specified below:

- Measuring the protective conductor resistance

- Measuring the insulation resistance

- Cable test

GOSSEN Müller & Weigert

21

Page 22

Operating manual for the TG basic 1 appliance tester

9.3.1. Protective conductor resistance

The same statements apply as in point 9.1.2.

9.3.2. Insulation resistance

The same statements apply as in point 9.1.3.

9.3.3. Cable test

This test provides an additional function that is not part of the DIN

VDE 0701-0702 standard.

This test checks a connection cable or extension cable for opencircuits in the live (L) and neutral (N) conductors and for shortcircuits between L and N.

Cable test assessment window:

Line opencircuit

Line shortcircuit

Line OK

Briefly pressing the „START“ button will repeat the test or perform

a new test if a new test object has been connected. Pressing the

„START“ button for longer than 2 s will display the quick guide.

GOSSEN Müller & Weigert

22

Page 23

Operating manual for the TG basic 1 appliance tester

9.4. Measuring the voltage at an external earthed mains

socket

The test allows checking of the voltage potentials between the

L→N, L→PE and N→PE terminals. The L→PE and N→PE

display depends on the position of the live conductor in the

earthed mains socket (right or left).

To perform the measurement, plug the IEC line provided with the

tester into the IEC socket of the tester.

The rotary switch must be in one of the following positions.

The measuring process starts automatically if voltage is present

at the socket.

EIN

ON

The measuring process starts automatically if voltage is present

at the socket.

Only the voltage potentials between the connection

&&

&

&&

terminals are measured. The measurement provides no

information as to whether the earthed mains socket has

been correctly installed.

No warning message is provided if a dangerous touch

&&

&

&&

voltage exists on the PE conductor.

GOSSEN Müller & Weigert

23

Page 24

Operating manual for the TG basic 1 appliance tester

10. Checking the battery voltage

Before each measurement, the tester automatically checks that

the charge level of the batteries is sufficient for correct execution

of the respective measurement.

If this is not the case, the following information is displayed:

In this case the tester must be switched off and the batteries

replaced as described in point 6.1.

11. Technische Daten

Protective conductor resistance:

Measuring range: 0.1…2.000

Display range: 0.05…2

Resolution: 0.001

Tolerance:

±±

± (5% + 2 digits)

±±

Measuring current/voltage: min.

ΩΩ

Ω

ΩΩ

ΩΩ

Ω

ΩΩ

ΩΩ

Ω

ΩΩ

±±

± 200 mA DC / > 4 V

±±

Insulation resistance:

Measuring range: 0.1…20 M

Display range: 0.1…20 M

ΩΩ

Ω

ΩΩ

ΩΩ

Ω

ΩΩ

Resolution:

im Bereich 0.1…9.999 M

ΩΩ

Ω

ΩΩ

im Bereich 10.00…20.00 M

Tolerance:

ΩΩ

Ω

ΩΩ

≥≥

≥ 0.001 M

≥≥

≥≥

≥ 0.01 M

≥≥

±±

± (5% + 2 Digit)

±±

ΩΩ

Ω

ΩΩ

ΩΩ

Ω

ΩΩ

Measuring voltage/current: min. 500 V DC / >1 mA

Substitute leakage current:

Measuring range: 0.1...20 mA

Display range: 0.1...20 mA

Resolution:

Range 0.1…9.999 mA

Range 10.0 …20.00 mA

Tolerance:

≥≥

≥ 0.001 mA

≥≥

≥≥

≥ 0.01 mA

≥≥

±±

± (5% + 2 Digit)

±±

Measurement voltage: approx. 32 V AC

GOSSEN Müller & Weigert

24

Page 25

Operating manual for the TG basic 1 appliance tester

Spannungsmessung an externer Schutzkontaktsteckdose:

Measuring range: 50…270 V AC

Display range: 50...270 V AC

Resolution: 1 V

Tolerance:

±±

± 5 %

±±

General technical data:

Power supply: 6 x 1.5 V batteries

Typ IEC LR6 (AA)

6 x 1.2 V NiMH

rechargeable batteries

Degree of pollution: 2

Overvoltage category: CAT II 300 V

Protection degree: IP40

Protection class: II

Electrical safety: EN61010-1/VDE0411

DIN VDE 0404 Parts 1,2

DIN VDE 0413, Parts 1,2,4

EMC emission: EN61000-6-3

EMC interference resistance: EN61326-1

Dimensions (L x W x H): Approx. 265 x 110 x 50 mm

Weight: Approx. 700 g

12. Notes on cleaning

When dirty, the tester is to be cleaned with a dry cloth (no

solvents) or an anti-static cloth.

The tester must be protected from shock and impacts.

13. Calibrating the tester

According to the DIN VDE 0701-0702:2008-06 standards:

„Measuring devices used for testing must be regularly

checked and calibrated.“

We recommend a calibration interval of one year. Shorter periods

are recommended if the tester is frequently used or used under

tough conditions. If the tester is seldom used then the calibration

interval can be extended up to a maximum of 3 years.

GOSSEN Müller & Weigert

25

Page 26

Operating manual for the TG basic 1 appliance tester

GOSSEN Müller & Weigert

26

Page 27

Operating manual for the TG basic 1 appliance tester

GOSSEN Müller & Weigert

27

Page 28

Operating manual for the TG basic 1 appliance tester

14. Manufacturer’s guarantee conditions

The TG basic 1 appliance tester is subject to a strict quality

inspection. Nevertheless, we grant a 24-month manufacturer’s

guarantee in the case of malfunctions during normal daily usage.

Manufacturing or material faults will be remedied, free of charge,

as long as the tester shows no signs of third party actions and is

unopened before it is sent back to us.

Damage resulting from the device being dropped or mishandled is

excluded from guarantee claims.

GOSSEN Müller & Weigert

GOSSEN Müllert & Weigert

Kleinreuther Weg 88

D-90408 Nuremberg, Germany

Phone +49(0)911 / 3502-0

FAX +49(0)911 / 3502-307

info@g-mw.de www .g-mw.de

Item: 2786688238 10.2011

Loading...

Loading...