USER`S MANUAL

Thermal Graphics Printers

IPP 144 - 40 G

IPP 144 - 40 GE

Paper Reroll Mechanism

IPP - AW

Safety instructions (EN 61010-1)

In order to preclude any danger to the operator, the following instructions

should be followed:

a) In case any damage or malfunction is detected, take the unit out of operation without delay.

b) Before disassembling the unit, disconnect all inputs / outputs and the supply voltage. When

mounting the unit and the connections, make sure all live components are protected from

being touched directly.

c) Comply with the usual regulations and safety provisions for low and high current systems, in

particular country-specific safety provisions (e.g. VDE 0100).

d) The maximum admissible potential existing between the pin groups as well as to the external

protective conductor must not be exceeded. Refer to the unit´s identification label.

e) When connecting the unit to other devices (e.g. PCs), the connection must be carefully

planned. Internal connections in external units (e.g. GND connected to protective earth) may

cause excessive voltage potential.

f) This device must be grounded! For low voltage 12VDC and 24V

Units with a.c. supply voltage must be connected the protective conductor.

g) Make sure that the unit is property mounted before connection and power on !

In order to preclude any damage to the unit, the following items must be

taken into account:

The maximum admissible potential between the pin groups must not be exceeded.

This applies in particular to high voltage tests.

Refer to the instruction manual !

systems use screened cable.

DC

Warning: Hazardous live voltage !

WARNING:

There is always hazardous voltage present in certain parts during the operation of electrical equipment.

Non-observance of the safety instructions can result in severe personal injury or damage to property. Only qualified personnel should

work on this equipment. The successful and safe operation of this equipment is dependant on proper transport, storage, set-up,

installation and careful operation and maintenance.

QUALIFIED PERSONNEL

Are personnel who are familiar with the set-up, installation, commissioning and operation of the product and have the qualifications

corresponding to their activities, e.g.:

- Are trained and authorised to energise, de-energise, clear, ground and tag circuits and equipment / systems in accordance with

established safety standards.

- Are trained in the proper care and use of protective equipment in accordance with established safety practices.

- Are trained in first aid.

Safety according to EN 61010-1, VDE 0411

CAT III > 150 V [ 300 V

Pollution degree : 2; indoor use; altitude <2000 m; relative humidity <80 % up to 31 °C;

T emperature: 5 °C to 40 °C;

Table of Contents

page

I. IPP 144 - 40 G / IPP 144 - 40 GE 3 - 60

1. General Features 3 - 5

2. Technical Data 6 - 9

2.1. Basic Version 6 - 8

2.2. Version E 9

3. Design and Installation 10 - 11

4. Connection 11 - 17

4.1. Pin assignment 11 - 13

4.2. Interface selection 14

4.3. Connecting Diagram serial 15 - 17

5. Operation 18 - 23

5.1. Operating Controls 18 - 19

5.2. Replacing the paper roll 20

5.3. Menu program 21 - 23

6. Adjustments 24 - 29

6.1. General Functions 24 - 25

6.2. Serial Interfaces 25 - 26

6.3. Date / Time 26 - 28

6.4. Date / Time Output 28 - 29

7. Functional Description 30 - 35

7.1. Start Printing 30

7.2. Addressing 30 - 31

7.3. Handshakes Messages 31 - 33

7.4. Version E (IPP 144-40 GE) 33 - 35

7.4.1. Texts Entry 33 - 34

7.4.2. Texts Output 35

page

8. Appendix 36 - 56

8.1. Menu program complete Selection 36 - 37

8.2. Character Sets 38 - 40

8.3. Details of Printer Control 41 - 53

Commands

8.3.1. Short View of Control

Commands 41

8.3.2. Print Character Commands 41 - 44

8.3.3. Print Position Commands 44 - 45

8.3.4. Bitmap image Commands 45 - 49

8.3.5. Line Feed Commands 49

8.3.6. Barcode Commands 50 - 53

8.4. Connection Examples

for GMW instruments 54 - 55

8.4.1. Connection with DPM / MF 54

8.4.2. Coupling with DAA 55

8.5. Examples for Automatic

Text Insert Mode 56

II.Paper Reroll

Mechanism IPP - AW 57 - 60

1.General information 57 - 58

Design / Installation 58

2.Technical data 59

3.Operation 60

III. Accessories 61

1

Index

page

Accessories 61

Addressing 26, 30

Addressing & protocol / text 31

Basic version 5

Baudrate 25

Barcode Commands 50

Bitmap image Commands 45

Character set 24, 38

Connection diagrams 11

Connection Examples 54

Control characters 38

Data format - serial 25

Date / time - output via interface II 28

Date / time - setting 26

End of paper indication 18

Environmental conditions 7

Enhanced version (E - version) 5

Graphic print-out directly 19

from WINDOWS®

Handshake serial - RTS / DTR 31

Handshake serial - XON / XOFF 32

Headline data & time 29

Input buffer 7

Installation 10

Interface selection 14

Key LINE FEED / ENTER 18

Key lock 19

Key MENU / SELECT 18

KEY RESET 19

Line Feed Commands 49

Line with (character per line) 24

Mechanical data 8

Menu program - complete selection 36

Menu program - entry 21

Menu program - quitting 22

Model types 4

page

Operating controls, general 18

Paper 6

Paper reroll mechanism 57

Parameters, changing 22, 23

Parameters, printing the current 21

Parity 25

Pin assignment current loop 16

Pin assignment - interface I 15

Pin assignment - interface II 17

Print Character Commands 41

Print Control Commands 40

Print format 24

Print interval - serial 32

Print interval - setting 24

Print mechanism 6

Print Position Commands 44

Protocol - serial 29

Replacing the paper roll 20

Snap lock 18

Software version 8

Start printing 30

Technical Data 6

Text adding, overwrite 33

Text call with measured data, serial 34

Text - deleting 33

Text entry 33

Text entry - block 34

Text entry - wildcards 28

Text output 35

Voltage supply 7

Wildcards for measure value 34

Windows programming software 5

2

I. IPP 144 - 40 G / IPP 144 - 40 GE

1. General Features

The Thermal Graphics Printer IPP 144-40 G (Industrial Process

Printer) is a device designed for outputting text, data and

graphics, i.e. measured value, machine and process states, error

messages, production data, etc.

T wo application examples:

.

If connected to a digital voltmeter , the IPP 144-40 G records

the measuring values (with date/time for the E version).

.

Its integrated interface allow the use of the IPP 144-40 G as

a peripheral for all PLCs (RS 232 C; RS 422; RS 485; USB;

Profibus DP).

The Thermal Graphics Printer is a DIN size panel mounting unit

which is able to print line widths of up to 48 characters per line.

The 14m paper roll (commercial grade document proof thermal

paper) is located inside the housing and can be easily replaced

by means of a swivel type front panel. Án end of paper indicator

lights up if the printer runs out of paper .

3

Each printer is addressable, which allows the connection of

up to 31 devices to one sender device via a data line at the

RS 485 interface, e.g. to a PLC.

Review of the

model types

Model

IPP 144-40 G

IPP 144-40 GE 232

IPP 144-40 GE 485

IPP 144-40 GE PB

IPP 144-40 GE USB

There are two version of the printer: The Basic V ersion

IPP 144-40 G with the interface I and the Enhanced V ersion

IPP 144-40 GE with the interfaces I and II.

There are three option for the voltage supply: 12V DC (10V ...19V

DC) or 24V DC (19V ...36V DC) or 1 10V/230V AC (switch-mode

power supply: 85V ...265V AC)

There are four option for the interface IIl :

RS 232 C, RS 485, ProfiBus or USB

Supply Voltage

12V DC 24V DC 110/230V AC

12V DC 24V DC 110/230V AC

12V DC 24V DC 110/230V AC

12V DC 24V DC 110/230V AC

12V DC 24V DC 110/230V AC

Interface I

Yes

Yes

Yes

Yes

Yes

The connector for the interface II of RS 232 C, RS 485 and

ProfiBus is a 9 pin D-Sub-socket. It is possible to change this

interface card in the factory . The interface option USB has a

special USB-B-socket. It is not possible to change this

interface card with the other cards. Special adapter cables

and converters are used in this situation.

4

WindowsProgramming

software

A Windows-Programming software has been developed.This

software will be available to progam the GE text memory , transfer

user defined fonts or symbols and set the printer configuration

parameters. Also this software package includes actual

Windows printer drivers.

The software will be on CD-ROM.

Basic Version

IPP 144-40 G

Enhanced

Version

IPP 144-40 GE

The basic version IPP 144-40 G provides one serial interface

capable of receiving only. Return (handshake) messages to

the sender are sent via hardware line. Texts and measuring

value to be printed must be transmitted from the sender device

since the basic version does not have an internal text memory .

It is possible to print with the basic version bitmap image and

barcodes. The bitmap image files and the barcode files are

generated with printer control commands in a terminal emulation

program.These files are transmitted by interface I to the

printer. It is possible to download this file onto the font ROM

chip in the printer. For the printer control commands and

download commands see section 8.3. in this manual.

Note: The cyrillic character set is on the font ROM chip.

If user defined fonts or symbols are downloaded onto the font

ROM chip, the cyrillic character set will be overwritten, and

the cyrillic character set will no longer be available.

The enhanced version IPP 144 - 40 GE provides a second,

bi-directinal serial interface capable of outputting return

messages under program control in compliance with a protocol.

In addition, this model includes a text memory capable of

storing up to 15 texts which are called by specifying the

corresponding text number. Moreover, date and time may be

printed with texts and data.

The printer interfaces of the IPP 144-40 GE can be set in the

menu program as serial transfer or standard Windows printer

drivers. So it is possible to print data (e.g.user defined fonts

and symbols) directly with Windows.

It is not possible for the user to upgrade the basic version to

the enhanced version; as this is a different factory version.

5

2. Technical Data

2.1.Basic Version

Print

mechanism

Paper

Type of printing Fixed head thermal line

Character representation 576 dots/line, 8 dots/mm

Print speed approx. 15 line/s (standard text mode)

Character/line 48 characters

24 characters

16 characters

8 characters

Character height 3 mm at 48 characters

4 mm at 24 characters

9 mm at 16 characters

18 mm at 8 characters

Character sets ASC II, german,

french, danish,

norwegian,

swedish / finnish,

spanish, english, cyrillic

Service life min. 10x106 Impulse or 50 km

T yp e commercial grade,

document proof

thermal paper

Width 80 mm (+0 / -1 mm)

Length approx. 14 m

(approx. 4.600 line

up to 48 characters per line)

Max. outer roll diameter 40 mm

Min. inner roll diameter 1 1,5 mm

Temperature standard paper: 0 °C to 60 °C

6

Input buffer

Serial

Interface I

Serial 16 kB

T y p e RS 232 C; RS 422; RS 485

or Current loop

Baudrate 110; 150; 300; 600; 1200;

2400; 4800;9600;19200;

38400

Data format 7 bit / 8 bit

1)

Parity bit even, odd, mark, space, no

1)

Voltage

supply

Ambient

conditions

Standards

Safety acc. to EN 61010-1:2001

CA T III > 150 V ≤ 300 V

pollution degree 2

DC 10 V ... 19 V

approx. 20 V A

2)

19 V ... 36 V

approx. 18 V A

2)

AC 85 V ... 265 V , 45 - 65 Hz,

approx. 15 W

switch-mode power supply

Storage temperature range -20 °C to +60 °C

Operating temperature range 0 °C to +45 °C

Climate relative humidity < 80 %

up to 31 °C

Protection type acc. to EN 60529/VDE 0470

housing IP 50

terminals IP 00

Insulation group C acc. to VDE 0110

Mech. strength acc. to IEC 1010

EMC

Emission EN 5501 1, Class A

EN 55022, Class B

Susceptibility EN 61000-4-2 B

EN 61000-4-3 A

EN 61000-4-4 B

CE

1)

See setting transmission parameters of the sender at page 9.

2)

Starting current approx. 1,2 A (10 V ... 19 V) or approx. 0,8 A

(19 V ... 36 V).

This value can be used to rate the external fuse.

7

Connections

Voltage supply Screw type/terminals

fixed: 0,2 to 4 mm²

flexible: 0,2 to 2,5 mm²

AWG: 24 to 12

Interface I 9pin D-Sub socket

Interface II 9 pin D-Sub socket

or

USB-B socket

Connection for paper

reroll mechanism 4pin MASCON, MLAS

Connection for

Alarm relay output

Screw type/terminal

fixed: 0,2 to 4 mm²

flexible: 0,2 to 2,5 mm²

AWG: 24 to 12

normally open

50 V AC, 2 A

30 V DC, 2 A

Miscellaneous

8

Dimensions

(W x H x D) 144 x 72 x 159 mm

Switchboard mounting screws against rear side

of switchboard

Internal fuse

( on power supply board) 12V DC : T 3,15 A

24V DC : T 2 A

1 10V - 230V AC : T 2 A

This operating manual applies to software version

5.01.05 and higher

2.2. V ersion E

Serial

Interface II

Text entry for

texts to be

stored

Text memory

Internal clock

Warning !

T y p e RS 232 C or RS 485

1)

ProfiBus or USB

Baudrate 110: 150; 300; 600; 1200;

2400; 4800; 9600;19200;38400

Data format 7 bit / 8 bit

Parity bit even, odd, mark, space, no

2)

2)

separate configuration

by interface II

T yp e CMOS-RAM, battery buffered

3)

Battery life 10 years typical

Memory size 600 Byte = 15 texts

T yp e CMOS, battery buffered

Accuracy ± 10 ppm = 0,8 sec / day

1)

Please specify when ordering; if nothing is specified, RS 232 C is

supplied.

2)

See Setting transmission parameters of the sender

3)

Lithium battery: 3 V

type: VARTA CR 2/3 AA Typ 6237

PANASONIC BR 2/3 A 1 P

^

3)

^

This product contains a Lithium battery which must not be

cut open, incinerated, exposed to temperature above

+60 °C or recharged.

Dispose of in accordance with national regulations.

9

Design

3. Design and Installation

Front

10

1 Paper and cutting edge

2 Key: LINE / FEED / Enter

3 Key: MENU / Select

4 Alarm LED (paper end indicator)

5 Serial interface

Interface II (only version E)

6 Serial Interface I

7 Voltage supply

Make sure that the unit is properly

mounted before connection and power on.

8 Alarm contact

(paper end only version E)

9 Snap lock

10 Mounting screws

11 Protective conductor

connection. Must be

connected to ground.

12 Connection / paper reroll

mechanism IPP-AW

Installation

The IPP 144 - 40 G fits into a DIN standard panel cut out. It

is inserted into the switchboard opening from the front side

and is fixed against the switchboard rear using mounting

screws. The switchboard thickness must not exceed 12 mm.

4. Connection

4.1. Pin assignments

Pin

assignment

WARNING: This device must be grounded -ACHTUNG: Dieses Gerät muss geerdet werden !

IPP 144 - 40 G

Opt.: . . . . . . .

EN 61010 -1:2001 CAT III

.

CE

Alarm

-

+

LN

1

85 V...265 V AC; 45...60Hz ; 15W

19 V...36 V DC; 18 VA

10 V...19 V DC; 20 VA

Interface II

RS 232 C

RS485

Profi Bus

USB

IPP-AW

Interface I

5

5

Sig GND

9

Sig GND

RXD (-

)

9

TXD

RTS

DTR

CLA

+5Vis

RTS

RTS

DTR

RXD

GND

1

6

GND

RXD (+)

1

6

DTR

Serien Nr.:

Serial No.:

No.de serie

Lithium battery inside ( VERSION E )

TXD

Connect the unit as shown in the connection diagramms.

Observe all national safety regulations, especially for the supply power

connections.

11

Serial

Interface I

Pin Signal

1 GND Ground (shield)

2 RXD (+) Receive data

3 +5 V Output +5 V / 20 mA

4 n.c.

5 RXD (-) Signal ground

6 DT R Open collector; active if

DTR is +8 V

12

7 DT R (Data Terminal Ready)

+8 V: ready to receive

-7 V: not ready to receive

8 RTS (Request To Send)

+8 V: ready to receive

-7 V: not ready to receive

(text buffer is full)

9 RTS Open Collector; active if

RTS is +8 V

The serial interface I has been designed to allow the

implementation of all widely used interfaces:

RS 232 C; RS 422; RS 485 and Current loop.

See chapter 4.3.: Connecting diagram

Serial

Interface II

(only

IPP 144 -40 GE)

Pin Signal

1 G ND Ground (shield)

2 RXD (+) Receive data

3 n.c.

4 TXD Transmit data

5 RXD (-) Signal ground

6 n.c.

7 D T R (Data T erminal Ready)

+8 V: ready to receive

-7 V: not ready to receive

8 R TS (Request T o Send)

+8 V: ready to receive

-7 V: not ready to receive

9 n.c.

This interface can either be operated under hardware

handshake (DTR, RTS) or software handshake

(XON / XOFF - Protocol). This does not require special

settings.

See chapter 4.3.: Connecting diagram

13

4.2. Interface selection (Interface I)

Slide snap lock to the right hand side, swivel front door out.

Now you can see the switch S 101 on the printed circuit

board.

- For RS 232 C, RS 422 and RS 485 set switch S 101

to the right hand side.

- For Current loop, set switch S 101 to the left hand

side.

14

IMPORTANT:

This switching only applies to interface I.

If the printer is connected to the sender device

(e.g. to a PLC) the interface parameters must be

matched to those at the sender device.

See chapter 6.2. which describes the setting of

the baudrate, data format, stop bit and parity bit.

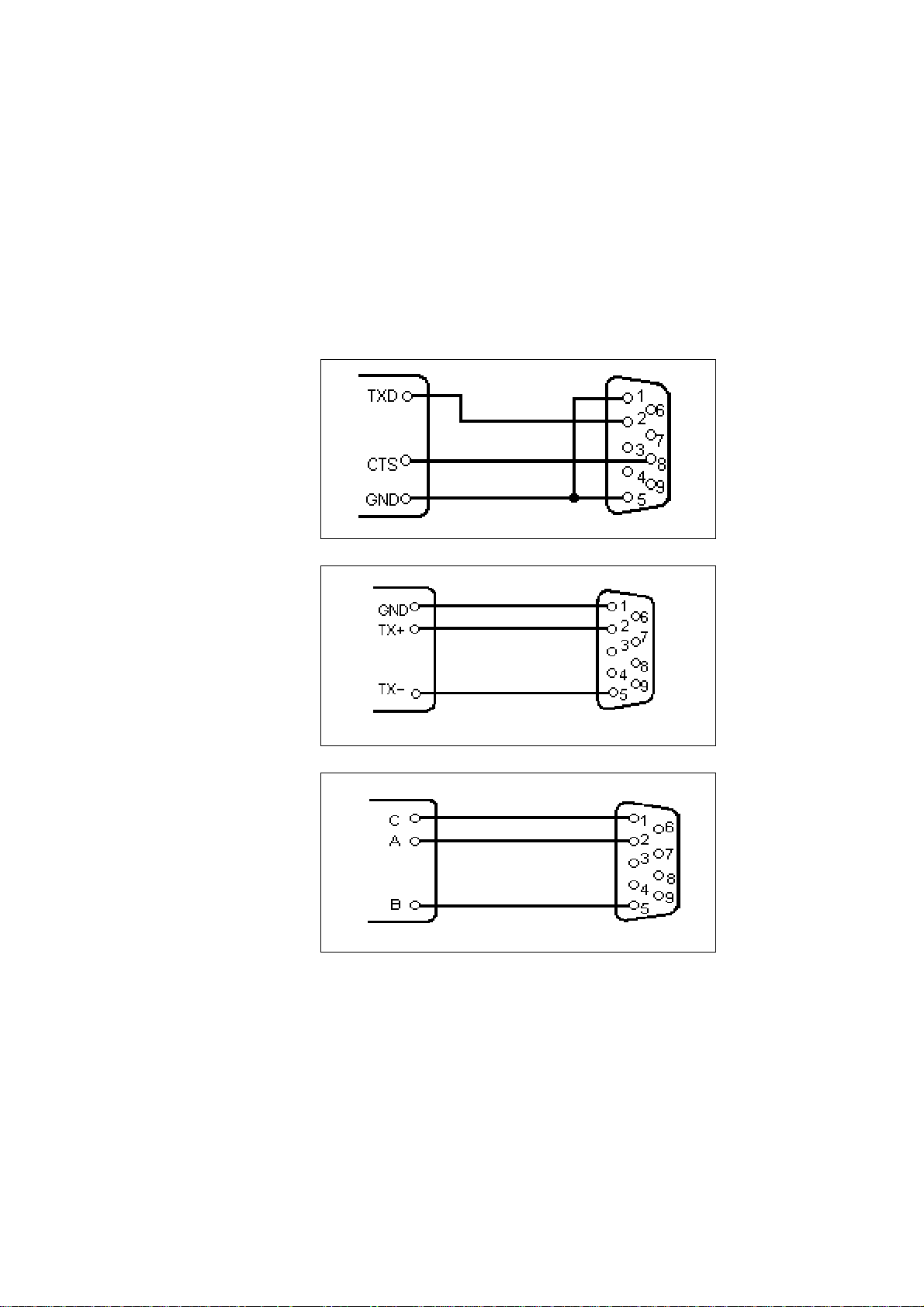

RS 232 C

RS 422

4.3. Connecting diagram

Interface I

Set slider switch S 101 to the right hand side !

(see „Interface selection“ 4.2.)

RS 485

Sender IPP 144

See explanation on page 17

15

Current loop

Sender active,

IPP 144 - 40 G

passive

Sender passive

IPP 144 - 40 G

active

Set slider switch S 101to the left hand side !

(see „Interface selection“ 4.2.)

Sender active IPP 144-40G passive

Sender passive IPP 144-40G active

16

100 Ohm

„I“identifies the direction in which the current flows (20 mA)

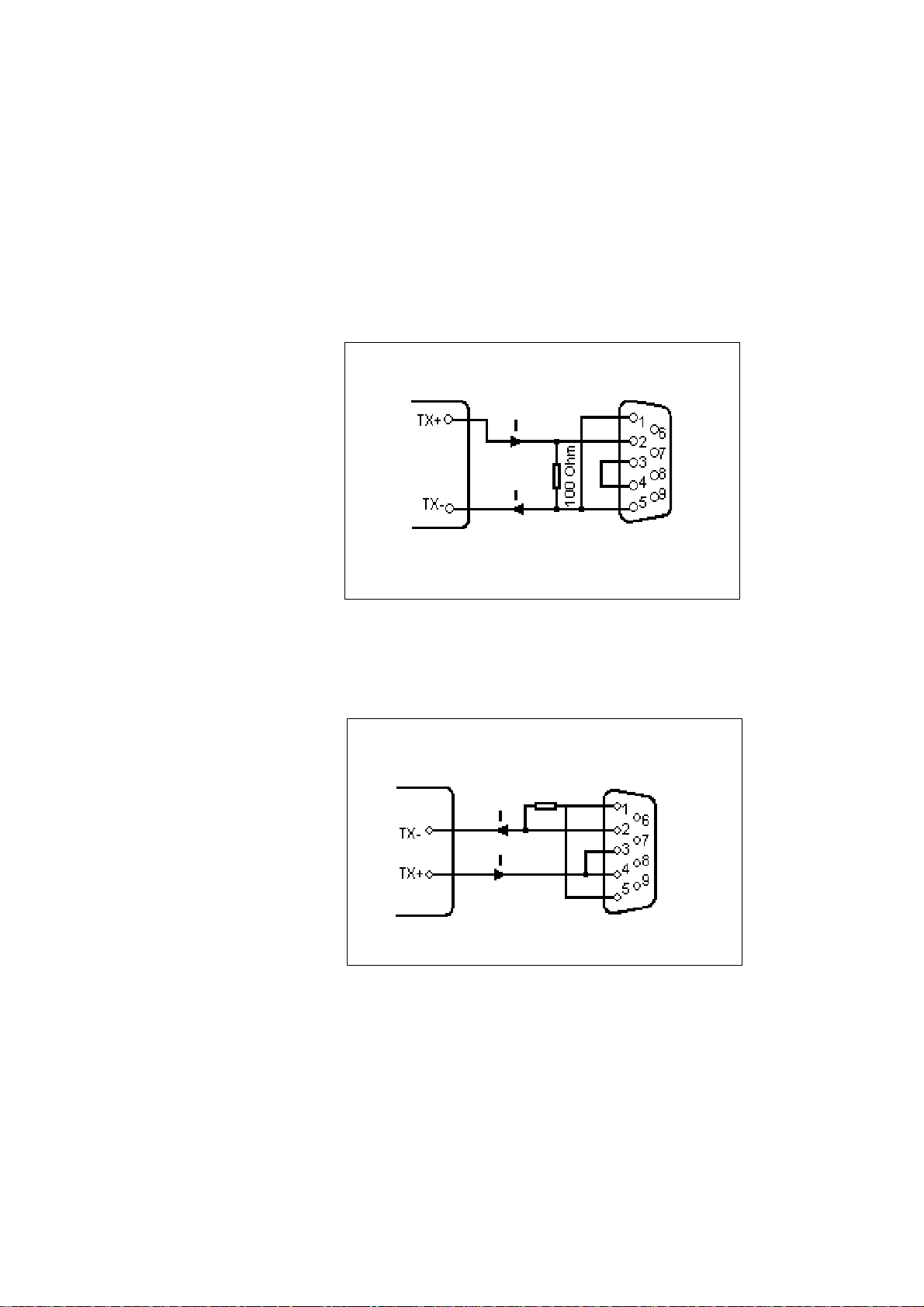

RS 232 C

RS 485

(Option)

ProfiBus

(Option)

Interface II

USB

(Option)

Sender / receiver IPP 144-40 GE

Explanation concerning the signal names underRS 485.

The names A, B, C correspond to the EIA 485 - Standard:

inactive or logical „1“; A > B

logical „0“: B > A

If an interface does not comply with that standard, the

connections of A and B must be interchanged.

Standard USB chassis socket type B

pin 1 +5V

pin 2 U SBD M

pin 3 USBDP

pin 4 G N D

17

5. Operation

5.1. Operating Controls

The numbers with the operating controls refer to the

diagrams in chapter 3.

LED

„Alarm“

(4)

LINE FEED /

ENTER

(2)

The ALARM LED has two functions.

1. T o indicate „end of paper“ or „no p aper“

2. To indicate the front door is open

Examples:

1. The front door is closed.

If this LED is lit, the printer has run out of paper . Insert a

new paper roll; see section 5.2. „Replacing the Paper Roll“.

the front press-button switches (LINE FEED & MENU keys)

are deactivated.

2. The front door is open.

The LED is lit. Printing may continue until the input buffer is

empty , and then the data transmission goes to st andby.

3. The front door is open and the printer has run out of

paper .

The LED lit. The printer stops printing and the front pressbutton switches are deactivated.

After replacing the paper roll the front press-button

switches are active. The ALARM LED remains ON until the

front door is closed. The printer can start working.

This key has two functions:

LINE FEED:

During operation used for manual paper feed.

In the menu program it is used to accept and save

the parameters selected via „Select“.

MENU /

SELECT

(3)

18

This key has two functions:

MENU:

If during operation this key is pressed continuously

for more than 3s, the printer switches to menu

program mode in which device parameters are printed

out and can be modified.

Select:

Within the menu program it is used for selecting the

device parameters.

Paper cutting

edge

(1)

In order to tear off the paper , pull the paper quickly

sideways and up.

Snap lock

(9)

Locking the

Menu / Select

key

RESET -key

Push this to the right hand side to open the front panel in

order to be able to replace the paper roll or to set the slider

switch S 101 which is used to set the desired interface (see

chapter 4.2. „Interface selection“) or to set the RESET

switch S 102.

If the jumper B is connected, the „MENU / SELECT“ key

is locked; menu parameters can neither be printed or

modified.

In order to print or modify parameters:

remove jumper B !

The key S102 resets the printer to the standby mode. The

menu parameters will not to be changed.

19

5.2. Replacing the Paper Roll

Proceed as described below:

1. For devices with a.c. powersupply be very careful.

Warning: Dangerous voltage

is accessible if replacing the paper roll after

opening of the front panel !

2. Push the snap lock to the right hand side and open the

front panel.

3. Tilt the wire frame upwards;

remove the old paper roll.

4. Insert new paper roll; make sure it rotates clockwise

during printing (see left side of the figure).

5. Trim the leading edge of the paper roll to get a clean

straight edge (see right side of the figure). Insert

paper into bottom of print mechanism (as shown in the

diagram below) until roller automatically takes it up.

6. Press the „LINE FEED / ENTER“ key until the paper

appears at cutting edge.

20

7. If you have fed too much paper , carefully rewind the roll.

push the wire frame back over the roll.

8. Close the front panel (snap lock must lock). The Alarm

LED extinguishes and the printer is ready .

5.3. Menu Program

All functions of the IPP 1444 are set via menu program

using the „ENTER“ and „SELECT“ keys and are saved when

the user quits the program.

From then the IPP 144 automatically uses these

parameters.

The print format for the printout of the parameters is always

NORMAL with 48 character per line, so that the parameters

can be read during printing.

The possible setting are explained in chapter 6.

Entering

the menu

program

Print current

parameters

Press the „MENU / SELECT“ key for approx.

3 seconds.

The IPP 144 reacts by printing

„ACTUAL P ARAMETRS ? PRESS „ENTER“

Press the „ENTER“ key,

the IPP 144 prints the currently set parameters.

The final printout says

„CHANGE P ARAMETERS ?“

21

The menu

program

„Change

Parameters“

Press „ENTER“ and „SELECT“ simultaneously

for approx. 4 seconds; the IPP 144 brings up

the first function which can be modified.

(see changing parameters)

The menu program „Change Parameters“ can be called in

one of two ways:

Quitting

the menu

program

If there are no keys pressed over a period of approximately

2 minutes, the program is terminated automatically and

any modifications made are not saved.

Without prior printing of the current parameters:

Press both keys following

„ACTUAL P ARAMETERS ? ...“.

With prior printing of the current parameters:

Press both keys following

„CHANGE P ARAMETERS ?“.

The program is terminated by simultaneously

pressing „ENTER“ and „SELECT“

Following the printout

„END“

all modified functions are saved.

22

Changing

parameters

The IPP 144 prints one of the changeable

parameters

Press „ENTER“ to accept the parameter and

to move to the next function.

Press „SELECT“ to display the next

parameter option.

Example:

SET BAUDRATE NO ?

„SELECT“ „ENTER“

YES ?

„ENTER“

BAUDRA TE 300

300

„SELECT“

600

„ENTER“

>>> 600

TO STORE BAUDRA TE; PLEASE PRESS „ENTER“

SET BAUDRA TE AGAIN, PLEASE PRESS „SELECT“

„ENTER“

SET DA T A FORMA T NO ?

In case

1: Baudrate 600 (Baud) 2: Baudrate 300 (Baud)

is saved is saved

23

6. Adjustment

6.1. General Functions

The various functions and device parameters are selected

and set via the menu program (see chapter 5.3.).

The appendix contains a summary .

PRINT

FORMA T

CHARACTER /

LINE

NORMAL: The printout can be read during printing, the

INVERSE: The printout is made top down, the last print

line is at the bottom. In this case the

printout is in the proper chronological order

after the paper has been torn off.

Print formats can be switched via the serial interface (see

appendix 8.2. „additional control characters“), if the input

buffer is empty!

90-degree rotation: It is possible to set the printing with

48: 48 character per line = standard character width

24: 24 character per line

16: 16 character per line

8: 8 character per line

The character width can be switched via the serial interface

(at the beginning of a line and only if the input buffer is empty).

last print line is at the top.

90-degree right or left rotation. This

function can not be set via the menu

program but via control commands

(see section 8.3. „Details of Printer

Control Commands“).

CHARACTER

SET

24

Available character sets are:

ASCII, GERMAN, FRENCH, SWEDISH/FINNISH (S/SF),

DANISH, NORWEGIAN, SP ANISH, UK (English) and

CYRILLIC.

Character sets see appendix 8.2. „Character Sets“ !

INTERFACE

SERIAL:

This sets the printer for data transmission via serial

interface.

EMUL.EPS.LQ580 ESC/P2:

This sets the printer for data transmission via EPSON

LQ580 ESC/P2 protocol.

EMUL.T ALLY T2024:

This sets the printer for data transmission via T ALL Y T2024

protocol.

Print graphics

directly from

WINDOWS

®

PRINT

INTERVAL

It is possible to print graphics, such as bmp-, jpg- or tif-,

directly from WINDOWS® programs.

Set the printer INTERFACE of EMUL.EPS.LQ580 ESC/P2

or EMUL.T ALL Y T2024. Use a 24-pin type WINDOWS

®

printer. The following configurations have been verified:

INTERFACE: EMUL.EPS.LQ580 ESC/P2

WINDOWS® printer driver: Epson Compatible 24 PIN and

Epson LQ560

Details:

If the width of the graphic exceeds the paper print width,

then the excess is discarded. It is recommended to use the

auto-sizing print option in WiNDOWS® programs, where

possible.

The printing of measuring values can be carried out under

internal timer control.

Setting range: 10 s ... 24 h in steps of 10 s.

The interval of starts after the printing of the line received

last.

For more information see chapter 7.3. „Handshake

Messages“ !

BAUDRA TE

6.2. Serial Interfaces

There areten options available:

1 10; 150; 300; 600; 1200; 2400; 4800; 9600; 19200 and

38400 baud.

25

DA TA FORMA T There are two formats available:

7 - bit- or 8 - bit - transmission

1 startbit / ... / parity / 1 stoppbit

Attention:

With 7 bit NO P ARITY, the sender must be set to 2

stoppbits !

PARITY There are five options available:

Even; Odd; Mark; Sp ace; No parity .

There is no check made.

PRINTER

ADDRESS

Date entry

Each printer IPP 144 - 40 G / IPP 144 - 40 GE can be

addressed. This allows the concurrent supply of different data to several printers via one data line.

Up to 31printers may be called from one sender (e.g. a

PLC). The respective address is set in the menu

program.

for more information see chapter 7.2. „Addressing“ !

6.3. Date / Time ( only E-version )

Date and time are factory set. In order to modify

these values the menu program must be called and

the following message must be displayed:

SET CALENDAR NO ?

„SELECT“

YES ?

26

„ENTER“

SET CALENDAR 15. 03.04

_5. 03. 04

The printed cursor to the left of the 5 indicates that

this position can be modified; in our example this is

the decimal digit of the day . The „Select“ key is

used to print the possible values successively; in

our example this is 0, 1, 2 and 3, To accept the

value press „Enter“; the cursor jumps to the next

position to the right ... etc.

>>> 24. 03. 04

Eventually , the current date is printed.

Note:

Incorrect entries, e.g. day 33 of a month, will not be

accepted by the printer.

Instead, it starts over at the base value 00.

Setting

the time

The time is set like the date. Af ter the current date has

been printed, the following line appears:

SET TIME NO ?

.

.

Hour

Minute

Second

.

SET TIME 12 : 31 : 33

_ 2 : 31 : 00

If the time is modified, the seconds are automatically set to

zero.

If the time has been entered and „Enter“ has been pressed,

the following is displayed:

>>> 22 : 31 : 00

TO STORE TIME; PLEASE PRESS „ENTER“

SET TIME AGAIN; PLEASE PRESS „SELECT“

If time has been entered correctly , press „Enter“. If the time

has been entered incorrectly , repeat the entry by pressing

„Select“.

27

Set Summer

Winter Time

Mode

Output

Set one hour plus or minus for Summer/ Winter Time Mode

following is displayed:

CHANGE TIME W<->S NO ?

If „YES“ is selected, the follow selectíons are displayed:

„W ---> S (+1 h)“

„S ---> W (-1 h)“

After setting time the current time will been printed. Press

„ENTER“ to store time or press „SELECT“ to set time again.

It means:

W...Winter T ime

S...Summer Time

6.4. Date / Time Output

(E - V ersion)

Date and time may be transmitted via the serial interface II

28

Request:

< Ctrl W > < CR >

Addressed:

<Ctrl E> Adr. <Ctrl E> <Ctrl W> <CR> <Ctrl D>

The IPP 144 returns date / time in the format:

< CR > < LF >

15.03.04 17:03:24

< CR > < LF >

During the transmission, nothing can be received

(RTS = LOW).

Serial

protocol

Print

date/time

„always“

The IPP 144 is capable of printing date and time together

with measured values or text as a protocol. In this case,

date and time precede the printout.

There are two options available:

Each transmission is preceded with the date/time (always).

Date and time only precede the transmission if control

command has been received.

this optional feature is selected in the menu program under:

PRINT DATE / TIME HEADLINE

Each transmission is preceded with the date/time

(always).

For several messages in a row (i.e. the IPP 144 is still

printing), the date & time is printed once only at the

beginning of the transmission.

e.g.:

15.03.04 16:57:30

Oil temperature 367,5 °C

Oil pressure o.k.

Boiler 1

Print date/

time with a

received

control

command

Pause >

15.03.04 16:58:59

Boiler 2 still active

Temperature 258,6 °C

PRINT DATE / TIME CTRL „ ^ „

Date and time only precede the transmission if the

character <Ctrl ^> has been received.

29

7. Functional Description

7.1. Start Printing

To start the printing, the IPP 144-40 G expect s only

the character

<CR> Carriage return, Enter

Note:

<LF> alone has by itself no effect combined with

other control characters (calling text, send clock, start

print interval -see following sections).

If these characters are transmitted without a print

triggering character, the IPP 144 - 40 G prints them

after approx. 3 seconds.

Other widely used print trigger characters such as

<FF> Form feed are ignored.

7.2. Addressing

Each IPP 144 - 40 G / IPP 144 - 40 GE printer is

addressable.Thus, several printers can be supplied

with different data via one data line.

Up to 31printers can be connected by one sender

device (e.g. a PLC). The respective address is set in

the menu program.

30

Note:

- Standard interface RS 232 only permit s

1 sender / 1receiver; Do not connect more than

4 IPP’s as receivers.

- Only interface RS 485 allows up to 32 receivers !

Address / ASCII character assignment example:

Address Address in corresponding

Protocol (HEX) ASCII - character

0 - without addressing

1311

. . .

. . .

. . .

30 4 E N

31 4 F O

Protocol &

Text

RTS / DTR

The addressing protocol is:

<Ctrl E> address <Ctrl E> characters ...<CR> <Ctrl D>

A text of more than one line is possible.

( <Ctrl E>, <Ctrl D>, see appendix).

A transmission is only accepted if the sequence <Ctrl E>

address <Ctrl E> is used !

e.g. print date/time/text:

<Ctrl E> address <Ctrl E> <Ctrl \> <CR> characters...

<CR> <Ctrl D>

7.3. Handshake Messages

Serial Interface

These lines indicate the printer status to the sender;

DTR (device is on) is rather insignificant and is in general

not used.

RTS high (+8 V) indicates: printer is ready to receive.

RTS low (-7 V) indicates: printer is not ready to receive.

The reasons for printer not being ready could be:

.

Out of paper

.

Print interval running

.

Buffer is full

Change menu

.

RTS / DTR are only used by the RS 232 C interface and

can be used for interface I and II.

31

Print

interval

(serial)

During the preset wait delay the interface is not ready to

receive. Af ter expiry of the wait delay the RTS signal

(or XON) becomes active again and requests the subsequent transmission.

The next interval begins upon receiving of <CR> or

<CR + LF>. <LF> on its own is not accepted.

XON / XOFF

The report functions „Printer read/not ready“ are handled

by this protocol if no handshake lines are connected

(RS 232 C, RS 422 or RS 485).

This function only applies to the E version, interface II.

XON is transmitted if the IPP 144-40 GE is ready to

receive.

XOFF is transmitted if the IPP 144-40 GE is not ready

to receive (see above).

Note:

If the IPP 144-40 GE is not ready to receive, it transmits

this character just once, not continuously .

No adjustments have to be made, this protocol always

runs parallel to the hardware handshake.

Improved handshaking for pre-stored texts

After receiving the control command <CR> the printer now

sets RTS at „BUSY“ or the signal XOFF is transmitted.

When the printing of pre-stored text is complete, RTS is

reset or the signal XON is transmitted.

This handshake can be used to control the data

transmission and prevent rapid text calls being lost or

overwritten.

Note:

Without Handshake the following can occur, if the text

calls are sent in too quickly:

Data input:

<Ctrl C> 1 <CR> <Ctrl C> 2 <CR> <Ctrl C> 3 <CR>

32

Actual Print-out:

Machine No. 3 pre-stored Text No. 1

2 just „2“ printed, Text No. 2 missing

3 just „3“ printed, Text No. 3 missing

With Handshake, provided RTS (or XON/XOFF protocol) is

used to control the data transmitter:

Data input:

<Ctrl C> 1 <CR> <Ctrl C> 2 <CR> <Ctrl C> 3 <CR>

Actual Print-out:

Machine No. 3 pre-stored Text No. 1

Automatic mode pre-stored Text No. 2

St atus NORMAL pre-stored Text No. 3

7.4. Version E (IPP 144 - 40 GE)

7.4.1.T ext Entry

T ext can only be entered via interface II.

The maximum text length is 40 characters; if the text length

exceeds 40 characters only the first 40 characters are

saved.

T ext will be input via Windows programming software. There

is a special task for inputting, adding, overwriting and

deleting texts. The text number must be two-digit.

Y ou must set the following printer parameters:

Baudrate: 9600

Data format: 8

Parity: NO P A RITY

Interface: SERIAL

For details of the Input task see the Windows programming

software manual.

33

Reserving

space for

measured

variables

In order to be able to insert measured value (variables) into

text afterwards, the location within the text must be marked

using „Ctrl V“, which reserves 6 spaces into which any

characters may be entered, since they are overwritten at a

later time anyway; they are merely wildcards.

Example:

Entry:

TEMPERA TURE <Ctrl V> XXXXX °C <CR>

<Ctrl> counts as one digit, so you only have to enter 5

wildcard characters.

The printout would look like this:

TEMPERA TURE 263,45 °C.

Creating a

text block

A text block is created by combining several texts.

A text block can be printed in a single call.

T o achieve this, place the beginning and the end of the text

in brackets at entry time. Use the control characters:

Ctrl X = opening bracket

Ctrl Y = closing bracket

The texts within a text block

must have continuous numbers !

To delete text within a text block without creating a

blank line, the text numbers following the deleted

line must be decreased by 1 to move them forward.

This is not done automatically but has to be entered

manually.

34

7.4.2. T ext Output

Calling via

serial

interface

In order to print text, the printer must receive a

transmission with the following format:

< Ctrl C > text number < CR >

The printer looks up the stored text related with that

number and prints it.

If there is no such text, nothing is printed.

Important notes:

<LF> on its own does not start the printing !

.

.

Between several text calls in a row there has to be a

gap of least 2 seconds to make sure no text is skipped

during printing !

.

Several text calls using <Ctrl C> and „normal“

transmissions must not be combined !

.

Combination of text and Date / time (protocol)

see chapter 6.4. !

The call for a printer with an address:

<Ctrl E> Adr. <Ctrl E> <Ctrl C> Nr . <CR> <Ctrl D>

Precede the call with the address (see chapter 7.2.).

Example for text entry see chapter 8.5.

35

Basic version

8. Appendix

8.1. Menu program / Complete Selection

SET INTERV AL NO ?

YES ?

SET INTERVAL 00 h 00 min 00 sec

00 h 00 min _0 sec

00 h 0_ min 50 sec

00 h _4 min 50 sec

0_ h 34 min 50 sec

_2 h 34 min 50 sec

>>> 12 h 34 min 50 sec

SET BAUDRATE NO ?

YES ?

BAUDRATE 19200

19200

38400

110

150

300

600

1200

2400

4800

9600

>>> 9600

SET DA T A FORMA T NO ?

YES ?

SET DA T A FORMA T 8

8

7

>>> 7

SET PARITY NO ?

YES ?

SET PARITY NO PARITY

NO PARITY

EVEN

ODD

MARK

SPACE

NO PARITY

>>> NO PARITY

PRINTER ADDRESS NO ?

YES ?

PRINTER ADDRESS 00

_0

10

20

30

00

0_

01

.

.

09

00

>>> 00

SET PRINT FORMAT NO ?

YES ?

PRINT FORMA T INVERSE

INVERSE

NORMAL

>> > NORMAL

SET CHARACTER/LINE NO ?

YES ?

CHARACTER/LINE 48 CHARACTERS

48 CHARACTERS

24 CHARACTERS

16 CHARACTERS

8 CHARACTERS

>>> 8 CHARACTERS

CHARACTER SET NO ?

YES ?

SET CHARACTER ASCII

ASCII

GERMAN

FRENCH

DANISH

NORWEGIAN

SPANISH

UK

CYRILLIC

ASCII

>>> ASCII

SET INTERFACE NO ?

YES ?

SET INTERFACE SERIAL

SERIAL

EMUL.EPS.LQ580 ESC/P2

EMUL.TALLYT2024

>>> EMUL.T ALLYT2024

*** END ***

36

Version E

SET TIME NO ?

SET TIME 15:57:26

>>> 15:48:00

TO STORE TIME, PLEASE PRESS „ENTER“

TO SET TIME AGAIN, PRESS „SELECT“

SET CALENDAR NO ?

SET CALENDAR 12.01.03

>>> 16.02.04

CHANGE TIME W<->S NO ?

CHANGE TIME W<->S 14:07:14

W --> S (+1h)

S --> W (-1h)

>>> 15:07:14

PRINT DATE/TIME NO?

PRINT DATE/TIME CTRL “ ^ “

>>> HEADLINE

SET ACCORDING TO THE BASIC VERSION

SET INTERV AL

SET BAUDRA TE

SET DA T A FORMA T

SET PARITY

PRINTER ADDRESS

SET PRINT FORMA T

SET CHARACTER/LINE

SET CHARACTER

SET INTERFACE

YES ?

_5:57:00

. .

. .

15:4_:00

YES ?

_2.01.03

1_.01.03

. .

. .

16.02.0_

YES ?

YES?

HEADLINE

*** END ***

37

8.2. Character Sets

Control Character used for Data Transmission

General purpose characters

Character HEX Significance Name

Ctrl D 04 End of transmission EO T

Ctrl E 05 Set address ENQ

Ctrl J 0A Line feed L F

Ctrl M 0D Carriage return CR

Ctrl Q 11 Ready to receive XON

Ctrl S 13 Busy XOFF

Additional characters used by the printer

Ctrl F 06 48 character / line

Ctrl R 1 2 24 character / line

Ctrl T 14 Inverted printing

Ctrl U 15 Normal printing

Ctrl W 17 transmit request: date / time

Ctrl ^ 1E Print: date / time in protocol

38

Ctrl C 03 Text call

Ctrl X 18 Start of text block

Ctrl Y 19 End of text block

Ctrl V 16 Reserve space for measure variable (6 digits)

Character set - various languages

The following HEX codes differ from the ASCII character

set:

Hex-Code 23 24 40 5B 5C 5D 5E 60 7B 7C 7D 7E

ASCII # $ @ [\]^`{¦ }~

German # $ § Ä Ö Ü ^ ` ä ö ü ß

S / SF # ЙДЦЕЬйдцеь

French # $ à ° ç § ^ ` é ù è

Danish # $ É Æ Ø Å Ü é æ ø å ü

Norwegian #

Spanish # $ à Í Ñ é ` ñ ´ ´

English $ @ [ \ ` | }

ЙЖШЕЬйжшеь

?

]^ { ~£

o u

:

*) The following characters have been modified as compared to the

IBM character set No. 437:

39

Character set: ASCII and cyrillic

it means:

1.Column = ASCII / 2. Column = cyrillic / 3. Column = Hexadecimal

40

8.3. Details of Printer Control Commands

8.3.1. Short View of Control Commands

Print Character Commands (Section 8.3.2.)

ESC % n Specifies/clears download character set

ESC - n Specifies/clears underline

ESC V n Specifies/clears character rotation

GS ! n Specifies character size

Print Position Commands (Section 8.3.3.)

ESC $ nL nH Specifies absolute position

ESC D Specifies horizontal tab position

Bitmap image Commands (Section 8.3.4.)

ESC * m nL nH Specifies column bitmap image

ESC A* nL nH Specifies raster bitmap image

GS * x y Defines download bitmap image

GS / m Prints download bitmap image

Line Feed Commands (Section 8.3.5.)

ESC 2 Specifies initial line feed

ESC 3 n Specifies line feed

Barcode Commands (Section 8.3.6.)

GS H n Selects print position of HRI character

GS h n Sets barcode height

GS w n Sets width of barcode

GS k m / GS k m n Prints barcode

Specifies /

clears

character

rotation

8.3.2. Print Character Commands

Comm an d s: ESC V n

<< Code >>

0x1B , 0x56, n (0≤n≤3 , 48≤n≤51 , initial value n=0)

<< Function >>

Specifies or clears character rotation.

The definition of parameters is as follows

n Function

0, 48 Cancels rotation

1, 49 Specifies 90-degree rigth rotation

3, 51 Specifies 90-degree left rotation

41

<< Details >>

Specifies 180-degree rot ation (Inverse-Print)

see section 6.1.

Rotated characters are not underlined even if character

rotation is specified (ESC !), (ESC -) or (FS -).

If a 90-degree right or left rotation is specified , the vertical

and horizontal magnifications of a character specified

before the rotation is reversed.

Specifies /

clears

underline

Command: ESC - n

<< Code >>

0x1B , 0x2D, n (0≤n≤2 , 48≤n≤50 , initial value n=0)

<< Function >>

Specifies or clears an underline

n Function

0, 48 Clears underline

1, 49 Sets a 1-dot wide underline and

specifies an underline

2, 50 Sets a 2-dots wide underline and

specifies an underline

<< Details >>

Rotated characters (ESC V) are not underlined.

If the underlining of characters is cleared with n=0 or

n=48, subsequent data are not underlined but the

previously set under size is retained. In addition,

a one-dot underline is set by default.

The size of an underline is the same for all character

sizes as specified.

Specifies

character size

42

Command: GS ! n

<< Code >>

0x1D , 0x21, n

(0≤n≤255 , 1≤ vertical magnification ≤ 8 ,

1≤ horizontal magnification ≤ 8 , initial value n=0)

<< Function >>

Specifies character size ( vertical and horizontal

magnification)

Bit Function Value

01

0

1 vertical

2 magnification see T able 2

3

4

5 horizontal

6 magnification see T able 1

7

T able 1 T able2

bit7 bit6 bit5 bit4 Magnification bit3 bit2 bit1 bit0 Magnification

0 0 0 0 1 (Std.) 0 0 0 0 1 (Std.)

0 0 0 1 2 (horizontal) 0 0 0 1 2 (vertical)

0 0 1 0 3 0 0 1 0 3

0 0 1 1 4 0 0 1 1 4

0 1 0 0 5 0 1 0 0 5

0 1 0 1 6 0 1 0 1 6

0 1 1 0 7 0 1 1 0 7

0 1 1 1 8 0 1 1 1 8

<< Details >>

This command is ignored if either a vertical or horizontal

magnification is outside the definable range.

In the standard mode, the vertical direction refers to the

direction of paper feed, and the horizontal direction the

direction right to the direction of paper feed. If characters

are 90-degree right or left are specified, the relationship

of the vertical and horizontal directions is reversed.

If characters with different vertical magnifications are

contained in the same line, they are aligned to the

baseline.

Specifies /

clears

download

character set

Command: ESC %n

<< Code >>

0x1B , 0x25 , n (0≤n≤255 , initial value n=0)

<< Function >>

Specifies or clears a download character set.

Only the lowest bit of n is effective. Download character

setting is specified if n=1 and cleared if n=0.

43

<< Details >>

Automatically specifies the internal character set if the

downloading of a character set is cleared.

8.3.3. Print Position Commands

Specifies

absolute

position

Sets

horizontal tab

position

Command: ESC $ nL nH

<< Code >>

0x1B , 0x24, nL , nH (0≤nL≤255 , 0≤nH≤255)

<< Function >>

Specifies the next print st art position as an absolute position

based on the left margin position.

The next print start position is (nL + nH x 256) dots away

from the left margin position.

<< Details >>

A print start position specified outside the print area is

ignored.

Command: ESC D n1 nk NULL

<< Code >>

0x1B , 0x44 , n1n

(k bites) , 00H (1≤k≤32 , 1≤n≤255)

k

Selects a tab position every 8 characters (at 9th point ,

17th point, 25th point ...), if the setting for character right

space = 0.

<< Function >>

Sets horizontal tab positions.

n refers to the number of points to the tab position from the

left margin or the start of the line.

k indicates the number of data of horizontal tab positions to

be set.

44

<< Details >>

A tab position to be set is (n x character width) from the

left margin or the start of the line. Character width includes

the right space of character (ESC SP), and increases in

proportion to the horizontal magnification of the character if

the magnification is larger than two.

Prints column

bitmap image

After this command is executed, the previously set

horizontal tab positions are cleared.

If n=8 is set for horizontal tab position, the next print

start position is moved to the 9th point by (HT: „Horizontal tab“).

The maximum allowable number of horizontal tab

positions is 32 (k=32). If this is exceeded, subsequent

data is treated as normal data.

Enter n1 nk for specifying tab positions in ascending

order. The data is ended with an 00H input. If n is equal

to or smaller than the previous value, the horizontal tab

setting process stops and subsequent data is processed

as normal data.

Use (ESC D NULL) to clear all horizontal tab positions.

Even if character width is changed after setting horizontal tab positions, the set horizontal tab positions are

retained.

8.3.4. Bitmap image Commands

Command: ESC *m nL nH d1 dk

<< Code >>

0x1B , 0x2A , m , nL , nH , d1 dk

where: m=0, 32, 0≤nL≤255 , 0≤nH≤3, 0≤d≤255

<< Function >>

Specifies a bitmap image in mode m for the number of dot s

specified by nL and nH.

m Mode No. of No. of

vertical dots Data (K)

0 8-dot single density 8 dots nL+nHx256

1 8-dot double density 8 dots nL+nHx256

3 2 24-dot single density 24 dots (nL+nHx256)x3

33 24-dot double density 24 dots (nL+nHx256)x3

<< Details >>

Processes the data after nL as normal data if m is

outside the definable range.

nL and nH denote the number of horizontal dots of the

bitmap image to be printed, which is (nL+nHx256).

45

If bitmap image data exceeding the number of printable

dots in a line is entered, the excess data is discarded.

d denotes bitmap image data. The bit for the dot to be

printed is „1“ and the bit the dot not to be printed is „0“.

Returns to normal data processing after bitmap image

processing.

Has no effect on print modes (underline, character size)

excluding NORMAL.

Prints the entered bitmap image magnified three times in

the vertical direction if m=0 or 1 (8-dot mode) is specified

and two times in the horizontal direction if m=0 or 32

(single density mode) is specified.

The data format of a bitmap is as follows:

Bitmap-Data format

Dot Col.1 Col.2 Col.n

1 MSB

: d1 d4 .... d 3n-2

8

9

: d2 d5 .... d 3n-1

16

17

: d3 d6 .... d 3n LSB

24

Prints raster

bitmap image

46

d 3(n+1)-2 d 3(n+2)-2 .... d 6n-2

d 3(n+1)-1 d 3(n+2)-1 .... d 6n-1

d 3(n+1) d 3(n+2) .... d 6n

Command: ESC A* nL nH d1 dk

<< Code >>

0x1B , 0x41 , 0x2A , nL , nH , d1 dk

where: 0≤nL≤255 , 0≤nH≤255, 0≤d≤255

<< Function >>

Specifies the raster bitmap image specified with

(nL + nH x 256) lines in the vertical direction.

<< Details >>

This command is effective only if this command is

entered at the start position of a line in the standard

mode.

d refers to bitmap image data. The bit for the dot to be

printed is „1“ and the bit for the dot not to be printed is

„0“.

The required number of image data per line is as follows

depending on the number of heating elements in the

head:

dots of heating element 192 dots 288 dots 384 dots 576 dots

No. data per line 24 bytes 36 bytes 48 bytes 72 bytes

The required total number of bitmap image data is

((nL + nH x 256) x no. of data per line) bytes.

The format of bitmap data for a printer with n heating

elements in the head is as follows:

MSB LSB

d1 d2 d3 ...... d (n/8)

d (n/8)+1 d (n/8)+2 d (n/8)+3 ...... d (2n/8)

d (2n/8)+1 d (2n/8)+2 d (2n/8)+3 ...... d (3n/8)

:

:

.......

d (nL+nHx256)x(n/8)

47

Defines

download

bitmap image

Command: GS * xy [d1] ... [d]x X y X 8

<< Code >>

0x1D , 0x2A , x , y , [d1] [d]x X y x 8

where:

0≤x≤255

0≤y≤48, where: x X y≤1536

0≤d≤255

<< Function >>

This command downloads bitmap image into the font ROM,

for example logos. The parameters x and y define the

dimension of the bitmap image.

<< Details >>

Frequent use of this command may cause damage to

the option font ROM. It is recommended to use this

command no more than 10 times a day .

The number of dots in the horizontal and vertical direction

is x X 8 dots and y X 8 dots respectively.

x specifies the number of dots in the horizontal direction.

y specifies the number of dots in the vertical direction.

d refers to bitmap image data. The bit for the dot to be

printed is „1“ and the bit for the dot not to be printed is „0“.

The relationship between a download bitmap image and

print data is as follows:

x X 8 dots

d1 d(y+1) ....

d2 d(y+2) ....

y X 8 dots : : :

: : :

dy d(2y) .... d(xXyX8)

Print

Command: GS / m

download

bitmap image

<< Code >>

0x1D , 0x2F , m ( 0≤m≤3 , 48≤m≤51 )

48

Bitmap image data

MSB

LSB

Sets initial

line feed

<< Function >>

Prints the defined downloaded bitmap image.

m specifies the required print mode.

m Print mode

0, 48 Normal mode

1, 49 Double-with mode

2, 50 Double-height mode

3, 51 Double-height/width mode

<< Detail >>

This command is ignored if download bitmap image data

is not defined.

Effective only when no data is contained in print buffer if

standard mode is selected.

Has no effect on print modes (underline, character size)

excluding NORMAL.

If the number of the defined download bitmap data

exceeds the print area, the excess data is not printed.

the maximum print width is 72 mm (576 dots per line).

8.3.5. Line Feed Commands

Command: ESC 2

<< Code >>

0x1B , 0x32

Sets

line feed

<< Function >>

Sets the amount of the initial line feed per line to 30 dots.

<< Details >>:

The amount of the initial line feed can be set separately

for the standard mode.

Command: ESC 3n

<< Code >>

0x1B , 0x33 , n (0≤n≤25 , initial value n=60)

<< Function >>

Sets the amount of line feed per line to n dot.

<< Details >>

Line feed can be set separately for the standard mode.

49

8.3.6. Barcode Commands

Selects

printing

position of

HRI character

Sets

barcode

height

Sets width

of barcode

Command: GS H n

<< Code >>

0x1D , 0x48 , n (0≤n≤3 , 48≤n≤51 , initial value n=0)

<< Function >>

Selects the print position of HRI characters when printing

a barcode.

<< Details >>

HRI refers to Human Readable Interpretation.

The HRI character font for barcode printing is fixed as

FONT A (12x24).

Command: GS h n

<< Code >>

0x1D , 0x68 , n (1≤n≤255 , initial value n=162)

<< Function >>

Sets barcode height to n dots.

Command: GS w n

<< Code >>

0 x 1D , 0 x 77 , n ( 2≤n≤6 , initial value n=3)

<< Function >>

Specifies barcode wid th.

Module width of 2-level-barcode

n multi-level-barcode Thin bar Thick bar

(dots) width (dots) width (dots)

2 2 2 5

3 3 3 9

4 4 4 11

5 5 5 14

6 6 6 18

50

<< Details >>

The multi-level-barcode refers to the following barcode

systems:

A) UPC-A

B) UPC-E

C) JAN13

D) JAN8

E) CODE93

F) CODE128

The 2-level-barcode refers to the following barcode

systems:

A) CODE39

B) ITF

C) CODABAR

Prints

barcode

Command: GS k m d1 dk NULL/GS k m n d1 dn

<< Code >>

0x1D , 0x6B , m , d1 dk 00H (0≤m≤6 , the definable

range of k and d varies with m.)

0x1D , 0x6B , m , n , d1 dn (65≤m≤73 , the definable

range of n and d varies with m.)

<< Function >>

Selects a barcode system and prints barcodes.

In the case of GS k m:

m Barcode-System Definable range of k Definable range of d

0 UPC-A fixed (11≤k≤ 12) 48≤d≤ 57

1 UPC-E fixed (11≤k≤ 12) 48≤d≤ 57

2 JAN13 (EAN) fixed (12≤k≤13) 48≤d≤ 57

3 JAN8 (EAN) fixed ( 7≤n≤ 8 ) 48≤d≤ 57

48≤d≤ 57

4 CODE39 variable (1≤ k) 65≤d≤ 90

32,36,37,43,45,46,47

5 ITF variable (1≤ k, even 48≤d≤ 57

number)

6 CODABAR variable (1≤ k) 48≤d≤ 57

65≤d≤ 68

36,43,45,46,47,58

51

In the case of GS k m n:

m Barcode-System Definable range of k Definable range of d

65 UPC-A fixed (1 1≤n≤ 12) 48≤ d≤ 57

66 UPC-E fixed (11≤n≤ 12) 48≤ d≤ 57

67 JAN13 (EAN) fixed (12≤n≤13) 48≤ d≤ 57

68 JAN8 (EAN) fixed ( 7≤n≤ 8 ) 48≤ d≤ 57

48≤ d≤ 57

69 CODE39 variable (1≤ n≤ 255) 65≤ d≤ 90

32,36,37,43,45,46,47

70 ITF variable (1≤ n≤ 255, 48≤ d≤ 57

even number)

48≤ d≤ 57

71 CODABAR variable (1≤ n≤ 255) 65≤ d≤ 68

36,43,45,46,47,58

72 CODE93 variable (1≤ n≤ 255) 0≤ d≤ 127

73 CODE128 variable (2≤ n≤ 255) 0≤ d≤ 127

<< Details >>

In the case of GS k m:

This command is terminated by the NULL code.

In the case of UPC-A and UPC-E, after 12 bytes of

barcode data are entered, the barcode is printed, and

subsequent data is processed as normal data.

In the case of JAN-13, after 13 bytes of barcode data are

entered, the barcode is printed, and subsequent data is

processed as normal data.

In the case of JAN-8, after 8 bytes of barcode data are

entered, the barcode is printed, and subsequent data is

processed as normal data.

The number of data of an ITF barcode must be an even

number. If is an odd number , the last dat a is ignored.

After the number of input data reaches 255, the

processing of the command starts automatically .

In the case of GS k m n:

n denotes the number of data. n bytes of subsequent

data are processed as barcode data.

If n is outside the definable range, the processing of the

command stops, and the subsequent data is processed

as normal data.

52

In the case of standard mode:

If d is outside the definable range, only paper feed is

executed, and subsequent data is processed as normal

data.

If the barcode width exceeds the print area of one line,

the barcode is not printed, and only paper feed is

executed.

Regardless of the amount of line feed specified by the

following commands, the paper is fed by the amount

equal to the barcode height (including HRI characters if

HRI character print is specified):

* (ESC 2:“ Sets initial line feed“)

* (ESC 3:“Sets line feed“)

Effective only if no data is contained in the print buffer . If

data is contained in print buffer , the data af ter m is

processed as normal data.

Moves the print position to the start of the next line after

barcode print is completed.

Has no effect on print modes (underline, character size)

excluding NORMAL.

53

8.4. Connection Examples for

Gossen Müller & Weigert instruments

8.4.1. Connection of the IPP 144-40 GE to the DPM-MF

for the insertion of measured value into texts

For this configuration you must input and save the text as shown in section

7.4.1. of this manual.

The printer receives the measuring values via interface I / RS 232 C (also

possible via interface II). T o selected the text see section 7.4.2 in this manual.

The relevant interface is the interface for which the parameters have to be set

in the menu program. The recommended configuration is: 8 data bits, no

parity , 1 stop bit, 9600 baud. With 7 bit, no parity, the sender must be set to

2 stop bits.

DPM...MF

TxD

CTS

GND

OC 1

OC 2

3

4

2

IPP 144-40 GE

RxD

8

RTS

Interface 1

1

5

GND

5

Sign.

GND

6

7

54

8.4.2. Connection of IPP 144 - 40 G with a DAA

message display to print fault messages

Messages can be sent by all DAA type B and C versions.

(The A version DAA are not capable of outputting data but

only of displaying them since there is only one serial interface

available which is used to receive data).

The connection of the printer is made via the interface II

(RS 232 C) of the DAA. The printout is normally triggered by

a control device (e.g. a PLC) with a strobe signal (strobe T)

via the terminal strip for control inputs (parallel interface) at

the DAA.

Strobe T

DAA

TxD

CTS

GND

2

5

2

8

1

7

5

RxD

RTS

GND

Sign.

GND

IPP 144-40 G

Interface RS - 232 C:

DAA 144 - 120 B: 9 pin D - SUB 9 pin D - SUB

DAA 288 - 120 B: 25 pin D - SUB

DAA 288 - 240 B, C: 25 pin D - SUB

The required connection cable is available as an accessory .

55

8.5. Examples for Automatic text Insert mode

Example 1:

Consignment

print-out, with

time & date,

marks and

weights

Example 2:

Quality test

print-out, with

several

measured

value

Data input:

10:15:33 15/10/03 <CR>1<CR> 123 <CR> 1 <CR> 1027<CR> 997 <CR> 30 <CR>

Actual Print-out: Pre-stored texts

10:15:33 15/10/03 1 ✴✴✴✴✴✴

Product Ref: 123 2 Product Ref: ✴✴✴✴✴✴

Operator No: 1 3 Operator No: ✴✴✴✴✴✴

Gross: 1027 kg 4 Gross: ✴✴✴✴✴✴

Nett: 997 kg 5 Nett: ✴✴✴✴✴✴

Tare: 30 kg 6 Tare: ✴✴✴✴✴✴

Six blocks of data are inserted and printed in sequence.

(„✴“ = spaces reserved for

variable data)

In this example, the IPP..GE automatically adds date & time from

its own real-time clock using the „PRINT DATE / TIME-HEADLINE“

menu option. Four blocks of variable data are sent to the printer.

Data input: 115<CR> 33.7<CR> 62.8<CR> 228.7<CR>

Actual Print-out: Pre-stored texts

13.10.03 13:49:52

Metrix Electronics Ltd. 1 Metrix Electronics Ltd.

Rankine Road, Daneshill West 2 Rakine Road, Daneshill West

GB-Basingstoke RG24 8PP 3 GB-Basingstoke RG24 8PP

T est Number: 1 15 5 Test Number: ✴✴✴✴✴✴

- - - TEST RESULTS - - - 6 - - - TEST RESULTS - - Ambient T emp 33.7 ° C 7 Ambient T emp ✴✴✴✴✴✴°C

Burn-in T emp 62,8 °C 8 Burn-in-Temp ✴✴✴✴✴✴°C

Nom. Supply 230 Vac 9 Nom. Supply 230 Vac

Actual 228.7 Vac 1 0 Actual ✴✴✴✴✴✴Vac

4

Example 3:

A simple way

to print a

group of texts

56

This mode can be used to print a group of texts, triggered by a

single <CR> input, even if no variable data is required to be

inserted.

NOTE: Text No. 7 is only pre-programmed with a variable data field.

Actual Printout: Pre-stored texts

15.10.03 10:34:53

Manufactured by:: 1 Manufactured by:

2

Metrix Electronics Ltd. 3 Metrix Electronics Ltd.

Rankine Road, Daneshill West 4 Rankine Road, Daneshill West

GB-Basingstoke RG24 8PP 5 GB-Basingstoke RG24 8PP

__________________ 6 _________________

7 ✴✴✴✴✴✴

All the texts up to Text No. 6 (without variable fields) are printed. Text No. 7

(the first variable field) just prints a blank line. (If there was any variable

data sent before the <CR> this would be inserted and printed here.)

II Paper reroll mechanism IPP - AW

1. General information

The IPP-AW is a paper reroll mechanism designed for use with the Thermal

Graphics Printer IPP 144-40 G. It has been designed to match the printer in

colour and style. It is preferably installed directly underneath the printer . The

printed paper is automatically wound on a drum by a motor. A front p anel

draw allows easy paper handling.

The paper reroll mechanism is a DIN size panel mounting unit. It is supplied

with power and controlled via connector cable which comes with the unit and

which is connected to connector 12 of the IPP 144-40 G (see chapter 3.). An

LED indicates the ready status. Depending on the distance beween the two

devices at least the last 9 lines printed remain visible.

57

Design

Installation

Front Rear

1 Status indicator 2 Opening for paper feed

3 Handle 4 Connector for connection

5 Mounting screws cable IPP 144-40;

6 Protective conductor connection (pin connections: Motor

(must be connected to ground) control, +5V, open, GND)

58

The paper reroll mechanism is inserted into the DIN size

panel cutout from the front side and is clamped against the

rear of the switchboard using the mounting screws. The

switchboard thickness must not exceed 12 mm.

Make sure that the unit is properly mounted

before connection and power on.

2. Technical data

Winding

Ambient

conditions

Standards

Miscellaneous

Connection

Motor with friction clutch, electronic lag 3 sec

Paper width: max. 80 mm

Paper length: max. 15 m

Store temperature range: -20 °C to +80 °C

Operating temperature range: 0 °C to +70 °C

Climate: relative humidity

< 80 % up to 31 °C

Protection type housing: IP 50 acc. to

EN 60528/VDE 0470

Mech.strength: T o IEC 1010

Safety: EN 61010-1:2001

CA TIII >150V≤300V

Pollution degree 2

EMC

Susceptibility: DIN EN 610004-1

to EN 610004-4

Emission: DIN EN 50081-2

Class B

Dimensions (WxHxD): 144 x 72 x 159 mm

Connector: MASCON female

multi point connector,

4 pin keyed

Connector cable: AWG 26,

approx. 100mm

Power supply: by IPP (5 V DC)

Maintenance

friction

clutch

CE

The torque of the friction clutch has been factory adjusted

and should not require adjustment.

The winding force of the motor can be adjusted by slightly

rotating the screw accessible through the left hand side

hole in the body:

➨➨

➨ less = turn left

➨➨

➨➨

➨ more = turn right

➨➨

59

3. Operation

Removing

the paper

Inserting

the paper

60

➨➨

➨ Use the handle (4) to pull out the front panel (1).

➨➨

➨ Remove the holder (3) with the paper from roll body,

rotate the notch of the holder as show in the diagram.

➨ Remove the paper drum from the holder.

➨ Wind the paper once around the drum body (2) in the

direction indicated by the arrow.

➨ Plug in the holder (3) in such a way that the pins fit

into the notches of the body .

➨ Close the front panel.

➨ Briefly press the „LINE FEED“ key at the

IPP 144 - 40 G until the paper has been straightened

out.

III Accessories

◆◆

◆ Paper reroll mechanism IPP - A W

◆◆

(incl. connection cable).

◆ Protection cover for use of IPP 144-40 G with IPP-A W,

Protection class: IP 64.

Dimensions: 155 x 155 [mm].

Material: Plexiglas and

Santoprene 101-80 rubber

◆ Connection cable for serial data transmission

to the following devices:

IBM-PC XT and A T or compatibles

Siemens PG 685 (V 24)

Siemens PG 675 / 685 (printer interface)

Siemens GP270 /TP270/MP370 TOUCH(RS232C)

(printer interface)

Message displays:

DAA 144-120B / 288-120B / 288-240B, C

others on request.

Connection cable for USB-interface:

USB-A connector - USB-B connector

◆ Windows programming software for IPP 144-40 GE version (CD-R)

61

GOSSEN Müller & Weigert

Kleinreuther Weg 88

D-90408 Nürnberg

T el.: 091 1/3502-0 Fax: 091 1/3502-307

E-mail: info@g-mw.de http://www .g-mw .de

We reserve the right to make alterations! 09.05 Order no.: 27866 88137

Loading...

Loading...