GMV SPA

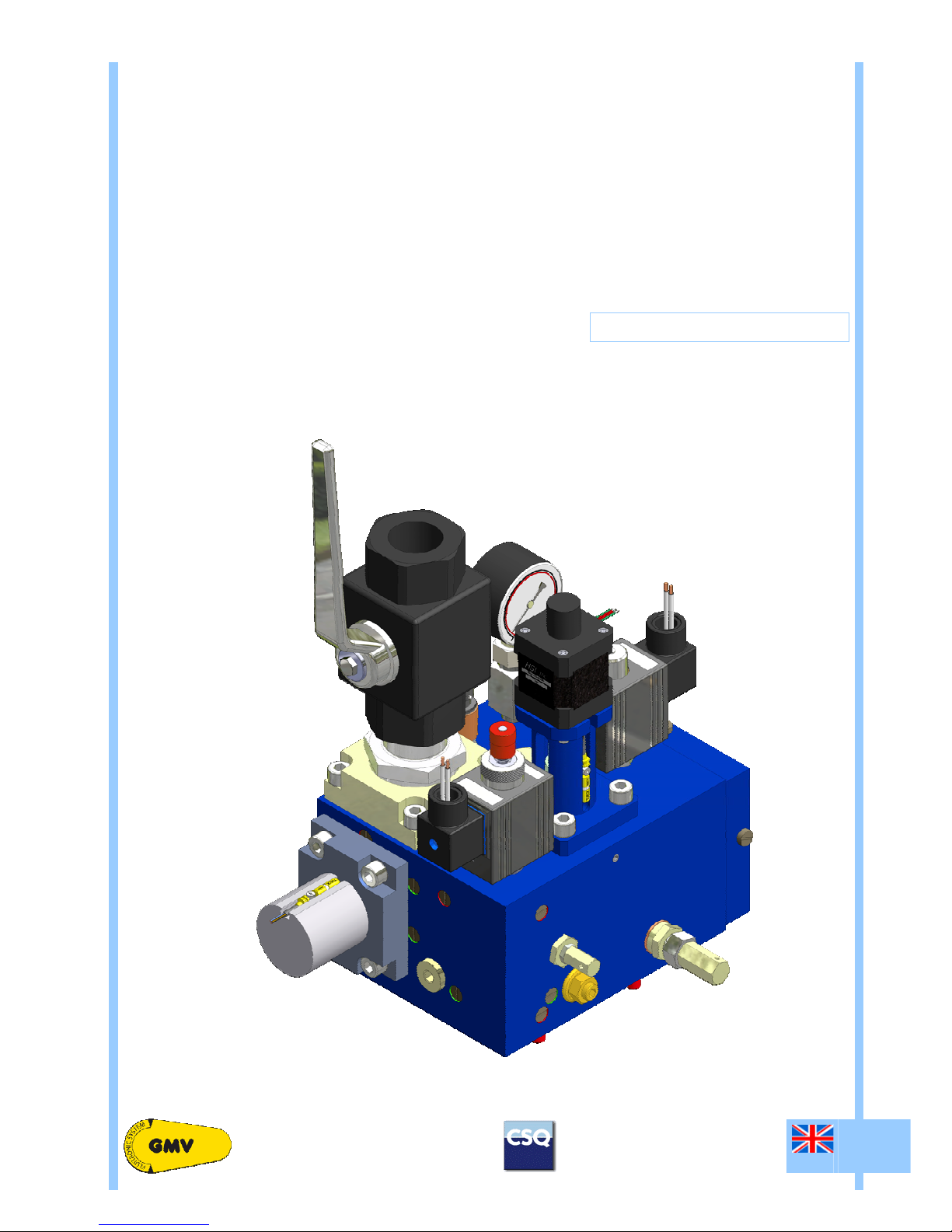

FLUID DYNAMICS EQUIPMENTS

AND COMPONENTS FOR LIFTS

UNI EN ISO 9001

Certified Company

1.05

ENG

English

NGV A3 VALVE

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANACE

1 0991 483 EN

AVAILABLE WITH TANK TYPE

GL, F1, T2, T3, T4, MRL-T, MRL-H

1 0991 483 EN - 21.12.2011

ENG

1.05

2 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

INDEX

0 GENERAL SECTION 5

0.1 INTRODUCTION INFORMATIONS 5

0.1.1 DEFINITIONS 5

0.1.2 TERMS AND SYMBOLS USED 5

0.1.3 RULES REFERENCE 5

0.2 DOCUMENTS RELATED WITH INSTALLATION 5

0.3 SAFETY PRECAUTION DURING INSTALLATION 5

0.4 TOOLING 5

0.5 GENERAL ORDERS 6

1 FEATURES AND REQUIREMENTS 7

1.1 THE NGV A3 VALVE 7

1.2 THE FLUID 7

1.3 HOW THE NGV A3 WORKS 8

1.4 THE DOUBLE SAFETY 9

1.5 MAIN FEATURES 9

2 INSTALLATION OPERATIONS 10

2.1 HYDRAULIC CONNECTIONS 10

2.1.1 MINIMUM DIMENSIONS AND HOLES FOR POWER UNIT 10

2.1.2 INPUT AND OUTPUT -POWER UNIT SIDE 11

2.2 HYDRAULIC CIRCUIT 11

2.3 ELECTRICAL CONNECTIONS 12

2.3.1 CONTROL PANEL REQUIREMENTS 12

2.3.2 INTERVENTION TIME 12

2.3.3 FAULT SCHEMAS 13

2.4 OPERATIONS PRELIMINARY TO CONNECTION 13

2.5 SCHEMAS OF THE CONNECTIONS TO CONTROL PANELS 14

2.5.1 MAIN SCHEMA 14

2.5.2 CONNECTION SCHEMAS FOR SIGNALS 15

2.5.3 CONNECTION SCHEMAS FOR POWER 15

2.6 CONNECTIONS TO THE TERMINAL 16

2.7 CONNECTIONS TO THE CARD 16

2.8 CONNECTION OF HYDRAULIC PIPES 17

2.8.1 CONNECTION WITH FLEXIBLE HOSE 17

2.8.2 CONNECTION WITH A RIGID PIPE 17

3 NGV A3 CONTROL BOARD 18

3.1 ELECTRICAL FEATURES 18

3.2 PERFORMANCES 18

3.2.1 SIGNALLERS 18

3.3 CONNECTIONS 19

3.3.1 CONTROL PANEL INTERFACE 19

3.3.2 VALVE INTERFACE 20

3.3.3 USER INTERFACE 21

3.4 SIGNALS AND COMMANDS SEQUENCE 22

3.4.1 UPWARD DIAGRAM 22

3.4.2 DOWNWARD DIAGRAM 23

3.5 DECELERATION DISTANCES 24

4 ADJUSTMENTS AND TEST 25

4.1 ADJUSTMENT OF THE OVERPRESSURE VALVE (OPP/MPS) 25

4.2 RAM PRESSURE ON THE VSMA ADJUSTMENT 26

4.3 PIPE RUPTURE VALVE (VC) TEST 26

4.4 TEST OF DEVICES THAT PREVENT UNCONTROLLED MOVEMENT 26

4.4.1 PREREQISITES 26

0.1.1 26

4.4.2 TEST IN UP DIRECTION 27

4.4.3 TEST IN DOWN DIRECTION 27

4.5 TEST OF THE DOUBLE SAFETY SYSTEM 28

4.5.1 SIMULATION OF THE VRP FAULT 28

4.5.2 SIMULATION OF THE VB FAULT 29

4.5.3 TEST OF THE MONITORING SYSTEM 29

4.6 FAULT SIMULATION ON OUTPUT RDY AND RUN 30

4.6.1 TEST RUN ALWAYS ON 30

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

3 / 46

1.05

ENG

4.6.2 TEST RDY ALWAYS OFF 30

4.6.3 TEST RUN ALWAYS OFF 30

4.6.4 TEST RDY ALWAYS ON 30

4.6.5 EXIT RUN-RDY TEST 30

5 PROGRAMMING 31

5.1 SYSTEM PARAMETERS 31

5.2 COMPLETE MENÙ 32

5.3 MENÙ 33

- 1 - DIAGNOSTICS 33

- 2 - ALLARM 33

- 3 - ALARM AND FAULT RESET 33

- 4 - ADJUSTMENTS 34

- 5 - SETTINGS 35

- 6 - UPWARD PARAMETERS 36

- 7 - DOWNWARD PARAMETERS 36

- 8 - OUTPUT FUNCTIONS 37

- 9 - TEST 37

- 10 - ADVANCED PROGRAMMING 38

5.4 CHART OF OUTPUT PROGRAMMABLE FUNCTIONS 38

5.5 CHART OF FAILURES 39

5.6 ACCESSORIES 39

6 MAINTENANCE AND FAULT ANALYSIS 40

6.1 PROGRAMMED MAINTENANCE 40

6.2 PERIODICAL MAINTENANCE AND CHECKS TABLE 40

6.3 MAINTENANCE SCHEDULES 40

6.4 FAULT ANALYSIS 42

6.4.1 TROUBLESHOOTING 43

6.5 ADJUSTING THE SENSORS 45

6.5.1 SENSOR S1 45

6.5.2 SENSOR S2 45

6.5.3 SENSOR S3 45

7 CERTIFICATES 46

ENG

All rights reserved.

Any kind of exploitation in any form and by any means is forbidden without a written permission of GMV Spa.

GMV Spa, within technical or manufacturing progress, reserves the right to modify parts or this manual without notice.

Drawings, descriptions and data included in this manual are indicatives.

For all the data not included in this manual refer to the documents of any single part.

To guarantee the products security, do not use spare parts not genuine or not approved by GMV Spa.

GMV Spa will not assume any responsibility if the instructions included in this manual are not observed.

/c2

DT 21/12/2011

2C

CR 21/12/2011

2c6

GF 21/12/2011

Information and support:

FLUID DYNAMICS EQUIPMENTS AND

COMPONENTS FOR LIFTS

UNI EN ISO 9001

Certified Company

GMV SPA

Via Don Gnocchi, 10 - 20016 PERO – Milano (Italy)

TEL. +39 02 33930.1 - FAX +39 02 3390379

http://www.gmv.it - e-mail: info@gmv.it

1 0991 483 EN - 21.12.2011

ENG

1.05

4 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

Main acronyms and abbreviations

# Description

1

Pressure safety valve adjustment (pressure limiter)

2

Pressure safety valve adjustment (hand pump)

3

Ram pressure adjustment (only 2:1 acting jacks)

4

Shut-off valve for pressure gauge exclusion

5

Screw for rupture valve test

AF

Valve to prevent ropes slacking

BOX

Interface box (NGVA3 / Control panel)

C1

Chamber of the VRP

C2

Inlet chamber

C3

VB outlet chamber

C4

Chamber of the VRP pilot spool

CARD

NGV A3 control card

D

Downward signal

DN

Downward

FLT

Filter

ISP

Inspection gauge fitting

J

Jack

K

Non-return valve

M1

Spool of the VRP

MAN

Pressure gauge

ML

Manual lowering button

M, MP

Motor / pump

MPS

Maximum pressure spool

NGV-A3

NGV A3 Valve (Complete)

OFF

Not powered

ON

Powered

OPP

MPS pilot valve

P

VRP pilot spool

PAM

Hand pump

PT

Pressure transducer

RDY

Ready - Ready signal (card output to control panel)

RO

Oil heating resistance

RT

Motor thermistors

RUN

Run - Start signal (card output to control panel)

S1 (VRP)

Sensor to control the VRP closing

S2 (VBC)

Sensor to control the VB closing

S3 (VBO)

Sensor to control the VB opening

SM

Stepping motor

TO

Oil thermostat

TT

Temperature transducer

UP

Upward / Up - command of starting upward (card to control panel)

V0

Speed : high

V1

Speed : medium

V2

Speed : inspection

VAL

Valve NGVA3 (Valve only)

VB

Main flow adjustment valve

VC

Rupture valve

VMD

Downward solenoid valve

VR

Non-return valve (flow)

VR1

Non-return valve (inlet)

VR2

Non-return valve (outlet)

VRP

Non-return valve - controlled

VS

Upward signal

VS1, VS2

Pressure safety valve

VSMA

Lowering valve manual / electrical

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

5 / 46

1.05

ENG

0 GENERAL SECTION

0.1 INTRODUCTION INFORMATIONS

0.1.1 DEFINITIONS

In this manual are used the definitions in EN81-1, EN81-2: Safety rules for the construction and installation of

lifts, EN81-28: Remote alarms on passenger lifts, EN1050: Safety of machinery - Principles for risk

assessment, ISO3864: Safety colours and safety signs, and the following apply:

0.1.2 TERMS AND SYMBOLS USED

NOTE

Indicates information which contents must be seriously taken in consideration.

WARNING

Indicates that the described operation is likely to cause, damages to the system or physical damages

if performed without complying with the safety standards.

0.1.3 RULES REFERENCE

For all definitions not included in this manual please refer to rules and local laws in force, following,

particularly:

EN 81-2: Safety rules for the construction and installation of lifts,

EN 1050: Safety of machinery - Principles for risk assessment,

ISO 3864: Safety colours and safety signs.

0.2 DOCUMENTS RELATED WITH INSTALLATION

The documents to use for the installation are those required by the EN81-2:1998 and by the rules in force,

particularly the following:

- THIS INSTALLATION MANUAL

- WIRING AND HYDRAULIC DIAGRAMS (EN81-2:1998 16.2 A) 6 AND 7).

All the documentation for a correct and safe installation, must be stored by the installation responsible.

Please remember that this documentation is considered part of the plant and must be complete, well stored

and unabridged in every part.

In order to maintain the readability, the documentation shouldn’t be damaged and shouldn’t have missing

parts. Moreover, do not tear or deteriorate sheets during consulting.

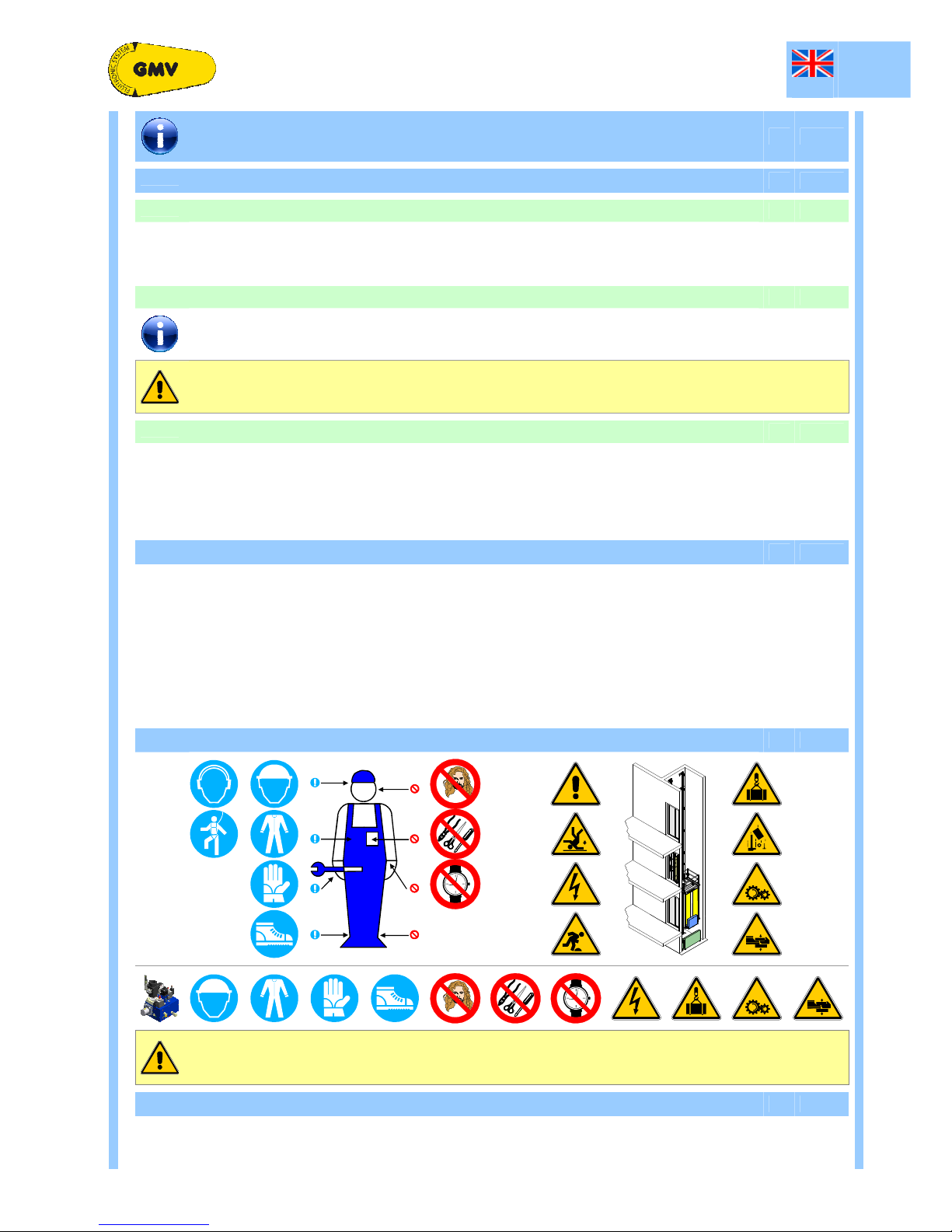

0.3 SAFETY PRECAUTION DURING INSTALLATION

WARNING

Before start all kind of installation operation.

ALWAYS verify that al the safety devices, mechanical or electrical, are active and working properly.

0.4 TOOLING

Use standard building-yard tooling for the installation.

1 0991 483 EN - 21.12.2011

ENG

1.05

6 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

0.5 GENERAL ORDERS

The valves shall be maintained in good working order in accordance with the European Standards.

To this effect, regular maintenance of the installation shall be carried out, to ensure, in particular, the safety

of the installation.

The safety of an installation shall take into account the ability to be maintained without causing injury or

damage to health.

Regular maintenance of the installation shall be carried out to ensure the reliability of the installation.

The access and the associated environment shall be maintained in good working order.

The competence of the maintenance person within the maintenance organization shall be continuously

updated.

NOTE

We inform the owner of the installation that the qualification of the maintenance organization needs to

be in conformity with the rules applicable in the country in which the installation operates; if no rules

exist, the qualification can be ensured by a certified EN ISO 9001 quality system supplemented if

necessary to take into account the specific features of the installation.

¥"

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

7 / 46

1.05

ENG

1 FEATURES AND REQUIREMENTS

1.1 THE NGV A3 VALVE

The NGV A3 Valve with:

· the new Fluitronic digital technology.

· the “Stepping System” device

· the possibility to use ecological fluid or traditional mineral oil

· the working pressure between 12 and 45 bar

Guarantees :

- Increased reliability of the control system

- Best performance

- Reduction of costs

- Reduction of the installed power (up to 20%)

- Reduction of consumptions up to 40% (*)

- Reduction of the travel time

- Reduced use of heat exchangers

- Constant downward speed regardless of the load

- Compliance with various regulatory and environmental requirements

(Ex. compliance with the Directive 2006/118/EC on the environment)

- More safety thanks to double lock, already integrated in the product

conforms to the rule EN 81-2:2010

Offer:

- Ideal solution for renovation and MRL systems

- The most advanced system of control for lift

- Technology in line with the latest trends in the control field

- Speed up to 1 m/s

- Downward speed greater than the upward up to +20%

- Ride comfort comparable to a VVVF electric and no consumption in

standby mode

- Maintenance speed adjustable

(*) Maximum value reached under optimal conditions and in combination

with other products GMV

- The driving option

INTERNAL FEED BACK (CAR LOAD / TEMPERATURE)

The choice to immediate savings, interfaced with all, existing and

new systems

Not require encoder, reduce consumption up to 20% *

The valve, stored the operating characteristics, reading changing of

pressure and temperature, make the appropriate corrections to

obtain car speed profiles with low deviations from the ideal profile.

* Compared to a traditional valve

1.2 THE FLUID

GMV use and recommend an hydraulic fluid ISO VG 46 that :

· Thanks to classification as category HEES, as rule ISO-UNI 6743-4 and

its biodegradability index > 90%, according to standard CEC L33-A93, is acceptable from an environmental point of view.

· Thanks to the synthetic base (ISO VG 46 ) and its viscosity index

(>140), higher than the traditional mineral oil, allowing greater stability,

ensuring better performance against wear and aging on systems as

lifts for persons and goods, in accordance with the environmental

directive 2006/118/EC.

· Thanks to a flash point above 220°C compared to the 140°C of the

traditional mineral oil it is safer and reduces the risk of fire.

1 0991 483 EN - 21.12.2011

ENG

1.05

8 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

1.3 HOW THE NGV A3 WORKS

The valve NGV is made with a non-return valve VR, a control spool VB controlled by a stepping motor and by

a system with pilot operated non-return valve VRP - P

(moved in opening by the electro-valve VMD)

Valve VR

It is a valve that prevent , during the downward, the oil inlet to the pump.

It forces the oil that comes from the VRP C2 to pass through the spool VB and then in the

C3 and in the tank T1.

Valve VRP-P

It is the pilot operated non-return valve, requested by rules.

During upward the valve works only as ON/OFF, the spool VRP opens or closes

depending on the oil that comes. Its position is determined by the ratio between the

pressure that develops in the chamber C2 and the one that occurs in chamber C1

During downward, instead, it opens the oil way to the valve block (chamber C2).

Its opening is made by the pushing of the piston P that is opened by the pilot operated

valve VMD

Spool VB

It’s the main part of the control block.

It adjusts the oil quantity that should be discharged and determines all the movements of

the car

Its movement is controlled by a stepping motor coupled to the spool VB, through a screwnut coupling (necessary to transform the rotatory motion into translatory).

The spool adjusts both the upward phase (with a direct control of the oil that should be

discharged and, indirectly the oil for the cylinder) than that of downward (directly)

All the other valves have features of safety, pilotage, etc. For example :

MPS+OPP

Maximum pressure valve with pilot

5

Overspeed screw

VSMA

Emergency lovering valve

S1

S3

VMD

J

VB

VSMA

3

PT

FLT

VR

P

C4

C2

S2

C1

M1

OPP

MPS

C3

T1

VRP

5

BHBLS

505152

V-VSV0V1V2V3V+

A+PEA-A-

D+D-E+E-

1

3

NGV-A3-01

EXP VMD

D-E+E-

111221223132

4142

X14

X15

X12 X11 X10 X9 X8

X7

X13

A-

+ - T+ T- P+ P-+ -+ -

X1

X3

X4 X6X5

X2

J2 J3

J6

J1

131

3

SM

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

9 / 46

1.05

ENG

1.4 THE DOUBLE SAFETY

For the double safety the system has two spools in series, the VRP and the VB.

Both work together to stop the car in different ways between upvward and downward

UPWARD

The spool VB controls acceleration and deceleration.

During the approach to the landing, the spool VB, will be almost fully open to discharge a quantity of oil

equal to:

Qt = Qp - Qc

where

Qt = Oil sent to the drain through the VB, Qp= Pump flow

Qc= Flow to the cylinder, corresponding to the car speed

The car stop at the landing is made by opening completely the VB and bringing the value of Qt = Qp. As a

result Qc becomes zero.

The car stops when the pressure of the chamber C2 become equal to the pressure of the chamber C1

(Static pressure of the system). In this case,

the VRP spool closes, because is pushed by the pressure and

by the spring, and the car stops at the landing.

DOWNWARD

The downward phase is simpler and, after the opening of the VRP spool, the car speed is controlled by the

VB spool. To a more opening of the spool corresponds an higher speed of the car

The phase of arrival at the landing is determined by the following events:

The VRP spool is opened by the push of the spools P, controlled by the VMD pilot valve

The VB spool closes to stop the car

The VMD valve, raised the landing, is de-energized and consequently the VRP spool closes.

During standard operation of the system, both upward and downward, the proper working of the two

spools (VRP and VB) acting in series, is controlled by three switches :

One, (S1) installed on the VRP, to control the full close position.

Two (S2, S3) installed on the VB, to control the full close and the full open positions

During all phases the system control that the spools reach the correct open and close position.

If this do not happen, the system send an alarm to the control panel, which must turn the system into the

out of service status

WARNING

Needful prerequisite of the control panel, when the system is outside of the doors unlocking zone, is

that it does not send commands to the card and/or the motor / pump.

1.5 MAIN FEATURES

Valve Type

NGV A3

Minimum operating pressure

12 bar

Maximum operating pressure

45 bar

Test speed

1 m/s

Temperature operating range

5°C - 70°C

Rated pump flow range

55 - 300 l/min

¥"

1 0991 483 EN - 21.12.2011

ENG

1.05

10 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

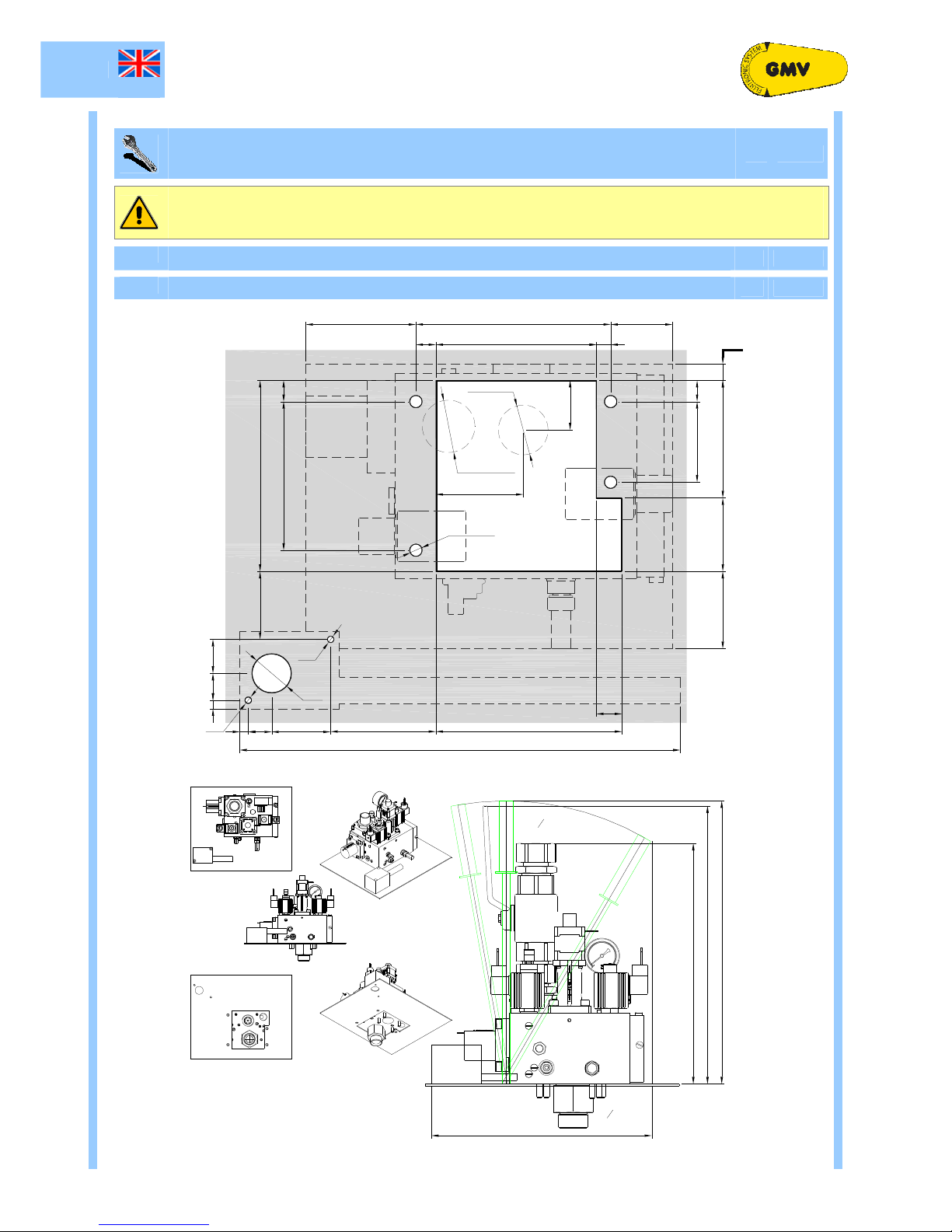

2 INSTALLATION OPERATIONS

ATTENTION

During the installation never exclude the safety devices and never connect the motor/pump directly to

the power supply

2.1 HYDRAULIC CONNECTIONS

2.1.1 MINIMUM DIMENSIONS AND HOLES FOR POWER UNIT

135

113

8352

131

18

14

105

137

15

10

1557

Ø9 x 4 fori

35

61.5

Ø28

M6

M6

16.5 41.5

19

24

48

74

1"1/4 G IN

1"1/4 G OUT

11.5

54.5

43.577.5

6

6

310

340

393

310

400

1"

1

4

IN

1"

1

4

OUT

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

11 / 46

1.05

ENG

2.1.2 INPUT AND OUTPUT -POWER UNIT SIDE

1"

1

4

OUT

M8

OUT

1"

1

4

IN

M8

OUT

M8

OUT

M8

OUT

M8

OUT

3

4

"

OUT

12x8

PAM

PAM 12x8 IN 1” ¼ OUT 1” ¼ OUT ¾” OUT M8

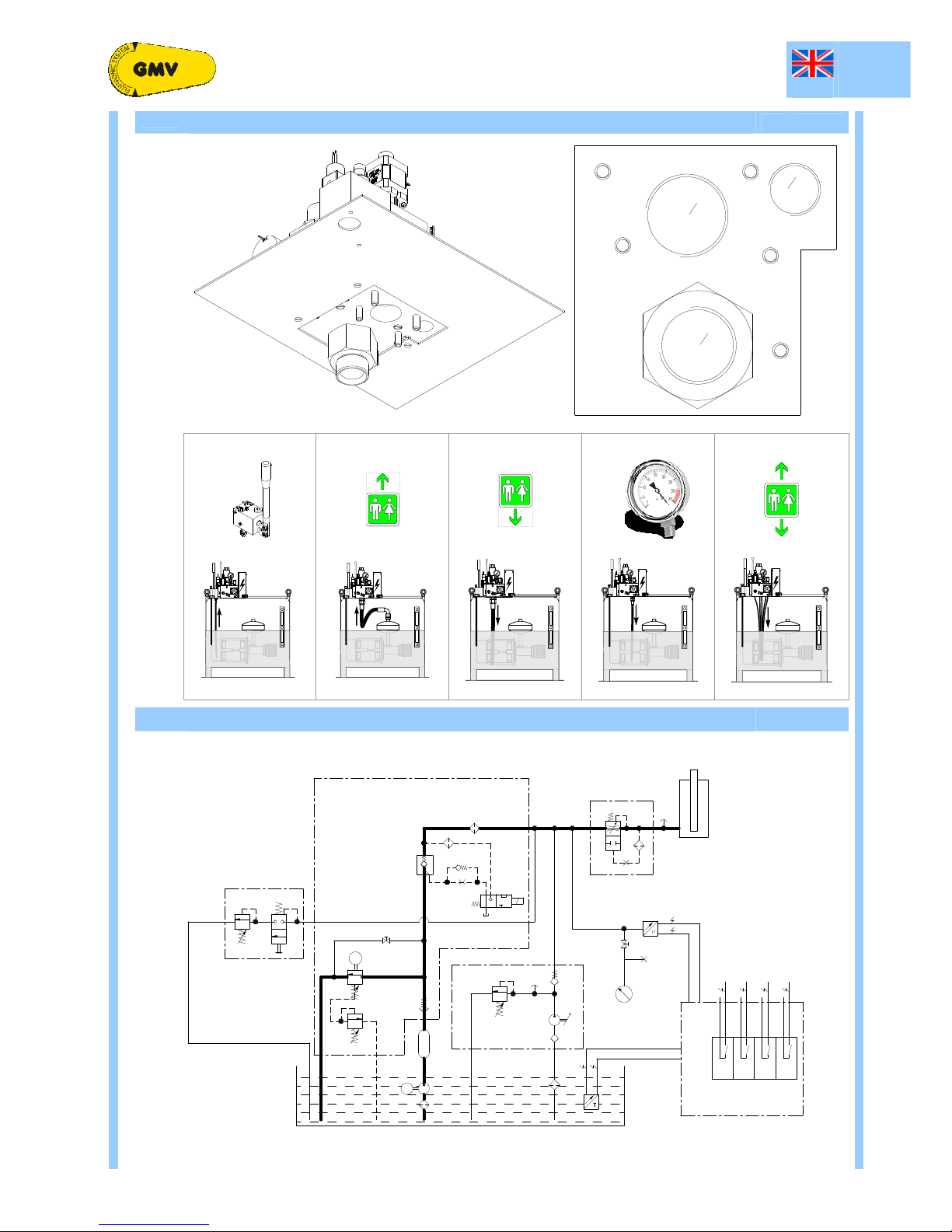

2.2 HYDRAULIC CIRCUIT

M

VS1

VB

VR1

VR

ML

VSMA

PAM

VR2

VS2

VC 3006/B

ISP

MAN

PT

4

2

1

5

3

SM

TT

VAL

CARD

J

NGV A3

VRP

K

VMD

1 0991 483 EN - 21.12.2011

ENG

1.05

12 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

2.3 ELECTRICAL CONNECTIONS

2.3.1 CONTROL PANEL REQUIREMENTS

The control panel must send to the power unit at least the following signals:

Mark Signal/comand Features

VS

Upward signal

10…40mA 12…48Vdc

V0

Speed : High

10…40mA 12…48Vdc

V1

Speed : Medium

10…40mA 12…48Vdc

V2

Speed : Inspection

10…40mA 12…48Vdc

D+

Downward signal

12…48Vdc, 60…180Vdc

D-

Downward negative pole

12…48Vdc, 60…180Vdc

The control panel must to receive and to understand correctly at least the following signals:

Mark Signal/comand Features

RDY

Ready

10mA…2A

RUN

Run

10mA…2A

UP*

Up

10mA…2A

OVL

Overload

10mA…2A

*Command used only to interface control panels that need different signals to start upward or doward travels

Outputs RDY, RUN and UP

- report to control panel about the system state,

- determine when the control panel must start or stop the motor /pump

WARNING

The control panel, when receive a FAULT signal from the NGV-A3 card (RUN and RDY output),

should not send commando to the valve and/or the motor/pump

In FAULT condition the motor/pump group should NOT be active

WARNING

To detect the unintended movement of the car the system use the circuit required by paragraph 7.7.1

and 14.2.1.2 of the rule EN 81-2:2010. This circuit, if it detects a movement of the car, with doors not

closed, outside the unlocking zone, prevents the control panel to send any command to the valve.

The system restore should be performed only by an authorized and properly trained person.

· Distance of setting: ± 200 mm

· Maximum time for the intervention of the circuit 270 ms

For other data or signals sequence see next paragraphs of this manual

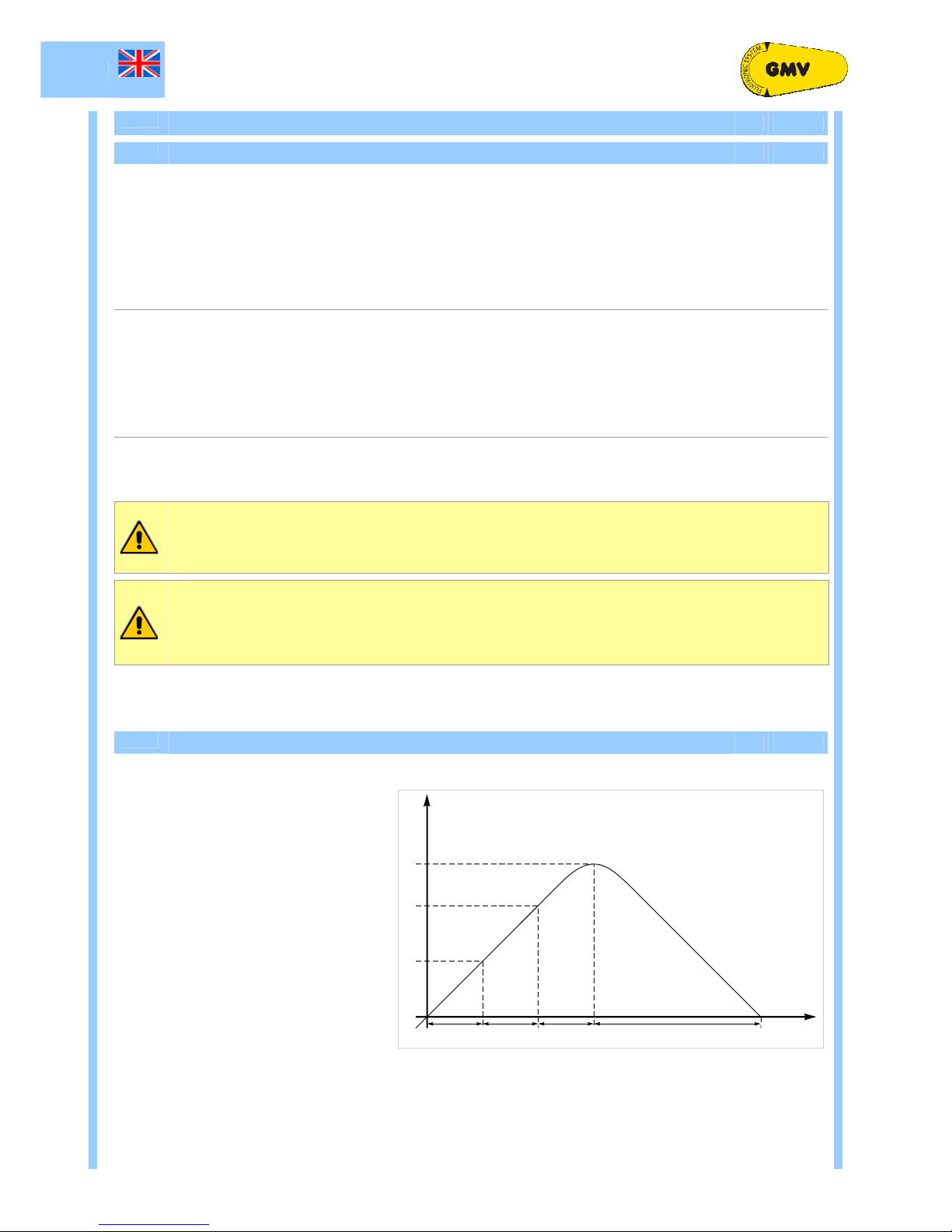

2.3.2 INTERVENTION TIME

0

Origin

1

Car speed in the instant of

intervention of the bracking

device ≤ 1,3 m/s

2

Speed

3

Response time of the device that

detects the unintended movement

of the car ≤ 270 ms

4

Response time of the braking

devices ≤ 200 ms

5

Time

6

Time from start of the unintended

movement to the instant in which

the car sensor leaves the doors

area (dimension = ± 200 mm)

7

Stoping time of the car ≤ 500 ms

8

Point in which the car stops

0-8 between 0 and 8 the maximum

distance travelled is ≤ 100 cm

2

3

6

0

8

745

1

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

13 / 46

1.05

ENG

2.3.3 FAULT SCHEMAS

A control panel installed with the valve NGV A3 must continuously monitor the signals RDY and RUN (UP)

that it receives from the card NGVA3-xx.

The control panel should go in error status, stop the system and do not send commands to the valve and / or

the motor / pump when, for more than 2s, signals RDY and RUN are simultaneously in the same condition.

The contemporary of the ON or OFF status require different behaviours, in particular:

If RDY and RUN are both in ON status, the control panel must detect the error, move the car to the nearest

landing and stop the system without allowing more travels;

If RDY and RUN are both in OFF status, the control panel must stop immediately the system and prevent any

further movement with the exception of the manual emergency operation.

FAULT

ALLOWED

ALLOWED

OK

OK

2s

2s

2s

2s

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OUT : RDY

OUT : RDY

OUT : RDY

OUT : RUN

OUT : RUN

OUT : RUN

IN : VS / D

OK

RDY FAULT

RUN FAULT

2.4 OPERATIONS PRELIMINARY TO CONNECTION

0 - OFF

0 - OFF

+

1 0991 483 EN - 21.12.2011

ENG

1.05

14 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

2.5 SCHEMAS OF THE CONNECTIONS TO CONTROL PANELS

In the following pages the schemas of the connections between valve / NGVA3 card and control panels

2.5.1 MAIN SCHEMA

T

TT

C°

BOX

QM

VAL

A3-Sxx-Wxx

UP

OVL

PMAX

PMIN

RUN

RDY

2A max

VSMA

VMD

PT

MAN

B

S1

SM

S3ò

S2ñ

3

5

1

4

ISP

PAMï

ML

BHBLS

505152

A+PEA-A-

D+D-E+E-

NGV-A3-01

EXP

µSD

COMM

PT01

111221223132

4142

X14

X15

X12 X11 X10 X9

X8

X7

X13

+ - T+ T- P+ P-+ -+ -

X1

X3

X4

X6

X5

X2

CAN BUS

D-D+ E+E-

VMD

X7

(1)

X6

D-E+E-

NGV-A3

S00 / S48 W25 / W50

CARD

¥"

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

15 / 46

1.05

ENG

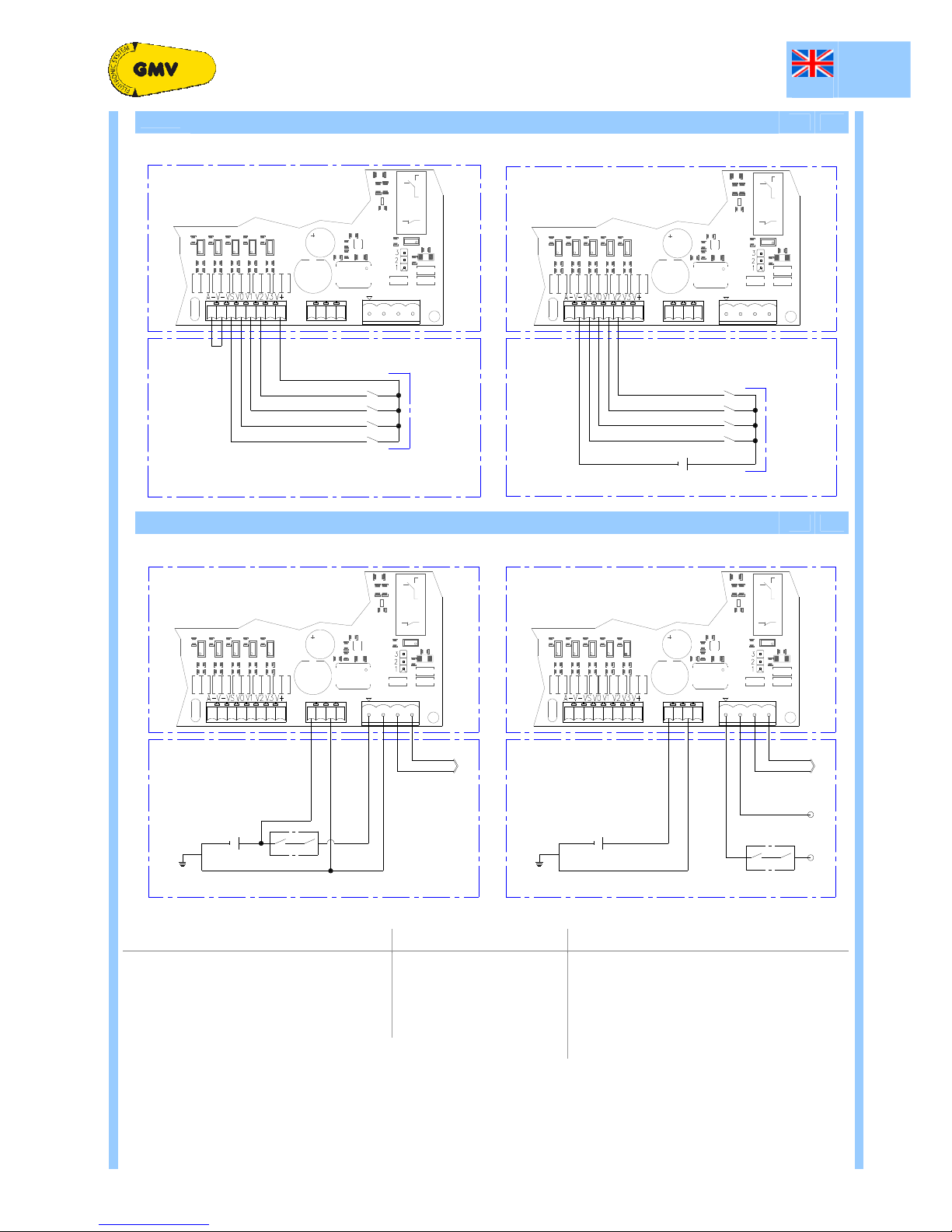

2.5.2 CONNECTION SCHEMAS FOR SIGNALS

Schema S00 Schema S48

V2

V1

V0

VS

QM

A+PEA-A-

D+D-E+E-

X4 X6

X5

CARD

S00

V+

J6

V2

V1

V0

VS

QM

A+PEA-A-

D+D-E+E-

X4 X6

X5

CARD

S48

J6

10...48 VDC

-

+

2.5.3 CONNECTION SCHEMAS FOR POWER

Schema W50 Schema W25

QM

A+PEA-A-

D+D-E+E-

X4

X6

X5

CARD

W50

J6

24 VDC = +/- 10%

50W

-

+

PE

EN81-2

J6=1-2

12- 48 VDC

QM

A+PEA-A-

D+D-E+E-

X4

X6

X5

CARD

W25

J6

-

+

24 VDC = +/- 10%

25W

PE

EN81-2

12- 48 VDC J6=1-2

60-180 VDC J6=2-3

VAL

NGV valve

QM

Control panel

BOX

NGV interface box

VSMA

Emergency downward valve

VS

Upward signal

CARD

NGV control card

VMD

Downward solenoid valve

V0

High speed

S1,S2,S3

Sensors (VRP,VBO, VBC)

SM

Stepping motor

V1

Medium speed

PT

Pressure transducer

D

Downward signal

V2

Inspection speed

(1)

Schema of the connections between D+D-E+E-VMD

TT

Temperature transducer

¥"

1 0991 483 EN - 21.12.2011

ENG

1.05

16 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

2.6 CONNECTIONS TO THE TERMINAL

A

U1

V1

W1

3 x

U1

V1

W1

U1-W2

V1-U2

W1-V2

U1

W2

V1

U2

W1

V2

U1

W2

V1

U2

W1

V2

RO2

RO1

TO1

TO2

RT1

RT2

RO2

RO1

TO1

TO2

RT1

RT2

T

M

3~

TORO

RT

150 mm

B

U1

W2

V1

U2

W1

V2

6 x

U1

W2

V1

U2

W1

V2

U1

W2

V1

U2

W1

V2

U1

W2

V1

U2

W1

V2

RO2

RO1

TO1

TO2

RT1

RT2

RO2

RO1

TO1

TO2

RT1

RT2

T

M

3~

TORO

RT

150 mm

2.7 CONNECTIONS TO THE CARD

BHBLS

505152

V-VSV0V1V2V3V+ A+PEA-A-

D+D-E+E-

1

3

NGV-A3-01

EXP VMDD-E+E-

1112212231324142

X14

X15

X12 X11 X10 X9 X8

X7

X13

A-

+ -T+ T- P+ P-+ -+ -

X1

X3

X4 X6X5X2

J2 J3

J6

J1

131

3

ò

X1-X2-X3

BHBLS

505152

V-VSV0V1V2V3V+ A+PEA-A-

D+D-E+E-

1

3

NGV-A3-01

EXP

VMD

D-E+

E-

111221223132

4142

X14

X15

X12 X11 X10 X9

X8

X7

X13

A-

+ - T+ T- P+ P-+ -+ -

X1

X3

X4 X6

X5

X2

J2 J3

J6

J1

131

3

÷÷

÷

§ 2.7

BHBLS

505152

V-VSV0V1V2V3V+ A+PEA-A-

D+D-E+E-

1

3

NGV-A3-01

EXP VMDD-E+E-

1112212231324142

X14

X15

X12 X11 X10 X9 X8

X7

X13

A-

+ -T+ T- P+ P-+ -+ -

X1

X3

X4 X6X5X2

J2 J3

J6

J1

131

3

ô

X4-X5-X6

BHBLS

505152

V-VSV0V1V2V3V+ A+PEA-A-

D+D-E+E-

1

3

NGV-A3-01

EXP

VMD

D-E+

E-

111221223132

4142

X14

X15

X12 X11 X10 X9

X8

X7

X13

A-

+ - T+ T- P+ P-+ -+ -

X1

X3

X4 X6

X5

X2

J2 J3

J6

J1

131

3

ø

ø

ø

§ 2.7

BHBLS

505152

V-VSV0V1V2V3V+ A+PEA-A-

D+D-E+E-

1

3

NGV-A3-01

EXP VMDD-E+E-

1112212231324142

X14

X15

X12 X11 X10 X9 X8

X7

X13

A-

+ -T+ T- P+ P-+ -+ -

X1

X3

X4 X6X5X2

J2 J3

J6

J1

131

3

J6

VMD

1

2

3

=

12-48 Vdc

1

2

3

=

60-180

Vdc

BHBLS

505152

V-VSV0V1V2V3V+ A+PEA-A-

D+D-E+E-

1

3

NGV-A3-01

EXP

VMD

D-E+

E-

111221223132

4142

X14

X15

X12 X11 X10 X9

X8

X7

X13

A-

+ - T+ T- P+ P-+ -+ -

X1

X3

X4 X6

X5

X2

J2 J3

J6

J1

131

3

ø

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

17 / 46

1.05

ENG

2.8 CONNECTION OF HYDRAULIC PIPES

ñ

8 ÷ 36 3/4" x 3/4" 3/4" - 3/4" x 3/4" 3/4"

42 ÷ 52

3/4" 3/4"

3/4" x M36" - 3/4" x M36

55 ÷ 100 1” x M36

1”

- 1” x M36

1”

100 ÷ 150

1”

1” x M45 1” x M45

180 ÷ 216 1”1/4

-

1”1/4 x M45

1”1/4 35

1”1/4 x M45

1”1/4

250 ÷ 300

1”1/4

1”1/4

1”1/4GM x 1”1/2GF

+ 1”1/2 x M52

360 ÷ 432 1”1/2 1”1/2 x M52

1”1/2 42 1”1/2 x M52 1”1/2

500 ÷ 600

1”1/2

-

2” 2” x 2” 2” - 2” x 2” 2”

2.8.1 CONNECTION WITH FLEXIBLE HOSE

· Remove the gear and the cutting ring from the terminal

connection of the silencer.

· Ensure that the terminal connection is well fixed on the

silencer.

· Clean and oil the threading and their seats.

· Fix the flexible hose verifying it is thoroughly tightened.

WARNING

Ensure that there is no dirty inside the tube. These

impurities could damage the sealing of the piston and of

the valve block and inhibit the correct operation of the

system.

2.8.2 CONNECTION WITH A RIGID PIPE

· Cut at 90° the head of the tube with a saw (do not use a tube-cutter)

· Do not let metal residuals fall into the tube and eliminate the burrs internally and externally.

· Remove the gear and the cutting ring of the terminal connection and insert it on the pipe.

· Ensure that the cutting ring is inserted as indicated in image

· Ensure that the terminal connection is well fixed on the silencer.

· Clean and lubricate the threading and the connection seat with

a slight oil veil.

· Insert the pipe into the cone at 24° up to lay it on the stop limit

of the cone itself.

· Screw thoroughly the gear by hand until it is felt that the cutting

gear lays perfectly to the nut.

· Then screw the nut using a wrench until the cutting edge of the

ring is in contact with the tube and prevents it from rotating.

· Keep the tube against its stop to avoid it rotates, screw the

fixing nut by 3/4 rev. In doing so the ring engraves with the

necessary depth the external part of the tube and rises a

border in front of its cutting edge.

· Loose the nut and check that the tube has all around a well

risen border. The border must cover 70% of the front part of

the cutting ring.

· Fix the tube, close the nut with a wrench until a certain

resistance is felt; from this moment on screw for a further 1/4

turn, contrasting wrench against wrench.

WARNING

Ensure that there is no dirty inside the tube. These impurities could damage the sealing of the piston

and of the valve block and inhibit the correct operation of the plant.

1 0991 483 EN - 21.12.2011

ENG

1.05

18 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

3 NGV A3 CONTROL BOARD

3.1 ELECTRICAL FEATURES

The hardware features of the card NGV-A3 are:

# DESCRIPTION VALUE

01 Standard supply voltage 24V=, ±10%

02 Extended supply voltage 12...42Vdc

03 Maximum consumption 25W

04 Voltage input VS-V0-V1-V2-V3 10...48Vdc (70Vp)

05 Voltage input D+ (VMD), two range selectable by jumper 12...48Vdc / 60...180Vdc

06 Power voltage sensors VRP and VB 12Vdc

07 Power voltage pressure transducer 12Vdc

08

Relays output, Volt free contact

according with EN81-2 for distances and insulation up to 250V

10mA@20Vdc / 2A@250Vac

3.2 PERFORMANCES

The card NGV-A3-01 has 3 different versions:

-01 Standard version : with power supply 24VDC

-02 Extended version : with all the available functions

-03 Reduced version : with power supply 24VDC and only serial connection on can bus

VERSION

# FUNCTION DESCRIPTION

01 02 03

01

Power supply Standard, 24V=, ±10% / Extended, 12...42Vdc

S E S

02 Opto-isolated inputs to command upward and speed level 5 5 03 Opto-isolated input to command downward (separate) 1 1 1

04

Relay output with voltage free contact

according to EN81-2 for distances and isolation up to 250V

7 7 -

05

Step Motor Command 12...52Vdc, 1,5Arms

with the possibility of monitoring the rated current and the connection breaking.

1 1 1

06 Input for pressure transducer interface, range 0...100 bar 1 1 1

07 Input for oil temperature transducer interface, range 0...100°C 1 1 1

08 Input for sensor ON/OFF 12V or linear sensor 0...5V (power supply 12V) 2 2 2

09 Input for sensor ON/OFF 12V 1 1 1

10 Rj45 port for PT01 / Pc / remote 2 2 1

11 Slot for µSD card - 1 12 Calendar watch with CR2030 battery 1 1 13 Can bus serial socket - 1 1

14 I/O extender connector 1 1 1

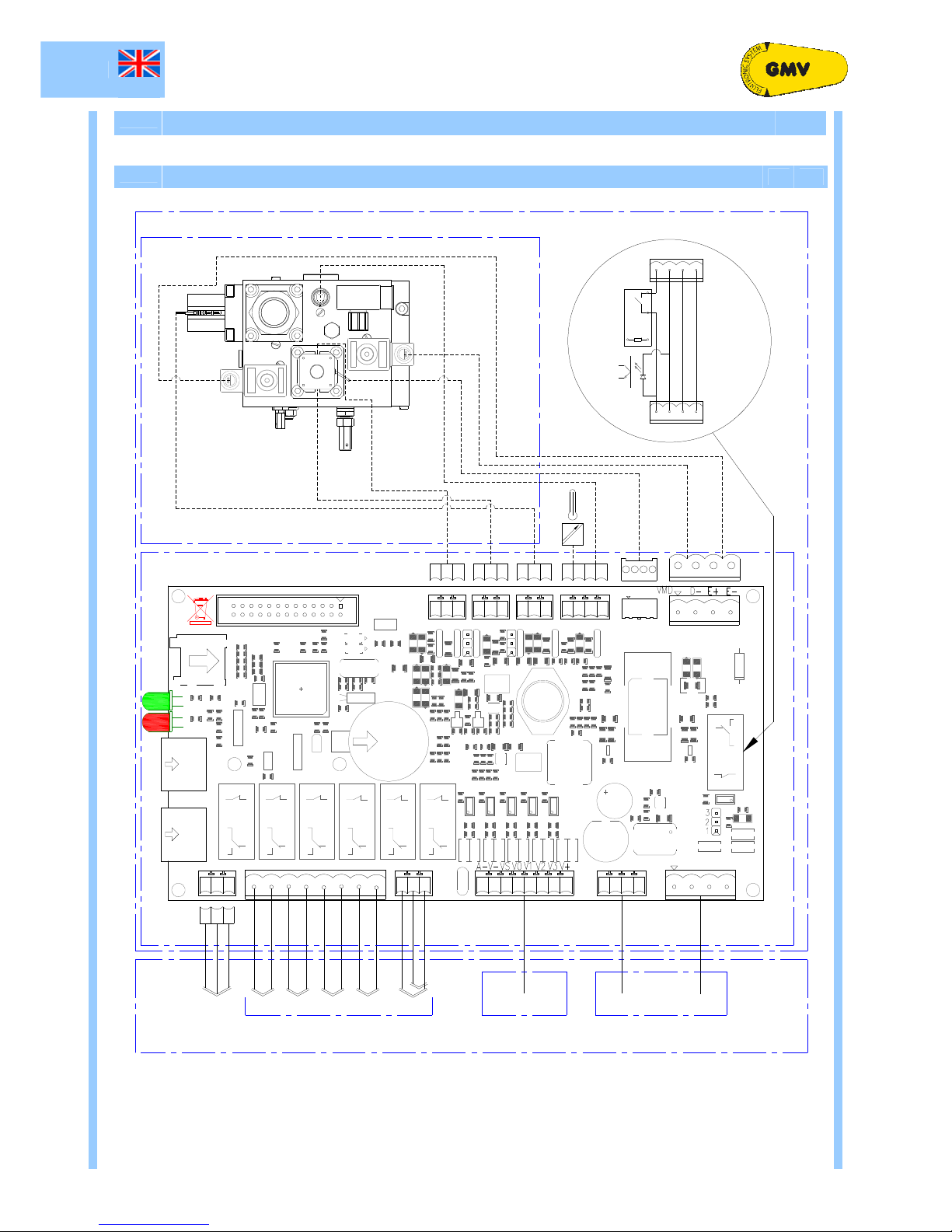

3.2.1 SIGNALLERS

GREEN LED OFF Not powered

FLASHING Power out of range

BHBLS

505152

1112212231324142

X14

X15

A-

X1

X3

X2

Power supply

status

ON Correctly powered

RED LED OFF No alarm

FLASHING Alarm that stops the system work

BHBLS

505152

1112212231324142

X14

X15

A-

X1

X3

X2

Alarm status

ON Alarm that do not stops the system work

PT01

Card status DISPLAY Show errors and settings

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

19 / 46

1.05

ENG

3.3 CONNECTIONS

3.3.1 CONTROL PANEL INTERFACE

The input circuits are divided in two groups, both isolated from the card power supply:

· V0,V1,V2,VS with common V- · D+ with common DEach group can be powered or by an external source within established limits, or directly by the card power,

connecting the commons (V- and/or D-) to the A-.

The interfacing with the control panel is made via removable terminal connectors defined as follows:

Connector X1, step 3,5 mm

Pos. Mark Features Description

1 BH Bus Can bus H

2 BL Bus Can bus L

3 SH Shield Shield

BHBLS

505152

111221223132

4142

X14

X15

X1

X3

X2

÷

Connector X2, step 5,0 mm

Pos. Mark Features Description

1 11

2 12

10mA...2A

20...250V

Programmable output relay (refer to programming

menu and programmable functions chart)

3 21

4 22

10mA...2A

20...250V

Programmable output relay (refer to programming

menu and programmable functions chart)

5 31

6 32

10mA...2A

20...250V

Programmable output relay (refer to programming

menu and programmable functions chart)

7 41

8 42

10mA...2A

20...250V

Programmable output relay (refer to programming

menu and programmable functions chart)

BHBLS

505152

111221223132

4142

X14

X15

X1

X3

X2

÷

Connector X3 step 3,5 mm

Pos. Mark Features Description

1 50

10mA...2A

20...250V

Output: RUN (NO)

2 51

10mA...2A

20...250V

Output: RDY (NO)

3 52

10mA...2A

20...250V

Common

BHBLS

505152

1112212231324142

X14

X15

A-

X1

X3

X2

Connector X4, step 3,5 mm

Pos. Mark Features Description

1 A- Power : negative (-)

2 V-

Inputs : negative

Make a short circuit with A- if you use V+ as power

or connect to input negative pole.

3 VS Input command : upward

4 V0 Input command : speed : high (nominal speed)

5 V1 Input command : speed : medium

6 V2 Input command : speed : inspection

7 V3

12...48Vdc,

10...40mA

Aux, not assigned

8 V+

Power : positive common.

For input command circuits without voltage.

Do NOT use if input commands are under voltage

52

V-VSV0V1V2V3V+ A+PEA-A-

D+D-E+E-

1

3

A-

X3

X4 X6

X5

J6

ø

Connector X5, step 3,5 mm

Pos. Mark Features Description

1 A+ Power : positive

2 PE PE, ground

3 A- Power : negative

4 A- Power : negative

52

V-VSV0V1V2V3V+

A+PEA-A-

D+D-E+E-

1

3

A-

X3

X4 X6X5

J6

ø

Connector X6, step 5,0 mm

Pos. Mark Features Description

1 D+ Input command : downward

2 D-

12...48Vdc,

60...180Vdc

Input downward : negative

3 E+ Input command : emergency solenoid valve

4 E-

Input emergency solenoid valve : negative

52

V-VSV0V1V2V3V+

A+PEA-A-

D+D-E+E-

1

3

A-

X3

X4 X6X5

J6

ø

1 0991 483 EN - 21.12.2011

ENG

1.05

20 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

Jumper J6 (to set connector X6 D+ D-)

Pos. Description

1-2

1

2

3

Input and downward command VMD 12…48Vdc

2-3

1

2

3

Input and downward command VMD 60…180Vdc

52

V-VSV0V1V2V3V+

A+PEA-A-

D+D-E+E-

1

3

A-

X3

X4 X6X5

J6

3.3.2 VALVE INTERFACE

The valve interfacing is made by these connections:

Connector X7, step 5,0 mm

Pos. Mark Features Description

1 VMD

2 D-

Downward command VMD

3 E+

4 E-

Emergency solenoid valve

NGV-A3-01

VMD

D-E+E-

X12 X11 X10 X9

X8

X7

+ - T+ T- P+ P-+ -+ -

J2 J3

131

3

ö

Connector X8, step 2,0 mm

Pos. Mark Features Description

1 PHA1

2 PHA2

Winding of motor phase 1

3 PHB1

4 PHB2

Winding of motor phase 2

NGV-A3-01

VMD

D-E+E-

X12 X11 X10 X9

X8

X7

+ - T+ T- P+ P-+ -+ -

J2 J3

131

3

ö

Connector X9, step 3,5 mm

Pos. Mark Features Description

1 T+ +Ref

2 T-

2KW max.

Temperature transducer PTC, 1KΩ a 25°C

3 P+ +12Vdc

4 P- 4…20mA return

Pressure transducer

NGV-A3-01

VMD

D-E+E-

X12 X11 X10 X9

X8

X7

+ - T+ T- P+ P-+ -+ -

J2 J3

131

3

õ

Connector X10, step 3,5 mm - (SensorS1 VRP - Settable)

Pos. Mark Features Description

1 + +12Vdc

2 0…12Vdc / 0…5V

3 - 0V

Sensor ON/OFF (12Vdc) / Linear sensor 0…5V

NGV-A3-01

VMD

D-E+E-

X12 X11 X10 X9

X8

X7

+ - T+ T- P+ P-+ -+ -

J2 J3

131

3

õ

Jumper J3 (to set connector X10)

Pos. Description

1-2

1

2

3

Sensor S1 VRP (ON/OFF)

2-3

1

2

3

Linear Sensor 0…5V

NGV-A3-01

VMD

D-E+E-

X12 X11 X10 X9

X8

X7

+ - T+ T- P+ P-+ -+ -

J2 J3

131

3

õ

Connector X11, step 3,5 mm - (Sensor S2 VB Close - Settable)

Pos. Mark Features Description

1 + +12Vdc

2 0…12Vdc / 0…5V

3 - 0V

Sensor ON/OFF (12Vdc) / Linear sensor 0…5V

NGV-A3-01

VMD

D-E+E-

X12 X11 X10 X9

X8

X7

+ - T+ T- P+ P-+ -+ -

J2 J3

131

3

õ

Jumper J2 (to set connector X11)

Pos. Description

1-2

1

2

3

Sensor S2 VB (ON/OFF)

2-3

1

2

3

Linear Sensor 0…5V

NGV-A3-01

VMD

D-E+E-

X12 X11 X10 X9

X8

X7

+ - T+ T- P+ P-+ -+ -

J2 J3

131

3

õ

Connector X12, step 3,5 mm - (SensorS1 VB Open)

Pos. Mark Features Description

1 + +12Vdc

2 0…12Vdc

3 - 0V

Sensor ON/OFF (12Vdc)

NGV-A3-01

VMD

D-E+E-

X12 X11 X10 X9

X8

X7

+ - T+ T- P+ P-+ -+ -

J2 J3

131

3

õ

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

21 / 46

1.05

ENG

3.3.3 USER INTERFACE

Connector X13, step 2,54 mm - (AUX 2 x 13)

Connector for extensions (Encoder, …)

EXP

X14

X12

X13

+ -

J2

J1

1

3

õ

Slot J1, µSD (serial SPI)

Slot for µSD memory cards (serial SPI)

EXP

X14

X12

X13

+ -

J2

J1

1

3

õ

Connector X14, RJ45 (PT01)

Socket RS232 for programmer PT01

Pos. Mark Features Description

1 +12 Power : 12Vdc

2 +12 Power : 12Vdc

3 RxD Data output (to PT01)

4 TxD

Data input (from PT01)

5

Not in use

6

Not in use

7 0V

Power : negative

8 0V Power : negative

EXP

X14

X12

X13

+ -

J2

J1

1

3

÷

Connector X15, RJ45 (COMM)

Socket RS232 for PC, Modem, …

Pos. Mark Features Description

1 +12 Power : 12Vdc

2 +12 Power : 12Vdc

3 RxD Data output (to Pc, Modem,…)

4 TxD

Data input (from Pc, modem,..)

5

Not in use

6

Not in use

7 0V

Power : negative

8 0V Power : negative

BHBLS

505152

111221223132

4142

X14

X15

A-

X1

X3

X2

÷

BHBLS

505152

V-VSV0V1V2V3V+

A+PEA-A-

D+D-E+E-

1

3

NGV-A3-01

EXP

µSD

COMM

PT01

LED RED

LED GREEN

VMD

D-E+

E-

VB OPEN TT PT

CAN BUS

AUX OUT

RUN

RDY

COM

111221223132

4142

X14

X15

X12 X11 X10 X9

X8

X7

X13

VB CLOSE VRP

A-

+ - T+ T- P+ P-+ -+ -

X1

X3

X4

X6

X5

X2

J2 J3

J6

J1

1

3

1

3

1 0991 483 EN - 21.12.2011

ENG

1.05

22 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

3.4 SIGNALS AND COMMANDS SEQUENCE

3.4.1 UPWARD DIAGRAM

15

D

RAL,S

14

13

9 10

11

12

8

7

6

3

4

5

2

0

1

MP

VS

VX

RDY

RUN

UP

16

17

(0)

18

V

[m/s]

C

[mm]

VN

Close

0

Open

VB/SM

ппчшш

N

G

V

-

A

3

-

0

1

E

X

P

µ

S

D

R

J

4

5

P

T

0

1

L

E

D

R

E

D

L

E

D

G

R

E

E

N

V

B

O

P

E

N

V

B

C

L

O

S

E

V

R

P

T

T

P

T

C

A

N

B

U

S

A

U

X

O

U

T

READY RUN CO

M

3.4.1.1 UPWARD SIGNALS AND COMMANDS SEQUENCE

Start travel sequence : RDY=ON + RUN=OFF ð (Vx=ON ð) VS=ON ð RDY=OFF – VB/SM=OPEN ð

RUN/UP=ON (ð MP=ON)

End travel sequence : (Vx=OFF ð VS=OFF ð) VB/SM=OPEN ð RUN/UP=OFF ð (MP=OFF ð)

VB/SM=CLOSE ð RDY=ON

MP Motor / pump Vx = V0, V1, V2 Speed (High, Intermediate, Inspection)

SM Stepping Motor VS Upward command

VS V0 V1 V2

Speed : High 1 1 0 0 1 Powered

Speed : Medium 1 X 1 0 0 Not powered

Speed : Inspection 1 X X 1 X Anything

Speed : levelling / re-levelling 1 0 0 0

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

23 / 46

1.05

ENG

3.4.2 DOWNWARD DIAGRAM

D

RAL,D

VMD

D

VX

RDY

RUN

(0)

9

10

11

12

8

7

6

3

4

5

201

V

[m/s]

C

[mm]

VN

Close

0

Open

VB/SM

ппрчш

N

G

V

-

A

3

0

1

E

X

P

µ

S

D

R

J

4

5

P

T

0

1

L

E

D

R

E

D

L

E

D

G

R

E

E

N

V

B

O

P

E

N

V

B

C

L

O

S

E

V

R

P

T

T

P

T

C

A

N

B

U

S

A

U

X

O

U

T

READY RUN CO

M

3.4.2.1 DOWNWARD SIGNALS AND COMMANDS SEQUENCE

Start travel

sequence :

RDY=ON+RUN=OFF ð Vx=ON ð D=ON ð RDY=OFF ð RUN=ON (ðVMD=ON)

End travel

sequence :

(Vx=OFF ð) D=OFF ð VB/SM=CLOSE ð RUN=OFF ð RDY=ON

D Downward command SM Stepping motor

MP Motor / pump VMD Downward solenoid valve

Vx = V0, V1, V2 Speed (High, Intermediate, Inspection)

D V0 V1 V2

Speed : High 1 1 0 0 1 Powered

Speed : Medium 1 X 1 0 0 Not powered

Speed : Inspection 1 X X 1 X Anything

Speed : levelling / re-levelling 1 0 0 0

1 0991 483 EN - 21.12.2011

ENG

1.05

24 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

3.5 DECELERATION DISTANCES

ON

UP

DN

OFF

V2

VS

MP

V1

V0

V0

V1

D

V2

1s

DRAL,D

DR

AL,

S

VN [m/s] D

RAL,S

[m]

Upward Extra Slow Slow Standard Fast

0,00 < V ≤ 0,15 0,19 0,15 0,13 0,12

0,15 < V ≤ 0,40 0,43 0,39 0,37 0,32

0,40 < V ≤ 0,65 0,81 0,71 0,63 0,61

0,65 < V ≤ 0,85 1,16 0,99 0,92 0,89

0,85 < V ≤ 1,00 1,40 1,27 1,17 1,10

VN [m/s] D

RAL,D

[m]

Downward Extra Slow Slow Standard Fast

0,00 < V ≤ 0,15 0,15 0,13 0,12 0,12

0,15 < V ≤ 0,40 0,41 0,36 0,34 0,31

0,40 < V ≤ 0,65 0,78 0,67 0,62 0,58

0,65 < V ≤ 0,85 1,14 0,98 0,88 0,83

0,85 < V ≤ 1,00 1,36 1,18 1,11 1,05

EXTRA SLOW SLOW STANDARD FAST

The distance between the deceleration sensor (D

RAL

) and the floor must be regulated according to the chart

above. If the levelling space is greater is possible to make an adjustment using the programmer as shown in

the chapter Programming.

D Downward command ON Powered

DN Downward UP Upward

M, MP Motor / pump V0, V1, V2 Speed (high, medium, inspection)

OFF Not powered VS Upward command

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

25 / 46

1.05

ENG

4 ADJUSTMENTS AND TEST

4.1 ADJUSTMENT OF THE OVERPRESSURE VALVE (OPP/MPS)

VALVE NGVA3

VSMA

VMD

PT

MAN

B

S1

SM

S3

S2

3

5

1

4

ISP

PAMï

ML

To adjust the overpressure valve:

1. Refer to the hydraulic circuit of the NGV valve

2. Close the ball valve (B), the lever must be found to 90° regarding the ball valve

3. Open the manometer shut-off valve (4)

4. Unscrew and remove the protection cap of the adjusting screw of the overpressure valve (1)

5. Loosen the locknut (1)

6. Start the motor-pump group

7. Start the 9.1 Overpressure Value control procedure on the PT01 programmer (please refer to the

Programming chapter)

8. Read the pressure on the programmer PT01

9. If the read value is different then the calibration one:

· Press the manual lowering button (ML) in order to decrease the pressure on the valve block

· Screw the adjustment screw 1 for increase the pressure on the MPS; unscrew the adjustment screw 1 for

reduce the pressure.

· Start the motor-pump group

· Start the Overpressure Value control procedure on the PT01 programmer

· Read the pressure on the programmer

· Repeat this procedure until the pressure value on the programmer is the same than the calibration one

10. Tighten the locknut 1

11. Put back and tighten the protection cap of the adjusting screw (1)

12. Re-open the ball valve (B)

PROGRAMMER PT01

1 0991 483 EN - 21.12.2011

ENG

1.05

26 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

4.2 RAM PRESSURE ON THE VSMA ADJUSTMENT

NOTE

Adjustment possible only with systems 2:1

To adjust the ram pressure on the VSMA :

1. Close the ball valve (B), the lever must be found to 90° regarding the ball valve

2. Unscrew and remove the protection cap of the adjusting screw of the VSMA valve (3)

3. Press the manual lowering button (ML)

4. Check the pressure gauge on the manometer (MAN) is around 5 bar. If it is 5 bar go to point 6, if it is less

then 5 bar go to point 5

5.

· Re-open the ball valve B

· Loosen the locknut (3)

· Tighten the screw (3) – one turn

· Tighten the locknut (3)

· Close the ball valve B

· Press the manual lowering button (ML)

· Repeat this procedure until the pressure is close to 5 bar

· Go to point 6

6. Put back and tighten the protection cap of the adjusting screw (3)

7. Re-open the ball valve (B)

4.3 PIPE RUPTURE VALVE (VC) TEST

WARNING

Before testing the pipe rupture valve, adjust this valve on the cylinder (refer to the

technical data on the plant and instructions of the rupture valve)

To test the pipe rupture valve follow the next procedure:

1. Move the car to the highest floor at full load (refer to system use manual)

2. After the car comes to a full stop loosen the locknut (5) and unscrew the screw (5) – 3

turns

3. Start the 9.2 Pipe Rupture test procedure on the PT01 programmer (please refer to the

Programming chapter)

4. Move the car to the lower floor. The valve, during downward, should be stop the car.

WARNING

If the valve do not stop the car, verify the settings of the rupture valve on the cylinder

5. At the end of the test fully tighten the screw (5) and tighten the locknut (5)

6. Use the hand pump to release / unlock the rupture valve

7. Exit from the 9.2 Pipe Rupture test procedure

4.4 TEST OF DEVICES THAT PREVENT UNCONTROLLED MOVEMENT

WARNING

Perform these tests only after the previous ones.

To verify that the devices that prevent uncontrolled movement work

correctly, you must proceed with the test required at point zc) of Appendix

D of the rule EN81-2 checking that the control panel and the system work

according to the rule. (EN81-2 §9.13.5).

4.4.1 PREREQISITES

To be according to the rule EN81-2 the following points must be

respected:

- The system shall be provided with a means /switch able to detect

unintended car movement

- The control panel, should NOT send commands to the valve and to

the motor / pump when the system is located, with open doors,

outside the doors unlocking zone.

NOTE

Before proceeding check on the installation manual of the electrical

part which operations, required for the test, should be performed

ò

ñ

P 1000

mm

O 1200

mm

O 200 mm

P 1000

mm

O 1200

mm

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

27 / 46

1.05

ENG

4.4.2 TEST IN UP DIRECTION

Cod.10911309

E00.001

Cod.10911309

E00.001

For safety it’s required that the test take place behind closed doors. Then proceed as follows:

1. Put at all landings the sign “Out of service”

8. Move the empty car to the floor below the top floor

9. Wait for the closing of the door

10. Start on the valve card NGVA3 the procedure 9.3 UCM UP TEST using the programmer PT01.

11. Start on the control panel the UP direction test procedure. This procedure must :

- To exclude the possibility to call the car form the landings

- Open the electrical safety chain at the landing doors level (for the system the doors must be open even

if physically closed)

12. Open, manually or electrically, the emergency lowering valve , moving in down direction the car until the

intervention of the re-levelling.

When the re-levelling occurs, the system start to move in up direction at rated speed and the switch intended

to detect unintended car movement must be activated and the car must stopped.

13. Verify that the car stops according to the rule EN 81-2.

14. Exit from the procedure 9.3 UCM UP TEST pushing the ESC key

15. Close the landing doors level of the electrical safety chain

16. Remove the signs “Out of service”

17. Restore the normal working status of the system.

NOTE

The switch to detect unintended car movement can be the same used to detect the movement of the

car, away from the landing unlocking zone with doors not in the locked and closed position,

4.4.3 TEST IN DOWN DIRECTION

Cod.10911309

E00.001

Cod.10911309

E00.001

For safety it’s required that the test take place behind closed doors. Then proceed as follows:

1. Put at all landings the sign “Out of service”

18. Move the fully loaded car to the floor below the top floor

19. Wait for the closing of the door

20. Start on the valve card NGVA3 the procedure 9.4 UCM DN TEST using the programmer PT01.

21. Start on the control panel the DOWN direction test procedure. This procedure must :

- To exclude the possibility to call the car form the landings

- Open the electrical safety chain at the landing doors level (for the system the doors must be open even

if physically closed)

22. Using the hand pump, moving in up direction the car until the intervention of the re-levelling.

When the re-levelling occurs, the system start to move in down direction at rated speed and the switch

intended to detect unintended car movement must be activated and the car must stopped.

23. Verify that the car stops according to the rule EN 81-2.

24. Exit from the procedure 9.4 UCM DN TEST pushing the ESC key

25. Close the landing doors level of the electrical safety chain

26. Remove the signs “Out of service”

2. Restore the normal working status of the system.

NOTE

The switch to detect unintended car movement can be the same used to detect the movement of the

car, away from the landing unlocking zone with doors not in the locked and closed position,

1 0991 483 EN - 21.12.2011

ENG

1.05

28 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

4.5 TEST OF THE DOUBLE SAFETY SYSTEM

4.5.1 SIMULATION OF THE VRP FAULT

This test allow to verify that the system stay stopped in event of failure of the VRP.

To perform the test you must simulate the failure of the VRP as follows:

4.5.1.1 POWER UNITS OUTSIDE THE WELL

1. Remove the VMD protection cap by turning it counterclockwise

2. [DOWN DIRECTION] Move the fully loaded car in down direction in the lower part of the well

3. During the travel, by turning clockwise, completely screw the test cap on the VMD (this operation open

the VRP and does not allow it to close).

4. Verify that the car stops at the target landing correctly and in compliance with the rule

5. Remove from the VMD the test cap by turning it counterclockwise (the VRP return in the normal working

condition and allow it to close)

6. Verify that in the menu (2.1 Alarm), at the end of the travel in down direction, is reported the fault nr.16

7. Reset all faults (3 Al/Flt reset)

8. [UP DIRECTION] Repeat the test moving the car empty in up direction in the upper part of the well.

9. During the travel, by turning clockwise, completely screw the test cap on the VMD

10. Verify that the car stops at the target landing correctly and in compliance with the rule

ATTENTION

During the test in up direction it is possible that the final limit switch is activated.

11. Remove from the VMD the test cap by turning it counterclockwise and put protection cap on VMD by

turning it clockwise

12. Verify that in the menu (2.1 Alarm), at the end of the travel in down direction, is reported the fault nr.22

13. Reset all faults (3 Al/Flt reset)

The test is ended.

4.5.1.2 POWER UNITS IN THE SHAFT (MRL)

Perform the test in down direction and after in up direction

1. Rotate counterclockwise and remove the VMD cap

27. Remove the coil from the VMD

28. Remove the coil from the solenoid emergency valve ML

and insert it on the VMD

29. [DOWN DIRECTION] Move the fully loaded car in down

direction in the lower part of the well

[UP DIRECTION] Move the empty car in up direction in

the upper part of the well …

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

29 / 46

1.05

ENG

30. During the travel, push and hold the remote emergency button (this operation

open the VRP and does not allow it to close)

31. Verify that the car stops at the target landing correctly and in compliance with

the rule

32. Release the remote emergency button (the VRP return in the normal working

condition and allow it to close)

33. Verify that in the menu (2.1 Alarm), at the end of travel, is reported the fault

nr. 16 [DOWN DIRECTION] or nr. 22 [UP DIRECTION].

34. Reset all faults (3 Al/Flt reset)

The test is ended

4.5.2 SIMULATION OF THE VB FAULT

This test allow to verify that the system stay stopped in event of failure of the VB.

To perform the test you must simulate the failure of the VB as follows:

4.5.2.1 SIMULATION OF THE VB FAULT IN DOWN DIRECTION

1. Connect the programmer PT01 to the card NGV-A3

2. Move the fully loaded car to the upper landing

3. Start the test procedure 9.5 VB TEST DOWN (Enter=Start)

4. Move the car in down direction

5. Verify that the car stops at the target landing correctly

6. End the test procedure 9.5 VB TEST DOWN (ESC=End)

7. Verify that are reported the fault nr. 17. (2.1 Alarm)

8. Reset all faults (3 Al/Flt reset)

The test is ended

4.5.2.2 SIMULATION OF THE VB FAULT IN UP DIRECTION

1. Connect the programmer PT01 to the card NGV-A3

2. Move the empty car to the lower landing

3. Start the test procedure 9.6 VB TEST UP (Enter=Start)

4. Move the car in up direction

5. Verify that the car stops at the target landing correctly

6. End the test procedure 9.6 VB TEST UP (Enter=End)

7. Verify that are reported the fault nr. 13 and nr. 14 (2.1 Alarm).

8. Reset all faults (3 Al/Flt reset)

The test is ended

4.5.3 TEST OF THE MONITORING SYSTEM

The NGV A3 card, each travel, automatically perform a check of the monitoring system and in event of fault

goes into alarm/fault.

To test of the monitoring system is therefore sufficient, at the end of any travel, make sure that (2.1 Alarm)

there is no one among the following faults: 06, 07, 13 ÷ 22

NOTE

If requested, it is possible to simulate a fault of the sensors removing from the card or the connector

X10 (FAULT 06) or the X11 (FAULT 14). During this event the card must go into alarm.

Using the programmer PT01, verify that an alarm is active (2.1 Alarm), insert the connector

previously removed (the alarm end) and reset the alarms (3.1 Al/Flt Reset)

¥"

1 0991 483 EN - 21.12.2011

ENG

1.05

30 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

4.6 FAULT SIMULATION ON OUTPUT RDY AND RUN

The test verifies the correct behaviour of the control panel when it receives signals RUN and/or RDY not

corrects. It is possible to simulate the failure when the system is stopped a), or during a travel of the system

b). To perform the test you must connect the programmer PT01 to the card NGV-A3 and continue

simulating faults as follow:

4.6.1 TEST RUN ALWAYS ON

1. Select 9.7 RUN-RDY TEST and push ENT

2. Select using keys Þ/Ý : RUN always ON

3. a) Push ENT with the system stopped .The control panel must recognize the error and to prevent any

movement of the system.

b) Make a call in up or down direction and push ENT during the travel. The control panel, after the arrival

at landing, after 2 sec, must recognize the error and to prevent any movement of the system.

4. At the end push ENT, Select using keys Þ/Ý : NO TEST and press ENT to restore the initial condition.

4.6.2 TEST RDY ALWAYS OFF

1. Select 9.7 RUN-RDY TEST and push ENT

5. Select using keys Þ/Ý : RDY always OFF

6. a) Push ENT with the system stopped and call the car in up or in down direction. The control panel must

recognize the error and to prevent any movement of the system.

b) Make a call in up or down direction and push ENT during the travel. The control panel, after the arrival

at landing, after 2 sec, must recognize the error and to prevent any movement of the system.

7. At the end push ENT, Select using keys Þ/Ý : NO TEST and press ENT to restore the initial condition.

4.6.3 TEST RUN ALWAYS OFF

1. Select 9.7 RUN-RDY TEST and push ENT

2. Select using keys Þ/Ý : RUN always OFF

3. a) Push ENT with the system stopped and call the car in up or in down direction. The control panel, after

2 sec, must recognize the error and to prevent any movement of the system.

b) Make a call in up or down direction and push ENT during the travel. The control panel, after 2 sec,

must recognize the error, to stop the system and to prevent any further movement.

4. At the end push ENT, Select using keys Þ/Ý : NO TEST and press ENT to restore the initial condition.

4.6.4 TEST RDY ALWAYS ON

1. Select 9.7 RUN-RDY TEST and push ENT

2. Select using keys Þ/Ý : RDY always ON

3. a) Push ENT with the system stopped and call the car in up or in down direction. The control panel, after

2 sec, must recognize the error and to prevent any movement of the system.

b) Make a call in up or down direction and push ENT during the travel. The control panel, after 2 sec,

must recognize the error and after the arrival at landing, to stop the system and to prevent any further

movement.

4. At the end push ENT, Select using keys Þ/Ý : NO TEST and press ENT to restore the initial condition

4.6.5 EXIT RUN-RDY TEST

Before to exit 9.7 RUN-RDY TEST verify that NO TEST is set as parameter value.

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

31 / 46

1.05

ENG

5 PROGRAMMING

It is possible to dialog with the NGV01 control board by the programmer PT01.

The connection between the programmer and the board is made by a network UTP RJ45 straight cable.

The programmer power supply comes from the control board through the connection cable.

It is possible to navigate into the menus and change the numeric values using the arrow keys Ý Þ, it is

possible to enter into the sub-menus and confirm the input data by the ENT key and finally it’s possible exit

and move the cursor left side by the ESC key.

Network cord UTP RJ45

WARNING

MIN = Car empty

MAX = Car with full

load

BHBLS

505152

V-VSV0V1V2V3V+ A+PEA-A-

D+D-E+E-

1

3

NGV-A3-01

EXP VMD

D-E+

E-

111221223132

4142

X14

X15

X12 X11 X10 X9 X8

X7

X13

A-

+ - T+ T- P+ P-+ -+ -

X1

X3

X4 X6

X5

X2

J2 J3

J6

J1

131

3

5.1 SYSTEM PARAMETERS

NOTE

It is recommended to indicate in the table below the parameters of your system

To write your parameters make easy future maintenance and repairs.

4 ADJUSTMENTS 6 UP PARAMETERS

4.1 Start UP min

6.2 Int. Speed V1

4.2 Slow UP min

6.3 Ins.Speed V2

4.3 High DN min

6.4 Slow Speed

4.4 Slow DN min

6.5 Relev. Speed

4.5 Start UP max

6.6 Acc.Profile

4.6 Slow UP max

6.7 Dec.Profile

4.7 High DN max

6.8 Start Delay

4.8 Slow DN max

7 DN PARAMETERS

4.9 Offset V0 UP

7.1 Nom. Speed V0

4.10 Offset V0 DN

7.2 Int.Speed V1

4.11 Offset V1 UP

7.3 Insp. Speed V2

4.12 Offset V1 DN

7.4 Slow Speed

5 SETTING

7.5 Relev. Speed

5.1 Lift Ratio

7.6 Acc.Profile

5.2 Jack Diam

7.7 Dec.Profile

5.3 Pump Flow

8 OUTPUT FUNC

5.5 Pstat. min

8.1 Output 11-12

5.6 Pstat.max

8.2 Output 21-22

8.3 Output 31-32

8.4 Output 41-42

1 0991 483 EN - 21.12.2011

ENG

1.05

32 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

5.2 COMPLETE MENÙ

◄

▼

1

NGV-A3 VX.XRXXHX

DIAGNOSTICS

►

5

NGV-A3 VX.XRXXHX

SETTINGS

►

8

NGV-A3 VX.XRXXHX

OUTPUT FUNC

1.1 Pressure // xx.x bar 5.1 Lift Ratio // x:x 8.1 Output 11-12 // FUN xx Nx

1.2 Temperature // xx.x C° 5.2 Jack Diam // xxx mm 8.2

Output 21-22 // FUN xx Nx

1.3 Ref.Speed // x.xx m/s 5.3 Pump Flow // xxx l/min 8.3

Output 31-32 // FUN xx Nx

1.4

In: S0123DICA

// 000000000

5.4 Map // xx 8.4

Output 41-42 // FUN xx Nx

1.5

Out: 1234YND

// 0000000

5.5 Pstat. min // xx.x bar

1.6 Supply // xx.x Vdc 5.6 Pstat.max // xx.x bar

1.7 Fly Time // 5.7 P min // xx.x bar

1.7.1 Total //xxx.x s 5.8 P full load // xx.x bar

1.7.2 Start -> Dec. // XXX.X s 5.9 P overload // xx.x bar

1.7.3 Dec. -> Stop //XXX.X s 5.10 P max // xx.x bar

5.11 Cool Temp // xx °C

5.12 Mode: Normal-Installation

▼

▼ ▼

2

NGV-A3 VX.XRXXHX

ALLARMS

6

NGV-A3 VX.XRXXHX

UP PARAMETERS

9

NGV-A3 VX.XRXXHX

TEST…

2.1 Alarm 01 // 00: No Alarm 6.1 Nom.Speed V0 // x.xx m/s 9.1 OverP. Value // Ent = Start

... ... 6.2 Int. Speed V1 // x.xx m/s 9.2 Pipe Rupture // Ent = Start

2.8 Alarm 08 // 00: No Alarm 6.3 Ins.Speed V2 // x.xx m/s 9.3 UCM UP test // Ent = Start

6.4 Slow Speed // x.xxx m/s 9.4 UCM Test up // Ent = Start

▼

6.5 Relev. Speed // x.xxx m/s 9.5 VB test down // Ent = Start

3

NGV-A3 VX.XRXXHX

AL/FLT RESET

6.6 Acc. Profile // XS,S,ST,F,C 9.6 VB test down // Ent = Start

3.1 Reset ? ESC=NO ENT=YES 6.7 Dec.Profile // XS,S,ST,F,C 9.7 Run-Rdy test // No test

6.8 Start Delay // x.x s 9.8 S3 tuning // Ent =Start

▼

▼

▼

4

NGV-A3 VX.XRXXHX

ADJUSTMENTS

7

NGV-A3 VX.XRXXHX

DN PARAMETERS

10

NGV-A3 VX.XRXXHX

ADVANCED

4.1 Start UP min // ±xx 7.1 Nom. Speed V0 // x.xx m/s 10.1 Password // -00000

4.2 Slow UP min // ±xx 7.2 Int.Speed V1 //x.xx m/s

4.3 High DN min // ±xx 7.3 Ins.Speed V2 // x.xx m/s

4.4 Slow DN min // ±xx 7.4 Slow Speed // x.xxx m/s

4.5 Start UP max // ±xx 7.5 Relev. Speed // x.xxx m/s

4.6 Slow UP max // ±xx 7.6 Acc. Profile // XS,S,ST,F,C

4.7 High DN max // ±xx 7.7 Dec.Profile // XS,S,ST,F,C

4.8 Slow DN max // ±xx

4.9 Offset V0 UP // xxx mm

4.10 Offset V0 DN // xxx mm

4.11 Offset V1 UP // xxx mm

4.12 Offset V1 DN // xxx mm

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

33 / 46

1.05

ENG

5.3 MENÙ

- 1 - DIAGNOSTICS

NGV VER XX.XXX

1-DIAGNOSTICS

Ý Þ

1.1 PRESSURE

XX.X bar

Pressure gauge [bar] read by the pressure transducer

Ý Þ

1.2 TEMPERATURE

XX.X °C

Temperature gauge [°C] read by the temperature transducer

Ý Þ

1.3 REF. SPEED

X.XXX m/s

Set point speed [m/s]

Ý Þ

State of the input signals: S0123DICA

1.4 INPUT S0123DICA

000000000

100000000=VS 010000000=V0 001000000=V1

000100000=V2 000010000=V3 000001000=D

000000100=IND 000000010=VBC 000000001=VBO

Ý Þ

State of the output signals: 1234YND

1.5 OUTPUT 1234YND

0000000

1000000=Out1 0100000=Out2 0010000=Out3 0001000=Out4

0000100=RDY 0000010=RUN 0000001=VMD

Ý Þ

1.6 SUPPLY

XX.X V

Supply voltage [V] of the control board

Ý Þ

1.7 FLY TIME

Fly time of the lift

ENT

1.7.1 TOTAL

XXX.X s

Total time of the lift travel

[s]

Ý Þ

1.7.2 START->DEC

XXX.X s

Ý Þ

Time between the start of

the lift end the start of the

deceleration phase [s]

1.7.3 DEC->STOP

XXX.X s

Time between the start of

the deceleration phase

and the stop of the lift [s]

V0

Vs/D

Start->Dec

Total

Dec->Stop

OFF ON

- 2 - ALLARM

NGV VER XX.XXX

2-ALARM

Ý Þ

2.1 ALARM

00:No Alarm

Active alarms. Each alarm is identified by a code explained in the

Failure Chart. Last 8 alarms are stored in memory

- 3 - ALARM AND FAULT RESET

NGV VER XX.XXX

3-AL/FLT RESET

Ý Þ

3.1 FAULT RESET

Pressing the ENT key on the programmer all the faults and the alarms

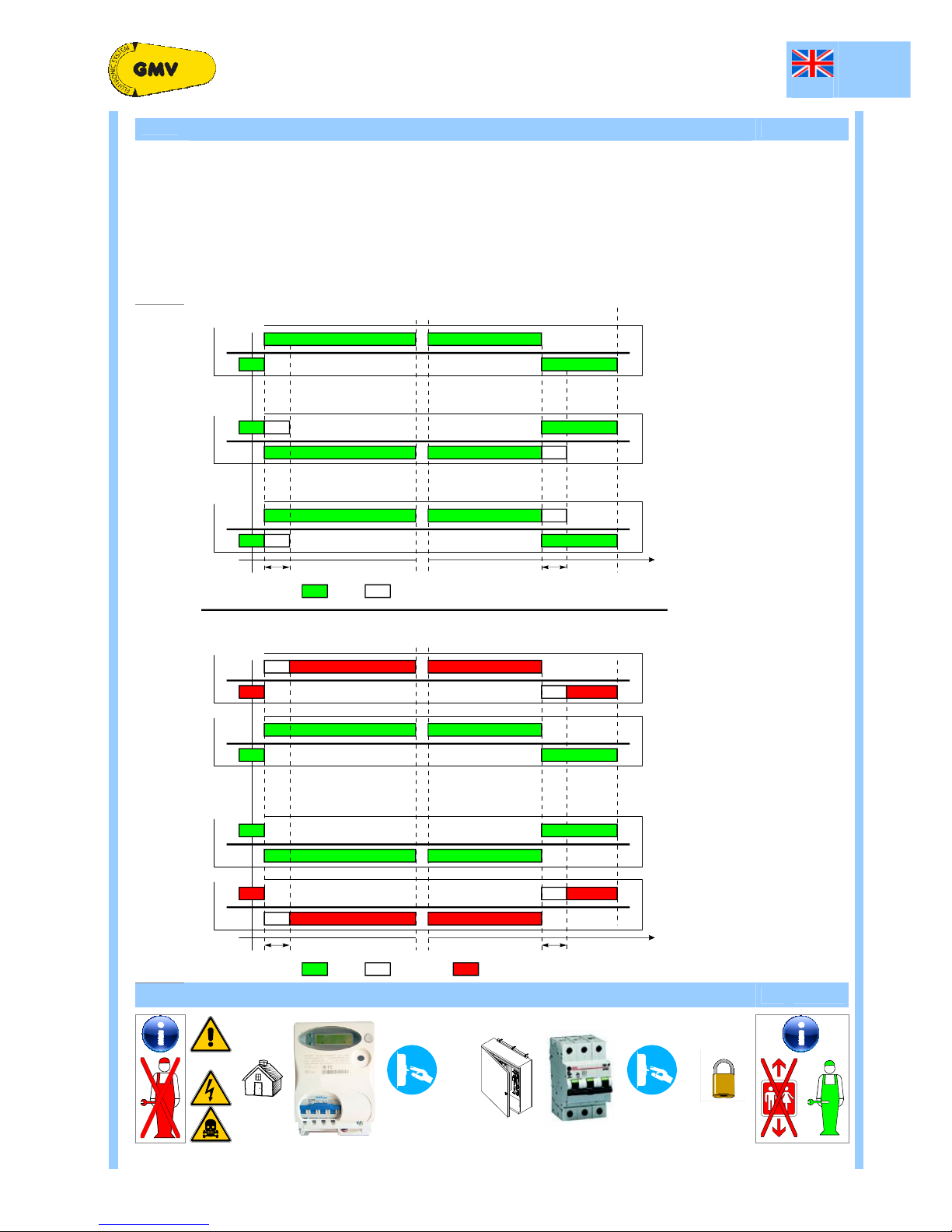

are deleted

1 0991 483 EN - 21.12.2011

ENG

1.05

34 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

- 4 - ADJUSTMENTS

NGV VER XX.XXX

4-ADJUSTMENTS

Optimal car motion

Real car motion

Ý Þ

A B

C

4.1 START UP MIN

±XX.X

UPWARD start adjustment (-99 ÷ +99)

A

+Ý -Þ

4.2 SLOW UP MIN

±XX.X

UPWARD levelling speed adjustment (-99 ÷ +99)

B

+Ý -Þ

4.3 HIGH DN MIN

±XX.X

DOWNWARD high speed adjustment (-99 ÷ +99)

C

+Ý -Þ

4.4 SLOW DN MIN

±XX.X

DOWNWARD levelling speed adjustment (-99 ÷ +99)

B

+Ý -Þ

4.5 START UP MAX

±XX.X

UPWARD start adjustment (-99 ÷ +99)

A

+Ý -Þ

4.6 SLOW UP MAX

±XX.X

UPWARD levelling speed adjustment (-99 ÷ +99)

B

+Ý -Þ

4.7 HIGH DN MAX

±XX.X

DOWNWARD high speed adjustment (-99 ÷ +99)

C

+Ý -Þ

4.8 SLOW DN MAX

±XX.X

DOWNWARD levelling speed adjustment (-99 ÷ +99)

B

+Ý -Þ

4.9 OFFSET V0 UP

XXX mm

+Ý -Þ

UPWARD levelling space

adjustment in NOMINAL speed

(0 ÷ 600 mm)

4.10 OFFSET V0 DN

XXX mm

+Ý -Þ

DOWNWARD levelling space

adjustment in NOMINAL speed

(0 ÷ 600 mm)

4.11 OFFSET V1 UP

XXX mm

+Ý -Þ

UPWARD levelling space

adjustment in INTERMEDIATE

speed (0 ÷ 600 mm)

4.12 OFFSET V1 DN

XXX mm

+Ý -Þ

DOWNWARD levelling space

adjustment in INTERMEDIATE

speed (0 ÷ 600 mm)

D

D

RAL

600 0

OFFSET

¥"

1 0991 483 EN - 21.12.2011

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

35 / 46

1.05

ENG

- 5 - SETTINGS

Data entered by GMV, run control during the installation of the system

NGV VER XX.XXX

5-SETTINGS

Ý Þ

5.1 LIFT RATIO

X:X

Ratio of the lift system (1:1; 2:1; 3:1)

Ý Þ

5.2 JACK DIAM.

XXX mm

Diameter or correspondent diameter of the jack [mm]

(see data on technical catalogue tables)

Ý Þ

5.3 PUMP FLOW

XXX l/min

Flow rate of the pump [l/min]

Ý Þ

5.4 MAP

XXXX

Map code of the power unit (not active)

Ý Þ

5.5 PSTAT MIN

XX.X bar

Minimum static pressure (5.0 ÷ 45.0 bar)

Ý Þ

5.6 PSTAT MAX

XX.X bar

Maximum static pressure (Pstat Min. ÷ 45.0 bar)

Ý Þ

5.7 P MIN

XX.X bar

Minimum pressure (1.0 ÷ 10.0 bar) medium value ±5 bar

Ý Þ

5.8 P FULL LOAD

XX.X bar

Full load pressure, 80% of nominal load (12.0 ÷ 45.0 bar)*

Ý Þ

5.9 P OVERLOAD

XX.X bar

Overload pressure, 110% of nominal load (12.0 ÷ 50.0 bar)*

Ý Þ

5.10 P MAX

XX.X bar

Pressione di massima, 140% del carico nominale (15.0 ÷ 70.0 bar)*

Ý Þ

* Re-calculated value when the P

stat,MIN

value (parameter 5.5) or the

P

stat,MAX

value (parameter 5.6) are modified

5.11 COOL TEMP.

XX °C

Maximum allowable fluid temperature

(5.0 ÷ 70.0 °C) set value 70°C

Ý Þ

5.12 MODE:

XX - XX

Mode: NORMAL Mode:INSTALLATION

NOTE

If the mode set is : NORMAL, the valve works as shown into the manual.

If the mode set is : INSTALLATION, the valve works at V2 speed regardless of signal it receives from

the control panel. The installation mode is used routinely during the installation of the system.

¥"

1 0991 483 EN - 21.12.2011

ENG

1.05

36 / 46

NGV A3 VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

- 6 - UPWARD PARAMETERS

NGV VER XX.XXX

6-UP PARAMETERS

Ý Þ

6.1 NOM.SPEED V0

X.XX m/s

Nominal speed [m/s] referred to the nominal pump flow, piston diameter

and size, value not modifiable.

Ý Þ

6.2 INT.SPEED V1

X.XX m/s

Intermediate speed [m/s]

(15 ÷ 75 % x Nominal Speed)

Ý Þ

6.3 INS.SPEED V2

X.XX m/s

Inspection speed (0.15 ÷ 0.63 m/s)

Ý Þ

6.4 SLOW SPEED

X.XX m/s

Levelling speed (0.01 ÷ 0.15 m/s, recommended 0.06 m/s)

Ý Þ

6.5 RELEV.SPEED

X.XX m/s

Re-levelling speed (0.01 ÷ 0.15 m/s, recommended 0.04 ÷ 0.06 m/s)

Ý Þ

6.6 ACC.PROFILE

XXXXXXXX

Acceleration profile (Fast – Standard – Slow – Extra Slow - Custom)

Ý Þ

6.7 DEC.PROFILE

XXXXXXXX

Deceleration profile (Fast – Standard – Slow – Extra Slow - Custom)

Ý Þ

6.8 START DELAY

X.X s

Delay start closing VB / Time to start the motor/pump (0,2…5,0 s)

- 7 - DOWNWARD PARAMETERS

NGV VER XX.XXX

7-DN PARAMETERS

Ý Þ

7.1 NOM.SPEED V0

X.XX m/s