English

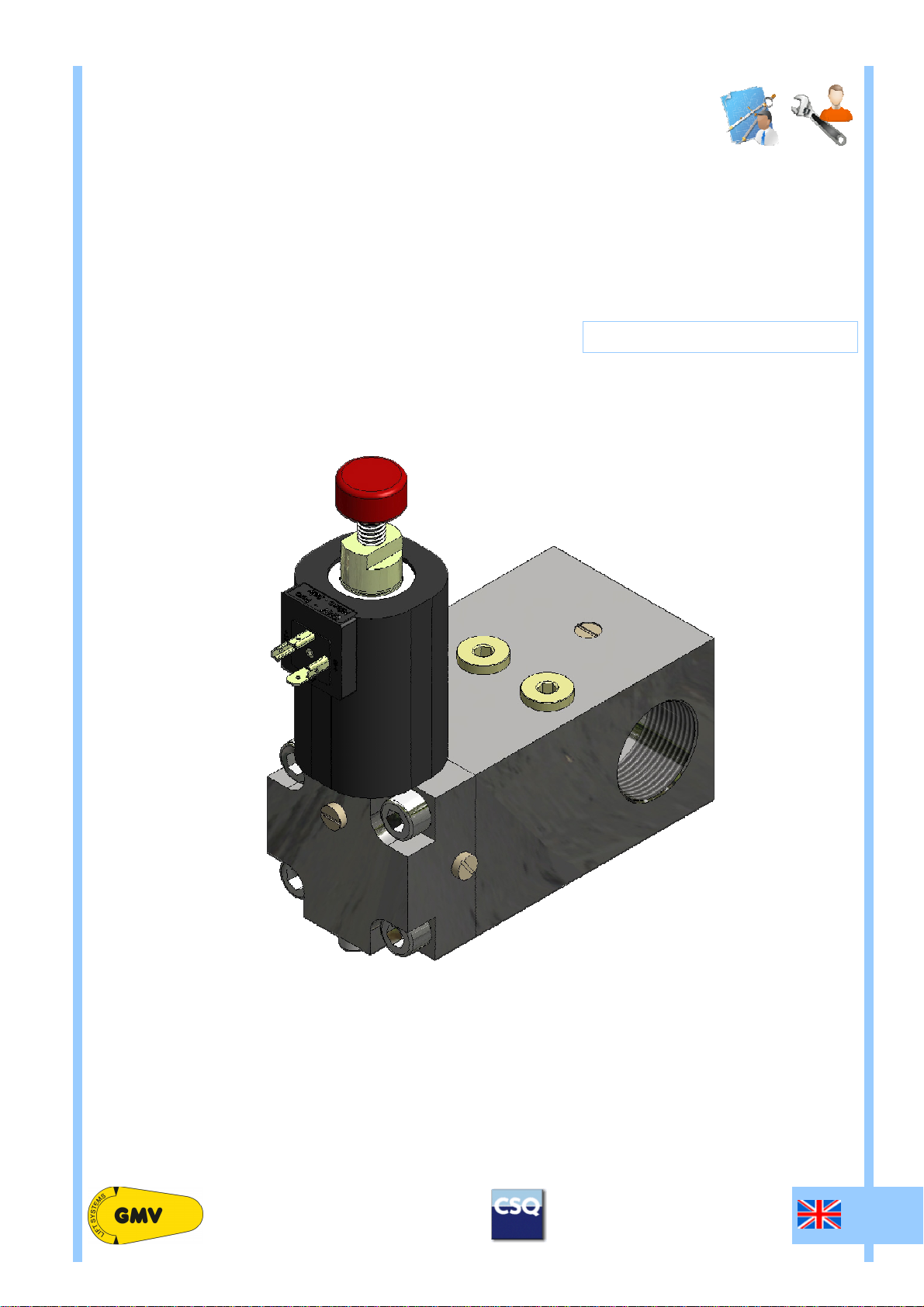

DLV VALVE

DLV-A3

VALVE MANUAL

I

NSTALLATION AND USE

A

VAILABLE WITH VALVE TYPE

3010 ¾”,1 1/4”, 1 ½”, 2”, NGV ¾”

1 0991 486 EN

GMV SPA

FLUID DYNAMICS EQUIPMENTS

AND COMPONENTS FOR LIFTS

UNI EN ISO 9001

Certified Company

ENG

ENG

1 0991 486 EN - 29.09.2016

DLV

2 / 11

INDEX

I

NSTALLATION, USE AND MAINTENANCE

VALVE MANUAL

0 GENERAL SECTION 3

0.1 INTRODUCTION 3

0.2 INSTALLATION RELATED DOCUMENTS 3

0.3 SAFETY PRECAUTION DURING INSTALLATION 3

0.4 GENERAL ORDERS 4

0.5 LIABILITY AND WARRANTY 4

1 FEATURES AND REQUIREMENTS 4

1.1

DLV A3 VALVE

1.2

DELIVERY PACKAGING

1.3

IDENTIFICATION PLATE

1.4 T

HE FLUID

1.5

CLEANING AND SAFETY PROTECTIONS

4

5

5

5

6

2 DLV A3 WORKING DESCRIPTION 6

2.1

DESCRIPTION

2.2

HYDRAULIC SCHEME

2.1

SEMPLIFIED HYDRAULIC SCHEME

6

7

7

3 INSTALLATION 8

3.1 H

YDRAULIC CONNECTION SAMPLES

3.2 D

IMENSIONS

9

8

4 ELETTRICAL CONNECTIONS 9

4.1

ELECTRICAL GETTING STARTED:ICONS

10

5 TEST AND ADJUSTMENTS 10

5.1

MONITORING SYSTEM CHECK

6 CERTIFICATES 11

10

1 0991 486 EN - 29.09.2016

DLV

VALVE MANUAL

I

NSTALLATION, USE AND MAINTENANCE

3 / 11

0 GENERAL SECTION

0.1 INTRODUCTION

Assembling,installation,start-up and hydraulic lift maintenance should be performed by experienced

personnel.Before starting any work on the hydraulic components,personnel showld carefully read these

instructions,particularly referring to 0.3 chap. “Safety precautions”.

This “Instruction Manual” in an integral part of the lift and should be protected and accessible.

DLV is a non return electrically-controlled valve,working in series with the main valve to stop the lift during an

unintended car movement from the floor.

DLV valve prevent only the downward unintended car movement.

The purpose of the valve is to work together with the main valve according to the Lift European Standards EN

81.2:1998 + A3:2009 which states that “in case of use of two electro-valves working in series, the self control

implies the separate verification of the opening and closing of each single valve when the car is empty. If a

fault is detected, the subsequent movement of the lift must be avoided”

0.2 INSTALLATION RELATED DOCUMENTS

The documents to use for the installation are those required by the EN81-2:1998 and by the rules in force,

particularly the following:

T

HIS INSTALLATION MANUAL

W

IRING AND HYDRAULIC DIAGRAMS

All the documentation for a correct and safe installation, must be stored by the installation responsible.

Please remember that this documentation is considered part of the plant and must be complete, well stored

and unabridged in every part.

In order to maintain the readability, the documentation shouldn’t be damaged and shouldn’t have missing

parts. Moreover, do not tear or deteriorate sheets during consulting.

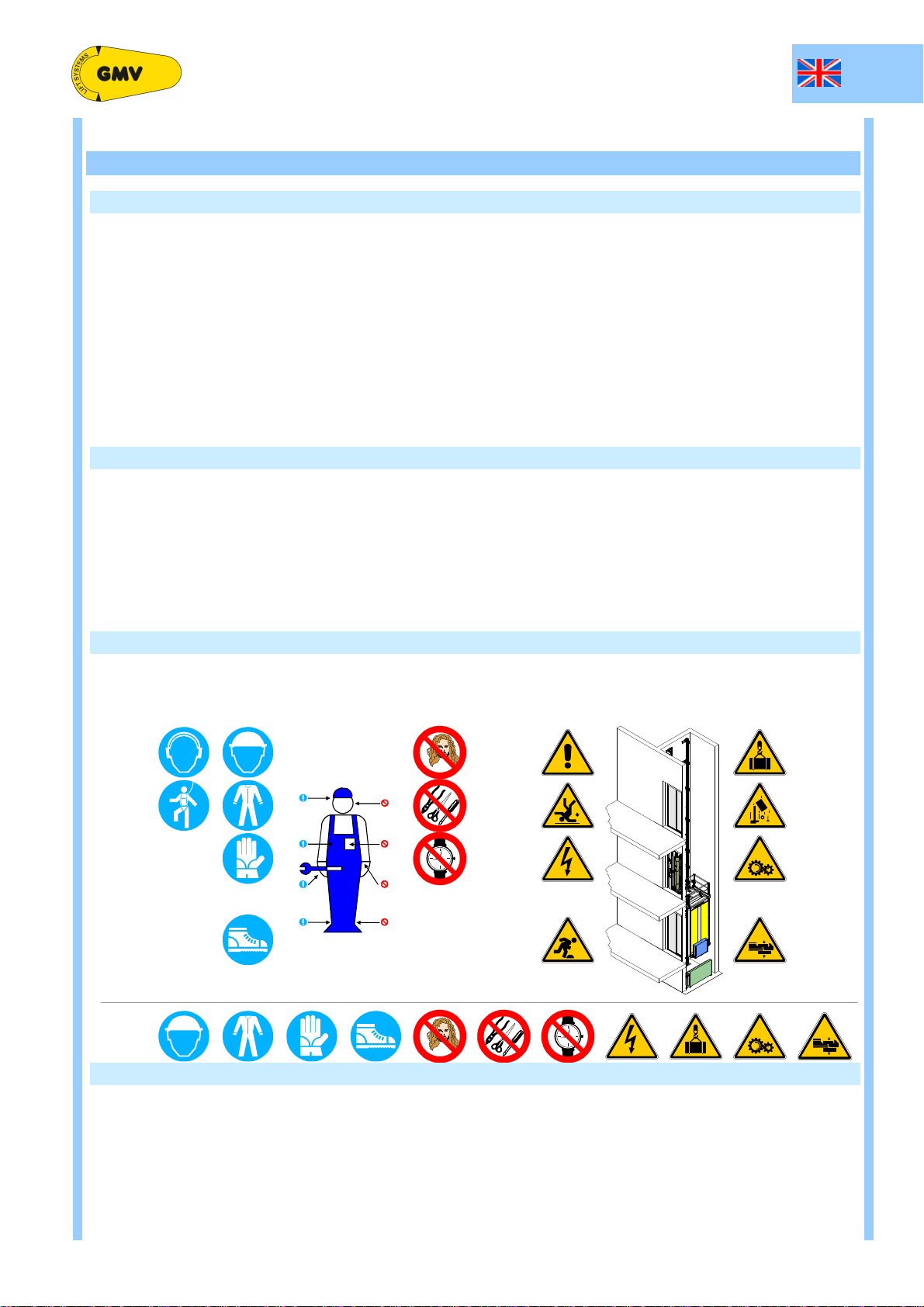

0.3 SAFETY PRECAUTION DURING INSTALLATION

Installers and maintenance staff are completely responsible for their own safety during their activities.They

should follow all the safety official rules to prevent accidents to the working staff.

In these instructions,the major points concerning the working safety and prevention,will be marked by the

following symbols:

(EN81-2:1998 16.2 A) 6

AND

7).

ENG

ENG

1 0991 486 EN - 29.09.2016

DLV

4 / 11

I

NSTALLATION, USE AND MAINTENANCE

VALVE MANUAL

0.4 GENERAL ORDERS

The valves shall be maintained in good working order in accordance with the European Standards.

To this effect, regular maintenance of the installation shall be carried out, to ensure, in particular, the safety of

the installation.

The safety of an installation shall take into account the ability to be maintained without causing injury or damage

to health.

Regular maintenance of the installation shall be carried out to ensure the reliability of the installation.

The access and the associated environment shall be maintained in good working order.

The competence of the maintenance person within the maintenance organization shall be continuously updated.

0.5 LIABILITY AND WARRANTY

These instructions are intended for people with experience in installation, adjustment and maintenance of

hydraulic lifts.

GMV disclaims any liability for damage caused by improper or different use from what described in these

instructions or inexperience or carelessness of those responsible to assemble, adjust or repair hydraulic

components.

GMV's warranty is voided if you install any components or parts not original, if you make unauthorized

changes or modifications or made by unauthorized or unqualified personnel.

Unless otherwise indicated, the following situations are forbidden for safety reasons:

- Any product modification;

The installation of the product for purposes other than those described;

Damage to the joints;

Carrying out maintenance or inspections improper or inadequate;

The use of improper accessories and not original spare parts or materials from GMV.

NOTES

To install or replace system components,we should pay attention to the following measures:

Indicates information which contents must be seriously taken in consideration.

WARNING

Indicates that the described operation may cause, damages to the system or physical damages if

performed without complying with the safety standards.

- Make the car lift rest on the buffers

- make sure the lift shouln’t be unintentionally powered,locking the main switch

- bring to zero the pressure before opening the hydraulic circuit,removing cups,unscrewing fittings

- In case of welding,be care the slags do not get in touch with the fluid,the jask and the gaskets

- Remove the fluid in excess,the leakages,keep clean the system to find out and consequently remove the

leakages

WARNING

Before starting all kind of installation operation:

ALWAYS verify that all the safety devices, mechanical or electrical, are active and working properly

1 FEATURES AND REQUIREMENTS

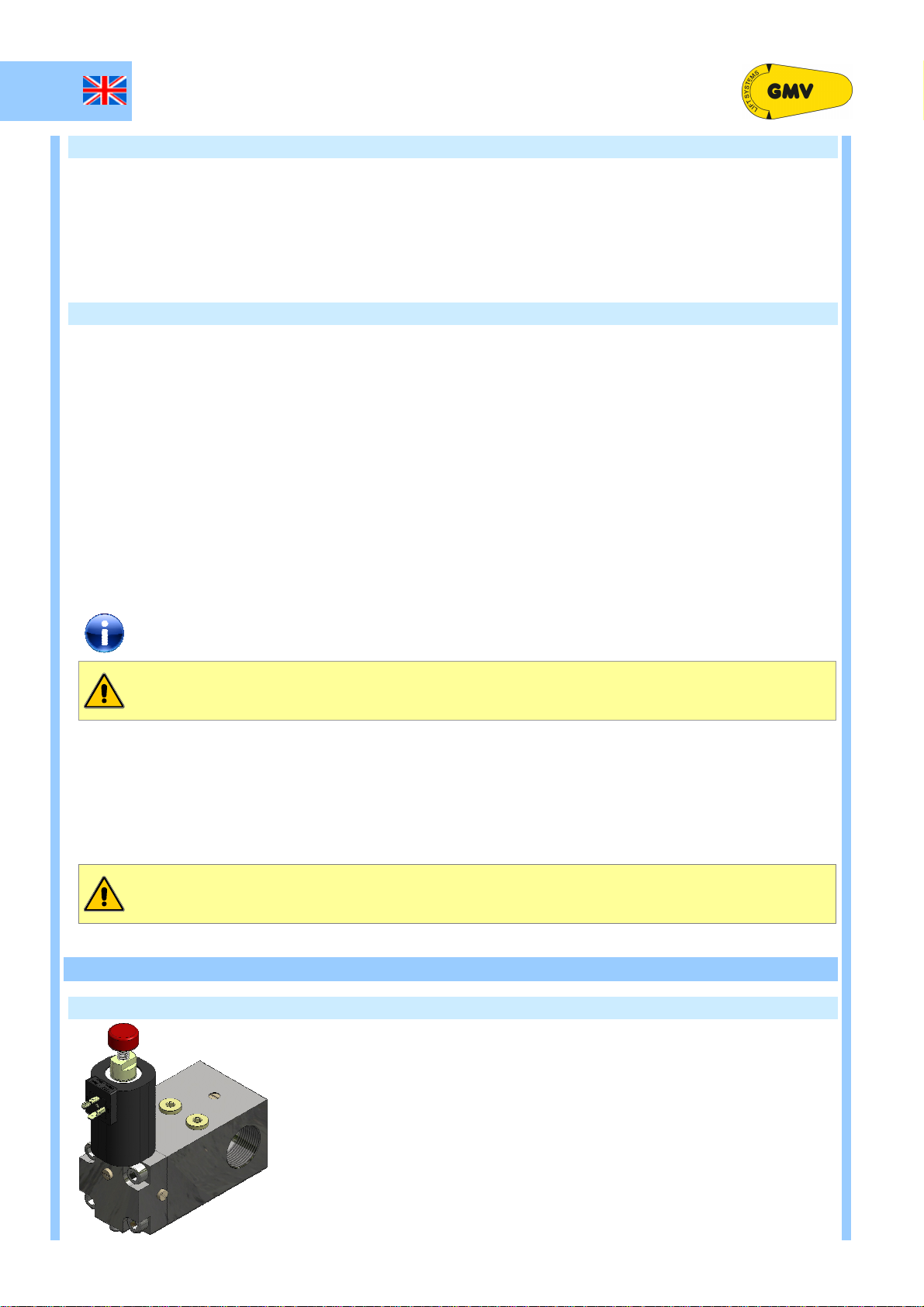

1.1 DLV A3 VALVE

The DLV A3 is a pilot-operated non-return valve that must be mounted

between the cylinder and the 3010 control valve or any other control valve

for lifts,traditional or electronic.

The valve should be installed as close as possible to the main hydraulic block

but in special cases can be installed also close to the cylinder without

compromising its function.

During the upward phase it works as a normal non-return valve . So the

pressure of the oil sent from the pump can control the opening degree.

In down direction however, when energized, the valve allows the passage of

oil from the cylinder to the main block and then into the tank.When deenergized, the solenoid valve immediately closes and stops the car.

1 0991 486 EN - 29.09.2016

DLV

VALVE MANUAL

I

NSTALLATION, USE AND MAINTENANCE

5 / 11

DLV are manifactured in different sizes and can be used for the following range(see the tab. 1).

Type

Max

interv.flow

l/min bar °C cSt Vdc

DLV A3 – ¾”

DLV A3 - 1” ¼

DLV A3 - 1” ½

DLV A3 - 2”

45 8 - 45

210 15 - 210

430 25 - 430

600 30 - 600

Nominal

flow

Working

press.

12 - 45 5 - 70

Working

temp.

Viscosity Tens.DLV Power

Vac W Vdc

30

110

220

230

30

30

45

14-290

(ISO VG 46

I≈120)

24-12

48-12

80-12

90-12

110-12

180-12/24

Emerg.

Pw.

12 24

Tab. 1

1.2 DELIVERY PACKAGING

Upon picking up the material,before signing the delivery,be care the goods match the packing list and the order

list.

The packing list should includes:

- Installation use and maintenance manual

- DLV device (factory assembled)

- Connection fittings

- Cartboard box

1.3 IDENTIFICATION PLATE

The indentification plate with the main factory data (see picture below), is directly placed on DLV.

The plate should include:

- Type of DLV device

- Serial number

- Year manifacturing

- Flow range

- Max static pressure

ENG

1.4 THE FLUID

The hydraulic fluid is very important for an hydraulic lift

Especially in systems with medium or intensive traffic,choosing a good fluid increases the temperature range of

comfortable working and enhances the service life of the components.

When we choose the fluid we must take into account both the characteristics of the elevator

(temperature , power unit ventilation room, amount of trafic) and the characteristics of the fluid

(temperature-viscosity).In case of replacement,follow the local pollution.Waste should be placed in a

proper box to protect the environment.

ENG

1 0991 486 EN - 29.09.2016

6 / 11

GMV use and recommend an hydraulic fluid ISO VG 46 that :

DLV

VALVE MANUAL

I

NSTALLATION, USE AND MAINTENANCE

• Thanks to classification as category HEES, as rule ISO-UNI 6743-4 and its

biodegradability index > 90%, according to standard CEC L33-A-93, is

acceptable from an environmental point of view.

• Thanks to the synthetic base (ISO VG 46 ) and its viscosity index (>140),

higher than the traditional mineral oil, allowing greater stability, ensuring

better performance against wear and aging on systems as lifts for

persons and goods, in accordance with the environmental directive

2006/118/EC.

• Thanks to a flash point above 220°C compared to the 140°C of the

traditional mineral oil it is safer and reduces the risk of fire.

1.5 CLEANING AND SAFETY PROTECTIONS

Ensure there is no dirty inside.The impurities could damage the sealing of the piston and of the valve block and

can cause failures.All the components to remove for control and repair,should be clean before the reinstallation.

Any leakage of fluid should be adsorbed with rags during the maintenance to avoid any release.

2 DLV A3 WORKING DESCRIPTION

2.1 DESCRIPTION

The DLV A3 is a pilot-operated downward non-return valve,normally closed,primarly made by an aluminium

body.

The F side must be connected to the primary valve.The H side must be connected to the ball valve and then to

the jack (see pict. 2 in sect.).Here below is shown the flow upward

[H] OUT

[F] IN

Pict 1

So let’s see what must be done during the normal working of the lift :

Upward:If the DLV A3 works as a standard non-return valve opening by the oil pressure,nothing is requested.

Downward:the valve DLV A3, has two working ways:

1. Contemporaneous

The DLV A3 is energized and de-energized at the same time of the main downward solenoid valve VMD.

In this way both valves are working as hydraulic valves in series and they require to be monitored. The

monitoring requires the type examination certificate. This monitoring must be done once a day by performing

(automatically)a specific sequence of actions.

1 0991 486 EN - 29.09.2016

DLV

VALVE MANUAL

I

NSTALLATION, USE AND MAINTENANCE

7 / 11

2. Timed

The DLV A3, respect to the main downward solenoid valve VMD, is energized about 1 second before and

de-energized almost 2 seconds after the arrival at landing.

In this way the DLV A3 is not an element working to control the lift and consequently does not require any

kind of monitoring. Its correct working can be verified during the standard maintenance operations every 6

months.

A3 intervention state of DLV

In the shaft must be present a system (ex. two contacts/switches) able to detect the unintended movement of

the car with open doors in up or down direction.

During an unintended movement in down direction, when the unintended movement is detected, the system

de-energize the DLV A3 valve to let it close and stop the lift.

During an unintended movement in up direction the system must switch off the motor/pump to stop this

movement. Consequently the valve will stop the car.In every case,after this phase,the system should go out of

service and it should be restored only by an authorized and properly trained person. The system which detects

the unintended movement and energizes the stopping device can be the existing one just used to define the

opening doors zone. The intervention zone, according to the EN 81-2, must be at maximum ± 200 mm from the

landing

2.2 HYDRAULIC SCHEME

Here below (pict.3) follows the DLV hydraulic scheme to show the placing of DLV,between the main valve and

the jack.

Legend

PT Pressure trasducer

DLV Non return pilot-operated valve

R/S Shut off valve/Silencer

VC Check valve

ISP Inspection pressure gauge fitting

MAN Pressure gauge

Pmax Maximum pressure switch

Pmin Minimum pressure switch

OLD Overload pressure switch

J Jack

[F] DLV connection main valve side

[H] DLV connection main jack side

2.1 SEMPLIFIED HYDRAULIC SCHEME

DLV A3 Non return pilot valve

Pict. 1

VAL Main valve

J Jack

ENG

J

[H]

DLV A3

[F]

VAL

ENG

1 0991 486 EN - 29.09.2016

8 / 11

DLV

I

NSTALLATION, USE AND MAINTENANCE

3 INSTALLATION

ATTENZIONE

During the installation:nvere exclude safety devices and never power-on the motor pump.

3.1 HYDRAULIC CONNECTION SAMPLES

VALVE MANUAL

DLV A3 - 3010 – MR with cabinet up to 150 lt DLV A3 - 3010 – MR no cabinet from 180 to 210 lt

DLV A3 - 3010 - MRL MC with cabinet up to 150 lt DLV A3 - 3010 - MRL MC no cabinet 180/210 lt

3.2 DIMENSIONS

DLV

VALVE MANUAL

I

NSTALLATION, USE AND MAINTENANCE

H

B

F

T

1 0991 486 EN - 29.09.2016

D

B

9 / 11

ENG

A

F

A

A

B

A

M8x1.25

D

A

VH

VB

B

DLV A B C H HT D

¾”

1” ¼

1” ½

2”

120 54 ≈6,5 54 175 ¾” G 26 48 19

153,5 80 ≈13 70 192 1” ¼ G 35 67,5 28,5 53

185 90 ≈9 90 212 1” ½ G 45 73 32 -

204 90 ≈15 115 237 2” G 57,5 89,25 39,5 -

4 ELETTRICAL CONNECTIONS

H

A

B

B

B

A, DB

A

A

BA BB A

A, AB

F, BF

C

2

+

Mode 1

-

Safety chain Car door safety Landing door safety

EN81-2 CD LD

3

+

Mode 2

VM D

DL V A3

-

E N 8 1 -2

ON

OFF

ON

OFF

EN 81-2

V M D D L V A 3

CO N TROLL ER

ON + 1 s

OFF

VM D DLV A 3

ON

OF F + 2s

Contemporaneous

Timed

INSTALLATION NOTES

Mode 1:to correctly install the DLV A3 on the valves 3010, 3100, GEV or similar, the following

devices (if presents) must be mounted, or transferred on the DLV:

- Pressure overload (installation on the DLV A3 optional if Mode 2)

- Pressure transducer (installation on the DLV A3 optional if Mode 2)

- Pressure gauge and pressure gauge inspection EN (installation on the DLV A3 recommended)

All above to provide a correct reading of the pressure value.

ENG

4.1 ELECTRICAL GETTING STARTED:ICONS

1 0991 486 EN - 29.09.2016

10 / 11

DLV

VALVE MANUAL

I

NSTALLATION, USE AND MAINTENANCE

0 - OFF

+

0 - OFF

5 TEST AND ADJUSTMENTS

5.1 MONITORING SYSTEM CHECK

To assure the correct working of the monitoring system of the DLV A3 the control panel should perform a

check operation behind closed doors, at least once a day.

The control panel, during the

test, must:

1. To move the car to the

lower floor

2. To close the doors

3. Wait that the system turns

into the “Free” status

4. Start the test following the

scheme ->

5. At the end of the test, if the

system is not in the “Out of

service” status, turn the

system in normal use.

]x[

]↕[

R _↑

L --►-- = Return at landing

If the control panel

receives a command

from a push-button

panel during the test,

stop the test, execute

the command (order /

call) and at the end,

restart from point 1

= Close

= Open

= NO

= YES

= Relevelling

With the car stopped at landing,energize only the DLV A3 valve,holding the main valve VMD de-energized.If all

the components work correctly,the car must stop at landing position.A timed check starts for two sec.to verify a

car movement.In case of movement detection without landing,the system must go into alarm and put the lift out

of service.In case of back-landing,another 2 seconds timed check starts,energizing the the DLV.If the relevelling

does not start,the system is ok.Otherwise,a VMD failure is confirmed (DLV de-energized).

1 0991 486 EN - 29.09.2016

DLV

VALVE MANUAL

I

NSTALLATION, USE AND MAINTENANCE

11 / 11

In the same way,is energized only the main valve VMD,holding the DLV A3 valve de-energized.If all the

components work correctly,the car must stop at landing position.A timed check starts for two sec.to verify a car

movement.In case of movement detection without landing,the system must go into alarm and put the lift out of

service.In case of back-landing,another 2 seconds timed check starts,energizing the VMD.If the relevelling does

not start,the system is ok.Otherwise,a DLV failure is confirmed (VMD de-energized).

ENG

6 CERTIFICATES

FLUID DYNAMICS EQUIPMENTS

AND COMPONENTS FOR LIFTS

All rights reserved.

Any kind of exploitation in any form and by any means is forbidden without a written permission of GMV Spa.

GMV Spa, within technical or manufacturing progress, reserves the right to modify parts or this manual without notice.

Drawings, descriptions and data included in this manual are indicatives.

For all the data not included in this manual refer to the documents of any single part.

To guarantee the products security, do not use spare parts not genuine or not approved by GMV Spa.

GMV Spa will not assume any responsibility if the instructions included in this manual are not observed.

Information and support:

GMV SPA

V

IA DON GNOCCHI, 10 -

TEL. +39 02 33930.1 - FAX +39 02 3390379

HTTP

://

Doc. n° 1 0991 486 EN Rev. 0.0 - 29.09.2016 File: DLVA3-02-10991486EN.doc - (J30)

WWW.GMV.IT - E-MAIL: INFO@GMV.IT

20016 PERO – M

ILANO (ITALY

)

UNI EN ISO 9001

C

ERTIFIED COMPANY

Loading...

Loading...