GMS B36 Operating & Maintenance Manual

B36

GÖÇMAKSAN

GÖÇMAKSAN

Rev:01/2013

B36

1

CONTENTS

CONTENTS .............................................................................................................................................. 1

LIST OF FIGURES .................................................................................................................................. 2

TAGS USED ON THE MACHINE.......................................................................................................... 3

INTRODUCTION .................................................................................................................................... 4

1. MAIN PARTS OF BENDING MACHINE ......................................................................................... 4

2. MACHINE ASSEMBLY ...................................................................................................................... 5

3. MACHINE RUNNING PROCEDURES ORDER ............................................................................... 6

4. TECHNICAL DATA ............................................................................................................................ 7

5. EQUIPMENT SUPPLIED WITH MACHINE ..................................................................................... 7

6. USING THE MACHINE .................................................................................................................... 8

6.1 Correct Connection of the Irons on the machine ............................................................................ 8

6.2. Incorrect placement of the irons to bu bent on the machine .......................................................... 8

6.3. Incorrect placement of the irons to be bent on the machine .......................................................... 9

7. PROHIBITED USAGE ON THE MACHINE ................................................................................... 10

8. SCOPE OF THE WARRANTY ......................................................................................................... 11

9. PROTECTORS TO BE USED WHEN WORKING WITH THE MACHINE .................................. 11

9.1. Protector apparel .......................................................................................................................... 11

9.2. Work clothes ................................................................................................................................ 12

10. HANDLING THE MACHINE ......................................................................................................... 12

11. CONTROLS AND SETTINGS ON THE MACHINE ..................................................................... 13

11.1. Thermal flow setting range and motor protection switch .......................................................... 14

11.2. Bent Bar Bending setting (45°) .................................................................................................. 15

11.3. Protractor Bending Setting (90°) ............................................................................................... 16

11.4. Hook Bending Settings (180°) ................................................................................................... 17

11.5. Stirrup Bending: ......................................................................................................................... 17

12. MAINTENANCE AND LUBRICATION INSTRUCTIONS .......................................................... 20

10. FAULTS AND SOLUTION OFFERS ............................................................................................. 20

14. MACHINE EQUIPMENT LIST ...................................................................................................... 23

15. MACHINE ASSEMBLY .................................................................................................................. 25

16. MACHINE ELECTRICITY SCHEME ............................................................................................ 26

17. ABOUT COMPANY ........................................................................................................................ 28

B36

2

LIST OF FIGURES

Figure 1: Main parts of bending machine ................................................................................................. 4

Figure 2: Leveling the machine on a solid ground .................................................................................... 5

Figure 3: Control buttons .......................................................................................................................... 6

Figure 4: Placing the irons on the machine correctly ................................................................................ 8

Figure 5: Incorrect connection of the irons on the machine ..................................................................... 9

Figure 6: Wrong placement of the irons on the machine ........................................................................ 10

Figure 7: Wrong positioning of the person making bend ....................................................................... 10

Figure 8: Handling the machine .............................................................................................................. 13

Figure 9: Machine control panel and functions ...................................................................................... 13

Figure10: Bent bar bending indicator ..................................................................................................... 16

Figure 11:Representation of Protector Bending...................................................................................... 16

Figure12: Hook Bending demo ............................................................................................................... 17

Figure13: Stirrup bending demo ............................................................................................................. 19

B36

3

MAIN SAFETY INFORMATION

➢ This symbol is put before the articles giving warning explanations in order to draw attention of the

trained operator to important functions.

€ This symbol is put before the articles giving warning explanations in order to draw attention of the

trained operator to electrical issues.

This symbol is put before the sentences in order to draw attention of the trained operator to the

master instructions and directive regarding to handling or safety.

TAGS USED ON THE MACHINE

Trademark plate of manufacturer company

Logo plate of manufacturer company

B 36

Model name tag of the machine

CE norm conformity tag

Plate on capacity and technical information of the machine

Machine user's and maintenance manual tag

Handling and carrying hook tag

Electricity panel warning tag

Grounding output tag

B36

4

INTRODUCTION

B 36 Mechanic Iron Bending Machine is made only with the purpose of steel material bending.

Using other than the indicated purposes are prohibited. It is possible to mount various apparatuses on

the machine optionally for bending in different shapes.

In order to obtain the best yield from the machine it should be in a situation so that it can be worked

easily and in a position that more productivity might be obtained from the operator. Because of this the

location where the machine is operated should be close to the iron stocks. Besides, it shall be more

useful to cover top of the location where the machine is operated with a shelter. We suggest two

workbenches to be located on two sides of the machine. Length of these workbenches should be as

long as the longest iron that will be bent. Since the operator will be able to work without turning,

lifting any kind of iron, it will enable the operator to work more effectively.

Important Warning !!!

• User's and maintenance manuals must be read.

• Machine should be operated by instructed workers.

• When adjustments such as controlling, maintaining, lubing are being made electricity of the

machine must be cut off.

• All of the explanations given under user's and maintenance manual must be complied.

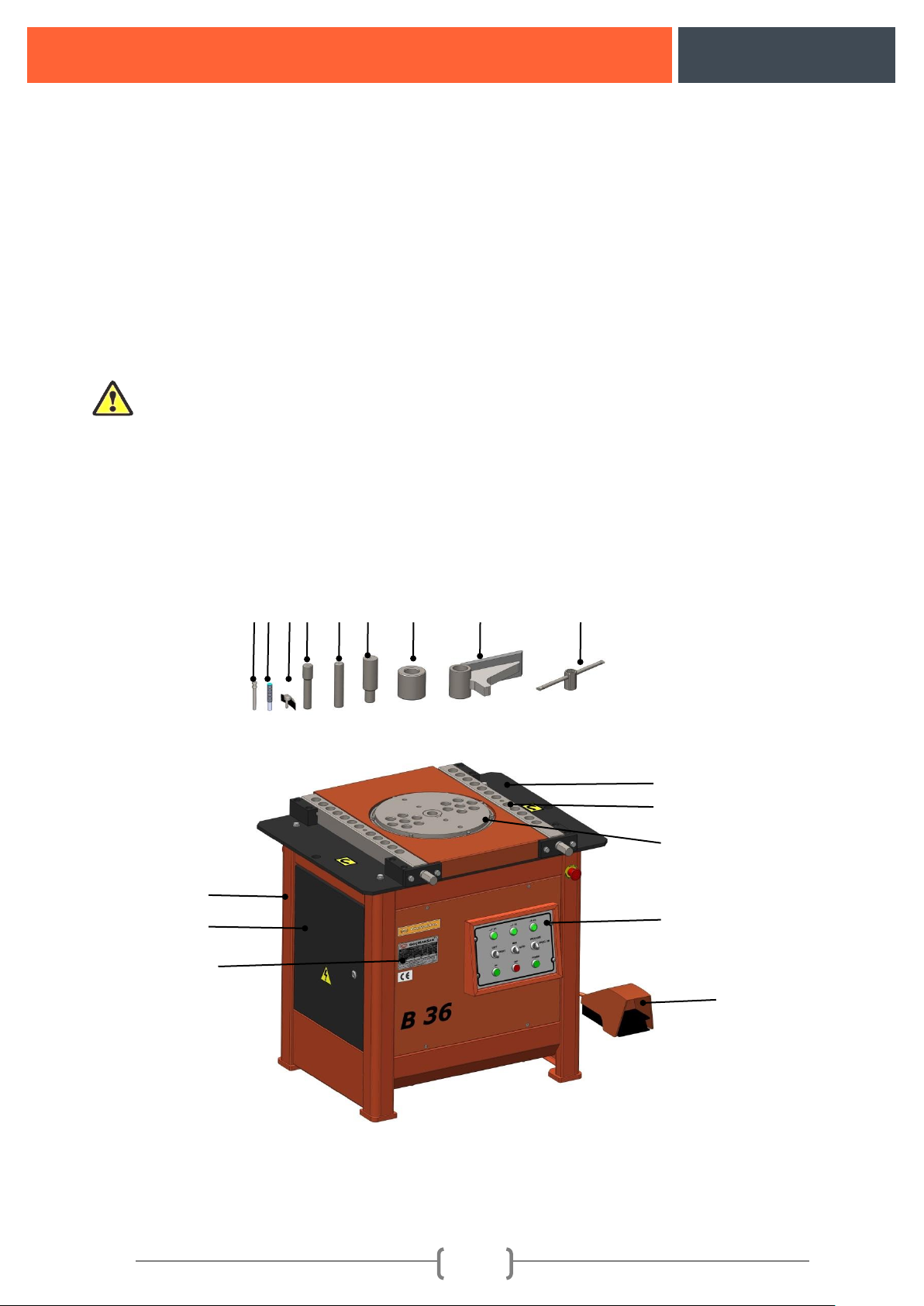

1. MAIN PARTS OF BENDING MACHINE

Figure 1: Main parts of bending machine

3 4 5 6 7 8 9

10

11

1 2 17

15

12

13

14

16

B36

5

1

Machine Frame

5

Zero Adjustment

Pin

9

Bending Sleeve

13

Bending Plates

2

Electricity Board Cap

6

Stirrup Pin

10

Retainer

14

Bending Flange

3

Switch Adjustment

Pin

7

Straight Pin

11

Adjustment

spanner

15

Control Panel

4

Sensor Pin

8

Bending Pin

12

Machine Table

16

Foot Pedal

17

Plate

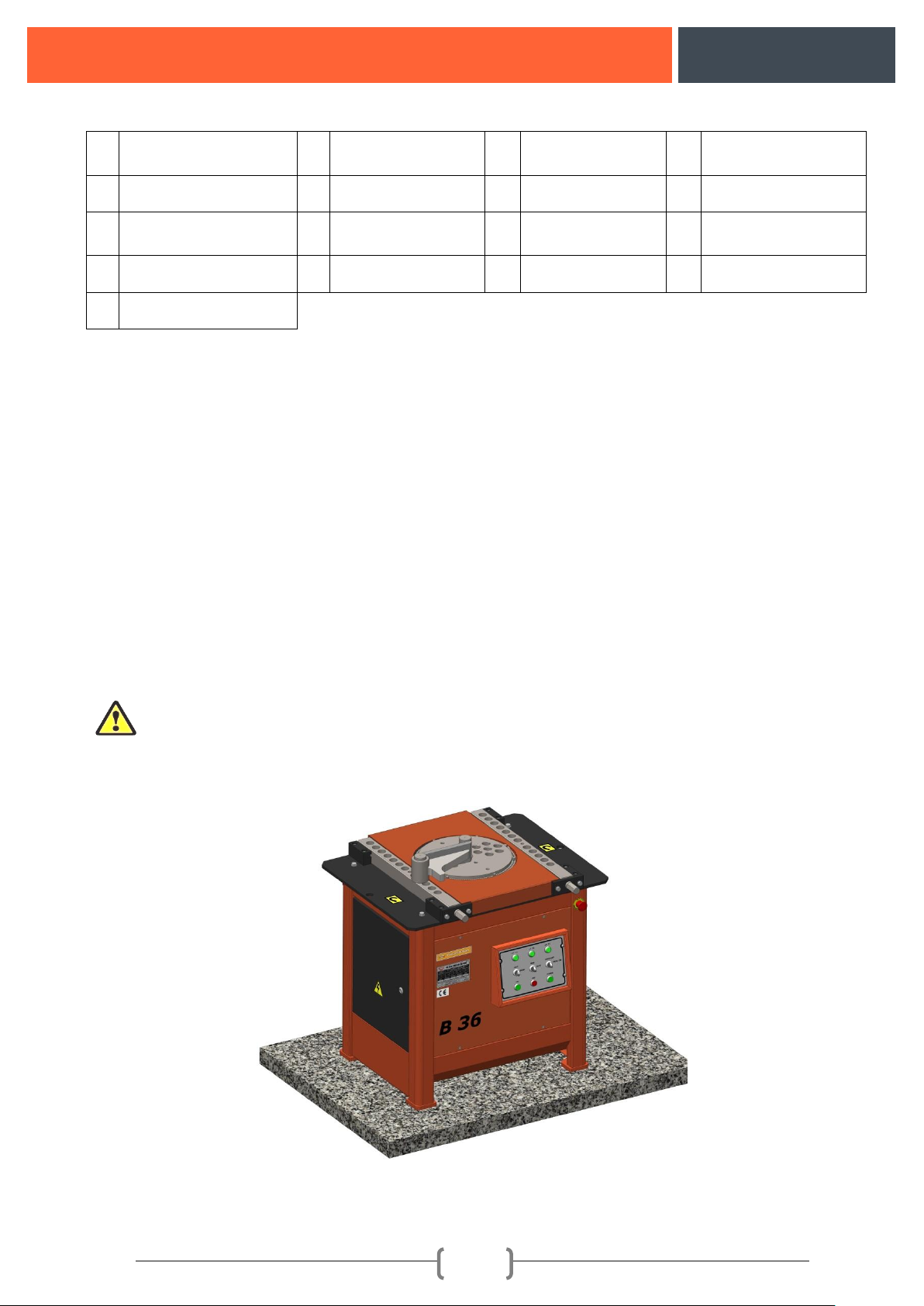

2. MACHINE ASSEMBLY

• Machine should be leveled on a solid ground. Figure 2

• Electricity connection of the machine should be made by competent technicians.

Explanation

Electricity Connection

For main electricity connection plug should be connected to supply line with a 5x4 mm²

isolated cable and then plugged into power outlet.

Grounding connection should be made for safety. Machine shouldn't be operated without

making grounding connection.

Connection of grounding line

The following procedures should be followed for this system.

Connect one end of the grounding to a copper wire (minimum 16 mm²) as it will enable

electrical conductivity. The other end should be either connected with a pipe that has a conductivity

capacity immerged into the ground (preferably into a humid ground) or the copper plate should be

buried into the ground as much as deep.

Figure 2: Leveling the machine on a solid ground

B36

6

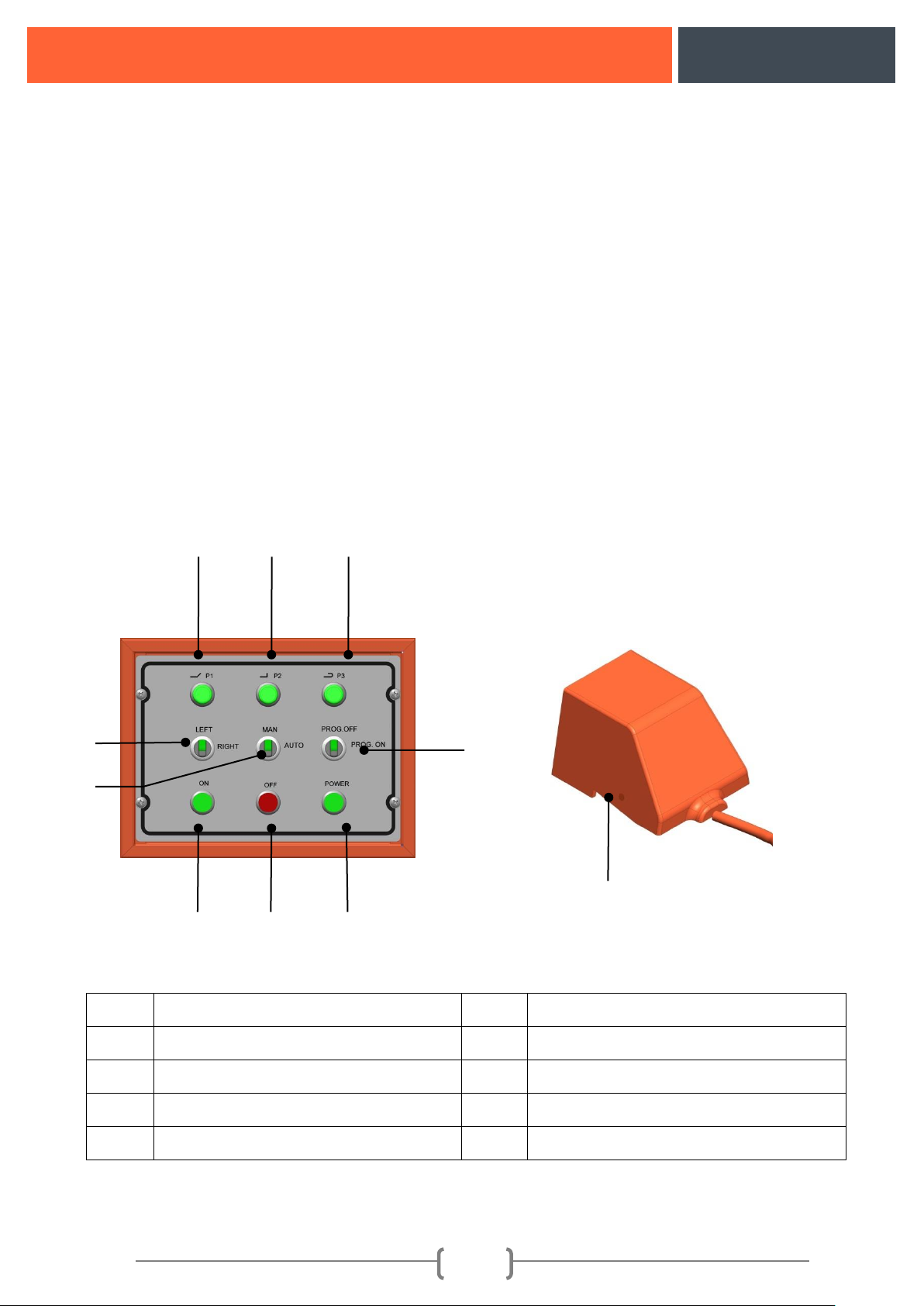

3. MACHINE RUNNING PROCEDURES ORDER

• Be sure that the machine is assembled in conformance with the Machine Assembly procedures.

• If there is any object on the machine (including the bending apparatus) they must be removed.

• LEFT-RIGHT switch on the control panel of the machine is turned to LEFT or RIGHT position,

MAN AUTO switch is turned to MAN position and machine turning direction is confirmed by

pressing on the foot pedal.

Explanation: Rotation direction is approved by taking the front of the machine as reference (Control

pane side) the clockwise as right and counter-clockwise as left. If the machine is rotating reverse of the

switch it means phases of the electricity supply are feeding reversely. This situation doesn't affect the

running system of the machine. In such case LEFT-RIGHT switch might be turned to the other side or

competent electricians might change the directions of the phases.

After fixing the direction of rotation bending adjustments should start.

Control buttons

Figure 3: Control buttons

1

P1 Button

6

Program On-Off Switch

2

P2 Button

7

On Button

3

P3 Button

8

Off Button

4

Left-Right Switch

9

Power Button

5

Man-Auto Switch

10

Foot Pedal

1 6 7 8 9

10 5 2 3 4

B36

7

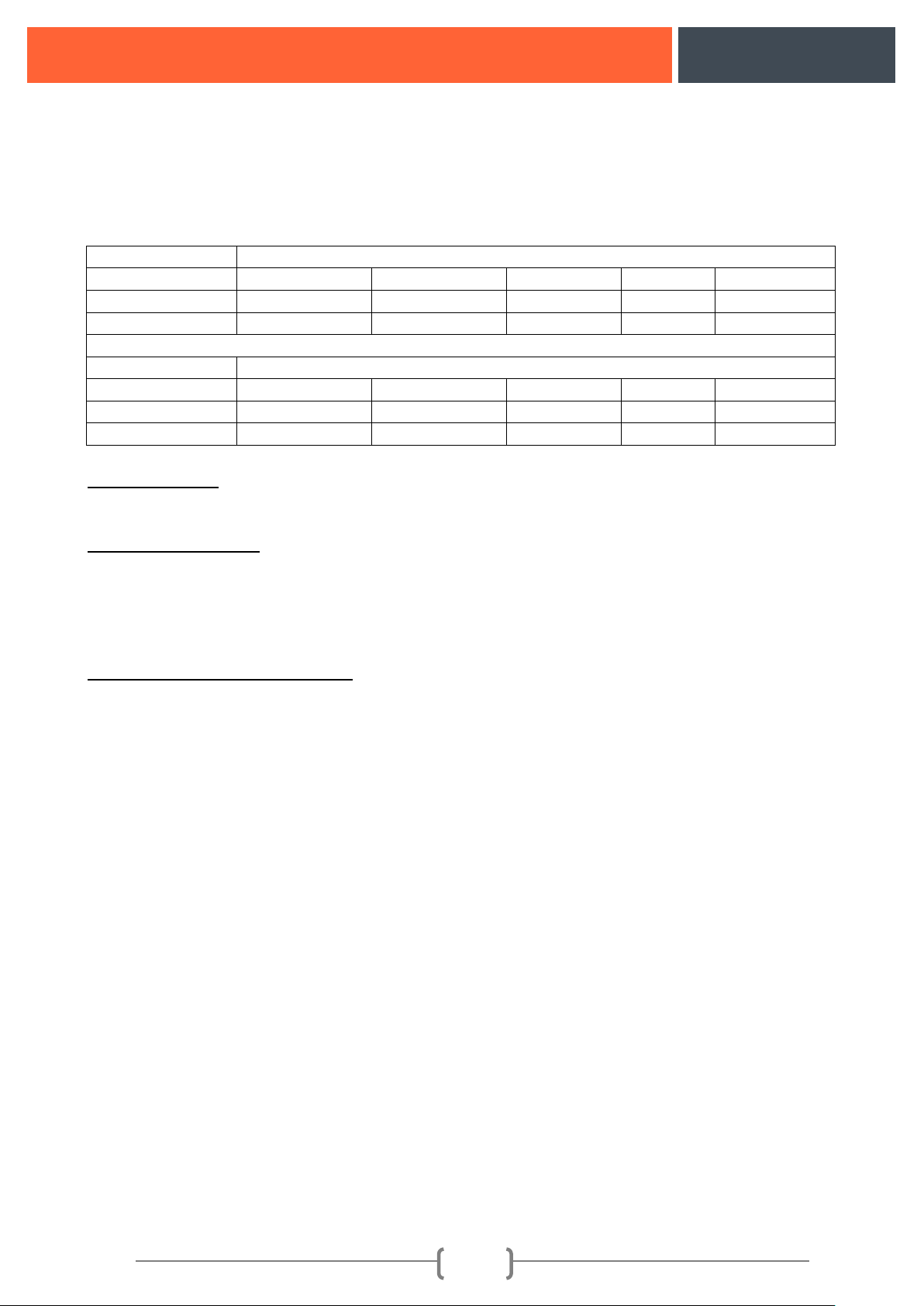

4. TECHNICAL DATA

Machine Bending Capacity:

Steel Quality

Diameter/Bending Capacity

45 kg/mm²

Ø 36x1

Ø 18x2

Ø14x2

Ø9x4

Ø6x6

65 kg/mm²

Ø 28x1

Ø 16x2

Ø14x2

Ø9x3

Ø6x4

85 kg/mm²

Ø 26x1

Ø 12x2

Ø9x2

Ø9x3

Ø4x6

Steel Quality

Diameter/Bending Capacity

45 kg/mm²

Ø 36x1

Ø 18x2

Ø14x2

Ø9x4

Ø6x6

65 kg/mm²

Ø 28x1

Ø 16x2

Ø14x2

Ø9x3

Ø6x4

85 kg/mm²

Ø 26x1

Ø 12x2

Ø9x2

Ø9x3

Ø4x6

Machine Model: B 36

Machine Name: Mechanical Iron Bending Machine

Machine Dimensions:

Width : 81 Cm

Length : 92 Cm

Height: 85 Cm

Weight : 407 Kg

Specifications of the Motor Used:

Motor power : 3 kW

Motor RPM : 1400 rpm

Motor Voltage : 380 V

Frequency : 50 Hz

5. EQUIPMENT SUPPLIED WITH MACHINE

• Pin: 5 Pieces

• Stirrup Pin : 1 Piece

• Straight Pin : 1 Piece

• Bending Sleeve 5 Pieces

• Adjustment spanner 1 Piece

• SWITCH pin 6 pieces

• Retainer : 1 Piece

B36

8

6. USING THE MACHINE

6.1 Correct Connection of the Irons on the machine

Fixing the iron to be bent on the

machine with the help of retainer

(4a)

Fixing the iron to be bent on the

machine with the help of bending

sleeves.(4b)

Fixing the irons to be bent on the

machine with the help of retainer in

multi-iron bending (4c)

Fixing the irons to be bent on the

machine with the help of bending

sleeves in multi-iron bending (4d)

Figure 4: Placing the irons on the machine correctly

6.2. Incorrect placement of the irons to be bent on the machine

Incorrect placement of a single iron

to be bent with bending sleeves

(5a)

Incorrect placement of a single iron to

be bent with retainer (5b)

(4a)

(4b)

(4c)

(4d)

Loading...

Loading...