Page 1

GMR maskiner a/s

Saturnvej 17

DK-8700 Horsens

Tel. +45 7564 3611

www.gmr.dk

DK GB DE

SE

FR

Registration for use ............................................................ 2

EC declaration of conformity .............................................. 3

General ............................................................................... 5

Tractor selection ................................................................. 7

Technical information .......................................................... 8

Handling and assembly .................................................... 13

Daily use ........................................................................... 19

Detaching the implement .................................................. 21

Maintenance and storage ................................................. 26

Labelling ........................................................................... 28

Customer services and claims.......................................... 30

User manual

STENSBALLE Rotary mowers

Page 2

Page 3

GMR maskiner a/s

Page 3

STENSBALLE rotary mowers

Operating Instructions

GB

Registration of Use

Stensballe manufactures quality machines for professional users.

The warranty period on our machines is 12 months from the purchase date, and covers any material or

manufacturing defects.

Any parts that have suffered damage as a result of material and production faults will be replaced by

GMR maskiner a/s at no extra charge.

Consequential damage and wearing parts will not be replaced.

A condition for the processing of claims is that this registration for use is submitted to GMR maskiner a/s

no later than 1 month after delivery to the user.

This can be done via our website www.gmr.dk or by completing and scanning/submitting the coupon

below to: GMR maskiner a/s

Saturnvej 17

8700 Horsens, Denmark

stensballe@gmr.dk

Registration for use:

Machine number

Delivery date

Model

End user

Address

Dealer

Page 4

Page 5

GMR maskiner a/s

Page 5

STENSBALLE rotary mowers

Operating Instructions

GB

EC declaration of conformity

EC declaration of conformity

Manufacturer: GMR maskiner a/s

Saturnvej 17, 8700 Horsens, Denmark

Tel.: +45 7564 3611

hereby declares that

machine: Stensballe

machine no.:

date:

is in conformity with the applicable requirements of:

Order of 10 June 2013 implementing Directive 2006/42/EC of the European

Parliament and of the Council as amended, as well as the EMC Directive

2004/108/EC as amended.

Standards applied:

DS/EN ISO 12100:2 011 Safety of machinery - General principles for design

- Risk assessment and risk reduction.

Signature:

Poul Møller Rasmussen

Production Manager

Page 6

GMR maskiner a/s

Page 6

STENSBALLE rotary mowers

Operating Instructions

GB

For safety reasons and to take full advantage of the mower, you should

read the user manual before starting to use the machine. You can nd

detailed technical information about each type of rotary mower and

spare parts on www.gmr.dk.

Contact your dealer if in doubt.

Use only original Stensballe parts in your rotary mower. To order

original parts, contact your dealer or GMR maskiner a/s directly.

This user manual includes an illustrated spare parts list. Read the

introduction to the spare parts list before ordering spare parts.

Your STENSBALLE rotary mower is fully assembled and tested at the

factory, and ready for use.

This user manual applies to all Stensballe rotary mowers. Any

differences in the use and operation of the various types are listed and

described.

Please note the following safety warnings found in this user manual:

Introduction

Mowers described

in this user manual

Safety warnings

CAUTION

Damage to machinery or accessories

A technical procedure or similar which may result

in damage to the machinery or accessories.

WARNING

Risk of personal injury or death

A technical procedure or similar which may be

hazardous and result in personal injury or death.

NOTE

Important information

A very important technical procedure or similar.

General information

Page 7

GMR maskiner a/s

Page 7

STENSBALLE rotary mowers

Operating Instructions

GB

General information

The plastic packaging that the mower is supplied in, is made from

polythene (PE), which can be recycled. The packaging should therefore

be disposed of at your nearest recycling centre.

• unauthorised persons to use the machine unattended.

• a PTO shaft to be used without a CE label.

• the machine to be used without factory installed safety guards.

• people to stand close to the machine while it is in use.

• drivers to leave the tractor cab while the machine is in operation

and the blades are rotating.

• the tractor to stop with the PTO output activated.

• settings to be adjusted while the tractor engine is running.

• the mower to be lifted while it is running.

• the specied speed on the PTO output to be exceeded.

• nuts and bolts are securely tightened and that blades and rotary

parts are inspected for defects.

• the user fully understands how to operate the tractor and the

machine's hydraulic functions and associated movements.

• the working area is checked for wires, steel pipe, large stones,

bottles and other hazardous items and these are removed before

work begins.

• the tractor is stopped and the PTO output is disengaged if

abnormal vibrations or noises are coming from the machine so the

cause can be investigated.

• the tractor's PTO never operates slower than 90% of the machine's

stated PTO rpm.

• the tractor's PTO is disengaged and the tractor is stopped before

performing any adjustments, maintenance or repairs on the

machine.

Packaging

Never allow:

Always ensure that:

Page 8

GMR maskiner a/s

Page 8

STENSBALLE rotary mowers

Operating Instructions

GB

Tractor selection

When choosing a tractor, you should make certain that the rotary

mower and the tractor form a stable unit during operation.

The tractor must be equipped with a front mounting unit with a oating

position function. If the tractor does not have a oating setting, it must

either be equipped with one or the mower must be equipped with a

tting frame with moveable arms.

Rotary mowers types RK/LH, TM/TH and FR/LK may only be tted and

used on tractors that are equipped with operating hydraulics, or tted

with an external hydraulic system. The hydraulic system's operating

lever must be lockable.

Triplex type rotary mowers may only be tted and used on tractors

that are equipped with at least two single or double-acting hydraulic

connections. Both must have a lockable oating position function.

• TM/TH, FR, HP

• BM/FM/FH model P, TM/TH, FR, THM, HC/HCH, R3H

• BM/FM/FH model P, THM/TH

Tractor selection

Tractor/model overview:

Up to 30 HP

From 31-50 HP

51 HP and greater

CAUTION

Locked oating position

If the tractor does not have a locked oating position,

driving on uneven terrain may lift the machine off

the ground and transfer the tractor's weight to the

machine. Both events may damage the wheels or

wheel forks.

Page 9

GMR maskiner a/s

Page 9

STENSBALLE rotary mowers

Operating Instructions

GB

Tractor selection

Noise The driver will be exposed to a noise level in the tractor cabin between

74-85 dB (A). These gures originate from data provided by most

tractor manufacturers in their product specications. The noise varies

between a minimum measured value (machine unloaded) and a

maximum measured value (machine loaded).

The gures require that the machine is tted to a tractor with a cab

that is noise protected with closed windows, and which operates in

an open environment. In addition, the recommended operating speed

is 4-10 km/h. The noise levels also require that the grass length is

10-15 cm and that there is no wind.

If the cab windows, roof window or similar are open, the noise level will

exceed the values stated here.

The rotary mower does not emit any specic type of noise. This means

that the tractor driver will only be exposed to noise from the tractor

itself.

If the driver nds the noise uncomfortable when operating the machine,

GMR maskiner a/s recommends that the driver should wear ear

protection.

Page 10

GMR maskiner a/s

Page 10

STENSBALLE rotary mowers

Operating Instructions

GB

Technical information

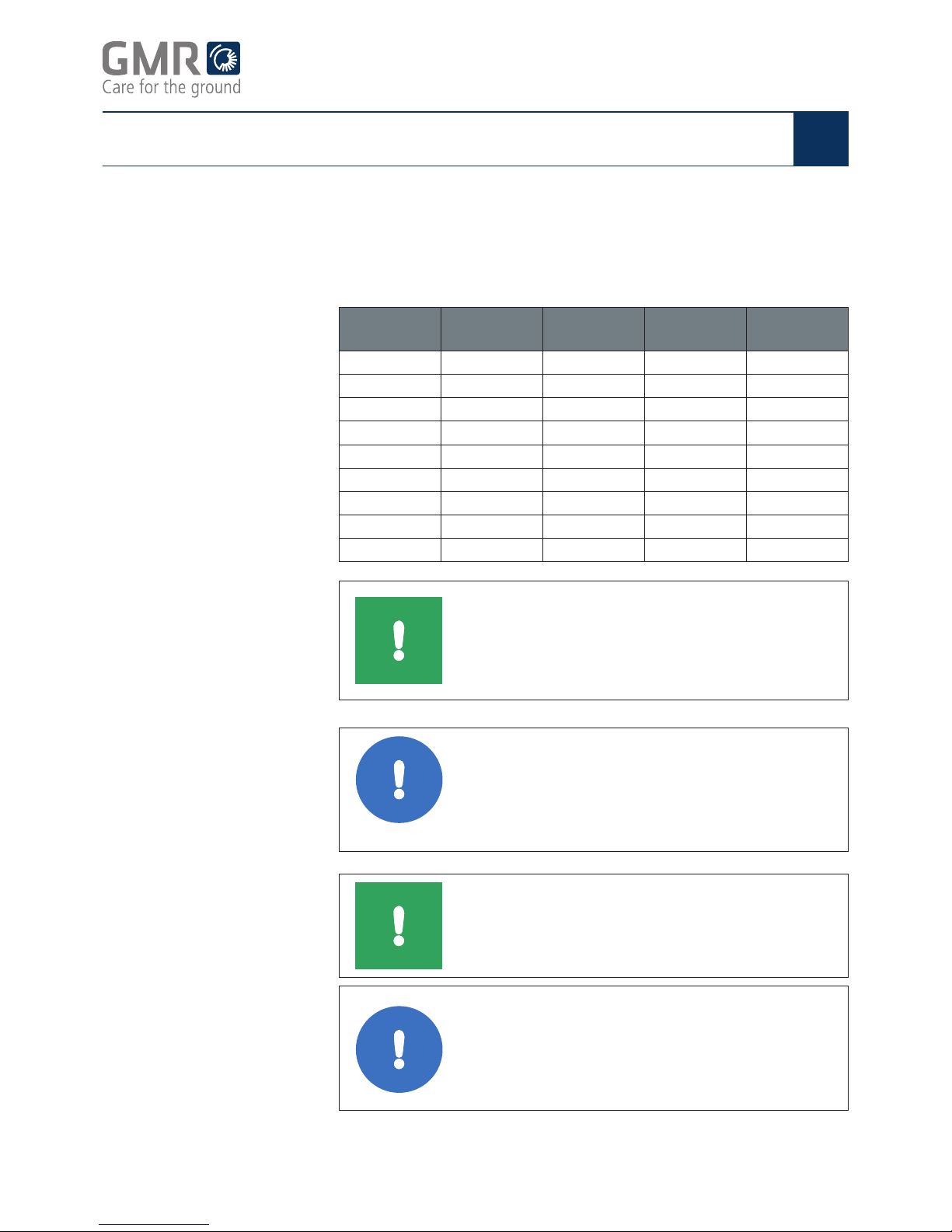

Total PTO power The following values represent the total PTO power for the whole

mower. This means that if the mower is operated with both a

mechanical and hydraulic PTO, both the mechanical and the hydraulic

power should be included in the gures.

Cutting

width

Min.

PTO power

Max.

PTO power

Capacity

at 4 km/h

Capacity

at 10 km/h

1150 mm 11 kW 18 kW 0.39 ha 0.97 ha

1300 mm 12 kW 21 kW 0.44 ha 1.1 ha

1500 mm 13 kW 25 kW 0.51 ha 1.3 ha

1800 mm 17 kW 30 kW 0.61 ha 1.5 ha

2100 mm 23 kW 35 kW 0.71 ha 1.8 ha

2500 mm 25 kW 37 kW 0.85 ha 2.1 ha

3000 mm 31 kW 46 kW 1.0 ha 2.6 ha

3500 mm 36 kW 54 kW 1.2 ha 3.0 ha

4000 mm 41 kW 60 kW 1.4 ha 3.4 ha

NOTE

Axle load

The tractor's maximum stated axle load must not

be exceeded. Contact your dealer if in doubt.

CAUTION

Damage to machinery or accessories

If you use tractors which can deliver more than

the stated maximum power, this could overload

and damage the mower.

NOTE

Nominal rpm

The nominal rpm is stated on the mower's xed

PTO shield.

CAUTION

PTO speed

If the PTO speed falls below 90% of the nominal

PTO speed, the mower will be overloaded and

damaged.

Page 11

GMR maskiner a/s

Page 11

STENSBALLE rotary mowers

Operating Instructions

GB

Handling and assembly

Lifting and moving

the mower

Type: HC/HCH and HP

as well as BRK, BR, RK,

TM/TH, FR, R3H, 2W and

Triplex

Always use a crane to move or lift the rotary mower to carry out

maintenance.

Use four straps or similar with eyes. Place a strap around each wheel

arm, and assemble the four straps in a focal point in the centre above

the mower. Lift the mower from this point.

Remove the PTO shaft before lifting. Please be aware that when the

mower is lifted, it may move unexpectedly. The mower should not be

lifted quickly or unintentionally, to avoid the risk of personal injury.

When lifting the Triplex mower, the side mowers may be in both the

operating and transport positions.

WARNING

Safety zone

When lifting the mower, all persons must stay clear

of the machine.

The safety zone is min. 2 metres.

Page 12

GMR maskiner a/s

Page 12

STENSBALLE rotary mowers

Operating Instructions

GB

Handling and assembly

Attaching the mower

to the tractor

3-point hitch

When tting for the rst time, remove the reusable plastic packaging.

• Check that the correct type of machine has been delivered.

• Check that the machine is complete and has not suffered damage

in transit.

• Check that the rpm and direction indicated on the PTO protection

on the angular gear are correct for the tractor (not applicable for

hydraulic machines).

Depending on the type of mower you are using, attach the mower with

either a 3-point hitch or an A-frame.

1. Drive the tractor at right angles to the mower.

2. Stop the tractor engine and PTO output.

3. Connect the hitch arms to the mower.

4. Connect the top bar to the mower.

5. Connect the PTO shaft to the tractor.

Check that the snap coupling clicks into place in both forks.

6. Attach the PTO shaft safety chains to the sides of the tractor

(mechanical machines only).

7. Connect the hydraulic hoses to the tractor using the snap couplings

(hydraulic machines only).

8. Check that the couplings are tted so the mower rotates in the

correct direction.

9. Check the snap couplings for impurities.

Clean the couplings if necessary.

Page 13

GMR maskiner a/s

Page 13

STENSBALLE rotary mowers

Operating Instructions

GB

Handling and assembly

Drive the tractor at right angles to the mower.

1. Lower the male section of the tractor and drive it under the female

section.

2. Lower the male section so it locks into the female section. Activate

the manual locking system, or check that the automatic locking

system is activated.

3. Lift the machine slightly.

4. Stop the tractor engine.

5. Connect the PTO shaft to the tractor.

6. Check that the snap coupling clicks into place in both forks.

7. Attach the PTO shaft safety chains to the sides of the tractor

(mechanical machines only).

8. Connect the hydraulic hoses to the tractor using the snap couplings

(hydraulic machines only).

9. Check that the couplings are tted so the mower rotates in the

correct direction.

10. Check the snap couplings for impurities.

Clean the couplings if necessary.

WARNING

Safety zone

Never manoeuvre the tractor hitch if there are people

in the vicinity.

The safety zone is min. 2 metres.

Example illustration. Design and positioning will vary depending on implement and tractor.

A-frame

Page 14

GMR maskiner a/s

Page 14

STENSBALLE rotary mowers

Operating Instructions

GB

Handling and assembly

Connecting the hydraulic

hoses

Mount the mower on the tractor by coupling the hydraulic hoses to the

tractor's double-acting output.

Remember to keep the hydraulic hoses correctly separated in pairs so

that the two hoses from one cylinder go to one double-acting hydraulic

output.

The outputs for A and B functions should have a oating position.

The illustration below shows the function chart for Triplex mowers.

CAUTION

Mechanical operation

Attaching the mower for the rst time:

Before coupling the PTO shaft to the tractor, position

the mower where the distance between the PTO

output and the mower's PTO input is shortest. This

ensures that the PTO shaft is not too long and is not

damaged when lifting the mower.

Follow the instructions in the user manual when

shortening the PTO shaft. Contact your dealer if you

have any questions about the above.

Page 15

GMR maskiner a/s

Page 15

STENSBALLE rotary mowers

Operating Instructions

GB

Handling and assembly

CAUTION

Hydraulic hoses

Connect the hydraulic hoses so that they

cannot come into contact with moving parts.

NOTE

Shortening the hoses

The hydraulic hoses are supplied in standard lengths.

If the hoses need to be shortened, this should be

done by the dealer.

CAUTION

Make sure that the machine's standard PTO speed

and direction of rotation can be met by the tractor.

Page 16

GMR maskiner a/s

Page 16

STENSBALLE rotary mowers

Operating Instructions

GB

Daily use

There are various ways to set the cutting height depending on the type

of mower used.

Use four straps or similar with eyes. Place a strap around each wheel

arm, and assemble the four straps in a focal point in the centre above

the mower. Lift the mower from this point.

Adjust the cutting height using the two spindle handles on the top of the

wheel boxes.

A height adjustment scale is attached to the side of the wheel box.

This is only a guide.

1. Determine the cutting height.

2. Measure the current cutting height from the ground to the lower

edge of the rotor guard in centimetres.

3. Start the tractor, lift the mower, and then stop the tractor again.

4. Adjust the wheels in relation to the measured cutting height. On

Triplex mowers, it may be necessary to set the centre mower one

ring higher than the side mowers to take account of the mower's

weight distribution and the ground's carrying capacity.

Example

Measured cutting height ........... 5 cm

Required cutting height ............ 4 cm

Remove the split pin and move the wheel up one ring (one ring = 1 cm),

then reattach the wheel and repeat for all eight wheels.

The mower may have one or two rollers which help to protect the

blades. The rollers have three adjustment options:

• Regular hilly terrain = top setting

• Average hilly terrain = middle setting

• Very hilly terrain = bottom setting

Height adjustment

Height adjustment

with lever

Type: FM, BM, FH

Height adjustment

on each wheel

Type: Triplex, BRK, RK,

TH/TM, 2W, HC/HCH, HP

Rollers

Page 17

GMR maskiner a/s

Page 17

STENSBALLE rotary mowers

Operating Instructions

GB

Daily use

The following applies to mowers where the cutting height is adjusted by

means of hydraulics controlled from the tractor cab.

1. Lower the mower to the lowest position and activate the hydraulics

for 10-20 seconds until all the adjustment cylinders are completely

in the outer position, and no air is left in the system. Use this

method to reset the cutting height, so all the cutting units are at

exactly the same height.

2. Raise the mower to the desired cutting height. Use the guide scale

on the inner, left cylinder.

If there is a difference in height, you can reset the system by lowering

the cutting height all the way to the bottom position, and activate the

hydraulics until all the cutting units are at the bottom, and no air is left in

the system. You can now set the height as described above.

Before you start the machine, you should inspect the working area and

remove any foreign objects.

If the machine is hydraulically driven, you must ensure that you are

well-acquainted with the machine's hydraulic functions.

STENSBALLE mowers are only designed to mow grass and no other

forms of vegetation. Avoid mowing areas with more robust vegetation.

Pay attention to any foreign objects and avoid them as much as

possible. Mowing in areas with more robust vegetation will lead to

greater wear on the blades and may lead to undue damage to the

machine and mean that your warranty will be voided.

Mowing in high and/or thick grass restricts the forward driving speed.

We recommend a speed range of 4-10 km/h. As the owner of this

mower, you should be careful to maintain the nominal rpm, despite

the load on the mower.

The machine must run on its own wheels while mowing. It must not

hang in the tractor's hitch.

Central, hydraulic

height adjustment

Type: BR/LM, FR/LM, FR/

LH, R3H, Triplex C

CAUTION

Foreign objects can cause major damage to the rotor

blades and other parts in the transmission.

If the rotor blades collect foreign objects, stop and

clean the mower immediately.

Page 18

GMR maskiner a/s

Page 18

STENSBALLE rotary mowers

Operating Instructions

GB

Daily use

Start-up procedure

for mechanically

driven machines

1. Check that the tractor's PTO output is disengaged.

2. Start the tractor and leave it idling at high speed.

3. Engage the tractor's PTO output and let the machine idle while

checking the machine's moving parts rotate freely and unhindered.

4. For Triplex mowers: Raise the side mowers to vertical, and make

sure that the engine is disengaged and the blades have stopped.

Lower the mowers again and set the valve to the oating position.

5. Increase the PTO rpm to the standard rpm and allow the machine

to run for 60 seconds. Check for abnormal vibrations or noises

coming from the machine.

If there are abnormal vibrations or noises, contact your dealer

immediately.

6. Reduce the tractor engine's rpm to idle and disengage the PTO

output to stop the mower.

1. Check that the tractor's hydraulic connection is in the neutral

position.

2. Start the tractor and leave it idling at high speed.

3. Engage the tractor's operating hydraulics and let the machine

idle while checking the machine's moving parts rotate freely and

unhindered.

On Triplex type mowers, raise the side mowers to vertical. Make

sure that the hydraulic engines are disengaged and the blades

have stopped. Lower the mowers again and set the valve to the

oating position.

4. Increase the tractor engine's rpm to the standard rpm and allow

the machine to run for 60 seconds. Check for abnormal vibrations

or noises coming from the machine. If there are abnormal

vibrations or noises, contact your dealer immediately.

5. Reduce the tractor engine's rpm to idle and set the hydraulic

control handle to the neutral position.

Start-up procedure

for hydraulically

driven machines

WARNING

Safety zone

During start-up and use, the mower must be lowered

to the ground, before engaging the mechanical or

hydraulic PTO output.

Disengage the PTO output before lifting. Failure to do

so means there is a risk of personal injury on contact

with rotating parts (blades).

Page 19

GMR maskiner a/s

Page 19

STENSBALLE rotary mowers

Operating Instructions

GB

Daily use

Transport

Side ejection

Special instructions

for Triplex mowers

Stop the tractor PTO output during transport between mowing areas

and raise the hitch into the top position. Check regularly that the hitch

is in the top position.

We recommend that mowers with side ejection are driven so the grass

is ejected to the side where the grass is mown.

Triplex mowers can benet from several different driving positions

for use in different situations.

There may be situations with trees in the middle of the eld, so it can

be an advantage to lift one of the side mowers.

Page 20

GMR maskiner a/s

Page 20

STENSBALLE rotary mowers

Operating Instructions

GB

Daily use

The mower is designed with a xed guard which follows the cutting

height. This means that when the mower is set at the high cutting

height, the guard will be the same distance from the ground.

When driving with the mower, the hitch must be in the oating position,

so the side mower can follow the terrain.

If the hitch is not in the oating position, the weight may transfer from

the tractor to the mower, which could overload both the centre mower

and the side mowers.

When driving with the Triplex mower, the hydraulic outputs must be in

the oating position, so the side mower can follow the terrain.

If the hydraulic outputs are not in the oating position, the weight may

transfer from the tractor to the mower, which could overload both the

centre mower and the side mowers.

WARNING

The tractor driver must stop the machine immediately

if anyone moves into the danger zone.

WARNING

Never lift the side mowers while anyone is within

the danger zone.

WARNING

Safety zone

When operating the mower, all persons must stay

clear of the machine.

The safety zone is min. 2 metres.

Danger zone

Floating position

Special instructions

for Triplex

Page 21

GMR maskiner a/s

Page 21

STENSBALLE rotary mowers

Operating Instructions

GB

Daily use

In case of a breakdown, proceed as follows:

1. Reduce the tractor's rpm to idle.

2. Disengage the tractor's PTO output or operating hydraulics.

3. Stop the engine before leaving the cab.

Contact your dealer if you cannot identify the cause of the breakdown.

If the mower fails during use, you must stop the tractor's mechanical

or hydraulic PTO output immediately. Then stop the tractor engine

before leaving the driver's cab. You can now inspect the mower to

nd the cause.

If the centre mower has stopped, the V-belts may be slipping due to

overloading or the V-belts may need tightening.

If the mower is forced too much, the tractor's hydraulic pressure relief

valves are activated and one or both side mowers stops mowing.

If the mowing action is failing and you need to restart, proceed as

follows:

Stop the tractor's PTO immediately if the rotary mower is not running,

and contact your dealer for assistance.

WARNING

Contact your dealer if you cannot identify the cause

of the mowing failure. You risk personal injury if you

troubleshoot without thorough knowledge of the

machine and technology in general.

Breakdown

Failure

Mechanical operation

Hydraulic operation

Restart

1. Stop the tractor's PTO and run back a little.

Then attempt a restart as follows:

2. Check that the PTO output is disengaged.

3. Start the tractor and drive the mower free of the grass.

4. Engage the PTO output.

5. If the rotary mower is now running, you can continue to mow the

grass, but drive a little more slowly than before.

Page 22

GMR maskiner a/s

Page 22

STENSBALLE rotary mowers

Operating Instructions

GB

Detaching the implement

Hydraulic oil

Danger signs

In case of heat:

In case of vibration

and noise:

When operating the mower, you should ensure that the temperature

does not exceed 80 °C. After prolonged heavy use of the mower, the oil

may get very hot.

If there are signs of heat generation, vibration or noise during operation,

you must stop the mower and then the tractor immediately.

Inspect the mower.

• Check for dry grass under the shielding/guards by the V-belts.

• Check if the gears and/or bearings are overloaded.

• Check all transmission parts.

• Check the blades carefully for damage (breakages).

Page 23

GMR maskiner a/s

Page 23

STENSBALLE rotary mowers

Operating Instructions

GB

Detaching the implement

Detaching the mower

All types

3-point hitch

A-frame

F model tractors

The method for detaching the mower varies depending on whether a

3-point hitch or an A-frame is used.

The mower must be detached on a level surface.

1. Carefully lower the mower down onto the surface and stop the

tractor engine.

2. Remove the PTO shaft from the tractor and attach the free end to

the mowers using the safety chain.

3. On hydraulically driven models: Remove the quick release

connections from the tractor and attach the dust caps. Next, lay

the hoses across the mower.

After completing steps 1-3 above, proceed as follows:

4. Remove the pin for the top bar on the mower, so that the top bar is

only attached to the tractor.

5. Remove the pins for the hitch arms.

6. Drive the tractor free of the mower.

After completing steps 1-3 above, proceed as follows:

4. Disable the locking system, so the male and female parts are

released from each other.

5. Start the tractor engine and lower the male part.

6. Drive the tractor free of the mower.

1. Disengage the top bar from the mower.

2. Remove the rear assembly pins.

3. Lower the mower to the ground and remove the front assembly

pins.

4. Drive the tractor free of the mower.

5. Insert the assembly pins and safety pins in the mower.

Page 24

GMR maskiner a/s

Page 24

STENSBALLE rotary mowers

Operating Instructions

GB

Maintenance and storage

Manual tilt-up

Hydraulic tilt-up

Use manual tilt-up when you need to clean the mower.

1. Lower the mower to the ground.

2. Disengage the PTO output.

3. Stop the tractor.

4. Remove the PTO shaft and place it to one side. Applies to

mechanical machines only.

5. Start the tractor and lift the hitch with the mower in the top position.

6. Tip the mower by hand into an almost vertical position.

7. Lock the mower in tilt-up position using pins through the mounting

bracket and frame. Depending on the type of tractor, it may be

necessary to turn the rear wheels so they are pointing forward.

8. Gently lower the mower to the ground, so the rear wheels are

resting on the surface.

9. Stop the tractor and remove the key before you leave the tractor

cab.

Some mowers may be equipped with hydraulic tilt-up.

1. Disengage the hydraulic PTO output.

2. Stop the tractor.

3. Remove the PTO shaft and place it to one side.

Applies to mechanical machines only.

4. Turn the lever on the switch valve to the tilt-up position.

5. Start the tractor.

6. Lift the hitch with the mower in the top position.

7. Activate the valve battery for tilt-up, and make sure the mower

moves freely and unhindered to the top position. Depending on the

type of tractor, it may be necessary to turn the rear wheels so they

are pointing forward, or to detach them completely with the wheel

forks.

8. When the mower is tipped right up, you can gently lower the mower

with the hitch so it rests on the ground.

9. Stop the tractor and remove the key before you leave the

tractor cab.

WARNING

Working under a raised mower

Never enter the space under a raised mower unless

it has sufcient support.

Page 25

GMR maskiner a/s

Page 25

STENSBALLE rotary mowers

Operating Instructions

GB

Maintenance and storage

After cleaning

Lubrication

Daily

After 50 operating hours

Angular gear

1. Start the tractor and raise the hitch into the top position.

2. Tilt the mower down to horizontal, and continue to activate the

hydraulic valve until the cylinder is completely in the outer position.

3. Lower the mower to the ground.

4. Stop the tractor and remove the key before you leave the tractor

cab.

5. Turn the lever on the switch valve back to the working position.

6. Attach the PTO shaft. (Applies only to mechanical machines)

The machine has labels attached for grease and oil lubrication,

respectively.

• Wheel bushings grease

• Wheel hub grease

• Bearing housing

for rotary shafts grease

• Cylinder eyes grease

• Adjustable tilting arm oil

• Fixed tilting arm grease

The angular gear is half lled with oil at the factory. According to the

gear manufacturer, the rst oil change should be performed after 50

working hours and subsequently at intervals of 500-800 hours, but at

least once per year.

To prevent sedimentation, we recommend that you change the oil while

it is warm. Use an SAE 90 EP oil. If necessary, use an oil syphon to

remove the used oil.

Page 26

GMR maskiner a/s

Page 26

STENSBALLE rotary mowers

Operating Instructions

GB

Maintenance and storage

The rotary mower is tted with 2 or 4 V-belts which are tightened with

the gear/engine bracket.

After the rst 5 hours of use, check that the V-belts are tight enough.

Tighten them if necessary. Then check after every 40 hours of

operation that the V-belts are tight enough and tighten them if

necessary.

New V-belts will stretch a lot during the rst few hours of use.

You must therefore retighten the V-belts after 5 hours of use.

1. Make sure that the tractor engine has stopped and the PTO output

is disengaged.

2. Remove the outer shielding/guards.

3. Unscrew the bolts in the gear bracket and tighten the belts by

adjusting the clamping bolt on the gear bracket, so that the free

section of the belts can be deformed by approx. 3 cm in either

direction by hand.

4. Then retighten the gear bracket.

5. Bolt the shields rmly back in place.

V-belts

Tightening and retightening

V-belts

Replacing V-belts

Rotary shafts

1. Make sure that the tractor engine has stopped and the PTO output

is disengaged.

2. Unscrew the bolts in the gear bracket.

3. Slacken the belts by loosening the locking nut on the adjustment

bolt on the front of the gear bracket and remove the locking nut.

4. Detach the gear bracket unit and remove the V-belts.

5. Place the new belts loosely around the front centre pulley and t

the gear bracket unit back in place.

Make sure that all the belts are behind the angular gear pulley, and

the clamping bolt passes through the hole in the front of the gear

bracket plate.

6. Insert the 4 set screws in the gear bracket and put the nuts on

without tightening them.

7. Attach the V-belts on the outer pulleys. Check that the belts are

sitting in the right guides.

8. Tighten the V-belts.

9. Tighten the gear bracket.

After the rst ve hours of operation:

• Check and retighten the pulleys.

• Check that the blades and any slide plates are tightened.

Page 27

GMR maskiner a/s

Page 27

STENSBALLE rotary mowers

Operating Instructions

GB

Maintenance and storage

Replacing the bearing unit

Special instructions

for HC/HCH

Blades

Follow the method described for replacing V-belts, but do the following

after removing the belts:

Remove the bearing unit without detaching the pulley by loosening

the 4 bolts that x the bearing unit to the rotor guard, and pulling the

bearing unit out of the bottom of the mower.

On HC/HCH mowers, the V-belt pulley must be detached before the

bearing unit can be removed.

The blades are made of boron-alloyed steel, drop-forged and hardened,

so they can cope with the loads and shocks that are expected to occur

during operation. The hardness of the blades is controlled constantly

and all blades are stamped with GMR followed by the spare part

number.

WARNING

Using blades made by other manufacturers risks fatal

injury.

The machine warranty will be void if they are used.

WARNING

Before sharpening the blades on Triplex side mowers,

the side mower must rst be secured as shown in the

illustration below. Failure to do so means there is a

risk of personal injury.

Page 28

GMR maskiner a/s

Page 28

STENSBALLE rotary mowers

Operating Instructions

GB

Maintenance and storage

Sharpening the blades The blades can be sharpened while they are mounted on the mower,

or they can be detached and sharpened. Always make sure that the

blades are sharpened evenly and are balanced. After sharpening,

hang the blade on a nail or similar to check the result.

The blade must always be sharpened on the inclined upper side.

1. Start the tractor engine.

2. Raise the mower to the top lifting position.

3. If the mower is equipped with the hydraulic tilt-up function, tilt the

mower into an almost vertical position.

4. Stop the tractor engine.

5. If the mower is not equipped with the hydraulic tilt-up function,

lift the front edge of the mower by hand into an almost vertical

position.

6. Secure the mower position with the supplied locking bolt through

one of the slots in the mounting brackets and the mounting bracket

plate on the centre mower.

7. It may be necessary to detach the rear support wheels and wheel

forks before tilting the mower vertically.

The blades can now be serviced. After sharpening, hang the blade on

a nail or similar to check the result.

WARNING

Never allow the blades to rotate when cleaning the

mower.

NOTE

To ensure a correct and ne cut, the blade material

must be sharpened to max. 5 mm. At this point,

the blades should be replaced.

See the illustration below.

Page 29

GMR maskiner a/s

Page 29

STENSBALLE rotary mowers

Operating Instructions

GB

Maintenance and storage

All moving parts on the mower are shielded to prevent accidents

related to the use of the machine.

All safety guards must be intact. In the event of damage or wear to the

guards, they must be replaced or repaired by the dealer. Safety guards

must only be removed using the proper tools.

Replace the hydraulic hoses when there are:

• leaks in the hose and rubber material.

• severe cracks in the rubber material.

Order new hoses from the spare parts list at the back of this manual.

• Clean the mower and loosen the V-belts at the end of the season.

• Clean the blades carefully and lubricate them with oil. This prevents

corrosion and extends the life of the blades.

• Check the oil level in the tank and top up if necessary.

• Store the mower in an area with low air humidity, protected from

rain and snow.

WARNING

Using the machine without safety guards risks fatal

injury.

Safety guards

Replacing

the hydraulic hoses

Storage

Page 30

GMR maskiner a/s

Page 30

STENSBALLE rotary mowers

Operating Instructions

GB

Labelling

Warning labels

The machine bears the following plates/labels. They must be attached

to the machine and be clearly visible. New plates/labels can be ordered

from the dealer.

Warning against contact with blades:

Warning of crushing hazard:

Do not pressure clean:

Page 31

GMR maskiner a/s

Care for the ground

www.gmr.dk

Type:

kW:

No.:

Kg.

Page 31

STENSBALLE rotary mowers

Operating Instructions

GB

Labelling

The machine is equipped with a type plate with an engraved machine

number. The rst two digits of the serial number indicate the year of

manufacture. The machine number is unique to the particular machine,

and GMR maskiner a/s will always be able to refer back to that machine

if the number is quoted.

This plate also states the weight of the machine in kg and its power

requirement in kW.

The label indicates that the machine complies with the EC Machinery

Directive, the year of manufacture and the manufacturer's website.

It is the dealer's responsibility to deliver the machine (and assemble if

required), to start it on delivery or rst use, and to instruct the operator

about the use and maintenance of the machine (including tightening

bolts and nuts).

The dealer is also obliged to make sure that the service manual and

spare parts list is delivered to the customer and that the registration for

use is completed correctly and sent to GMR maskiner a/s no later than

1 month from the date of sale. (See page 3)

Type plate

CE labelling

After-sales service

Page 32

GMR maskiner a/s

Page 32

STENSBALLE rotary mowers

Operating Instructions

GB

Customer services and claims

Claims The warranty period on GMR machines is 12 months from the purchase

date, and covers any material or manufacturing defects. These parts

will be replaced by GMR maskiner a/s free of charge. Consequential

damage and wear and tear will not be replaced.

Any components which are not manufactured by GMR maskiner a/s are

included under the terms of the warranty to the extent authorised by the

supplier of the parts in question.

GMR maskiner a/s reserves the right to assign a claim of this kind

to the relevant supplier and not to reach a decision until the relevant

supplier has responded.

The following must be observed when working on a claim:

• report the claim to GMR maskiner before the repair is started

• agree a time period with GMR maskiner for qualied technicians to

carry out the repair

• any labour costs will only be approved at a xed net price.

If GMR maskiner a/s has not authorised repair work in advance, any

invoice submitted for repair work will not be approved.

At GMR maskiner a/s' request, before the claim can nally be handled,

any parts that were replaced must be sent carriage paid to the factory.

GMR maskiner a/s retains the exclusive right to determine the extent to

which a part shall be replaced or repaired.

The warranty does not cover:

• normal wear and tear or damage which has resulted from

inadequate maintenance.

• damage caused by collision.

• non-compliance with the product's technical specications or if the

product is used for a purpose other than that described in the user

manual.

If the product is altered or if non-original spare parts are used, all rights

under the warranty will be rendered void.

The purchaser does not have the right to require that design changes

on future models are implemented in a pre-existing machine.

Page 33

GMR maskiner a/s

Page 33

STENSBALLE rotary mowers

Operating Instructions

GB

Customer services and claims

In the event

of a complaint:

Complaints must be registered directly with GMR maskiner a/s.

Complete a complaint report, stating the machine type, production

number and date of its delivery to the customer, and send it to us. This

is done via the dealer login on our website www.gmr.dk.

If questions arise about claims on imported machines, we reserve

the right to present the claim to the manufacturer before making any

decision about whether the claim can be accepted.

Our machinery is subject to the EC Machinery Directive and quality

assured within the European Union. We make every effort to comply

with these requirements and do our utmost to supply high quality

machinery.

Horsens, 01.06.2017

GMR maskiner a/s

Page 34

Copyright, GMR maskiner a/s ©

Saturnvej 17

DK-8700 Horsens

www.gmr.dk

25012018

Loading...

Loading...