GMR STAMA Micro, STAMA Parker, STAMA Multi, STAMA Evo, STAMA Mini Operating Instructions Manual

...Page 1

GMR maskiner a/s

Saturnvej 17

DK-8700 Horsens

Tel. +45 7564 3611

www.gmr.dk

DK GB DE

SE

FR

Registration of Use ............................................................. 3

EU declaration of conformity .............................................. 5

General information ............................................................ 6

Safety requirements ........................................................... 7

Operating ............................................................................ 9

Maintenance ..................................................................... 10

Lead-acid batteries ............................................................11

Lithium-ion batteries ......................................................... 18

Marking/labelling............................................................... 23

Customer services and claims.......................................... 24

Operating Instructions

STAMA Micro, Parker, Mini, Multi,

Evo, Maxi EL

Page 2

Page 3

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Registration of Use

Page 3

Operating Instructions

GB

Registration for use:

Machine number

Delivery date

Model

End user

Address

Dealer

STAMA manufactures quality machines for professional users.

The warranty period on our machines is 12 months from the purchase date, and covers any material

or manufacturing defects.

Any parts that have suffered damage as a result of material and production faults will be replaced

by GMR maskiner a/s at no charge.

Compensation will not be given for consequential damage or wearing parts.

A condition for the processing of claims is that this registration for use is submitted to GMR maskiner a/s

no later than 1 month after delivery to the user.

This can be done on our website at www.gmr.dk

or by lling in and forwarding or scanning the form below to: GMR maskiner a/s

Saturnvej 17

DK-8700 Horsens

stensballe@gmr.dk

Page 4

Page 5

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

EU declaration of conformity

Page 5

Operating Instructions

GB

EU declaration of conformity

Manufacturer: GMR maskiner a/s

Saturnvej 17, 8700 Horsens, Denmark

Tel.: +45 7564 3611

hereby declares that

machine: STAMA

machine no.:

date:

is in conformity with the applicable requirements of:

Directive 2006/42/EC of the European Parliament and of the

European Council of 17 June 2006 on the approximation of

the laws of the Member States relating to machinery.

Signature:

Page 6

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

General information

Page 6

Operating Instructions

GB

Please read the Operating Instructions before you start to use your new

STAMA truck.

If you are in any doubt, contact the dealer.

Use only original STAMA parts in your electric truck. To order original

parts, contact your dealer or GMR maskiner a/s directly.

The truck is fully assembled and tested at the factory. It is ready for

use.

The STAMA truck is a product, the design of which is based on

the practical experiences of users, e.g. graveyards and housing

associations.

General comments

Page 7

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Safety requirements

Page 7

Operating Instructions

GB

The truck starts smoothly and continues to accelerate until it reaches

maximum speed.

Acceleration

Intended use

Normal use

The truck is intended to carry stone, gravel, soil, branches and waste.

Max last, Micro = 350 kg

Max last Parker = 500 kg

Max last, Mini = 750 kg

Max last, Multi, Evo and Maxi = 1000 kg

The operator must sit on the seat when driving. The truck stops if

contact with the seat is interrupted for more than 1 second.

Light The operator must ensure that there is sufcient light when driving the

truck so that potential obstacles are clearly visible.

Maximum speed Micro 12 km/h

Parker and Mini 15 km/h

Mini 15 km/h

Multi and Evo 20 km/h

Maxi 16 km/h

The top speed is electronically controlled and can be lowered. Contact

GMR maskiner.

Trailer total weight Without park brake With park brake

Mini and Parker 350 kg 700 kg

Multi 500 kg 1000 kg

Maxi 500 kg 1000 kg

Evo 970 kg 1940 kg

Page 8

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Safety requirements

Page 8

Operating Instructions

GB

Vibrations There are no signicant vibrations as the machine is electrically

powered.

Disposal When disposing of the truck, the battery should be recycled. The

remainder of the truck should be disposed of by a scrap dealer.

WARNING

Moving parts

Take care not to allow people or objects to get

crushed when tipping the truck bed.

WARNING

Safety guards

When the truck is in operation, all safety guards must

be secured.

WARNING

Maintenance

Before starting maintenance work, bring the truck to a

complete standstill to ensure that there is no danger

of personal injury due to moving parts.

The truck speed should be adapted to the conditions, i.e. reduce

speed at corners and in narrow passages. There is a risk that the truck

may overturn when travelling on an incline. Never drive on an incline

of more than 20° across the direction of travel. When travelling fully

loaded down a steep hill, the truck must travel at very slow speed

(tortoise mode). If you drive too fast down a hill, the truck may (worst

case) run out of control. Make sure the brakes are in good working

order at all times.

Max. incline in direction of travel:

• about 40% over a distance of 0.5 metres

• about 20% over a distance of 1-2 metres

• about 15% over a distance of 3-5 metres

If the incline is steeper and the truck fully loaded, there is a risk that the

truck will stall on the incline and (worst case) may roll backwards.

Speed, slopes and in-

clines

Page 9

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Operating

Page 9

Operating Instructions

GB

Preparation

Before starting, check that:

• The battery is fully charged

• The battery electrolyte density is correct

• The battery is clean

• There is no battery error or operating fault

Turn the main switch. Micro truck: the main switch is on the right-hand

side of the vehicle under the truck bed. Mini truck: the main switch is to

the right of the steering column. Multi truck: the main switch is on the

back of the seat box. On the Maxi truck the main switch is on the lefthand side of the vehicle under the seat box.

Turn and hold the ignition key on the dashboard in that position until

the display lights up and the hydraulic pump has accumulated servo

pressure.

Pre-start inspection

Pre-start inspection

Operating

Direction of travel Read the "Preparation" section before operating the truck.

Select direction of travel – forward or reverse – using the selector on

the dashboard. Regulate speed using the foot pedal. The foot pedal

also acts as an engine brake (release pressure on the foot pedal).

Release the foot pedal. The motor brakes. If you need to brake harder,

use the foot brake.

Stopping

Unloading/tipping

Activate switch on the dashboard. Unloading/tipping starts.

To stop the truck and all its moving parts, turn the ignition switch to the

OFF position and then turn the main switch anticlockwise.

Emergency stop

Page 10

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Operating

Page 10

Operating Instructions

GB

To prevent unnecessary breakdowns and excessive wear-and-tear,

your truck should be maintained at regular intervals.

Electric motor

NEVER use a high-pressure/steam cleaner to clean the motor as this

can cause condensate to form.

The truck must be serviced twice a year by a GMR-approved

technician.

If the truck does not work properly, read the alarm code and contact an

authorised technician.

Error code:

14 Main relay does not crank due to pump start

16 / 22 Electronics overheating

28 Operating motors overheating

17 / 23 Battery voltage low

39 Main relay does not crank

47 Error in start sequence, forward/reverse selector switch

and accelerator, seat switch released

To cancel the error, try switching the forward/reverse selector switch to

neutral. Then switch the ignition switch to OFF and restart. If there is an

alarm code in the display all the time, you must contact an authorised

workshop.

For a full list of error codes in English, contact GMR maskiner.

The hydraulic system is generally maintenance-free. However, you

should replace hydraulic uid once a year or after 500 operating hours.

We recommend Shell Tellus Artctic 32 Hydraulic uid.

Hydraulic system

Gear motor

Lubricating mechanical

parts

Grease the ball bearings about six times a year.

Type SAE 80W90 gear oil must be changed after 500 hours of

operation or at least once a year.

Micro, Parker and Mini 0.25 litres

Multi, Evo and Maxi 0.50 litres

Page 11

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Lead-acid batteries

Page 11

Operating Instructions

GB

WARNING

Risk of personal injury/death

The charging of lead-acid batteries can be hazardous,

due to the formation of explosive hydrogen gas.

Lead batteries

WARNING

Risk of personal injury/death

Flames and sparks are not permitted in the vicinity

of the battery. Power down the mains supply contact

before releasing the charger clamp.

WARNING

Risk of personal injury/death

Some internal parts of the charger carry live current

and represent a risk of personal injury. The charger

frame must therefore only be opened by specially

qualied personnel.

COMMENT

Important information

The charger is not suitable for domestic use or for

use in ofces or similar electrical environments.

The battery charger is an automatic, microprocessor controlled

charging unit, which is intended specically to charge open lead-acid

batteries. Charging specications according to DIN 41774.

General comment

The charger must be located in a dry, well-ventilated space.

• The charger should be connected to the mains power supply It must be earthed and fused. Connect in accordance with the

specications on the charger type plate.

• The charger can be adjusted to the appropriate mains voltage. (This

may only be performed by an authorised technician. If the charger

frame is opened, the guarantee will be considered null and void).

• The charger may only be adjusted when the unit is powered down.

Installation

Page 12

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Lead-acid batteries

Page 12

Operating Instructions

GB

Depending on type and production year, your truck will have one of two

different types of battery charger.

Function

SMC-HF 600/800

Curtis 1621

• Connect the battery. Switch on the mains supply. The POWER ON

diode is lit when the unit is charging.

• When the charging level reaches 2.43 V per cell, the charger

reduces charging to a pre-programmed voltage charge level and the

next diode lamp lights up. The charger charges at constant voltage

for about 60% of the main charging period.

• Then the pulsed maintenance charging phase starts. A green diode

lights up.

The battery is now fully charged.

Recharging

• If the battery does not reach 2,43 V per cell after 10 hours of

recharging, switch off the charger. The lower red diode lamp lights

up. The red diode lamp indicates that there is an error or that

charger safety is compromised.

• If the total charging time exceeds 16 hours, the charger switches

to maintenance charging.

• In the event of a power cut, the charging timer is interrupted. The

timer restarts when the power is resumed. The charger's charging

diode lamp is extinguished during a power cut.

Operating errors

Page 13

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Normal operation

Page 13

Operating Instructions

GB

Before charging

Don't forget to switch the charger off or press the pause button each

time you connect or disconnect the battery to/from the charger.

To avoid sparks, power down the charger before disconnecting the

charger and battery connectors.

Drive the machine close to the charger. The

charger and battery connectors must be within

easy reach of each other.

Turn ignition switch to 0. Cut the power.

Connect the charger connector to the battery

connector on the machine.

Switch on the charger.

Check that the charger starts to charge.

The Red lamp lights up (NB: on some

chargers, this lamp is Yellow).

The charging process is optimal at room

temperature. If the battery is to be stored

for a longer period of time, it should be fully

charged before storage.

Page 14

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Normal operation

Page 14

Operating Instructions

GB

After charging

Don't forget to switch off the charger or press the pause button each

time you connect or disconnect the battery to/from the charger.

To avoid sparks, power down the charger before disconnecting the

charger and battery connectors.

Check that the charger has fully

charged the battery.

The Green lamp is lit.

Power down the charger or press

the pause button.

Disconnect the charger connector from

the battery connector.

COMMENT: Never pull on the cables.

Wipe the battery and close the battery lid.

Connect the battery connector to the truck and

drive.

Check battery uid level at least every

14 days. If necessary, top up the battery uid.

ALWAYS top up after charging.

NEVER top up before charging.

Page 15

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Max.

Min.

Lead-acid batteries

Page 15

Operating Instructions

GB

Manual top-up

with battery uid

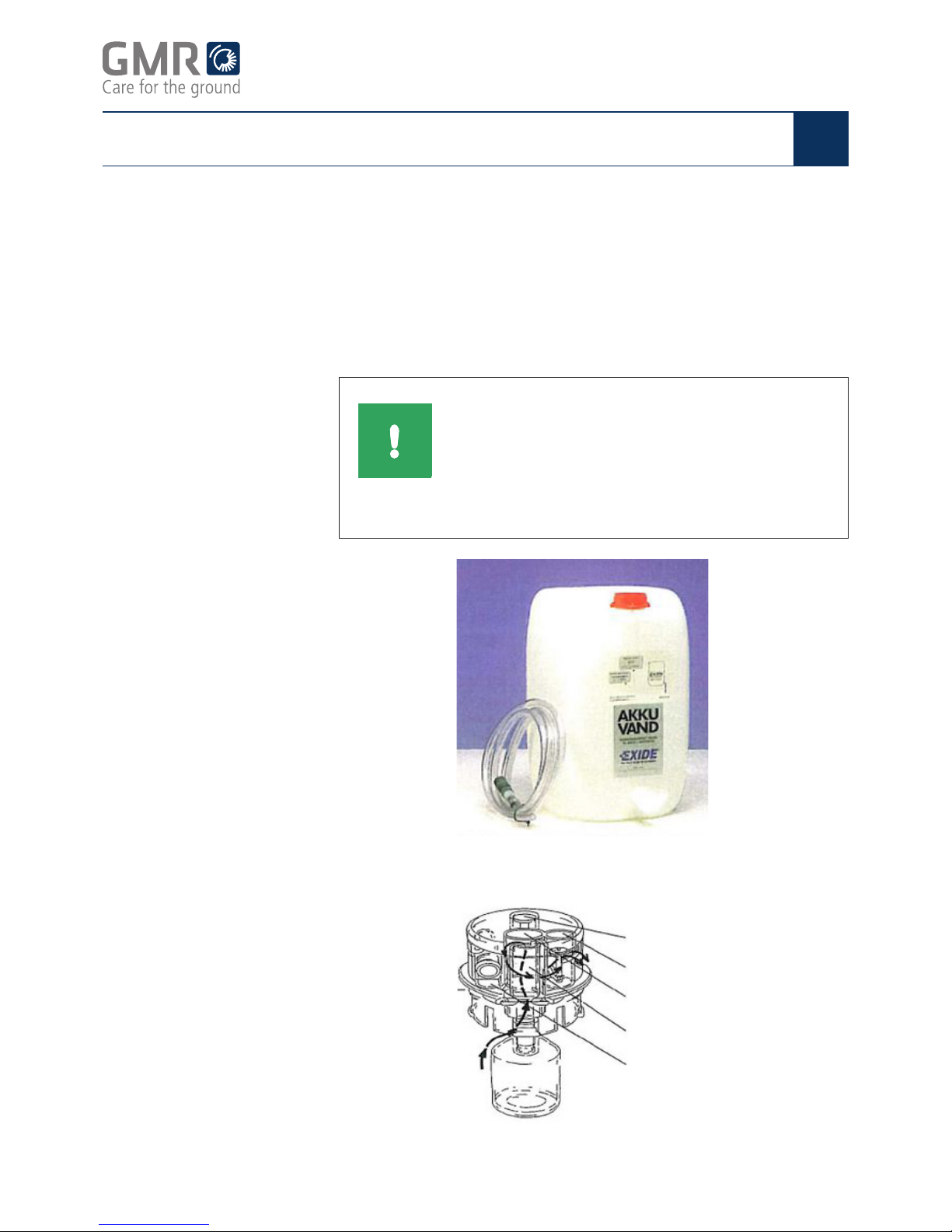

COMMENT: NEVER add acid to the battery, only battery uid.

Do not store battery uid in a metal container. To top up, use equipment

made of plastic or other non-conductive material, which can also

withstand contact with water and acid.

If the acid level is too high, there is a risk

that it will spill over during charging, which

may damage the battery or underlay.

If the battery has toppled or if acid has

leaked from it, contact GMR maskiner a/s.

Always keep the battery clean and avoid

acid spills. If metal parts are tainted with

acid, clean them. To protect them from

further adverse effects, lubricate with

acid-free Vaseline.

Boards and separators must always be

covered by the acid. Never top up with

more battery uid than indicated on the

drawing.

Page 16

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Normal operation

Page 16

Operating Instructions

GB

The battery lling system (BFS) caps work best when water pressure is

0.3-2.0 bar, which corresponds to water column pressure when pouring

from a height of 3-20 metres.

If the pressure is too low, the caps may fail to close at the correct level in

the cells and continue to ll. The battery will then overow, which affects

electrolyte density and may damage the battery box and underlay.

The canister must be placed at least three metres above the cell caps,

preferably higher.

T-cylinder for water connection

Degassing cylinder

Fluid cylinder

Valve cylinder

Indicator cylinder

Automatic top-up with a

BFS and water caniste

COMMENT

Important information

If a battery has overowed, the electrolyte level

must be regulated. This must be only be done by

Exide Batteriservice, Motive Force. Call +45 702 78

702. Contact GMR maskiner a/s to order electrolyte

regulation

Page 17

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Normal operation

Page 17

Operating Instructions

GB

Position the canister at the correct height and check the BFS system

regularly. If you do not, your battery may get damaged.

The battery manufactur-

er's guarantee provisions

For further information about the different types of batteries,

click: http://www.gnb-nordic.com/anden-info/garanti/motive/

Page 18

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Lithium batteries

Page 18

Operating Instructions

GB

The lithium battery pack contains a number of individual LFP cells. The

pack has a nominal voltage of about 3.3 V per cell. This is the safest

type of lithium battery on the market.

LFP batteries have a at discharge curve, i.e. the voltage remains at

about 3.2 V until the battery is about 80% discharged, after which the

voltage diminishes sharply. To minimise the risk of damage and prolong

the lifetime of the batteries, we recommend that they are never more

than 80% discharged.

LFP battery discharge curve at different temperatures

Voltage (V)

Discharged capacity (%)

LFP batteries have a longer lifetime than conventional lead-acid

batteries. They can withstand more than 3,000 70% depth of discharge

(DOD) cycles. The voltage of LFP batteries must not fall under 2.5 V

per cell. If voltage falls below this level, the cells may be irreparably

damaged.

Battery lifetime

The battery pack

(LFP = Lithium Ferro

phosphate)

Page 19

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Lithium batteries

Page 19

Operating Instructions

GB

Battery management

system

BMS = Battery Management

System

The lithium-ion battery pack is tted with BMS, a system which monitors

the voltage in each individual battery cell. A combined battery sensor/

balancing unit is tted to the top of each cell.

The PCB is tted directly onto the cell's + and - terminals and has two

functions:

1. The board constantly monitors cell voltage so that it remains within

the permitted range (2.6-4 V). If voltage is within the permitted

range, a green diode lamp lights up, The unit's output signals to the

main monitoring system that everything is in good working order.

2. The unit also helps to balance the cells while the battery pack is

recharging. When the charge voltage exceeds 3.6 V, the unit starts

to deduct balancing energy from + to - , increasing to 1 ampere

when maximum voltage (4.0 CV) is achieved. When the PCB is

balancing (deducting power), a red diode lamp lights up (at the same

time as the green one). The red diode lamp on the sensors does not

signal that there is an error.

Stama trucks with reset

button (until 2014)

The PCB outputs are daisy chained and monitored by a

micro-controller-based (MCU) monitoring system.

Page 20

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Lithium batteries

Page 20

Operating Instructions

GB

There are two diode lamps on the MCU:

The green diode lamp indicates that

there is a 12 V supply to the PCB.

As long as the monitoring circuit is intact, the MCU ensures that a small

12 V relay remains connected. The 12 V relay supplies all remaining

units which take energy from the battery, e.g. the key switches, main

and pump relays.

The MCU monitors the cell circuit. If the circuit is broken, the red diode

lamp ashes. After 10 seconds, the relay is disconnected and the red

diode lamp lights up.

The MCU is disconnected if the main switch is disconnected.

The red diode lamp indicates that the

monitoring circuit is broken, i.e. that

there is a problem with at least one of

the cells.

MCU diode lamps

A break in the MCU circuit can be caused by a cell with excessively

low voltage. If this is the case, recharge the battery. Press reset button

briey.

Resetting the MCU

Insufcient cell voltage

Open main switch If there is a break in the MCU circuit caused by the main switch having

been opened, just press the reset button briey. The truck does not

need recharging.

If the MCU is triggered during charging, the charging voltage may

be too high or the battery imbalanced. Try pressing the reset button

repeatedly.

If one of the red cell sensor diode lamps lights up much earlier than the

others, the voltage in this cell is too high. The cell may be damaged.

If the cell is damaged, contact GMR maskiner a/s.

Excessive charging

voltage or imbalanced

battery

Stama trucks with no reset

button (after 2014)

Stama trucks which do not have a reset button are tted with a simple

BMS, in which the MCU is replaced by a simple BMS relay, which

requires no resetting. If all the battery sensors light up green, the

BMS relay is activated and the machine can be started. If just one of

the sensors does not light up green, the relay is not activated and the

batteries will not be excessively discharged.

Page 21

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Lithium batteries

Page 21

Operating Instructions

GB

The battery charger charges all the batteries serially and

simultaneously to a charge voltage of 3.65 V per cell. The charger

charges constantly until the desired voltage level is achieved. Then the

charge voltage is reduced until full starting voltage is achieved. The

starting voltage is maintained until the charger is switched off.

Before the charge voltage is reached, all the cell sensors' red diode

lamps should light up.

The battery pack is fully charged in seven hours.

Lithium-ion batteries should not be subjected to charge voltage over

a prolonged period of time because constant high charge voltage

reduces battery capacity. Disconnect the charger when the batteries

are fully charged.

During storage, the battery discharges 3% a month and, to avoid

reaching full depth of discharge, it must therefore be recharged at least

every six months. Lithium batteries are maintenance-free.

Lithium-ion battery charger

Lithium batteries can withstand frost, and can be used down to minus

20 °C, though with reduced capacity.

Cold

• If they are corroded, clean cell terminals with a dry brush.

• Keep electrical connections dry at all times.

If you have a question or need more information material,

contact GMR maskiner a/s.

COMMENT

Important information

To avoid irreparable damage, NEVER allow lithium

batteries to discharge completely.

CAUTION

Damage to machinery or attachments

Do not open the cells as this can ultimately

(worst case) cause irreparable damage.

CAUTION

Damage to machinery or attachments

Lithium batteries must be at least +5 ˚C before

they may be recharged. If colder batteries are

charged they can be permanently damaged.

Page 22

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Lithium batteries

Page 22

Operating Instructions

GB

Battery indicator

If the word SYNCHRONIZE ashes in the display, the battery charge

level reading is invalid. This happens if the indicator has been

disconnected from the battery. Fully recharge the battery to ensure that

the indicator measures correct battery charge level. SYNCHRONISE

disappears from the display.

Displays

Battery

power

(voltage)

Current power

consumption

or charging.

Minus - is

consumption

Ampere hours

used since

charging

Battery

power

remaining (%)

Remaining

operating

hours at

current

consumption

Battery alarm The battery indicator is set to the relevant size of battery. This must not

be changed except by agreement with GMR.

When the batteries have only a few percent of full power remaining, the

indicator triggers an alarm ((%)), and the truck runs at reduced speed.

The truck should be recharged.

Like an electricity meter, the battery

indicator measures power entering

and leaving the lithium-ion battery.

The battery indicator also calculates

power reserves. The indicator is always

connected to the battery – even when

the main switch is OFF.

1. CHARGE: Recharge the battery!

2. Numerical eld

5. Battery charge level

6. Charging indicator

7. Battery alarm

8. Unit of measurement

9. SYNCHRONIZE: Battery indicator

is not synchronised correctly

10. Next view

11. Menu button (not normally used)

12. Previous view

Page 23

GMR maskiner a/s

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Care for the ground

www.gmr.dk

Type:

kW:

No.:

Kg.

Marking/labelling

Page 23

Operating Instructions

GB

The truck is marked with various labels and signs. These must remain

on the truck at all times. If labels and signs are damaged or obscured

by paint, they must be replaced.

New labels and signs are available from the manufacturer or

contact your dealer.

Warning signs The machine carries warning signs.

Labels and signs:

Type plate/serial

number plate machine number and

other specications

CE label The CE label indicates that the truck complies with the

EC Machinery Directive, and states production year.

Other labels The truck also carries the manufacturer's own labels (logos, etc.)

and a technical data label.

Page 24

GMR maskiner a/s

Side 24

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Operating Instructions

GB

Customer services and claims

Claims The warranty period on GMR machines is 12 months from the purchase

date, and covers any material or manufacturing defects. These parts

will be replaced by GMR maskiner a/s free of charge. Consequential

damage and wear and tear will not be replaced.

Any components which are not manufactured by GMR maskiner a/s are

included under the terms of the warranty to the extent authorised by the

supplier of the parts in question.

GMR maskiner a/s reserves the right to assign a claim of this kind

to the relevant supplier and not to reach a decision until the relevant

supplier has responded.

The following must be observed when working on a claim:

• report the claim to GMR maskiner before the repair is started

• agree a time period with GMR maskiner for qualied technicians to

carry out the repair

• any labour costs will only be approved at a xed net price.

If GMR maskiner a/s has not authorised repair work in advance, any

invoice submitted for repair work will not be approved.

At GMR maskiner a/s' request, before the claim can nally be handled,

any parts that were replaced must be sent carriage paid to the factory.

GMR maskiner a/s retains the exclusive right to determine the extent to

which a part shall be replaced or repaired.

The warranty does not cover:

• normal wear and tear or damage which has resulted from

inadequate maintenance.

• damage caused by collision.

• non-compliance with the product's technical specications or if the

product is used for a purpose other than that described in the user

manual.

If the product is altered or if non-original spare parts are used, all rights

under the warranty will be rendered void.

The purchaser does not have the right to require that design changes

on future models are implemented in a pre-existing machine.

Page 25

GMR maskiner a/s

Side 25

STAMA Micro, Parker, Mini, Multi, Evo, Maxi EL

Operating Instructions

GB

Customer services and claims

In the event

of a complaint:

Complaints must be registered directly with GMR maskiner a/s.

Complete a complaint report, stating the machine type, production

number and date of its delivery to the customer, and send it to us. This

is done via the dealer login on our website www.gmr.dk.

If questions arise about claims on imported machines, we reserve

the right to present the claim to the manufacturer before making any

decision about whether the claim can be accepted.

Our machinery is subject to the EC Machinery Directive and quality

assured within the European Union. We make every effort to comply

with these requirements and do our utmost to supply high quality

machinery.

Horsens, 01.06.2017

GMR maskiner a/s

Page 26

Copyright, GMR maskiner a/s ©

Saturnvej 17

DK-8700 Horsens

www.gmr.dk

01032018

Loading...

Loading...