GMN High Precision Ball Bearings User Manual

High Precision

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

High Precision

Ball Bearings

Ball Bearings

40000307

QUALITY

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

QUALITY

MANAGEMENT

MANAGEMENT

The quality policy of GMN Paul Müller Industrie GmbH & Co. KG, is

based on the principle to offer the best possible solutions to all

demands of our customers and to get and keep the confidence and

satisfaction of our customers.

The target of delivering perfect products to our customers includes a

careful handling of all related treatments and services.

The company satisfies the requirements to be state of the art referring

products, treatments and services.

In Nürnberg, GMN Paul Müller

Industrie GmbH & Co. KG

produces with an experience of

more than 95 years high

precision ball bearings,

machining spindles, free-wheel

clutches, non-contact seals and

air bearings for a wide scope.

Most of the products are made

for special applications

on customer requests.

A world wide net of service

stations support all demands

of our customers.

All divisions of GMN Paul Müller Industrie GmbH & Co. KG

(motion-technology, high precision ball bearings and spindle technology)

are certified in accordance with DIN EN ISO 9001:2000.

is the trademark

of GMN Paul Müller Industrie

GmbH & Co. KG.

This catalog reflects the latest

design features at the time of

printing. The company reserves

the right to change designs and

specifications at any time.

Reprint, photomechanical

reproductions as well as

reproduction from clippings

only with license of

Paul Müller Industrie

GmbH & Co. KG.

GMN Paul Müller Industrie GmbH & Co. KG

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

Catalogue

High Precision Ball Bearings

Catalogue No. 40000307

3

Technical information

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

... about the product

• Spindle ball bearings · Deep groove ball bearings · Boundary dimensions 6-15

• Bearing series spindle ball bearings 7-10

• Cages 11-15

• Seals, materials 12-15

• Hybrid bearings with ceramic balls 13-15

•Precision classes and tolerance tables 16-20

... for design of the bearing application

•Preload, rigidity, lift-off force 21-23

• Bearing arrangements 24-29

• Lubrication 30-31

• Accuracy of associated components 32-33

... for bearing calculation

• Method of calculation 34-15

• Nominal and modified lifetime 35-15

• Static load rating 36-15

• Service life of the grease 37-15

• Limiting speed 38-39

Contents

... for assembly

• Basic rules for storage and assembly 40-15

• Failure analysis 40-15

Bearing tables

Spindle bearings

• Designation code 41-15

• Interchangeability chart 42-15

• Explanation of notations 43-15

• Bearing characteristics 44-61

Deep groove bearings

• Designation code 62-15

• Explanation of notations 63-15

• Bearing characteristics 64-65

Special solutions

General

• Special bearings/units 66-15

•Technology 66-15

• Engineering / Service 66-15

Example applications

•Vacuum technology 67-15

•Touchdown bearings 67-15

• Measurement technology 67-15

• Machine tools 67-15

Appendix

• Dictionary English – German 68-70

4

Should this catalogue leave any questions unanswered …

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

… then our product engineering

expertise is here to help you.

Whether you have questions regarding application,

availability, load, speed or correction factors

– we will be pleased to assist you in obtaining

the optimum from our bearings.

Please call us: +49 (0) 9 11 - 56 91- 225/2 29/2 17/3 26

Telefax: +49 (0) 9 11 - 56 91- 587

E-Mail: vertrieb.kula@gmn.de

5

Spindle bearings

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

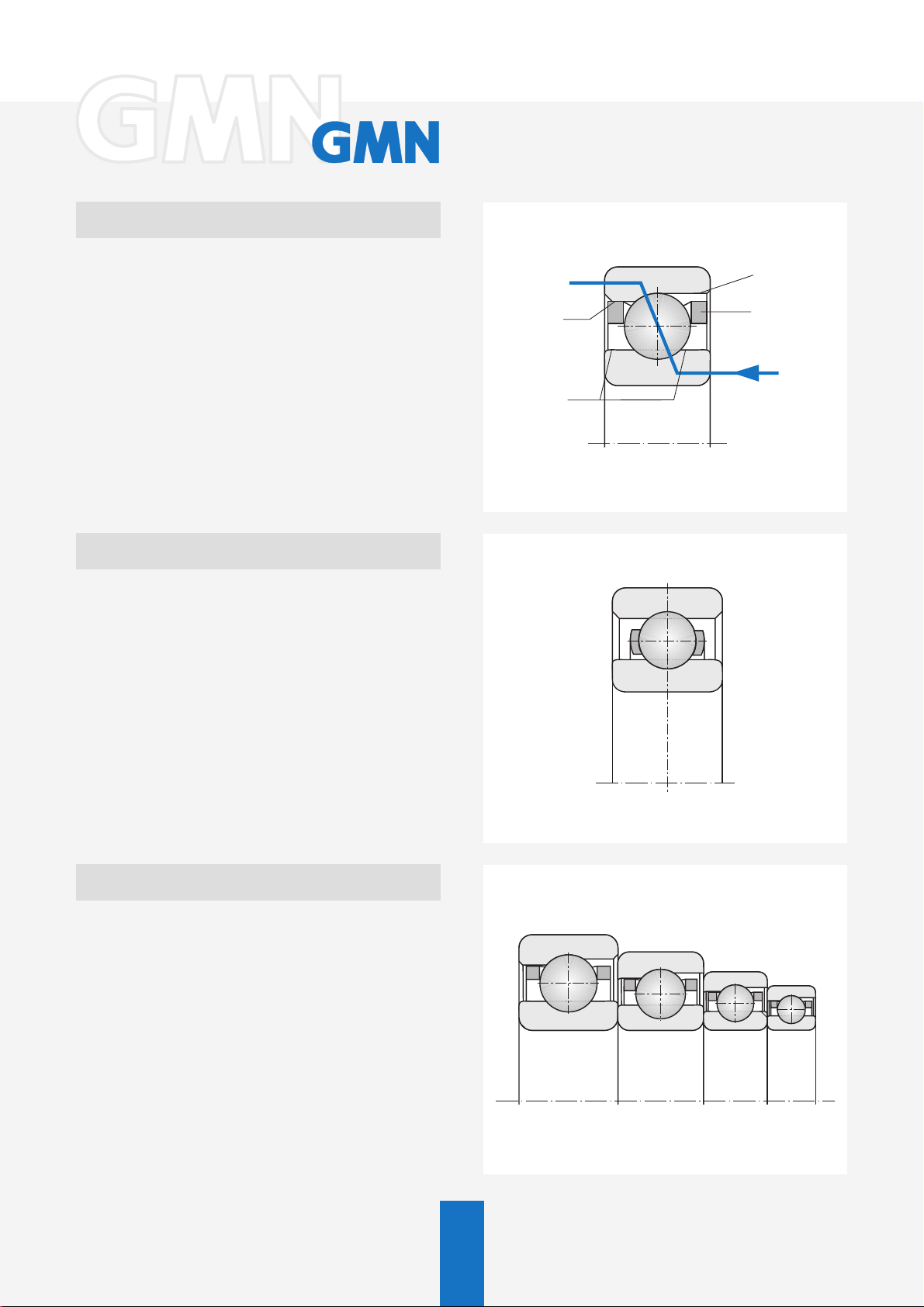

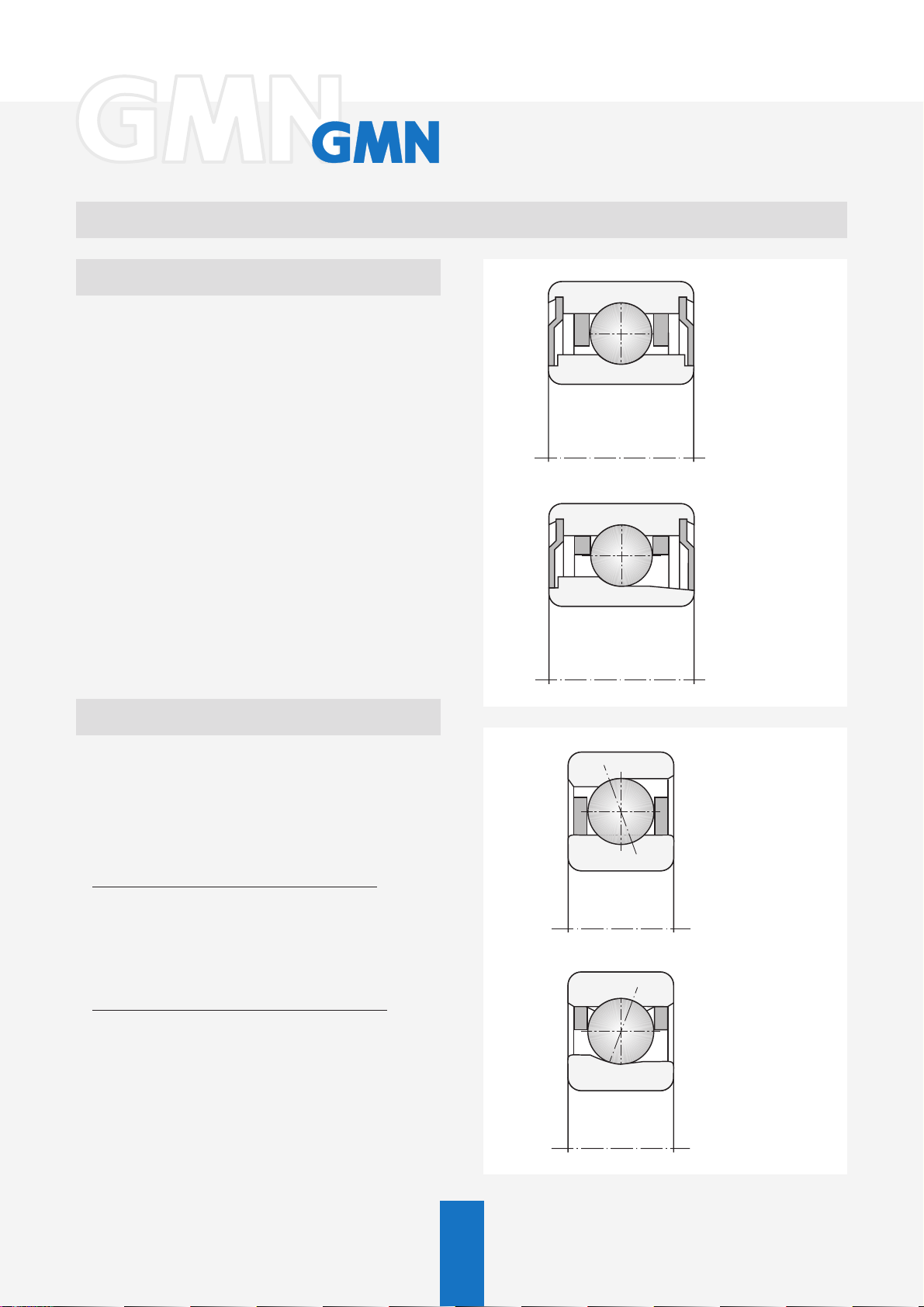

Spindle bearings are angular contact bearings.

Characteristics

• Support of axial load in one direction only

• Adjustment against a second bearing is necessary

• Higher ball complement than with deep groove

bearings

• High rigidity and loading capacity

• Suitable for high speeds

The forces are transmitted from one raceway to the

other under a specific contact angle.

Deep groove bearings

Deep groove bearings are radial deep groove ball bearings

Characteristics:

• Support of axial and radial loads in both directions

• Suitable for high speeds

Outer ring

1 land

Inner ring

2 lands

Outer ring

open side

One-piece

cage guided

on the

outer ring

Boundary dimensions

The boundary dimensions of ball bearings conform to

the boundary dimensions laid down in DIN, ISO and

ABMA Standards.

Depending on the series each bore size comes in several

outside diameters and widths.

Series offered by GMN:

• Spindle bearing: 618..,619..,60..,62..

• Deep groove bearing: 60.., 62..

62 60 619 618

6

Bearing series S…

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

• GMN standard spindle bearing

• Non-separable type

Bearing series SM …

• Geometry of inner ring modified for extremely high

speeds

• Smaller load rating and static rigidity compared

to bearing series S ...

• Equal or higher service life as with bearing series

S ... due to lower friction

• Non-separable type

Bearing Series KH …

• Optimised spindle bearing for extremely high speeds

and increased service life

• Smaller load rating and static rigidity compared

to bearing series SM

• Sealed, with for-life lubrication or open for oil lubrication

• Non-separable type

7

…about the product

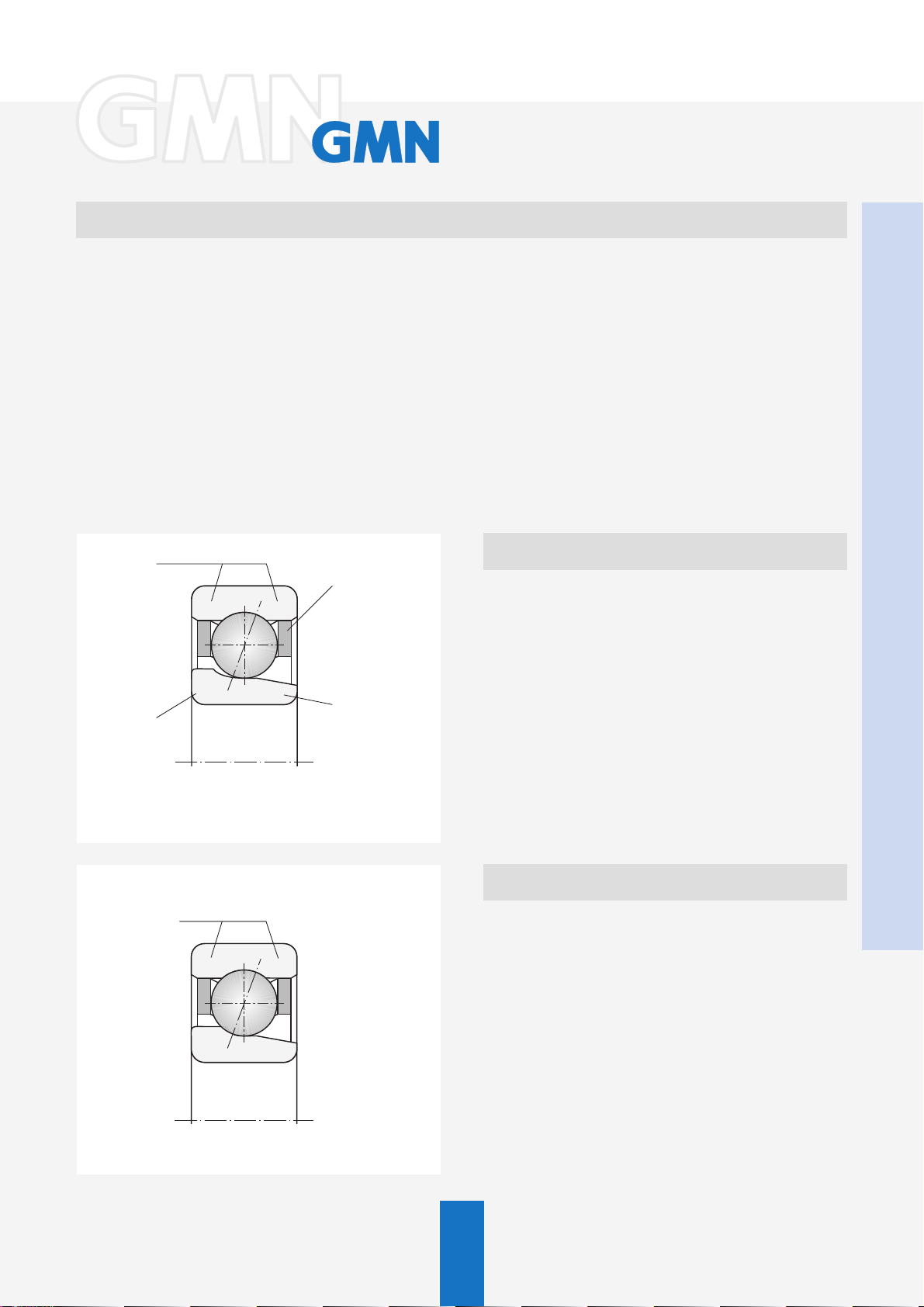

Bearing series SH …

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

A special design of series SM ..

• Optimised oil feeding, one land in inner ring

6

• Speed coefficient n x dm = 2.4 · 10

mm/min reliably

possible with cooling lubrication

• Non-separable type

• Available only on request

Bearing series SMA …

Special design of series SM

• Oil feed via outer ring

• Optimised for oil-minimized lubrication and extremely

high speeds

• High degree of reliability in operation is ensured by

force-feed lubrication

• Non-separable type

• Only available on request

Oil inlet

Inner ring

Open side

Oil outlet

Oil outlet

Inner ring

1 land

Bearings of this series are only

available to precision classes

HG, UP, P2 and ABEC 9

Oil supply

Bearing series SMI …

A special design of series SM

• Oil feed via inner ring

• Optimised for oil-minimized lubrication and extremely

high speeds.

• High degree of reliability in operation is ensured by

force-feed lubrication

• Non-separable type

• Available only on request

Oil supply

8

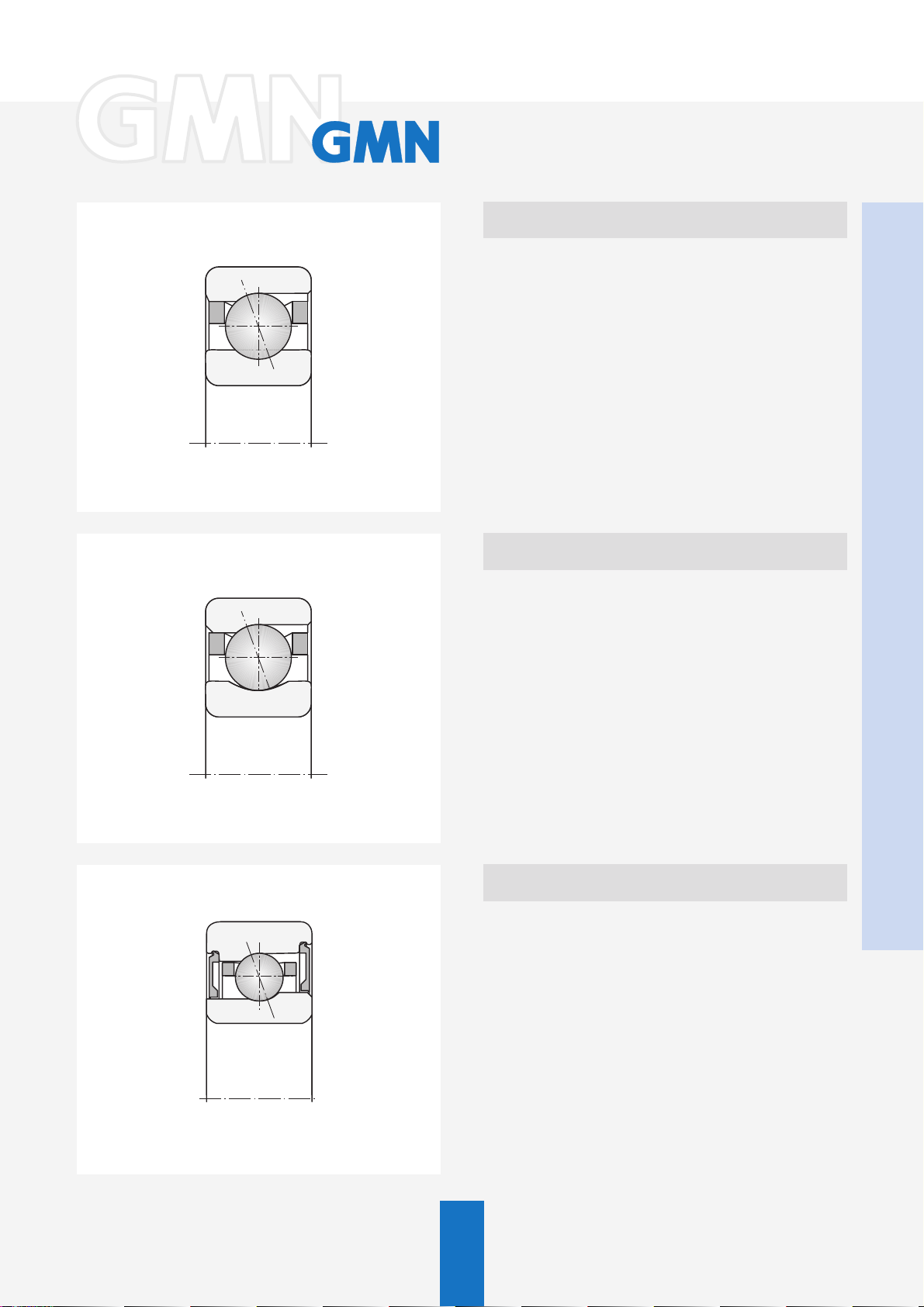

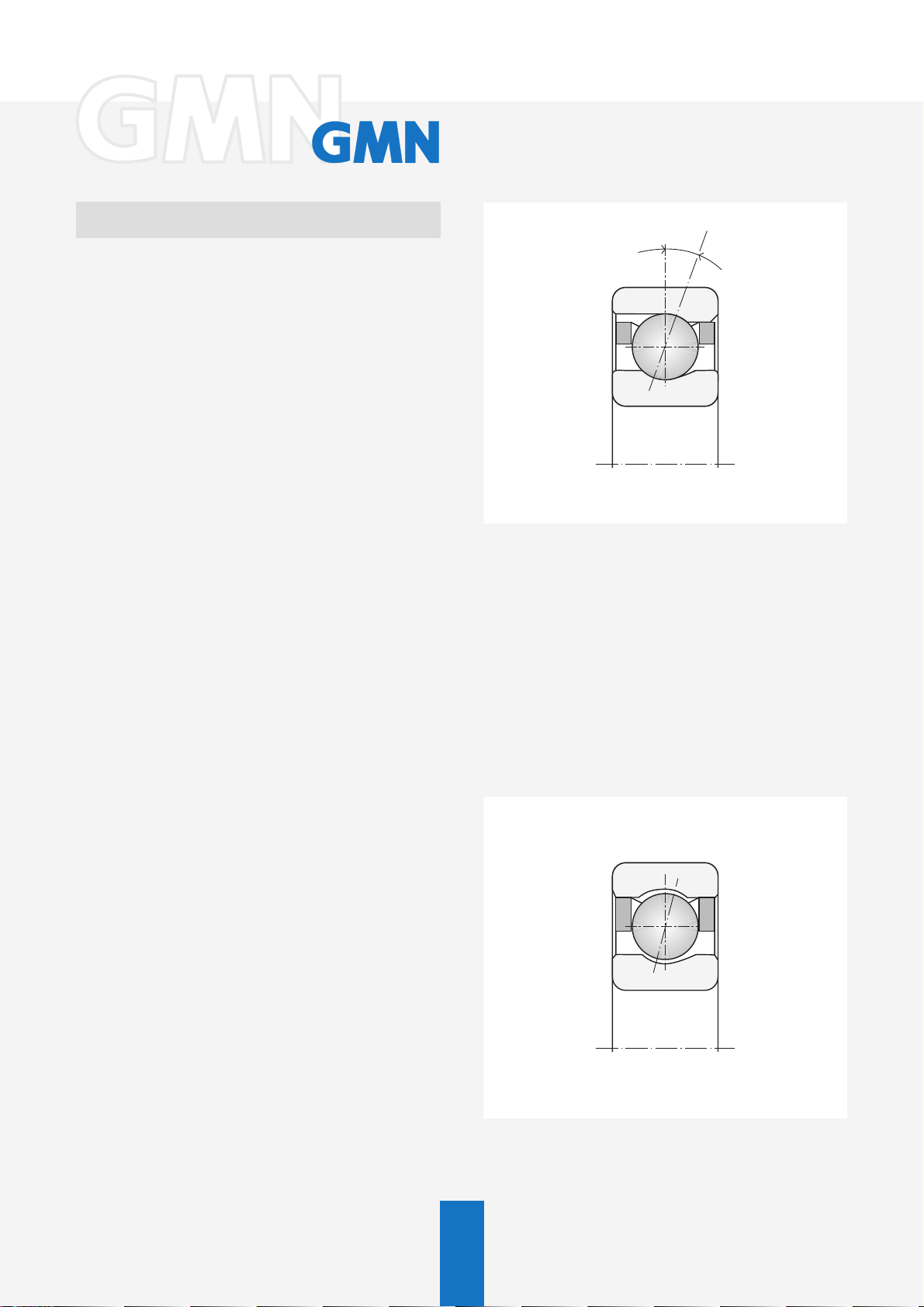

Separable type

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

• Simple mounting due to separate installation of inner

and outer ring (when necessary).

• Balancing of rotating components with installed inner

ring.

• A defined axial clearance of the bearing system is

possible.

Outer ring

2 lands

Inner ring

1 land

Outer ring

2 lands

Bearings of this series are only

available to precision classes

HG, UP, P2 and ABEC 9

One-piece cage

(ball retaining)

guided on the

outer ring

Inner ring

removable

Open side

Bearing series BHT …

• The cage retains the balls in the outer ring, which

means the balls do not fall out when the one-land

inner ring is removed.

• The one-piece cage is guided on both lands of the

outer ring.

• The contact conditions are the same as with bearing

series SM …

• Due to the ball retaining design of the cage, the ball

complement is less than for bearing series SM.

Bearing series BNT …

• Corresponds essentially to bearing series BHT …

• However the contact conditions are the same as

for bearing series S …

• Due to the ball retaining design of the cage, the ball

complement is less than for bearing series S …

…about the product

9

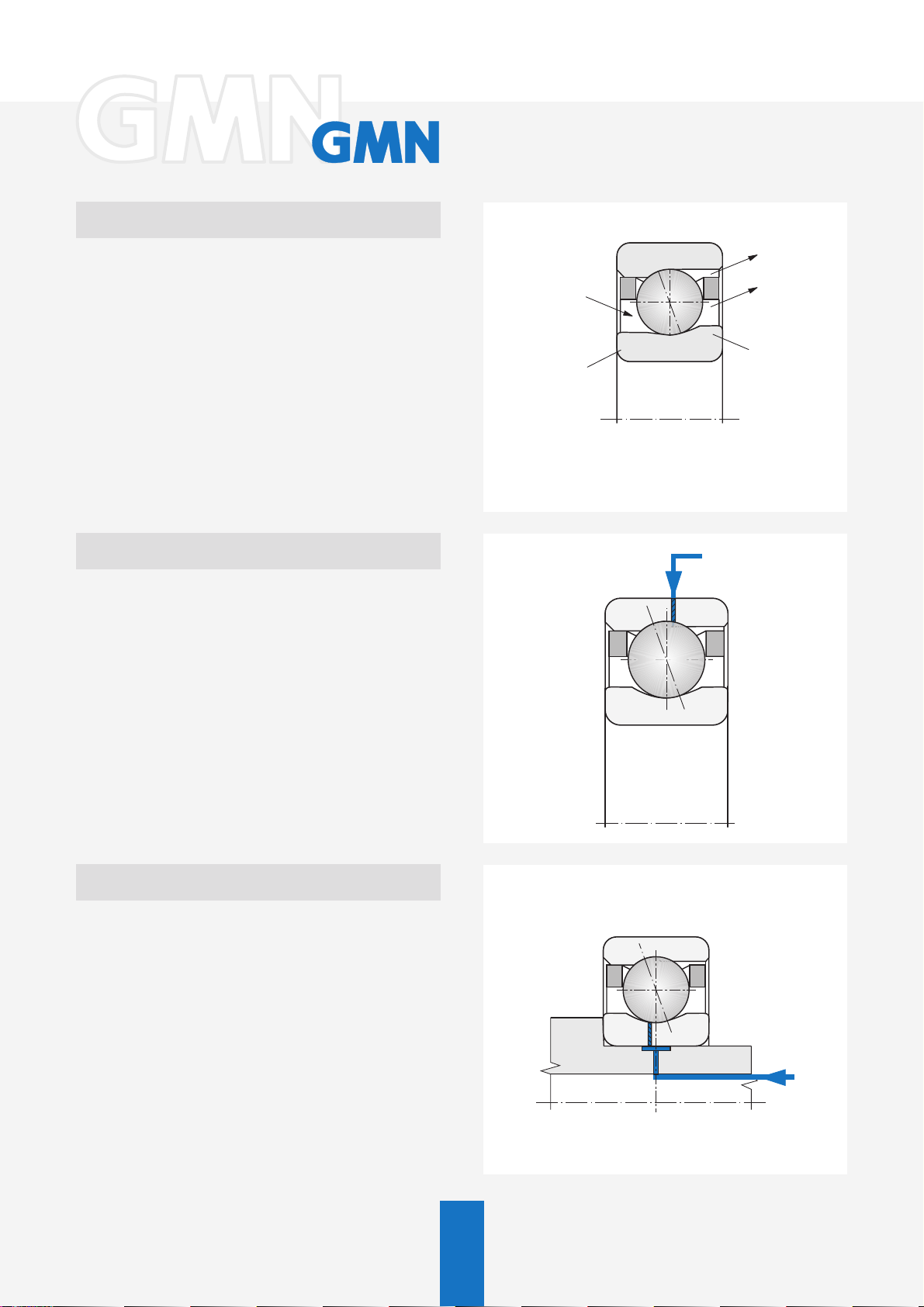

Special bearing design Available only on request

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

Bearing series …X and BHT …X

• Non-separable type

• High-precision ball bearings of extra wide design with

shields on both sides for high speed and grease

lubrication are used in drilling, milling or grinding

spindles for special operating conditions.

• The non-contact shields form a labyrinth seal together

with the recess in the inner ring.

• The bearing friction is scarcely influenced by this. Due

to the labyrinth seal, the lubricant is retained in the

bearing so that the bearing can achieve long running

times, corresponding to operating speeds, with only

one grease fill (for-life lubrication).

… X

Bearing series S …TB, SN …TA

With grease lubricated spindle bearings and cage guided

on one land, cage vibration can be generated at critical

speed ranges.

There are two other alternatives in addition to the TXM

cage that is proven against cage vibrations:

1. Use of TB- cage with bearing series S…

•

The cage is guided on the inner ring by two lands.

Smaller load rating and static rigidity than bearings with

TA or TXM cages.

2. Use of TA-cage with bearing series SN …

•

The cage is guided on the outer ring by two lands.

The contact conditions are the same as with bearing

series SM…

Please contact GMN for selection of these bearing

designs.

BHT… X

S…TB

SN…TA

10

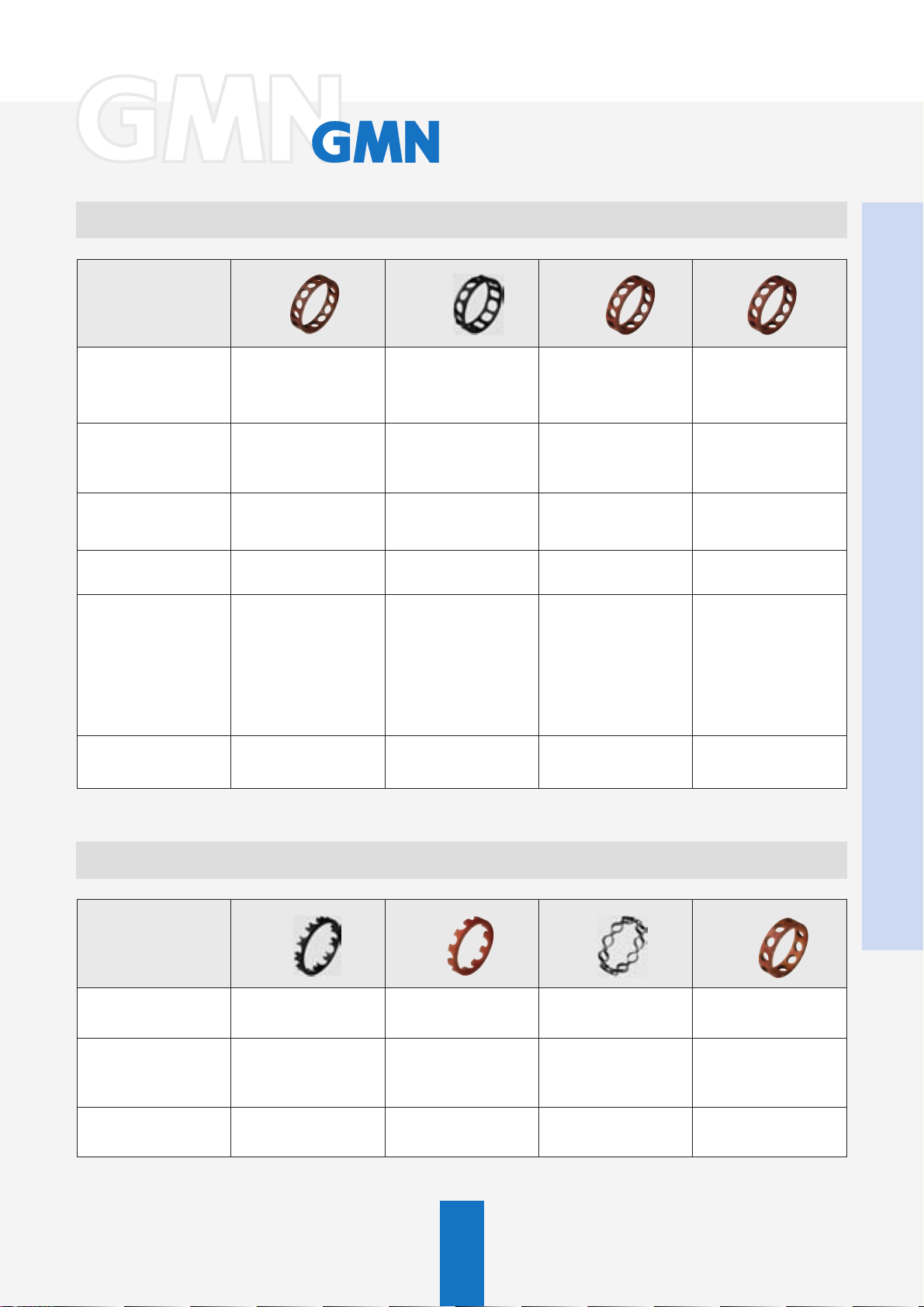

Cages for spindle bearings

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

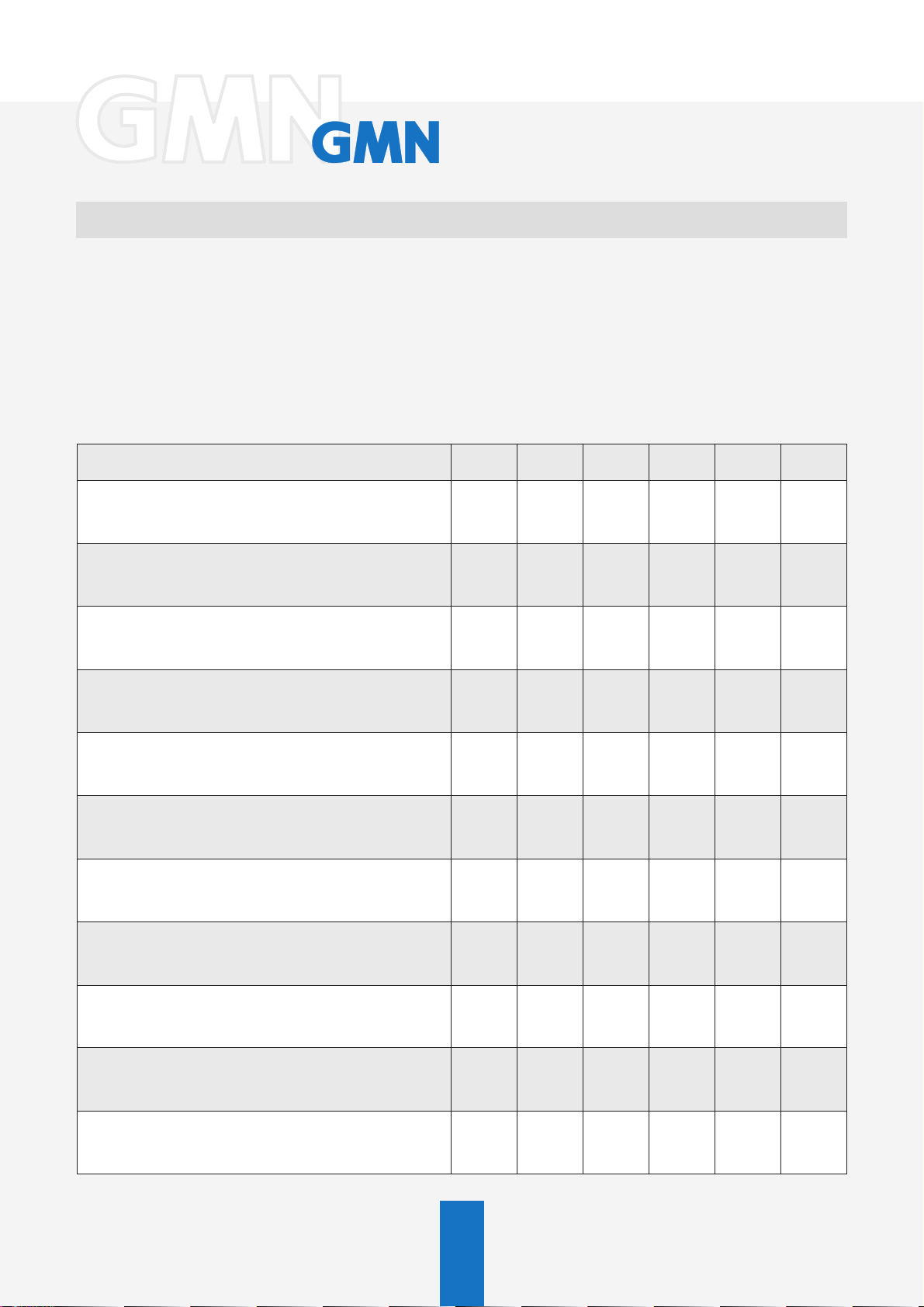

Cage TA TXM TAM TB

Material Textile reinforced Polyetheretherketone Textile reinforced Textile reinforced

Permissible 120 °C 250 °C 120 °C 120 °C

operating

temperature

Cage On outer ring On outer ring On outer ring On inner ring

guidance ball retaining ball retaining

Manufacture Machined Moulded Machined Machined

Notes Standard cage

Mounting For bearing series For bearing series For bearing series On request

Cages made of special material with special treatment like Torlon, aluminium bronze as well as special designs are available on request.

phenolic resin (PEEK), phenolic resin phenolic resin

S, SM, KH, SH, SMI S and SM BHT and BNT

and SMA

thermoplast, carbon

fibre reinforced

Developed for grease

lubrication

Grease remains in the

ball/cage area;

High service life,

high resistance to wear;

good alternative for

cage vibrations

Smaller load rating than

bearing with TA cage

Cages for deep groove bearings

Cage T9H TBH J TA, TB

Material Glass-fibre reinforced Textile reinforced Strip steel Textile reinforced

Permissible 140 °C 120 °C 220 °C 120 °C

operating

temperatur

Design One piece, One piece, Two piece, Two piece,

Cages made of special material like aluminium bronze, Canevasit, Torlon, PEEK and others are available on request.

…about the product

polyamide phenolic resin phenolic resin

crown type crown type clamped or riveted riveted

11

Seals

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

For long maintenance-free operation, deep groove

bearings and spindle bearings are charged with lubricant

ready for operation (for-life lubrication) and shielded/

sealed.

Spindle bearings are fitted with non contact "RZ” seals

and deep groove bearings are fitted with "Z” metal shields

(fixed in the outer ring by means of snap rings).

Materials

Ball bearing - Rings

• Standard:

Vacuum degassed chrome steel 100 Cr 6

(is equivalent to material no. 1.305, SAE 52100, SUJ2)

Heat treated for operating temperatures up to 150 °C

• HNS-Steel (

For applications which demand

– higher speeds

– higher resistance to wear

– higher loading capacity

– higher resistance to heat

– higher corrosion resistance

(on request)

• For higher temperatures up to 500 °C:

High temperature steel (on request)

High Nitrogen Steel):

Advantages

• Simple design possible

• Protection against foreign particles

• Protection against the escape of lubricant

Balls

• Standard:

Vacuum degassed chrome steel 100 Cr 6

(is equivalent to material no. 1.305, SAE 52100, SUJ2)

• Ceramic material silicon nitride Si

3N4

• For higher temperatures up to 500 °C:

High temperature steel (on request)

12

Hybrid bearings with ceramic balls

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

Hybrid ball bearings with steel rings and ceramic

balls have today become indispensable for many

advanced applications. The advantages have been

clearly demonstrated in numerous trials and successful

use in the field.

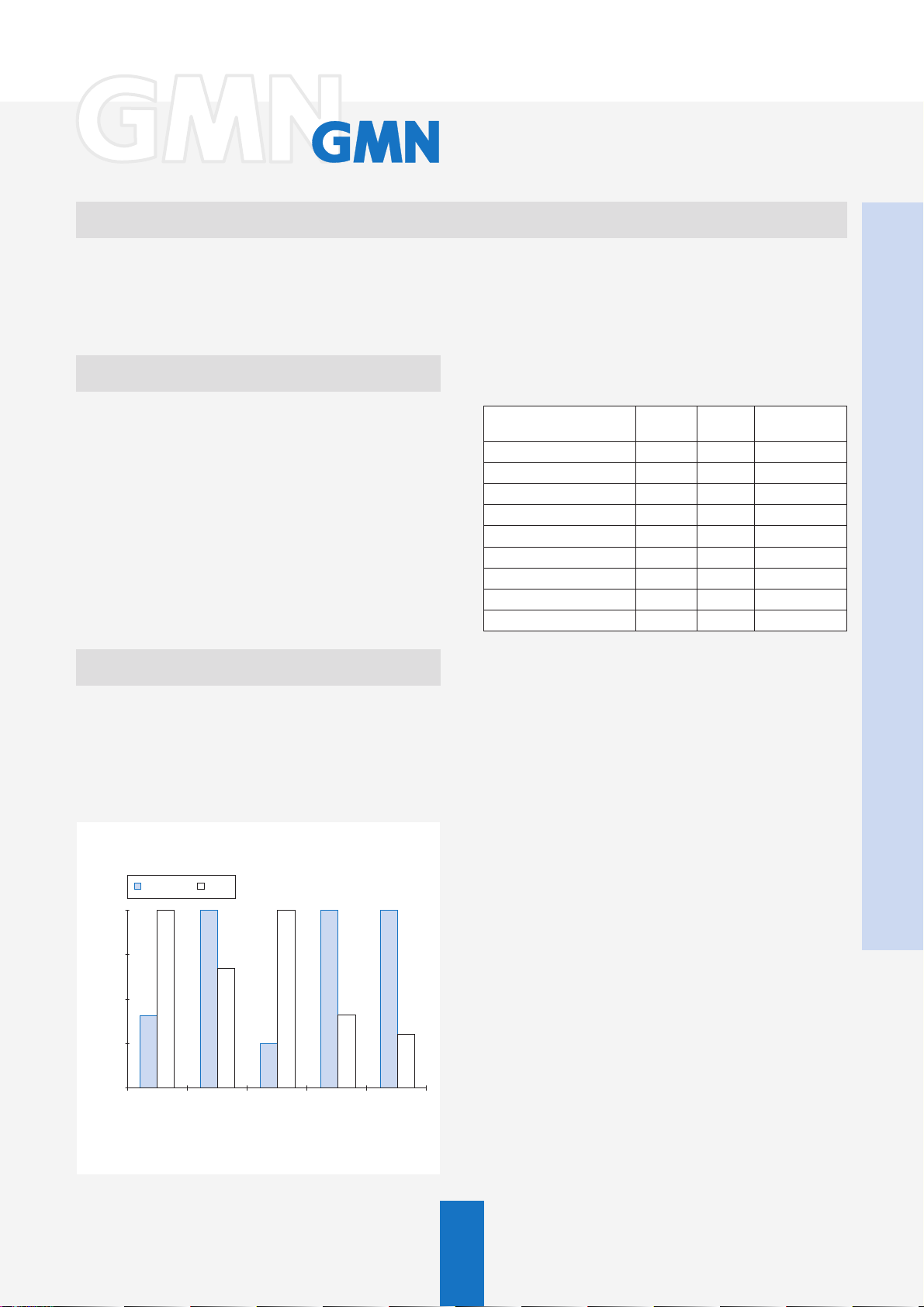

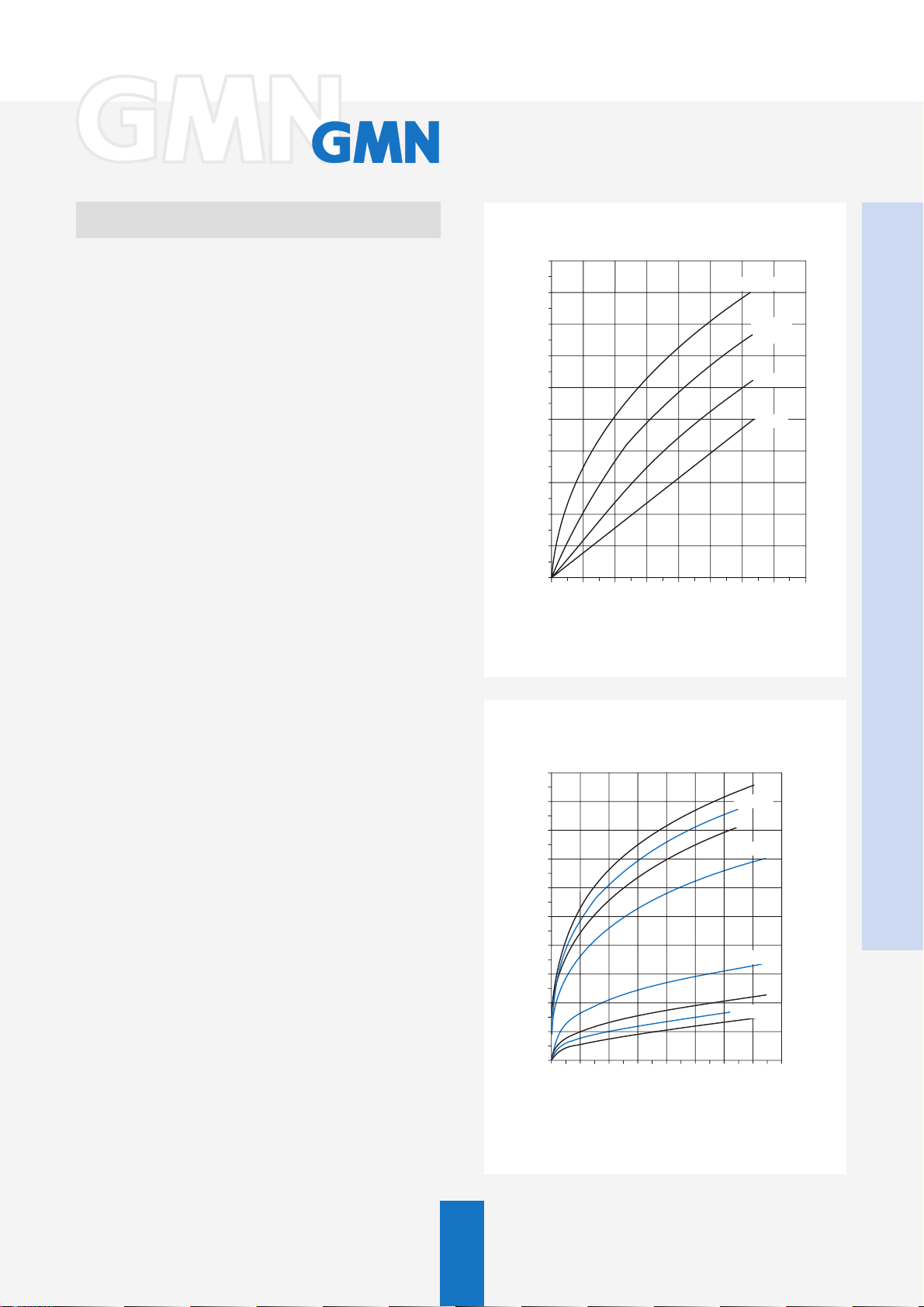

Properties of ceramic

The ceramic material silicon nitride Si3N4 is excellent

for use in precision ball bearings. A comparison between

silicon nitride and conventional bearing steel 100 Cr 6

is shown in diagram 1.

Further advantages of ceramic are:

• Low chemical affinity to 100 Cr 6

• Low friction coefficient

• Little heat transfer

• Corrosion resistant

• Non-magnetic

• Electrically isolating

Advantages for the user

Longer service life

Experience shows that double the service life in comparison to conventional bearings can be reached by

using hybrid bearings. Depending on the operating

conditions life times rates still higher can be achieved.

Ceramic

100%

Steel

Properties Unit Ceramic Ball bearing steel

(at ambient temperature) Si

Density g/cm

-6

Coefficient of expansion 10

Young’s modulus GPa 315 210

Poisson’s ratio – 0.26 0.3

Hardness (Vickers) HV10 – 1600 700

Tensile strength MPa 700 2500

Fracture toughness MPa m

Thermal conductivity W/mK 30-35 40-45

Spec. electric resistance Ωmm

Properties of silicon nitride and ball bearing steel

/K 3.2 11.5

2

3N4

3

3.2 7.8

0,5

720

/m 1017 - 10

100 Cr 6

18

0,1 - 1

The reasons for this are:

• Low surface adhesive wear

The lower affinity to steel reduces the adhesive wear,

which is caused by the cold welding effect on

irregularities in the raceway and ball surface.

• Low abrasive wear out

With steel balls, contaminants and particles from the

process of running in are embedded into the surface.

With every revolution of the ball, these foreign particles

damage the raceway. These particles make little impact

on the extremely hard ceramic ball.

…about the product

75%

50%

25%

0%

Density Young’s

Diagram 1

modulus

Coefficient

of expansion

Hardness

HV10

Temperature

range

• Insensitivity to poor lubrication

Low adhesion and friction allow the hybrid bearing

to perform well even under poor lubrication.

• Longer grease service life

Lower operating temperature and favourable tribolic

features, extend the service life of the grease.

13

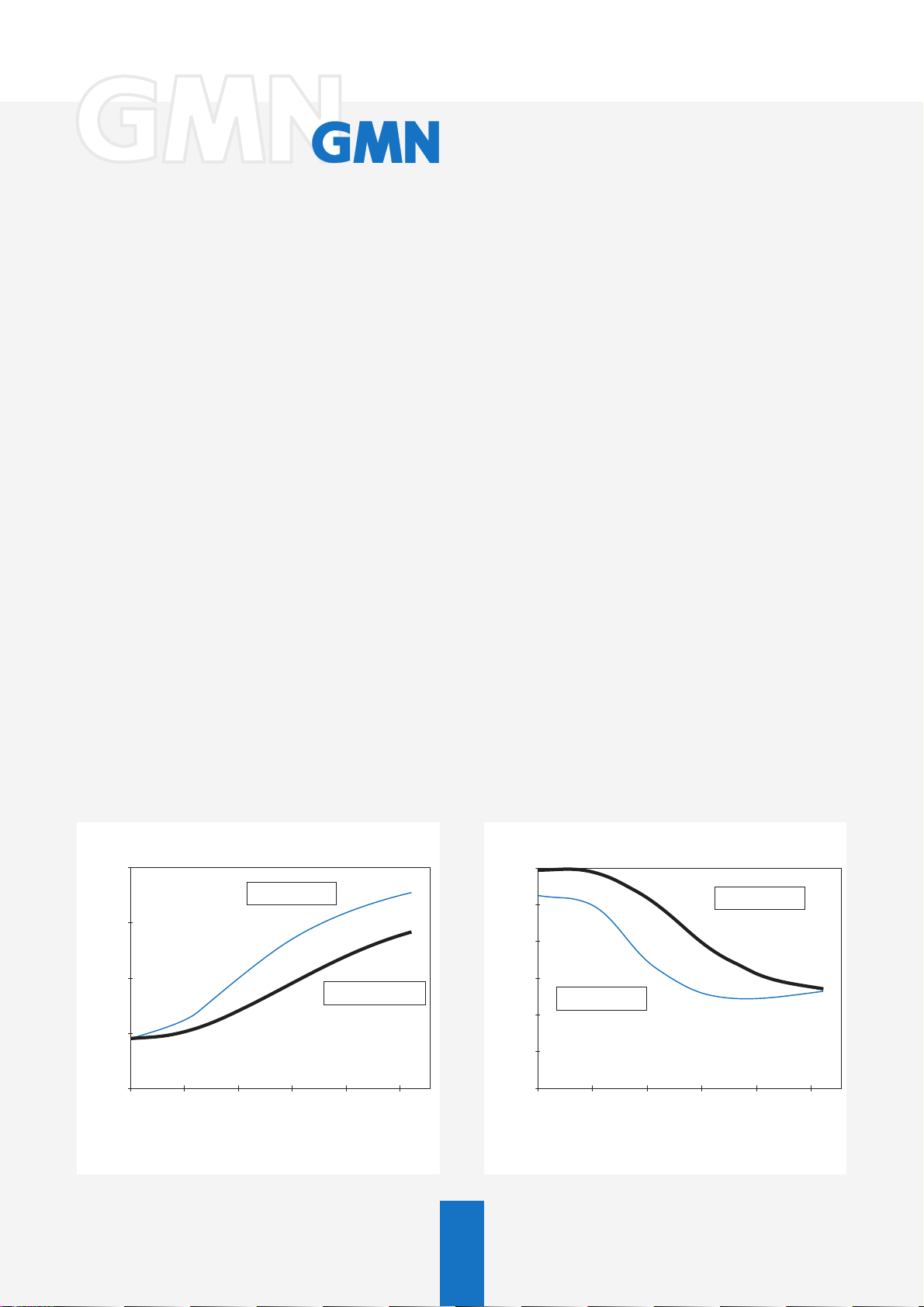

Higher speeds

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

Low cost lubrication

The attainable speeds depend above all on the thermal

conditions in the bearing. Because of lower friction, the

hybrid bearing generates less power loss. Therefore the

speed limit is increased dramatically. Depending on the

application, speed rises of up to 30 % are possible

compared to bearings with steel balls.

• Low rolling friction

The rolling friction is reduced, as the centrifugal force

of the lighter ceramic ball is less. The contact ellipse

is less because of the higher Young's modulus.

• Low sliding friction between ball and raceway

At high speeds, sliding friction is responsible for most

of the total friction.

One of the criteria for the sliding friction is a low

spin/roll ratio.

The service life is negative affected by values

above 0.25.

Diagram 2 shows the advantages of ceramic balls.

• Avoid ball skidding

The balls skid on the raceway if the preload between

the rings is to small. This negative process usually

occurs in case of an insufficient preload of the bearing

or an excessive acceleration. With hybrid bearings

the minimum preload can be reduced as they have a

smaller inertia and generate a smaller spinning moment.

• Grease lubrication can be used in higher speed

ranges.

• The limiting speed for minimum oil lubrication

increases significantly. In many cases, it can replace

the expensive oil jet lubrication.

Higher rigidity

• The radial rigidity of hybrid bearings is approximately

15% higher at low speeds because of the higher

Young's modulus.

• With higher speeds, the centrifugal force affects the

internal load distribution and the dynamic rigidity is

reduced. Diagram 3 shows reduced loss of rigidity for

hybrid bearings.

• A high rigidity improves the accuracy and shifts the

critical fundamental frequency of the bearing

arrangement.

Improved machining accuracy

The following factors lead to an improvement of the

surface quality and accuracy of machined parts.

• Higher rigidity of bearing arrangement

• Small thermal expansion

• Low vibration impulse by ceramic balls

0.4

0.3

0.2

0.1

Spin/roll ratio

0.0

0 0.5 1 1.5 2 2.5

Diagram 2

Steel 100 Cr 6

n · d

– factor [106 mm/min]

m

Ceramic Si3N

120

100

80

Radial rigidity [Nmicrons]

60

40

20

0

0

Steel 100 Cr 6

0.5 1 1.5 2 2.5

n · d

– factor [106 mm/min]

m

4

Ceramic Si3N

4

Diagram 3

14

Load ratings

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

Examples of application

DIN/ISO standards do not specify any calculation

methods for the determination of load ratings of hybrid

bearings. If the classical fatigue theory is used, the load

ratings and the service life will be lower than those for

steel balls. However, experience shows that the actual

service life is significantly longer. Due to this, GMN uses

the same load ratings as for conventional bearings.

• Spindles for machine tools:

State of the art machining processes like high speed

milling require a new concept of bearing arrangement

for spindles. The application of hybrid bearings has

resulted in a remarkable improvement of performance.

For some years we at GMN have successfully used

many spindles with hybrid bearings for our own

production processes.

• Special bearing arrangements:

With vacuum pumps, reliability of the bearings is of

utmost importance, as breakdown can result in high

costs.

More applications are:

• Medical equipment like X-ray tube bearings

• Touchdown bearings for magnetic bearings

• Bearings for aeronautic and aerospace

Summary

When conventional bearings fail, the technological and

economical solution is often to use hybrid bearings.

It is important always to take the whole system into

consideration and to carry out a “weak point” analysis.

GMN is pleased to share its knowledge on this subject

with you.

…about the product

15

Precision classes and tolerance tables

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

The tolerances for dimensional, form and running

accuracy of GMN high precision ball bearings are specified

in international (ISO 492) and national standards

(DIN 620). GMN high precision bearings are manufactured

to precision class 4 and class 2 (P4 and P2) as well

as ABEC 7 and ABEC 9.

For special applications, e.g. vacuum pumps, gyroscopes

as well as measuring engineering and optical systems,

GMN manufacture bearings to the internal tolerance

classes HG (high precision) and UP (ultra precision).

Apart from the requirements mentioned, the tolerance

classes contain additional selection criteria.

Innen ring limits in micron

d over 2,5 10 18 30 50

bore diameter, nominal [mm] to 10 18 30 50 80

욼

dmp

deviation of a single mean bore diameter HG 0-3.0 0-3.0 0-3.0 0-5.0 0-5.0

욼

bearing series 60, 62 P4 0-4.0 0-4.0 0-5.0 0-6.0 0-7.0

ds

variation of a single bore diameter HG 0-3.0 0-3.0 0-3.0 0-5.0 0-5.0

V

bearing series 618, 619 P4 4.0 4.0 5.0 6.0 7.0

dp max

variation of bore diameter in a single radial plane – HG 3.0 3.0 3.0 5.0 5.0

out of roundness UP 3.0 3.0 3.0 3.0 4.0

V

bearing series 60, 62 P4 3.0 3.0 4.0 5.0 5.0

dp max

variation of bore diameter in a single radial plane – HG 3.0 3.0 3.0 5.0 5.0

out of roundness UP 3.0 3.0 3.0 3.0 4.0

V

dmp max

variation of mean bore diameter in several planes – HG 2.0 2.0 2.0 3.0 3.0

taper UP 2.0 2.0 2.0 2.0 2.5

K

ia max

radial runout of assembled bearing inner ring HG 2.0 2.0 2.0 2.0 3.0

S

d max

inner ring reference face runout with bore – HG 3.0 3.0 3.0 4.0 4.0

side runout UP 2.0 2.0 2.0 2.0 2.0

S

ia max

assembled bearing inner ring face runout with raceway – HG 3.0 3.0 4.0 4.0 4.0

axial runout UP 2.0 2.0 2.5 2.5 2.5

욼

single bearing P4 0-040 0- 80 0-120 0-120 0-150

BS

deviation of a single width of the inner ring – HG 0-040 0- 80 0-120 0-120 0-150

width tolerance UP 0-025 0- 80 0-120 0-120 0-150

욼

matched bearing P4 0-250 0-250 0-250 0-250 0-250

BS

deviation of a single width of the inner ring – HG 0-250 0-250 0-250 0-250 0-250

width tolerance UP 0-250 0-250 0-250 0-250 0-250

V

P4 2.5 2.5 2.5 3.0 4.0

BS max

inner ring width variation HG 2.0 2.0 2.0 2.0 2.0

P4 0-4.0 0-4.0 0-5.0 0-6.0 0-7.0

UP 0-3.0 0-3.0 0-3.0 0-3.0 0-4.0

P2 0-2.5 0-2.5 0-2.5 0-2.5 0-4.0

UP 0-3.0 0-3.0 0-3.0 0-3.0 0-4.0

P2 0-2.5 0-2.5 0-2.5 0-2.5 0-4.0

P2 2.5 2.5 2.5 2.5 2.5

P2 2.5 2.5 2.5 2.5 4.0

P4 2.0 2.0 2.5 3.0 3.5

P2 1.5 1.5 1.5 1.5 2.0

P4 2.5 2.5 3.0 4.0 4.0

UP 1.5 1.5 1.5 2.0 2.0

P2 1.5 1.5 2.5 2.5 2.5

P4 3.0 3.0 4.0 4.0 5.0

P2 1.5 1.5 1.5 1.5 1.5

P4 3.0 3.0 4.0 4.0 4.0

P2 1.5 1.5 2.5 2.5 2.5

P2 0-040 0- 80 0-120 0-120 0-150

P2 0-250 0-250 0-250 0-250 0-250

UP 2.0 2.0 2.0 2.0 2.0

P2 1.5 1.5 1.5 1.5 1.5

16

All GMN high precision ball bearings are also available

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

in compliance with the American ABMA standards.

The relationship between the various STANDARDS

ISO DIN ABMA

class 4 P4 ABEC7

is explained below.

class 2 P2 ABEC9

The following tolerance symbols are laid down in

DIN ISO 1132-1.

Outer ring limits in micron

D over 6 18 30 50 80

outside diameter, nominal (mm) to 18 30 50 80 120

욼

Dmp

deviation of a single plane mean outside diameter HG 0-3.0 0-3.0 0-3.0 0-4.0 0-4.0

욼

bearing series 60, 62 P4 0-4.0 0-5.0 0-6.0 0-7.0 0-8.0

Ds

variation of a single outside diameter HG 0-3.0 0-3.0 0-3.0 0-4.0 0-4.0

V

bearing series 618, 619 P4 4.0 5.0 6.0 7.0 8.0

Dp max

variation of outside diameter in a single radial plane – HG 2.0 2.0 2.0 4.0 4.0

out of roundness UP 2.0 2.0 2.0 4.0 4.0

V

bearing series 60*, 62* P4 3.0 4.0 5.0 5.0 6.0

Dp max

variation of outside diameter in a single radial plane – HG 2.0 2.0 2.0 4.0 4.0

out of roundness UP 2.0 2.0 2.0 4.0 4.0

V

Dmp max

variation of mean outside diameter in several planes – HG 1.0 1.0 1.0 2.0 2.0

taper UP 1.0 1.0 1.0 2.0 2.0

K

ea max

radial runout of assembled bearing outer ring HG 2.0 2.0 2.0 3.0 3.0

S

D max

variation of outside surface generatrix inclination with HG 4.0 4.0 4.0 4.0 5.0

outer ring reference face – side runout UP 2.0 2.0 2.0 2.0 2.5

S

ea max

assembled bearing outer ring face runout with raceway – HG 5.0 5.0 5.0 5.0 5.0

axial runout UP 2.0 2.0 2.0 2.0 2.5

욼

single bearing P4

CS

deviation of single width of the outer ring – HG

width tolerance UP

욼

matched bearing P4

CS

deviation of single width of the outer ring – HG

width tolerance UP

V

P4 2.5 2.5 2.5 3.0 4.0

CS max

outer ring width variation – HG 2.0 2.0 2.0 2.0 2.0

width variation UP 2.0 2.0 2.0 2.0 2.0

P4 0-4.0 0-5.0 0-6.0 0-7.0 0-8.0

UP 0-3.0 0-3.0 0-3.0 0-4.0 0-4.0

P2 0-2.5 0-4.0 0-4.0 0-4.0 0-5.0

UP 0-3.0 0-3.0 0-3.0 0-4.0 0-4.0

P2 0-2.5 0-4.0 0-4.0 0-4.0 0-5.0

P2 2.5 4.0 4.0 4.0 5.0

P2 2.5 4.0 4.0 4.0 5.0

P4 2.0 2.5 3.0 3.5 4.0

P2 1.5 2.0 2.0 2.0 2.5

P4 3.0 4.0 5.0 5.0 6.0

UP 2.0 2.0 2.0 3.0 3.0

P2 1.5 2.5 2.5 4.0 5.0

P4 4.0 4.0 4.0 4.0 5.0

P2 1.5 1.5 1.5 1.5 2.5

P4 5.0 5.0 5.0 5.0 6.0

P2 1.5 2.5 2.5 4.0 5.0

Identical to 욼

P2

Identical to 욼

P2

P2 1.5 1.5 1.5 1.5 1.5

BS for the inner ring of the same bearing

BS for the inner ring of the same bearing

* For bearings with shields (Z, 2Z) V

Dp max

is not restricted

…about the product

17

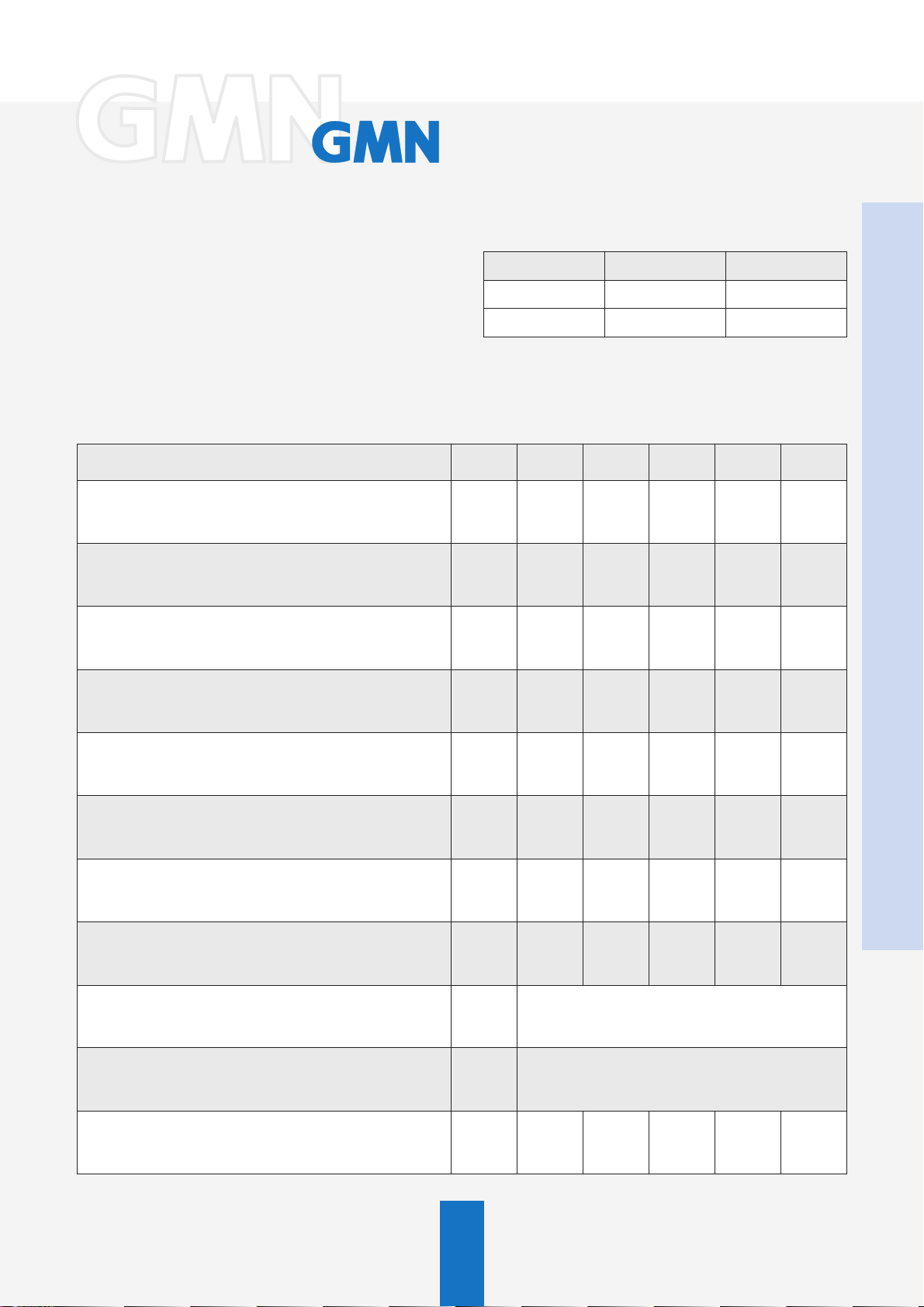

Contact angle 움

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

The contact angle is formed by a straight line drawn

between the points of contact of the balls with the

raceways and a plane perpendicular to the bearing axis.

Externally applied loads are transmitted from one ring

to the other along this line.

The contact angle depends on the radial clearance and

the raceway curvature. A uniform load distribution within

two or more bearings is given only when all bearings

have identical contact angles. GMN provide such selected

bearing pairs plus documentation on request.

When using such bearings provision must be taken to

ensure that both bearings have the same contact angle

after mounting and adjustment to operating conditions.

The contact angle is designed into the bearing and

changes during operation with speed, the external forces

and the difference in temperature between the inner and

outer ring.

With increasing contact angle

• Limiting speed decreases

• Radial rigidity decreases

• Axial rigidity increases

= Nominal contact angle

움

0

움

0

GMN manufacture spindle bearings with 15° and 25°

contact angles.

Other contact angles available on request.

Internal Clearance

The internal clearance defines the amount by which one

bearing ring can be displaced relative to the other without

gauging load.

• Radial clearance: Displacement in radial direction

• Axial clearance: Displacement in axial direction

The internal clearance of a bearing is not a quality feature.

18

Form and running accuracy

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

Low vibration level and high running accuracy are ensured

by random sample production control on the rings and

the balls. Form accuracy and surface finish are checked

by using advanced precision measuring instruments,

the runouts of assembled bearings are checked 100%.

Vibration

The vibration level depends, among other things, on:

• Form accuracy and surface finish of raceways and

balls

• Cage design

• Cleanliness and method of lubrication

A 100% vibration test is carried out with all GMN high

precision ball bearings. The spectral analysis carried out

regularly by taking random samples gives information

on the inner and outer ring as well as ball form accuracy.

The vibration spectrum of a ball bearing is essentially

discreet, the dominating frequencies are design related.

The specific frequencies of a bearing can be calculated

with the aid of the formulae shown opposite.

Apart from highly advanced manufacturing machines

constant production control ensures the uniform quality

of GMN high precision ball bearings.

Sophisticated measuring systems and quality assurance

methods ensure a high degree of accuracy, low friction,

a high degree of quiet running, highest speeds and a

long service life.

Ball pass frequency f

Z

=· fi ·

f

AR

2

1 – cos α

Ball pass frequency f

Z

f

=· fi ·

iR

2

1 + cos α

Ball spin frequency f

f

T

i

fw =·

2

– cos

D

W

Cage rotation frequency f

f

i

fK =·

2

D

W

1 – cos α

T

on the outer ring

AR

D

W

T

on the inner ring

iR

D

W

T

w

D

W

2

T

K

0

[1/sec]

0

[1/sec]

0

α0[1/sec]

[1/sec]

19

= Shaft frequency 1/sec

f

i

= Ball diameter in mm

D

w

T= Pitch diameter in mm

Z= Number of balls

= Contact angle

α

0

…about the product

Radial runout

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

Meeting the radial runout of the inner and outer ring,

specified in the various standards, is 100% controlled.

On request the highest point (max wall thickness) is

Matching accuracy

The matching accuracy of ± 2 microns for a single

bearing ensures a uniform load distribution and a uniform

operating temperature within the series. GMN offers

bearing pairs with increased matching accuracy

Grading

When two or more matched bearings carry a load

together the bore and outside diameter should be

identical. Due to the selective pairing of bore and outside

diameter the fitting on the shaft and in the housing are

facilitated. On special request GMN grades the tolerances

of bore and outside diameter. The suffix here to is "X".

Tolerances smaller than 3 microns are not graded. The

grading groups can, for practical reasons, only be

selected, but not manufactured separately.

The groups are marked on the box as follows:

marked by a point on the face. This is an additional help

for the user to minimise wobble.

(± 1 micron) on request. When specifying the type of

matching, like DB, DF or DT for pairs or groups matching

takes place to an optimum for precision class HG and

UP.

Grade Bore Outer diameter

X11 O O

X12 O U

X21 U O

X22 U U

X10 O –

X20 U –

O= Upper tolerance half

–= No grading

U= Lower tolerance half

20

O

U

O

U

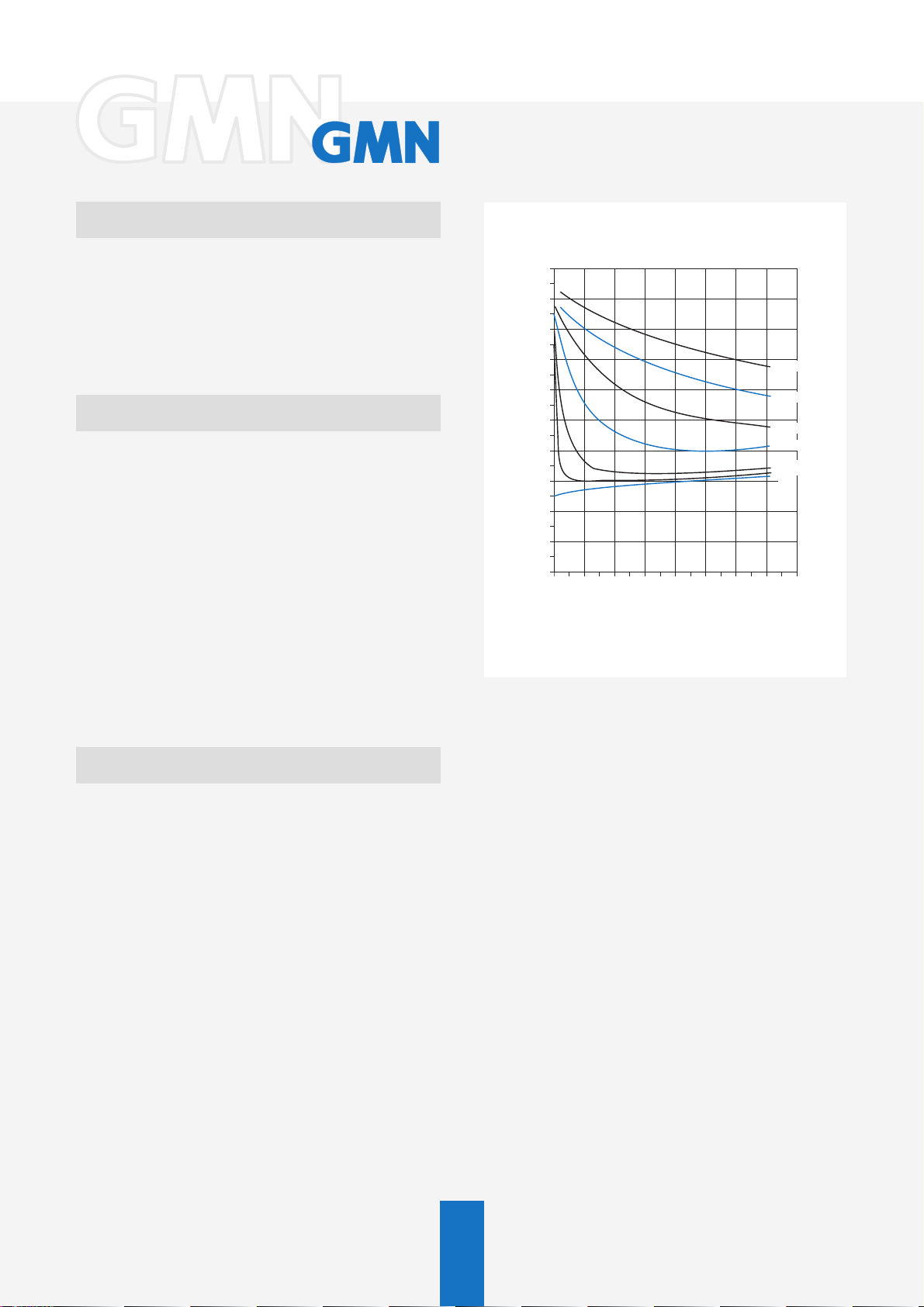

Preload

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

The preload is defined as a permanent axial load applied

to a bearing.

The advantages of a preload:

• High running accuracy and low vibration level of the

bearing arrangement, as the internal clearance is

eliminated.

• Reduction of deflection (diagram 1)

• Increase of rigidity of the bearing (diagram 2)

• Reduction of the sliding friction share at high speeds,

as the change of the contact angle between inner and

outer ring is reduced. A measure of the sliding friction

share is the spin/roll ratio (diagram 3)

• Prevents ball skid during high acceleration

• Increases the load-carrying capacity of the bearing

arrangement.

60

54

48

42

36

30

24

Axial deflection inmicron

18

12

6

0

061218 24 30 36 42 x48 10

Diagram 1

No preload

Preload

120 N

400 N

800 N

2

Axial load [N]

200

180

160

140

120

100

80

Rigidity (N/micron)

60

40

20

0

04080120 160 200 240 280 320

Diagram 2

radial

axial

Axial load [N]

α0=15°

α0=25°

... for design of the bearing application

α0=25°

α0=15°

21

Rigidity

中国地区代理销售服务商

上海旭精轴承贸易有限公司

TEL:0086-21-37829707 /37829708

FAX:0086-21-37829709

The rigidity is defined as the external load of a bearing,

which causes a deflection of 1 micron of the bearing

rings to each other.

The values for axial rigidity are shown in the bearing

tables.

Lift off force

The lift off force is the limit for the external axial load.

Exceeding this value leads to removal of the preload.

Condition is a mutual preloaded bearing set.

Consequences when external load exceeds lift off force:

• The balls and the raceways of the relieved bearing are

no longer in permanent contact

• Wear rises as sliding friction increases

The values of the lift off force are shown in the bearing

tables.

0.40

0.36

0.32

0.28

0.24

0.20

0.16

Spin/roll ratio

0.12

0.08

0.04

0.00

Diagram 3

070 560490420350280210140

Axial load [N]

n = 100 000

n = 80 000

n = 60 000

n = 40 000

n = 20 000

n = 10 000

n = 1

1/min

Minimum preload at high speeds

A minimum preload at high speeds is indispensable to

limit the sliding friction share.

Effect of insufficient minimum preload:

• The balls and raceways are no longer in permanent

contact

• Wear rises as sliding friction increases

• Reduction of service life

The values for minimum preload are shown in the bearing

tables.

22

Loading...

Loading...