GML 8200 User Manual

G e o r g e M a s s e n b u r g L a b s

GML 8200 Parametric Equalizer Series II

The GML 8200 Parametric Equalizer is the reference standard parametric equalizer,

from the engineer who invented the concept. Its revolutionary circuitry was first

envisioned by George Massenburg and is now embodied in this fifth-generation

progressive design.

Owner's Manual

Version 1.0

April, 2001

All materials herein © GML, LLC.

GML,LLC

P.O. Box 1366

Franklin, TN 37065

615.790.1016 (ph)

615.794.4802 (fax)

gmlinc@ix.netcom.com

INTRODUCTION

The GML 8200 Parametric Equalizer is the reference standard parametric equalizer,

from the engineer who invented the concept. Indeed, the revolutionary circuitry first

envisioned by George Massenburg and embodied in this fifth-generation progressive

design affects audio signals in a most musical fashion. The Model 8200 benefits from

nearly twenty years of limited manufacturing, precise listening analysis, widespread

usage by demanding industry professionals, and continuous evaluation by the GML

Engineering Department.

FEATURES

The GML Model 8200 Parametric Equalizer has become the reference standard due in

large part to its features:

• All-discrete, Class-A design; no integrated circuits to compromise the

audio path

• No interstage or coupling capacitors to add distortion or degrade over time

• Transformerless; precision electronically balanced input buffer and DC-

servo stabilized direct-coupled output

• Carbon-film precision potentiometers, manufactured to GML exacting

standards

• Designed with GML 9202 low-noise, low-distortion, wide dynamic range,

wide bandwidth precision discrete opamp

• No tantalum, ceramic, or electrolytic capacitors in the signal path

• Precious-metal interconnects

• High-quality XLR interconnects, Au over Ag

• Illuminated push-button switches for "EQ In" and "EQ Out"

• LED power indicator

• Multi-colored knobs, GML standard

• Rugged and stylish black-anodized aluminum chassis

• Reverse-anodized lettering, much more permanent than ink or paint

processes

• Quality PCB manufacturing, assembly, and chassis construction

OPERATION

The GML Model 8200 Series II Parametric Equalizer offers astonishing precision and

sonic accuracy when sculpting the response of any source. Its operational

characteristics have been honed through many years of use in the most critical

recording and mixing situations and have proven both reliable and amazingly

accommodating.

The basis of the parametric design topology, in general, specifies control over not only

gain or attenuation, but also over both frequency and “Q” factor in multiple user-defined

bands. In the case of parametric equalization, “Q” is defined as the center frequency of

the alteration (whether gain or attenuation) divided by the bandwidth of that alteration. It

follows, then, that low values of “Q” affect a wide range of frequencies around the cut or

boost, while high values of “Q” specify a narrow slope around the center frequency.

Another important aspect of true parametric equalization, as embodied in the Model

8200, is the existence of overlapping frequency bands, which provide great precision

and flexibility.

Specifically, the 8200 provides complete control over a wide frequency range and “Q”

setting, along with 15 dB of cut or boost on five individual bands, with the front panel

controls for frequency and “Q” mounted concentrically. The addition of the “Q”

characteristic represents the foremost advance in equalizer technology since the

invention of the transistor as a replacement for bulky and noisy vacuum tubes, and

empowers the user to maintain precise and musical control over the tonal attributes of

the spectrally processed signal. (Graphical representation of the Q characteristic and gain steps

may be found in Appendix A of this manual.).

The availability of up to 15 dB of gain or attenuation is significant in the audio world,

since most contemporary equalizers offer at most 12 dB of cut or boost, and usually not

over such flexible overlapping multiple bands. Thus, it is possible to achieve any

particular “sound” that is desired, no matter if the goal is a subtle alteration or an audible

coloration effect.

Front panel controls on the Model 8200 Series II Parametric Equalizer include an

illuminated in/out pushbutton switch for each channel, five color-coded bands per

channel with amplitude and dual-concentric frequency and "Q" potentiometers, plus a

power indication LED. The amplitude pots are continuously variable between +15 dB

and -15 dB, with highly accurate 0 dB settings. Each band offers a wide array of

frequencies to select on the outer knob of the dual-concentric potentiometer, with a

good deal of overlap between bands to accommodate almost any combination of cuts

and boosts. The Low and High bands offer counter-clockwise detents for shelving

curves in addition to the variable "Q" values from 0.4 to 4 found in the other three

bands--all on the central knobs of the dual-concentric potentiometers. Frequency

markings can be found along the inner, larger ring of numbers, while the outer, smaller

numbers encircling the dual-concentric potentiometer denotes "Q" value.

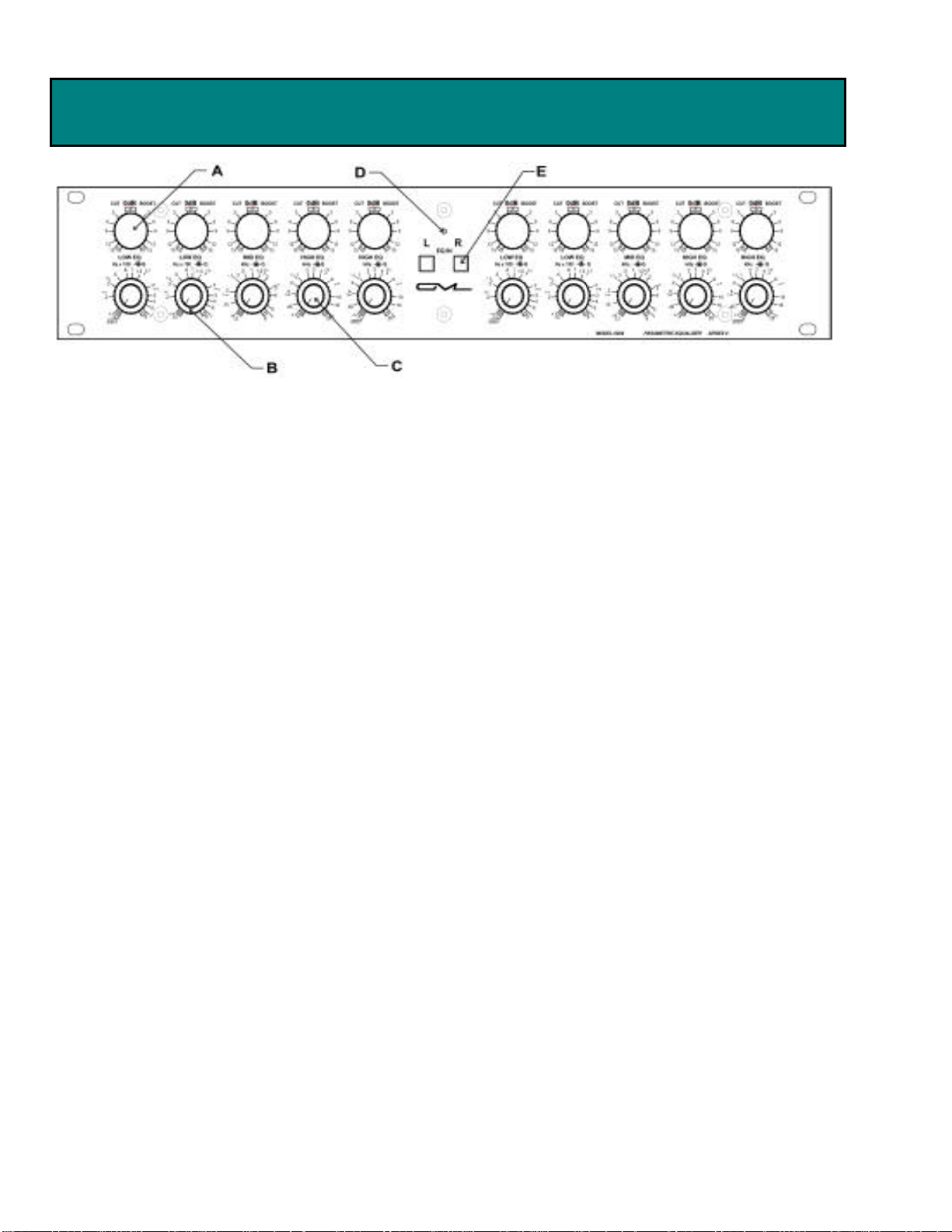

MODEL 8200 PARAMETRIC EQUALIZER SERIES II

FRONT PANEL

A. The Cut/Boost potentiometer controls the amount of gain or attenuation for each

band. Maximum level of cut or boost is 15 dB, continuously variable, with a highly

accurate 0 dB setting (no detent). The element of the potentiometer is precisiontrimmed carbon film, for the highest signal integrity and longest life.

B. The Frequency potentiometer determines the center frequency for each band.

Frequency ranges differ for the bands to accommodate maximum flexibility, and are

continuously variable. The inner ring of numerical markings denote center frequency

in concert with the pointer; these markings are estimations and will vary slightly from

unit to unit due to component tolerances. Carbon film is the element of this

potentiometer.

C. The Q potentiometer is mounted concentrically with the Frequency potentiometer but

rotates independently. This controls the sharpness of the peak or dip for each band,

with a counter-clockwise detent for shelving on the LOW and HIGH bands. The

outer ring of small numerical markings denote Q value, which is continuously

variable from 0.4 (widest Q) to 4.0 (sharpest Q). This is a carbon-film potentiometer.

D. The Power Indication LED allows visual confirmation of the presence of appropriate

power supply voltages, +/- 28 V.

E. The EQ IN switch toggles between the active (switch in, lamp ON) and bypassed

(switch out, lamp OFF) modes of operation. No signal is present at the switch itself;

this is merely a latching DC voltage switch to control a high quality signal relay

located near the back of the unit.

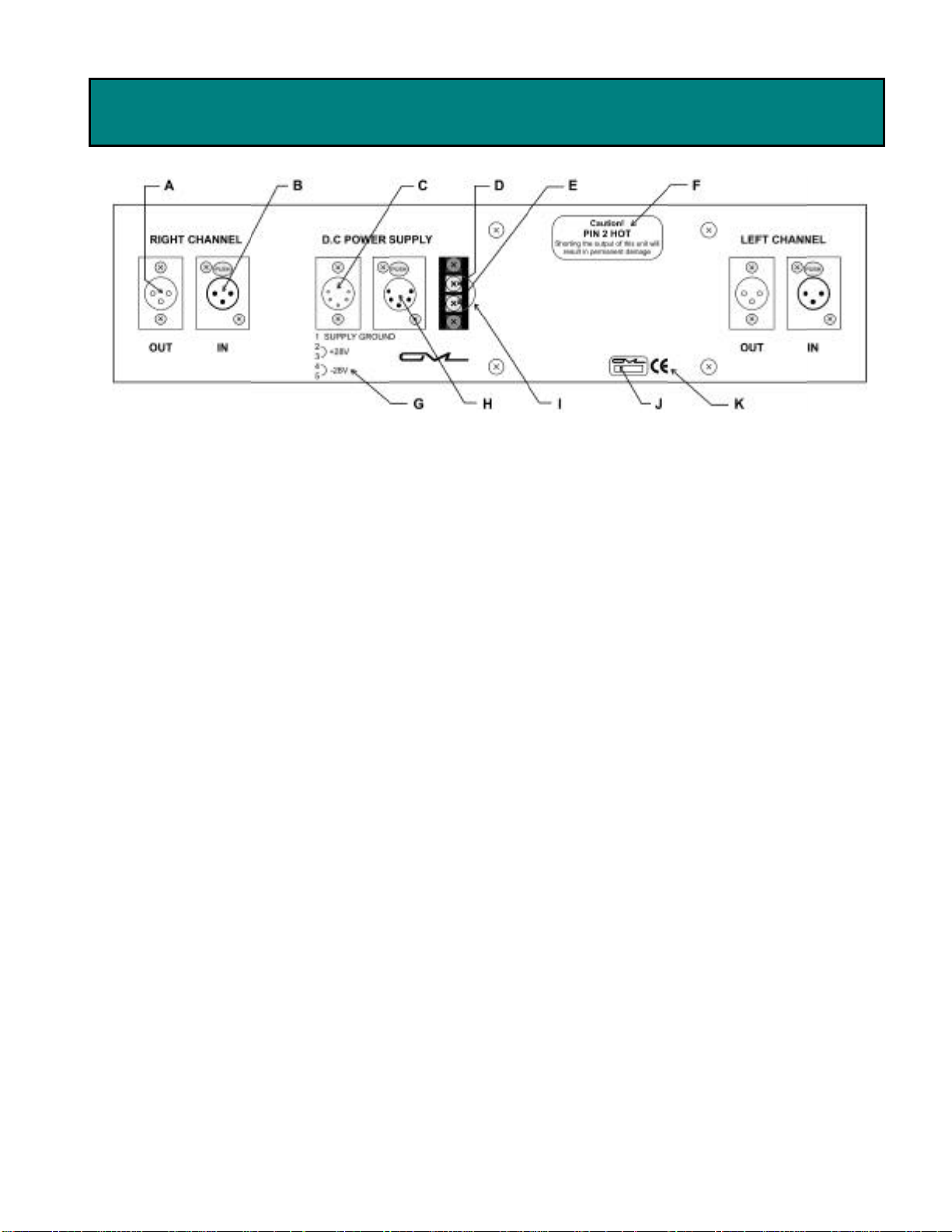

MODEL 8200 PARAMETRIC EQUALIZER SERIES II

BACK PANEL

A. The Output connector provides a professional interconnect to external devices. Precious

metal, durable XLR connectors are provided for each channel. Outputs are D.C. servo

corrected, direct-coupled to preserve signal integrity.

B. The Input connector features durable precious metal construction. This female XLR feeds

the precision electronically balanced input stage.

C. The 5-pin D.C. Power Supply Input allows interconnection of the external supply required for

the unit to operate. A 6 ft. 5-pin power supply cable ships standard with new units.

D. The Electronics Ground terminal connects to circuit ground in the unit.

E. The Chassis Ground terminal gives a common point of continuity for the chassis. This

terminal is normally tied to the Electronics Ground terminal (D); however, in certain

situations it may be advantageous and/or necessary to keep these ground references

independent (to eliminate ground loops in some installations, for instance).

F. The Output Warning sticker reminds users of the inherent danger and imminent damage

associated with shorting the output. Normally, this denotes that pin 2 is wired as the hot

output pin; however, older units and custom-order units may be wired pin 3 hot.

G. The D.C. Power Supply Pin-Out Legend reveals the appropriate voltages from the external

power supply.

H. The D.C. Power Supply Throughput is a 5-pin XLR connector that allows a second unit to be

connected to the same external power supply without the need for a "Y" cable.

I. The Ground Strap normally connects electronics ground and chassis ground; however, it

may be removed by the user if it is thought to be beneficial for a particular installation.

J. The GML Serial Number Tag contains a permanent imprint of the unit's assigned serial

number.

K. The CE (European Electromagnetic Compatibility) marking indicates full compliance with EN

55013:1990 (Electromagnetic Disturbance, Sects. 3.2, 3.5) and EN 55020:1988

(Electromagnetic Compatibility, Sects. 4.3, 5.4, 6.2, 7.0, 8.0).

Loading...

Loading...