Page 1

User Handbook

Gas Measurement Instruments Ltd

Page 2

Issue 8

10/05/17

Part Number: 48160

GMI welcomes comments on all our publications. Your

comments can be of great value in helping us to improve our

customer publications. Please send any comments that you

have to customerservice@gmiuk.com

Copyright © Gas Measurement Instruments Ltd 2008

Page 3

COPYRIGHT

COPYRIGHT

This User Handbook is copyright of Gas Measurement Instruments

Ltd (GMI) and the information contained within, is for use only with

SHIPSURVEYOR instruments. Reproduction, in whole or in part,

including utilisation in machines capable of reproduction or retrieval

without written permission of GMI is prohibited. Reverse engineering

is not permitted.

LIABILITY

Every care has been taken in the preparation of this document, but

GMI do not accept any responsibility for errors or omissions and their

consequences. Information in this document is subject to change

without notice. This document does not constitute a specication or

basis for a contract. Your statutory rights under law are not affected.

MODIFICATION NOTICES

GMI aim to notify customers of relevant changes in the product

operation and maintain this manual up to date. In view of the policy

of continuous product improvement there may be operational

differences between the latest product and this manual.

This Handbook is an important part of the SHIPSURVEYOR product.

Please note the following points:

• It should be kept with the instrument for the life of the product.

• Amendments should be attached.

• This Handbook should be passed on to any subsequent

owner / user of the instrument.

• Although every care is taken in the preparation of this

Handbook, it does not constitute a specification for the

instrument.

SOFTWARE

Software supplied on EPROM or similar device for use in a particular

product, may only be used in that product and may not be copied

without the written permission of GMI. Reproduction or disassembly

of such embodied programmes or algorithms is prohibited. Ownership

of such software is not transferable and GMI does not warrant that

the operation of the software will be error free or that the software

will meet the customer’s requirements.

i

Page 4

USER HANDBOOK

DISPOSAL ADVICE

When no longer in use, dispose of the instrument carefully and with

respect for the environment. GMI will dispose of the instrument

without charge if returned to the factory.

SAFETY

• The instrument must be regularly serviced and calibrated by

fully trained personnel in a safe area.

• Batteries: Alkaline or *Rechargeable batteries must be

exchanged (*and recharged) in a safe area and fitted

correctly before use.

Never use damaged batteries or expose to extreme heat.

See Chapter 5 : OPERATOR MAINTENANCE.

• Only GMI replacement parts should be used.

• If the instrument detects gas, follow your own organisation’s

procedures and operational guidelines.

• Shipsurveyor instruments are certied as

ATEX II 2 G Exd ia IIB T3 Gb (-20oC < Tamb < 50oC).

IEC Ex d ia IIB T3 (-20oC < Ta < +50oC)

• This equipment conforms to standard EN 50104.

• This equipment is also designed and manufactured to comply

with MED Directive 0038/YY (Module B&E). Further detail

of the Marine Equipment Directive, is located on the MED

declaration of conformity, supplied with the instrument.

Any right of claim relating to product liability or consequential

damage to any third party against GMI is removed if the warnings

are not observed.

WARNING: To prevent ignition of flammable or combustible

atmospheres, remove batteries before servicing.

WARNING: To prevent ignition of flammable or combustible

atmospheres, read, understand and adhere to the manufacturer’s

live maintenance procedures.

WARNING: To reduce the risk of ignition of a flammable or

explosive atmosphere, batteries must be changed only in a

location known to be non-hazardous.

ii

Page 5

COPYRIGHT

WARNING: To reduce the risk of explosion, do not mix old

batteries with used batteries or mix batteries from different

manufacturers.

WARNING: Never attempt to recharge non rechargeable cells.

CAUTION: Not for use in oxygen enriched atmospheres.

CAUTION: Replace instrument batteries only with approved

batteries, as follows:

ATEX APPROVED INSTRUMENTS:

Alkaline (LR20 ‘D’ size): Duracell Procell; Duracell

Industrial; Duracell Plus; Energizer Ultra; Energizer

Industrial.

Rechargeable (LR20 ‘D’ size): Uniross 2600mAh NiMH.

AREAS OF USE

Do not use instrument in potentially hazardous atmospheres

containing greater than 21% Oxygen. The enclosure material

is polypropylene and must not be exposed to environments

which are liable to result in mechanical or thermal degradation

or to damage caused by contact with aggressive substances.

Additional protection may be required in environments where the

instrument enclosure is liable to damage.

STORAGE, HANDLING AND TRANSIT

Rechargeable batteries contain considerable energy and care

should be taken in their handling and disposal. Batteries should be

removed if the instrument is stored for longer than 3 months. The

instrument is designed to handle harsh environments and is IP54

rated. If not subjected to misuse or malicious damage, the instrument

will provide many years of reliable service. The instrument contains

electrochemical sensors with a life of 2 years. Under conditions of

prolonged storage the sensors should be removed. The sensor

contains potentially corrosive liquid and care should be taken when

handling or disposing of the sensor, particularly when a leak is

suspected.

WARRANTY

The SHIPSURVEYOR instrument has a warranty against faulty goods

or workmanship of 2 years. Consumable and Mechanical parts are

not included in this. These are covered under GMI standard warranty

conditions. For details, please contact GMI Ltd (UK).

iii

Page 6

USER HANDBOOK

iv

Page 7

CONTENTS

COPYRIGHT ..................................................................i

LIABILITY .......................................................................i

MODIFICATION NOTICES .............................................i

SOFTWARE ...................................................................i

DISPOSAL ADVICE ...................................................... ii

SAFETY ......................................................................... ii

AREAS OF USE ........................................................... iii

STORAGE, HANDLING AND TRANSIT ....................... iii

WARRANTY ................................................................. iii

INTRODUCTION ................................................ 1-1

GENERAL INFORMATION .................................. 2-1

2.1 Instrument Models / Ranges ................................ 2-1

2.2 Details of Operating Ranges................................ 2-2

2.2.1 LEL, 0 - 100 % ............................................... 2-2

2.2.2 Volume Gas, 0 - 100 % (CGI mode only) ....... 2-3

2.2.3 Oxygen (O2), 0 - 25 % .................................... 2-3

2.2.4 Hydrogen Sulphide (H2S), 0 - 100 ppm .......... 2-4

2.2.5 Carbon Dioxide (CO2), 0 - 20 % ..................... 2-4

2.2.6 Carbon Monoxide (CO), 0 - 1000 ppm ........... 2-5

v

Page 8

USER HANDBOOK

2.3 Operating Modes ................................................. 2-6

Conned Space Monitor (CSM) Operation ............. 2-6

Combustible Gas Indicator (CGI) Operation ........... 2-6

2.4 Alarms .................................................................. 2-7

2.5 Datalogging.......................................................... 2-7

2.5.1 Location (LOC) Selector ................................. 2-8

2.6 Max / Min Values ................................................. 2-8

2.7 Construction......................................................... 2-8

2.8 Batteries............................................................... 2-8

2.9 Filters ................................................................... 2-9

2.10 Liquid Crystal Display (LCD).............................. 2-9

2.11 Before Use Checks .......................................... 2-10

OPERATION ........................................................ 3-1

3.1 Instrument Features............................................. 3-1

3.2 Operating Buttons ................................................ 3-2

3.3 Probe Handle / Quick Connect ............................ 3-3

3.4 Operating Modes - Switch ON ............................. 3-3

3.5 Language Option ................................................. 3-4

3.6 Instrument Identication ...................................... 3-5

3.7 Time / Date .......................................................... 3-6

3.8 Calibration Due Date ........................................... 3-6

3.9 Service Due Date............................................... 3-12

vi

Page 9

CONTENTS

3.10 Sensor Zeroing ................................................ 3-18

3.10.1 Instrument Will Not Zero - Zero Fault ......... 3-18

3.10.2 Instrument Will Not Zero - Gas Present ..... 3-20

3.11 Alarm Warning (CGI mode only) ...................... 3-21

3.12 Warm-up Complete .......................................... 3-22

3.13 Alarms (CSM mode only) ................................. 3-22

3.14 LEL / Vol Gas Range Selection (CGI mode only) ....

................................................................................. 3-23

3.15 Switch Pump OFF / ON (CGI mode only) ........ 3-23

3.16 Zero All Ranges (CGI mode only) .................... 3-23

3.17 Datalogging...................................................... 3-24

3.17.1 CSM Mode ................................................. 3-24

3.17.2 CGI Mode ................................................... 3-25

3.18 Max / Min Values ............................................. 3-25

3.19 Location (LOC) Selector .................................. 3-28

3.19.1 To select a location (LOC): ........................ 3-28

3.20 Acknowledge Alarms (CSM mode only)........... 3-30

3.21 Switch the instrument OFF .............................. 3-31

3.22 Button Operation Summary ............................. 3-32

ALARMS .............................................................. 4-1

4.1 Gas Alarms .......................................................... 4-1

4.1.1 FLAMMABLE (LEL) ALARMS ....................... 4-2

4.1.2 OXYGEN (O2) ALARMS ................................ 4-2

4.1.3 TOXIC ALARMS (e.g. CO) ........................... 4-3

vii

Page 10

USER HANDBOOK

4.2 Alarm Types ......................................................... 4-4

4.2.1 LATCHING / NON-LATCHING ...................... 4-4

4.2.2 MUTING / ACKNOWLEDGING ..................... 4-4

4.3 Default Alarm Settings ......................................... 4-4

4.3.1 Default Alarms Table ...................................... 4-5

4.4 Alarm Examples ................................................... 4-6

4.4.1 EXAMPLE 1 (LEL HiHi ALARM)................... 4-6

4.4.2 EXAMPLE 2 (O2 LoLo ALARM) .................... 4-7

4.4.3 EXAMPLE 3 (CO STEL ALARM) ................. 4-8

4.5 Fault Alarms ......................................................... 4-9

4.5.1 Fault Alarms - CSM Mode ............................ 4-10

4.5.2 Fault Alarms - CGI Mode ...............................4-11

4.5.3 ZERO FAULT .............................................. 4-12

4.5.4 SENSOR FAULT ......................................... 4-13

4.5.5 FLOW FAULT .............................................. 4-14

4.5.6 MEMORY FAULT (Calibration / Conguration) ...

.............................................................................. 4-15

4.5.7 MEMORY FAULT (General Instrument) ...... 4-16

4.5.8 LOW BATTERY ........................................... 4-16

4.5.9 BATTERY EXHAUSTED ............................. 4-17

OPERATOR MAINTENANCE ............................. 5-1

5.1 Batteries............................................................... 5-1

5.1.1 Replace Alkaline / Rechargeable Cells .......... 5-2

viii

Page 11

CONTENTS

5.2 Filter Replacement............................................... 5-5

5.2.1 Internal Filter .................................................. 5-5

5.2.2 Probe Handle (Accessory) - Part No. 48120 .. 5-5

CALIBRATION .................................................... 6-1

6.1 Calibration Validity ............................................... 6-2

ACCESSORIES................................................... 7-1

ADDITIONAL INFORMATION ............................ 8-1

8.1 Training ................................................................ 8-1

8.2 World Wide Web .................................................. 8-1

TYPICAL OPERATING PARAMETERS ..............A-1

Dimensions ............................................................. A-2

Weight ..................................................................... A-2

Operating Temperature ........................................... A-2

Humidity .................................................................. A-2

Construction ............................................................ A-2

Display .................................................................... A-2

Warm-Up / Stabilization Time .................................. A-2

Typical Flow Rate Information .................................A-2

Response Time (T90) ..............................................A-2

Power Source .......................................................... A-2

ix

Page 12

USER HANDBOOK

QUICK OPERATING INSTRUCTIONS ...............B-1

CHECKLIST ...............................................................B-2

SAFETY ..................................................................... B-2

AREAS OF USE ........................................................ B-3

OPERATION ..............................................................B-4

Switch ON ............................................................... B-4

Range Selection (CGI only) .................................... B-5

Switch Pump OFF / ON (CGI only) ......................... B-5

Zero All Ranges (CGI only) in Fresh Air .................. B-5

Manual Datalogging ................................................ B-5

Max / Min Values .....................................................B-5

Enter (LOC) Location List ....................................... B-6

Acknowledge Alarms (CSM only) ............................B-6

Switch OFF ............................................................. B-6

INDEX...................................................................... I

x

Page 13

1

INTRODUCTION

The GMI - SHIPSURVEYOR instrument is a single

instrument solution for all your safety monitoring and inerting

applications.

This extremely versatile instrument complies with international

marine regulations for Conned Space Monitoring, Inerting,

Pre-entry Testing, Tank Cleaning and many other marine

applications.

Fig. 1-1 Shipsurveyor Instrument

As a minimum, the instrument provides measurement of

Lower Explosive Level (LEL) and Volume ammable gas

for Shipping Industry surveying and leak detection. Other

gas ranges are available, as detailed in Chapter 2 of this

handbook.

The SHIPSURVEYOR has a variety of user congurable

options. This handbook details the default conguration,

with possible options detailed in italic text.

1-1

Page 14

USER HANDBOOK

The instrument is supplied in a sturdy carrying case that is

able to accommodate a selection of accessories.

For a comprehensive list of accessories that are supplied in

the carrying case and additional accessories available, refer

to Chapter 7 ‘ ACCESSORIES’.

The main features of the SHIPSURVEYOR are:

• A gas detection instrument that is simple to

operate with easy maintenance procedures.

• Two button operation allowing the user access to all

features.

• Two operating modes: Confined Space Monitor

(CSM) mode and Combustible Gas Indicator (CGI)

mode.

• LCD with backlighting which displays the current

gas readings together with operational and status

information.

• Clear battery life indication.

• Audible and Visual alarms enabled in CSM mode

only. Alarm levels are pre-set and an optional

periodic confidence signal is emitted. The

audible and visual condence signals will provide

assurance that the instrument is sensing for gas

without the need for the operator to constantly

view the display. The signals, which consist of

an audible ‘beep’ and a visual pulse of the LED

approximately every eight seconds, are active in

CSM mode.

• Manual and automatic datalogging is available in

CSM mode.

Manual datalogging is available in CGI mode.

1-2

Page 15

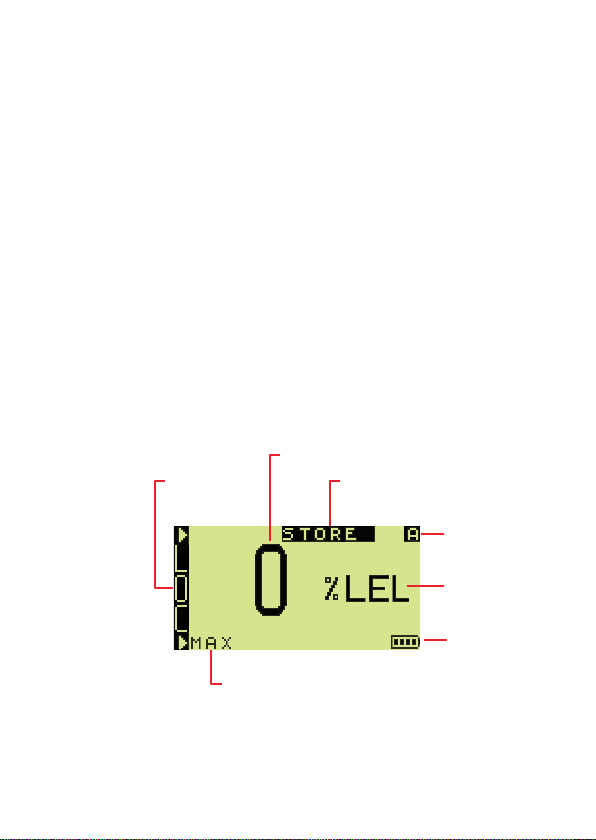

Manual

Datalogging

Live Reading

View Max Values

(or Min if option displayed)

Location

Selector

Alarms

Activated

Gas

Range

Battery

Status

INTRODUCTION

• Rugged polypropylene case, sealed to IP54 rating

and suitable for outdoor use.

• Directly interfaces with GMI Auto Calibration Unit.

During normal operation, the top and / or bottom line of the

instrument display indicates button press options.

If the option is not highlighted, a single press of the adjacent

button selects that option.

If the option is highlighted, a press and hold of the adjacent

button selects that option.

An audible ‘beep’ will be heard for a single button press,

and two ‘beeps’ will be heard for a press and hold, of either

buttons.

Fig. 1-2 illustrates a typical CSM mode LEL display for a

Shipsurveyor 1.

Note: A congurable option allows the instrument to display

this range type as LFL (Lower Flammable Limit).

Fig. 1-2 CSM Button Press Options

1-3

Page 16

USER HANDBOOK

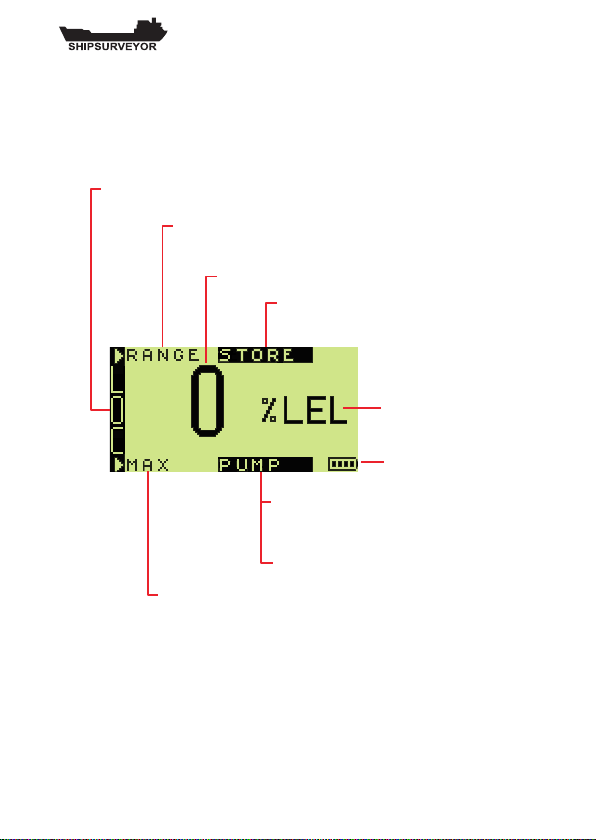

Manual

Datalogging

Toggle Pump

OFF / ON

Zero All Ranges

Live Reading

Location Selector

View Max Values

(or Min if option displayed)

Toggle Flammable Range

(LEL to VOL)

Gas

Range

or

Battery

Status

Fig. 1-3 illustrates a typical CGI mode LEL display for a

Shipsurveyor 1.

Note: A congurable option allows the instrument to display

this range type as LFL (Lower Flammable Limit).

Fig. 1-3 CGI Button Press Options

Note: Figs. 1-2 and 1-3 illustrate instrument displays

with datalogging enabled (including LOC panel

and STORE option). If instrument LOC selector is

disabled, the display does not show the LOC panel.

1-4

Page 17

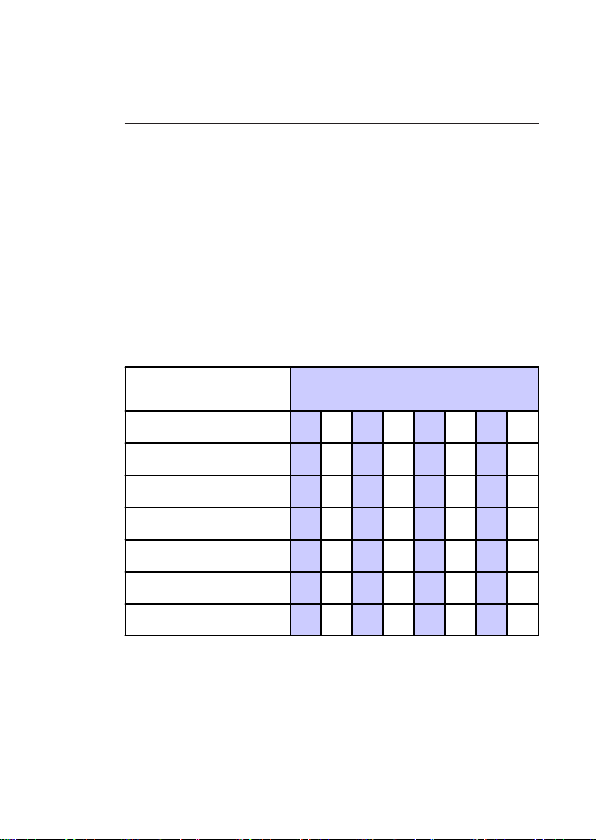

SENSORS FITTED

(* IR = infrared)

SHIPSURVEYOR MODELS

1 2 3 4 5 6 7 8

0-100% LEL (IR)

X X X X X X X

0-100% VOL GAS (IR)

X X X X X X X

0-25% Oxygen

X X X

X X X X

0-100ppm Hydrogen Sulphide

X X X

0-20% Carbon Dioxide (IR)

X X X X

0-1000ppm Carbon Monoxide

X X

2

GENERAL INFORMATION

2.1 Instrument Models / Ranges

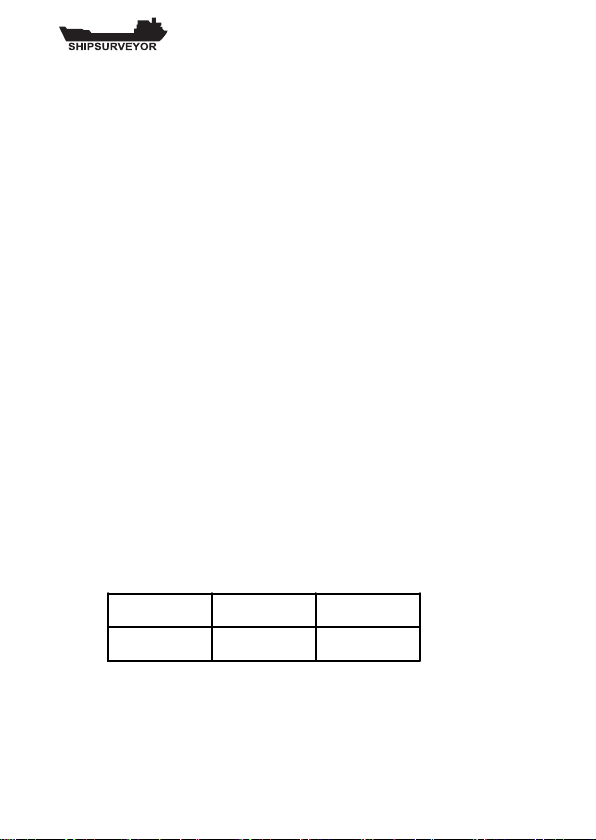

There are eight (8) models in the SHIPSURVEYOR range of

instruments. Not all detection ranges may be included in the

version of instrument selected by your company.

The table below illustrates each model and corresponding

gas sensor ranges included:

Fig. 2-1 Gas Ranges / Instrument Model

2-1

Page 18

USER HANDBOOK

2.2 Details of Operating Ranges

The basic instrument can measure 0-100% LEL and

0-100% VOL GAS.

Other models can measure the following gas types:

• Oxygen (O2)

• Hydrogen Sulphide (H2S)

• Carbon Dioxide (CO2)

• Carbon Monoxide (CO)

2.2.1 LEL, 0 - 100 %

The LEL range indicates the explosivity of the ammable

gas in the sample. This is displayed as a percentage of the

lower explosive limit (LEL) of the gas.

% LEL is displayed clearly in the LCD. From 0 - 100% LEL,

the digital display resolves to 1% LEL.

A congurable option allows the displayed LEL value to

have a resolution of 0.1% LEL from 0 - 9.9%, and 1% LEL

from 10 - 100%.

When the reading reaches 100% LEL, EEE (over-range) is

displayed. The user can, by using the top button, change

range to % Volume Gas in CGI mode only.

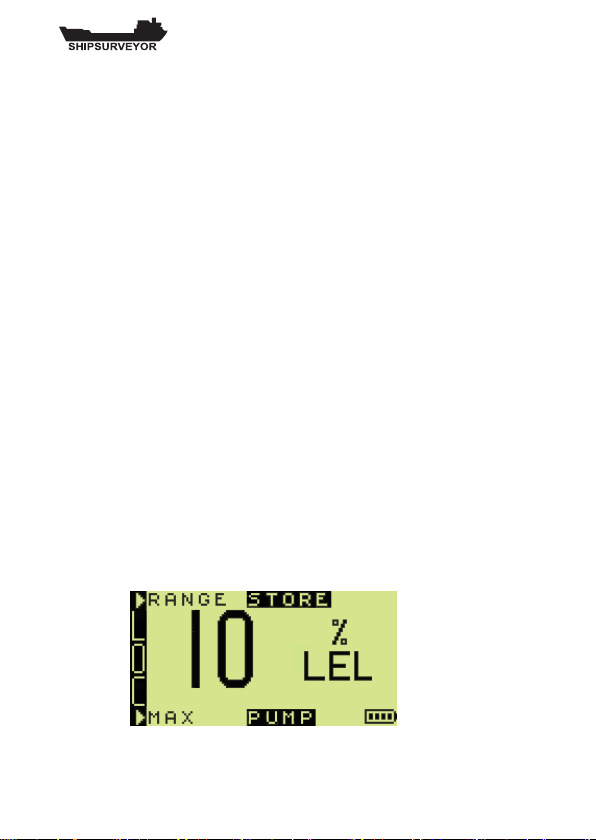

An example of a 10% LEL gas detection reading is illustrated

in Fig. 2-2 (example from Shipsurveyor 1 model).

2-2

Fig. 2-2 LEL Example (CGI mode)

Page 19

GENERAL INFORMATION

2.2.2 Volume Gas, 0 - 100 % (CGI mode only)

This range displays the total volume of a ammable gas.

% VOL is displayed clearly in the LCD. The displayed VOL

gas value has a resolution of 0.1% VOL from 0 - 9.9%, and

1% VOL from 10 - 100%.

A congurable option allows the displayed VOL gas value

to have a resolution of 1% VOL from 0 - 100%.

Fig. 2-3 illustrates a typical VOL Gas display (example from

Shipsurveyor 1 model).

Fig. 2-3 Volume Gas Example

2.2.3 Oxygen (O2), 0 - 25 %

This range displays the % of oxygen in the sample.

% O2 is clearly displayed in the LCD. The displayed oxygen

value has a resolution of 0.1% O2 from 0 - 20.9%, and 1%

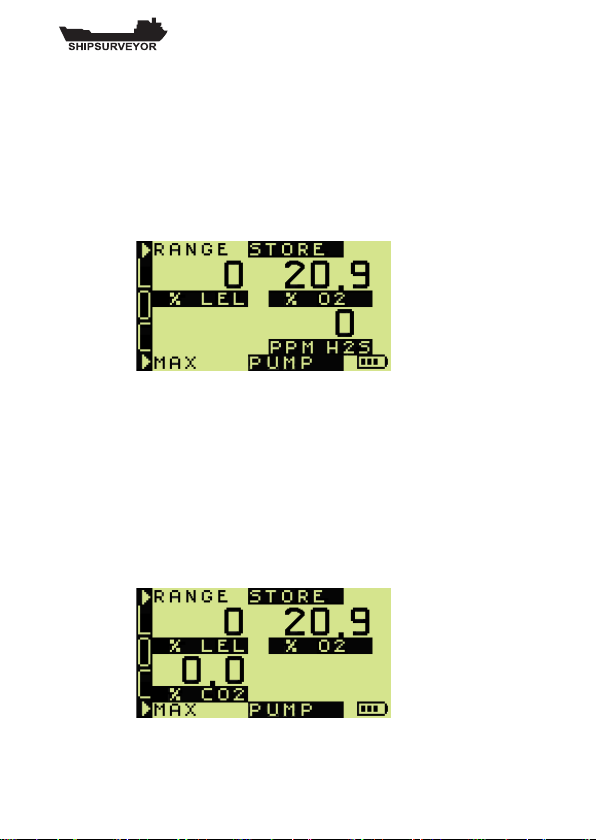

from 21 - 25%. Fig. 2-4 illustrates a typical display including

Oxygen (example from Shipsurveyor 2 model).

Fig. 2-4 Oxygen Example

2-3

Page 20

USER HANDBOOK

2.2.4 Hydrogen Sulphide (H2S), 0 - 100 ppm

This range displays the parts per million (ppm) of Hydrogen

Sulphide in the sample.

H2S is clearly displayed in the LCD. The displayed

hydrogen sulphide value has a resolution of 1 ppm.

Fig. 2-5 illustrates a typical display including Hydrogen

Sulphide (example from Shipsurveyor 3 model).

Fig. 2-5 Hydrogen Sulphide Example

2.2.5 Carbon Dioxide (CO2), 0 - 20 %

This range displays the percentage of Carbon Dioxide in

the sample.

CO2 is clearly displayed in the LCD. The displayed carbon

dioxide value has a resolution of 0.1% CO2 from 0 - 5%,

and 0.5% from 5 - 20%. Fig. 2-6 illustrates a typical display

including Carbon Dioxide (example from Shipsurveyor 4

model).

2-4

Fig. 2-6 Carbon Dioxide Example

Page 21

GENERAL INFORMATION

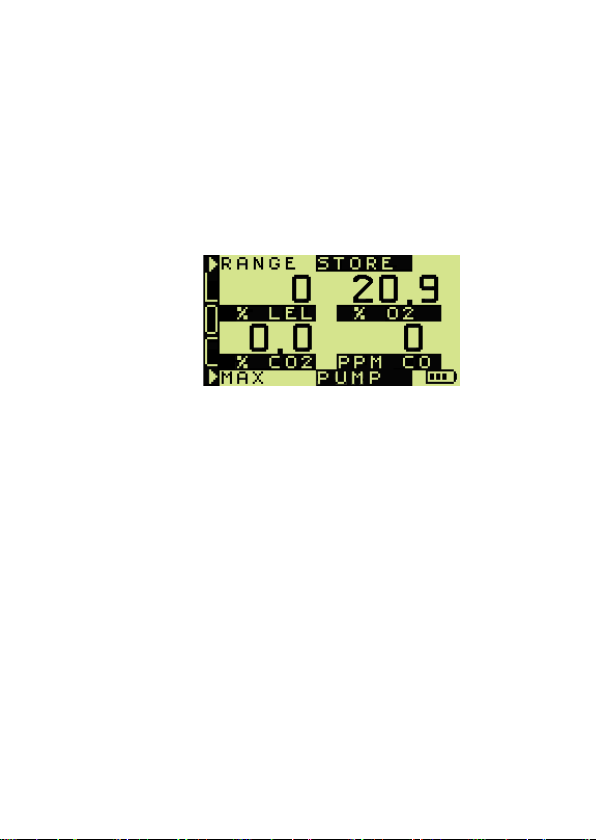

2.2.6 Carbon Monoxide (CO), 0 - 1000 ppm

This range displays the parts per million (ppm) of Carbon

Monoxide in the sample.

CO is clearly displayed in the LCD. The displayed carbon

monoxide value has a resolution of 1 ppm. Fig. 2-7 illustrates

a typical display including Carbon Monoxide (example from

Shipsurveyor 5 model).

Fig. 2-7 Carbon Monoxide Example

2-5

Page 22

USER HANDBOOK

2.3 Operating Modes

Conned Space Monitor (CSM) Operation

In this mode the instrument operates as a safety monitor

for use when entering confined spaces which may

contain hazardous gas mixtures (ammable, toxic and/or

asphyxiant). The instrument continually samples the ambient

atmosphere to which the operator is exposed and generates

alarms for low oxygen, high oxygen, high ammable gas,

high toxic gas, Short Term TWA (STEL) and Long Term

TWA (LTEL).

During normal operation in CSM mode, the instrument

emits a condence beep and illuminates a pair of red LED’s

briey every 8 seconds. This function is programmable in

the instrument setup software.

The condence signal function makes the user aware that

the instrument is sensing for gas without the need for the

operator to constantly view the display:

The condence beep and / or LED indication can be disabled.

Combustible Gas Indicator (CGI) Operation

In this mode the instrument operates as a gas indicator

drawing a sample via a probe from points where gas is

suspected to be present. Alarms are disabled in CGI mode

as the instrument is generally used for measuring gas levels

rather than monitoring for the presence of gas.

2-6

Page 23

GENERAL INFORMATION

2.4 Alarms

The SHIPSURVEYOR alarms are disabled in Combustible

Gas Indicator (CGI) mode. When operating in Conned

Space Monitor (CSM) mode, both audible and visual alarms

are active, (refer to Conned Space Monitor Operation in

Chapter 3). The audible alarm is rated at 85 dB(A). The

visual alarm consists of two (2) pairs of red LED’s ashing

alternately in the display panel.

The instrument, by default, will have alarm levels pre-set,

(refer to ‘Default Alarms’ table in Chapter 4).

It is the responsibility of the user to ensure that the alarm

levels, where set in the instrument, are appropriate for

the safe operation and legal requirements for the country

/ industry in which the unit is being used.

Latching alarms can only be cleared manually after the

detected gas level has fallen below the alarm limit.

An option allows the alarms to be non-latching. These clear

automatically when the gas levels fall below the alarm limit.

Another option allows the audible alarm to be muted.

TWA alarms, by default, are non-latching.

2.5 Datalogging

The SHIPSURVEYOR memory can store over 1000 logged

entries in date order. The memory will overwrite entries in

the event of an overow.

The instrument, by default, has automatic and manual

datalogging enabled when operating in CSM mode. Manual

datalogging allows the user to store a snapshot of the gas

readings at any time.

When the instrument is operating in CGI mode, only manual

datalogging is enabled. There is no automatic datalogging

available in this mode.

2-7

Page 24

USER HANDBOOK

Alkaline Rechargeable

Two (2) Cells

> 20 hrs > 8 hrs

2.5.1 Location (LOC) Selector

The SHIPSURVEYOR instrument features a ‘LOC’ location

selector, allowing the user to allocate datalogged readings

to a location (LOC) of a vessel. Refer to Chapter 3.18 for

more details.

2.6 Max / Min Values

The SHIPSURVEYOR instrument records the maximum /

minimum gas values for each sensor, since switch-on.

2.7 Construction

The instrument is housed in a tough, impact resistant,

moulded case made of polypropylene.

The top panel features a carbon loaded polycarbonate

LCD cover.

The battery cover is attached to the main instrument body

by means of two stainless steel hexagonal screws.

The instrument is sealed against dust and water to IP54

standard. The instrument sensors are protected from dust

and water by an integral hydrophobic lter.

2.8 Batteries

The SHIPSURVEYOR instrument can operate on either two

(2) alkaline or rechargeable cells. Typical operating times

are as follows:

Fig. 2-8 Typical Battery Operating Times

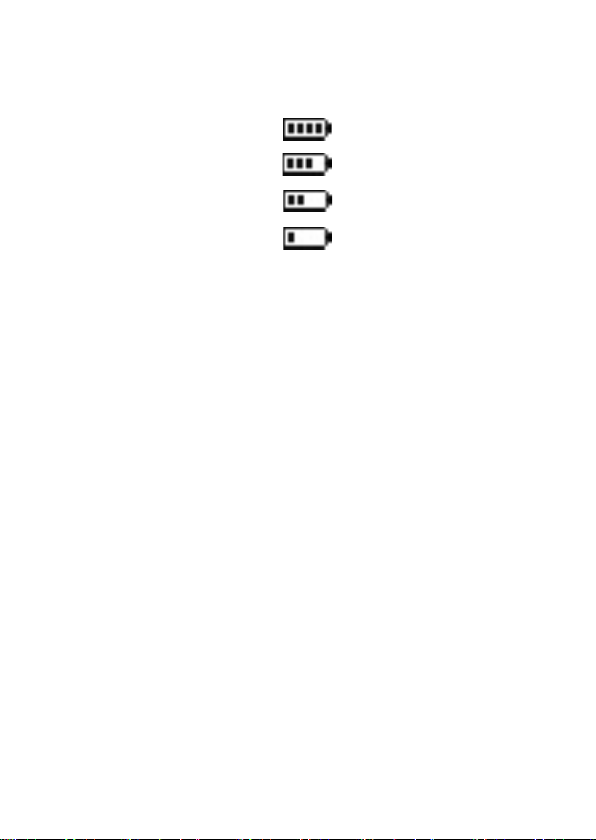

A battery symbol, as illustrated in Fig. 2-9, provides an

indication of remaining battery life. The symbol is displayed in

2-8

Page 25

GENERAL INFORMATION

100%

75%

50%

25%

the bottom RH corner of the display during normal operation.

Fig. 2-9 Remaining Battery Life

Refer to Chapters 4.5.7 and 4.5.8 for detailed battery

warnings.

To replace batteries, refer to Chapter 5, ‘OPERATOR

MAINTENANCE’.

2.9 Filters

Note: The SHIPSURVEYOR instrument has an integral

hydrophobic lter tted.

To remove / install integral hydrophobic filter, refer to

‘MAINTENANCE MANUAL’ (GMI Part No. 48166).

Where possible an external lter (accessory) should always

be used to prevent ingress of dust / water.

2.10 Liquid Crystal Display (LCD)

The dot matrix LCD (128 x 64) shows the current gas

readings in a clear, digital form. Operational and status

information is also displayed. Backlighting is controlled by an

optical sensor that illuminates automatically during warm-up,

when an alarm is active, and also in low lighting conditions.

2-9

Page 26

USER HANDBOOK

2.11 Before Use Checks

The following checks should be carried out before every

operation:

• The instrument is clean and in good condition.

• The sample line and any accessories are in

good condition and leak free. Make sure that the

instrument displays a flow fault when the

instrument inlet / sample line is blocked. If a

ow fault is not displayed, check tightness of all

ttings.

• Any accessory lters used are clean and in good

condition.

• The batteries have sufficient power left for the

intended use of the instrument.

• The instrument is still within the calibration period

and is calibrated for the gas that you are intending

to sample.

• All gas ranges are operational and zeroed

correctly.

2-10

Page 27

SHIPSURVEYOR

ALARM CONDITION (4 RED) LED's

and CONFIDENCE SIGNAL in CSM mode (outer 2 RED LED's)

POWER ON

(GREEN) LED

FAULT LED

(YELLOW)

3

OPERATION

3.1 Instrument Features

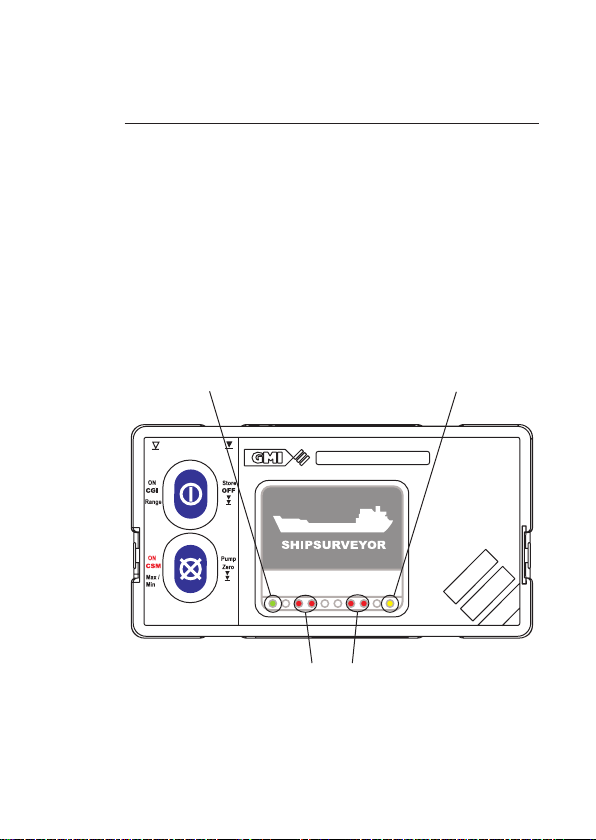

The SHIPSURVEYOR front panel features two operating

buttons, a Liquid Crystal Display (LCD) illuminated in low

lighting conditions, and a series of status LED’s as illustrated

in Fig. 3-1,

Fig. 3-1 Instrument Front Panel

3-1

Page 28

USER HANDBOOK

The POWER ON LED is green in colour and indicates that

the instrument is powered ON.

The ALARM LED’s are red in colour and, when ashing,

indicate that the instrument is in an alarm condition.

Refer to Chapter 4 ‘ALARMS’ for details.

The CONFIDENCE SIGNAL LED’s (CSM mode only) are

also red in colour and provide assurance that the instrument

is sensing for gas without the need for the operator to

constantly view the display.

The FAULT LED is yellow in colour and when illuminated,

indicates that a fault has been detected. Refer to Chapter

4.2 ‘Fault Alarms’, for details.

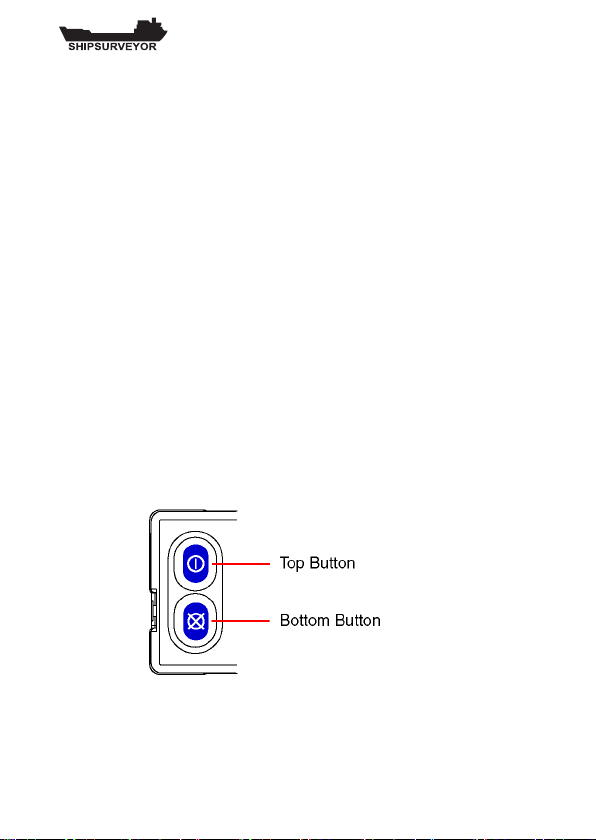

3.2 Operating Buttons

The SHIPSURVEYOR features two operating buttons, as

illustrated in Figure 3-2.

All functions are easily accessible by a single press or a

press and hold of the relevant button.

Each button press is acknowledged with a ‘beep’ sound.

Each press and hold is acknowledged by two ‘beeps’.

Fig. 3-2 Switch Panel

Refer also to paragraph 3.21 ‘Button Operation Summary’

later in this chapter.

3-2

Page 29

OPERATION

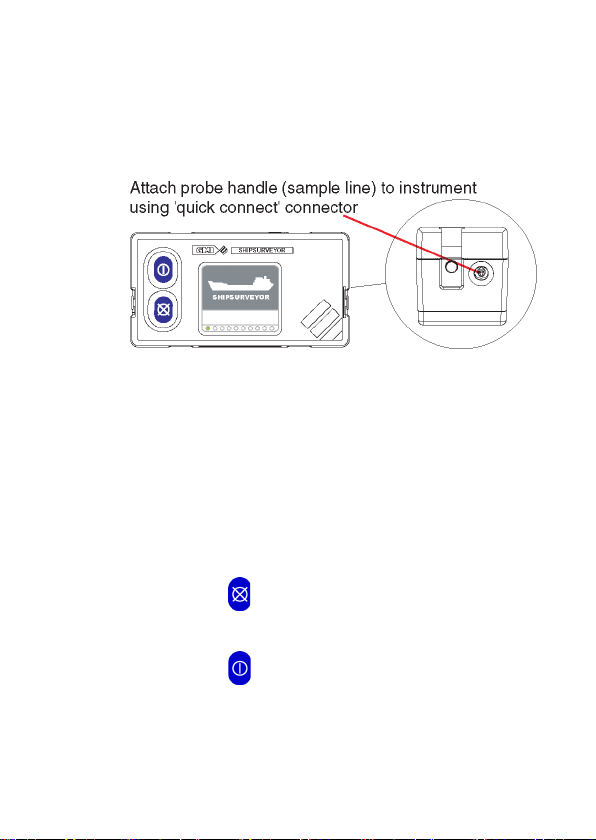

3.3 Probe Handle / Quick Connect

The SHIPSURVEYOR instrument is equipped to accept

probe types listed in Chapter 7 ‘Accessories’.

Fig. 3-3 Probe Connection

3.4 Operating Modes - Switch ON

The SHIPSURVEYOR is a dual conguration instrument.

It operates as a Conned Space Monitor (CSM) or as a

Combustible Gas Indicator (CGI) depending on the button

used to switch it on.

For Confined Space Monitor (CSM) operation, the

instrument must be switched on by pressing and holding the

Bottom Button for approximately one second in fresh air.

For Combustible Gas Indicator (CGI) operation, the

instrument must be switched on by pressing and holding

the Top Button for approximately one second in fresh air.

3-3

Page 30

USER HANDBOOK

The title screen is displayed, as illustrated in Fig. 3-4, the

pump is activated and the instrument begins its warm-up

routine that lasts approximately 60 seconds. During the

warm-up cycle, a countdown timer appears in the top right

hand corner of the display.

The display backlight illuminates and remains ON during

warm-up.

Fig. 3-4 Title Screen

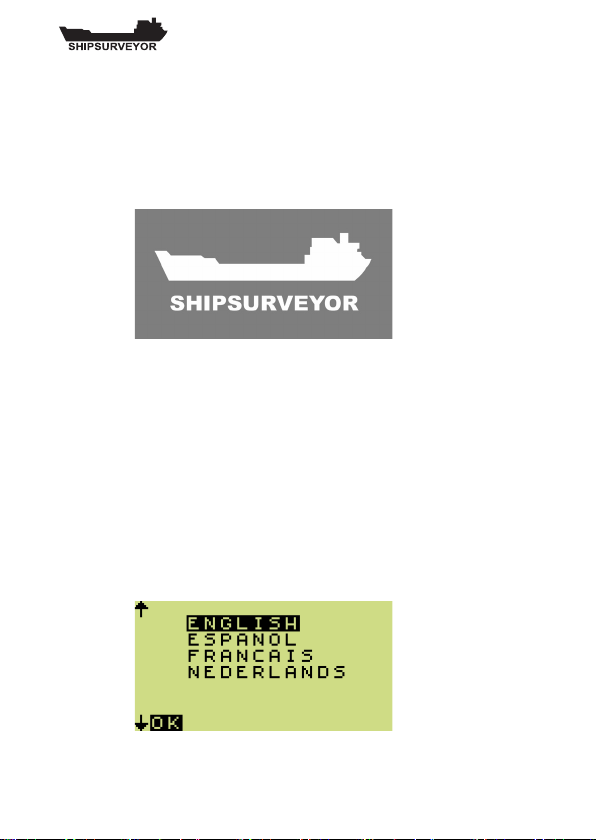

3.5 Language Option

The language setup has three congurable options:

• English (Default)

• Other (single) language

• Choice of language

During the warm-up cycle, the language screen, as illustrated

in Fig. 3-5, is only displayed if ‘choice of language’ is

congured. This allows the user to select a pre-programmed

language from the menu. The previously selected language

is highlighted in the display.

3-4

Fig. 3-5 Language Selection

Page 31

OPERATION

Note: If choice of language is not congured, the warm-

up cycle will automatically continue with the

congured language.

To select the required language option

• Single press the Top Button , or single press

Bottom Button , to highlight required language.

• Press and hold OK (the Bottom Button) to

conrm selection.

3.6 Instrument Identication

During the warm-up cycle, the instrument display identies

the model, serial number, software version, datalogging,

battery status and calibration gas information as illustrated

in Fig. 3-6:

Fig. 3-6 Instrument Identication

Note: The battery symbol is indicated during the warm up cycle, then on the bottom RH corner of the

display during normal operation.

3-5

Page 32

USER HANDBOOK

3.7 Time / Date

The current time and date is displayed during the warm-up

cycle, as illustrated in Fig. 3-7.

Fig. 3-7 Time and Date

3.8 Calibration Due Date

The CAL DUE period can be set from 1 to 400 days and is

set to 365 days by default.

The CAL DUE date is automatically reset when the

instrument is successfully calibrated.

The CAL DUE feature has ve (5) congurable options:

1. CAL DUE DATE MESSAGE IS NOT DISPLAYED

(OPTION)

2. CAL DUE DATE MESSAGE IS DISPLAYED

(OPTION)

Cal Due date message is displayed, as illustrated in

Fig. 3-8.

3-6

Page 33

OPERATION

Fig. 3-8 Calibration Due Date

If the Cal Due date has expired, i.e. overdue, the

screen illustrated in Fig. 3-9 is displayed.

Fig. 3-9 Calibration Expired

After approximately ve (5) seconds, the

instrument warm-up continues.

3. CAL DUE DATE MESSAGE IS DISPLAYED WITH

USER ACKNOWLEDGE IF EXPIRED (DEFAULT)

Cal Due date message is displayed, as illustrated

in Fig. 3-10.

3-7

Page 34

USER HANDBOOK

Fig. 3-10 Calibration Due Date

If the Cal Due date has expired, i.e. overdue, the

screen illustrated in Fig. 3-11 is displayed.

Fig. 3-11 Calibration Overdue

The user must acknowledge that Cal Due date has

expired.

To accept expiry (continue):

• Press YES (Top Button) to continue

the warm-up cycle.

To acknowledge expiry:

• Press NO (Bottom Button) to abort.

The screen, illustrated in Fig. 3-12 is

displayed.

3-8

Page 35

OPERATION

Fig. 3-12 Switch OFF

• Press and hold the Top Button to

switch the instrument OFF.

4. CAL DUE DATE MESSAGE IS DISPLAYED

- USER ACKNOWLEDGE FOR EXTENDED

PERIOD IF EXPIRED (OPTION)

Cal Due date message is displayed, as illustrated in

Fig. 3-13.

Fig. 3-13 Calibration Due Date

If the Cal Due date has expired, i.e. overdue, but

within the ‘extended period’, the screen illustrated in

Fig. 3-14 is displayed.

3-9

Page 36

USER HANDBOOK

Fig. 3-14 Calibration Overdue

The user must acknowledge that Cal Due date has

expired.

Note: The extended period can be set from 1 to 31

days.

To accept extended expiry (continue):

•

Press YES (Top Button) to continue

the warm-up cycle.

Note: When the extended period option expires, the

user will be forced to switch the instrument

OFF.

To reject the extended expiry:

• Press NO (Bottom Button) .

The screen, illustrated in Fig. 3-15, is displayed.

3-10

Fig. 3.15 Calibration Expired

Page 37

OPERATION

To proceed with the shut-down sequence:

• Press and hold the Top Button to

switch the instrument OFF.

5. CAL DUE DATE MESSAGE IS DISPLAYED USER SHUT-DOWN IF EXPIRED (OPTION)

Cal Due date message is displayed as illustrated in

Fig. 3-16.

Fig. 3-16 Calibration Due Date

If Cal Due date has expired, the screen illustrated in

Fig. 3-17 is displayed.

Fig. 3.17 Calibration Expired

To proceed with the shut-down sequence:

• Press and hold the Top Button to

switch the instrument OFF.

3-11

Page 38

USER HANDBOOK

3.9 Service Due Date

The Service due date can be set by the workshop and is set

to two (2) years by default from last service date. The date

can be set over a period of 1 to 36 months in 1 month steps.

Note : The service due date, if enabled, will only

be displayed if less than 90 days from the

current date.

The SERVICE DUE feature has ve (5) congurable options:

1. NOT USED (DEFAULT)

Service Due date message is not displayed during

warm-up (Default).

2. SERVICE DUE DATE MESSAGE IS DISPLAYED

(OPTION)

Service Due date message is displayed, as illustrated

in Fig. 3-18.

3-12

Fig. 3-18 Service Due Date

Page 39

OPERATION

If the Service Due date has expired, i.e. overdue, the

screen illustrated in Fig. 3-19 is displayed.

Fig. 3-19 Service Expired

After approximately ve (5) seconds, the

instrument warm-up continues.

3. SERVICE DUE DATE MESSAGE IS DISPLAYED USER ACKNOWLEDGE IF EXPIRED (OPTION)

Service Due date message is displayed, as

illustrated in Fig. 3-20.

Fig. 3-20 Service Due Date

If the Service Due date has expired, i.e. overdue,

the screen illustrated in Fig. 3-21 is displayed.

3-13

Page 40

USER HANDBOOK

Fig. 3-21 Service Overdue

The user must acknowledge that Service Due date

has expired.

To accept expiry (continue):

• Press YES (Top Button) to continue

the warm-up cycle.

To acknowledge expiry:

• Press NO (Bottom Button) to abort.

The screen illustrated in Fig. 3-22 is

displayed.

Fig. 3-22 Switch OFF

• Press an hold the Top Button to switch the

instrument OFF.

3-14

Page 41

OPERATION

4. SERVICE DUE DATE MESSAGE IS DISPLAYED

- USER ACKNOWLEDGE FOR EXTENDED

PERIOD IF EXPIRED (OPTION)

Service Due date message is displayed, as

illustrated in Fig. 3-23.

Fig. 3-23 Service Due Date

If the Service Due date has expired, i.e. overdue, but

within the ‘extended period’, the screen illustrated in

Fig. 3-24 is displayed.

Fig. 3-24 Service Overdue

The user must acknowledge that Service Due date

has expired.

Note: The extended period can be set from 1 to 31

days.

3-15

Page 42

USER HANDBOOK

To accept extended expiry (continue):

• Press YES (Top Button) to continue

the warm-up cycle.

Note: When the extended period option expires,

the user will be forced to switch the

instrument OFF.

To reject the extended expiry:

• Press NO (Bottom Button) .

The screen, illustrated in Fig. 3-25, is displayed.

Fig. 3.25 Service Expired

To proceed with the shut-down sequence:

• Press and hold the Top Button to

switch the instrument OFF.

3-16

Page 43

OPERATION

5. SERVICE DUE DATE MESSAGE IS DISPLAYED USER SHUT-DOWN IF EXPIRED (OPTION)

Service Due date message is displayed as illustrated

in Fig. 3-26.

Fig. 3-26 Service Due Date

If Service Due date has expired, the screen illustrated

in Fig. 3-27 is displayed.

Fig. 3.27 Calibration Expired

To proceed with the shut-down sequence:

• Press and hold the Top Button to

switch the instrument OFF.

3-17

Page 44

USER HANDBOOK

3.10 Sensor Zeroing

The nal feature in the instrument warm-up cycle is sensor

zeroing.

During this check, the screen illustrated in Fig. 3-28 is

displayed.

Fig. 3-28 Sensor Check Display

When all sensors have been correctly zeroed, the instrument

is ready for use.

3.10.1 Instrument Will Not Zero - Zero Fault

If a sensor fails to zero because of a fault, the screen

illustrated in Fig. 3-29 is displayed, providing the user with the

option to continue working and use the remaining operational

sensor(s). (Details of the failed sensor will be datalogged).

3-18

Fig. 3-29 Failed Sensor Display

Page 45

OPERATION

To accept sensor fault and continue operation:

• Press and hold YES (Top Button) to

continue using operational sensor(s).

Note: A spanner symbol ashes in the faulty range

(LEL in example), as illustrated in Fig. 3-30.

alternates with

Fig. 3-30 Faulty Range Display

To reject sensor fault and proceed with the shut-down

sequence:

• Press and hold NO (Bottom Button) to

switch the instrument OFF.

3-19

Page 46

USER HANDBOOK

3.10.2 Instrument Will Not Zero - Gas Present

If a sensor fails to zero because of gas in the atmosphere,

the gas reading ashes as illustrated in Fig. 3-31.

alternates with

Fig. 3-31 Gas Present During Warm-up

To correct this fault, switch the instrument OFF then ON

again in fresh air.

3-20

Page 47

OPERATION

3.11 Alarm Warning (CGI mode only)

When the instrument has been switched ON in CGI mode

and if congured, a ‘WARNING’ ashes in the display as

illustrated in Fig. 3-32, to alert the user that alarms are

disabled in this mode.

alternates with

Fig. 3-32 Alarm Disabled Warning

To continue operation:

• Press and hold ‘YES’ (Top Button) for one

second.

To abort instrument warm-up:

• Press and hold ‘NO’ (Bottom Button) for one

second. The instrument automatically switches OFF.

3-21

Page 48

USER HANDBOOK

3.12 Warm-up Complete

The instrument will now display the current gas readings

for the selected mode. Fig. 3-33 illustrates the display for a

Shipsurveyor 1 in CGI mode.

Fig. 3-33 LEL Display

3.13 Alarms (CSM mode only)

If alarms are enabled, an ‘A’ character is displayed in the top

RH corner of the screen as illustrated in Fig. 3-34.

Fig. 3-34 Alarm Enabled Identier

Alarm levels are set as per the configuration of the

instrument.

3-22

Page 49

OPERATION

3.14 LEL / Vol Gas Range Selection (CGI mode only)

When the warm-up cycle is complete, the instrument

automatically selects the LEL range as default.

To select Vol Gas range:

• Single press ‘RANGE’ (Top Button) .

3.15 Switch Pump OFF / ON (CGI mode only)

When the warm-up cycle is complete, the instrument pump

is automatically set to ON.

To switch the pump OFF / ON:

• Press and hold ‘PUMP’ (Bottom Button) for one

second.

3.16 Zero All Ranges (CGI mode only)

To zero all ranges, e.g. If the instrument displays a gas

reading when operating in fresh air:

To zero all ranges in fresh air:

•

Press and hold the Bottom Button for

approximately ve (5) seconds The following screen

is displayed:

Fig. 3-35 Zero All Ranges

3-23

Page 50

USER HANDBOOK

• Press and hold ‘YES’ (Bottom Button) for one

second to zero all ranges and return to live

readings.

Alternatively,

• Press and hold ‘NO’ (Top Button) for one

second to return to live readings without zeroing.

3.17 Datalogging

The SHIPSURVEYOR can store over 1000 logged entries in

date order. In addition, it can store up to 300 location entries.

Location (LOC) entries allows logged data to be associated

with particular areas of the vessel.

3.17.1 CSM Mode

The instrument, by default, has automatic and manual

datalogging enabled when operating in CSM mode.

During automatic datalogging the instrument stores the

values of all gas ranges together with the current time and

date at 60 second intervals. This interval can be set between

1 second and 10 minutes.

Manual datalogging allows the user to store a snapshot

reading at any time.

To manually store a reading:

• Press and hold ‘STORE’ (Top Button) for one

second.

3-24

Page 51

OPERATION

3.17.2 CGI Mode

When the instrument is operating in CGI mode, only manual

datalogging is available:

To manually store a reading:

• Press and hold ‘STORE’ (Top Button) for one

second.

3.18 Max / Min Values

The SHIPSURVEYOR instrument records the maximum

and minimum gas values for each sensor, since switch-on.

Note: Only the Oxygen (O2) sensor will display a minimum

value. All other sensors will indicate zero.

To view max values:

• Start from the normal operating display, illustrated in

Fig. 3.36.

Fig. 3-36 Normal Operating Display

3-25

Page 52

USER HANDBOOK

• Press ‘MAX’ (Bottom Button) to display

each recorded maximum gas reading since switchon. ‘MAX’ alternates with the range name as

illustrated in Fig. 3-37.

alternates with

Fig. 3-37 Max Displayed Values

Note: The display will automatically return to live

readings if no buttons are pressed within ten (10)

seconds. The stored values are retained in the

instrument memory unless they have been reset

by a press and hold of ‘CLEAR’ (Top Button) .

To view min values:

Note: ‘MIN’ button press option is only displayed in

instruments with an Oxygen (O2) sensor tted.

3-26

Page 53

OPERATION

• Press ‘MIN’ (Bottom Button) to display the

recorded minimum oxygen reading. ‘MIN’ alternates

with the range name as illustrated in Fig. 3-38.

alternates with

Fig. 3-38 Min Displayed Values

Note: The display will automatically return to live readings if

no buttons are pressed within ten (10) seconds. The

stored value is retained in the instrument memory

unless it has been reset by a press and hold of

‘CLEAR’ (Top Button) .

To return to live readings:

• Press and hold ‘LIVE’ (Bottom Button) for one

second to return to live readings.

3-27

Page 54

USER HANDBOOK

3.19 Location (LOC) Selector

The SHIPSURVEYOR instrument features a ‘LOC’ location

selector allowing the user to allocate datalogged readings

to a location (LOC) of a vessel.

For example, if ‘HOLD1’ is selected, all subsequent

datalogging (manual and automatic) will be referenced to

‘HOLD1’.

300 Location (LOC) names are available and can be

customised to meet individual user requirements.

Location (LOC) names can only be customised and

stored in the instrument using the Shipsurveyor Data

Downloading Software (GMI Part No. 48150).

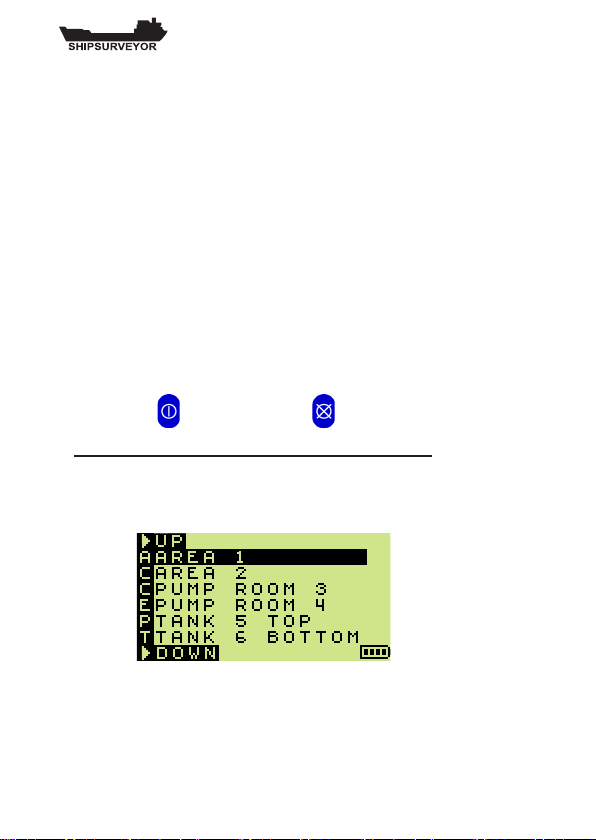

3.19.1 To select a location (LOC):

The location list can be accessed by simultaneously pressing

the Top Button and Bottom Button for two (2) seconds.

1. Location data already stored in the instrument:

If location data has previously been stored in the

instrument, it will now be displayed as illustrated in

Fig. 3-39.

3-28

Fig. 3-39 ‘LOC’ Display

Page 55

OPERATION

To select next entry in ‘LOC’ list :

• Press Bottom Button .

To quickly scroll down:

• Press and hold Bottom Button .

To select previous entry in ‘LOC’ list:

• Press Top Button .

To quickly scroll up:

• Press and hold Top Button .

If a location is highlighted and the user exits the location

(LOC) list, then that location will be associated with all

subsequent datalogging.

To exit ‘LOC’ list:

• Press and hold Top Button and Bottom Button

simultaneously for three seconds.

The instrument will return to displaying the gas

readings.

2. No Location data stored in the instrument:

If no location data has been stored in the instrument, the

display will be as illustrated in Fig. 3-40.

The instrument will still datalog, but no location data will be

associated with the stored readings.

3-29

Page 56

USER HANDBOOK

Fig. 3-40 ‘LOC’ Display

3.20 Acknowledge Alarms (CSM mode only)

The SHIPSURVEYOR default alarm function means that

instantaneous alarms will be latching and both the audible

and visual functions will operate. (Where an alarm level

is exceeded, the instrument LED’s ash and the sounder

pulses rapidly). Latching alarms must be cleared manually.

To clear a latching alarm:

• Press and hold the Bottom Button , for one

second, after the detected gas level has fallen below

the alarm limit. Refer to Chapter 4.4.1.

The option for the alarms is non-latching. These clear

automatically when the gas levels fall below the alarm limit.

The audible alarm can be muted.

To mute a non-latching alarm:

• Press and hold the Bottom Button for one

second. Refer to Chapter 4.4.3.

Note: An alarm remains muted until a new alarm

event occurs.

3-30

Page 57

OPERATION

3.21 Switch the instrument OFF

Before switching OFF from the normal operating mode, make

sure that the instrument is in fresh air in order to purge any

remaining gas from the instrument.

To initiate the shutdown sequence:

• Press and hold the Top Button .

The OFF sequence countdown begins and the user

must keep the buttons depressed for a further three

(3) seconds to switch the instrument OFF.

The countdown sequence is illustrated in Fig. 3-41.

Fig. 3-41 Countdown Sequence to OFF

Note 1: The OFF sequence can be aborted by

releasing the Top Button, providing access

to the previous operating display.

Note 2: The countdown sequence will commence at

‘9’ if an alarm is active when the shutdown

sequence is initiated.

3-31

Page 58

USER HANDBOOK

3.22 Button Operation Summary

3-32

Page 59

SHIPSURVEYOR

ALARM CONDITION (4 RED) LED's

and CONFIDENCE SIGNAL in CSM mode (outer 2 RED LED's)

POWER ON

(GREEN) LED

FAULT LED

(YELLOW)

4

ALARMS

4.1 Gas Alarms

The SHIPSURVEYOR alarms, by default, are enabled

when operating in Conned Space Monitor (CSM) mode

as indicated by an ‘A’ symbol in the top right corner of the

display. Both audible and visual alarms are active. The

audible alarm is rated up to 85 dB(A). The visual alarm

consists of two (2) pairs of red LED’s in the display panel as

illustrated in Fig. 4-1. When ashing, the red LED’s indicate

that the instrument is in alarm condition.

Fig. 4-1 Instrument Display Panel

4-1

Page 60

USER HANDBOOK

Alarm levels are set at the time of instrument manufacture.

It is important that the user ensures that the levels are in

accordance with their company’s alarm levels and with health

and safety legislation. The alarm levels are user congurable.

All gas ranges can have alarm limits that trigger the alarm if

the measured gas reading exceeds the set level. If a preset

alarm level is exceeded, the audible alarm sounds, the LED’s

ash, and the gas range name alternates with the alarm type.

Note: Alarms are disabled in Combustible Gas Indicator

(CGI) mode.

4.1.1 FLAMMABLE (LEL) ALARMS

Note: A congurable option allows the instrument to display

this range type as LFL (Lower Flammable Limit).

Two (2) instantaneous alarm levels (Hi and HiHi) are

congurable, each with different alarm indications, refer

to Fig. 4-1. Both are rising alarms, i.e. if the detected gas

concentration rises above the specic alarm level, the alarm

is triggered. All alarms are user congurable to meet the

needs of different companies.

4.1.2 OXYGEN (O2) ALARMS

Three (3) instantaneous alarm levels (HiHi, Lo and LoLo) are

congurable, each with different alarm indications, refer to

Fig. 4-1. These consist of one rising, and two falling alarms

(necessary to trigger alarms in oxygen decient scenarios).

All alarms are user congurable to meet the needs of different

companies.

4-2

Page 61

ALARMS

4.1.3 TOXIC ALARMS (e.g. CO)

Two (2) instantaneous alarm levels (Hi and HiHi) are

congurable, each with different alarm indications, refer

to Fig. 4-1. Both are rising alarms, i.e. if the detected gas

concentration rises above the specic alarm level, the alarm

is triggered. All alarms are user congurable to meet the

needs of different companies.

Additionally, two (2) Time Weighted Average (TWA) alarm

levels (STEL and LTEL) are configurable with alarm

indications, refer to Fig. 4-1.

Two (2) TWA alarms are congurable for each toxic range

within the instrument.

Note: A Time Weighted Average (TWA) value is the mean

average gas level over a specic period. The Short

Term Exposure Limit (STEL) is 15 minutes and the

Long Term Exposure Limit (LTEL) is 8 hours. The time

weighted averages are averaged over a full 24 hour

period whether the instrument is ON or OFF. Such

averaging essentially makes the instrument single

user applicable.

The option is available to restart the averaging after

each instrument switch-off, thus allowing for multiple

user application.

4-3

Page 62

USER HANDBOOK

4.2 Alarm Types

4.2.1 LATCHING / NON-LATCHING

Each alarm can be latching or non-latching.

Latching alarms can only be cleared by the user when the

gas level returns to within the alarm limits. A latching alarm

cannot be muted.

Non-latching alarms clear automatically when the gas level

returns to within the alarm limits. A non-latching alarm can

be muted.

4.2.2 MUTING / ACKNOWLEDGING

Muting of an alarm is achieved by a press and hold of the

Bottom Button. Muting means that the audible alarm is

cancelled. The audible alarm is reactivated if a new alarm

occurs.

Acknowledging is only applicable to latching alarms and

allows audible / visual alarms to be cancelled after the gas

readings have returned to safe concentrations.

4.3 Default Alarm Settings

Fig. 4-2, shows the GMI default selections. Latching or nonlatching options exist in all allowable alarms.

If an alarm is disabled (Dis), it will not function.

4-4

Page 63

4.3.1 Default Alarms Table

Alarm

Type

Level Latch D isplay Audible Vis ual

(RED LED's)

LE L Hi - Dis Hi 1 beep

per second

4 - slo w

flas hing

LEL Hi Hi 20% Y Hi Hi C ontinuo us

warble

Alternate pairs

flas hing

O

2

HiHi 23% Y Hi Hi C ontinuo us

warble

Alternate pairs

flas hing

O

2

Lo - Dis Lo 1 beep

per second

4 - slo w

flas hing

O

2

LoLo 19.5% Y LoLo C ontinuo us

warble

Alternate pairs

flas hing

H2S Hi - Dis Hi 1 beep

per second

4 - slo w

flas hing

H2S HiHi 15ppm Y HiHi Cont inuous

warble

Alternate pairs

flas hing

H2S STEL 10ppm N STEL 1 beep

per second

4 - slo w

flas hing

H2S LTEL 5ppm N LTEL 1 beep

per second

4 - slo w

flas hing

CO Hi - Dis Hi 1 beep

per second

4 - slo w

flas hing

CO Hi Hi 300ppm Y Hi Hi C ontinuo us

warble

Alternate pairs

flas hing

CO STEL 200ppm N STEL 1 beep

per second

4 - slo w

flas hing

CO LTE L 35ppm N LTEL 1 beep

per second

4 - slo w

flas hing

CO2 Hi - Dis Hi 1 beep

per second

4 - slo w

flas hing

CO2 HiHi 2.5% Y Hi Hi C ontinuo us

warble

Alternate pairs

flas hing

CO2 STEL 1.5% N STEL 1 beep

per second

4 - slo w

flas hing

CO2 LTEL 0.5% N LTE L 1 beep

per second

4 - slo w

flas hing

ALARMS

Fig. 4-2 Alarm Indication

4-5

Page 64

USER HANDBOOK

4.4 Alarm Examples

The following examples, in CSM mode, illustrate

the instrument’s display in various alarm conditions.

Examples are based on Default Alarm settings as

detailed in Fig. 4-2.

4.4.1 EXAMPLE 1 (LEL HiHi ALARM)

Fig. 4-3, illustrates a Shipsurveyor 1 instrument following a

‘HiHi’ alarm condition. The audible alarm emits a continuous

warble and the red LED’s ash in alternate pairs.

alternates with

Fig. 4-3 LEL HiHi Alarm

The alarm is latching, and therefore, can only be

acknowledged (cleared) by the user when the gas level

returns below the 20% LEL alarm limit.

4-6

Page 65

ALARMS

To clear the latching alarm:

• Press and hold ‘ACK’ (Bottom Button) for one

second.

4.4.2 EXAMPLE 2 (O2 LoLo ALARM)

This example, Fig. 4-4, illustrates a Shipsurveyor 2

instrument following a ‘LoLo’ alarm condition. The audible

alarm emits a continuous warble and the red LED’s ash in

alternate pairs.

alternates with

Fig. 4-4 O2 LoLo Alarm

The alarm is latching, and therefore, can only be cleared

by the user when the oxygen level rises above the 19.5%

O2 alarm limit.

4-7

Page 66

USER HANDBOOK

To clear the latching alarm:

• Press and hold ‘ACK’ (Bottom Button) for one

second.

4.4.3 EXAMPLE 3 (CO STEL ALARM)

This example, Fig. 4-5, illustrates a Shipsurveyor 5

instrument following an ‘STEL’ alarm condition. The audible

alarm beeps every second and all four (4) red LED’s ash

slowly.

alternates with

Fig. 4-5 CO STEL Alarm

The alarm is non-latching and therefore can be muted by the

user, and is reset automatically when the STEL level returns

below the 200ppm CO alarm limit.

4-8

Page 67

ALARMS

SHIPSURVEYOR

4 RED LED's - USED TO INDICATE FAULTS

POWER ON

(GREEN) LED

FAULT LED

(YELLOW)

To mute the non-latching alarm:

• Press and hold ‘MUTE’ (Bottom Button) for one

second.

4.5 Fault Alarms

The SHIPSURVEYOR instrument features a series of fault

alarms to alert the user that the instrument is not functioning

correctly. The audible and visual indications used are both

fault / type and mode (CSM or CGI) dependent.

Visual alarms are indicated by a series of LED’s, as illustrated

in Fig. 4-6. The power ON LED will remain illuminated during

all fault alarm indications.

Fig. 4-6 Instrument LED Panel

4-9

Page 68

USER HANDBOOK

Alarm Type

(CSM Mode)

Mute Display Audible V isual

(LED )

LOW

BATTE RY

No LO<>BAT

Co ntinuo us

To ne

Yellow &

4 Red

BATTE RY

EXHAUSTED

No BAT<>B AT

Co ntinuo us

To ne

Yellow &

4 Red

ZERO

FAULT

Ye s

Fla shi ng

Spanner

Co ntinuo us

To ne

Yellow &

4 Red

SENSOR

FAULT

No

Follo wing

Ranges Failed

Co ntinuo us

To ne

Yellow &

4 Red

FLOW

FAULT

No 'F LOW FA ULT'

Co ntinuo us

To ne

Yellow &

4 Red

IR SUPPLY

FAULT

No ' P '

Co ntinuo us

To ne

Yellow &

4 Red

COMMS.

FAULT

No ' I '

Co ntinuo us

To ne

Yellow &

4 Red

MEMORY

FAULT

No ' C '

Co ntinuo us

To ne

Yellow

4.5.1 Fault Alarms - CSM Mode

The following table, Fig. 4-7, illustrates the fault alarms in

CSM mode. Muting options exist in selected alarms.

4-10

Fig. 4-7 Fault Alarms in CSM Mode

Page 69

ALARMS

Alarm Type

(CGI Mo de)

Mute Display Audible Vis ual

(LED )

LOW

BATTE RY

No LO<>BAT No Yellow

BATTE RY

EXHAUSTED

No BAT<>B AT No Yellow

ZERO

FAULT

N/A

Fla shi ng

Spanner

No Yellow

SENSOR

FAULT

N/A

Follo wing

Ranges Failed

No Yellow

FLOW

FAULT

N/A 'F LOW FAULT' No Yellow

IR SUPPLY

FAULT

No ' P '

Co ntinuo us

To ne

Yellow &

4 Red

COMMS.

FAULT

No ' I '

Co ntinuo us

To ne

Yellow &

4 Red

MEMORY

FAULT

No ' C '

Co ntinuo us

To ne

Yellow

4.5.2 Fault Alarms - CGI Mode

The following table, Fig. 4-8, illustrates the fault alarms in

CGI mode. Muting options exist in selected alarms.

Fig. 4-8 CGI Mode Fault Alarms

4-11

Page 70

USER HANDBOOK

4.5.3 ZERO FAULT

If a zero fault occurs in CSM mode, the instrument’s audible

alarm will activate. The visual alarm (yellow and four red

LED’s) will also activate.

If a zero fault occurs in CGI mode, only the visual alarm

(yellow LED) will activate.

In both modes, a spanner symbol ashes in the display

adjacent to the corresponding gas type (H2S), as illustrated

in Shipsurveyor 3 example, Fig. 4-9.

alternates with

Fig. 4-9 Zero Fault

To correct the zero fault, switch the instrument OFF then ON

again in fresh air. If this does not correct the fault, return the

instrument for service.

4-12

Page 71

ALARMS

4.5.4 SENSOR FAULT

If a sensor fault occurs in CSM mode, the instrument’s

audible alarm will activate. The visual alarm (yellow and four

red LED’s) will also activate.

If a sensor fault occurs in CGI mode, only the visual alarm

(yellow LED) will activate.

In both modes, a warning display is followed by a display

showing a spanner symbol adjacent to the faulty range, as

illustrated in Shipsurveyor 3 example, Fig. 4-10.

Fig. 4-10 H2S Sensor Fault

The instrument should be returned for service.

4-13

Page 72

USER HANDBOOK

4.5.5 FLOW FAULT

A ow fault will occur if the ow path is restricted.

If a ow fault occurs in CSM mode, the instrument’s audible

alarm will activate. The visual alarm (yellow and four red

LED’s) will also activate.

If a ow fault occurs in CGI mode, only the visual alarm

(yellow LED) will activate and the instrument’s pump will

stop running.

In both modes, the FLOW FAULT display will alternate

between the two screens, illustrated in Fig. 4-11.

alternates with

Fig. 4-11 Flow Fault

4-14

Page 73

ALARMS

Follow the instructions as displayed, i.e.

- Check the ow path

- Remove the blockage

- Acknowledge the alarm

To acknowledge ow fault alarm:

• Press and hold ‘ACK’ (Bottom Button) for one

second.

4.5.6 MEMORY FAULT (Calibration /

Conguration)

During warm-up, if the ‘Calibration Required’ screen

is displayed as illustrated in Fig. 4-12, the instrument

has detected a calibration / conguration memory fault

and is unable to continue without re-calibration and / or

conguration set-up.

Fig. 4-12 Calibration / Conguration Memory Fault

The instrument must be returned for service.

4-15

Page 74

USER HANDBOOK

4.5.7 MEMORY FAULT (General Instrument)

At any time during operation, if a ‘C’ character is ashing

in the top RH corner of the display as illustrated in

Fig. 4-13, the instrument has detected a memory fault and

is unable to continue. The fault activates the audible alarm

and the (yellow) fault LED is illuminated.

Fig. 4-13 General Instrument Memory Fault

The instrument must be returned for service.

4.5.8 LOW BATTERY

During operation, ‘LO’ alternating with ‘BAT’ is displayed, as

illustrated in Fig. 4-14, when typically 30 minutes operating

time remains at normal temperature and depending on

battery type.

4-16

Fig. 4-14 LO-BAT

Page 75

ALARMS

In CSM mode, the instrument audible alarm will activate. The

visual alarm (yellow and four red LED’s) will also activate.

In CGI mode, only the visual alarm (yellow LED) will activate.

4.5.9 BATTERY EXHAUSTED

When ‘BAT’ ashes in the display, as shown in Fig. 4-15, the

instrument batteries are almost exhausted.

Fig. 4-15 BAT-BAT

In CSM mode, the instrument audible alarm will activate. The

visual alarm (yellow and four red LED’s) will also activate.

In CGI mode, only the visual alarm (yellow LED) will activate.

In both modes, the instrument automatically switches OFF.

The instrument batteries must be replaced.

(Refer to Chapter 5, ‘Operator Maintenance’).

4-17

Page 76

USER HANDBOOK

4-18

Page 77

5

OPERATOR MAINTENANCE

5.1 Batteries

The SHIPSURVEYOR contains two alkaline or rechargeable

batteries that provides the power required to operate the

instrument.

The alkaline batteries should be replaced, or the rechargeable

batteries recharged in the following situations:

• The‘LO-BAT’agisashinginthedisplay.

Indicates that the remaining operating time of the

instrument is low.

• The‘BAT’agisashinginthedisplay.

Indicates exhausted batteries and automatic switch-

off.

The procedure to remove / discard alkaline cells or to remove

rechargeable cells for charging is detailed in paragraph

5.1.1.Re-ttingofthecellsisalsoincludedinthisparagraph.

The rechargeable cells should be charged using a

commercialtypecharger.

5-1

Page 78

USER HANDBOOK

5.1.1 Replace Alkaline / Rechargeable Cells

WARNING 1: To prevent ignition of flammable or

combustible atmospheres, remove

batteries before servicing.

WARNING 2: To prevent ignition of flammable

or combustible atmospheres, read,

understand and adhere to the

manufacturer’s live maintenance

procedures.

WARNING 3: To reduce the risk of ignition of a

flammable or explosive atmosphere,

batteries must be changed only in a

location known to be non-hazardous

(safe area).

WARNING 4: To reduce the risk of explosion,

do not mix old batteries with new

batteries or mix batteries from different

manufacturers.

WARNING 5: Never attempt to recharge non

rechargeable cells.

5-2

Page 79

OPERATOR MAINTENANCE

The following procedure shouldonlybecarriedoutin a

safe area:

1) Using the Hex Driver, loosen the two instrument base

screwsthenremovethebatterycover.

2) Removebatterycover.

5-3

Page 80

USER HANDBOOK

3) Remove the alkaline / rechargeable batteries.

4) Charge rechargeable batteries using a commercial

type charger.Charging duration is dependent on

chargertypeandconditionofrechargeablebatteries.

5) Check battery compartmentfordamagetospring

contacts or corrosion on springs.

6) Insert new alkaline / fully charged rechargeable

batteries, observing correct polarity indicationin

batterycompartmentbase.

7) Replacebatterycoverandfastenbothbasescrews.

8) Check that the instrument switches on and works to

specication.

5-4

Page 81

5.2 Filter Replacement

HYDROPHOBIC FILTER

PROBE HANDLE ASSEMBLY

COTTON PARTICULATE FILTER

5.2.1 Internal Filter

The SHIPSURVEYORinstrumenthasanintegralhydrophobic

ltertted.Toreplacethislter,refertoMaintenanceManual

(GMIPartNo.48166).

5.2.2 Probe Handle (Accessory) - Part No. 48120

Hydrophobicandcottonparticulateltersintheprobehandle

minimise the danger of water and dust ingress.

Toreplacethelter(s),proceedasfollows:

OPERATOR MAINTENANCE

1) Unscrewtheprobehandleassembly.

2) Removethecottonparticulatelteranddiscard.

3) Removethehydrophobiclter.

4) Clean the probe handle to make sure that it is free

from dirt and water.

5) Fitanewcottonparticulatelter.

6) Fit the hydrophobic lter. The yellowlabelonthe

filter fits againsttheyellowlabelon the probe

handle.

5-5

Page 82

USER HANDBOOK

7) Reassembletheprobehandleassembly.

5-6

Page 83

6

CALIBRATION

The instrument has been calibrated for a particular ammable

gas mixture. Where any doubt exists, the instrument should

be returned to GMI or an authorised distributor for calibration.

Three methods of calibration are possible:

• Field Calibration.

• Manual or Automatic Calibration using exiCal Plus

software CD-ROM (GMI Part No. 99553). CD-ROM

includes user instructions.

• The GMI Instrument Management System (IMS)

provides all the facilities of Automatic Calibration

with the added feature of instrument database

management.

Note: The calibration systems above (hardware and

software) are manufactured by GMI. For more details

contact GMI or an authorised distributor.

6-1

Page 84

USER HANDBOOK

6.1 Calibration Validity

Calibration validity is the responsibility of the user. Under

normal operating conditions a 12 month period can be

expected. This is no guarantee however, as the precise

application of the product is unknown to GMI. Individual

codes of practice may dictate shorter periods.

Regular checking establishes a pattern of reliability and

enables the calibration check period to be modied in line

with operational experience. The higher the risk, the more

frequently calibration should be checked.

6-2

Page 85

7

ACCESSORIES

Instrument complete with (c/w) Hard Case & Accessories:

48021 Shipsurveyor 1 (LEL ; Vol Gas)

48022 Shipsurveyor 2 (LEL ; Vol Gas ; O2)

48023 Shipsurveyor 3 (LEL ; Vol Gas ; O2 ; H2S)

48024 Shipsurveyor 4 (LEL ; Vol Gas ; O2 ; CO2)

48025 Shipsurveyor 5 (LEL ; Vol Gas ; O2 ; CO2 ; CO)

48026 Shipsurveyor 6 (LEL ; Vol Gas ; O2 ; H2S ; CO)

48027 Shipsurveyor 7 (O2 ; CO2)

48028 Shipsurveyor 8 (LEL ; Vol Gas ; O2 ; H2S ; CO2)

7-1

Page 86

USER HANDBOOK

Note: All Shipsurveyor instruments are supplied in a hard

Carry Case c/w: Neck / Shoulder Harness; 4mm Hex

Driver; Probe Handle c/w 1m (39ins.) Conductive Tubing;

15cm (6ins.) Open End Probe; Box (10) Cotton Filters x 2;

User Handbook; Quick Operating Instructions; Calibration

Certicate; Conguration Report; Datalogging & exiCal Plus

(Calibration) Software & IrDA Adaptor.

Accessories available for SHIPSURVEYOR:

Part Number Description

48100 Hard Carry Case

48101 Leather Field Case

12370 Neck / Shoulder Harness

12371 Waist Harness

48120 Probe Handle c/w 1m (39in.) Conductive

Tubing

12358 Hydrophobic Filter

10077 Cotton Filters (Box of 10)

12688 Sample Line Adaptor

12712 Clear Sample Line - per metre

48102 Ball Float

48142 Sample Line Adaptor c/w Waist

Harness, Quick Connect, and

Conductive Tubing x 10m (32ft.)

48145 Sample Line Adaptor c/w Waist

Harness, Quick Connect, and

Conductive Tubing x 25m (80ft.)

48147 Sample Line Adaptor c/w Waist

Harness, Quick Connect, and

Conductive Tubing x 35m (114ft.)

13427 35cm (14in.) Open End Probe

13413 35cm (14in.) S/Steel Open End Probe

12287 50cm (20in.) S/Steel Open End Probe

7-2

Page 87

ACCESSORIES

48110 Rechargeable Option Kit

(Charger, Universal Power Supply,

2 Rechargeable Batteries)

47280 Rechargeable Batteries x 2

48150 Data Downloading Package

99553 exiCal Plus Calibration Software

CD-ROM

48151 exiCal Plus Calibration Package

48160 Shipsurveyor User Handbook

48164 Shipsurveyor Conguration &. Field

Calibration User Handbook

48166 Shipsurveyor Maintenance

Manual

Note: For other sampling probes and accessories, contact

GMI Ltd.

7-3

Page 88

USER HANDBOOK

7-4

Page 89

8

ADDITIONAL INFORMATION

8.1 Training

Training courses are available on all GMI products. Contact

GMI Marketing Department for further details:

Tel: +44 (0) 141 812 3211

Fax: +44 (0) 141 812 7820

e-mail: sales@gmiuk.com

8.2 World Wide Web

Visit GMI web site at www.gmiuk.com

8-1

Page 90

USER HANDBOOK

8-2

Page 91

A

TYPICAL OPERATING

PARAMETERS

Typical operating parameters for the SHIPSURVEYOR

instrument are as follows:

Gas Range Resolution Accuracy

Range

LEL 0 to 9.9% 0.1% *

10 to 100% 1%

VOL 0 to 9.9% 0.1%

10 to 100% 1%

O2 0 to 20.9% 0.1%

21 to 25% 1%

H2S 0 to 100ppm 1ppm

CO2 0 to 5% 0.1%

5 to 20% 0.5%

CO 0 to 1000ppm 1ppm

* Congurable option, see page 2-2.

Notes:

All the values above are at normal temperature and pressure.

Humidity is between 0% and 100% RH (non-condensing).

Pressure changes at the inlet and exhaust should be minimised as they

may cause transient changes in reading.

+

2% / + 5% of reading

+

1% / + 5% of reading

+

0.1% / + 5% of reading

+

5% of reading

+

1ppm / + 5% of reading

+

0.1% / + 5% of reading

+

5% of reading

+

5ppm / + 5% of reading

A-1

Page 92

USER HANDBOOK

Dimensions

180mm (7.1in.) x 95mm (3.7in.) x 100mm (3.9in.)

Weight

1.35kg (3.0lb.) with two alkaline batteries

Operating Temperature

-20 oC to 50 oC (-4 oF to 122 oF)

Humidity

0 – 100% RH, non-condensing.

Construction

Moulded polypropylene case protected to IP54

Display

Dot Matrix LCD (128 x 64)

Warm-Up / Stabilization Time

~ 60 seconds

Typical Flow Rate Information

Nominal pump ow rate is 0.5 to 0.7 litres per minute.

Typical ow fail rate is 0.1 to 0.2 litres per minute.

Response Time (T90)

Typical O

response time (0.0 to 18.8% O

2

) > 15 seconds.

2

Power Source

Two ‘D’ size alkaline cells typically providing in excess of 20

hours runtime at 20oC (68oF).

or

Two ‘D’ size rechargeable cells typically providing in excess

of 8 hours runtime at 20oC (68oF).

A-2

Page 93

B

QUICK OPERATING INSTRUCTIONS

The following multi-language instructions provide the user

with a quick guide to the operation of the . . .

SHIPSURVEYOR instrument.

Each language and page reference is as follows:

• English - pages B-2 to B-6

B-1

Page 94

USER HANDBOOK

CHECKLIST

1. Check the instrument has no obvious faults.

2. Read and understand handbook before use.

3. Switch ON

4. Check battery levels.

5. Check “ZERO” in fresh air.

6. Check that the sample line and any accessories are in good

condition and leak free. Make sure that the instrument displays

a ow fault when the instrument inlet / sample line is blocked.

If fault is not displayed, check tightness of all ttings.

SAFETY

• The instrument must be regularly serviced and calibrated by fully

trained personnel in a safe area.

• Batteries: Alkaline or *Rechargeable batteries must be exchanged

(*and recharged) in a safe area and tted correctly before use.

Never use damaged batteries or expose to extreme heat.

See Chapter 5: OPERATOR MAINTENANCE.

• Only GMI replacement parts should be used.