Page 1

Personal Surveyor 200

Gas Measurement Instruments Ltd

User Handbook

Page 2

Issue 8

12/10/2016

Part Number: 64171

GMI welcomes comments on all our publications. Your

comments can be of great value in helping us to improve

our customer publications. Please send any comments

that you have to customerservice@gmiuk.com

Copyright © Gas Measurement Instruments Ltd 2012

Page 3

COPYRIGHT

COPYRIGHT

This User Handbook is copyright of Gas Measurement Instruments Ltd (GMI) and

the information contained within is for use only with the GMI Personal Surveyor 200

(PS200) series instruments. Reproduction, in whole or in part, including utilisation

in machines capable of reproduction or retrieval without written permission of GMI

is prohibited. Reverse engineering is not permitted.

LIABILITY

Every care has been taken in the preparation of this Handbook, but GMI do

not accept any responsibility for errors or omissions and their consequences.

Information in this Handbook is subject to change without notice. This Handbook

does not constitute a specication or basis for a contract. Your statutory rights

under law are not affected.

MODIFICATION NOTICES

GMI aim to notify customers of relevant changes in the product operation and

maintain this Handbook up to date. In view of the policy of continuous product

improvement there may be operational differences between the latest product

and this Handbook.

This Handbook is an important part of the PS200 product.

Please note the following points:

• It should be kept with the instrument for the life of the product

• This Handbook should be passed on to any subsequent owner / user of

the instrument

• Although every care is taken in the preparation of this Handbook, it does

not constitute a specication for the instrument.

SOFTWARE

Software supplied on micro-controller or similar device for use in a particular

product, may only be used in that product and may not be copied without the written

permission of GMI. Reproduction or disassembly of such embodied programmes

or algorithms is prohibited. Ownership of such software is not transferable and

GMI does not warrant that the operation of the software will be error free or that

the software will meet the customer’s requirements.

DISPOSAL ADVICE

When no longer in use, dispose of the instrument carefully and with respect for

the environment. Refer to WEEE directive statement, such as:

In compliance with the WEEE directive, GMI will dispose of the instrument without

charge if the instrument is returned to GMI.

i

Page 4

USER HANDBOOK

SAFETY

• The instrument must be regularly serviced and calibrated by fully trained

personnel in a safe area thus user adjustment is not required.

• Replacement or charging of the equipment is only permitted in a non hazardous area.

• Only GMI replacement parts should be used.

• Instrument must be re-charged in a safe area before use. Refer to

Chapter 6 : ‘RECHARGE BATTERY’.

• If the instrument detects gas, follow your own organisation’s procedures

and operational guidelines.

• Gas can be dangerous and care should always be taken in its use.

• This equipment is designed and manufactured to protect against other

hazards as dened in ATEX Directive 94/9/EC.

Any right of claim relating to product liability or consequential damage to any third

party against GMI is removed if the above warnings are not observed.

ADDITIONAL SAFETY DETAILS - CSA ONLY

CAUTION: Before each days Usage, test on a known concentration of methane,

equivalent to 25 - 50% of full scale concentration. Accuracy must be within

0 to +20% of actual. Accuracy may be corrected by calibration. (Refer to

Chapter 7 : ‘CALIBRATION’).

ATTENTION: Avant chaque utilisation journalière, testez la réaction de l’appareil

en utilisant une concentration connue en méthane, correspondant à 25-50%

de la lecture à fond d’échelle. La précision doit se situer entre 0 et +20% de la

valeur réelle. La précision peut se corriger en étalonnant l’appareil (voir Chapitre

7 : CALIBRATION).

CAUTION: Any rapid up-scale readings followed by a declining or erratic reading

may indicate a gas concentration beyond the upper scale limit, which may be

hazardous.

ATTENTION: Toute lecture dépassant rapidement le maximum de l’échelle et

suivie par une diminution ou une lecture erronée, indique une concentration de

gaz supérieure à la valeur maximale de cette échelle. Cette lecture n’est pas

signicative.

CAUTION: Substitution of components may impair intrinsic safety.

ATTENTION: le remplacement d’un composant peut porter atteinte à la sécurité

intrinsèque du produit.

CAUTION: Do not charge in a hazardous area. Um = 6V.

ATTENTION: Ne pas charger en zone dangereuse. Um = 6V.

NOTE: CSA have only assessed the LEL combustible gas detection portion of

this instrument for performance.

ii

Page 5

COPYRIGHT

NOTE : CSA a seulement évalué la partie LIE pour la mesure des performances

en détection de gaz inammables.

NOTE: The instrument contains internal checking of sensor sensitivity, which during

calibration will prevent the sensor being calibrated if it has been contaminated

or reached its end of life. In addition to this the Instrument Management System

(IMS) can be used to track the condition of sensors from stored calibration results.

AREAS OF USE

Exposure to certain chemicals can result in a loss of sensitivity of the ammable

sensor. Where such environments are known or suspected it is recommended that

more frequent response checks are carried out. (Refer to Chapter 3: ‘MANUAL

BUMP TEST’). Chemical compounds that can cause loss of sensitivity include

Silicones, Lead, Halogens and Sulphur.

Do not use instrument in potentially hazardous atmospheres containing greater

than 21% Oxygen.

SPECIAL CONDITIONS OF USE

No precautions against electrostatic discharge are necessary for portable

equipment that has an enclosure made of plastic, metal or a combination of the

two, except where a signicant static generating mechanism has been identied.

Activities such as placing the item in a pocket or on a belt, operating a keypad

or cleaning with a damp cloth, do not present a signicant electrostatic risk.

However, where a static-generating mechanism is identied, such as repeated

brushing against clothing, then suitable precautions shall be taken, e.g. the use

of anti-static footwear.

STORAGE, HANDLING AND TRANSIT

The instrument is designed to handle harsh environments. The instrument is

sealed to IP67 and, if not subjected to misuse or malicious damage, will provide

many years of reliable service.

The instrument can contain electrochemical sensors. Under conditions of prolonged

storage these sensors should be removed. The sensor contains potentially

corrosive liquid and care should be taken when handling or disposing of the sensor,

particularly when a leak is suspected.

WARRANTY

The GMI PS200 instrument has a standard warranty of 2 years against faulty

consumable, mechanical and electronic parts, e.g. pump, sensors, lters, battery,

exi-PCB etc.

For further details, please contact GMI.

Please note however, that the warranty does not include damage caused by

misuse, e.g. mechanical impact or water ingress and provided that any service or

calibration work has been carried out by the manufacturer or authorised agent.

iii

Page 6

USER HANDBOOK

iv

Page 7

CONTENTS

COPYRIGHT i

LIABILITY i

MODIFICATION NOTICES i

SOFTWARE i

DISPOSAL ADVICE i

SAFETY ii

AREAS OF USE iii

SPECIAL CONDITIONS OF USE iii

STORAGE, HANDLING AND TRANSIT iii

WARRANTY iii

INTRODUCTION 1-1

1.1 GENERAL DESCRIPTION 1-1

1.2 FEATURES 1-4

1.3 DATA LOGGING 1-5

1.3.1 Archiving Stored Readings 1-6

1.4 FILTERS 1-6

1.5 CONSTRUCTION 1-6

1.6 IDENTIFICATION LABEL 1-6

v

Page 8

USER HANDBOOK

1.7 CERTIFICATION 1-7

1.7.1 Certication Marks 1-8

1.7.2 Performance 1-8

OPERATION 2-1

2.1 OPERATING PROCEDURE 2-1

2.2 SWITCH THE INSTRUMENT ON 2-2

2.2.1 Instrument Identication 2-3

2.2.2 Battery Status 2-3

2.2.3 User Name / Number Only (Option) 2-4

2.2.4 Date and Time 2-4

2.2.5 Bump Due Date (Option) 2-5

2.2.6 Calibration Due Date 2-6

2.2.7 Service Due Date (Option) 2-7

2.2.8 Select Calibration Gas (Option) 2-8

2.2.9 Sensor Conrmation Check 2-9

2.2.10 Memory Fault 2-11

2.2.11 Normal Operating Display 2-11

2.3 SWITCH THE DISPLAY BACKLIGHT ON / OFF 2-12

2.4 MANUAL DATALOG 2-12

2.5 VIEW MAXIMUM AND MINIMUM RECORDED

VALUES SINCE SWITCH ON 2-12

2.6 ALARMS RESET OR ACKNOWLEDGE 2-15

2.6.1 Condence Signal 2-15

2.7 REMOTE SAMPLING (with pump option) 2-16

2.7.1 Pump Operation: 2-16

vi

Page 9

CONTENTS

2.8 SELF TEST 2-17

2.9 SWITCH THE INSTRUMENT OFF 2-18

MANUAL BUMP TEST OPTIONS 3-1

3.1 BACKGROUND 3-1

3.2 MANUAL BUMP OPTIONS 3-2

3.3 INITIATING A MANUAL BUMP TEST 3-2

3.3.1 Regulator Valve Selection

(Pumped Instrument Only) 3-3

3.4 APPLYING TEST GAS 3-4

3.5 QUICK / FULL BUMP TEST 3-4

3.5.1 Quick Bump Test 3-4

3.5.2 Full Bump Test 3-4

3.6 ALARM CONFIRMATION 3-5

3.7 BUMP TEST RESULT 3-5

ALARMS 4-1

4.1 GAS ALARMS 4-1

4.1.1 Flammable LEL Alarm Limit 4-3

4.1.2 Over-Range Flammable Gas Alarm Function 4-3

4.1.3 Oxygen (O2) Alarm Limits 4-3

4.1.4 Toxic Alarm Limits 4-3

4.2 ACKNOWLEDGE GAS ALARMS 4-5

4.3 MUTE ALARMS 4-5

4.4 HIGH FLAMMABLE GAS OVER-RANGE ALARM 4-5

vii

Page 10

USER HANDBOOK

4.5 FAULT ALARMS 4-7

4.5.1 Low Battery 4-7

4.5.2 Zero Fault 4-8

4.5.3 Sensor Fault 4-9

4.5.4 Flow Fault (Pumped Instruments Only) 4-11

4.5.5 Calibration Required 4-12

4.5.6 Calibration Expired 4-13

OPERATOR MAINTENANCE 5-1

5.1 CLEANING 5-1

5.2 REPLACE INSTRUMENT FILTERS 5-1

5.2.1 Replace Sensor Hydrophobic Filter 5-2

5.2.2 Replace Sample Inlet (Dust) Filter 5-3

5.2.3 In-line Hydrophobic Filter (Accessory) 5-4

RECHARGE BATTERY 6-1

6.1 RECHARGE INSTRUMENT BATTERY 6-1

6.1.1 Recharge Instrument using the Charging /

Comms Clip 6-2

6.1.2 Recharge Instrument using the 5-way Charger

6-4

6.1.3 Recharge Instrument using the 12V / 24V

In-Vehicle Charging Adaptor 6-5

6.1.4 Recharge Instrument using the In-Vehicle

Charging Cradle 6-7

viii

Page 11

CONTENTS

CALIBRATION 7-1

7.1 GENERAL DESCRIPTION 7-1

7.2 CALIBRATION VALIDITY 7-2

ACCESSORIES 8-1

ADDITIONAL INFORMATION 9-1

9.1 TRAINING 9-1

9.2 WEBSITE 9-1

TYPICAL OPERATING PARAMETERS A-1

PHYSICAL PROPERTIES A-1

ENVIRONMENT A-1

TYPICAL FLOW RATE INFORMATION A-2

WARM-UP / STABILIZATION TIME A-2

ALARMS A-2

DISPLAY A-2

POWER SOURCE A-2

CONSTRUCTION A-2

IP RATING A-2

RESPONSE TIMES (T90) A-2

ix

Page 12

USER HANDBOOK

LEL SENSOR TYPES B-1

INDEX i

x

Page 13

1

INTRODUCTION

1.1 GENERAL DESCRIPTION

The GMI PS200 series combines quality, ruggedness and

advanced technology in a user friendly, portable gas detector.

It is compact, lightweight, water resistant, extremely robust

and is suitably certied to recognised International Standards.

The PS200 is designed for conned space monitoring, for

example, in sewers, underground piping, or within tanks and

other personal monitoring applications. With audible, visual

and vibrating alarms, it provides early warning of dangerous

gas levels.

The instrument is available as either a pumped or diffusion

model and is powered by an internal Li-ion (lithium ion)

rechargeable battery with an operating time of up to 80 hours

for non-pumped operation (20 hours for pumped operation).

Operating time is sensor dependent. Maximum recharge

time is 4 hours.

Operated via two push buttons, this instrument provides the

user with a simple to use, yet state-of-the-art, gas detector.

(Fig. 1-1).

The PS200 series features high visibility LED’s, a display that

changes colour from green to red when an alarm is present,

a sounder with a 90dB minimum output and a vibrating

alarm. Users can be condent that, should gas levels exceed

congured threshold limits or a sensor / ow / battery fault

exists, a clear and unmistakeable indication is evident.

1-1

Page 14

USER HANDBOOK

Fig. 1-1 PS200 Series Instrument

The PS200 Series has the ability to detect up to four (4) of the

following gases simultaneously:

• 0 to 100% LEL Hydrocarbons

• 0 to 25% Oxygen (O2)

• 0 to 1000ppm Carbon Monoxide (CO)

• 0 to 100ppm Hydrogen Sulphide (H2S)

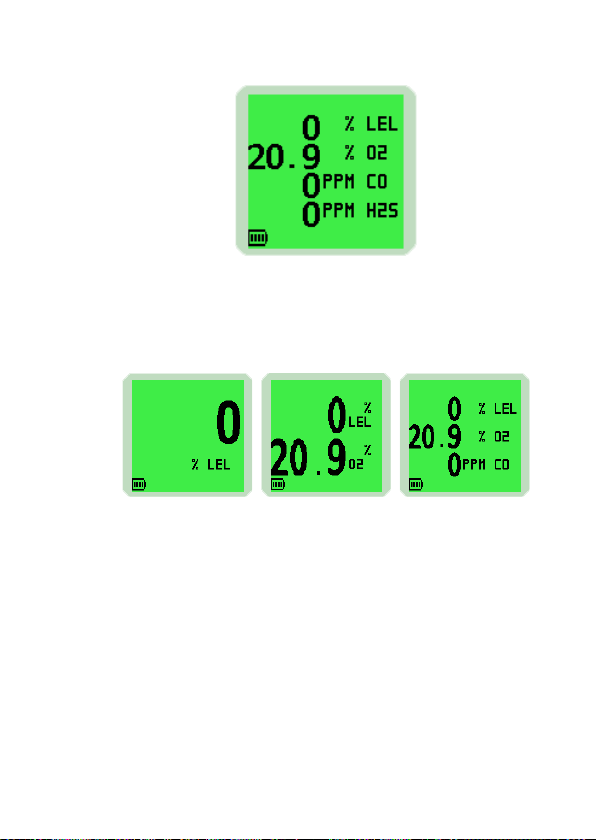

The instrument display identies the gas(es) the instrument

is monitoring. An example of a four gas instrument display is

illustrated in Fig. 1-2.

1-2

Page 15

INTRODUCTION

Fig. 1-2 Display Example (4-Gas)

Note: If congured with less sensors, the character size is

adjusted accordingly to maximise the display, as illustrated

in Fig. 1-3.

1-Gas 2-Gas 3-Gas

Fig. 1-3 Display Examples

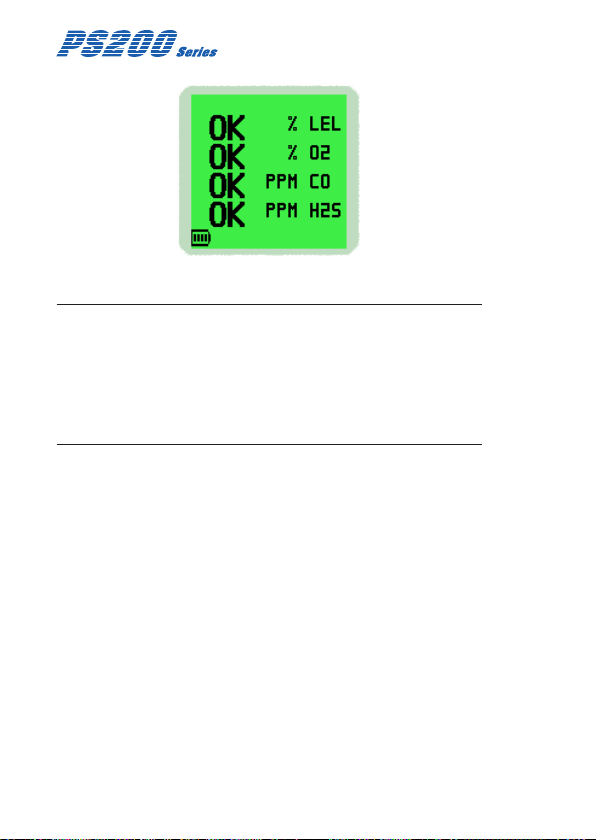

The display, illustrated in Fig’s 1-2 and 1-3, details the current

gas readings and operational / status information. Alternatively,

the instrument can be set up to display a simple ‘OK’ message,

as illustrated in Fig. 1-4.

1-3

Page 16

USER HANDBOOK

Fig. 1-4 ‘OK’ Display Example (4-Gas)

Note: This Handbook describes the operation of a standard

4-gas instrument. On other models, operation is similar to the

example shown. Operational differences are highlighted if and

where they exist. Congurable options are available that allow

the instrument to be set up to suit your particular requirements.

These options are detailed in italic text, where applicable.

1.2 FEATURES

The main features of the PS200 series instrument are:

• Compact, lightweight and extremely robust.

• Simultaneous detection and display of up to four (4)

gases.

• Simple 2 button operation.

• Clear audible, visual (hi-viz) ashing LED’s and vibrating

alarms.

• Audible and visual condence signal (fully congurable)

every 15 seconds, confirming to the user that the

instrument is correctly energised and operating normally.

1-4

Page 17

INTRODUCTION

• Alphanumeric display with screen backlighting.

Backlighting is coloured green during normal operation

and red during alarm condition.

• Internal electric pump (optional) with a nominal ow rate

of 0.5 to 0.7 litres per minute.

• Both manual and fully automatic data logging.

• Powered by an internal Li-Ion (Lithium Ion) rechargeable

battery, this will provide an operating time of up to:

14 hours (non-pumped) or 8 hours (pumped)

or

80 hours (non-pumped) or 20 hours (pumped)

When tted with the SGX VQ548MP sensor.

• Recharge time is up to 4 hours.

• Robust alligator clip to allow tting to belt, pocket, etc.

• Communications interface to allow downloading of

stored data.

• Fully certied to international standards.

• Comprehensive range of accessories available.

‘TYPICAL OPERATING PARAMETERS’ are detailed in

Appendix ‘A’ of this Handbook.

1.3 DATA LOGGING

Data logging is a standard feature of all PS200 series

instruments and allows gas measurements, event logs, bump

tests and calibration details to be automatically stored and

later downloaded to a Personal Computer (PC) via a USB

connection.

The instrument can store in excess of 24 hours of readings at

a recording interval of 1 minute, 180 On / Off event logs and

alarms, 180 bump test logs and 8 calibrations.

1-5

Page 18

USER HANDBOOK

1.3.1 Archiving Stored Readings

Stored readings can be downloaded from the PS200 series

instrument to a PC, using the standard charging / comms cable

and additional software. Contact the GMI Sales Department

for further details.

1.4 FILTERS

The instrument is protected from water and dust ingress by

hydrophobic and dust (sample inlet) lters.

These lters should be checked regularly and replaced if

necessary (refer to ‘FILTER REPLACEMENT’ section in

Chapter 5 ‘OPERATOR MAINTENANCE’).

1.5 CONSTRUCTION

The PS200 series is housed in a tough, impact resistant

moulded case. Sealed to IP67, it can withstand physical impact

testing to EN 60079 section 1-5.

1.6 IDENTIFICATION LABEL

The label on the rear of the instrument includes serial number

and relevant certication details.

1-6

Page 19

INTRODUCTION

1.7 CERTIFICATION

The PS200 series instrument is certified as follows:

Note: Check instrument labels for actual certication.

ATEX II 2G Ex ia d IIC T4 Gb (Ta = -20oC to +50oC)

IECEx Ex ia d IIC T4 Gb (Ta = -20oC to +50oC)

or

ATEX II 1G Ex ia IIC T4 Ga (Ta = -20oC to +50oC)

IECEx Ex ia IIC T4 Ga (Ta = -20oC to +50oC)

(when tted with the SGX VQ548MP sensor)

Combustible Instruments:

Class I, Div.1 Groups A, B, C and D T4

Class I, Zone 1 AEx ia d IIC T4 Gb Ex ia d IIC T4 Gb

or

Class I, Div.1 Groups C and D T4

Class I, Zone 0 AEx ia IIB T4 Ga Ex ia IIB T4 Ga

(when tted with the SGX VQ548MP sensor)

Non-combustible Instruments:

Class I, Div.1 Groups A, B, C and D T4

Class I, Zone 0 AEx ia IIC T4 Ga Ex ia IIC T4 Ga

MED (Marine Equipment Directive) - A.1 / 3.30

0038/YY (Module B&E)

0518 European Mark of Conformity

1-7

Page 20

USER HANDBOOK

OCP 0017

Segurança

ATENÇÃO: NÃO RECARREGAR

EM AREA CLASSIFICADA

DNV 16.0082 X Um=6V

14-AV4BO-0010

Ex ia d IIC T4 Gb (Ta = -20oC to +50oC)

IECEx SIR11.0019

TP TC 012/2011

TP TC 020/2011

1.7.1 Certication Marks

Refer to the following for details:

www.europe.eu.atex

www.iecex.com

1.7.2 Performance

This apparatus conforms to standard EN 50104.

Complies with:

EN 60079-29-1 (Flammable)

IEC 60079-29-1 (Flammable)

EN 50104:2010 (Oxygen)

ANSI / ISA S12.13.01 - 2000 (Combustible)

C22.2 No.152 - M1984 (Combustible)

1-8

Page 21

OPERATION

2.1 OPERATING PROCEDURE

2

CAUTION: The GMI PS200 instrument can be supplied with

Check the following before use:

• The PS200 instrument is clean and in good condition.

• The hydrophobic and inlet lters are clean and in good

• The sample line (pumped instruments) and any other

• Switch instrument ON in fresh air and check that the

• Verify there are no faults.

• Attach optional accessories, as required.

• All gas ranges are operational and the instrument is

a ammable gas sensor. This sensor is designed

for use in concentrations of gas not exceeding

the Lower Explosive Limit (LEL). Exposing the

sensor to high concentrations of ammable gas

above the LEL can cause damage to the sensor

and inhibit its proper operation. The GMI PS200

has an inbuilt safety alarm feature to prevent

this. Refer to ALARMS section of this handbook

for details.

condition.

accessories used are in good condition and leak-free.

battery is fully charged.

zeroed.

2-1

Page 22

USER HANDBOOK

• The instrument is within the calibration period you have

decided is necessary for your application.

• If oxygen sensor is tted, check oxygen readings to

ensure correct operation. The oxygen sensor responds

to the user breathing on the instrument front face (sensor

area) by displaying a decreased value, i.e. below 20.9%.

Switch the instrument OFF, in fresh air, after use.

Additional:

• Perform regular leak check on pumped instruments, by

placing thumb over sample inlet nozzle and making sure

that instrument displays ‘FLOW FAULT’.

• Perform regular bump tests using either the Auto Bump

/ Calibration Station or by performing manual bump tests.

2.2 SWITCH THE INSTRUMENT ON

Press and hold the Right Hand (RH) button for one

second to switch the instrument ON. Refer to Fig. 2-1.

The instrument begins its warm-up routine, which lasts

approximately 30 seconds. During the warm-up, a countdown

timer appears in the top (RH) corner of the display.

Note: The display backlight illuminates green and remains

ON during warm-up. When warm-up is complete, the screen

light automatically switches off.

2-2

Page 23

OPERATION

RIGHT HAND (RH)

BUTTON

Fig. 2-1 PS200 Switch ON

2.2.1 Instrument Identication

During warm-up, the instrument display identies the serial

number, software version and battery status information as

illustrated in Fig. 2-2:

Fig. 2-2 PS200 Series Identication Display

2.2.2 Battery Status

Provides the user with the battery charge level, as shown in

previous display. This will be indicated by a battery symbol

with a bar graph showing FULL, 75%, 50% and 25%, which

is shown continually during normal operation.

2-3

Page 24

USER HANDBOOK

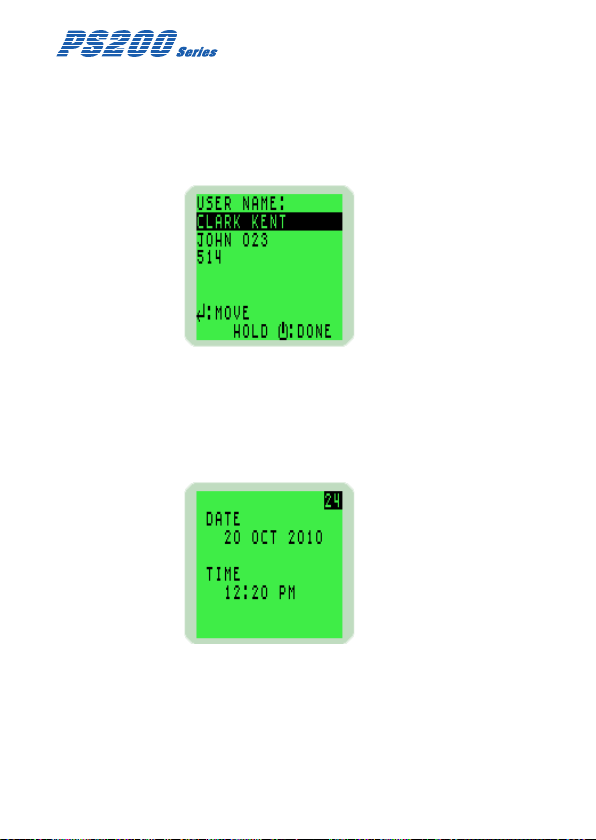

2.2.3 User Name / Number Only (Option)

This congurable option, disabled by default, allows the user

to select a name or identication code, as illustrated in Fig.

2-3. This name or code will be included with all Bump,

Calibration and Event logs.

Fig. 2-3 User Name

2.2.4 Date and Time

The date and time from the instrument’s built-in clock is

displayed on the screen during warm-up, as illustrated in

Fig. 2-4.

2-4

Fig. 2-4 Date and Time

Page 25

OPERATION

2.2.5 Bump Due Date (Option)

This congurable option is disabled by default but can be

congured to either, indicate briey that bump test is due, as

illustrated in Fig. 2-5, indicate that bump test is overdue then

pause awaiting user acceptance, as illustrated in Fig. 2-6, or

force the user to switch instrument OFF when overdue.

Fig. 2-5 Bump Due Date

Fig. 2-6 Bump Overdue

To continue instrument operation, press the Right Hand (RH)

button once to acknowledge bump test is overdue.

To abort the warm-up routine and automatically switch the

instrument OFF, press the Left Hand (LH) button once.

2-5

Page 26

USER HANDBOOK

2.2.6 Calibration Due Date

The calibration due date appears on the display, as illustrated

in Fig. 2-7.

A congurable option is available not to display this screen.

Fig. 2-7 Calibration Due Date

If the Calibration Due Date has expired, the following warning

is displayed:

Fig. 2-8 Calibration Overdue

To continue instrument operation, press the Right Hand (RH)

button once to acknowledge calibration is overdue.

To abort the warm-up routine and automatically switch the

instrument OFF, press the Left Hand (LH) button once.

2-6

Page 27

OPERATION

Alternatively, a congurable option is available to force the

user to switch the instrument OFF.

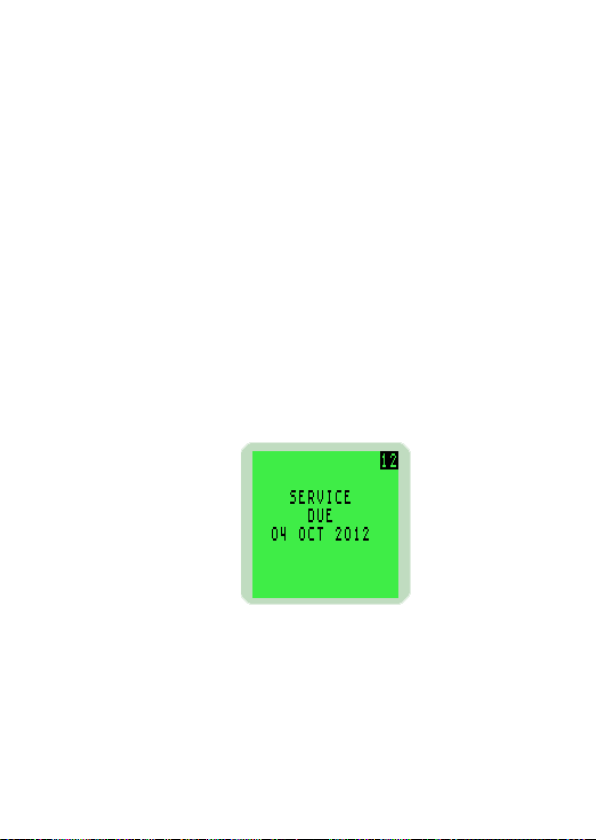

2.2.7 Service Due Date (Option)

This congurable option, disabled by default, allows the user

to select from a number of options listed, when the service

date expires on the instrument.

In all instances, if enabled, message is only displayed if within

90 days of service due date.

• To indicate the service due date briey during instrument

warm-up routine.

• To indicate that service is overdue then pause awaiting

user acceptance, or rejection, to continue.

• To force the user to switch the instrument OFF when

service is overdue.

The service due date appears on the display, as illustrated

in Fig. 2-9.

Fig. 2-9 Service Due Date

2-7

Page 28

USER HANDBOOK

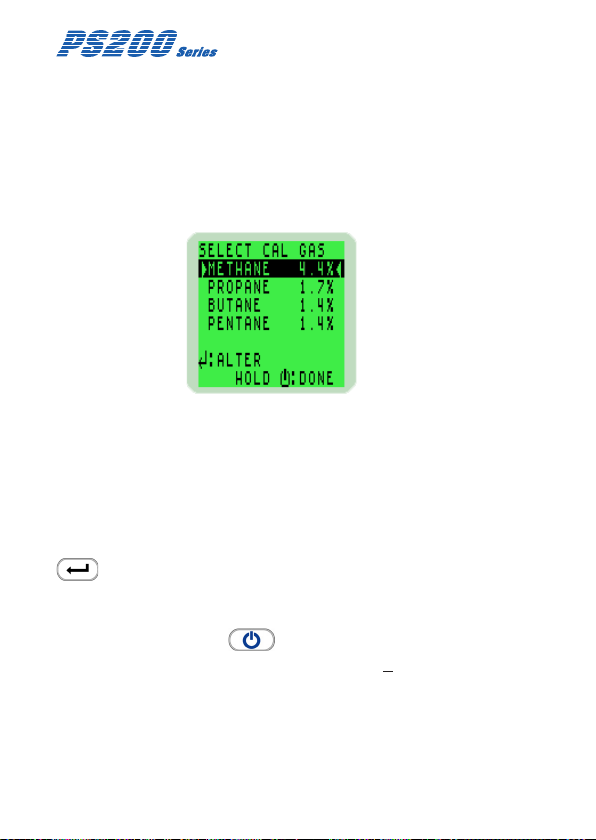

2.2.8 Select Calibration Gas (Option)

This congurable option is available to allow the user to

measure a different ammable gas from that which was

originally used to calibrate the instrument.

This action allows the instrument software to compensate and

display more accurate readings.

The default is to select calibration gas at ‘Setup’.

Fig. 2-10 Cal Gas Selection

When this option is displayed, as shown in Fig. 2-10, the gas

that was originally used to calibrate the instrument is identied

between two arrowheads.

Note: The instrument calibration certicate also identies the

original calibration gas type.

To select a different gas type, press the Left Hand (LH) button

to step through the available options from Methane,

Propane, Butane and Pentane.

When the required option is highlighted, press and hold the

Right Hand (RH) button to select.

Note: Accuracy for the re-selected gas type is + 20%.

2-8

Page 29

OPERATION

2.2.9 Sensor Conrmation Check

The symbol appears adjacent to each sensor type to

conrm that the sensor has been zeroed correctly.

Fig. 2-11 Sensor Check Displays

If a sensor fails to zero correctly, the display will be red, the

audible / visual alarms activate and a symbol is displayed

adjacent to the faulty gas type, as illustrated in Fig. 2-12:

Fig. 2-12 Failed Sensor

To acknowledge this fault, press the Right Hand (RH) button

once. This will clear the audible / visual alarm and

display a ashing spanner symbol alternating with the faulty

sensor zero reading.

2-9

Page 30

USER HANDBOOK

A faulty LEL sensor zero reading is shown in Fig. 2-13:

Fig. 2-13 Acknowledge Alarm

A congurable option is available to force the user to switch the

instrument off if a zero fault is detected, as shown in Fig. 2-14:

Fig. 2-14 Switch OFF

Note: If a sensor fault is detected during normal operation of

the instrument, the backlight illuminates red, an audible / visual

alarm is activated immediately and a spanner symbol is shown

adjacent to the faulty sensor type in the display.

2-10

Page 31

OPERATION

2.2.10 Memory Fault

During warm-up, if the ‘MEMORY FAULT’ screen is displayed,

as illustrated in Fig. 2-15, the instrument has detected a

memory fault and is unable to continue.

Fig. 2-15 Memory Fault

Please contact GMI, as the instrument must be returned for

service.

2.2.11 Normal Operating Display

When warm-up is completed successfully, the backlight

switches off and the normal operating screen is displayed,

as illustrated in Fig. 2-16. The display varies depending on

he number of sensors tted:

1-Gas 2-Gas

2-11

Page 32

USER HANDBOOK

3-Gas 4-Gas

Fig. 2-16 Normal Operating Display

2.3 SWITCH THE DISPLAY BACKLIGHT ON / OFF

The display screen backlight can be manually switched ON

when working in poor lighting conditions.

Press the Right Hand (RH) button once to switch the

screen backlight ON. It remains ON for 20 seconds and then

automatically switches OFF.

2.4 MANUAL DATALOG

A manual datalog can be stored at any time during operation

and is achieved simply via a single press of the Left Hand

(LH) button .

2.5 VIEW MAXIMUM AND MINIMUM RECORDED VALUES SINCE SWITCH ON

The instrument records the maximum and minimum gas values

for each sensor, since switch-on.

To view max / min values, proceed as follows:

1. Start from the normal operating display, as shown in Fig.

2-17. Press the Right Hand (RH) button once to

switch the instrument backlight ON.

2-12

Page 33

OPERATION

Fig. 2-17 Normal Operating Display

Press the Right Hand (RH) button again, while

the screen light is ON, to view the maximum gas values

stored in the instrument.

The example in Fig. 2-18 illustrates the maximum (MAX)

gas values stored in a 4-gas instrument.

Fig. 2-18 Maximum Gas Values

2. Press the Right Hand (RH) button again to

view the minimum gas values stored in the instrument.

Note: This screen is only displayed when an Oxygen

sensor is tted in the instrument.

2-13

Page 34

USER HANDBOOK

The example in Fig. 2-19 illustrates the minimum (MIN)

gas values stored in a 4-gas instrument.

Fig. 2-19 Minimum Gas Values

3. These readings can be reset by pressing and holding

the Right Hand (RH) button for 2 seconds when

either MAX / MIN screen is displayed.

The instrument will return to the normal operating screen.

Fig. 2-20 Normal Operation

2-14

Page 35

OPERATION

2.6 ALARMS RESET OR ACKNOWLEDGE

When the instrument detects an alarm set point has been

reached, the audible, visual and vibrating alarm will be

activated to alert the user.

The alarms are individually programmable to be either

Latching, (i.e. alarm will stay on until the user resets by a

press and hold of the Right Hand (RH) button when

the gas reading has returned within the preset alarm limits),

or Non-Latching (i.e. the audible and visual alarm will reset

automatically when the reading returns within the preset alarm

limits). Refer to Alarms Table, Chapter 4, for individual alarms.

Note: Default alarms are set in accordance with current

international standards.

The audible alarm on each pre-set alarm can be muted for a

period of 60 seconds by a press and hold of the Right Hand

(RH) button . After this period, should the gas value

remain outwith the pre-set alarm limit, the non-latching audible

alarm will become active again. If latching, the audible alarm

will become active again regardless of gas value.

2.6.1 Condence Signal

During normal operation, the instrument sounds a condence

beep and illuminates the green LED’s briey every 15 seconds.

This function makes the user aware that the instrument is

operating correctly:

Note: The condence beep and / or LED’s can be disabled.

2-15

Page 36

USER HANDBOOK

2.7 REMOTE SAMPLING (with pump option)

Remote sensing is possible with the internal electric pump

option, or by using a hand aspirator. Connect the sample

line to the sample connector at the bottom of the instrument.

On pumped models, the pump is OFF after start-up.

Warning (Hand Aspirator): The PS200 Series is designed

to be used with a built-in pump for remote sampling. A

hand aspirator can be used for indicative sampling, but it

must be noted that when using a hand aspirator, a reading

error in the region of + 20% is possible. In addition,

whereas the pump can sample quickly and accurately with

up to 30 metres of sample line, the hand aspirator must

only be used with up to 10 metres of sample line and the

sample time is extended. The sample line must be intact

and the proper ow established.

2.7.1 Pump Operation:

Press and hold the Right Hand (RH) button to start or

stop the pump.

When the pump is running, a pump symbol , illustrated in

Fig. 2.21, rotates in the display.

Note 1: It is only possible to switch the pump ON / OFF

when instrument alarms are inactive.

Note 2: Pump cannot be switched OFF if instrument is

congured with setting ‘PUMP ALWAYS ON’.

2-16

Page 37

OPERATION

Fig. 2-21 Pump Symbol Displayed

2.8 SELF TEST

The PS200 series instrument has the ability to perform a

self test. The test can be performed any time during normal

operation of the instrument.

In this mode, the instrument tests the buzzer, LED’s,

vibration function and displays both the ammable gas type

used for calibration and the current username.

To perform a self test, press and hold the Left Hand (LH)

button .

2-17

Page 38

USER HANDBOOK

2.9 SWITCH THE INSTRUMENT OFF

Press and hold both the Left Hand (LH) button and the

Right Hand (RH) button to switch the instrument OFF.

The instrument display starts a countdown from three (3) to

OFF. Both buttons must be pressed together until the display

goes blank.

Fig. 2-22 Switch OFF

While both buttons are pressed, the audible alarm sounds

every second to alert user that the instrument is switching OFF.

2-18

Page 39

3

MANUAL BUMP TEST OPTIONS

3.1 BACKGROUND

A bump test veries sensor response and alarm operation

by exposing the instrument to a known concentration of gas.

The PS200 series of instruments can be bump tested either

manually or automatically (using the Auto Bump / Calibration

Station).

This chapter describes the manual bump test options that

validate either the alarm operation (quick bump), or both alarm

operation and sensor response (full bump). By default, both

of these options are disabled.

To facilitate manual bump testing, a test kit (Part No. 64051)

is available and contains the necessary test gas, regulator

and Tygon® tubing to ensure a proper bump test is performed.

CAUTION: When performing a bump test, the

test gas concentration should be high

enough to trigger the instrument’s

alarms. Should any instrument fail a

bump test, then a full calibration must

be performed.

A Quick bump test only checks the

operation of the audible and visual

alarms and does not validate sensor

accuracy or response time.

3-1

Page 40

USER HANDBOOK

3.2 MANUAL BUMP OPTIONS

The PS200 series provides two bump test options, QUICK

and FULL.

The QUICK bump test validates that the alarm threshold has

been exceeded for each range.

The FULL bump test checks the response of all ranges against

set limits.

By default, both of these options are disabled.

3.3 INITIATING A MANUAL BUMP TEST

To initiate a manual bump test, switch the instrument ON with

a long press of the LH button.

During warm-up, the user will be prompted to conrm a bump

test is required, as indicated in Fig. 3-1. Press the RH button

to continue.

Fig. 3-1 Conrm Bump Test

When warm-up is complete, the user is prompted to apply test

gas, as shown in Fig. 3-2.

3-2

Page 41

MANUAL BUMP TEST OPTIONS

Fig. 3-2 Apply Gas Screen (4-gas model)

3.3.1 Regulator Valve Selection (Pumped Instrument Only)

Note: This option will only be displayed on a pumped PS200

instrument, which has the pump option enabled.

During warm-up, following bump test conrmation, as shown

in Fig. 3-1, the user is prompted to select if the pump is to be

used during a manual bump test, as illustrated in Fig. 3-3.

Fig. 3-3 Regulator Valve Choice

To select NO, and use a direct ow regulator valve to apply

gas, press the LH button .

To select YES, and use a demand or balanced ow regulator

valve to apply gas, press the RH button .

3-3

Page 42

USER HANDBOOK

3.4 APPLYING TEST GAS

Apply the test gas to the instrument (via the direct ow

regulator set to 0.5 l/min), as shown in Fig. 3-4.

Fig. 3-4 Bump Test Kit

Note: When using a demand or balanced ow regulator valve,

the PS200 pump will draw test gas at a ow rate ~ 0.5 l/min.

3.5 QUICK / FULL BUMP TEST

This stage of the bump test is dependent on whether QUICK

or FULL bump is congured.

3.5.1 Quick Bump Test

As the alarm threshold for each range is exceeded, the audible

/ visual / vibration alarms will activate and a symbol will

appear, otherwise a symbol will be displayed.

3.5.2 Full Bump Test

After a short period of time, the gas readings are checked

against congurable limits. The audible / visual / vibration

alarms will activate and a symbol will appear if the

readings are within these limits, otherwise a symbol will

be displayed.

3-4

Page 43

MANUAL BUMP TEST OPTIONS

3.6 ALARM CONFIRMATION

The user is then prompted to conrm if the audible and visual

alarms were activated, as shown in Fig. 3-5.

Fig. 3-5 Conrm Alarms (4-gas model)

Note: The audible, visual and vibrating alarms activate for

2 seconds only (default setting) when activated during the

bump test.

3.7 BUMP TEST RESULT

After selecting ‘YES’ the user is informed of the bump test

pass as shown in Fig. 3-6.

Fig. 3-6 Bump Test Pass

The bump test gas should now be removed.

3-5

Page 44

USER HANDBOOK

The bump test result including date and time will be

automatically datalogged.

When the gas readings fall below their alarm set-points, or after

60 seconds, the bump test is complete, and the instrument will

automatically return to normal operation.

Should any gas range fail the bump test, the alarm conrmation

display will be red and a symbol will be displayed as shown

in Fig. 3-7.

Fig. 3-7 Bump Test Fail - Alarm Conrmation

After selecting ‘YES’ or ‘NO’ the user is informed of the bump

test fail and instructed to switch the instrument off, as shown

in Fig. 3-8.

Fig. 3-8 Bump Test Fail - Switch Off PS200

If an instrument fails a bump test, then a full re-calibration is

necessary.

3-6

Page 45

ALARMS

4

CAUTION: HIGH OFF-SCALE READINGS MAY INDICATE

4.1 GAS ALARMS

Gas alarms are enabled when the instrument is switched on

and warm-up is complete.

All gas ranges have alarm limits that trigger the alarm if the

measured gas value exceeds the set level. If a preset alarm

level is exceeded, the instrument vibrates, the display backlight

illuminates red, the audible alarm sounds, the LED’s ash red

and the gas range in alarm ashes on the display.

The alarms are individually programmable to be either

‘Latching’ or ‘Non-Latching’.

A ‘Latching’ alarm will stay on until reset by the user with a

press and hold of the Right Hand (RH) button when

the gas readings are safe.

A ‘Non-Latching’ alarm will reset automatically when the gas

readings are safe.

The following table illustrates the factory default alarm

indications:

AN EXPLOSIVE CONCENTRATION.

4-1

Page 46

USER HANDBOOK

ALARM TYPE LATCHING MUTE AUDIBLE VIBRATING VISUAL

LEL (HI) Disabled Disabled Siren N / A Slow

LEL (HIHI) Ye s Disabled Siren Ye s Flashing

(HIHI) Yes Disabled Siren Ye s Flashing

O

2

(LO) Disabled Disabled Siren N / A Slow

O

2

(LOLO) Ye s Disabled Siren N / A Flashing

O

2

Toxic 1 (HI) Disabled Disabled Siren N / A Slow

Toxic 2 (HIHI) Ye s Disabled Siren Ye s Flashing

Toxic 3 (STEL) Yes Disabled Siren Yes Flashing

Toxic 4

(LTEL / TWA)

Low Battery Fault N / A N / A Regular

Zero Fault N / A N / A Regular

Sensor Fault N / A N / A Regular

Flow Fault

(Pumped Instr. Only)

Calibration Required N / A N / A Regular

Calibration Expired N / A N / A Regular

Over Range (LEL) Ye s N / A Siren Ye s Flashing

Yes Disabled Siren Ye s Flashing

Beep

Beep

Beep

N / A N / A Regular

Beep

Beep

Beep

(RED LED)

Flashing

Flashing

Flashing

N / A Slow

N / A Slow

N / A Slow

N / A Flashing

N / A Slow

N / A Slow

Flashing

Flashing

Flashing

Flashing

Flashing

N/A = Not Applicable

PS200 Series (Default) Alarm Indications

4-2

Page 47

ALARMS

4.1.1 Flammable LEL Alarm Limit

Two alarm levels, ‘HI’ and ‘HIHI’, are available, each with

different pitch and tone. All alarms are user congurable to

meet the specic needs of different companies.

4.1.2 Over-Range Flammable Gas Alarm Function

The ammable sensor is designed for use in the LEL range

only. Exposure to high concentrations of ammable gas,

such as lighter fuel, can damage the ammable sensor. If the

ammable gas readings exceed 100% LEL, a safety alarm

will be activated. The instrument should then be switched OFF

and returned to fresh air.

4.1.3 Oxygen (O2) Alarm Limits

Three alarm levels, ‘HIHI’, ‘LO’ and ‘LOLO’ are available, each

with different pitch and tone. All alarms are user congurable

to meet the specic needs of the end user.

4.1.4 Toxic Alarm Limits

When operating normally, the instrument calculates the Short

Term Exposure Limit (STEL) and Long Term Exposure Limit

(LTEL), known as Time Weighted Average (TWA) readings, for

each toxic gas range alarm. TWA alarms are programmable

for each toxic range tted to the instrument. Additionally, two

alarm levels ‘HI’ and ‘HIHI’ are available.

Note: A Time Weighted Average (TWA) value is the mean

average gas level over a specic period. The STEL is 15

minutes and the LTEL is 8 hours. Typically, TWA alarms make

the instrument single user applicable. An option is available

to restart the averaging after each instrument switch-off, thus

allowing for multiple user application.

4-3

Page 48

USER HANDBOOK

Note: The toxic gas alarm levels – instantaneous, STEL

and LTEL are set at the time of instrument manufacture.

It is important that the user ensures that the levels are in

accordance with their company’s alarm levels and with health

and safety legislation. The alarm levels may be changed, if

required, via the instrument set up menu.

In the following examples, Fig. 4-1 illustrates a 4-gas

instrument signalling a ‘LOLO’ Oxygen alarm and Fig. 4.2

shows a 4-gas instrument signalling a ‘HIHI’ LEL alarm. If more

than one gas alarm level is exceeded, the gas value will ash

for each gas type in alarm.

Fig. 4-1 ‘LOLO’ Alarm

4-4

Fig. 4-2 ‘HIHI’ Alarm

Page 49

ALARMS

4.2 ACKNOWLEDGE GAS ALARMS

Once in a safe area, or the gas reading has returned within the

preset limits, press and hold the Right Hand (RH) button

to mute the alarm sounder and extinguish the gas LED’s.

4.3 MUTE ALARMS

If congured, a muted alarm will be silenced for 60 seconds.

Mute ‘disabled’ cannot silence the alarm until gas falls below

the alarm level.

If alarm conguration allows muting of audible alarm, the

following applies:

Non-latching: Once alarm has been muted, the audible

alarm is cancelled for a period of 60 seconds, and if gas

concentration during that time falls below alarm set point, the

visual alarm clears automatically.

Latching: If audible alarm has been muted and if gas

concentration during that time falls below alarm set point,

visual alarm requires to be acknowledged to clear.

4.4 HIGH FLAMMABLE GAS OVER-RANGE ALARM

Caution: Exposing the LEL sensor to concentrations of

ammable gas above 100% LEL can damage

the sensor.

In order to protect the user from danger in the event of the

ammable gas (LEL) sensor being over exposed to a high

concentration of ammable gas, the instrument has an over-

range alarm.

4-5

Page 50

USER HANDBOOK

If the LEL sensor is exposed to a gas reading above 100%

LEL, the instrument vibrates, the displayed value changes

to 4 rising arrows, the backlight illuminates red, the tone of

the audible alarm changes, and the visual alarm LED’s ash

quickly. The ashing message ‘DANGER OVER RANGE’ is

displayed, as shown in Fig 4-3:

Fig. 4-3 Over Range Alarm

Switch OFF by a press and hold of both buttons together.

A timer, counting down from 10 seconds to zero, is displayed

together with the message ‘GET OUT’ alternating with ‘HIGH

GAS’, as shown in Fig. 4-4:

. . . alternating until zero is reached

Fig. 4-4 ‘Get Out’ / ‘High Gas’ Timer

The instrument must be returned to a gas free area or sample

clean air. The instrument must now be switched OFF.

4-6

Page 51

ALARMS

Note: To avoid accidental switch-off in this dangerous state,

the off cycle is increased to 10 seconds.

4.5 FAULT ALARMS

Refer to Alarms Table, in paragraph 4.1 of this handbook, to

identify the audible / visual indication for any of the following

faults.

4.5.1 Low Battery

The ‘LOW BATTERY’ warning ashes when approximately

30 minutes operating time remains.

The display will be red, the audible alarm sounds once every

two seconds and the red LED’s ash.

Fig. 4-5 Low Battery Warning

The instrument battery must be re-charged.

Note: Gas alarms continue to operate after the ‘LOW

BATTERY’ warning appears.

4-7

Page 52

USER HANDBOOK

The ‘BAT FAULT’ warning ashes when approximately

3 minutes operating time remains, as illustrated in Fig. 4-6.

The display will be red, the audible alarm sounds continuously

and the red LED’s remain on. After 3 minutes, the instrument

automatically switches off.

Fig. 4-6 Exhausted Battery Warning

4.5.2 Zero Fault

A “ZERO FAULT” warning and a ashing spanner symbol

appears after warm-up if the instrument is switched on in the

presence of gas or the instrument has been unable to zero

all sensors correctly.

The screen backlighting illuminates red, the audible alarm

sounds once every 2 seconds and the red LED’s ash.

It is strongly recommended the instrument is returned

to a gas free area. Switch the instrument OFF and then

switch ON again in fresh air. If the fault persists, return the

instrument to a GMI approved Service / Repair facility.

The instrument can however still be used to detect and alarm

on the other sensor(s) tted. Press the Right Hand (RH)

button , as per the screen prompt, to continue.

4-8

Page 53

ALARMS

The faulty sensor will cause the instrument to display a

ashing spanner symbol to warn the user that this sensor is

not working correctly, as shown in Fig. 4-7:

Fig. 4-7 Zero Fault

4.5.3 Sensor Fault

Note: The PS200 instrument features continual toxic sensor

integrity detection. This may generate a sensor fault

indicated by a red illuminated backlight, audible

beeping and ashing red LED’s. Unlike zero fault,

it would only occur immediately after switch-on and

occasionally during operation. If this fault occurs, allow

instrument to run in fresh air for up to 20 minutes. If

fault does not clear, return instrument to an approved

Service / Repair facility.

There are three types of sensor fault as illustrated in the

following displays:

1. If a “SENSOR FAULT” warning and a spanner symbol

appears adjacent to a gas type, as illustrated in Fig. 4-8,

then the sensor requires replacement or an electrical

fault exists. Return instrument to an approved service

/ Repair facility.

4-9

Page 54

USER HANDBOOK

Fig. 4-8 Sensor Fault

2. If a “ZERO FAULT” warning and a ashing spanner

symbol appear, alternating with a zero LEL reading as

illustrated in Fig. 4-9, apply test gas for two minutes to

allow the display to return to zero then switch instrument

OFF and ON again. If fault remains, return instrument to

a GMI approved Service / Repair facility.

Fig. 4-9 Check Fault

3. If a “ZERO FAULT” warning and a ashing spanner symbol

appear, alternating with an LEL gas value as shown in

Fig. 4-10, leave instrument on for 30 to 60 minutes then

switch instrument OFF and ON again. If fault remains,

return instrument to a GMI approved Service / Repair

facility.

4-10

Page 55

ALARMS

Fig. 4-10 Check Fault

4.5.4 Flow Fault (Pumped Instruments Only)

If a ow fail or sample fault exists, a ‘FLOW FAULT’ warning

is displayed, as illustrated in Fig. 4-11. The display will be red

and both the audible alarm and red LED’s will be activated.

Check sample line, lter or probe for blockage, if applicable.

Clear the blockage then restart the pump by a press and hold

of the Right Hand (RH) button .

Fig. 4-11 Flow Fault

4-11

Page 56

USER HANDBOOK

4.5.5 Calibration Required

If the instrument requires calibration then during warm-up,

a ‘CALIBRATION OVERDUE’ warning is displayed. The

instrument will operate using its previous calibration settings,

however, as the sensors response may have diminished, the

instrument should be recalibrated and tested.

Fig. 4-12 Calibration Overdue

Press the Right Hand (RH) button once to acknowledge

that calibration due date is overdue, cancel the audible / visual

alarm, and continue to the next display. A ‘CAL EXPIRED’

warning, red backlighting and red LED’s will ash every 30

seconds.

Press the Left Hand (LH) button once to abort the

warm-up routine and automatically switch OFF the instrument.

4-12

Page 57

ALARMS

Alternatively, during warm-up, a configurable option is

available to force the user to switch OFF the instrument.

The following ‘CALIBRATION REQUIRED’ warning is

displayed and the instrument is unable to continue without

recalibration.

Fig. 4-13 Calibration Required

4.5.6 Calibration Expired

During normal operation of the instrument where the

calibration date has expired, a ‘CAL EXPIRED’ warning will

ash in the display every 30 seconds.

Fig. 4-14 Calibration Expired

4-13

Page 58

USER HANDBOOK

4-14

Page 59

5

OPERATOR MAINTENANCE

5.1 CLEANING

CAUTION: Do not use polishes containing silicon or

solvent to clean the instrument as these may damage

the ammable gas sensor (if tted). Do not use abrasive

materials or strong volatile chemical solutions as these

could damage the impact resistant casing.

The outer, impact resistant, casing of the PS200 Series

instrument may be cleaned using a non-abrasive moist cloth.

Rub the cloth over the outer casing to remove any dirt and

grime.

In extreme cases, a mild soap solution may be used with a

non-abrasive cloth to remove any stubborn marks.

5.2 REPLACE INSTRUMENT FILTERS

The instrument has 2 lters protecting the instrument from

contamination. A hydrophobic lter is located behind the

lter cover on the front face of the instrument. The sample

inlet (dust) lter is located in the sample inlet connector at

the bottom of the instrument. The lters should be inspected

periodically for contamination or damage.

To inspect / replace the lters, proceed as follows:

5-1

Page 60

USER HANDBOOK

LOCATING PEGS (2)

LOCATING SLOTS (2)

CAPTIVE SCREW LOCATING LUGS

HYDROPHOBIC

FILTER

(Part No. 64254)

FILTER COVER

ASSEMBLY

(Part No. 64240)

5.2.1 Replace Sensor Hydrophobic Filter

1. Using a No.1 Pozidrive® screwdriver, unscrew the captive

screw and remove the lter cover by sliding it away from

the display screen to disengage the locating lugs from

the corresponding slots in the lter recess.

2. Carefully lift then remove the hydrophobic lter from the

Fig. 5-1 Replace Sensor Filter

instrument lter recess.

Note the locating pegs in the instrument lter recess and

mating pin-holes in the hydrophobic lter. Ensure correct

orientation of lter during assembly.

5-2

Page 61

OPERATOR MAINTENANCE

SAMPLE

INLET FILTER

(Part No. 64084)

INLET NOZZLE ASSEMBLY

QUICK CONNECT

POZI PAN SCREW (2)

3. Fit a new Hydrophobic Filter (Part No. 64254).

4. Carefully place the hydrophobic lter in position over the

instrument sensors, locating lter pin holes over locating

pegs in instrument lter recess.

5. Place the lter cover over the lter recess then carefully

slide it towards the display screen until the lugs are

located in the mating slots in the instrument lter recess.

Press the cover down on to the lter then, using a No.1

Pozidrive® screwdriver, tighten the captive screw until

secure.

Note: Care must be taken not to overtighten the cover screw.

5.2.2 Replace Sample Inlet (Dust) Filter

Fig. 5-2 Replace Inlet Filter

5-3

Page 62

USER HANDBOOK

1. Using a No.1 Pozidrive® screwdriver, unscrew then

remove the 2 Pozi Pan screws then remove the inlet

nozzle complete with inlet lter located in the inner recess

of the nozzle.

2. Push the sample inlet lter disc out of inner recess by

inserting a matchstick, or similar, into the inlet nozzle

outer recess..

3. Fit a new Sample Inlet Filter (Part No. 66084).

4. Press the new sample inlet lter disc into the inlet nozzle

shallow recess, with rough disc surface towards inner

surface of recess (sample side).

5. Fit the inlet nozzle. The inlet nozzle is moulded to t in

one direction only. Make sure that orientation is correct to

locate easily into the instrument front cover inlet.

6. Fit then tighten the 2 Pozi Pan screws using a No.1

Pozidrive® screwdriver.

Note: Care must be taken not to overtighten the screws.

5.2.3 In-line Hydrophobic Filter (Accessory)

The in-line hydrophobic lter assembly consists of the lter and

a luer tting on one side of the lter and a push-t connection

on the other, and is available as an accessory (Part No.

66485). The lter assembly is used to protect the instrument

from the ingress of water when sampling in moist conditions.

The lter is located between two lengths of sample line

tubing (Part No. 64118) and attached to the instrument via a

Sample Line Connector (Part No. 66045) as illustrated in

Fig. 5.3.

5-4

Page 63

OPERATOR MAINTENANCE

Fig. 5.3 In-line Hydrophobic Filter

To replace the lter, proceed as follows:

1. Unscrew the luer tting from one side of the lter in a

counter clockwise direction, detach the tubing from the

other side then remove the hydrophobic lter.

Note: If re-tting the same lter, make sure that lter

direction of ow orientation is maintained. This can be

easily identied by position of yellow label on lter, i.e.

facing instrument.

2. Fit a new In-line Hydrophobic Filter (Part No. 66484).

Note that the lter should be tted with the yellow label

facing the instrument.

3. Attach the luer tting, with sample line attached, to

the mating side of the lter then tighten in a clockwise

direction to secure. Do not overtighten the tting.

4. Attach the sample line to the other side of the lter making

sure that it is securely tted.

5-5

Page 64

USER HANDBOOK

5-6

Page 65

6

RECHARGE BATTERY

6.1 RECHARGE INSTRUMENT BATTERY

Use only GMI chargers to recharge PS200 series instruments.

WARNING: Charging is only permitted in a non-

CAUTION: Switch the instrument off when charging

The battery should be recharged in the following situations:

• The ‘LOW BATTERY’ ag appears on the display.

• The instrument will not switch On.

When the ‘LOW BATTERY’ icon appears on the display,

there is approximately 30 minutes operation left at normal

temperatures. The instrument will then switch Off

automatically.

There are four options available to the user to charge

the PS200 instrument battery, as follows:

1. Using the Charging Comms Clip (Part No. 64260)

together with the Mains Adaptor and cable (Part No.

64247) supplied with the instrument.

hazardous area.

the internal battery.

6-1

Page 66

USER HANDBOOK

2. Charging up to five (5) instruments in the 5-Way

Charger (Part No. 64138) supplied complete with

universal PSU (Part No. 64299).

3. Using the 12V / 24V - USB Vehicle Charging Adaptor

(Part No. 64248).

4. Using the In-Vehicle Charging Cradle (part no. 64491)

supplied complete with USB Vehicle Charging Adaptor.

In all four options:

Once the instrument is connected to the charger, charging will

commence automatically.

During charging, the battery symbol and ‘CHARGING’

indication ashes in the display. Maximum recharge duration

is 4 hours allowing minimum instrument run times.

On completion of charging, the ‘full’ battery symbol is

displayed together with ‘CHARGED’ indication.

The instrument will not be damaged if left connected to the

charger.

6.1.1 Recharge Instrument using the Charging /

Comms Clip

The charging / comms clip (Part No. 64260), together with the

cable (supplied with Mains Adaptor), enables the instrument

battery to be charged by connecting the instrument to any of

the following power sources:

- 5V USB Mains Adaptor (Part No. 64247)

- USB port of a Personal Computer (PC) or Laptop

- 12V / 24V - USB Vehicle Adaptor (Part No. 64248)

The clip is easily connected to the instrument charging contact

pads and features a mini-USB socket to enable connection of

mini-USB charging / comms cable with a standard type USB

connector at the other end.

6-2

Page 67

RECHARGE BATTERY

CONTACT

PADS (4)

LOCATING SLOT

LOCATING TONGUE

CHARGING / COMMS CLIP

(Part No. 64260)

MINI USB SOCKET

MINI USB

TO USB CABLE

To connect charging / comms clip to the instrument, push the

clip in direction of arrows as illustrated, engaging tongue on

clip in instrument locating slot until rmly seated.

Fit standard type USB connector to power source, as selected

from the list.

On completion of charging, disconnect standard type USB

connector from power source then mini-USB from clip. Grip

charging / comms clip and rmly pull away from instrument

until tongue on clip disengages with location slot in instrument.

Fig. 6-1 Charging Cable Connection

6-3

Page 68

USER HANDBOOK

6.1.2 Recharge Instrument using the 5-way Charger

The 5-way charger (Part No. 64138) allows the user to charge

up to ve PS200 instruments simultaneously.

Fig. 6-2 5-Way Charger

The 5-way charger accommodates up to ve PS200 series

instrument(s) with or without protective rubber boot tted, as

illustrated in Fig. 6-2.

The charger is connected to mains supply using a universal

power supply unit (PSU) supplied with the charger.

The charger can be freestanding, wall or workbench mounted

by securing with suitable xings (not supplied).

Before the instrument is located in any of the ve charging

bays, it is recommended that the instrument is switched OFF,

the ‘alligator clip’ is in the closed position and the ‘belt hook’

is upright.

Install the instrument in one of the vacant charging bays

making sure that the locating tongue engages in corresponding

slot in the base of the instrument and ensuring that the

instrument is rmly seated in charging unit.

Charging is fully automated.

Instrument(s) can remain installed in the charger after charging

is complete.

6-4

Page 69

RECHARGE BATTERY

IN-VEHICLE (USB)

CHARGING ADAPTOR

(Part No. 64248)

USB to MINI-USB

CABLE

(incl. in Part No. 64247 Mains Adaptor)

6.1.3 Recharge Instrument using the 12V / 24V In-Vehicle Charging Adaptor

The 12V to 24V DC USB In-Vehicle Charging Adaptor (Part

No. 64248), as illustrated in Fig. 6-3, is designed to provide

the GMI PS200 series instrument with corrected power for

battery charging. The power transformer is a switch mode dc

transformer operating from a 12 to 24 volt dc supply.

Fig. 6-3 In-Vehicle Charging Adaptor

The Charging / Comms clip (Part No. 64260), supplied with

the instrument, is connected to the base of the instrument as

illustrated in Fig. 6-4. The mini-USB plug from the charging

cable (supplied with Part No. 64247 Mains Adaptor) is then

connected to the clip. The standard USB plug can now be

connected directly into the USB socket on the USB Charging

Adaptor. With all connections in place, insert the adaptor into

the vehicle accessory socket. A red LED on the front of the

USB Charging Adaptor indicates ‘power ON’.

6-5

Page 70

USER HANDBOOK

MINI-USB to USB

CABLE

(incl. in Part No. 64247 Mains Adaptor)

CHARGING COMMS CLIP

(Part No. 64260)

Fig. 6-4 Connect Cable to Charging / Comms Clip

Note:

1. The charging adaptor is designed to fit a standard

accessory socket that may vary in size in certain vehicle

types. Always ensure that you use a proper tting socket.

2. Some vehicle types and models do not provide power to

the accessory socket when the vehicle ignition is switched

off. Charging will only take place when the accessory

socket is powered. A red LED on the charging adaptor

indicates that power is ON.

3. Care should be taken not to leave the instrument on

charge for excessive periods when the vehicle ignition

is switched off as this will reduce the battery power of

the vehicle.

6-6

Page 71

RECHARGE BATTERY

USB cable

6.1.4 Recharge Instrument using the In-Vehicle Charging Cradle

The charging cradle (Part No. 64491) enables the instrument

battery to be charged by connecting the USB cable to a vehicle

power source. Either, via an inbuilt USB socket or via the

vehicle charging adaptor (supplied), as illustrated in Fig. 6-5.

Vehicle Accessory

Socket

Vehicle Charging

Adaptor

USB Socket

Charging Cradle

Fig. 6-5 Charging Cradle USB Cable Connection

The charging cradle is mounted to a vehicle by securing with

suitable xings (not supplied).

To charge the instrument:

1. Ensure the instrument is switched off.

2. Fully open the instrument alligator clip.

3. Move the PS200 down over the charging contacts and

onto the location blade, as illustrated in Fig. 6-6.

6-7

Page 72

USER HANDBOOK

Alligator Clip

Open

Charging

Contacts

Location

Blade

Fig. 6-6 Connect PS200 to the Charging Cradle

4. Close the alligator clip, clamping onto the assembly

frame, to hold the instrument in position.

5. The PS200 will now indicate charging.

6. When charging is complete, unfasten the alligator clip

and lift the PS200 upwards to remove from the charging

cradle.

6-8

Page 73

7

CALIBRATION

7.1 GENERAL DESCRIPTION

The instrument has been calibrated for particular gases.

Where any doubt exists the product should be returned to

GMI or an authorised distributor for calibration.

WARNING: The instrument must be calibrated and

congured by authorised personnel only.

Three methods of calibration are possible:

• Field Calibration.

• Manual Calibration using flexiCal Plus software

CD-ROM (Part No. 99553). CD-ROM includes user

instructions.

• Automatic Calibration. The GMI Automatic Bump /

Calibration Station (Part No. 64052 / 64052Q), shown in

Fig. 7.1, provides controlled delivery of gases permitting

users to bump test and calibrate the instrument in

a controlled manner whilst maintaining a record of

calibration results on a PC.

Note: The detailed calibration methods, consisting of

both hardware and software, are manufactured by GMI.

For further details contact GMI or an authorised distributor.

7-1

Page 74

USER HANDBOOK

Fig. 7-1 PS200 Auto / Bump Calibration Station

7.2 CALIBRATION VALIDITY

Calibration validity remains the responsibility of the user.

Under normal operating conditions a 12 month period can

be expected. This is no guarantee, however, as the precise

application of the product is unknown to GMI. Individual codes

of practice will dictate shorter periods.

Regular calibration establishes a pattern of reliability and

enables the calibration check period to be modied in line with

operational experience. As a guide, the higher the risk, the

more frequently calibration should be checked.

7-2

Page 75

ACCESSORIES

Accessories supplied with the instrument

Part Number Description

64260 Charging / Comms Clip (mini-USB)

64247 Mains Adaptor

(c/w USB / mini-USB cable)

64190 User CD-ROM (incl. Handbook)

64172 Quick Operating Instructions

64136 3.0 metres (9ft.9in.) PVC Sample

Line Tubing & Connector - Pumped

Instruments Only.

Additional accessories available for the instrument

Part Number Description

64100 Plastic Carrying Case

(Instrument + Accessories)

64102 CalGas Carrying Case

(Capacity - 2 Cylinders)

64303 Rubber Boot (Instrument)

66485 In-Line Hydrophobic Filter Assy.

66484 Hydrophobic Filter (for 66085)

66084 Sample Inlet Filter

66123 Hand Aspirator

8

8-1

Page 76

USER HANDBOOK

Part Number Description

66478 Hand Aspirator

c/w 3.0 metres (9ft.9in.) tubing

64118 PVC Sample Line Tubing - per metre

66112 Sample Line Extender

66545 Ball Float

Charging Accessories

Part Number Description

64138 5-Way Charger

(c/w Universal PSU 64299)

64491 In-Vehicle Charging Cradle

(c/w 64248)

64248 In-Vehicle Charging Adaptor

(12v / 24V - USB)

Manual Bump / Field Calibration Kit

Part Number Description

64051 Manual Bump Kit

(c/w Combi Test Gas 99146,

Direct Flow Regulator, tubing &

sample line connector)

Automatic Bump / Calibration Accessory

Part Number Description

64052 Automatic Bump / Calibration Station

(6mmttings&incl.PSU/USB/

Software)

64052Q Automatic Bump / Calibration Station

(

1

/4 in.ttings&incl.PSU/USB/

Software)

99118 On Demand Flow Regulator

8-2

Page 77

ACCESSORIES

Gas Kits for Auto Bump / Calibration Station

(Cylinder / Regulator / Tubing)

Part Number Description

99146 Combi Test Gas Cylinder

(2.5% CH4, 500ppm CO, 50ppm

H2S, 18% O2, balance N

).

2

64060 TestGasKit(6mmttings)

(Combi Test Gas Cyl. 99146,

On Demand Flow Regulator

c/w 6 mm tubing).

64060Q Test Gas Kit (

1

/4 in.ttings)

(Combi Test Gas Cyl. 99146,

On Demand Flow Regulator

c/w

1

/4 in. tubing).

Documentation

Part Number Description

64171 User Handbook (PDF)

64191 Quick Operating Instructions (PDF)

Software

Part Number Description

64197 Data Downloading (CD-ROM)

- includes user instructions

64184 Auto Bump / Cal Station

(USB Flash Drive)

- includes user instructions

8-3

Page 78

USER HANDBOOK

8-4

Page 79

9

ADDITIONAL INFORMATION

9.1 TRAINING

Training courses are available on all GMI products.

Contact GMI Marketing Department for further details:

Tel: +44 (0) 141 812 3211

Fax: +44 (0) 141 812 7820

e-mail: sales@gmiuk.com

9.2 WEBSITE

Visit GMI web site at www.gmiuk.com

9-1

Page 80

USER HANDBOOK

9-2

Page 81

TYPICAL OPERATING PARAMETERS

Typical operating parameters are as follows:

Gas Range Resolution

Range

LEL 0 to 100% 1%

Oxygen 0 to 25% 0.1%

Carbon 0 to 1000 ppm 1 ppm

Monoxide

Hydrogen 0 to 100 ppm 1 ppm

Sulphide

PHYSICAL PROPERTIES

Weight:

Without Pump: 215 g (7.6oz.)

With Pump: 230 g (8oz.)

Dimensions (H x W x D):

121 mm (4.8in.) x 59 mm (2.3in.) x 32 mm (1.3in.).

ENVIRONMENT

Operating Temperature Limits:

-20oC (-4oF) to + 50oC (+122oF)

Storage temperature Limits:

-40oC (-40oF) to + 65oC (+149oF)

Humidity: 0 to 95% R.H. non-condensing

A

A-1

Page 82

USER HANDBOOK

TYPICAL FLOW RATE INFORMATION

Pumped Instruments: Nominal pump ow rate is 0.5 to 0.7

Typical ow fail rate is 0.1 to 0.2

WARM-UP / STABILIZATION TIME

< 40 seconds

ALARMS

Highly visible ashing LED, piercing >90dB audible

DISPLAY

Green / Red LCD backlit display

POWER SOURCE

Lithium Ion rechargeable battery:

Runtime up to 14 hours (8 hours pumped)

Charging time up to 4 hours

When using the SGX VQ548MP sensor:

Runtime up to 80 hours (20 hours pumped)

CONSTRUCTION

High impact rubberized polycarbonate case

IP RATING

IP67

RESPONSE TIMES (T90)

LEL = 10 secs. (IEC 60079-29-1)

O2 = 12 secs. (BSEN 50104)

CO = < 20 secs.

H2S = < 20 secs.

litres per min. Max. 30 metres (97ft.)

sample line

litres per min.

A-2

Page 83

B

LEL SENSOR TYPES

There are three LEL sensor types available for the PS200 instrument.

The following table shows the benefits of each sensor and the

combustible gases the sensors will detect:

LEL

Sensor

Standard

Filtered

Part No 66725

Enhanced

Filtered

Part No 64825

Low

Power

Part No 66750

Benet Gases Detected Certication

Detects

most

combustible

gases

Enhanced

H2S and

Silicone

poisoning

resistance

Improved

battery life

C1 - C8 Hydrocarbons

Includes but not

limited to: Methane,

Ethane, Propane,

Butane, Pentane,

Hexane, Heptane,

Octane & Hydrogen

C1 - C6 Hydrocarbons

Includes but not

limited to: Methane,

Ethane, Propane,

Butane, Pentane,

Hexane & Hydrogen

C1 - C5 Hydrocarbons

Includes but not

limited to: Methane,

Ethane, Propane,

Butane, Pentane

Gas Groups

IIC

A,B,C & D

IIC

A,B,C & D

IIB

C & D

Warning: PS200 instruments tted with the low power LEL sensor

cannot be retrotted with standard or enhanced lter LEL

sensors and vice versa.

Division / Zone

Class I, Div 1,2

Zones 1,2

Class I, Div 1,2

Zones 1,2

Class I, Div 1,2

Zones 0,1,2

B-1

Page 84

USER HANDBOOK

B-2

Page 85

INDEX

Symbols

5-way Charger 6-4

A

ACCESSORIES 8-1

ACKNOWLEDGE 2-15

ACKNOWLEDGE GAS

ALARMS 4-5

ADDITIONAL

INFORMATION 9-1

ALARM CONFIRMATION

3-5

ALARMS 4-1, A-2

ALARMS, FAULT 4-7

ALARMS, GAS 4-1, 4-5

ALARMS, MUTE 4-5

ALARMS RESET OR

ACKNOWLEDGE 2-15

APPLYING TEST GAS 3-4

AREAS OF USE iii

Automatic Calibration 7-1

B

BACKLIGHT, DISPLAY

2-12

BATTERY, INSTRUMENT

6-1

Battery, Low 4-7

BATTERY, RECHARGE

6-1

Battery Status 2-3

Bump Due Date 2-5

BUMP OPTIONS 3-2

BUMP TEST OPTIONS

3-1

BUMP TEST RESULT 3-5

C

CALIBRATION 7-1

Calibration, Automatic 7-1

Calibration Due Date 2-6

Calibration Expired 4-13

Calibration, Field 7-1

Calibration Gas 2-8

Calibration, Manual 7-1

Calibration Required 4-12

CALIBRATION VALIDITY

7-2

CERTIFICATION 1-7

i

Page 86

USER HANDBOOK

Certication Marks 1-8

Charger, 5-way 6-4

CLEANING 5-1

CONFIDENCE BEEP 2-15

Condence Signal 2-15

Connect PS200 to the

Charging Cradle 6-8

CONSTRUCTION 1-6, A-2

COPYRIGHT i

CSA ii

D

DATA LOGGING 1-5

Date 2-4

DESCRIPTION, GENERAL

1-1

DISPLAY A-2

DISPLAY BACKLIGHT ON /

OFF 2-12

Display, Operating 2-11

DISPOSAL ADVICE i

E

EN 60079 1-6

ENVIRONMENT A-1

F

FAULT ALARMS 4-7

Fault, Flow 4-11

Fault, Memory 2-11

Fault, Sensor 4-9

Fault, Zero 4-8

FEATURES 1-4

Field Calibration 7-1

Filter, Hydrophobic 5-2

FILTERS 1-6

FILTERS, INSTRUMENT

5-1

Flammable LEL Alarm Limit

4-3

Flow Fault 4-11

FLOW RATE

INFORMATION A-2

Full Bump Test 3-4

G

GAS ALARMS 4-1, 4-5

Gas, Calibration 2-8

GAS OVER-RANGE

ALARM 4-5

GAS, TEST 3-4

GENERAL DESCRIPTION

1-1

ii

Page 87

INDEX

H

HANDLING iii

HIGH FLAMMABLE GAS

OVER-RANGE ALARM 4-5

Hydrophobic Filter 5-2

I

Identication, Instrument

2-3

IDENTIFICATION LABEL

1-6

INFORMATION,

ADDITIONAL 9-1

INITIATING A MANUAL

BUMP TEST 3-2

Inlet (Dust) Filter 5-3

In-line Hydrophobic Filter

(Accessory) 5-4

INSTRUMENT BATTERY

6-1

INSTRUMENT FILTERS

5-1

Instrument Identication

2-3

INSTRUMENT OFF 2-18

INSTRUMENT ON 2-2

INTRODUCTION 1-1

In-Vehicle Charging

Adaptor 6-5

In-Vehicle Charging Cradle

6-7

IP67 1-6

IP RATING A-2

L

LEL Alarm Limit 4-3

LEL SENSOR TYPES B-1

LIABILITY i

LOGGING, DATA 1-5

Low Battery 4-7

LOW BATTERY 6-1

LTEL 4-3

M

MAINTENANCE,

OPERATOR 5-1

MANUAL BUMP OPTIONS

3-2

MANUAL BUMP TEST 3-2

MANUAL BUMP TEST

OPTIONS 3-1

Manual Calibration 7-1

MANUAL DATALOG 2-12

Marks, Certication 1-8

iii

Page 88

USER HANDBOOK

MAXIMUM 2-12

Memory Fault 2-11

MINIMUM 2-12

MODIFICATION NOTICES i

MUTE ALARMS 4-5

N

Normal Operating Display

2-11

O

OFF, INSTRUMENT 2-18

ON, INSTRUMENT 2-2

Operating Display 2-11

OPERATING

PARAMETERS A-1

OPERATING

PROCEDURE 2-1

OPERATION 2-1

OPERATOR

MAINTENANCE 5-1

Option, Pump 2-16

OPTIONS, BUMP 3-2

OVER-RANGE ALARM 4-5

Over-Range Flammable

Gas Alarm Function 4-3

Oxygen (O2) Alarm Limits

4-3

P

PARAMETERS,

OPERATING A-1

Performance 1-8

PHYSICAL PROPERTIES

A-1

POWER SOURCE A-2

PROCEDURE,

OPERATING 2-1

PROPERTIES, PHYSICAL

A-1

Pump Option 2-16

Q

Quick Bump Test 3-4

QUICK / FULL BUMP TEST

3-4

R

RATE, FLOW A-2

RATING, IP A-2

RECHARGE BATTERY

6-1

RECHARGE

INSTRUMENT BATTERY

6-1

Recharge Instrument using

the 5-way Charger 6-4

iv

Page 89

INDEX

Recharge Instrument using

the 12V / 24V In-Vehicle

Charging Adaptor 6-5

Recharge Instrument using

the Charging / Comms Clip

6-2

Recharge Instrument using

the In-Vehicle Charging

Cradle 6-7

Regulator Valve Selection

3-3

REMOTE SAMPLING 2-16

REPLACE INSTRUMENT

FILTERS 5-1

Replace Sample Inlet

(Dust) Filter 5-3

Replace Sensor

Hydrophobic Filter 5-2

Required, Calibration 4-12

RESET, ALARMS 2-15

Resolution A-1

RESPONSE TIMES A-2

RESULT, TEST 3-5

S

SAFETY ii

SAFETY, ADDITIONAL

DETAILS - CSA ONLY ii

Sample Inlet (Dust) Filter

5-3

SAMPLING, REMOTE

2-16

Select Calibration Gas 2-8

SELF TEST 2-17

Sensor Conrmation Check

2-9

Sensor Fault 4-9

Sensor Hydrophobic Filter

5-2

Service Due Date 2-7

Signal, Condence 2-15

SOFTWARE i

SOURCE, POWER A-2

SPECIAL CONDITIONS OF