Page 1

Model TS420

r

Oxygen Deficiency Detector

The information and technical data disclosed in this

document may be used and disseminated only for the

purposes and to the extent specifically authorized in

writing by General Monitors.

Instruction Manual 11/00

General Monitors reserves the right to change

published specifications and designs without prio

notice.

*MANTS420*

Part No. MANTS420

Revision B/11-00

Page 2

Model TS420

WARRANTY STATEMENT

General Monitors warrants the Model TS420 to be free from defects in workmanship or material

under normal use and service within two (2) years (sensor cells one (1) year) from the date of

shipment. General Monitors will repair or replace without charge any equipment found to be

defective during the warranty period. Full determination of the nature of, and responsibility for,

defective or damaged equipment will be made by General Monitors’ personnel. Defective or

damaged equipment must be shipped prepaid to General Monitors’ plant or the representative

from which shipment was made. In all cases this warranty is limited to the cost of the

equipment supplied by General Monitors. The customer will assume all liability for the misuse

of this equipment by its employees or other personnel. All warranties are contingent upon

proper use in the application for which the product was intended and do not cover products

which have been modified or repaired without General Monitors’ approval or which have been

subjected to neglect, accident, improper installation or application, or on which the original

identification marks have been removed or altered. Except for the express warranty stated

above, General Monitors disclaims all warranties with regard to the products sold, including all

implied warranties of merchantability and fitness and the express warranties stated herein are

in lieu of all obligations or liabilities on the part of General Monitors for damages including, but

not limited to, consequential damages arising out of/or in connection with the use or

performance of the product.

WARNING - THE TS420 DETECTS OXYGEN DEFICIENT ENVIRONMENTS AND

EXPOSURE TO OXYGEN DEFICIENT ENVIRONMENTS MAY RESULT IN SICKNESS OR

DEATH.

The TS420 Toxic Gas Detector contains components, which can be damaged by static

electricity. Special care must be taken when wiring the system to ensure that only the

connection points are touched.

The TS420 is rated intrinsically safe as denoted by the symbol “Ex ia” on the instrument label.

Substitution of electrical components within the TS420 may impair intrinsic safety.

Damage to the TS420 housing such that any internal components or potting can be or is

exposed compromises the intrinsic safety of the device and as such should not be used in a

hazardous environment. Such damage includes complete fracture of the plastic housing or

cracks that may be opened to expose any internal components or potting. Destruction of the

sensor cap will not affect the intrinsic safety of the TS420; however, calibration accuracy and

the watertight nature of the TS420 will be compromised.

WARNING - DO NOT USE A TS420 WITH A DAMAGED HOUSING IN A HAZARDOUS

ENVIRONMENT.

IMPORTANT - Each oxygen sensor cell is shipped separate from the TS420. This ensures that

a fresh sensor cell will be used during initial start-up. DO NOT install the cell into the TS420

until you are ready to apply power to the system. When installing this unit, an initial field

calibration must be completed, since the TS420 is not factory calibrated to the specific cell.

i

Page 3

System Integrity Verification

General Monitors mission is to benefit society by providing solutions through industry leading

safety products, services and systems that save lives and protect capital resources from the

dangers of hazardous flames, gases and vapors.

The safety products you have purchased should be handled carefully and installed, calibrated

and maintained in accordance with the respective product instruction manual. Remember

these products are for your safety.

To ensure operation at optimum performance General Monitors recommends that certain

maintenance items are performed.

Commissioning Safety Systems

Before power up, verify wiring, terminal connections and stability of mounting for all integral

safety equipment including, but not limited to:

! Power supplies

! Control modules

! Field detection devices

! Signaling / output devices

! Accessories connected to field and signaling devices

After the initial application of power (and any factory specifies warm-up period) to the safety

system, verify that all signal outputs, to and from devices and modules, are within the

manufacturers’ specifications. Initial calibration / calibration checking / testing should be

performed per the manufacturers’ recommendations and instructions.

Proper system operation should be verified by performing a full, functional test of all component

devices of the safety system, ensuring that the proper levels of alarming occur.

Proper system operation should be verifies by performing a full, functional test of all component

devices of the safety system, ensuring that the proper levels of alarming occur.

Fault/Malfunction circuit operation should be verified.

Model TS420

ii

Page 4

Periodic Testing/Calibration of Field Devices

Periodic testing/calibrating should be performed per the manufacturers’ recommendations and

instructions. Testing/Calibrating procedures should include, but not be limited to:

! Verify zero reading

! Apply a known concentration of gas, or a simulated test device provided by the

manufacturer

! Verify integrity of all optical surfaces and devices

! For flame detectors, use the appropriate test lamp

When testing produces results outside of the manufacturers’ specifications, re-calibration or

repair/replacement of the suspect device(s) should be performed as necessary. Calibration

intervals should be independently established through a documented procedure, including a

calibration log maintained by plant personnel or third party testing services.

Periodic System Verification

The following system verifications should be performed at least annually:

Verify wiring, terminal connections and stability of mounting for all integral safety equipment

including, but not limited to:

! Power supplies

! Control modules

! Field detection devices

! Signaling / output devices

! Accessories connected to field and signaling devices

Proper system operation should be verified by performing a full, functional test of all component

devices of the safety system, ensuring that the proper levels of alarming occur.

Fault/Malfunction circuit operation should be verified.

Model TS420

iii

Page 5

A

1. Mount and Wire the Detector (pages 5 through 9)

There are no standard rules for detector placement since the optimum sensor location is

different for each application. The customer must evaluate conditions at the facility to make this

determination. Generally, the TS420 should be easily accessible for calibration checks. The

TS420 should be mounted pointing down to prevent water build-up on the detector head. The

detector assembly should not be placed where it may be coated by contaminating substances.

Although the Model TS420 is RFI resistant, it should not be mounted in close proximity to radio

transmitters or similar equipment.

Some general guidelines for sensor location:

! The TS420 should be used in locations that are tightly enclosed with poor or no

ventilation, such as utility tunnels or underground storage areas. These areas are likely

to have dangerously low oxygen concentrations.

! Observe the TS420’s environmental specifications when locating the unit.

The environmental specifications covering the electrochemical cell are found in the Appendix,

Section 5.1.4.

Detectors should be mounted in an area that is as free from wind, dust, water, shock and

vibration as possible.

WARNING - Operation above or below temperature limits will provide unstable readings, which

may cause false alarms or failure to alarm. See Section 5.1.4 for guidelines.

General Monitors discourages painting of detector assemblies. If the detector head is painted

over, the gas will not be able to diffuse into the sensor. If the TS420 body is painted over, the

LCD display cannot be read.

The TS420 is shipped without the sensor installed. The sensor must be installed into the

detector and calibrated for proper operation. See Sections 3.3 and 3.4 for installation

instructions and Section 4.3 for calibration instructions.

Once correctly installed, the TS420 requires little or no maintenance other than periodic

calibration checks to ensure system integrity. General Monitors recommends a calibration

check schedule be established and that the complete system, including all alarm circuitry, be

tested at least annually.

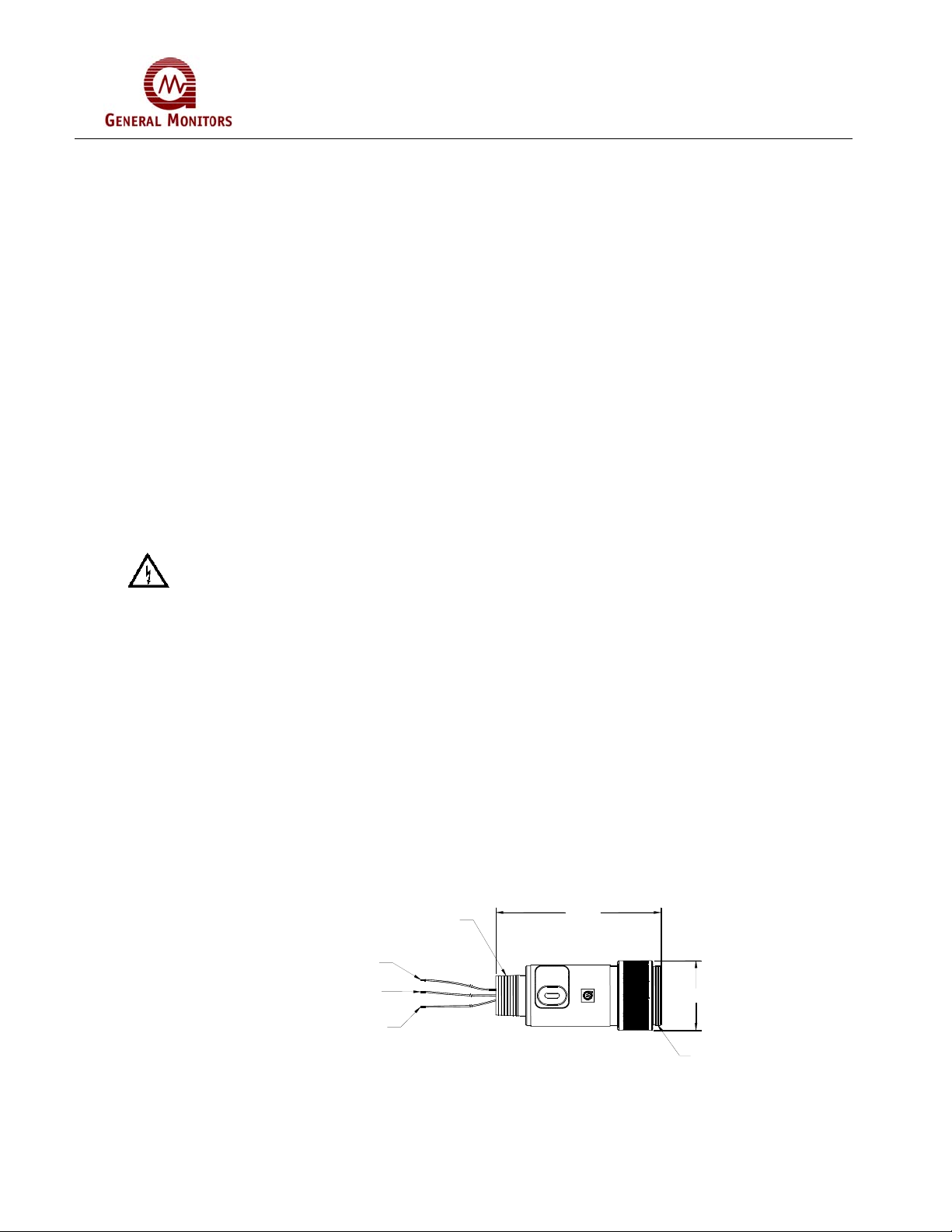

The overall and mounting dimensions for the TS420 (Figure Q-A) should be used when making

installation determinations. Mechanical specifications can be found in the Appendix, Section

5.1.2.

Model TS420

Quick Start Guide

4.50"

E

D

Y

L

L

O

N

A

O

M

C

N

E

T

H

G

I

T

D

N

A

H

S

L

A

R

R

O

E

T

I

N

N

E

Ø1.75"

LOOP+ (RED)

LOOP- (WHITE)

FRAME GROUND

(GREEN/YELLOW)

3/4 NPT

1 1/2-20 UN-2

Figure Q-A Outline and Dimensional Drawing

iv

Page 6

Intrinsically Safe Barriers

In order for the TS420 to be used with classified equipment inside of the hazardous area, it is

necessary for the customer to purchase either a Galvanic or Zener Diode Barrier, which should

be mounted in the non-classified area between the TS420 and the facilities’ control room. A list

of recommended manufacturers and part numbers follows for galvanic barriers:

Stahl - 9303/11-22-11 Elcon - mD323 or mD325

MTL - MTL7206 or MTL5041 Turck - mk33-Li-ExO

Pepperl+Fuchs - KFD2-CR-EX1.30-300

These are recommended active type barriers for intrinsically safe applications. Each application

is different and it is the ultimate decision of the user to determine the appropriate I/S barrier for

their application.

NOTE - To maintain intrinsic safety, wire length and gauge are limited by the capacitance and

inductance of the wire, Ci and Li of the TS420, and the barrier ratings. See Section 5.1.5 for

instructions on calculating these values.

Align the TS420 so that the LCD display is easily viewed. Teflon tape may be used on the

TS420’s threads.

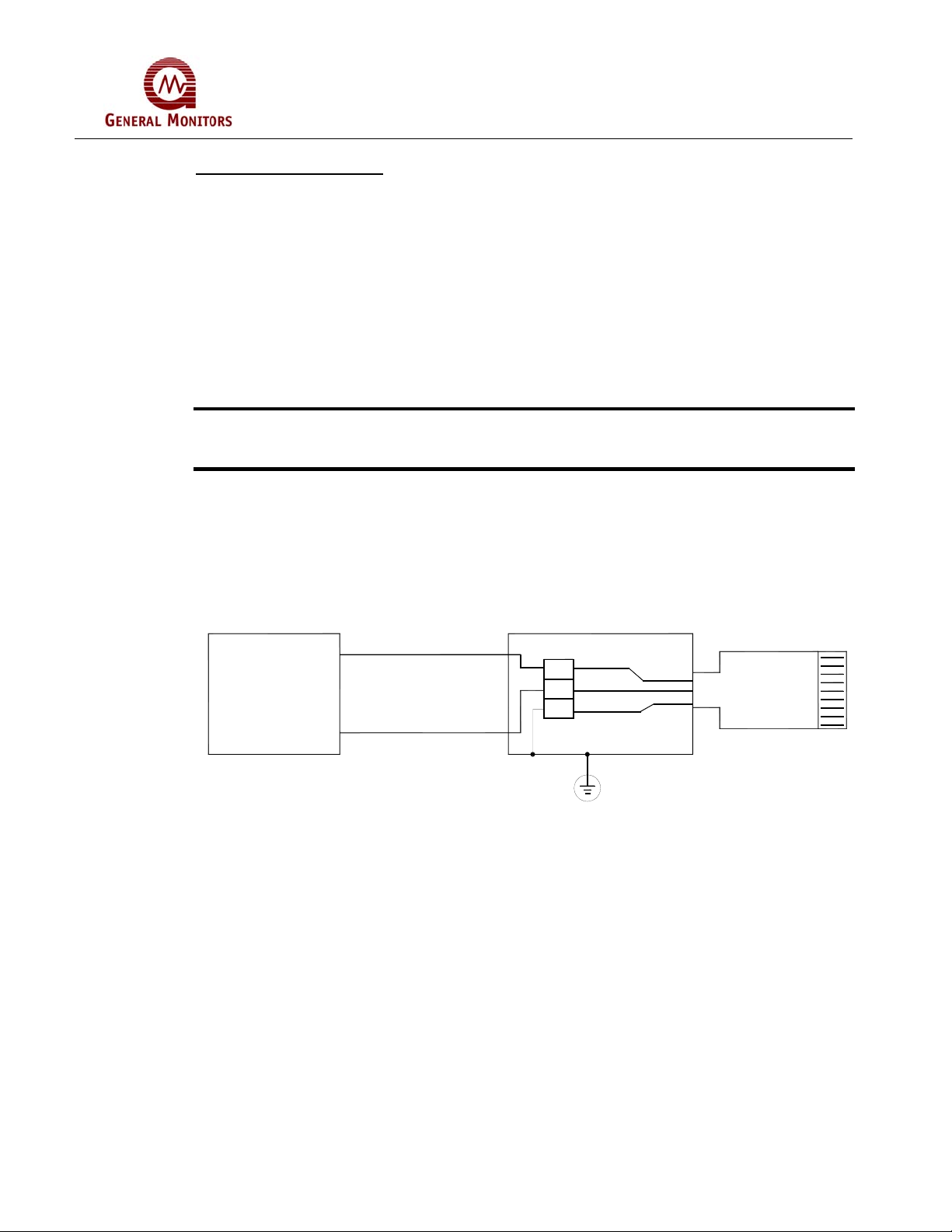

The two wires at the base of the TS420 provide a 4-20mA loop-powered output. The red wire

is the “loop +” lead and the white wire is the “loop -” lead (Figure Q-B). A third green/yellow

wire is provided for frame ground.

Model TS420

Quick Start Guide

JUNCTION BOX

LOOP + (RED)

RED

CONTROL

ROOM

LOOP - (WHITE)

WHITE

GRN/YEL

TS420

Figure Q-B Wiring Diagram

It is recommended that a two wire, shielded cable be used for making power and output signal

connections on the TS420.

Connect the green/yellow frame ground wire to the grounding terminal or lug inside the junction

box being used with the TS420.

Ensure the junction box frame is connected to frame ground or connected to the cable shield,

which is connected to frame ground at the controller.

Connect the red wire to the +24VDC terminal. Connect the white wire to the signal input

terminal on the readout/relay display module, FMD Field Mounted Display, S4100E smart

sensor, industrial analog to digital converter, computer-based monitor, PLC, DCS, etc.

Since the TS420 is designed to operate continuously, a power switch is not included, in order to

prevent accidental system shutdown.

v

Page 7

NOTE - Power must remain disconnected until all wiring connections are made.

The absolute maximum distance between the TS420 and the power supply is 8000 feet (2438

meters). Depending on the application, general purpose or intrinsically safe, the cable length

will depend on the intrinsically safe barrier chosen and the cable used. See the Appendix,

Section 5.1.5, for the intrinsically safe system requirements. In addition, cable length

specifications can also be found in the Appendix, Section 5.1.3. In all cases, the cable run

should be as short as possible.

2. Apply power to the detector.

Before applying power to the system for the first time, all wiring connections should be checked

for correctness. The sensor should be allowed to stabilize prior to calibration. The stabilization

time should be one (1) hour for all sensors.

Initial Power-up

The TS420 has been shipped un-calibrated, therefore, the first time power is applied, the

TS420 will enter Start-up mode (3.6mA) for a short interval, then may transition to fault mode

(flashing MODE LCD with the CAL LCD off and the analog output current at 3.5mA) until

calibrated (See Section 4.3 for Calibration Procedure).

After calibration is complete, the TS420 will proceed to Operate mode (17.38mA = 20.9% V/V

O

) where any detected oxygen will show as a proportional analog output current between 4

2

and 20mA (4mA = 0% V/V O

, 20mA = 25% V/V O2). The MODE LCD will be on steady and the

2

CAL LCD off with normal atmosphere and both the MODE and CAL LCD's will flash when

oxygen deficiency is detected. (O

level < 19%).

2

General Monitors recommends the TS420 be calibrated again within the first twenty-four (24)

hours after the initial calibration. Calibrations should be performed with new units and units that

have been off power for more than one (1) week. See “Calibration”, Section 4.3, for more

details.

Power-up After Initial Calibration

When the TS420 is powered up, after it has been previously calibrated, the unit will enter a

Start-up mode (3.6mA) for approximately 50 seconds, which allows the sensor to stabilize

before proceeding to the Operate mode (17.38mA). During Start-up, the “MODE” LCD will

flash, the “CAL” LCD will be off and the analog output current will be 3.6mA.

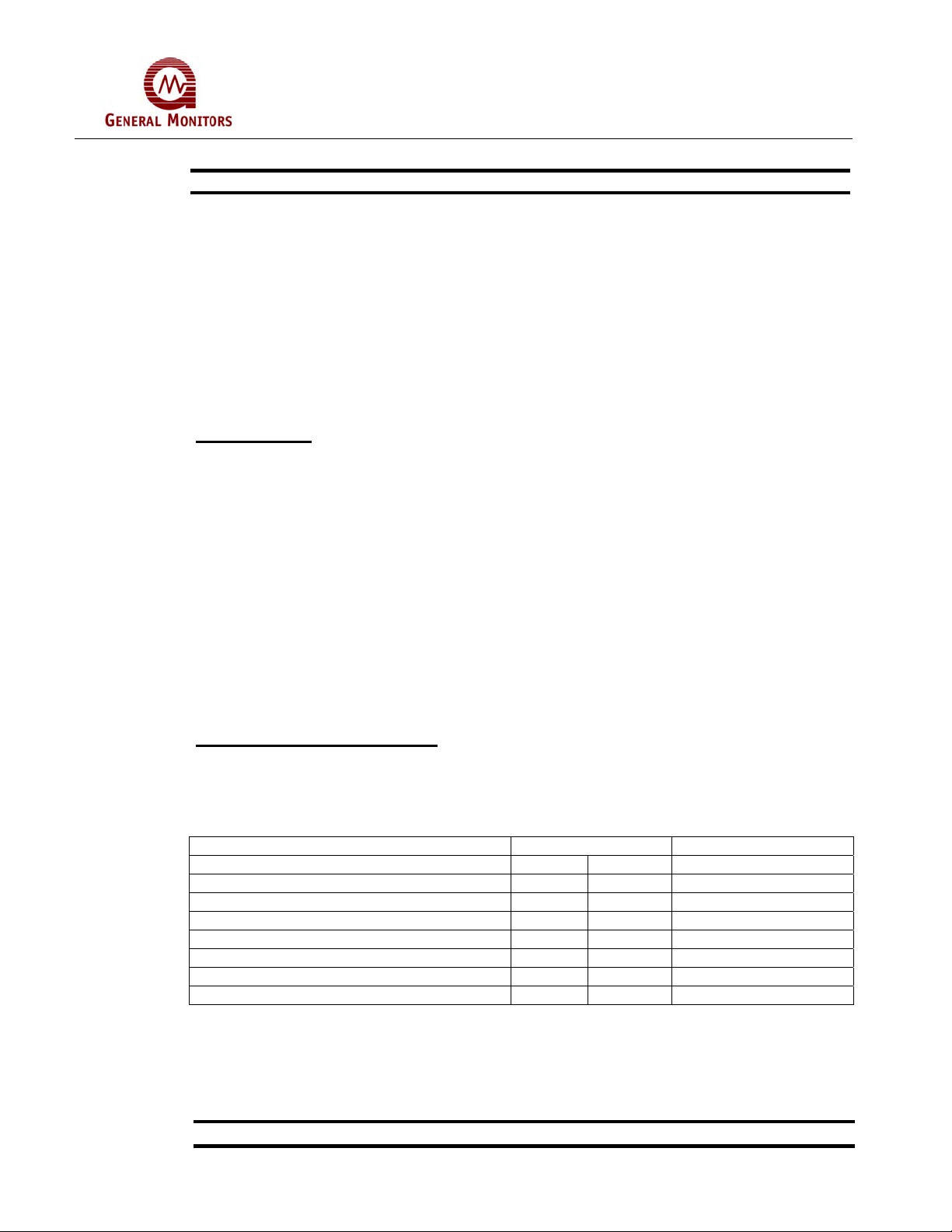

OPERATING MODES INDICATOR ANALOG OUTPUT

CAL MODE

START-UP

❏ ✹

OPERATE

AMBIENT O2 = 20.9%

DEFICIENT ATMOSPHERE, O2< 19%

1

❏ ■

✹ ✹

FAULT

NO POWER

SYSTEM

❏ ❏

❏ ✹

Model TS420

Quick Start Guide

3.6mA

17.38mA

4.0-16.16mA

0.0mA

3.5mA

Figure Q-C Operating Modes, Indicators and Outputs

1. Segment may flash Synchronously or alternating.

Perform a calibration and the TS420 will return to operate mode (17.38mA).

NOTE - The TS420 will not allow you to enter calibration mode during Start-up mode (3.6mA).

vi

Page 8

3. Calibrate the Detector.

Activating the “CAL” switch will automatically disable the external alarm circuits by fixing the

analog output current to 3.75mA.

General Monitors recommends that the TS420 be calibrated within the first twenty-four (24)

hours after initial start-up, and that calibration be checked at least every ninety (90) days to

ensure the integrity of the system.

NOTE: A calibration check consists of applying a 20.9% V/V O

scale concentration of gas to the sensor and observing the reading on the display device being

used.

General Monitors is not implying that the customer should expect problems with sensor life or

stability. “Frequent” calibration checks merely ensure the integrity of the life protecting

equipment, and are recommended for problem environments (i.e. sensors accidentally being

painted over, etc, see Appendix 5.4).

A calibration schedule should be established and followed. A logbook should also be kept

showing calibration dates and dates of sensor replacement.

Calibration Procedure:

1. If it is suspected that the air is not at “normal” levels (20.9% O

calibrate the sensor with clean air. The 20.9% O

gas cylinder (GMI P/N 1400262-11) can be

2

used. Apply the clean air source prior to entering calibration mode and allow the sensor to

stabilize for at least one (1) minute before proceeding.

2. Place the magnet over the GMI Logo on the body of the unit and hold it there until the “CAL”

LCD indicator appears, then remove the magnet. The analog output current will drop to

3.75mA.

3. The “CAL” and “MODE” LCD indicator will flash, indicating that the unit is now calibrating.

4. After approximately 30 seconds, the display will change from a flashing “CAL” and “MODE”

LCD to a solid “MODE” LCD, indicating that the calibration is complete and the unit has reentered “OPERATE” mode. Remove any calibration gas.

6. The unit is now calibrated and the new values have been stored in the NOVRAM (nonvolatile memory).

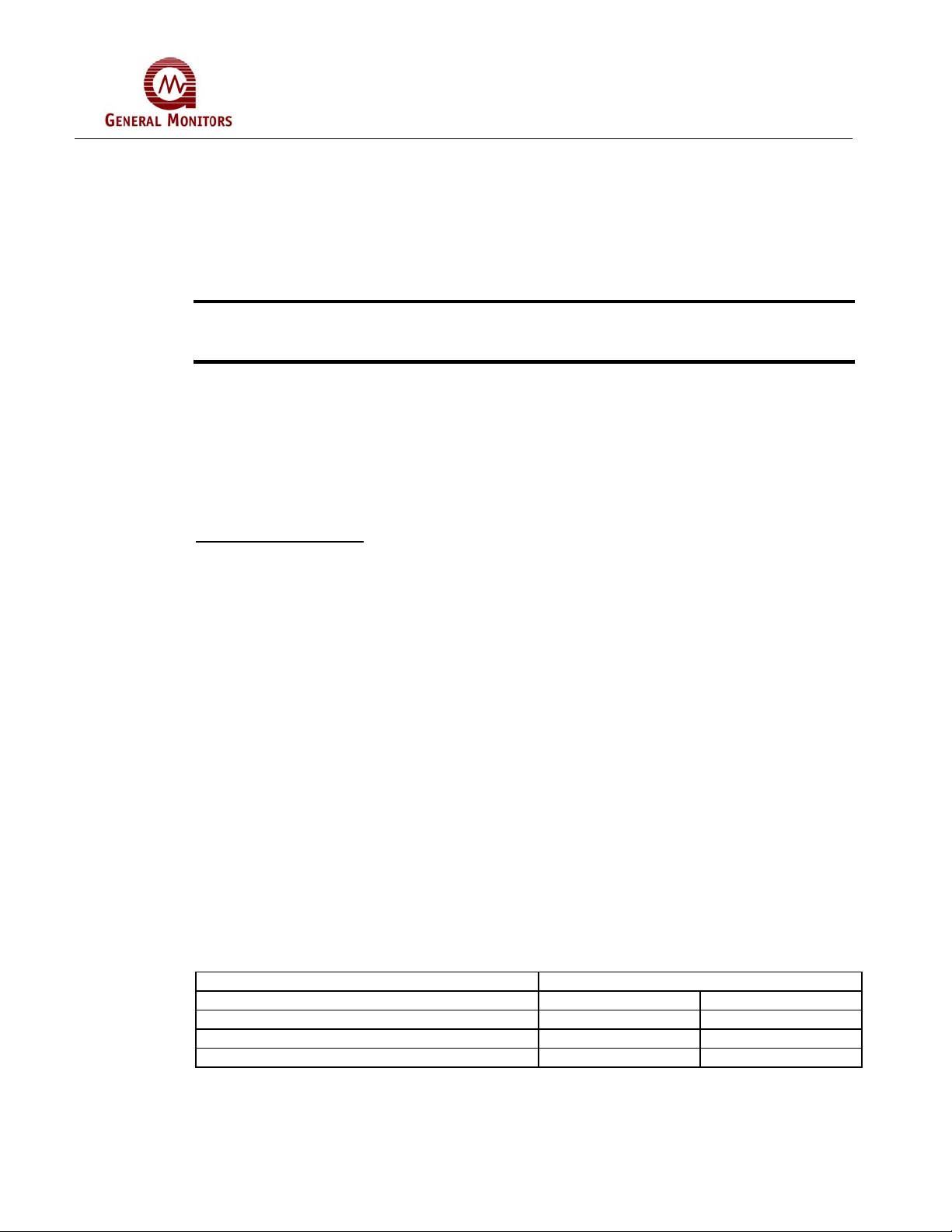

Figure Q-D shows a flow diagram of the codes that will appear in the display window during the

calibration procedure.

If there is a problem and the TS420 cannot complete the calibration sequence, a fault indicator

will be displayed, and the analog output current will drop to 3.5mA.

CALIBRATION INDICATOR

CAL MODE

Magnet Applied

Magnet Recognized

Cal Proceeding

Model TS420

Quick Start Guide

(“normal” ambient air) of full-

2

), it will be necessary to

2

❑ ■

■ ❑

✹ ✹

Figure Q-D Flow Diagram

vii

Page 9

NOTE - If the unit fails to calibrate a flashing “MODE” LCD will be displayed. The sensor must

see “clean” air for at least fifteen (15) minutes before a second calibration is attempted by

reapplying the magnet.

The instrument is now ready to operate! Please consult the manual for more information

on the instrument’s many features.

If you have any problems in the set-up or testing of the detector, please refer to the “Trouble

Shooting Section”, or call the factory direct.

Worldwide Service is available by calling:

Lake Forest, California Phone: +1-949-581-4464

(24 hr. service) Fax: +1-949-581-1151

Houston, Texas Phone: +1-281-855-6000

Fax: +1-281-855-3290

Ireland Phone: +1-353-91-751175

Fax: +1-353-91-751317

Singapore Phone: +1-65-748-3488

Fax: +1-65-748-1911

United Arab Emirates Phone: +1-971-4-8815751

Fax: +1-971-4-8817927

United Kingdom Phone: +1-44-1625-619-583

Fax: +1-44-1625-619-098

Model TS420

Quick Start Guide

viii

Page 10

Model TS420

Table of Contents

WARRANTY STATEMENT ..........................................................................................i

System Integrity Verification .........................................................................................ii

Commissioning Safety Systems......................................................................................ii

Periodic Testing/Calibration of Field Devices ...............................................................iii

Periodic System Verification ........................................................................................iii

Table of Contents ........................................................................................ix

Table of Figures .........................................................................................x

1.0 Introduction .........................................................................................1

1.1 General Description...................................................................................1

1.2 Features and Benefits ...............................................................................1

1.3 Applications .........................................................................................1

2.0 Detector Assembly .........................................................................................3

2.1 Sensor Assembly.......................................................................................3

2.2 Control Electronics ....................................................................................4

3.0 Installation .........................................................................................5

3.1 Receipt of Equipment ................................................................................5

3.2 Detector Location Considerations .............................................................5

3.3 Installation Instructions ..............................................................................6

3.3.1 Intrinsically Safe Barriers..............................................................6

3.3.2 Maintenance .................................................................................6

3.4 Wiring Connections ...................................................................................7

4.0 Operation .........................................................................................8

4.1 Applying Power .........................................................................................8

4.2 Operating Modes .......................................................................................9

4.3 Calibration .........................................................................................9

4.4 Calibration Equipment .............................................................................10

4.5 Sensor Replacement Procedure .............................................................11

4.6 Sensor Care and Maintenance................................................................13

5.0 Appendix .......................................................................................14

5.1 Specifications .......................................................................................14

5.1.1 System Specifications ................................................................14

5.1.2 Mechanical Specifications ..........................................................14

5.1.3 Electrical Specifications..............................................................14

5.1.4 Environmental Specifications .....................................................15

5.1.5 Intrinsically Safe System Requirements.....................................16

5.1.6 Sample Calculation.....................................................................16

5.2 Engineering Documentation ....................................................................17

5.2.1 Outline & Dimensional Drawing..................................................17

5.2.2 Control Drawing ..........................................................................18

5.2.3 Sample Installation .....................................................................19

5.2.4 Junction Boxes ...........................................................................20

5.2.5 Splash-Guards............................................................................21

5.2.6 Accessories ................................................................................22

5.2.7 Calibration Accessories ..............................................................22

5.3 Ordering Information................................................................................23

5.4 Calibration Schedule for Problem Environments.....................................24

5.5 Spare Parts & Accessories......................................................................25

ix

Page 11

Table of Figures Page

Figure Q-A Outline and Dimensional Drawing ......................................................................iv

Figure Q-B Wiring Diagram................................................................................................... v

Figure Q-C Operating Modes, Indicators and Outputs..........................................................vi

Figure Q-D Flow Diagram .................................................................................................... vii

Figure 1 Model TS420 ...................................................................................................... 1

Figure 2 Oxygen Deficiency Sensor Assembly ................................................................ 3

Figure 3 LCD Display Location......................................................................................... 4

Figure 4 Wiring Diagram................................................................................................... 7

Figure 5 Operating Modes, Indicators and Outputs.......................................................... 8

Figure 6 Flow Diagram ................................................................................................... 10

Figure 7 Calibration Cup................................................................................................. 10

Figure 8 Calibration Plug ................................................................................................ 10

Figure 9 Change in % Oxygen in the atmosphere

with Relative Humidity at constant Temperature................................. 11

Figure 10 Sensor Alignment ............................................................................................. 12

Figure 11 Calibration Kit with Bottle.................................................................................. 13

Figure 12 Outline and Dimensional Drawing .................................................................... 17

Figure 13 Control Drawing................................................................................................ 18

Figure 14 Sample Installation ........................................................................................... 19

Figure 15 10252 Round Aluminum Junction Box ............................................................. 20

Figure 16 31305-2 Aluminum Junction Box...................................................................... 20

Figure 17 45160-1 Plastic Junction Box, NPT; 45160-2 Plastic Junction Box, M20 ........ 21

Figure 18 70631-2 Splash - Guard ................................................................................... 21

Figure 19 45170-1 Flow Block.......................................................................................... 22

Figure 20 45147-1 Flow Block Retainer ........................................................................... 22

Figure 21 914-152 Calibration Plug .................................................................................. 22

Figure 22 1400152-1 Calibration Cup .............................................................................. 22

Calibration Schedule for Problem Environments........................................................................ 24

Model TS420

x

Page 12

Model TS420

1.0 Introduction

1.1 General Description

The Model TS420 is a 4-20mA, loop-powered Oxygen Deficiency detector used for monitoring

Oxygen levels. The micro-processor based electronics process information at the sensor site

and are contained within a corrosion and solvent resistant plastic housing. An LCD display

provides status indications that can be viewed through a window in the housing. The analog

signal (0 to 25% V/V O

operation.

The TS420 is entity-approved as intrinsically safe for use in Class I, Divisions 1 & 2, Groups A,

B, C and D, Class II, Groups E, F and G & Class III hazardous areas. It can also be used in

general-purpose (non-hazardous) applications.

NOTE - Intrinsically safe applications require an I/S barrier mounted in a safe area. See

Section 3.3.1 for guidelines.

1.2 Features and Benefits

Microprocessor-Based Electronics: monitors for fault conditions, processes input signals

from the sensor and provides outputs in the form of display codes and an analog signal.

One Person Adjustment-Free Calibration: initiate the calibration sequence with a magnet,

apply 20.9% V/V O

calibration. No user adjustments are required.

Two Segment LCD: indicates gas presence, operational modes, fault codes and calibration

cues.

4 to 20 mA Output: transmits fault, calibration, and gas concentration levels to a remote

display, computer or other device.

1.3 Applications

This is a partial listing of applications.

! Wastewater Treatment Plants

! Chemical and Petrochemical Plants

! Refineries

! Pulp & Paper Plants

! Micro-chip Manufacturing

! Pharmaceuticals

! Food & Beverage

! Utilities

full scale) provides remote and/or discrete indications of the sensor’s

2

, and wait for the display to indicate that the unit has completed the

2

Figure 1 Model TS420

1

Page 13

This page left intentionally blank

Model TS420

2

Page 14

2.0 Detector Assembly

2.1 Sensor Assembly

General Monitors uses a two-electrode electrochemical cell (Figure 2) to provide a stable and

accurate gas detector.

Model TS420

Remove paper liner from gasket, if present.

Figure 2 Oxygen Deficiency Sensor Assembly

The oxygen sensor is of the self-powered, diffusion limited, metal air battery type. It contains an

anode, electrolyte and an air cathode to which the diffusion of oxygen is severely restricted by a

diffusion barrier. At the air cathode, oxygen is reduced to hydroxyl ions, which in turn oxidize

the metal anode. This action produces a current that is proportional to the rate of consumption

of oxygen.

3

Page 15

2.2 Control Electronics

The Model TS420’s electronics are contained within a plastic housing so that sensor

information can be processed at the point of detection. The Model TS420 provides a 4-20 mA

output signal proportional to 0 to 25% V/V O

Ambient Air is approximate 20.9% V/V O

decreases the 4-20 mA signal decreases.

The TS420 provides a two-digit LCD (Liquid Crystal Display). This display (Figure 3) provides

status such as gas present, fault and calibration cues to the operator. The MODE LCD is on

steady during normal operation to show that the sensor is functioning properly.

Monitored faults are: data memory failure, failed to calibrate and sensor removed.

Engineering specifications covering the sensor cell and control electronics are found in the

Appendix, Section 5.1.

full-scale gas concentration at the detector.

2

. This level equals 17.38 mA. As the oxygen level

2

Model TS420

E

D

L

O

A

M

C

DISPLAY

Figure 3 LCD Display Location

4

Page 16

3.0 Installation

3.1 Receipt of Equipment

All equipment shipped by General Monitors is packed in shock absorbing containers, which

provide considerable protection against physical damage. The contents should be carefully

removed and checked against the packing slip. If any damage has occurred or if there is any

discrepancy in the order, notify General Monitors as soon as possible. All subsequent

correspondence with General Monitors must specify the equipment part number and serial

number.

Each TS420 is thoroughly checked by the factory. However, a complete check-out and initial

calibration is necessary upon initial installation and start up to ensure system integrity.

3.2 Detector Location Considerations

There are no standard rules for detector placement since the optimum sensor location is

different for each application. The customer must evaluate conditions at the facility to make this

determination. Generally, the TS420 should be easily accessible for calibration checks. The

TS420 should be mounted pointing down to prevent water build-up on the detector head. The

detector assembly should not be placed where it may be coated by contaminating substances.

Although the Model TS420 is RFI resistant, it should not be mounted in close proximity to radio

transmitters or similar equipment.

Some general guidelines for sensor location:

! The TS420 should be used in locations that are tightly enclosed with poor or no

ventilation, such as utility tunnels or underground storage areas. These areas are likely

to have dangerously low oxygen concentrations.

! Observe the TS420’s environmental specifications when locating the unit.

The environmental specifications covering the electrochemical cell are found in the Appendix,

Section 5.1.4.

Detectors should be mounted in an area that is as free from wind, dust, water, shock and

vibration as possible.

WARNING - Operation above or below temperature limits will provide unstable readings, which

may cause false alarms or failure to alarm. See Section 5.1.4 for guidelines.

General Monitors discourages painting of detector assemblies. If the detector head is painted

over, the gas will not be able to diffuse into the sensor. If the TS420 body is painted over, the

LCD display cannot be read.

Model TS420

5

Page 17

3.3 Installation Instructions

The TS420 is shipped without the sensor installed. The sensor must be installed into the

detector and calibrated for proper operation. See Section 4.5 for installation instructions and

Section 4.3 for calibration instructions.

Once correctly installed, the TS420 requires little or no maintenance other than periodic

calibration checks to ensure system integrity. General Monitors recommends a calibration

check schedule be established and that the complete system, including all alarm circuitry, be

tested at least annually.

The overall and mounting dimensions for the TS420 (Figure 12) should be used when making

installation determinations. Mechanical specifications can be found in the Appendix, Section

5.1.2.

3.3.1 Intrinsically Safe Barriers

In order for the TS420 to be used with classified equipment inside of the hazardous area, it is

necessary for the customer to purchase either a Galvanic or Zener Diode Barrier, which should

be mounted in the non-classified area between the TS420 and the facilities’ control room. A list

of recommended manufacturers and part numbers follows for galvanic barriers:

Stahl - 9303/11-22-11 Elcon - mD323 or mD325

MTL - MTL7206 or MTL5041 Turck - mk33-Li-ExO

Pepperl+Fuchs - KFD2-CR-EX1.30-300

These are recommended active type barriers for intrinsically safe applications. Each application

is different and it is the ultimate decision of the user to determine the appropriate I/S barrier for

their application.

NOTE - To maintain intrinsic safety, wire length and gauge are limited by the capacitance and

inductance of the wire, Ci and Li of the TS420, and the barrier ratings. See Section 5.1.5 for

instructions on calculating these values.

Align the TS420 so that the LCD display is easily viewed. Teflon tape may be used on the

TS420’s threads.

3.3.2 Maintenance

The removal of particulate matter from sensor accessories may be done through the use of

clean water only. Solvents should not be used. The accessories should be thoroughly dried,

with compressed air if necessary, before refitting to the sensor body. Do not apply compressed

air directly to the sensor.

Some typical items to check during maintenance examinations are:

! The sensor mounting, to see it is secure.

! The sensor, to see it is clear of oil, water, dust or paint which might clog it.

! The cable connections for tightness and possible damage.

! All detector placements are up-to-date with the layout of the plant, e.g. modifications to

the plant.

! The complete system, to see it has a back up supply for the full-prescribed time.

Model TS420

6

Page 18

3.4 Wiring Connections

The two wires at the base of the TS420 provide a 4-20mA loop-powered output. The red wire

is the “loop +” lead and the white wire is the “loop -” lead (Figure 4). A third green/yellow wire is

provided for frame ground.

It is recommended that a two wire, shielded cable be used for making power and output signal

connections on the TS420.

Connect the green/yellow frame ground wire to the grounding terminal or lug inside the junction

box being used with the TS420.

Ensure the junction box frame is connected to frame ground or connected to the cable shield,

which is connected to frame ground at the controller.

Connect the red wire to the +24VDC terminal. Connect the white wire to the signal input

terminal on the readout/relay display module, FMD Field Mounted Display, S4100E smart

sensor, industrial analog to digital converter, computer-based monitor, PLC, DCS, etc.

Since the TS420 is designed to operate continuously, a power switch is not included, in order to

prevent accidental system shutdown.

NOTE - Power must remain disconnected until all wiring connections are made.

The absolute maximum distance between the TS420 and the power supply is 8000 feet (2438

meters). Depending on the application, general purpose or intrinsically safe, the cable length

will depend on the intrinsically safe barrier chosen and the cable used. See the Appendix,

Section 5.1.5, for the intrinsically safe system requirements. In addition, cable length

specifications can also be found in the Appendix, Section 5.1.3. In all cases, the cable run

should be as short as possible.

JUNCTION BOX

LOOP + (RED)

RED

CONTROL

ROOM

LOOP - (WHITE)

WHITE

GRN/YEL

Model TS420

TS420

Figure 4 Wiring Diagram

7

Page 19

4.0 Operation

4.1 Applying Power

Before applying power to the system for the first time, all wiring connections should be checked

for correctness. The sensor should be allowed to stabilize prior to calibration. The stabilization

time should be one (1) hour for all sensors.

Initial Power-up

The TS420 has been shipped un-calibrated, therefore, the first time power is applied, the

TS420 will enter Start-up mode (3.6mA) for a short interval, then may transition to fault mode

(flashing MODE LCD with the CAL LCD off and the analog output current at 3.5mA) until

calibrated (See Section 4.3 for Calibration Procedure).

After calibration is complete, the TS420 will proceed to Operate mode (17.38mA = 20.9% V/V

O

) where any detected oxygen will show as a proportional analog output current between 4

2

and 20mA (4mA = 0% V/V O

the CAL LCD off with normal atmosphere and both the MODE and CAL LCD's will flash when

oxygen deficiency is detected. (O

General Monitors recommends the TS420 be calibrated again within the first twenty-four (24)

hours after the initial calibration. Calibrations should be performed with new units and units that

have been off power for more than one (1) week. See “Calibration”, Section 4.3, for more

details.

Power-up After Initial Calibration

When the TS420 is powered up, after it has been previously calibrated, the unit will enter a

Start-up mode (3.6mA) for approximately 50 seconds, which allows the sensor to stabilize

before proceeding to the Operate mode (17.38mA). During Start-up, the MODE LCD will flash,

the CAL LCD will be off and the analog output current will be 3.6mA.

OPERATING MODES INDICATOR ANALOG OUTPUT

START-UP

OPERATE

AMBIENT O2 = 20.9%

DEFICIENT ATMOSPHERE, O2< 19%

FAULT

NO POWER

SYSTEM

, 20mA = 25% V/V O2). The MODE LCD will be on steady and

2

level < 19%).

2

CAL MODE

❏ ✹

❏ ■

1

✹ ✹

❏ ❏

❏ ✹

Model TS420

3.6mA

17.38mA

4.0-16.16mA

0.0mA

3.5mA

Figure 5 Operating Modes, Indicators and Outputs

1. Segment may flash Synchronously or alternating.

Perform a calibration and the TS420 will return to operate mode (17.38mA).

NOTE - The TS420 will not allow you to enter calibration mode during Start-up mode (3.6mA).

8

Page 20

4.2 Operating Modes

The TS420 has four distinct operating modes: Start-up, Normal Operation, Calibration and

Fault. The mode is indicated by both the analog output and the LCD display. See Figures 5

and 6.

4.3 Calibration

Activating the “CAL” switch will automatically disable the external alarm circuits by fixing the

analog output current to 3.75mA.

General Monitors recommends that the TS420 be calibrated within the first twenty-four (24)

hours after initial start-up, and that calibration be checked at least every ninety (90) days to

ensure the integrity of the system.

NOTE: A calibration check consists of applying a 20.9% V/V O

scale concentration of gas to the sensor and observing the reading on the display device being

used.

General Monitors is not implying that the customer should expect problems with sensor life or

stability. “Frequent” calibration checks merely ensure the integrity of the life protecting

equipment, and are recommended for problem environments (i.e. sensors accidentally being

painted over, etc, see Appendix 5.4).

A calibration schedule should be established and followed. A logbook should also be kept

showing calibration dates and dates of sensor replacement.

Calibration Procedure:

1. If it is suspected that the air is not at “normal” levels (20.9% O

calibrate the sensor with clean air. The 20.9% O

used. Apply the clean air source prior to entering calibration mode and allow the sensor to

stabilize for at least one (1) minute before proceeding.

2. Place the magnet over the GMI Logo on the body of the unit and hold it there until the “CAL”

LCD indicator appears, then remove the magnet. The analog output current will drop to

3.75mA.

4. The “CAL” and “MODE” LCD indicator will flash, indicating that the unit is now calibrating.

4. After approximately 30 seconds, the display will change from a flashing “CAL” and “MODE”

LCD to a solid “MODE” LCD, indicating that the calibration is complete and the unit has reentered “OPERATE” mode. Remove any calibration gas.

6. The unit is now calibrated and the new values have been stored in the NOVRAM (nonvolatile memory).

Figure 6 shows a flow diagram of the codes that will appear in the display window during the

calibration procedure.

If there is a problem and the TS420 cannot complete the calibration sequence, a fault indicator

will be displayed, and the analog output current will drop to 3.5mA.

gas cylinder (GMI P/N 1400262-11) can be

2

Model TS420

(“normal” ambient air) of full-

2

), it will be necessary to

2

9

Page 21

CALIBRATION INDICATOR

CAL MODE

Magnet Applied

Magnet Recognized

Cal Proceeding

Figure 6 Flow Diagram

NOTE - If the unit fails to calibrate a flashing “MODE” LCD will be displayed. The sensor must

see “clean” air for at least fifteen (15) minutes before a second calibration is attempted by

reapplying the magnet.

4.4 Calibration Equipment

General Monitors offers flow calibration kits as the method of introducing calibration gas to the

TS420. (See Section 5.5).

Calibration is performed with 20.9% V/V O

NOTE - When removing regulator from gas cylinders, open value on regulator to ensure that

gas is purged and pressure in the regulator is relieved. Be sure to follow this recommendation

when switching cylinders.

WARNING – Do not use a gas cylinder if the regulator gage shows the cylinder pressure in the

black area just above 0 psi. Unstable calibration could result.

If the TS420 is to be used with the optional Splash-Guard, all calibrations must

using the calibration cup (Figure 7) with the Splash-Guard installed onto the TS420. In addition,

all gas checks must be performed using the calibration cup with the Splash-Guard installed.

This performs two functions:

1. It provides a more accurate representation of the amount of gas getting to the sensor.

2. It checks that the Splash-Guard is not clogged and that gas can get to the sensor.

.

2

Model TS420

❑ ■

■ ❑

✹ ✹

be performed

Figure 7 Calibration Cup

If the Splash-Guard will not be used, the TS420 must be calibrated and gas checked with the

calibration plug (Figure 8)

Figure 8 Calibration Plug

10

Page 22

NOTE – Calibrating the TS420 in normal atmospheric air may introduce a considerable error

due to the affects of temperature and humidity. Ambient temperature and humidity can affect

the amount of oxygen in the atmosphere (see Figure 9).

21.00

20.50

Model TS420

20.00

% Oxygen

19.50

19.00

0 102030405060708090100

Relative Humidity (%)

0C

20C

40C

Figure 9 Change in % Oxygen in the atmosphere with Relative Humidity at constant Temperature

4.5 Sensor Replacement Procedure

The following is the procedure to replace a TS420 sensor.

IMPORTANT - Each sensor is shipped in a plastic bottle. DO NOT remove the sensor until you

are ready to apply power to the system. To ensure proper sensor response, each TS420 must

be calibrated in the field upon initial installation.

1. Unscrew the TS420 sensor cap.

2. Pull sensor out of the TS420 using your fingers. The sensor is a plug-in type, and the

sensor will have a snug fit.

NOTE - The TS420 output will drop to 3.5mA when the sensor is removed, indicating a fault

condition.

3. If the new sensor is in a plastic storage container, then remove lid ring and uncap jar.

Remove the sensor from the container. Save the storage container for later use.

Remove paper liner on sensor gasket if present.

11

Page 23

Model TS420

4. Examine the sensor and ensure that it is the correct gas type for your application.

5. Align the arrow on the sensor label with the notch on the TS420 body. Install the

sensor by pushing sensor’s pins into pin sockets on the TS420, see Figure 10.

Figure 10

CALIBRATION

CUP

Sensor Alignment

CALIBRATION

PLUG

Remove paper

liner from

gasket, if

present

12

Page 24

Model TS420

Figure 11, Calibration Kit with Bottle

6. Screw on TS420 sensor cap.

7. Apply power to the unit and allow the sensor to stabilize prior to initial calibration. The

stabilization time should be at least one (1) hour for all sensors.

8. Calibrate new sensor (see Section 4.3).

NOTE - The TS420 will stay in fault anytime the sensor is removed. Calibration is required to

reset the TS420.

4.6 Sensor Care and Maintenance

If power is removed from the TS420 for periods greater than one hour, the sensor should be

removed from the TS420 and placed in the original storage container shipped with the sensor.

Storage of the sensor in the original container guards against sensor contamination from

solvents, lubricant humidity, etc.

NOTE - Do not short the sensor pins.

In the case of long intervals of non-use, the sensors should be stored as described above in a

cool, dry place, preferably refrigerated between 0 and 20°C.

In all cases, after the sensor has been removed from the TS420, the cap should be replaced on

to the TS420 body and the gas port taped off to prevent any corrosion damage to the exposed

socket pins.

4.7 Fault Codes & The Remedies

The TS420 has self-diagnostics incorporated into the microprocessor program. If a fault is

detected, the output signal will drop to 3.5mA and the MODE LCD will be flashing to indicate

the fault.

When a calibration fault has occurred and has been corrected, the unit will stay in fault until it

has been successfully calibrated.

The Fault Codes are:

Fault (No Power): Neither LCD will be on. Output signal will be 0.0mA.

Remedy: Check wiring, ensure power is applied to unit.

Fault (System): The “MODE” LCD will be flashing. Output signal will be 3.5mA.

Remedy: Attempt recalibrating the detector. If the fault persists, replace the sensor and after

sensor has stabilized (one (1) hour minimum). Recalibrate. If fault still persists, contact factory

or your sales representative.

13

Page 25

5.0 Appendix

5.1 Specifications

5.1.1 System Specifications

Sensor Type:

Electrochemical cell

Typical Life (sensing element):

2 years in normal air

Warranty:

Two years for the electronics

One year for the sensor cell

Malfunctions Monitored:

Calibration Errors

Data Memory Errors

Measuring Range:

Oxygen 0-25% V/V O

Response Time:

T90 < 15 sec

Repeatability:

+ 1 % full scale

Approvals:

UL, CUL, CSA, CENELEC and CE approved.

NOTE - Not approved for use in atmospheres > 21%V/V O

5.1.2 Mechanical Specifications

Weight (approx.): 0.5 lbs. (0.23 kg)

Length: 4.5" (114 mm)

Diameter: 1.75"(44 mm)

Mounting: 3/4" NPT

Housing: Plastic

5.1.3 Electrical Specifications

Recommend two wire 14, 16 or 18 AWG shielded cable.

General Purpose Installations

Maximum distance between the TS420 and the power source @ 24VDC nominal (600 Ω load

resistor maximum) is 8000 feet (2438 meters).

Intrinsically Safe Installations

See Sections 5.1.5 through 5.1.7.

2

Model TS420

.

2

14

Page 26

Intrinsically Safe Parameters

U

/V

= 35VDC

i

MAX

I

/I

= 100mA

i

MAX

C

= 0

i

L

= 500 µH

i

Input Power:

10 to 35VDC range; 3.5 to 22mA loop powered

Output Current:

(600 Ω max. @ 24VDC) (120 Ω max. @ 10VDC)

Signal Range 3.5 to 22mA

Fault 3.5mA

Start-up 3.6mA

Calibration 3.75mA

Detection Range 4 to 20mA

Over-range 22mA

Electrical Classification:

Class I, Divisions 1 & 2, Groups A, B, C & D;

Class I, Zone 0, AEx ia IIC T6; EX ia IIC T6; Eex ia IIC T6

Class II, Groups E, F & G,

Class III,

IP67, Type 4X

RFI/EMI Protection:

Complies with EN50081-2, EN50082-2

Status Indicator:

Liquid Crystal Display with Normal, Fault, and Calibration cues

5.1.4 Environmental Specifications

Operating Temperature Range:

-4°F to +122°F (-20°C to +50°C)

Storage Temperature Range:

-4°F to +122°F (-20°C to +50°C)

Humidity Range:

0 to 99% relative humidity non-condensing

Pressure Range:

Atmosphere ± 10%

Model TS420

15

Page 27

Model TS420

5.1.5 Intrinsically Safe System Requirements

NOTE - Refer to control drawing 45217 Rev A. (Section 5.2.2)

The TS420 is approved as intrinsically safe on its own (entity approved). However, when

installing the TS420 into a system, there are requirements, which must be strictly followed to

maintain the intrinsic safety of the system. These requirements are:

1. U

2. I

i/IMAX

3. The inductance of the cable and the TS420 (L

inductance rating (La).

4. The capacitance of the cable and the TS420 (C

capacitance rating (Ca).

To calculate maximum cable length, use the following formulas, and use the shorter of the two

calculations.

Capacitance:

Max. Cable Length = C

Inductance:

Max. Cable Length = L

5.1.6 Sample Calculation

What is the maximum allowable cable length when using an MTL 7206 barrier and BELDEN

8760 2-conductor shielded cable?

BELDEN 8760 Parameters: C/ft = 24 pF/ft, L/ft: not available

MTL 7206

C

L

U

I

MAX

MAX

i/VMAX

i/IMAX

1. U

35VDC ≤ 35VDC

2. Ii/IMAX (TS420) ≥ Ii/IMAX (MTL 7206)

100mA 93mA

3. Cable inductance not available.

4. Max. cable length = C

= 0.12µf - 0µf

Max. Cable length = 5000 feet

of the field device (TS420) must be less than or equal to U

i/VMAX

of the field device (TS420) must be greater than or equal to I

) must be less than the barrier’s maximum

i

) must be less than the barrier’s maximum

i

(Barrier) - Ci(TS420) (ft)

MAX

Wire Capacitance/Ft

(Barrier - Li(TS420) (ft)

MAX

Wire Inductance/Ft

: TS420:

= 0.12 µf Ci = 0 µf

= 4.0 mH Li = 500 µH

= 35V Ui/V

= 93mA Ii/I

/VMAX (TS420) ≤ Ui/VMAX (MTL 7206)

i

(MTL 7206) - Ci (TS420)

MAX

= 35V

MAX

= 100mA

MAX

C/L (Belden 8760)

24pF/ft

of barrier.

MAX

of the barrier.

MAX

16

Page 28

A

5.2 Engineering Documentation

5.2.1 Outline & Dimensional Drawing

Model TS420

LOOP+ (RED)

LOOP- (WHITE)

FRAME GROUND

(GREEN/YELLOW)

3/4 NPT

Y

L

N

O

N

E

T

H

G

I

T

D

N

A

H

4.50"

E

D

L

O

A

M

C

L

S

A

R

R

O

E

T

I

N

N

E

Figure 12 Outline and Dimensional Drawing

Ø1.75"

1 1/2-20 UN-2

17

Page 29

5.2.2 Control Drawing

Model TS420

Figure 13 Control Drawing

18

Page 30

5.2.3 Sample Installation

Y

N

T

1

S

O

-

P

I

S

0

T

N

A

6

C

1

"

X

5

4

N

/

4

O

3

U

J

B

R

O

S

O

T

N

N

E

E

S

E

R

G

D

E

R

K

C

A

L

B

E

T

I

H

W

H

T

R

A

E

S

A

R

m

A

V

O

0

5

0

G

0

T

3

2

1

F

C

=

4

C

u

=

I

E

S

T

0

x

x

a

T

X

=

a

m

i

E

O

m

V

I

C

D

T

A

E

R

A

S

)

N

U

O

I

O

T

A

D

C

R

O

L

A

S

U

Z

O

A

D

R

H

A

Z

C

A

I

H

I

(

P

U

O

R

G

L

L

A

W

)

N

O

I

T

A

A

C

O

E

L

R

S

U

A

O

D

E

R

F

A

Z

A

A

H

S

N

O

N

(

R

E

I

R

R

A

B

C

G

N

I

M

D

D

T

E

A

N

P

L

E

.

C

Y

M

D

L

T

U

A

R

N

T

T

D

E

S

O

N

M

A

C

I

O

L

D

2

T

L

C

E

N

E

I

F

O

L

I

R

T

O

A

A

T

C

T

E

S

B

N

E

G

x

N

N

I

7

M

O

T

C

T

3

I

G

L

4

F

A

2

E

W

C

I

7

L

A

R

B

2

T

A

4

C

C

N

1

E

L

A

E

I

E

V

:

D

E

L

T

E

O

N

B

S

U

B

S

E

D

L

B

N

I

G

A

H

N

C

-

I

E

5

T

S

8

T

I

2

U

F

C

O

M

R

T

C

T

G

S

E

N

L

I

D

T

U

N

I

T

D

I

H

F

-

N

E

O

G

S

C

N

U

I

1

O

L

2

S

R

A

Y

C

E

S

E

F

u

H

A

3

V

m

1

m

5

.

2

.

3

3

0

4

9

=

+

T

7

0

N

7

U

L

H

T

S

M

=

R

=

=

x

x

E

I

R

R

A

B

x

x

a

a

a

a

m

m

m

m

V

L

I

C

R

E

I

F

I

A

L

2

P

0

5

M

A

A

T

P

I

R

T

S

I

S

T

S

U

A

P

H

N

R

I

C

E

Y

O

W

R

R

O

W

E

A

P

T

O

R

E

Z

Y

W

M

I

L

O

P

R

P

P

P

c

U

d

S

V

8

2

Model TS420

H

u

0

0

5

=

i

L

0

t

f

2

6

4

1

S

4

T

5

L

=

A

)

t

f

N

/

R

F

E

p

4

T

2

N

(

I

/

-

)

F

)

u

x

0

a

-

m

F

C

(

u

3

E

1

T

.

C

0

O

(

N

O

A

=

F

T

E

I

R

C

C

E

N

A

P

A

P

T

E

A

I

C

C

C

N

A

R

A

P

E

I

T

A

I

R

C

C

R

A

N

A

P

O

B

A

D

X

C

E

A

E

S

R

M

A

I

B

=

W

M

E

T

S

Y

S

E

D

O

R

T

C

E

L

E

G

N

I

D

N

U

O

R

G

E

D

O

R

T

C

E

L

E

G

N

I

D

N

U

O

R

G

/

H

H

)

T

T

)

i

G

G

C

N

N

(

E

E

E

L

L

C

E

E

N

L

L

A

B

B

T

I

A

A

C

C

C

A

X

X

P

A

A

A

M

M

C

T

N

E

V

5

R

.

R

4

1

U

=

C

0

X

3

)

A

A

M

m

T

2

2

A

(

-

E

)

G

V

A

1

.

T

2

L

+

O

0

V

A

5

)

E

m

H

V

3

A

C

I

m

F

5

9

m

2

u

3

V

.

R

E

I

R

R

A

B

x

a

m

V

=

V

5

3

0

2

4

S

T

x

a

m

V

2

R

3

4

E

2

1

E

(

.

I

D

(

R

0

R

-

E

D

I

)

R

R

L

R

E

V

A

I

E

R

5

I

B

.

R

F

A

1

x

R

+

B

a

<

A

0

x

m

B

I

7

a

E

3

x

G

>

m

)

a

L

A

A

A

m

T

<

m

m

C

L

2

0

H

2

<

O

0

(

u

(

1

V

F

0

-

u

0

0

0

0

5

2

2

V

4

4

0

0

8

S

2

S

2

2

4

4

T

T

<

S

S

x

N

T

T

a

V

I

i

i

0

m

M

L

I

C

1

5

9

9

1

-

R

6

.

E

2

P

1

P

G

R

N

-

I

A

R

S

I

I

/

I

W

S

N

A

Figure 14 Sample Installation

19

Page 31

5.2.4 Junction Boxes

Model TS420

Figure 15 10252 Round Aluminum Junction Box

1

8

9

0

5

4

6

7

C

C

C

A

L

4

B

B

2

U

U

0

S

S

m

S

S

A

+

-

1

2

3

C

+

F

2

G

O

4

M

V

Figure 16 31305-2 Aluminum Junction Box

20

Page 32

Model TS420

Figure 17 45160-1 Plastic Junction Box, NPT; 45160-2 Plastic Junction Box, M20

5.2.5 Splash-Guard

Figure 18 70631-2 Splash - Guard

21

Page 33

Model TS420

5.2.6 Accessories

Figure 19 45170-1 Flow Block Figure 20 45147-1 Flow Block Retainer

5.2.7 Calibration Accessories

Figure 21 914-152 Calibration Plug

Figure 22 1400152-1 Calibration Cup

22

Page 34

5.3 Ordering Information

TS420 - 3 0 0 - 101 - 1 0

Junction Box:

0 = None

1 = 45160-1 Junction Box – Plastic NPT

3 = 10252 Junction Box – Round, Aluminum

Model TS420

23

Page 35

5.4 Calibration Schedule for Problem Environments

Detector Serial Number:________________________ Location:_____________________

1) Installation and preliminary calibration. Record date after preliminary calibration is

performed:

Date:_______________

2) 24-hour calibration. Record date after 24-hour calibration is performed:

Date:_______________

3) 7 day calibration check (Record date and reading of calibration check. Repeat after 7

days if reading deviates more than ±10%. Otherwise go to step 4).

Date Reading Date Reading Date Reading

________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________

4) 14 day calibration check (Record date and reading of calibration check. Repeat after

14 days if reading deviates more than ±10%. Otherwise go to step 5).

Date Reading Date Reading Date Reading

________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________

5) 30 day calibration check (Record date and reading of calibration check. Repeat after

30 days if reading deviates more than ±10%. Otherwise go to step 6).

Date Reading Date Reading Date Reading

________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________

6) 60 day calibration check (Record date and reading of calibration check. Repeat after

60 days if reading deviates more than ±10%. Otherwise go to step 7).

Date Reading Date Reading Date Reading

________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________

7) 90 day calibration check:

Date Reading Date Reading Date Reading

________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________

________ ________ ________ ________ ________ ________

Model TS420

24

Page 36

5.5 Spare Parts & Accessories

TS420 Spare Parts

The Model TS420 has potted electronics, therefore, there are no replacement boards available

for this unit. The part numbers of the TS420 itself are:

TS420

Oxygen Deficiency 45200-1

Sensor Cap 45103-1

Replacement Sensors

Oxygen Deficiency Sensor 45213-1

TS420 Mounting Accessories

Splash-Guard (Standard) 70631-2

Flow Block (Incl. Ret./Cal Plug) 45170-1

Retainer, Flow Block 45147-1

Alum. Junction Box (Small) 10252

Alum. Junction Box (Large) 31305-2

Plastic Junction Box (3/4” NPT) 45160-1

Plastic Junction Box (M20) 45160-2

Cable Grip 961-008

¾” NPT, Adapter, Plastic 961-009

¾” NPT Adapter, Steel 961-007

20 mm x ¾” NPT Adapter, Brass 961-006

TS420 Calibration Accessories

Tubing 931-085

Regulator (500ml/Min) 922-023

Calibration Plug 914-152

Calibration Cup 1400152-1

Calibration Kits (cylinder, regulator & tubing)

O2 20.9% 1400263-11

Spare Cylinders

O2 20.9% 1400262-11

Model TS420

25

Loading...

Loading...