Page 1

Application Manual

General Motors

Powertrain Group

Gasoline 4.3L

V6 90 Degree

2001 Model Year

Page 2

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

ENGINE

APPLICATION MANUAL

Gasoline 4.3L V6 90 Degree

Engines RPO : L35

Model Year: 2001

General Motors Powertrain Group

895 Joslyn Ave

MC: 480-710-225

Pontiac MI 48340

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

i

Page 3

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

1 . 0 INTRODUCTION

This manual assists the reader in the application of the 4.3L V6 90 Degree family of engines to

Transportation Vehicles, Marine and Industrial applications. It gives an overview of the engine, its

features, and systems. Details are provided on typical interfaces between the engine, related

subsystems, and the vehicle.

Caution:

The performance of the engine is dependent on the specific application. It is recommended that the

owner of this document be contacted before specific application decisions are made.

2 . 0 PRODUCT SUMMARY

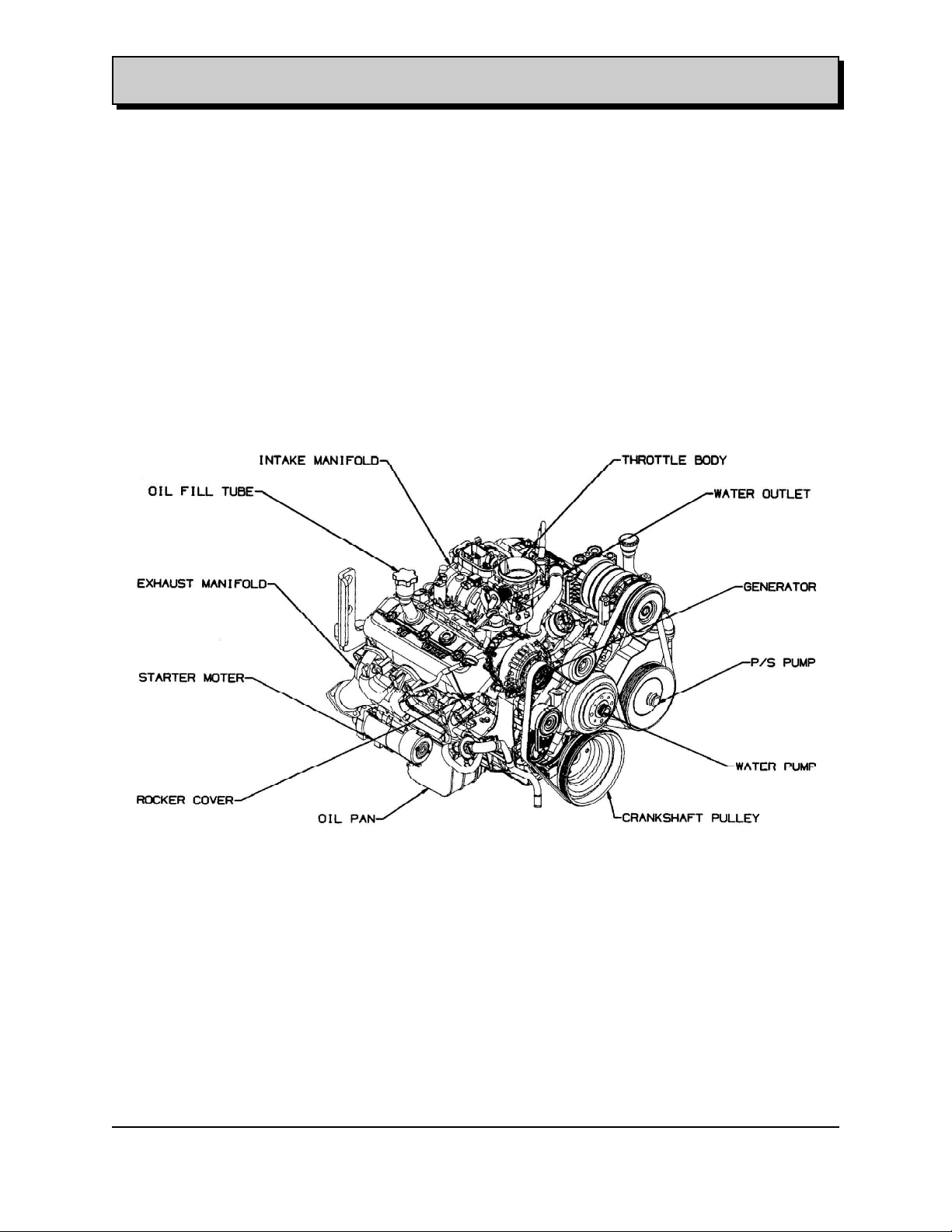

2 .1 APPEARANCE

The figure 2.1-I shows the 4.3L V6 90 Degree Engine.

L35 Isometric View

Figure: 2.1-I

2 . 2 FEATURES

The model year 2001 for 4.3L V6 90 Degree Engine has one version: L35.

This Engine has specific values of power and torque, which allow for a very wide range of

application up to 15000 Lbs. GVW.

The more distinctive common features of this family of engines are:

-Optimized Intake Manifold

-Stiff Oil Sump

-High reliability and durability

-OBDII compliant

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

1

Page 4

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

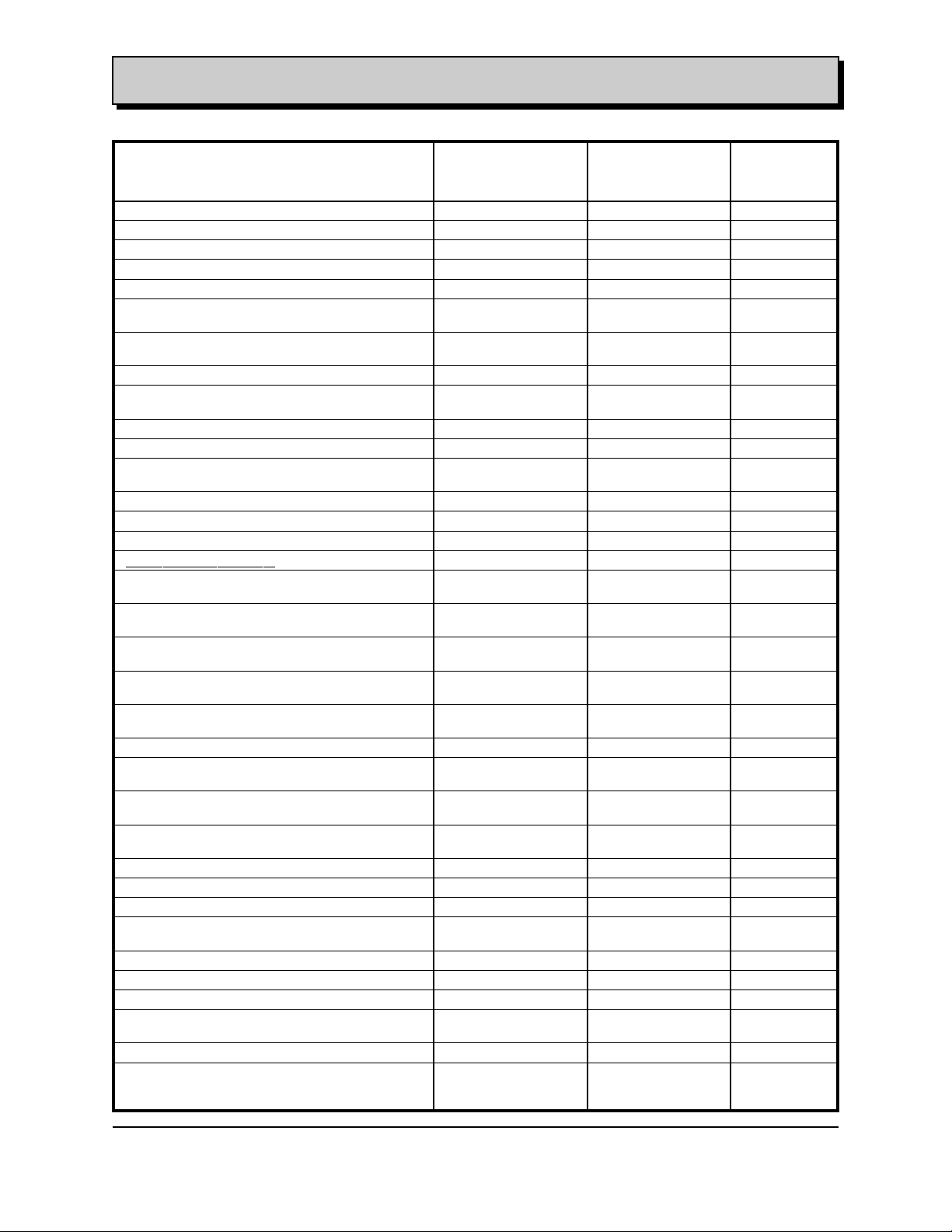

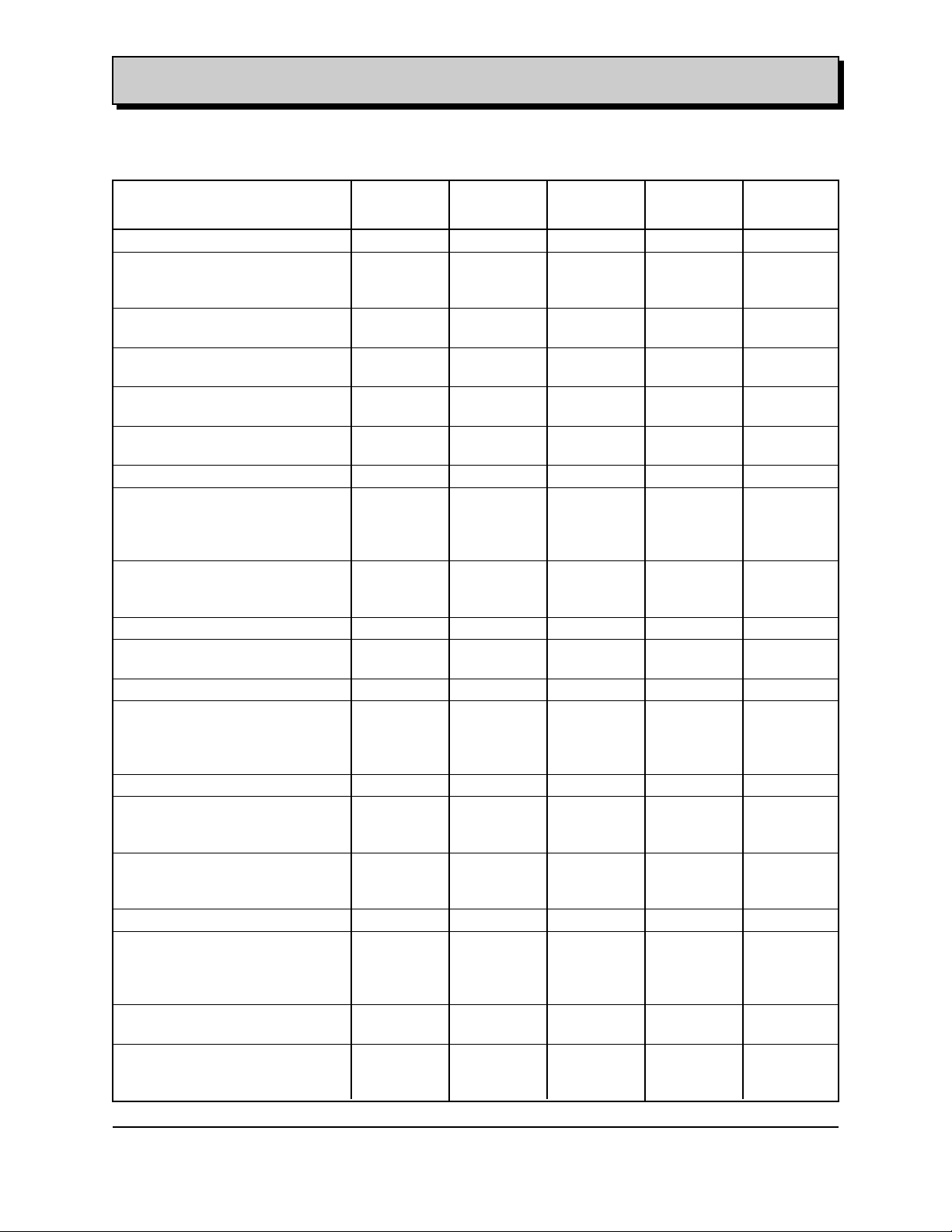

2 . 3 PRODUCT SPECIFICATION SUMMARY

2.3.1 SPECIFICATION

ENGINE L35 L35 UNITS

Truck Application Marine

Application

PERFORMANCE

Rated Power 200 223 hp

Rate Power Speed 4600 4800 rpm

Rated Torque 260 275 Lb. ft

Rated Torque Speed 2800 3800 rpm

Torque Extension Speed Range

(From Peak Torque to Peak Power) 1800 1000 rpm

Exhaust Restriction at Rated Power 8.85 to 8.58 0 in hg

(Better than) @ 4600 rpm Piezometer

Inlet Restriction at Rated Power w/Filter -0.89 0 in hg

Redline Speed 5000 5000 rpm

Fuel Cut-Off Speed, Nominal Conditions 5200 5200 rpm

Fuel Cut-Off Speed, Cold Conditions 5200 5200 rpm

Maximum Upshift Speed 5100 Man - 5200 Auto N/A rpm

Minimum Idle Speed 525 650 rpm

Minimum Unassisted Start Temperature -20 -20 Degree C

PHYSICAL/CONTENT

Type: 4 Cycle 4 Cycle

Service Type Naturally Aspirated Naturally Aspirated

Configuration: V V

Bank Angle: 90 90 Degree

Number of Cylinders: 6 6

Valvetrain Configuration: OHV OHV

Number of Valves per Cylinder: 2 2

Displacement: 4302 4302 cc.cm

Bore: 101.6 101.6 mm

Stroke: 88.4 88.4 mm

Compression Ratio: 9.4:1 9.4:1

Firing Order: 1-6-5-4-3-2 1-6-5-4-3-2

Rotational Direction: CW CW

Fuel Injection Pump Electronic Electronic

Certification Federal & California N/A

Engine Mass 200 200 Kg

Spark Plugs 41-932 (0.060”) 41-932 (0.060”)

Oil Filter PF-52 PF-52

Controller Electronic Electronic

SubSystems

Air Intake Subsystem

Throttle Body Type SCPI SCPI

Max Air Flow Rate: 158@ 4600 rpm 158@ 4600 rpm Gr/sec

Intake manifold : Symmetrical Runner Symmetrical Runner

Lower Intake: Aluminum Aluminum

Upper Intake: Composite Composite

@ 4600 rpm Piezometer

(-40) (-40)

Sequential Central Sequential Central

Port Injection Port Injection

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

2

Page 5

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

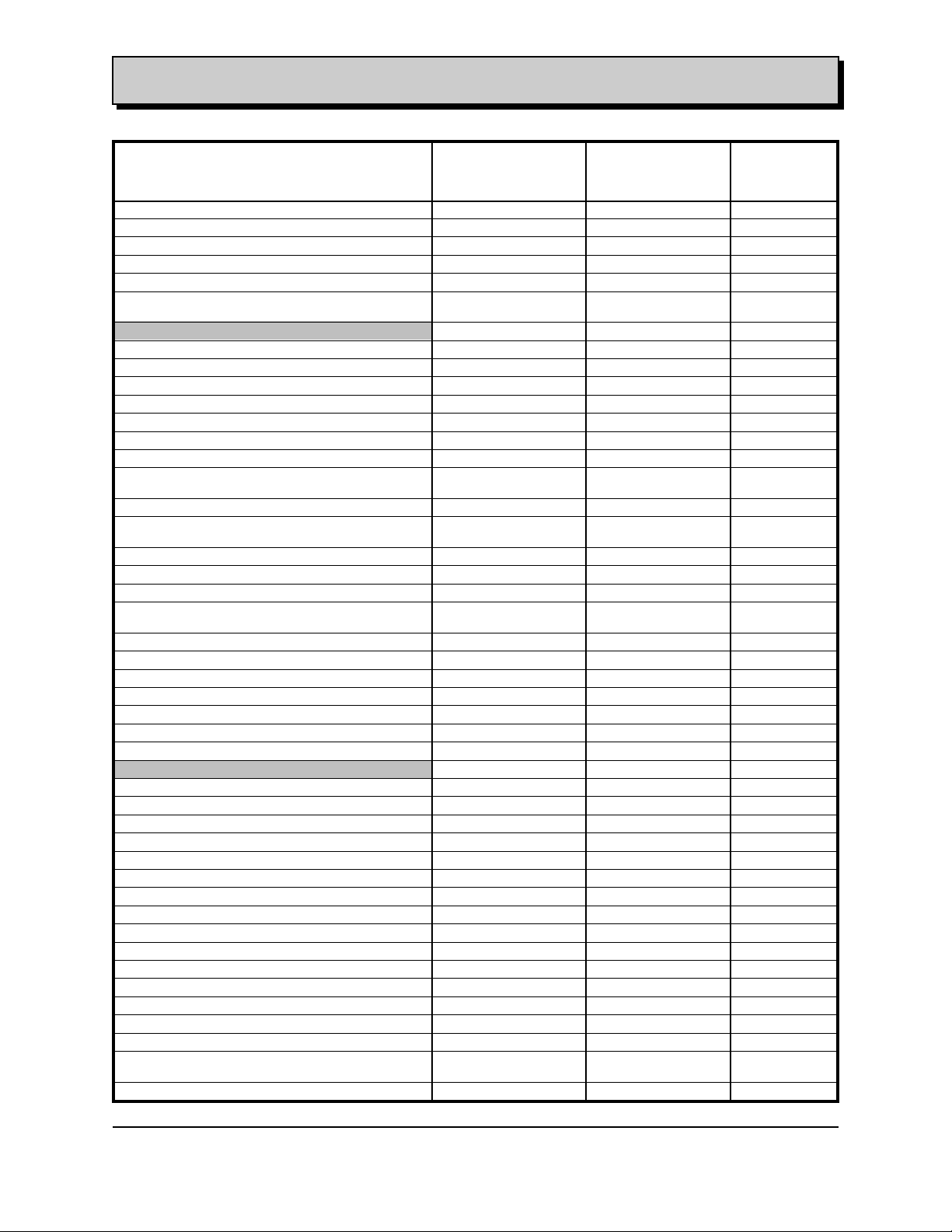

ENGINE L35 L35 UNITS

Truck Application Marine

Application

Cylinder Head Subsystem

Cylinder Head

Material Cast-Iron Cast-Iron

Cylinder Head Type: OHV OHV

Valves Actuation: Push Rod Push Rod

Rocker Arm Ratio 1.5:1 1.5:1

Valve Train

Valves per Cylinder: 2 2

Valves Angle from Vertical: 15 15 Degree

Lifters - Type Hydraulic Roller Hydraulic Roller

Valve Guides Cast Iron Cast Iron

Intake Valves

Material 1541 Steel 1541 Steel

Head Diameter 49.3 49.3 mm

Stem Diameter 7.965 7.965 mm

Length 123.68 123.68 mm

Seats 45 Degree 45 Degree

Lift 11.2 11.2 mm

Exhaust Valves

Material 21 - 4N 21 - 4N

3140 Welded Tip 3140 Welded Tip

Head Diameter 38.1 38.1 mm

Stem Diameter 7.965 7.965 mm

Length 124.84 124.84

Seats 45 Degree 45 Degree

Lift 11.0 11.0 mm

Main Block Subsystem

Block Assembly:

Material Cast-Iron Cast-Iron

Cylinders Cast Iron Cast Iron

Lower Structure Four main bearing Four main bearing

Bore Spacing 111.76 111.76 mm

Deck Height 234.7 234.7 mm

Connecting rods:

Material - Forged-SAE 1141 Forged-SAE 1141

Length - 154.9 154.9 mm

Bolts 9 9 mm

Bearings Aluminum Tin Aluminum Tin

Rod Length to Stroke Ratio 1.68:1 1.68:1

Piston

Type - Strutless Strutless Cam Turned

Material - Eutectic Cast Eutectic Cast

Weight 437 437 Gr

GM232-M GM232-M

Stainless Steel with Stainless Steel with

GM232-M GM232-M

Supports Supports

Silicon Alloy Silicon Alloy

Flat Top Flat Top

Aluminum Alloy Aluminum Alloy

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

3

Page 6

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

ENGINE L35 L35 UNITS

Truck Application Marine

Application

Piston Pins

Type - Fixed 24X70 Fixed 24X70 mm

Material - Steel SAE 1019 Steel SAE 1019

Piston Rings

Compression Rings Number: 2 2

Top Compression Steel Barrel Steel Barrel

Second Compression Cast Iron Cast Iron

Oil Control Rings Number - 1 1

Type - Low Tension Low Tension

Material - Plated Steel Plated Steel

Camshaft

Material - 5150 5150

Description Gun Drilled Gun Drilled

Base Circle Diameter: 39.4 39.4 Mm

Drive Chain Pitch Roller 3/8 3/8

Camshaft Valve Timing:

Intake Valve........Opens -33 -33 Crk Degree

Closes 286 286 Crk Degree

Exhaust Valve.....Opens -271 -271 Crk Degree

Closes 48 48 Crk Degree

Camshaft Bearings Steel Backed Steel Backed

Valve Springs

Material Super Clean Super Clean

Type Double Shot Double Shot

Dimension 4.6 mm 4.6 mm

Closed (Valve Closed) 356 356 Newtons

Open (Rate) 65 65 Newtons/mm

Crankshaft

Material - Cast Nodular Cast Nodular

Number of Counterweights 6 6

Main Journal Diameter - 62.2 62.2 Mm

Crank Pin Journal Diameter 57.1 57.1 Mm

Bearings Aluminum Tin Aluminum Tin

Torsional Damper Ring Inertia Ring Inertia Rubber Mounted

Crankcase Ventilation Negative Closed Negative Closed

1.5mm 1.5mm

1.5 mm 1.5 mm

3 Pieces 3 Pieces

Steel Billet Steel Billet

BTDC BTDC

ATDC ATDC

BTDC BTDC

TDC TDC

Copper/Lead Copper/Lead

Cr-Si Cr-Si

Peened Peened

Round Round

Undercut Rolled Fillet Undercut Rolled Fillet

Silicon Alloy Silicon Alloy

(Vacuum created from (Vacuum created from

Intake Manifold) Intake Manifold)

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

4

Page 7

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

ENGINE L35 L35 UNITS

Truck Application Marine

Application

Balance Shaft

Type First Order First Order

Material Nodular Cast Nodular Cast

Rotation CCW CCW

Speed Same as Crank. Same as Crank.

Drive Helical Gear 14 ° Helical Gear 14 °

Oil Lubrication

Main and Rod Bearings Pressure Pressure N/a

Camshaft Pressure Pressure N/a

Timing Gear Splash Splash N/a

Connecting Rods Pressure Pressure N/a

Valve Mechanism Pressure Pressure N/a

Cylinder Walls Splash Splash N/a

Piston & Pins Splash Splash N/a

Cylinder Head Hollow Hollow N/a

Oil Capacity

Oil 5W-30W 5W-30W N/a

W/ Filter 4.5 4.5 Qts

W/o Filter 4.0 4.0 Qts

Oil Filter

Type Full Flow Full Flow N/a

Capacity 0.3 0.3 Qts

Oil Pump

Type Spur Gear Spur Gear N/a

Normal Pressure 40-45 psi 40-45 psi @ 2000 RPM

Idle Pressure 20-25 psi 20-25 psi @ Idle

Oil Flow @ 1000 RPM 2 2 GPM

Drive Camshaft Camshaft N/a

Fuel Injection System

Mean Features

Injection Pump Make Delphi Delphi

Type Top Feed Top Feed

Model SCFI SCFI

Injection Timing Sequential Sequential

Operating Pressure 425 +/- 9 425 +/- 9 KPa

Opening Pressure 285 +/- 9 285 +/- 9 KPa

Fuel Pump

Fuel Pump Make Delphi Delphi

Type 44MM -G-Rotor 44MM –G-Rotor

Minimum Fuel Flow 25 25 Gram/Sec

Maximum Fuel Flow TBD TBD Gram/Sec

Fuel Pump Voltage Range 6-12 6-12 Volts

Fuel Pump Pressure 425 425 Kpa

Fuel Filter Delphi Delphi

Type Full Full

Material Nylon 66 Nylon 66

Off Cam Off Cam

Push Rod Push Rod

Mineral Mineral

PF-47 PF-47

Recirculation Recirculation

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

5

Page 8

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

ENGINE L35 L35 UNITS

Truck Application Marine

Application

Regulator Delphi Delphi

Nominal Pressure 425 425 Kpa

Injectors Delphi Delphi

Recommended Fuel 87 87 Octane = (R+M)/2

Water Pump Type: Centrifugal Centrifugal

Water Pump Maximum Flow @ Engine RPM: 76.5 76.5 GPM @ 4600

Maximum Sustained Coolant Temperature: 262 262 F

Thermostat Setting

Starts to Open 180 180 F

Full Open 262 262 F

Bearing Type Ball/Roller Ball/Roller

Impeller Material Cast iron Cast iron

Housing Material Cast iron Cast iron

By Pass Recirculation Type External External

Water Jackets full length of Cylinder Yes Yes

Water Jackets all around Cylinder Yes Yes

Water Jackets open at head face No No

Surge Tank System No No

Coolant Fill LocationDeaeration Tank Deaeration Tank

Circulation Thermostat Type Bypass Bypass

- direction of rotation : CCW CCW

- drive ratio (relative to crankshaft) 1.25 1.25

Cartridge Cartridge

RPM

2.3.2 Fuel Requirements

The 4.3L V6 90 Degree Engine System meets the emissions standard established in the FMVS

and EPA regulations with fuel quality in accordance with the API standards.

The engine must operate on the following types of fuels:

Unleaded Gasoline 87 (R+M)/2 (ASTM D4814),

Unleaded Gasoline 87 (R+M)/2 with up 15 % MTBE (Methyl Tertiary-Butyl Ether),

Canadian Gasoline 87 (R+M)/2 (CGSB 3.5-92) w/ MMT @ 18 mg/L manganese,

Reformulated Gasoline,

Premium Unleaded 91 (R+M)/2,

Export Gasoline as low as 80 (R+M)/2,

South American Gasoline with Peroxide contamination to 2.5%

Methanol mixes with gasoline to 15 %,

Ethanol mixes with gasoline to 25 %, Brazilian fuel system (SCPI) required.

Leaded Gasoline. Special cylinder heads required- NM8

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

6

Page 9

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

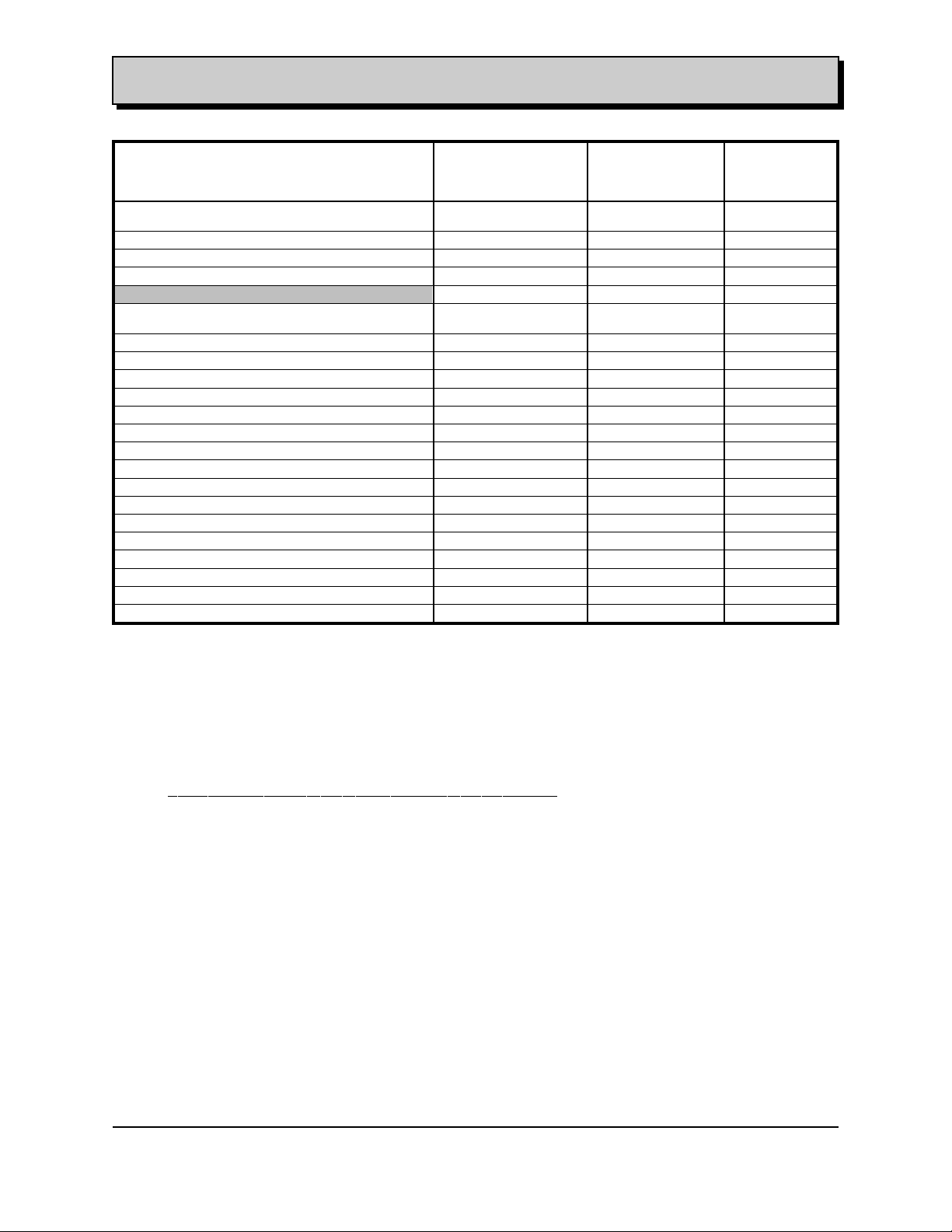

2. 3 . 2 Performance

2.3.2.1 Engine Power & Torque

The performance of the 4.3L V6 Engine is specified in the following paragraphs.

The Fig 2.3.2.1-I shows the following performance characteristics for the L35 engine: Power,

Torque and Speed Range.

The engine will deliver the power and torque levels within +/-5% (after run in) as shown in

Table 2.3.2-I.

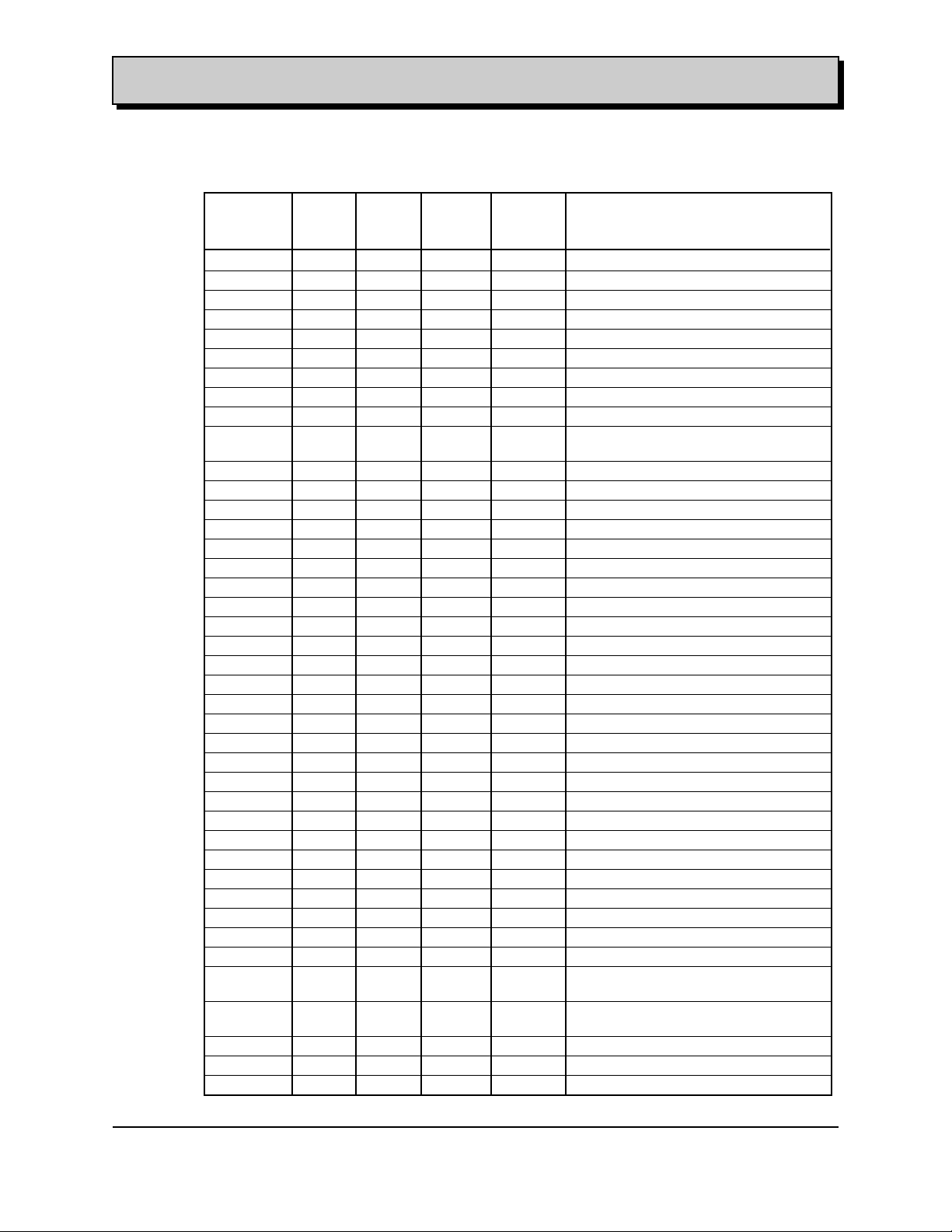

RPM Truck Marine Industrial Notes

Applications Applications Applications

Power Torque Power Torque Power Torque

HP Lbs.-ft HP Lbs.-ft HP Lbs.-ft

800 32.4 210.4 35.7 233.5 N/A N/A

1200 50.7 221.9 57.0 248.6 35 200

1600 72.6 238.1 78.7 257.7 60 210

2000 93.8 246.1 99.1 260.2 80 220

2400 116.3 254.3 120.3 262.5 105 230

2800 137.9 258.2 143.4 269.1 118 220

3200 157.5 257.9 166.4 272.7 120 210

3600 174.7 254.4 188.2 274.1 119 200

4000 188.5 247.1 206.2 270.2 118 190

4400 195.8 233.0 217.6 259.5 N/A N/A

4600 198.1 226 220.8 252.0 N/A N/A

4800 197.8 216.3 221.6 242.3 N/A N/A

5200 192.3 194.2 216.0 218.0 N/A N/A

Fig 2.3.2.1 -I 4.3L V6 Engine Power & Torque

Test Conditions for Truck Applications

* Based on the following conditions (measured at maximum rated speed W.O.T):

-Exhaust restriction 8.5” of Hg

-Air Intake temperature 77° F

-Intake restriction - 1” of Hg

-SAE J1349

Test Conditions for Marine & Industrial Applications

* Based on the following conditions (measured at maximum rated speed W.O.T):

-Exhaust restriction: 0 of Hg

- Air Intake temperature: 77 ° F

-Intake restriction - 1” of Hg

-GMPT Test #20

-This data reflects the Maximum values obtained with Different Intakes Manifolds & Fuel

Systems

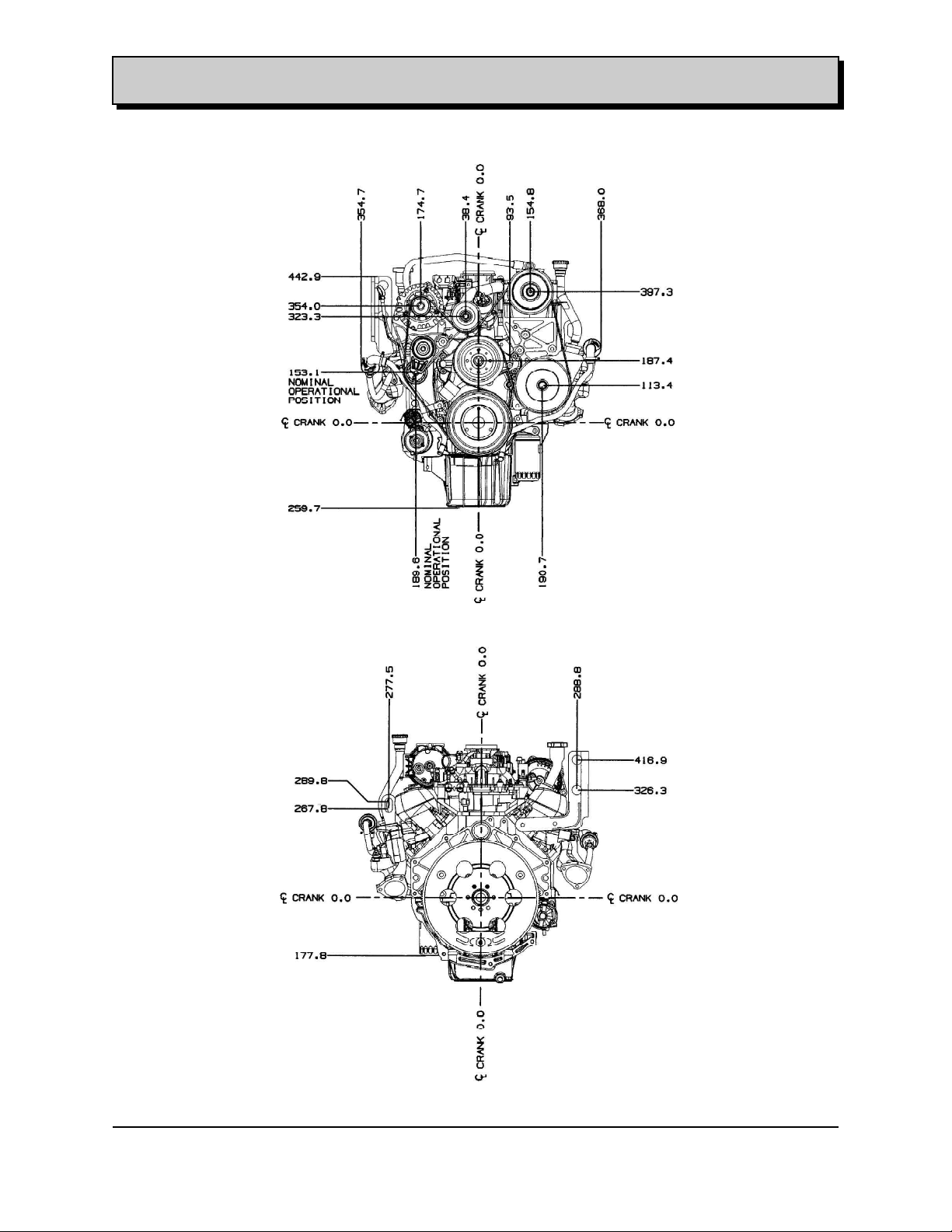

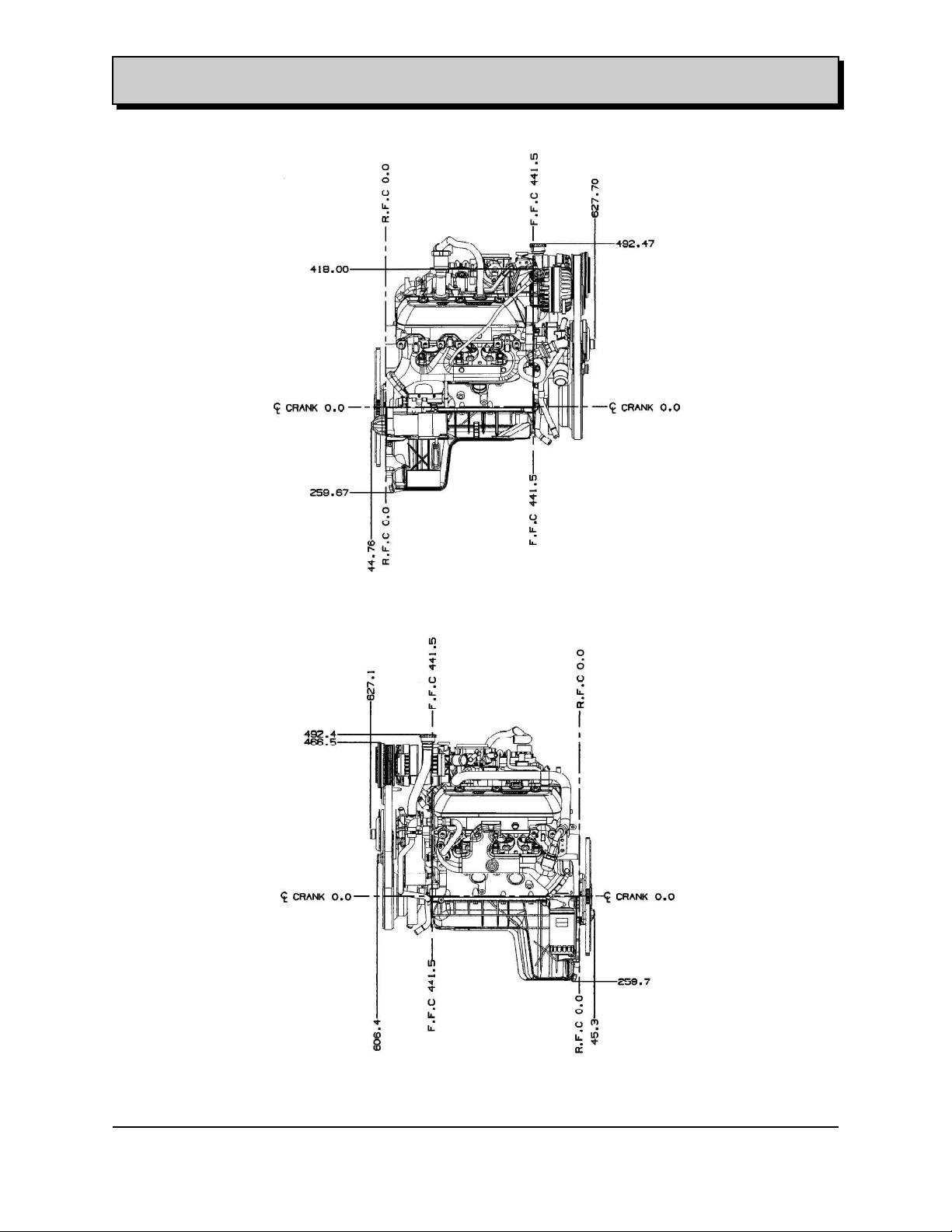

2 . 4 FEATURE LOCATION ILLUSTRATIONS

Front, Rear, Rh and Lh views of the 4.3L V6 90 Degree are included here with its overall dimensions

for preliminary packaging evaluations.

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

7

Page 10

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

L35 Main Views

L35 Front View

L35 Rear View

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

8

Page 11

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

L35 RH Side View

L35 LH Side View

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

9

Page 12

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

2 . 5 CONFIGURATION AS SHIPPED

2. 5 . 1 Engine as Shipped

Engine as shipped from the engine plant is to conform to a common state of dress as described

below. The following components are installed at the engine plant:

Harmonic balancer Crankshaft sensor

Direct drive accessories (not belt driven) E.G.R. system

Engine lift brackets Engine oil

Engine oil dipstick and tube Exhaust manifold(s)

Exhaust manifold heat shields (As required) Engine Fuel system

Heater hose nipples Coolant temperature sensor/switch

Manifold air pressure sensor Oil pressure sensor/switch

Oil filter (except remote mounted) Transmission alignment dowels

Water pump Flywheel and or Flexplate

Crankcase ventilation system

2 . 6 IDENTIFICATION AND MARKING

2.6.1 VIN Identification Labeling

There are two places for the stamping of the V.I.N.: one is provided side by side on the left hand

side of powertrain and the other is in rear face of cylinder case.

2.6.2 Emissions Certification Labeling

A vehicle emission control label that meets the format and content requirements of Federal

Regulation 40 CRF 86.095-35 and CARB Regulation Title XIII California Code of Regulations

Section 1965 shall be attached to the vehicle subsystem in the location required by the

regulations above.

Incomplete Vehicles manufactured in two or more stages shall meet the certification labeling

requirements of the regulations above.

Emissions Certification is not provided for Marine Industrial Applications.

2.6.3 Engine Identification - Broadcast Codes

The 4.3L V6 Engine has an identification number cast into the cylinder case front LH side.

Also, an Engine Verification Label is applied to the rear of the left bank cylinder head. This is the

single label location for passenger car engines. In addition to the LH rear head location, the

truck engines have another identical label applied to the oil pan (near the bottom of the engine)

on the right side.

The labels show the following information:

• First Two characters: 10 - Indicates an engine not a transmission.

• Next 3 characters: Broadcast code (engine configuration which includes a cross reference to

model year of build):

- Model year (1st letter)

characters: Julien Date of Build

• Last 4 Characters: Sequence number of build on that date.

Translated the engine verification number shown in the sample label below identifies an engine,

broadcast code (XJB) (1999 5.3L Federal Auto), built at Romulus on February 10 , 1999;

sequence number 1034.

Example: * 10XJB W990411034*

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

10

Page 13

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

2.6.3.1 Engine Option Description

RPO Description Notes

L35 4.3L V-6 Engine w/ SCPI

M30/MT1 Automatic Transmission

M50/MG5 Manual Transmission

K18 Air Injection (Electric pump)

KC4 Engine Oil Cooler

KL5 Gaseous Fuel Compatible

NA1 Below 8500# GVW

NA3 Emission System - Japan

NA4 Above 8500# GVW

NB6 Emission System - Calif. Tier 1 (-K18 on CK Manuals)

NC1 Emission System - Calif. LEV (+K18 on CK / -K18 on M/L)

NC8 Emission System - Calif. ULEV (-K18 on ML)

NF2 Emission System - Federal Tier 1 (-K18 on CK & P)

NF4 Emission System - Clean Fuel Fleet

NF7 Emission System - Federal N LEV

NM2 Emission System - Leaded Fuel (Export for ML & P)

NM8 Leaded Fuel System Compatible (Export for ST)

NN8 Emission Override - Unleaded Fuel (Export)

NW7 Traction Control

RHD Right Hand Drive

S5I Brazil Equipment

W99 Venezuela Equipment

TZ0 Mexican Equipment (Manual Transmission)

ZK3 G-Van Pull Ahead (Vehicle only)

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

11

Page 14

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

2.6.3.2 Engine Broadcast Codes & Part Numbers

Part TON ROM Broad Vehicle Description

Number Cast

Code

12559672 X AAA CK L35+M30+NF2 (-K18)

12559676 X AAF CK L35+M30+NC1 (+K18)

12559673 X AAB CK L35+MG5+NF2 (-K18)

12559677 X AAH CK L35+MG5+NC1 (+K18)

12559680 X ABA G-LD L35+M30+NA1-K18

12559681 X ABB G-HD L35+MT1+NA4 (-K18)

12559682 X ABC G-LD L35+M30+NA1+NF4+K18

12559684 X ACA ML L35+M30+NA3/NC1/NC8/NF2/NF4/

NF7

12559685 X ACB ML L35+M30+NM2

12559687 X ADA P L35+MT1+NF2-KL5

12559688 X ADB P L35+MT1+KL5+NF2

12559691 X X AFC S L35+M30-K18-NM8 (+NN8)

12559707 X AFL S L35+M30+NM8

12559692 X X AFD S L35+M50-K18-NM8 (+NN8)

12559708 X AFN S L35+M50+NM8

12559701 X X AFJ S L35+M30+K18+NF4

12559702 X X AFK S L35+M50+K18+NF4

12559695 X X AHC T L35+M50-K18-NM8-RHD

12559696 X X AHD T L35+M30-K18-NM8-RHD

12559709 X AHP T L35+M50+NM8-W99

12559710 X AHS T L35+M50+W99+NN8

12560378 X AHX T L35+M30+RHD-NM8-K18

12560379 X AHY T L35+M50+RHD-NM8-K18

12559711 X AHT T L35+M30+NM8

12559705 X X AHL T L35+M30+NF4+K18

12559706 X X AHN T L35+M50+NF4+K18

12560483 X 1LB —- Marine (Volvo) 2Bbl w/Dist.

12560485 X 1LJ —- Marine (Merc) 2Bbl w/o Dist.

12560484 X 1LC —- Marine 4Bbl w/ Dist.

12560486 X 1LK —- Marine 4Bbl w/o Dist.

12560481 X 1LT —- Indust 2Bbl Gaseous - Bucks

Irrigation

12560482 X 1LX —- Indust 2Bbl Gas - Williams

Powertrain

12559712 X 1LA T L35+M50+S5I (Brazil)

12559713 X 1LD T L35+M30+S5I (Brazil)

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

12

Page 15

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.0 GMPT SYSTEM INTERFACES

3.1 INTERNAL INTERFACES TO GMPT

3.1.1 Engine Interface to transmission

The transmission shall be attached to the rear end of the engine, which provided the flange face

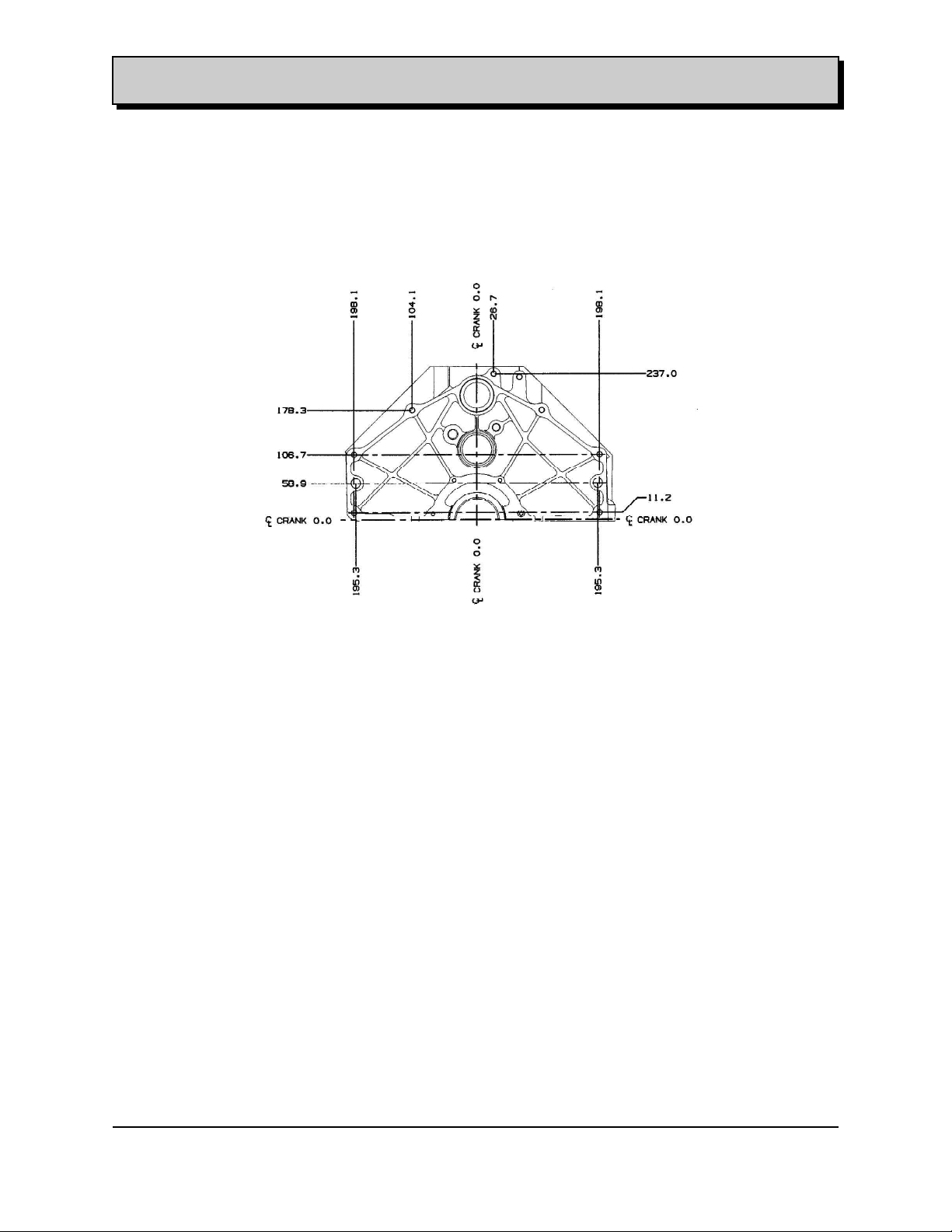

attachment illustrated in the figure 3.1.1- I.

Figure 3.1.1-I: Transmission attachment

3.1.1.1 Automatic Transmission

The 4.3L V6 engine could be mated to either: the GM Automatic Transmission Hydra Matic

4L60E or the GM Automatic Transmission Hydra Matic 4L80E

Figure 3.2.1-I to 3.2.1-XVIII shows the PCM Engine to Automatic Transmission Mechanization

Diagram.

3.1.1.2 Manual Transmission and Clutch

The GM Manual Transmission recommended is a Five Speed Manual (MW 3)

The following engine-transmission, clutch interface issues must be considered:

Manual transmissions require the engine crankshaft pilot bearing to be able to support up to 920

lbs (4292 N) of radial load due to transmission internal gear forces.

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

13

Page 16

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

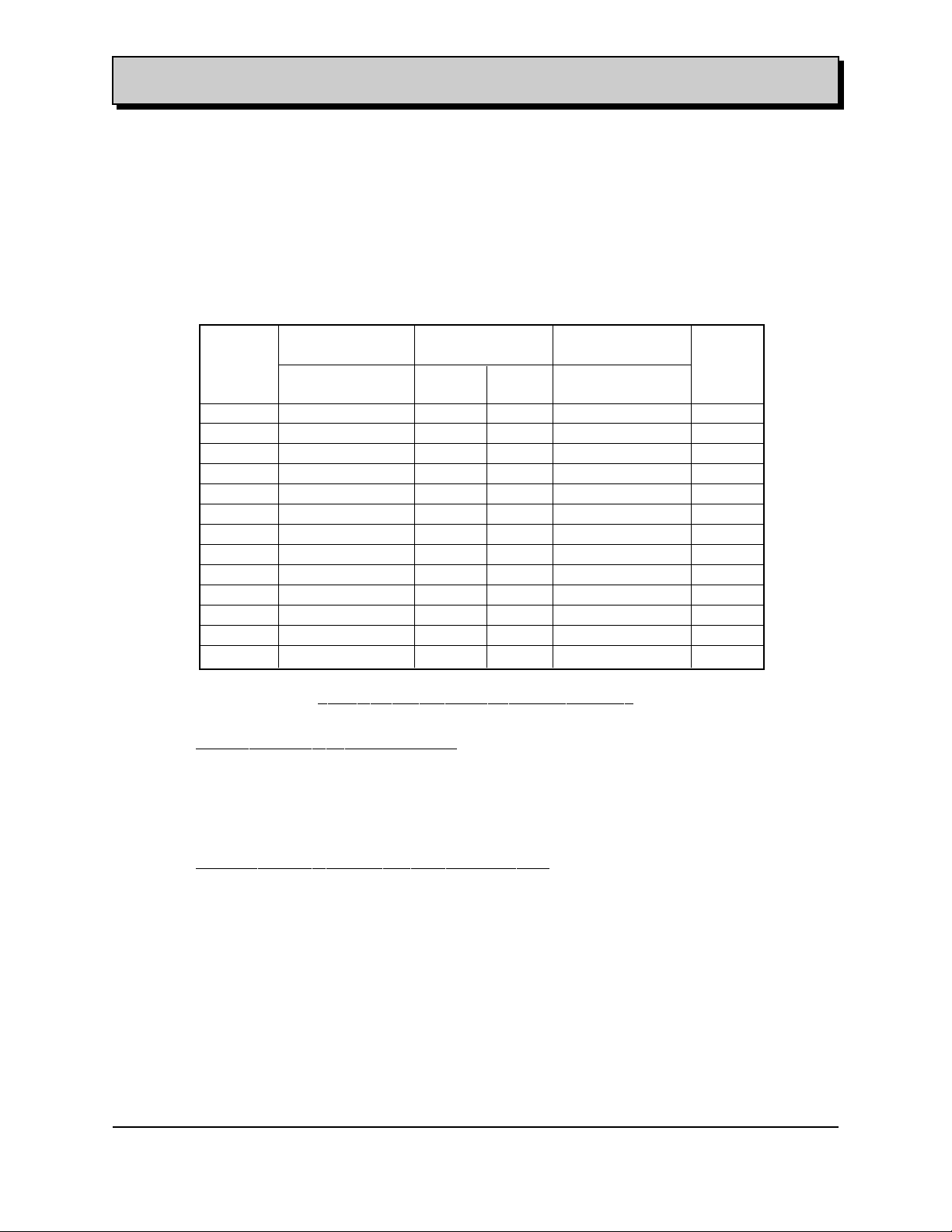

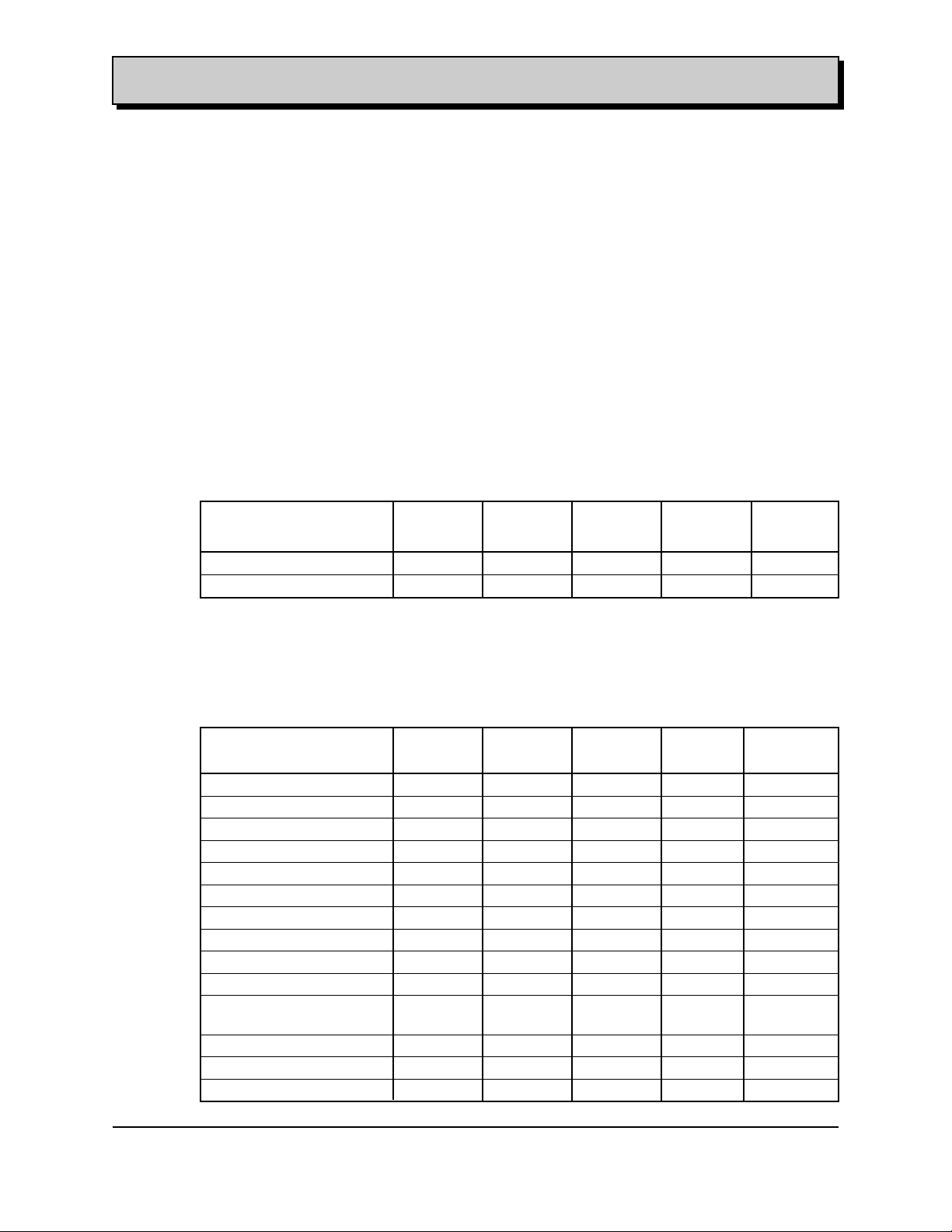

The following table shows the different Transmissions and Components coupled to the L35 engine and

GM platforms.

Transmission P-Truck C/K Truck G-Van M/L -Van S/T Truck

( UPC: 7 )

Auto 4L80E MT1 24210752 N/A 24210754 N/A N/A

Bolt/Screw/Stud 15724226 N/A 15724226

11514224 11514224 N/A N/A

Auto 4L60E M30 N/A 24211665 24211668 24211663 24211662

24211666 24211664 24211663

24211667

Brace N/A N/A N/A 15992466 N/A

Bolt/Screw/Stud N/A 11515768 11515768 15724226 11517000

15724226 15724226 11517000 1261968

25624806

Manual 5-Speed MW3 15020892 N/A N/A N/A N/A

15031131

Bolt/Screw/Stud 11514224 N/A N/A N/A N/A

Manual 5-Speed MG5 N/A 15769087 N/A N/A N/A

15769088

Bolt/Screw/Stud N/A 11515768 N/A N/A N/A

Manual 5-Speed MW2 N/A N/A N/A N/A 15045050

Bolt/Screw/Stud N/A N/A N/A N/A 11515768

Manual 5-Speed M50 N/A N/A N/A N/A 15769696

15769697

15769698

Bolt/Screw/Stud 11517000

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

14

Page 17

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.1.2 Engine Interface to PCM ( Vehicular and Marine/Industrial Application)

The 4.3L V6 90 Degree Engine uses the Powertrain Control Unit (PCM) to control the engine,

automatic transmission, the vehicle performance parameters and the onboard diagnostic system.

3.1.2.1 Inputs from the Engine to the PCM

The following Inputs are internal engine parameters and must be supplied to the Powertrain

Control Module:

Barometric Pressure (Or Manifold Absolute Pressure) - POA Engine Assembly

Mass Airflow Sensor (Air Cleaner/Air Duct)

Engine Speed

Crankshaft Sensor and Camshaft Sensor

Knock Sensor

Air intake Temperature Sensor (POA MAF) - (Only for the GMT-800 Truck)

Engine Coolant Temperature ECT Sensor-POA Engine Assembly

Engine Oil Pressure Sensor

3.1.2.2 Outputs from PCM to the Engine

Fuel Injectors Management – (Injection Pulse Width Signal)

Idle Air Control Motor (IACV)

Ignition Control Coil Module

Linear EGR Valve Solenoid

Evap. System

Purge Solenoid

Secondary Air (AIR) System

A/C Control

Serial Data

3.1.3 PCM Interface to Transmission

The PCM uses an Electronic Transmission Control Algorithm to monitor and control the transmission.

This algorithm is actually a combination of four algorithms, these algorithms monitor and control

the various aspects of the transmission shifting.

3.1.3.1 Input Algorithm:

The Input Algorithm samples all external sensors and scale these values.

3.1.3.2 Shift Control Algorithm:

The Shift Control Algorithm determines which gear ratio the transmission is currently in and

changes the state of the control solenoid to accomplish a shift.

The shift pattern is controlled by a set of tables. These contain the vehicle speed at which the

shift is to occur as a function of throttle position.

In the manual mode, the current gear may be determined by the operator’s movement of the

gearshift selector lever.

3.1.3.3 Shift Quality Algorithm:

The Shift Quality Algorithm determines shift quality (or firmness).

This is accomplished by controlling the pressure control solenoid, which regulates the torque

signal modulation pressure.

This pressure is determined by a table that is based on vehicle speed and Throttle position.

Garage Shift quality (shifting from Park or Neutral to Drive or Reverse when the vehicle is

stationary) is also controlled by torque signal pressure.

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

15

Page 18

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.1.3.4 TCC Control Algorithm

The TCC algorithm determines when the torque converter clutch is applied or released, using

a set of tables. These tables also determine and control the rate of application and release of

the TCC based on Throttle position

3.1.3.5 Inputs from Transmission to PCM

The following are external Inputs coming from the Transmission to the PCM:

Transmission Speed Sensor

Transmission Fluid Temperature Sensor

Transmission Range Pressure Sensor

3.1.3.6 Output to the Transmission from PCM

TCC Solenoid

Transmission Shift solenoids

Pressure Control Solenoid

3.1.4 PCM Interface to Vehicle

3.1.4.1 External Inputs of the Engine

The following are external Inputs coming from the vehicle to the PCM:

A/C Status

Ignition Voltage

Serial Data (Diagnostics)

Brake/ Clutch Status

4WD Lo Switch (If Applicable)

Diagnostic Enable

Cruise Control Inputs

Tow/Haul Input Switch

3.1.4.2 Output to the Vehicle:

Data link Connector

MIL “Service Engine Soon” Lamp

“Service Throttle Soon” (STS) Lamp

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

16

Page 19

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

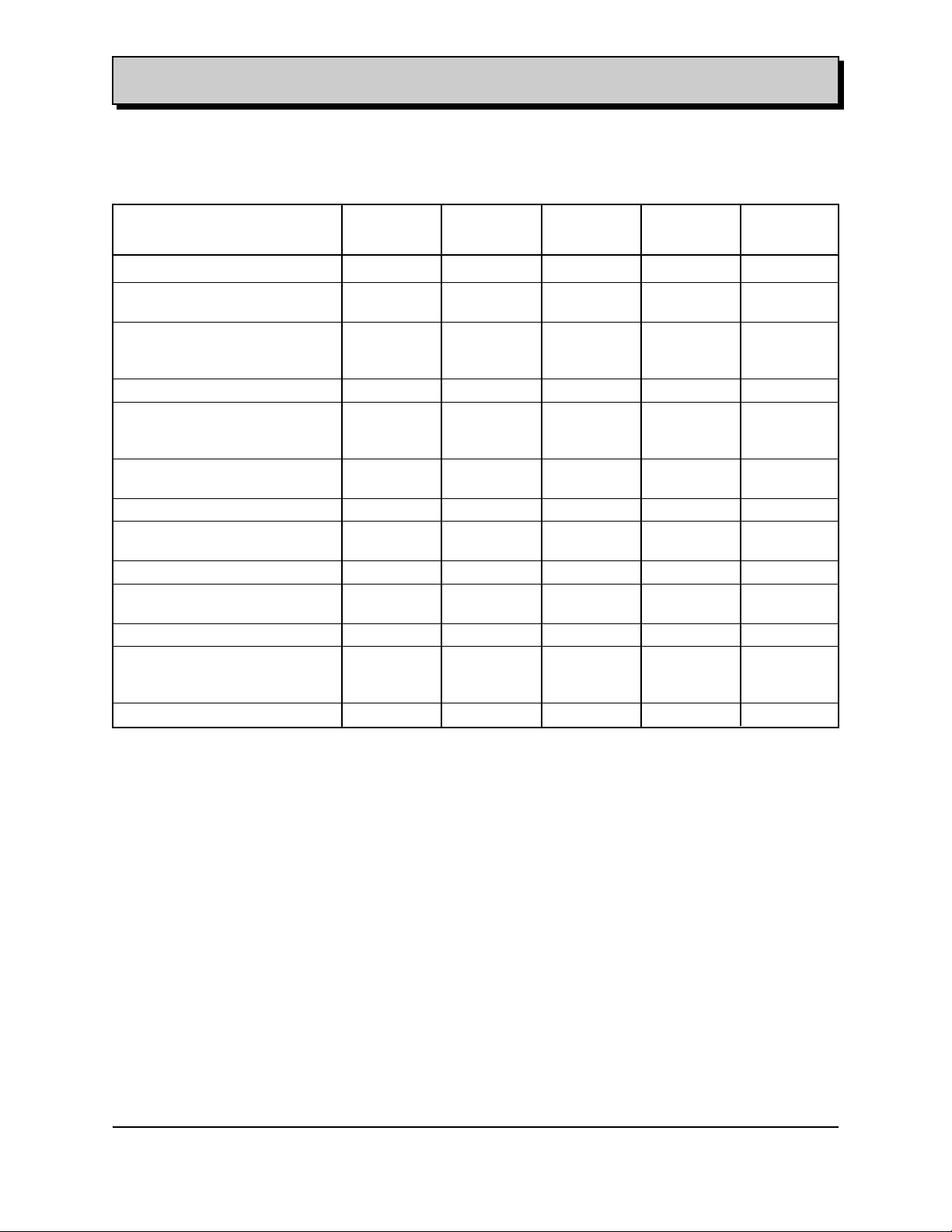

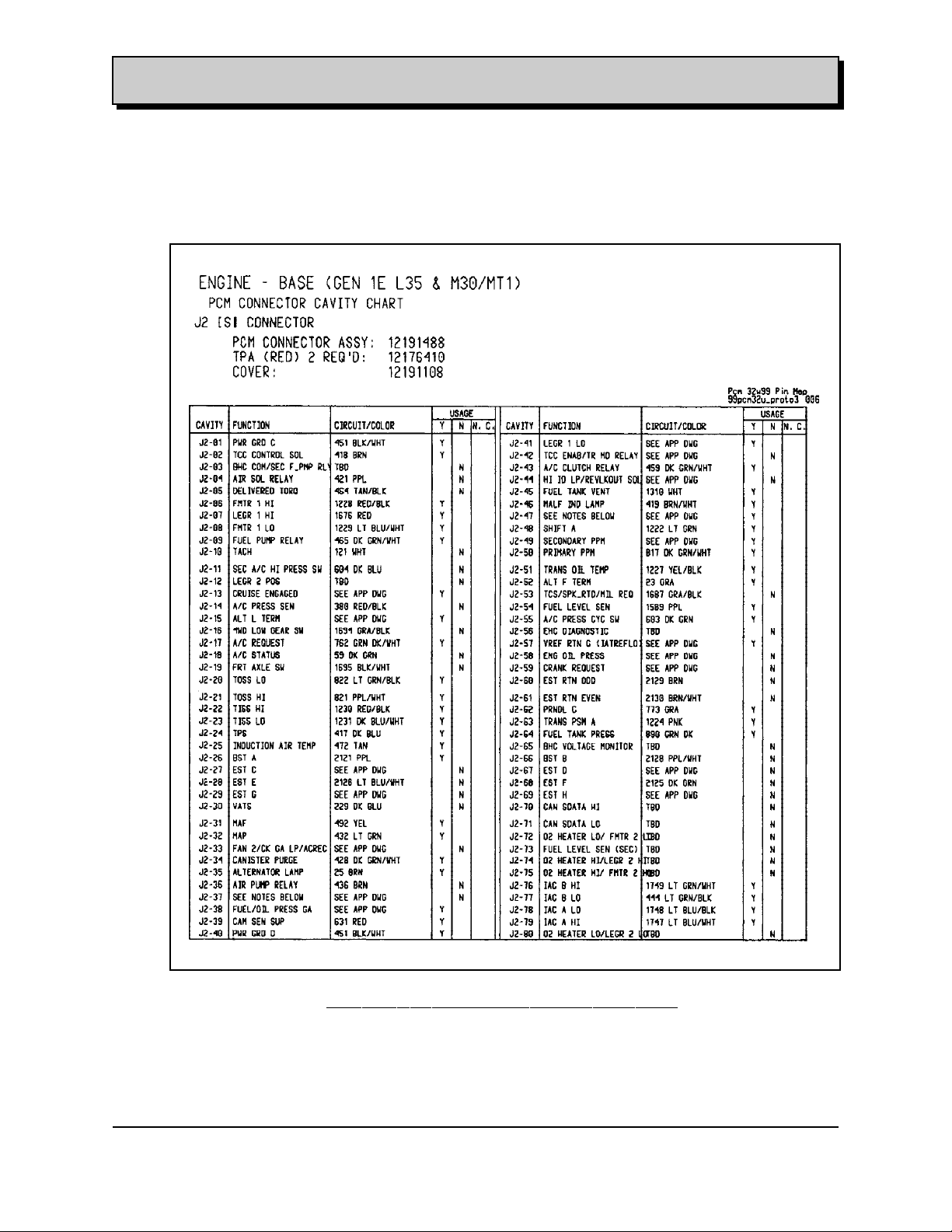

3.1.5a PCM Pin Out and Pin In – Truck Applications

See Figure 3.1.5 - I Powertrain Control Module Diagram to reference the following pin out and

pin in connector information

Figure : 3.1.5a - I PCM Pin Out /In Connector C1

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

17

Page 20

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure : 3.1.5a -II PCM Pin Out /In Connector C2

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

18

Page 21

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

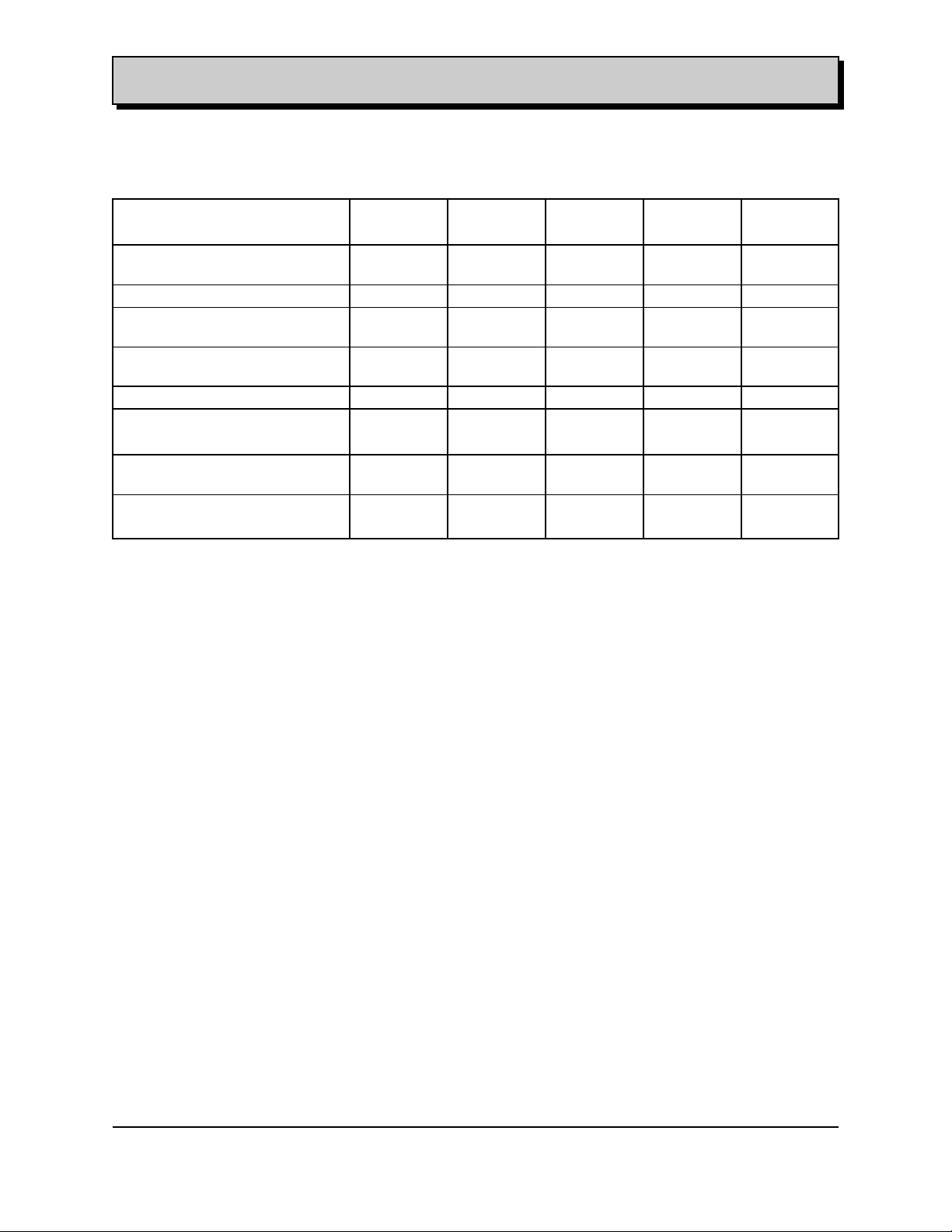

The following table shows the different PCM ASM and Components coupled to the L35 engine per GM

platforms.

PCM

( 12 F ) P-Truck C/K Truck G-Van M/L -Van S/T Truck

Module ASM 9368071 12201281 12201281 12201281 12201281

52370668

Housing Extension 15003789

Bracket 15005865 15047570 15766026 15047570 15767011

15714426

Bolt/Screw/Nut 3846202 11516568 11514519 11516568 11516568

11514139 11514006

Sensors P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 12 F )

Oxygen Sensor 25312191 25312191 25312191 25312191 25312191

25312201 25314006 25314006 25314006 25314006

Mass Air Flow Sensor 25168491 Include in Air Include in Air Include in Air Include in Air

SubSystem SubSystem SubSystem SubSystem

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

19

Page 22

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

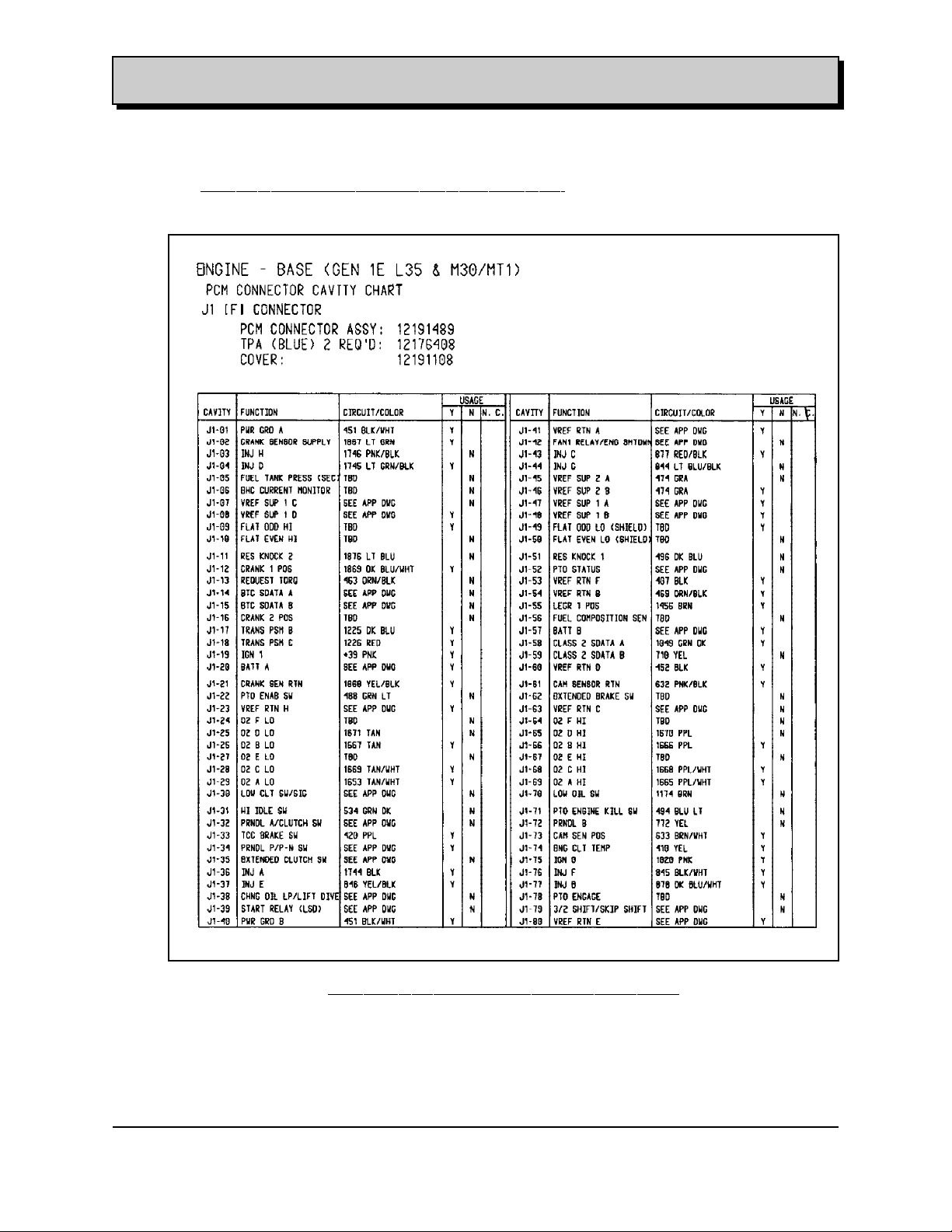

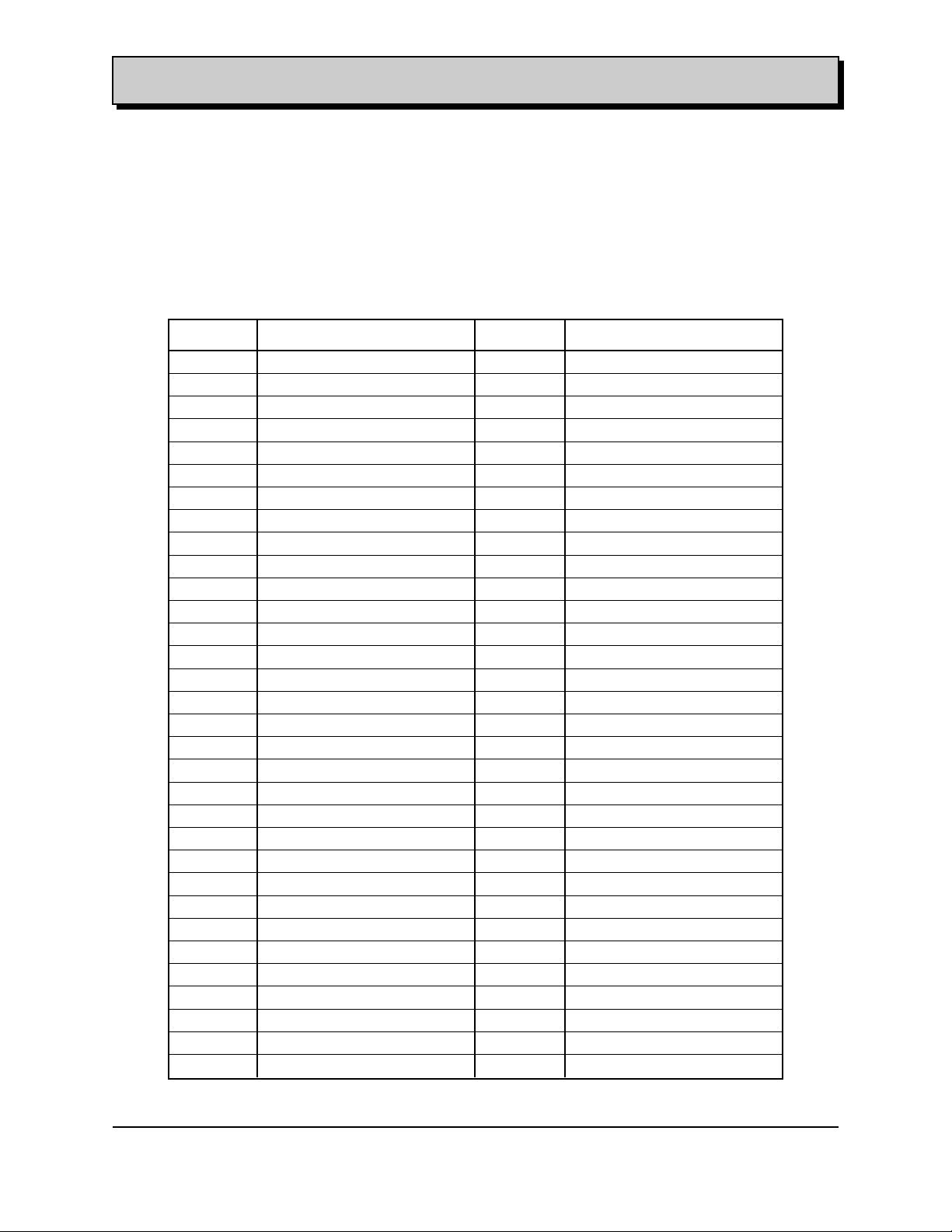

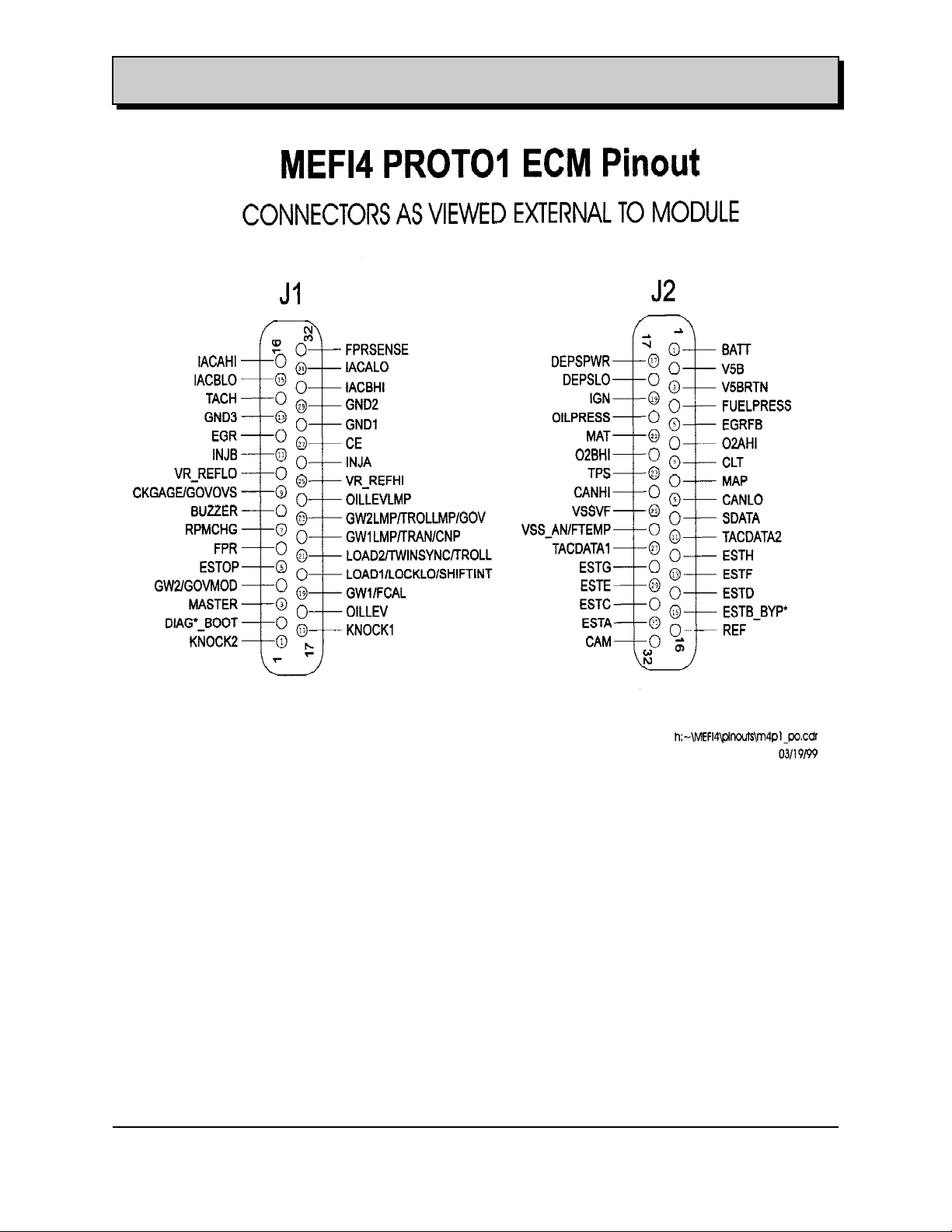

3.1.5b PCM Pin Out and Pin In – Marine and Industrial Applications

Marine Applications use a different control module : MEFI – 4 Multiport Electronic Fuel Injection.

Interfaces as those described for vehicles application, OBD II, and Emissions requirement are

not longer needed.

Table A.1 shows the connector pin out for MEFI Electronic Control Module (ECM) Part Number

12569494 Rev B.

Table A.1 – Pinout

PIN MEFI4 PIN NAME PIN MEFI4 PIN NAME

J1-1 KNOCK2 J2-1 BATT

J1-2 DIAG*_BOOT J2-2 V5B

J1-3 MASTER J2-3 V5BRTN

J1-4 GW2/GOVMOD J2-4 FUELPRESS

J1-5 ESTOP J2-5 EGRFB

J1-6 FPR J2-6 O2AHI

J1-7 RPMCHG J2-7 CLT

J1-8 BUZZER J2-8 MAP

J1-9 CKGAGE/GOVOVS J2-9 CANLO

J1-10 VR_REFLO J2-10 SDATA

J1-11 INJB J2-11 TACDATA2

J1-12 EGR J2-12 ESTH

J1-13 GND3 J2-13 ESTF

J1-14 TACH J2-14 ESTD

J1-15 IACBLO J2-15 ESTB_BYP*

J1-16 IACAHI J2-16 REF

J1-17 KNOCK1 J2-17 DEPSPWR

J1-18 OILLEV J2-18 DEPSLO

J1-19 GW1/FCAL J2-19 IGN

J1-20 LOAD1/LOCKLO/SHIFTINT J2-20 OILPRESS

J1-21 LOAD2/TWINSYNC/TROLL J2-21 MAT

J1-22 GW1LMP/TRAN/CNP J2-22 O2BHI

J1-23 GW2LMP/TROLLMP/GOV J2-23 TPS

J1-24 OILLEVLMP J2-24 CANHI

J1-25 VR_REFHI J2-25 VSSVF

J1-26 INJA J2-26 VSS_AN/FTEMP

J1-27 CE J2-27 TACDATA1

J1-28 GND1 J2-28 ESTG

J1-29 GND2 J2-29 ESTE

J1-30 IACBHI J2-30 ESTC

J1-31 IACALO J2-31 ESTA

J1-32 FPRSENSE J2-32 CAM

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

20

Page 23

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

21

Page 24

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.1.6 Engine interface to exhaust

3.1.6.1 Content

The engine is provided with exhaust manifolds for vehicles and Industrial Applications.

The exhaust manifold system includes the manifold, fasteners to the cylinder head, and

partial or full cover type heat shield. The exhaust manifold may also incorporate provisions

for EGR attachment.

Vehicle Exhaust System

The 4.3L V6 90 Degree Engine shall be attached to the vehicle and interface with the

Vehicle Exhaust System.

The Vehicle Exhaust System will be designed or adapted considering the following Issues:

Vehicle Exhaust System Back pressure: All performance parameters specified in paragraph:

2.3.2.1 were measured with a maximum exhaust restriction of 8.5” of Hg.

Thermal Management of Exhaust

Thermal management of exhaust

The following issues must be considered:

a. Location of Catalytic Converter: The location of the catalytic converter is determined by

resolving three competing needs. The first need is to locate the converter such that it is

close enough to the engine so that sufficient heat is transferred to the converter via the

exhaust stream so as to initiate catalytic activity and therefore constituent conversion

soon enough to meet emission requirements. The second need is to locate the catalytic

converter far enough downstream from the engine in the vehicle’s exhaust system so that

the converter will not be damaged during extended duration high exhaust gas stream

temperature excursions resulting from high speed and load operation of the engine. The

third need is to locate the converter in a position in the chassis where it will package with

sufficient clearance to surrounding components or systems to prevent heat related

failures in those systems or components.

b. Location of Oxygen Sensor(s)

All OBD II compliant exhaust systems contain enough oxygen sensors to guarantee

proper monitoring of the exhaust gases. Each engine cylinder bank requires an oxygen

sensor for air/fuel ratio control. An oxygen sensor is required behind each catalytic

converter for diagnosis purposes. Post converter oxygen sensors are also implied for

slow air/fuel ratio trim. Oxygen sensor wiring connections must be located to as to avoid

moisture contamination.

c. Converter Volume and Flow

d. Location of muffler

e Vibration/shock of catalytic converter

f. Material life for exhaust system through catalytic converter

g. Thermal Characteristics

h. Exhaust Leakage

The exhaust system must be leak free for the emission useful life of the vehicle.

In order to have a working definition of leak free, the exhaust system is divided into three

zones:

Zone A (A/F Control) Cylinder head / exhaust manifold interface to

control oxygen sensor

Zone B (Converter Feedstream) Control oxygen sensor to converter

Zone C (Diagnostic Feedstream) Converter to 12 inches downstream of the

diagnostic oxygen sensor

Maximum allowable leakage in each zone is 2 liters/minute at 15 kPa.

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

22

Page 25

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

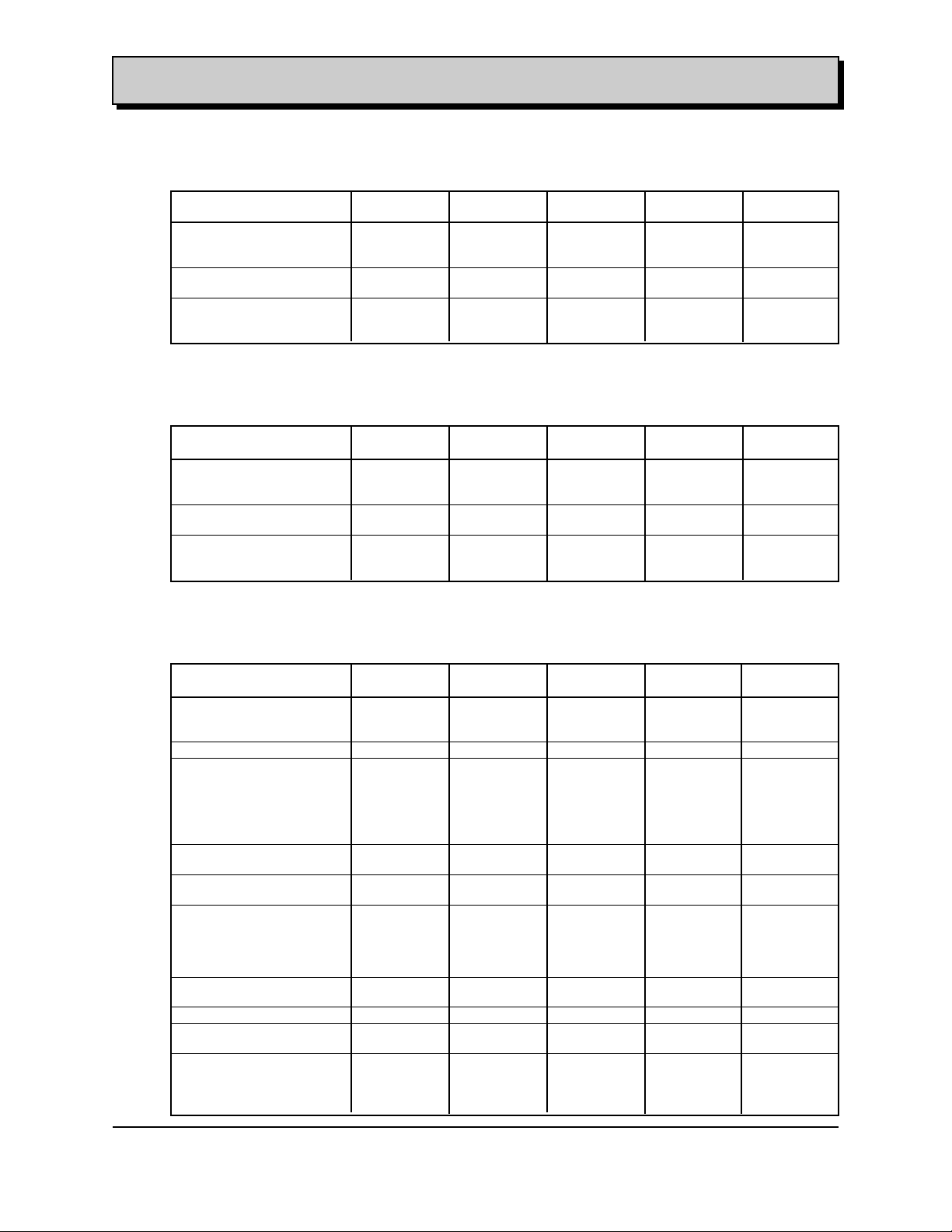

The following table shows the different Exhaust Assemblies and Components coupled to the L35 engine

per GM platforms.

Exhaust P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 8 C )

Manifold ASM 15986438 15029769 15029769 15029769 15029769

Pipe ASM Exhaust 15045399 15749444 15744824

15034810 15744826

15743099 15744828/9

Manifold Seal 12555091 15035747 11514597 12555091 12555091

15035748

Manifold Gasket 15997189 15997189 15997189 15997189 15997189

15767098

Shield 15753676 15027911 15027911 15736668

Screw/Bolt/Nut 11514597 15733192 15997953 15023752 15023752

15733192 15032594 11514597 11514597

Converter ASM 25160620 15052911 15159709 15744810 15744810

15986441 15756278 15160977 15749445 15749445

15700838 12568312

15747730

Converter Pipe ASM 15986425 15709444 15709444 N/A N/A

15986425

15986428

Converter Gasket 15027074 15027074 15027074 15027074 15027074

Shield 15739194 TBD 15739194 15027095 TBD

1507912 1507912 15150934

Clamp 15529483 15529483 15529483 15529483 15529483

Screw/Bolt/Nut 15709703 15709703 15709703 15709703 15709703

9442939 15997953 15997953 15997953 15997953

11517501 11517501 11517501 11517501

Muffler ASM 15727690 15040396 15008799 15756876 15756876

15040397 15159716 15756877 15756877

15061814 15761545

Exhaust Pipe ASM 15727691 15756780 15739879 N/A 15156883/4

15156936/5

Shield 15739195 15739195 15990607 15990607

Hanger/Bracket 15986421 15986421 15986421 15152715 15023065/6

15986422 15986422 15986422 15976360

15976332

Clamp 15595047 15595047 15595047 15595047 15595047

15529483 15529483 15529483 15529483 15529483

Screw/Bolt/Nut 11515799 11515799 11515799 11500831 11500831

11515216 11515216 11515216 11515768 11515768

9424320 9424320 9424320 15695050

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

23

Page 26

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.1.6.2 Back Pressure

Exhaust back pressure shall not exceed 8.5 inches of Hg at rated speed and load. Lower

exhaust back pressure is desired from a performance and fuel economy standpoint.

3.1.6.3 Packaging

The vehicle assembly plant attaches the exhaust pipe to the manifold with the proper

fasteners and a gasket or seal. Exhaust manifold takedowns will be 2 or 3 fastener designs.

Consult GM application engineer.

The current exhaust manifolds are made from Nodular Iron with incorporated and

detachable heat shields.

Fasteners at the manifold takedown must be capable of withstanding temperatures up to

800°C and will require stainless steel or sermagard coated steel. The gasket/seal must also

withstand these temperatures and will require stainless steel or stainless steel with mica or

grafoil.

The heat shield provided on the exhaust manifold will reduce radiant heat to nearby critical

components and reduce or minimize the number of separate shields required by the vehicle.

3.1.6.4 Exhaust Gas Recirculation (EGR)

EGR P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 6 L 3 )

EGR ASM Valve 17200268 17200268 17200268 17200268 17200268

3.1.6.5 Secondary Air

GMPT will indicate the needs for secondary air recirculation.

The following table shows the different Secondary Air and EGR Assemblies and

Components coupled to the L35 engine per GM platforms.

Engine Secondary Air P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 6T )

Pump Air Inj ASM 15059238 15053709 15056764

Hose ASM 15022544 N/A 15023825

Hose ASM By Pass 15022570 N/A 15760279

Stud 20513798 N/A

Washer 15953691

Strap 11509086

Bolt Screw 11508706

Pipe ASM 12561825 12562572 12561250/51

Check Valve (or Bypass) 12567731 12567745 15037955

Check Valve (or Bypass) 12567732 12567746 15056713

Bolt Screw 12558020 11515210 15695050

9440034

Gasket 12561871 12561871 12561871

Shield 15026631

Nut 11514596

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

24

Page 27

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.1.7 Engine Interface to Cruise Control

Figure 3.2.1-I to 3.2.1-XVIII shows the PCM Engine to Vehicle Mechanization Diagram with this

interface. The following table shows the different Cruise Control Modules and Components used

with the L35 engine and GM platforms.

Cruise Control P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 6 N 4 )

Cruise Control Module 25315559 25315559 25315090 25315087 15028014

Cable 15040802 15040802 15031096 15045430 15045460

15040801 15040801 15751730

Bolt/Screw 11517009 11517009 15685170 11515928 11508010

11518009 11518009 15983425 11517507

15685170 15685170

3.1.8 Accelerator Pedal

Figure 3.2.1-I to 3.2.1-XVIII shows the PCM Engine to Vehicle Mechanization Diagram with this

interface. The following table shows the different Pedal Accelerator Assemblies and

Components used with the L35 engine and GM platforms.

Pedal Accelerator P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 6 N 2 )

Pedal Accelerator ASM 15944514 15944514 15756441 15756441 15015757

15160381 15716466

Cable 15148661 15038820 15031093 15031093 15010419

15148662 15741073 15153422

Bolt/ Screw 9433298 11514516 11514516 15010419

11516150

11517519

15717608

25315088

15729139

3.1.9 Engine to Evaporative Fuel System

Figure 3.2.1-I to 3.2.1-XVIII shows the PCM Engine to Vehicle Mechanization Diagram with this

interface. The following table shows the different Fuel Lines, Fuel Tank and Evaporative

Assemblies and Components coupled to the L35 engine per GM platforms.

Fuel Evaporative P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 8 D )

Canister ASM 17098106 15056485 17098085 17098085 17201171

Shield 15004076

Hose 10282447 15759042 N/A 15012787 9439150

15721451 15759043 15150414

15733597 15726983

15721447 15768562

15721448

15731510

Clamp 10108259 10108259 N/A 10108259 10108259

11516221 11516221 11516221 11516221

Separator 17096210 N/A 15032645 15032645 15032645

15032646 15032646 15032646

Bracket 15009801 15056490 15769694 15769694 15049107

15013689 15742240

15746404 15734230

17565062 15992101

15731699

Harness 12556909 12555973 12561900 12561900 11509087

Strap 11509087 11509087 15000499 11509087 11509087

Valve 12559015 15032643 15032643 15759225 25658328

15032644 15032644 12559015

Bolt/Screw/Nut 11508797 11516573 11515211 11515211 11515654

3847758 11513914 11508797 11508797 11515656

3975550 3847758 11515658

11515211 3975550

17097127

17097120

12566190

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

25

Page 28

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.1.10 Accessory Drive System

The engine is released with an accessory drive system whose components are dimensioned

and released as indicated in the paragraphs 3.1.11 to 3.1.16.

The maximum torque from the front crankshaft pulley is 150 ft lb., regardless of the engine

speed; so it is recommended that the Belt System Drive maximum Torque requirement not to

exceed 140 ft lb.

For torque values above 140 ft. lb. the customer shall provide different PTO assembly.

3.1.11 Standard Accessory Descriptions

GMPT accessory drive design release engineer will provide attachment points and drive of these

components on the engine.

The following table 3.1.11-I shows the different combinations of components coupled to the L35

engine accessory drive brackets per GM platforms.

3.1.12 Cooling Fan

Cooling Fan assembly is not part of the engine scope or extent of supply.

Cooling fan is designed, dimensioned and released by the GM - HVAC engineering group taking

in consideration the Heat Rejection (indicated in the paragraph 3.4.5) needed to evacuate from

the engine through the radiator assembly.

If the Fan is driven from the crankshaft front pulley and the maximum torque values specified in

paragraph 3.1.10 shall be taken in consideration.

3.1.13 Alternator

Alternator is not part of the engine scope or extent of supply.

Alternator is designed, dimensioned and released by the GM - Electrical engineering group

taking in consideration all vehicles electrical power needs.

If the alternator is driven from the crankshaft front pulley and the maximum torque values

specified in paragraph 3.1.10 shall be taken in consideration.

3.1.14 Power Steering Pump

Power Steering Pump is not part of the engine scope or extent of supply.

Power Steering Pump is designed, dimensioned and released by the GM - Chassis engineering

group taking in consideration the vehicles drive needs.

If the power steering pump is driven from the crankshaft front pulley and the maximum torque

values specified in paragraph 3.1.10 shall be taken in consideration.

3.1.15 AC Compressor

AC Compressor assembly is not part of the engine scope or extent of supply.

AC Compressor is designed, dimensioned and released by the GM - HVAC engineering group

taking in consideration the Vehicle Air Conditioned needs.

AC Compressor is driven from the crankshaft front pulley and the maximum torque values

specified in paragraph 3.1.10 shall be taken in consideration.

3.1.16 Crank Shaft Nose Load

Crankshaft maximum load at the nose will not exceed 140 Lbs.

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

26

Page 29

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

The application engineer can provide information above accessory bracket assemblies available for

various engine applications.

MY-2001 MY-2001 MY-2001 MY-2001 MY-2001

Steering Pump System P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 9E )

Steering Pump 26042592 15772602 26070078 26057292 26058060

26068923 26070099

26081015

15754215/16

Steering Pump Pulley 10085755 10085755 10085755 10085755 10085755

Steering Pump Bracket RR 10236998 10236998 10236998 N/A 10236998

Steering Pump Reservoir 15682455 N/A 26073040/1 26057780 N/A

Steering Pump Cooler 26063303/5 26063303/5 26063303/5 N/A N/A

Steering Pump Hose 3931898 26051184 26040765 26057733 26057936

Steering Pump Hose 3773687 26068830 26063303 26063303 26042259

Steering Pump Hose 3786228 N/A N/A 26055306 26055306

Steering Pump Strap 11501907 N/A N/A 11509086 11509086

Steering Pump Pipe 15983287 26051176 26051176 26050743 15159570

Steering Pump Clamp 11516255 11516255 11516223 15735493 22514443

Steering Pump Bracket Nut 10242827 10242827 10242827 10242827 10242827

Steering Pump Stud 10224557 10224557 10224557 10224557 10224557

Steering Pump Nut 10242827 10242827 10242827 10242827 10242827

Steering Pump Bolt 11516349 11516349 11516349 11516349 11516349

Steering Pump Bolt 10244162 10244168 10244168 10244168 10244168

Steering Pump Bolt 11517950 11517950 11517950 11517950 11515586

Steering Pump Bolt 52476687 52476687 52476687 52476687 52476687

HVAC Compressor ASM P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 1A 2G )

Compressor 1136580 15766590 15766591 15765192 15765201/2

Brace N/A N/A N/A 12555015 N/A

Bolt Screw 11516285 11516285 11516285 11516285 11516285

Bolt Screw N/A 11516704 N/A 11516246 N/A

Bolt Screw N/A N/A N/A 10157953 N/A

Engineer WE08 XS03-U101 0AHD U101 0UR1-U101

Bracket HVAC ASM ( 9E ) 12554522 12554522 12554522 12554522 12554522

Generator ASM

( 6Y1 ) P-Truck C/K Truck G-Van M/L -Van S/T Truck

Alternator 10480270/1 10480388/90 15768829/30 10480326 10480288

Screw/Bolt Alternator 11516704 11516704 11516285 11516285 11516285

Screw/Bolt Alternator 11516283 11516283 11516283 11516283 11516283

Screw/Bolt Tensioner 10244168 10244168 10244168 10244168 10244168

Nut Tensioner 10242827 10242827 10242827 10242827 10242827

Stud Tensioner 10224557 10224557 10224557 10224557 10224557

Generator Bracket Rr 10237271 N/A N/A N/A N/A

Screw/Bolt Bracket Rr 11516284 N/A N/A N/A N/A

Bolt Screw

Bolt Screw

Engineer WE08 UT06 OAKQ UQ12 UT06

Bracket ASM 10236997 10236997 10236997 10236997 10236997

Table 3.1.11-I Accessory Drive Brackets Components Combination

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

27

Page 30

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.2 INTERFACES WITH VEHICLE SUBSYSTEMS

3.2.1a GMPT interface with Electrical Supply System-Truck Application

Battery Type Description

Model 78A-72

Voltage 12

Amps ( Minimum ) 600

Minutes Reserve Capacity 115

Amps/hrs.-20 hr. rate 69

Alternator Type Description

Rating (idle/max. rpm) 50 / 120 Amps

Ratio (alt. crank/rev) 2.52:1

Volt Nominal Output 12 volts

Regulator Type Description

Electronic Integral to alternator

Electric Ignition Type Description

High Energy Single Coil Electronic Distributor

Spark Plug Type Description

AC 41-931-Dual Pad Platinum Gap 1.5mm

See Table 3.1.11-I Accessory Drive Brackets Components Combination for Generator usage

information.

The following table shows the different Harnesses and components used with the L35 engine

per GM platforms.

Electrical

( 12 H ) P-Truck C/K Truck G-Van M/L -Van S/T Truck

Harness ASM 15323118 12172550 15059848 15045564 15328570

15301067 12172551 15059849 15045565 15328572

15301068 12172552 15059850 15045566 15328574

12153424 12172553 15059851 15062567 15328576

12153346 15059852 15062568 15328577

15301097 15059853 15062569 15328578

15311589 15059854 15062570 15365302

15323111 15059855 15763497 15365303

15323112 15059856 15365306

15059857 15365307

15059858 15770834

Harness Extension 15323114 15969147 15709061 15709061 N/A

15323164 15328807 15319959 15319959

15323165 15038561 15350451 15350451

Bracket 15985078 15033674 15738436 15993897 15999051

15002035 15733696 15741029

15708423

15023004

15985076

11501907

11509087

15517469

15990187

Strap 11501907 11501907 11501900 11501900 11509086

11509087 11509087

15517469 15517469

Bolt/Screw/Nut 3975550 11516587 11516587 9419301 9440034

566314 15714906 15714906 11516567 11500815

9440963 11516793 11516793 15994522 15961952

9440034 15709062 15709062 11503740 11506117

11509572 15735328 15735328 11515971 15961953

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

28

Page 31

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1-I to 3.2.1-XVI shows the PCM Engine to Vehicle Mechanization Diagram for the PTruck platform application.

Figure Number Description

Figure 3.2.1 - I Cooling, MAP, TPS and OIL Sensors

Figure 3.2.1a – II EGR, Purge & Vent Solenoid Fuel Canister

Figure 3.2.1a - III VSS (TISS & TOSS), Air Pump & Solenoid Relay

Figure 3.2.1a - IV Engine to Transmission (Auto & Manual)

Figure 3.2.1a - V Engine Injectors

Figure 3.2.1a - VI TCC Switch & Cruise Control

Figure 3.2.1a - VII Starter, Alternator & IP Gages

Figure 3.2.1a - VIII Brake, ABS Switch, Serial Data Link I/P Cluster & Cruise Module

Figure 3.2.1a - IX Oxygen Sensors

Figure 3.2.1a - X Idle Air Controller & Knock Sensor

Figure 3.2.1a - XI Fuel System and Optional ETC

Figure 3.2.1a - XII Engine Ignition System

Figure 3.2.1a - XIII Engine Crank & Cam Sensors

Figure 3.2.1a - XIV HVAC

Figure 3.2.1a - XV Power Distribution

Figure 3.2.1a - XVI Note & references

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

29

Page 32

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - I - P/Truck - Mechanization Diagram – Cooling, MAP, TPS and OIL Sensors

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

30

Page 33

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a – II – P/Truck - Mechanization Diagram – EGR, Purge & Vent Solenoid Fuel Canister

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

31

Page 34

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - III - P/Truck - Mechanization Diagram-VSS (TISS & TOSS), Air Pump & Solenoid Relay

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

32

Page 35

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - IV - P/Truck - Mechanization Diagram – Engine to Transmission (Auto & Manual)

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

33

Page 36

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - V - P/Truck - Mechanization Diagram – Engine Injectors

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

34

Page 37

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - VI - P/Truck - Mechanization Diagram – TCC Switch & Cruise Control

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

35

Page 38

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - VII - P/Truck - Mechanization Diagram – Starter, Alternator & IP Gages

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

36

Page 39

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - VIII - P/Truck - Mechanization Diagram –

Brake, ABS Switch, Serial Data Link I/P Cluster & Cruise Module

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

37

Page 40

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - IX - P/Truck - Mechanization Diagram – Oxygen Sensors

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

38

Page 41

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - X - P/Truck - Mechanization Diagram – Idle Air Controller & Knock Sensor

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

39

Page 42

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - XI - P/Truck - Mechanization Diagram – Fuel System and Optional ETC

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

40

Page 43

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - XII - P/Truck - Mechanization Diagram – Engine Ignition System

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

41

Page 44

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - XIII - P/Truck - Mechanization Diagram – Engine Crank & Cam Sensors

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

42

Page 45

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - XIV - P/Truck - Mechanization Diagram – HVAC

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

43

Page 46

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - XV - P/Truck - Mechanization Diagram – Power Distribution

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

44

Page 47

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1a - XVI - P/Truck - Mechanization Diagram – Note & references

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

45

Page 48

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.2.1b GMPT interface with Electrical Supply System- Marine and Industrial Application

Figure 3.2.1b-I to 3.2.1b-II shows the PCM Engine to Vehicle Mechanization Diagram for the

Marine and Industrial Applications

Figure Number Description

Figure 3.2.1b - I Cam, Crank, MAP,TPS and OIL Sensors

Figure 3.2.1b – II Engine Injectors, Spark Plugs

Figure 3.2.1b - I - Mechanization Diagram – Cam, Crank, MAP, TPS and OIL Sensors

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

46

Page 49

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Figure 3.2.1b – II - Mechanization Diagram – Engine Injectors, Spark Plugs

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

47

Page 50

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.2.2 GMPT interface with Electrical Starting System

L35

Motor

PG260 Current Drain 312 Amps

Power Rating Kw 1.4Kw

Motor Drive Engagement Type Solenoid Actuated

Positive Engagement

Gear Reduction Type Pinion Engages From: Front

The following table shows the different Starters and Components coupled to the L35 engine and

GM platforms.

Engine Starter P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 6 Y 2 )

Starter ASM 12563829 12564107 12564107 12564107 12564107

Shield 12561327 12561327 12561327 12561327 12561327

Bolt/Screw 12561387 12561387 12561387 12561387 12561387

12555162 12555162 12555162 12555162 12555162

1246249 1246249 1246249 1246249 1246249

• Ignition voltage to PCM must be maintained at or above 7 volts during cranking.

• The operation of the 4.3L V6 90 Degree Engine System shall not adversely affect any of the

vehicle electrical subsystems.

• Conversely, the operation of any vehicle electrical subsystem shall not adversely affect the

operation of the 4.3L V6 90 Degree Engine System.

• Before performing any welding, disconnect negative battery cable and PCM connectors to

avoid damage to other systems components.

• All engine electrical systems and controllers are not to exceed the allowable levels of radiated

electromagnetic emissions described in specification GM 9114P dated December 14, 1994.

• Engine Electric Wiring Harness Including Connections Provisions For:

Battery, Grounding Requirements, Mounting (Wiring Retention for Function and

Appearance), Starter, Alternator, Sensors and Switches, Thermal Environment, IP Signal

Information, Oil Life, Monitoring, Oil Level Sensing, PCM & Governor Wiring Assembly.

• All Electrical Connector Insertion Forces Less than 80 Newton’s.

• The electrical generator assembly is not part of the engine scope of supply.

The following table shows the different Pre-Heaters and Components coupled to the L35 engine

and GM platforms.

Engine Pre Heather P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 6Y 2C )

Pre Heather ASM 12556261 12556261 12556261 12556261 12556261

Screw/Bolt 15969147 15969147 15969147 15969147 15969147

11509126 11509126 11509126 11509126 11509126

11515763 11515763 11515763 11515763 11515763

Cord ASM 52353022 52353022 52353022 52353022 52353022

15726112 15726112 15726112 15726112 15726112

Strap 15517469 15517469 15517469 15517469 15517469

3.2.3 GMPT interface with CHASSIS BRAKE ABS System

Figure 3.2.1-I to 3.2.1-XVIII shows the PCM Engine to Vehicle Mechanization Diagram with this

interface.

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

48

Page 51

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.2.4 GMPT Interface with HVAC System

In order to properly attach the engine to the vehicle and interface with the Vehicle Cooling

System the following cooling issues must be considered:

This engine is designed to operate with a surge tank that shall be located at the highest point of

the cooling system.

a. Coolant contamination level e. By-pass System

b. Corrosion protection 1. Deaeration

1. Coolant change intervals 2. Fill rate & capacity

2. Coolant type 3. System pressure and Draw Down

c. Ports/Sealing f. Engine Oil Cooler

1. Water pump d. Temperature Management

1. Thermostat and Low Coolant Sensor location

Figure 3.2.1-I to 3.2.1-XVIII shows the PCM Engine to Vehicle Mechanization Diagram with this

interface.

3.2.4.1 Fan Cooling System

Figure 3.2.1-I to 3.2.1-XVIII shows the PCM Engine to Vehicle Mechanization Diagram with

this interface. The following table shows the different Fan ASM and Components coupled to

the L35 engine per GM platforms.

Engine Air Fan ASM P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 6K1 )

Tensioner 12561094 12561094 12561094 12561094 12561094

Bolt/Screw Tensioner 11517648 11517648 N/A N/A N/A

11517649 N/A 11517649 11517649 11517649

Belt 12559620 12569349 12564749 12564762 12564761

12564759/60 12569350 12564760 12564759 12564763

12564763/4 N/A 12564761 N/A 12564759

N/A N/A 12564763 N/A N/A

Blade ASM FAN 15738321 15017911 15002575 15976889 15600390

Blade ASM FAN N/A N/A 15657381 N/A 15976889

Bolt/Screw Blade 15548719 11516869 15548719 15548719 15548719

Clutch ASM FAN 15735393 22149836 22135998 15976997 15154901

15735394 22149880 22136704 N/A 22136712

N/A 15710101 N/A N/A N/A

Engine Pulley Crank Shaft 10085754 10085754 10085754 10085754 10085754

Bolt/Screw Pulley Crank Shaft 10179287 10179287 10179287 10179287 10179287

Pulley FAN 12550053 12550053 12550053 12550053 12550053

Bolt/Screw Pulley Fan 11516292 11516292 11516292 11516292 11516292

Pulley ASM Belt Idler 12555609 12555609 10239930 10239930 10239930

Pulley ASM Belt Idler 12556612 12556612 12557819 12557819 12557819

Pulley ASM Belt Idler 12557819 N/A N/A N/A N/A

Bolt/Screw Fan Idler 11515756 11515756 11515756 11515756 11515756

12550053 N/A N/A N/A N/A

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

49

Page 52

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.2.4.2 Coolant Properties

GMPT engines are liquid cooled and designed to operate with a mix of ethylene glycol and

water. GMPT recommends a daily audit of glycol to water concentration and a yearly audit of

water quality at the vehicle assembly fill station.

Mixture Ratio 52 % Ethylene Glycol and 48 % Water By Volume

Ethylene Glycol Specifications Any Meeting GM 6277 M Specification

Water Specifications Maximum Contaminants Or Range

- Total Solids 350 PPM

- Total Hardness 150 PPM

- pH 6.9-9.0

- Calcium And Magnesium 100 PPM (COMBINED)

- Chlorides 50 PPM

- Sulfates 100 PPM

- Bicarbonates 150 PPM

3.2.4.3 Coolant Radiator (Recommended Minimum Values)

Cooling Radiator L35 UNITS

Radiator Heat Evacuation To Coolant 4460 BTU/Min

Total Average Heat Coefficient- 34 BTU/Hr-sq. ft-F

GM Recommend Better Than

Radiator Efficiency - 60%

GM Recommend Better Than

Radiator Type Crossflow

Radiator Capacity (minimum) 11.8 Liters

GM Recommend Better Than

Minimum Radiator Frontal Area TBD by Customer Sq. Meter

Radiator Total Area TBD by Customer Sq. Meter

Radiator Coolant Flow GPM

@ Rated Power

Radiator Coolant Peak Pressure 103 kPa

Thermostat Open 170 F

Thermostat Fully Open 190 F

Radiator Coolant Inlet Location & Size Top/ 46.2 mm

Radiator Coolant Outlet Location & Size Bottom/ 60.0 mm

Fan Engine Driven

1:25 Ratio to Crank

3.2.4.3.1 Heater Performance

Three coolant temperature performance exist in support of heater performance for the

purpose of providing adequate cab heat. These temperatures shall be selected through

the thermostat setting.

3.2.4.3.1.1 Fast Warm-Up

The engine can provide a minimum of 170°F coolant to the heater in 10 minutes after

the engine started to run from cold conditions.

3.2.4.3.1.2 Uniform Comfort.

The engine can provide 190°F +/-5°F coolant to the heater at 20 minutes after the

engine started to run from cold conditions.

3.2.4.3.1.3 Degradation of Comfort

The engine can provide 190°F +/-5°F coolant to the heater during the 20 minutes

idle, after the engine started to run from cold conditions.

A thermostat temperature of 190°F is assumed. A higher thermostat temperature is

acceptable.

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

50

Page 53

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

The following table shows the different Radiator ASM and Components coupled to the L35

engine per GM platforms.

Engine Coolant Radiator P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 13A )

Radiator ASM 52473151 52486600 15766916 52482175 52472963

Radiator ASM N/A 52486601 15762434 N/A 52472964

Radiator ASM N/A N/A 15762437 N/A N/A

Radiator ASM N/A N/A 15766914 N/A N/A

Cap Radiator 15977333 15982188 15982188 15982188

Reservoir Coolant ASM 15687277 15030565 15720807

15058245 15720808

Bolt Screw or Retainer 11509745 11515904 22535007 15999164

Bolt Screw or Retainer N/A N/A N/A N/A 15685170

Bracket ASM 15996772 15958651 N/A

Cap Reservoir 14054390

Hose Reservoir Coolant 9439035 15007480

Hose Reservoir Coolant 9439124 15689607

Hose Reservoir Coolant 9439145

Clamp 3786276 1622710 1622710 1626260

Clamp 14029188

3.2.4.3 Operating Conditions and Measures

3.2.4.3.1 Heat Rejection

Heat rejection levels for combined engine coolant and oil are measured per GM Test #9

and are summarized in the table below. The values for the specific heat rejection to the

coolant and Lube oil are shown below in table 3.5.3.1-I.

RPM L35 L35 Condition

Truck Marine

Applications Applications

Heat rejection Heat rejection

BTU/Min BTU/Min

2000 1339 n/a Road Load

2800 2038 n/a Road Load

3600 2937 n/a Road Load

1600 1536 n/a 7.2% Grade

2400 2226 n/a 7.2% Grade

2000 2209 2336 WOT

3000 3001 3202 WOT

4000 3910 4274 WOT

4200 4080 4314 WOT

4400 4309 4799 WOT

4600 4460 4716 WOT

750 486 539 Idling

1300 1016 1074 Parked

2200 1756 1826 Parked

Table 3.5.3.1-I 4.3L V6 90 Degree Engine Heat Rejection

3.2.4.3.2 System Pressure

GMPT engines are designed to operate with a pressurized cooling system and surge tank.

System pressure is controlled with a spring loaded pressure (RC33) relief cap with a nominal

setting of 15 Psi.

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

51

Page 54

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.2.4.3.3 Coolant Operating Temperatures

This engine has been validated for continuous duty including continuous operation at

WOT with the coolant temperature under thermostat control (see thermostat start to

open and full open temperatures). Limited operation above thermostat full open

temperature is allowed as shown in the table below.

OPERATION MAX ALLOWABLE TEMP

Extended Idle (Up To 30 Minutes) In Ambient up to >38 C 262.4 F

City Traffic Operation In Ambient

- Up To 109.4 F 237.2 F

- Up To 118.4 F 255.2 F

Grades

- Trucks At GCW, 7.2% Grade, 100 F, Ambient 250 F

- Passenger Cars At GVW, 7.2% Grade, 100 F , Ambient 250 F

High Speed Operation

- Passenger Cars At GVW, 167 kph, Up To 48 C Ambient 237 F

Soaks Following Grade Operation 262 F

3.2.4.3.4 Flow Rates

Flow to the radiator and heater vary with pump speed, thermostat valve position, and

pressure drop across the heat exchangers.

RPM L35 Condition

All Applications

Coolant Flow

GPM

2000 32.5 Road Load

2800 46.1 Road Load

3600 59.9 Road Load

1600 26.1 7.2% Grade

2400 37.7 7.2% Grade

2000 32.6 WOT

3000 49.5 WOT

4000 66.6 WOT

4200 70.1 WOT

4400 73.6 WOT

4600 76.5 WOT

750 12.1 Idling

1300 21.2 Parked

2200 36.0 Parked

Figure: 3.2.4.3.4 - I - Water Pump Flow Rates

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

52

Page 55

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.2.4.3.5 Coolant Fill

Assembly Plant- GMPT requires the engine cooling system to be at least 95% filled

(from a dry system no bleed valves) before the engine is started.

Service- GMPT requires a clear unobstructed view of the coolant deaeration tank be

provided in an underhood location. The system should be designed to be capable of

replacing 95% of the coolant drained during a service situation without starting the

engine or opening any bleed valves.

3.2.4.3.5.1 System Drain Down

The system is to be designed to displace all air in the engine, hoses, heater(s), and

radiator into the deaeration tank while the engine is operating. After the engine,

upper radiator hose, and radiator are charged with coolant the charge must be

maintained at all times prior to low coolant light activation. The only air in the

cooling system should be located in the deaeration tank.

Letting air enter the engine, upper radiator hose, or radiator can allow coolant in the

system to drain down, which is unacceptable. Drain down can result in a false

indication of the coolant level at the deaeration tank.

It also forces the system to run aerated coolant for a short time after every cold start

while the engine, upper radiator hose, and radiator are recharged with coolant.

3.2.4.3.5.2 Service Fill/Procedure

Capability to fill the system to 95% or more of capacity without running the engine.

This ensures enough coolant is in the system to prevent engine damage if run for

extended periods of time without checking the coolant level. Rear heater systems

generally can not be filled without running the engine making it difficult to achieve a

90% static fill. However, rear heaters are difficult to drain as well and typically do

not have to be refilled during service fill. If the rear heater is drained, a few minutes

of running at moderate engine speeds is usually adequate to flush the air out of the

heater and achieve a 90% fill.

3.2.4.3.5.3 Fill Rate

The system should be able to achieve a 95% static fill at the 3 GPM rate.

This indicates adequate sizing of the deaeration tank fill line and proper venting of the

system.

3.2.4.3.5.4 Drawdown Capacity

The cooling system must be capable of losing approximately 10% or 2.4L (2.5 QTS.)

of coolant without aeration occurring or loss of flow. Run at 3500 RPM with a

blocked open thermostat.

This allows the engine to operate without damage when only a 95% fill is obtained.

3.2.4.3.5.5 Deaeration Capability

The ability for the system to run un-aerated within 20 minutes after a service fill.

Run with an operating thermostat and at 3500 RPM. The system needs to be able

to purge air into the deaeration tank during closed and partially open thermostat

conditions.

3.2.4.3.5.6 Air Handling Capability

The ability to lose no more than 50% of the water pump flow with 0.2 CFM of air injected

into the engine. The air is injected into an area after the water pump to simulate a

combustion leak into the coolant. Coolant loss during the test should not exceed the

Drawdown capacity. Test run at 3500 RPM with a blocked open thermostat.

3.2.4.3.5.7 Low Coolant Light Calibration

The low coolant light is to be calibrated to activate prior to coolant aeration

occurring. Normally the low coolant light should come on when the amount of

coolant lost is less than or equal to the Drawdown capacity.

In some installation (see 3.5.3.5.1) the Low Coolant Light will have to come on prior

to the Drawdown capacity to prevent drain down.

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

53

Page 56

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.2.4.4 Coolant and Heater Subsystem Descriptions

3.2.4.4.1 Coolant Inlet- Water Pump Inlet Restriction

Typical Diameter: 60 mm +/- 0.3 mm.

The suction at the water pump inlet should not exceed approximately 1.0" HG (-1.0" HG

pressure) when run at 3500 RPM without a pressure cap. Exceeding this suction could

cause the lower radiator hose to collapse if the system loses cap pressure.

3.2.4.4.2 Coolant OutletTypical Diameter: 46.2 mm +/- 0.3 mm.

3.2.4.4.3 Heater FeedTypical Diameter: 15.9 mm +/- 0.3 mm or 19.05 mm +/- 0.3 mm

3.2.4.4.4 Heater Return

Typical Diameter: 15.9 mm +/- 0.3 mm or 19.05 mm +/- 0.3 mm

3.2.4.4.5 Coolant Hose Material

GMPT requires hose material meeting GM specification 6140m, 6250m, 6278m, or

6149m (hose material specifications vary by the severity of the environment they will be

subjected to).

Reference radiator and heater hose dimensional specifications listed on drwg. #

12552514. Suggested lubricant for ease of hose assembly to inlet nipple is GM

9985406

3.2.4.4.6 Hose Clamps

GMPT requires the use of constant tension clamps for all hose connections.

Reference dimensional information on hose clamp drwg. # 11516215 and equivalents.

3.2.4.4.7 Thermostat

- start to open temperature- 170°F

- full open temperature- 190°F

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

54

Page 57

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

3.3.1 GMPT Interface with CHASSIS Fuel System

Figure 3.2.1-I to 3.2.1-XVIII shows the PCM Engine to Vehicle Mechanization Diagram with this

interface.

RPM L35 L35 Units

Truck Marine

Application Application

800 17.16 17.7 PPH

1200 26.45 27.3 PPH

1600 35.12 37.9 PPH

2000 44.17 46.7 PPH

2400 54.79 56.1 PPH

2800 64.74 67.9 PPH

3200 75.30 76.3 PPH

3600 84.40 85.1 PPH

4000 94.33 94.9 PPH

4400 102.80 104.3 PPH

4800 105.4 112.2 PPH

5200 106.97 119.0 PPH

Figure: 3.3.1 - I 4.3L V6 90 Degree Engine - Fuel requirements vs. Engine Speed

The following table shows the different Fuel Lines, Fuel Tank and Evaporative Assemblies and

Components coupled to the L35 engine per GM platforms.

Fuel P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 8 A )

Pipe ASM Fuel N/A N/A 15030585 15000300 N/A

Pipe ASM Fuel Feed N/A N/A 15043227 15023800 15023800

15043228 15023801 15023801

15023802 15023802

Fitting Fuel Pipe 15550219 15550219 N/A 15036790 15036790

Hose 15733594 15765804 N/A 15054322 15054322

15035085 15765806

15721387

Fuel Filter 15530354 N/A 25121800 25171788 25171788

25055129

Bracket N/A 15013855 15009324 N/A N/A

Clip/Clamp 343449 343449 343449 343449 343449

15973085 15973085 15973085 15973085 15973085

15677730 15677730 15677730 15677730 15677730

Bolt/Screw/Nut/Stud 11515211 11515211 11515211 15604106 15604106

11516076 11516076 11516076 15708937 15708937

11508279 11508279 11508279 3932368 3932368

9428638 9428638

File: c:\data\manuales\v6-truck\am43v6#3.doc

Contact:Luis Nespolo - (248) 857-1558 Printed: 8/15/00

55

Page 58

ENGINE APPLICATION MANUAL GM Powertrain

Gasoline 4.3L V6 90 Degree Revised: 08/15/2000

Fuel Tank P-Truck C/K Truck G-Van M/L -Van S/T Truck

( 8 B )

Fuel Tank ASM with Pump N/A 15759638 15017931 15747872 15013150

15759639 15017932 15066407 15028431

15767150 15020046 15048831

15062877 15761468

15762977

15762978

Fuel Tank ASM no Pump 15721311 N/A N/A N/A N/A

Fuel Pump 25315352 N/A N/A 15062879 N/A

25314575

Fuel Valve 15978533 N/A N/A N/A N/A

Pipe Filler 15030687 15747585 15052676 15061623

15015206 15062980

15062981

Strap 15311568 15745095 15015617 15745065 15015589

15745096 15015618 15032208

15770877 15745014

15770878 15745015

Cap 22616285 15763225 15746557 22660002 22660002

Bolt/Screw/Nut/Stud 9428638 11516551 11516523 15604106 15604106