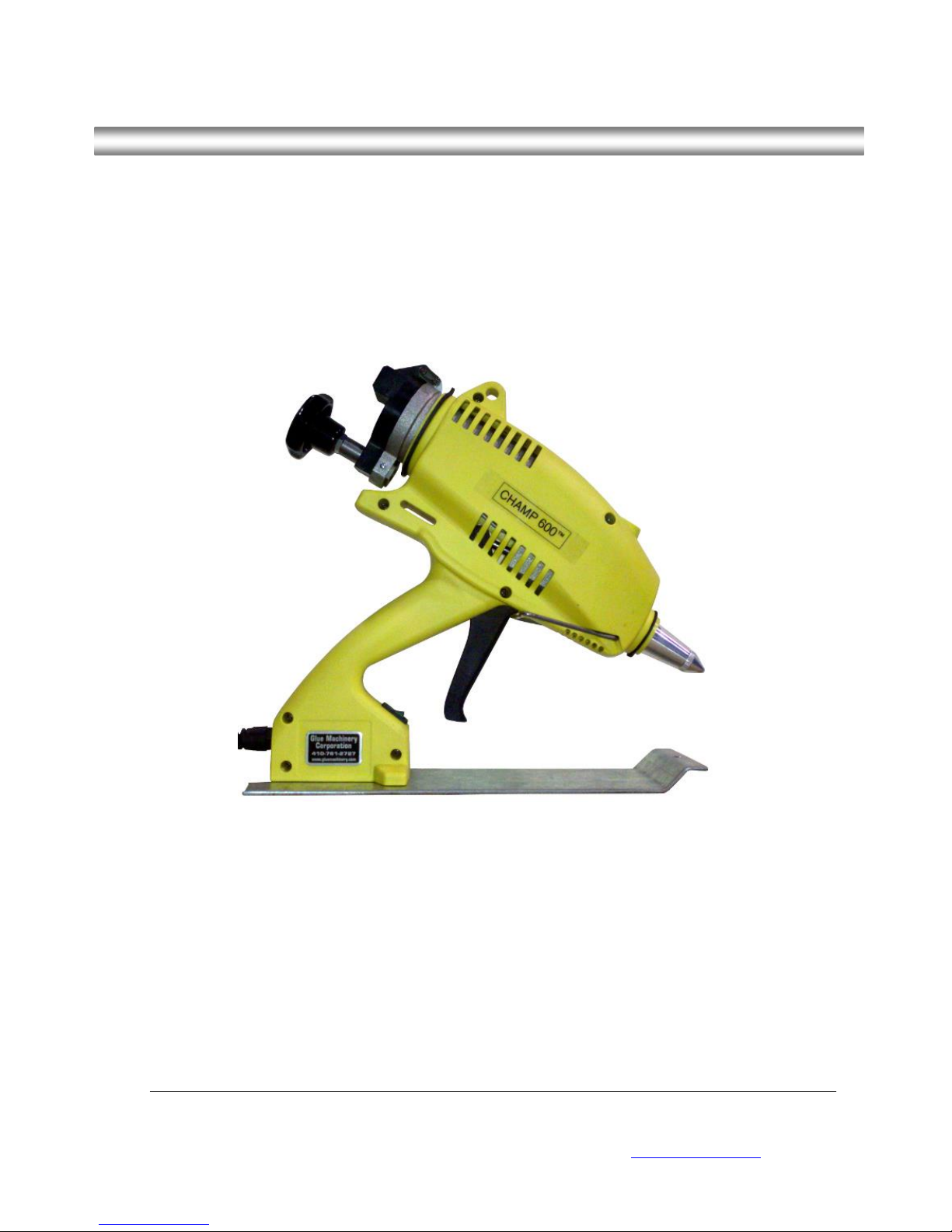

Glue Machinery Champ 600 Operating Instructions Manual

Operating Instructions for

Champ™ 600

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email: info@gluemachinery.com

Glue Machinery Corporation™

4234 Boston St, Baltimore, Maryland 21224

Champ™ 600 Hot Melt Glue Gun

2

Product Description ......................................................

3

Trouble-Shooting ............................................................

4

General Safety Instructions ............................................

5

Start-up .............................................................................

7

Operation ........................................................................

12

Drawings / Spare Parts........................................................

18

Additional Information .......................................................

21

Electrical Schematic……………………………………….

23

Customer Service Policies………………………………..

24

Table of Contents

Glue Machinery Corporation™

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email: info@gluemachinery.com

4234 Boston St, Baltimore, Maryland 21224

Champ™ 600 Hot Melt Glue Gun

3

Weight of the gun

2.69 lb / 1220 g

Power Supply

120V or 240V

Power Consumption

500 Watt

Current consumption

4.2 A at 120V / 2.1 A at 240V

Degree of protection

I

Class of protection

IP 30

Temperature control

Thermostat

Temperature limitation

Temperature controller

Operating temperature

68 – 392 ºF / 20 – 200 °C

Consistency of temperature

±41 ºF / ± 5 °C

Heat-up time

Approx. 10 min.

Gross Tank Capacity

0.55 lb / 250 ml

Conveying system

Mechanics

Length of electric cord

70.9 in / 1.8 m

Dear customer,

Thank you for purchasing the Champ™ 600 Hot Melt Glue Gun. The glue gun you purchased will help you to

glue parts together easily and effectively. Before using the gun, please read these instructions thoroughly.

Product Description

Proper Use

The gun works with and dispenses hot glue. Therefore, the glue gun should only be used by qualified people.

Handling the gun properly will save you unnecessary accident hazards and problems.

Personal injury or material damage caused by an improper use of the Hot-Melt Glue Gun shall not be the

manufacturer's but the user's responsibility.

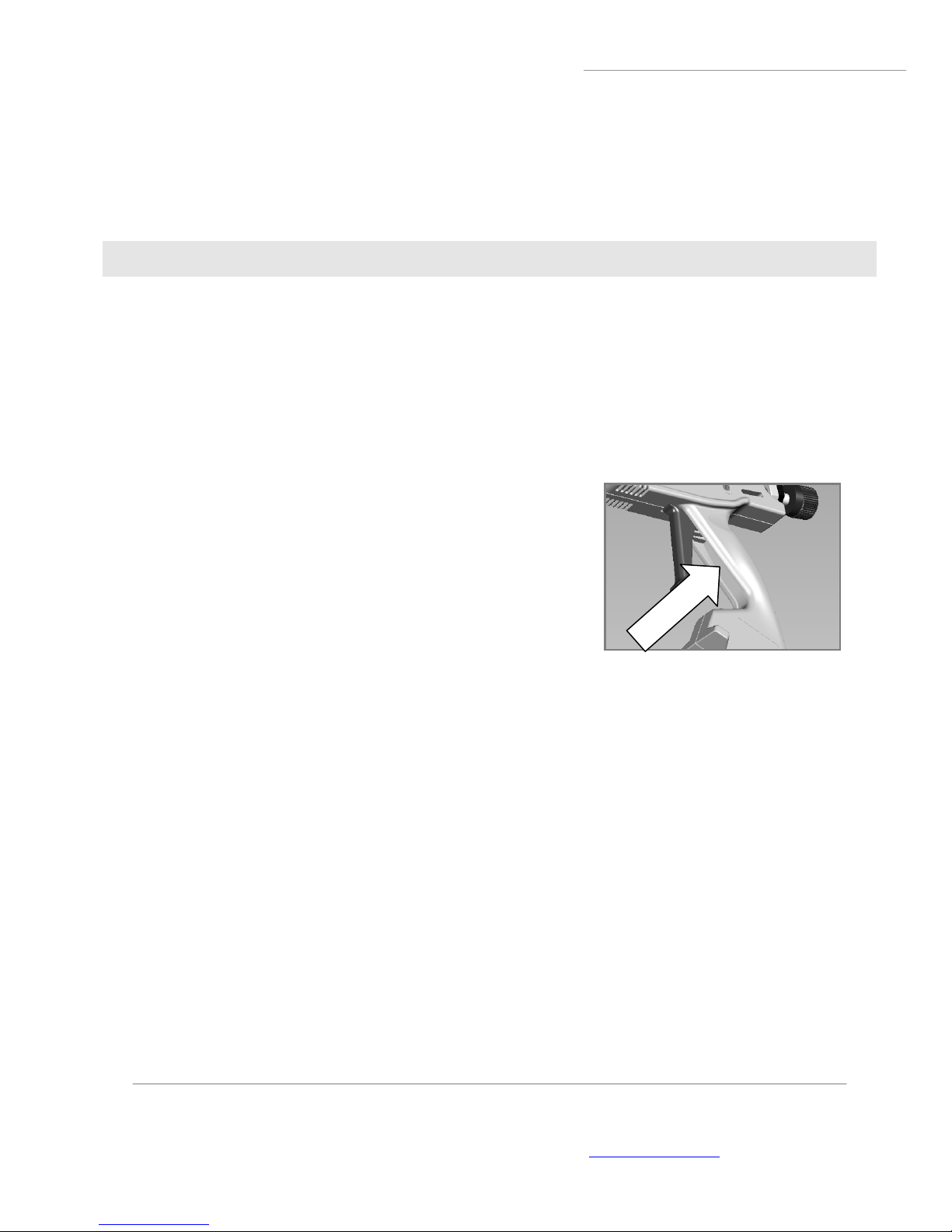

The following illustration shows where to find the serial number of the applicator:

Technical Data

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email: info@gluemachinery.com

Glue Machinery Corporation™

4234 Boston St, Baltimore, Maryland 21224

Champ™ 600 Hot Melt Glue Gun

4

Problems

Possible Causes/

Faulty Operation

Trouble-Shooting

Little or no glue extrudes

through nozzle even though

the adhesive is fully molten.

clogged nozzle

temperature too low

unscrew nozzle, clean or replace it

check temperature

check and clean vent hole on tank closure

cap/lid

Glue is too thin or too thick to

flow as required

temperature too high or

too low

check temperature

Glue drips out of nozzle

clogged nozzle

unscrew nozzle, clean it carefully or replace

it. Unscrew nozzle at working temperature,

wear gloves (risk of burning).

No temperature

gun switched off

connect plug to socket properly.

if necessary, return gun to Glue Machinery

Corporation

Trouble-Shooting

Possible Fault Signals and Assistance in Trouble-Shooting

In case of damage, send glue gun to Glue Machinery Corporation™. We will not be responsible for any

repair made by the customer.

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email: info@gluemachinery.com

Glue Machinery Corporation™

4234 Boston St, Baltimore, Maryland 21224

Champ™ 600 Hot Melt Glue Gun

5

General Safety Instructions

User’s Care and Diligence

The Glue Gun has been designed and fabricated according to the applicable harmonized standards and further

technical specifications. So, it is state of art and ensures a maximum of safety.

This safety, however, can only be achieved in practice, if all necessary measures have been taken. The user of

the device shall be obliged to plan these measures and to make sure that they are taken.

In particular, the user shall ensure that

- the gun is in working order

- the required personal protective equipment (protective gloves) for the operating personnel is available and

used

- the entire operating instructions are in legible condition and available to the operator

- only sufficiently qualified and authorized personnel operates and maintains the gun

- this personnel is regularly instructed in the applicable aspects of operational safety and environmental

protection, and knows the operating instructions and, in particular, the safety instructions.

Make the information available:

This operating manual shall be kept on the site of operation. It must be ensured that all persons operating the

gun can look into the manual at any time. In addition to the operating manual, the instructions pursuant to the

Factory Act and the regulations as regards the use of equipment shall always be at the operator’s disposal.

Safety Symbols

This operating manual shall give concrete advice as to safety to draw the user’s attention to remaining unavoidable hazards. These hazards imply dangers to

persons

product and equipment

The symbols used in the operation manual shall, in particular, call attention to the safety instructions!

This symbol indicates that there is, above all, danger to persons, but also to

equipment and material.

Caution: Hot surface!

Accident Prevention Regulations VBG 125 - W26

Hot surfaces such as machine parts, tanks or materials, but also hot liquids cannot

always be perceived. The utmost caution is advised when this symbol is attached to a

component.

Always wear protective gloves when you have to touch hot surfaces!

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email: info@gluemachinery.com

Glue Machinery Corporation™

4234 Boston St, Baltimore, Maryland 21224

Champ™ 600 Hot Melt Glue Gun

6

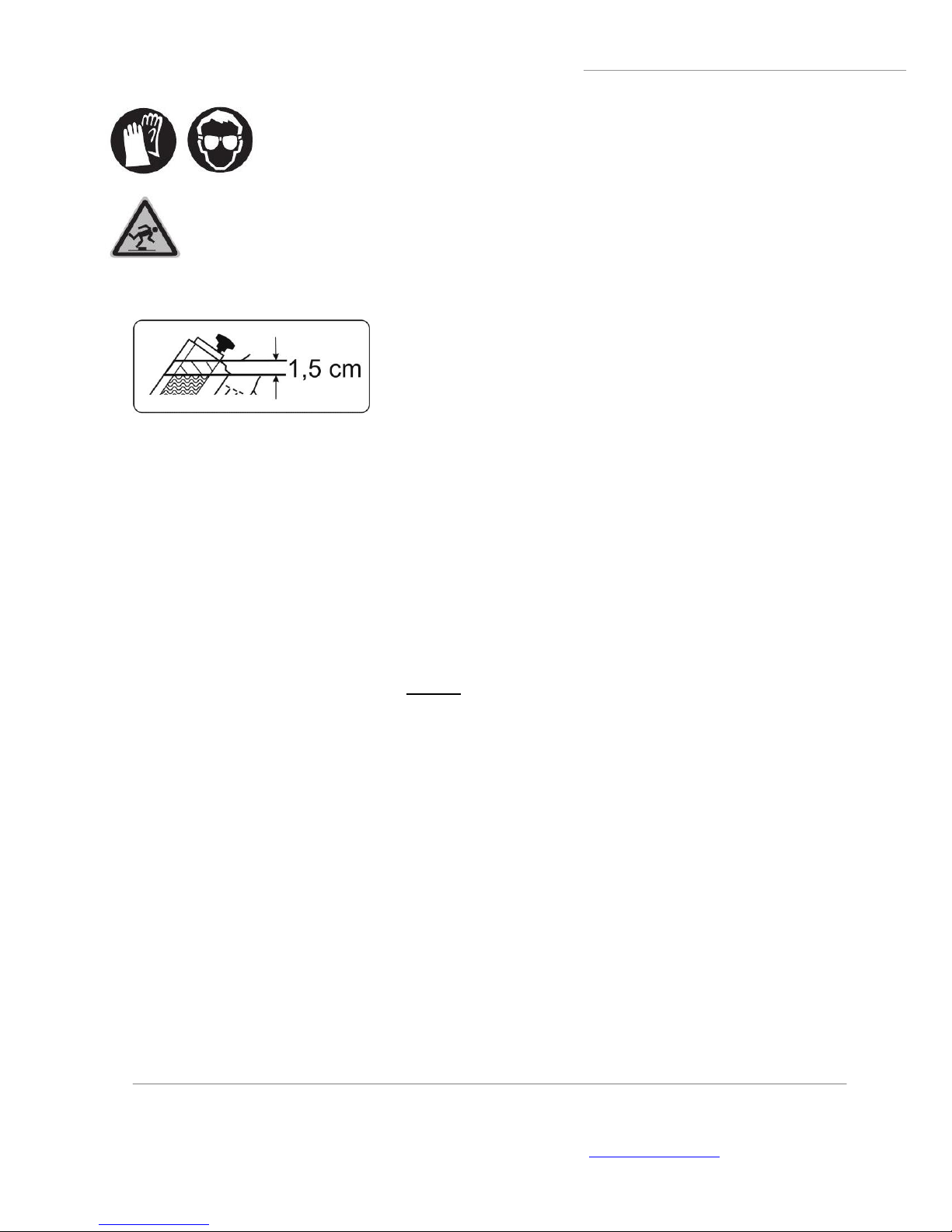

Wear protective gloves and safety goggles whenever you work with the applicator.

To avoid accidents lay the cables so that they will not cause any risk of stumbling.

Only fill the tank up to 1,5 cm (~0.6 inch) under the upper rim.

Never exceed working temperature of the hot melt.

o Overheating may lead to decomposition which may affect health.

Never start working without having mounted a nozzle.

Do not direct glue jet towards people.

Prior to any nozzle replacement, unplug connecting cable.

When a nozzle is replaced, liquid glue may leak out. Warning: Risk of burning!

Never bring the hot nozzle in contact with the cable.

Ensure sufficient ventilation.

Do not inhale vapour escaping from the glue. Attention: inhaling this vapour may cause irritations

of the respiratory tract.

When your skin comes into contact with hot glue, cool it with cold water immediately.

Do not try to remove hot melt from the skin first. If necessary consult your doctor.

If hot adhesive gets into your eyes, immediately cool/run them under running water for about 15

minutes and consult your doctor at once!

Never work without protective gloves and glasses!

Never fill in any solvents or paraffines to avoid risk of explosion.

Note: - Do not lay heated gun on its side. Keep the heated gun in an upright position

with nozzle pointed down.

- Never overcharge gun

- Press trigger only when gun is heated

- Before you change the glue type, pump residual quantity out of the nozzle

- Do not direct glue jet towards people

- Do not carry out overhead work

- Do not hold nozzle top upward

- Never work without having mounted a nozzle

- Stop using the gun, if casing is damaged due to shock, breakage or heavy

wear.

Glue Machinery Corporation™

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email: info@gluemachinery.com

4234 Boston St, Baltimore, Maryland 21224

Champ™ 600 Hot Melt Glue Gun

7

Start-up and Operation

To avoid risk of tripping/falling:

Lay all instrument connections (cable, hoses, and lines) so that they do not cause any risk of stumbling (cable

conduits, bridges)!

Operation of the Glue Gun

An illuminated on/off-switch indicates that the applicator is switched on or off.

Warning: Once the gun has warmed up, nozzle and cover are extremely hot!

Never work without wearing protective gloves!

Minor leaking while the applicator is warming up is due to the hot-melt expanding in the nozzle and heating

chamber.

The Champ™ 600 glue applicator is factory-set to 360ºF. The temperature is continuously adjustable at the

upper side of the applicator, using a screw driver. The right-end stop is the maximum temperature of 435ºF.

To lower the temperature, turn screw counter clockwise (See Manual Thermostat Adjustment Instructions on

Page 8).

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email: info@gluemachinery.com

Glue Machinery Corporation™

4234 Boston St, Baltimore, Maryland 21224

Champ™ 600 Hot Melt Glue Gun

8

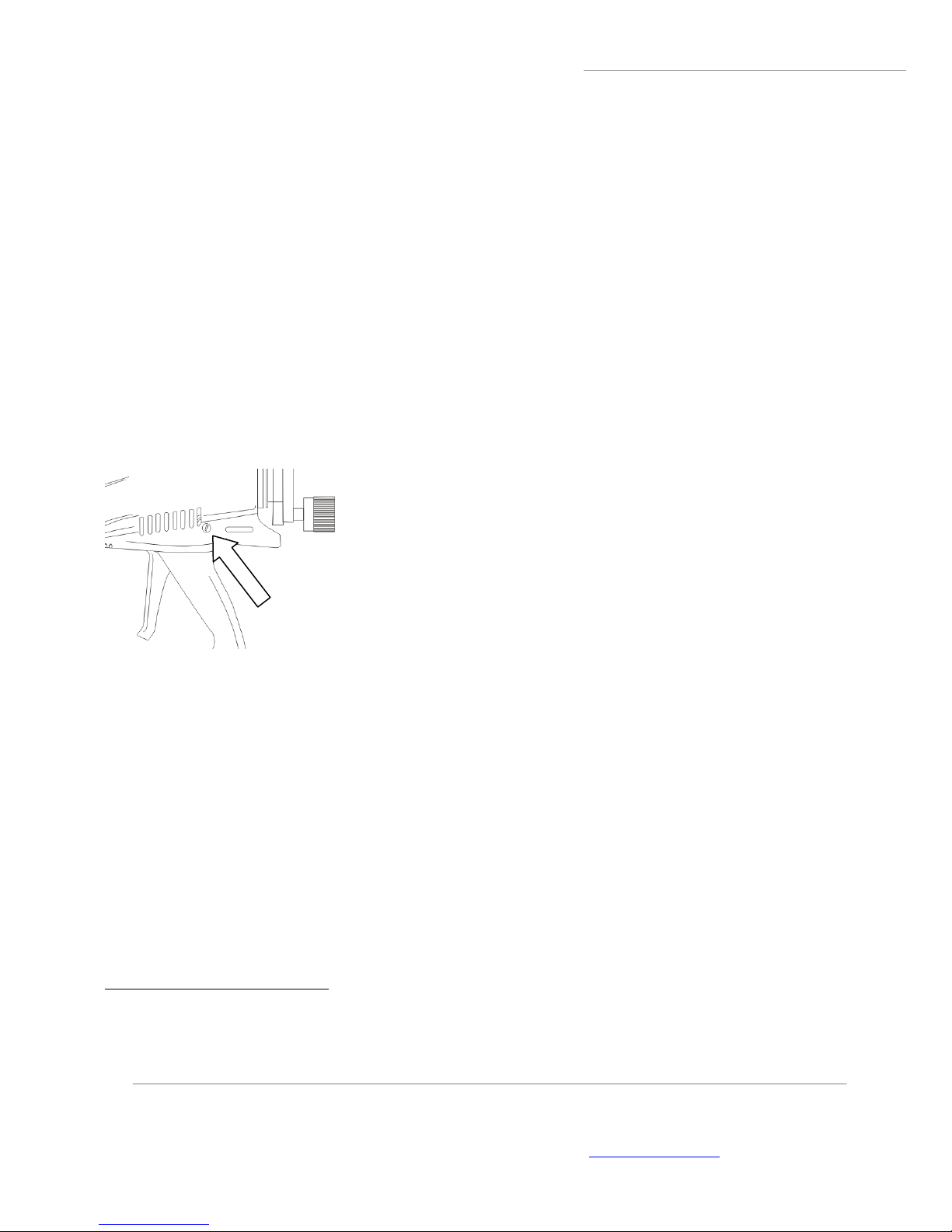

Temperature Adjustment

Manual thermostat adjustment instructions for Champ™ 600

1. Read and understand the manual prior to operating this equipment. Wear proper protective equipment while

operating or servicing this equipment. Only trained operators should be designated to make thermostat

adjustments to this equipment.

2. With the equipment hot, dispense all of the material from the tank; this is required to properly adjust.

Disconnect the equipment from power before servicing the thermostat. Locate the thermostat adjustment port;

this will be located on the top of the Champ™ 600 case.

3. Using a 3/16” slotted screwdriver, insert the screwdriver into the port engaging the flats on the top of the

thermostat stud. Turn the thermostat stud counter clockwise until stop, reconnect the equipment to power and

turn on. Do not force the thermostat if there is any resistance.

If fumes come from the tank at any point during this procedure, turn the equipment off and turn the

thermostat adjustment stud counterclockwise until stop and restart the adjustment.

4. Let the equipment heat for 15 minutes while closely monitoring the internal tank temperature at the bottom

most location of the tank with a thermometer, bead probe sensor or laser temperature probe. Once this

temperature has stabilized this will be your factory set lowest temperature.

5. Power the equipment off and disconnect from the machine from the power source. Turn the thermostat

adjustment stud clockwise 1/2 turn then reconnect the equipment to power and turn on. Let the equipment heat

for 15 minutes while closely monitoring the internal tank temperature at the bottom most location of the tank with

a thermometer. Again, once this has stabilized this will be your average mid-range operating temperature.

5a. If higher tank operation temperatures are required, turn off the power and disconnect the equipment

from power. Turn the thermostat adjustment stud clockwise 1/4 turn then reconnect the equipment to

power and turn on. Let the equipment heat for 15 minutes while closely monitoring the internal tank

temperature at the bottom of the tank with a thermometer. Repeat this step until the desired higher

operating temperatures are achieved or the maximum clockwise stop is reached.

6. Once the desired operating temperature is achieved, fill the tank with approved hot melt adhesive and close

and secure the tank lid. Let the equipment heat for 20 minutes then slowly squeeze the trigger to properly prime

the piston pump while closely monitoring the dispensing material for degradation. If the material appears to be

darker than the hot melt prior to melting or it smokes when extruded please consider lowering the gun

temperature. Please note that all hot melts have a “Pot Life” and will start degrading with high temperature

exposure over time.

Basic Factory Settings:

Low temperature 295°F / Average mid-range temperature 360°F / Maximum temperature 435°F

Recommend thermometer: G71E47-001 Infrared Laser Thermometer

Estimated temperature change with 1/4 turns to the thermostat stud: 25°F

Average temperature fluctuations for mechanical thermostat 20°F +/-

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email: info@gluemachinery.com

Glue Machinery Corporation™

4234 Boston St, Baltimore, Maryland 21224

Champ™ 600 Hot Melt Glue Gun

9

2

The Champ™ 600 glue applicator must only be used to dispense non-reactive hot-melts. Never fill the

gun with other materials. The hot-melt glue applicator is capable of working with all non-reactive hotmelt types which are designed for working temperatures of up to max. 435ºF.

As soon as the gun is warmed up (approx. 5 min.), open the lid and load granulate up to 1,5 cm (~ 0.6

inch) under the lower rim of the feeding opening.

Close the cover and allow the applicator to melt the glue.

The cover must only be opened when the gun is warmed up.

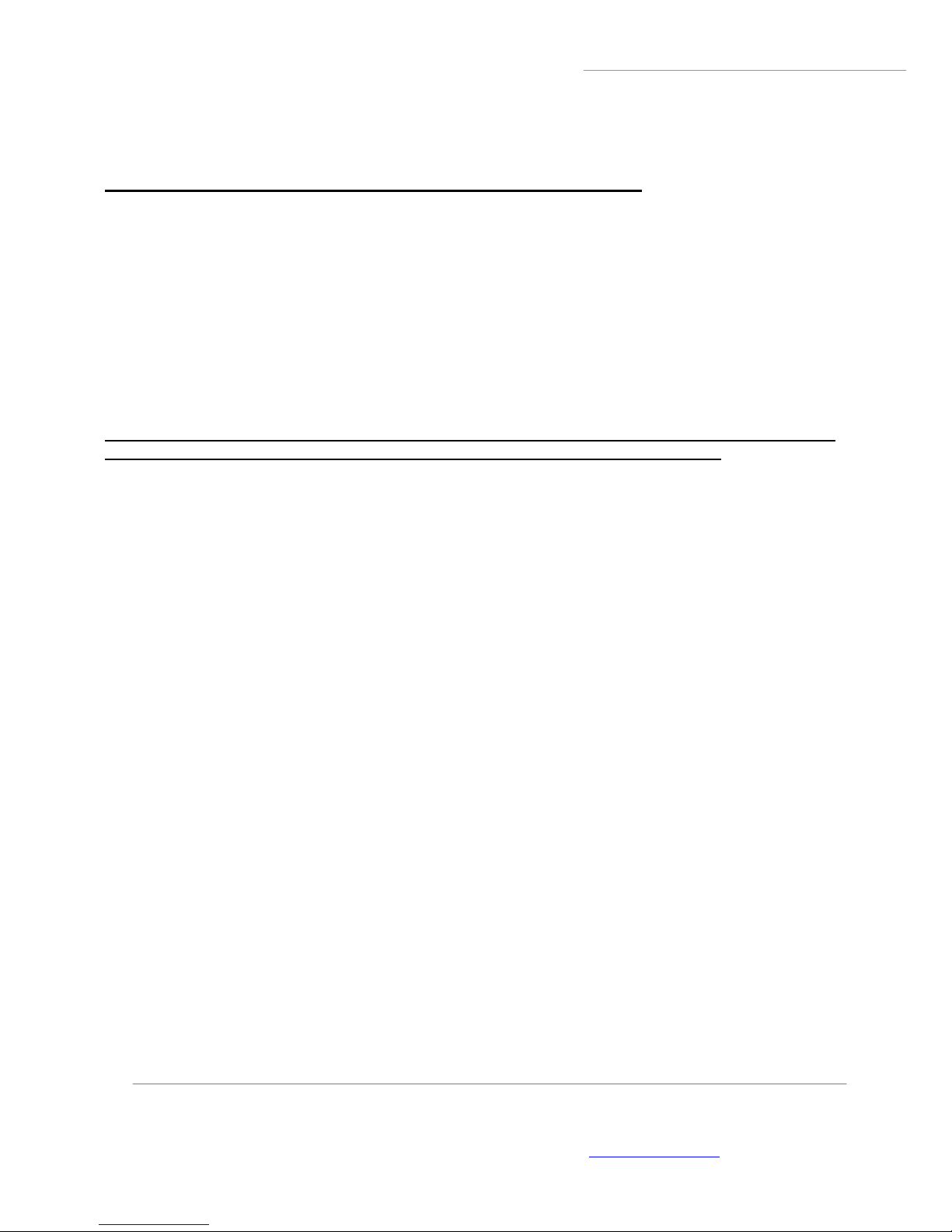

Adjusting the Trigger

The adjustment of the trigger influences the lever stroke and the amount of glue that can be dispensed at once.

A screwdriver can be used to turn the adjustable screw on the left side of the applicators’ casing. The longer the

lever stroke, the more glue can be dispensed at once.

Application of Hot Melts

Only start glueing when the glue has properly molten.

Make yourself familiar with the instrument first. Apply a little glue in varying forms (small, large dots) on a piece

of paper or cardboard. Observe the correct working temperatures of the individual hot melts.

Never start working without having mounted a nozzle!

Press the trigger only when gun has warmed up!

Vent in the corner must, by all means, be left open.

Always deposit the glue applicator on the wire stand or the respective plate2.

The glue applicator must not be laid on its side.

Do not open the lid before the applicator has warmed up.

Plate is an optional accessory No. 2100

Glue Machinery Corporation™

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email: info@gluemachinery.com

4234 Boston St, Baltimore, Maryland 21224

Champ™ 600 Hot Melt Glue Gun

10

Nozzle Replacement

Only replace nozzles when the glue gun is warm (instrument temperature 140 – 176°F (60 - 80°C) and empty.

You are advised to wear protective gloves.

Prior to exchanging nozzles, unplug connecting cable!

Replacing a cold nozzle may damage the gun. If the nozzle is replaced when it is too hot, liquid adhesive may

leak out.

Attention: Risk of burning!

- If your skin contacts with hot glue, cool it immediately with cold water.

- Do not try to remove hot melt from the skin first. If necessary, consult your doctor.

- If hot adhesive gets into your eyes, immediately cool them under running water for about 15 minutes.

- Consult your doctor at once!

Never start working without having mounted a nozzle!

Do not direct glue jet towards people!

Glue Machinery Corporation™

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email: info@gluemachinery.com

4234 Boston St, Baltimore, Maryland 21224

Loading...

Loading...