R

FOX-UP

INSTALLATION AND OPERATING INSTRUCTIONS

MONTAGE- UND BEDIENUNGSANLEITUNG

INSTALLATIE- EN BEDIENINGSHANDLEIDING

INSTRUCTIONS D’INSTALLATION ET D’UTILISATION

R

Installation and operating instructions - English ...........................................................................1

Montage- und Bedienungsanleitung - Deutsch ...........................................................................27

Installatie- en bedieningshandleiding - Nederlands ..................................................................53

Instructions d’installation et d’utilisation - français .................................................................. 79

INSTALLATION AND OPERATING INSTRUCTIONS - ENGLISH

Due to an easy mounting, the units of the Fox Up series are suitable in new buildings and for refurbishment purposes. Fox Up allows for

hygienic air exchange in line with the standards. The units work as a decentralized system and are mounted completely in the outer walls.

There is no need for piping across rooms or floors nor for complex cleaning concepts.

OPERATING INSTRUCTIONS

Storing the manual

All service providers involved in mounting, connection and the set-up of the Fox up ventilators needs the information of this manual in order

to do the work correctly. Please make sure that the manual is available for them.

Please give all users a copy of this manual for consultation when the installation is delivered, it contains important notes on maintenance,

operation and maintenance.

INSTALLATION INSTRUCTIONS - CONTENTS

1. General notes ............................................................................................................................................................................................................2

2. Productinformation..................................................................................................................................................................................................3

3. Delivery units / Delivery contents ..........................................................................................................................................................................4

4. Dimensions / Technical Data ..................................................................................................................................................................................5

5. Selecting installation site ...................................................................................................................................................................................... 6

6. Installation of wall duct .......................................................................................................................................................................................... 6

7. Installation of electronic control system ............................................................................................................................................................. 8

8. Electrical connection of electronic control system / ventilation unit .............................................................................................................. 9

9. Installation ............................................................................................................................................................................................................... 11

10. Start-up report ........................................................................................................................................................................................................ 13

EN

11. Operating instructions ...........................................................................................................................................................................................14

Symbols

The following symbols are used in this manual to indicate special instructions:

General note / Information

Danger due to electrical voltage Installation note / Warning

Warning

1

R

1. GENERAL NOTES

Fox up ventilation units are built in accordance with the latest technological standards and acknowledged safety regulations.

Installation and maintenance on the ventilation unit should only be carried out by specially trained personal in accordance

with the regulations on occupational safety and accident prevention.

The electrical connection must be carried out according the applicable national regulation. During installation

and maintenance work, all poles must be disconnected from the mains with a contact gap of at least 3 mm.

Disconnections must be fixed in the open position!!

The unit may only be used for its intended purpose. Improper use, installation or maintenance work carried out incorrectly and structural

modifications may affect the function and safety of the ventilation unit. In this case the warranty claims will not be valid.

Read these instructions carefully before beginning any installation or maintenance work and follow the advice given on installation and

maintenance.

Before installing the unit, check that the delivery is complete and intact, and contact us, at the address below, if any parts are missing or

damaged.

Intended use

Fox up ventilation units with heat recovery are designed for controlled room ventilation. The units should only be used to deliver air. The delivery of aggressive, flammable or dust-containing media is not permitted. Never operate the unit without the filter in place. The connection

of ventilation pipes from other ventilation systems is not permitted.

Fox up ventilation units are not suitable for construction drying, and should only be used once construction work has been finished.

Operating the unit in conjunction with heat-producing appliances may require additional safety devices. Relevant information is available

from a regionally qualified chimney sweep.

Placing the unit

Fox up ventilation units may only be installed and operated indoors. When selecting a site, please make sure that the unit is accessible for

service and maintenance. The unit must not be installed close to flammable liquids or gases. A mains supply (230 V/50 Hz) is required to

operate the unit.

Installation

When installing the unit, please observe the recognized codes of practice with regard to unit installation, electrical work, fire protection,

etc., as well as the standards for the ventilation of residential buildings.

2

2. PRODUCTINFORMATION

2.1 Mode of operation

The Fox up ventilation unit is a decentralized ventilation system for a controlled room ventilation with heat recovery. The use

of several units in pairs allows entire housing units / buildings to be ventilated.

If operated with heat recovery, the ventilation unit works in 2 prefixed time intervals. In the first interval (extraction phase),

the “used” air in the room is sucked into the ventilation unit by the fan and carried to the outside. During this process, the air flows through

the ceramic heat accumulator inside the ventilation unit, which extracts the heat from the air and stores it.

In the second interval (delivery phase), “fresh” outside air is sucked in via the ventilation unit’s exterior opening. It passes through the unit,

and is heated by the heat accumulator before entering the room. In this way, up to 90% of the heat contained in the extracted air can be

transferred to the fresh air fed into the room. The principle of recharging and discharging a heat accumulator is referred as regenerative

heat transfer.

When a single unit is used, an overpressure (delivery phase) or under pressure (extraction phase) is created in the room being ventilated,

this depends on the operating phase. To guarantee a balance between the volumes of air delivered and extracted, it is recommended that

Fox up units be used in pairs. The control of the ventilation units allows up to three pairs of units to be operated simultaneously.

2.2 Planning notes

Before installing Fox up ventilation units, a ventilation plan should be made. This specifies the number of ventilation units,

their locations, the ventilation principle (transverse ventilation, single-room ventilation). Also it specifies the position and

number of the associated electronic control systems. Fox up ventilation units allow the following variations in ventilation:

• Single-room ventilation with one ventilation unit, alternating between delivery and extraction modes with heat recovery at intervals,

alternatively delivery* or extraction* mode (* depending on the electrical connection, see page 9).

• Transverse ventilation with ventilation units operating in pairs, alternating between delivery and extraction modes with heat recove-

ry. While one unit of a pair runs in delivery mode, the designated second unit operates in extraction mode. The air direction of both units

swapping in the next interval, alternatively delivery* or extraction* mode (* depending on the electrical connection, see page 9)

.

Where possible, Fox up ventilation units should be used in pairs see Mode of operation. The pairs of units can be used in one or multiple

rooms. It can also be arranged across more than one floor within a unit. The air must be free to flow between the rooms which needs to be

ventilated by means of sufficient dimensioned overflow openings (e.g. door air grilles or shortened door leaves).

To prevent that odors are being transferred to other rooms (delivery phase of ventilation unit), two units operating in a push-pull arrangement should always be installed when airing/ventilating kitchens, bathrooms or toilets with windows.

Fox up units should not be used in internal, windowless exhaust-air rooms such as kitchens, bathrooms and toilets. It is not permissible to

connect the units to a shaft or pipe. In this case, the use of an exhaust fan in accordance with the national norm is recommended, e.g. the

BRAVO fan type.

EN

The units are also unable to be installed in cellar rooms with light shafts, since it is possibility that the outgoing air is recirculated. When

the units are installed on a façade there needs to be a minimum distance of 1.2 m between individual units in order to avoid recirculation.

We recommend not using the unit in a location on the building that is exposed to the wind with a average wind speed of more then 5 m/s.

To prevent the ventilation units from causing inconvenience draughts, they should not be positioned directly next to people who are a

longer time in one place (seating, beds). Make sure that the flow of air into the room is not obstructed by furniture or curtains

3

R

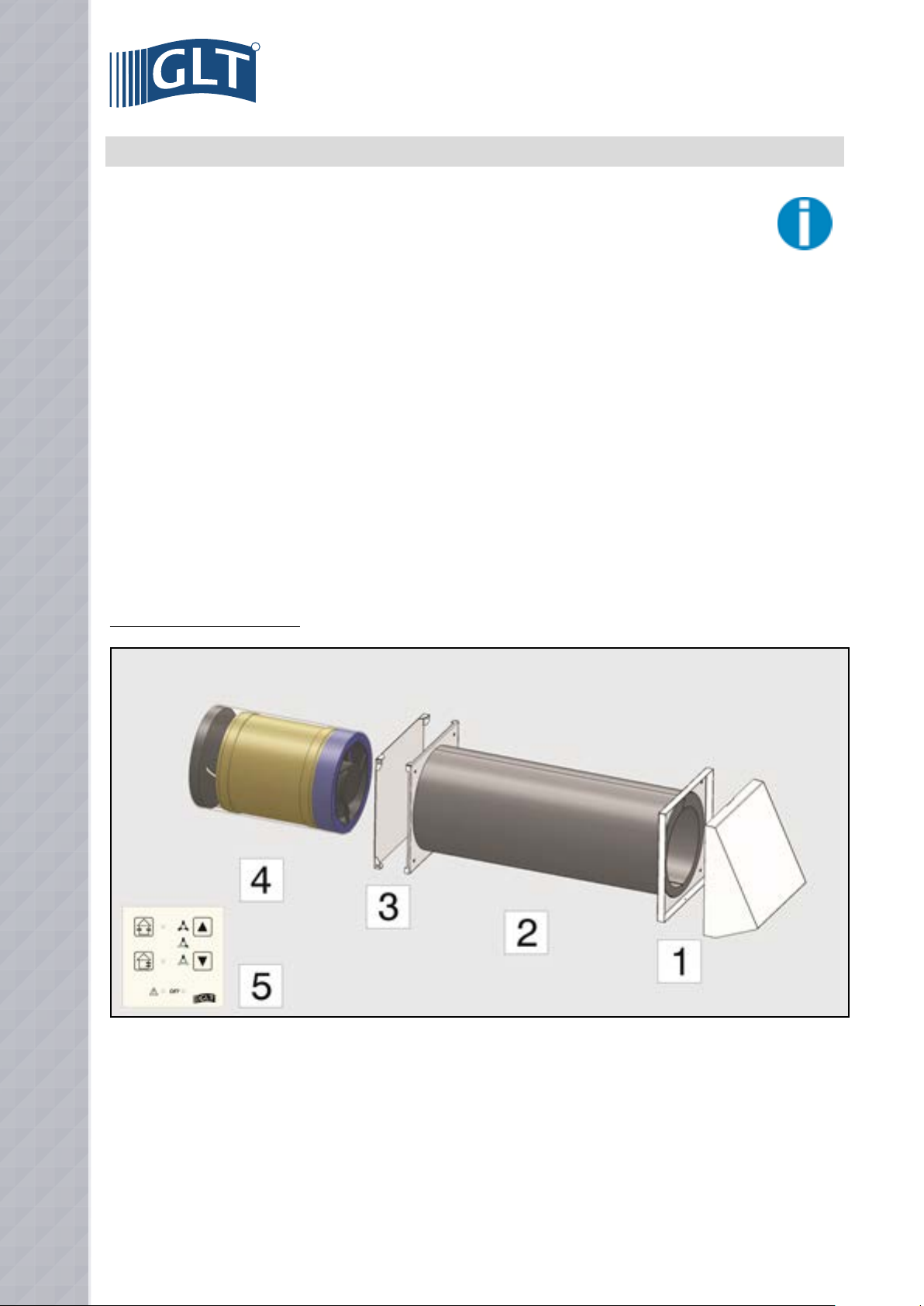

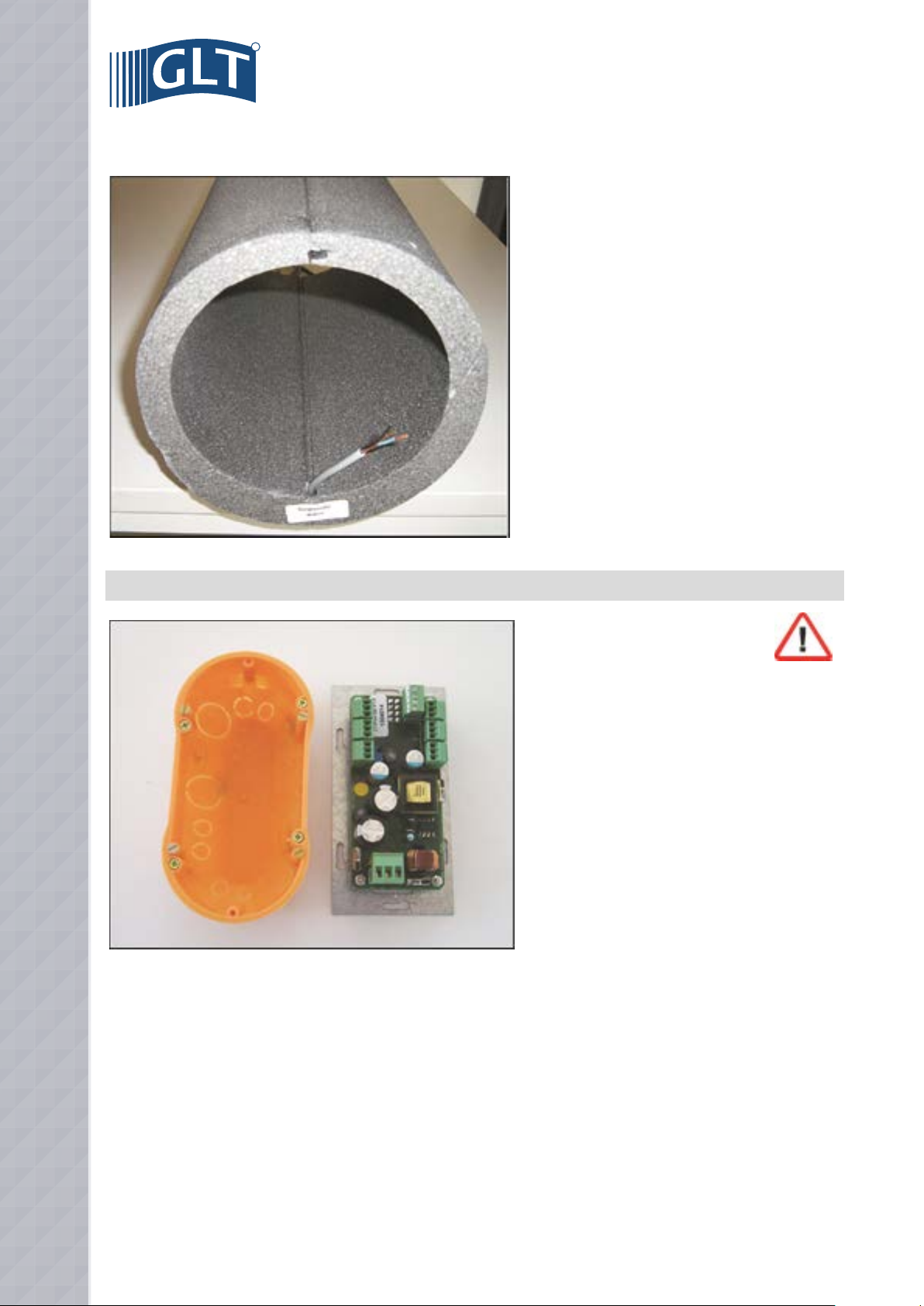

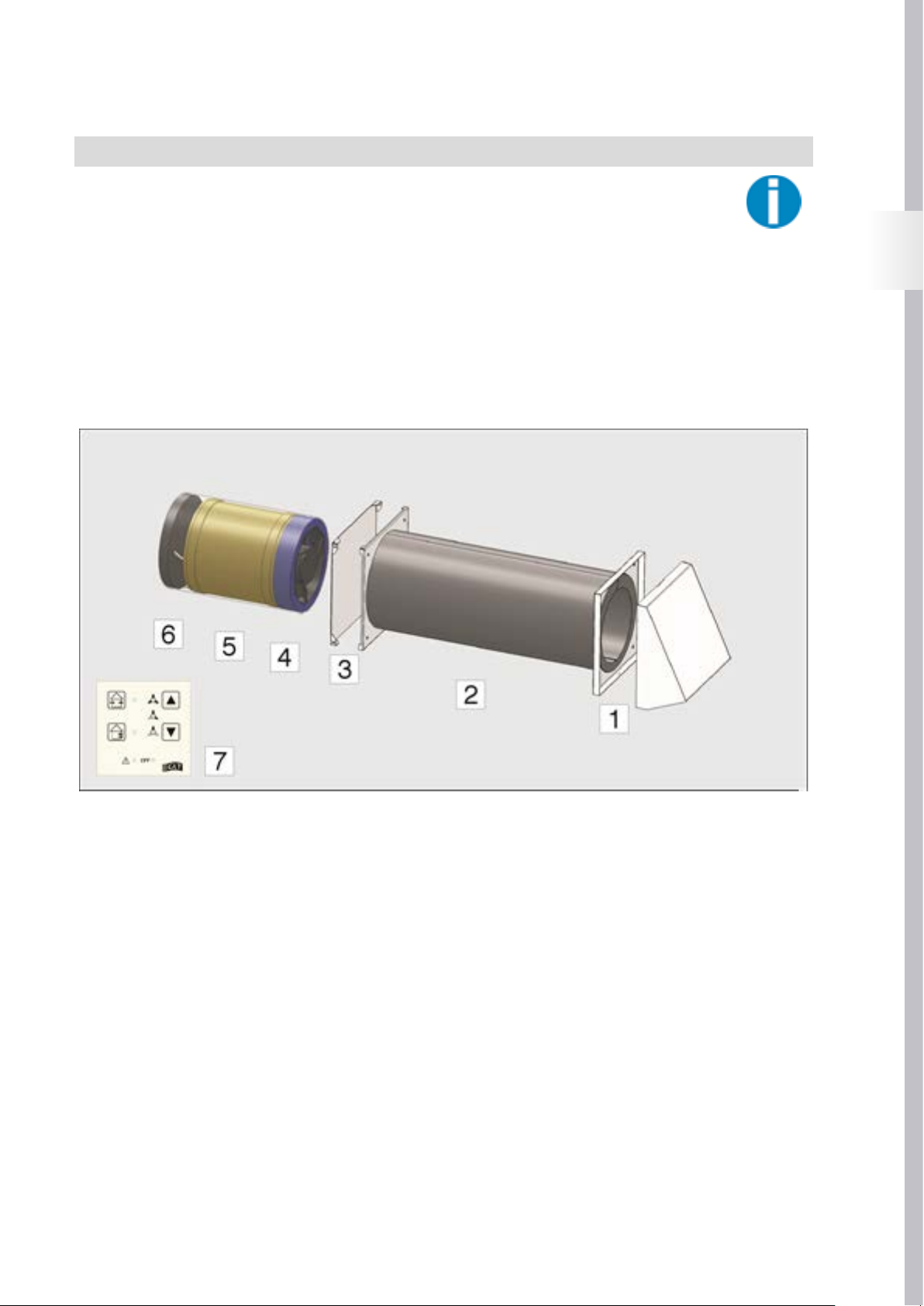

3. DELIVERY UNITS / DELIVERY CONTENTS

A complete Fox up ventilation unit consists of an EPS wall duct and a fan unit for insertion into the wall duct. The fan unit

consists of a reversible fan (12 V/DC) and a ceramic heat accumulator for heat recovery.

Air is fed into the room through a design plate with filter insert, and carried to the outside through a weatherproof protective

hood.

The unit is operated via an electronic control system with control panel, and up to six ventilation units (3 x delivery, 3 x

extraction) can be controlled by the electronic control system. The electronic system is installed in a double-cavity wall box for flush-mounted fitting.

The following delivery units are available for the various installation steps:

• Fox up-GP-Design, item no. 1145200: basic package consisting of wall duct (500 mm long), fan unit, inner plate, weatherproof protec-

tive hood and electronic control system with hollow-wall flush-mounted box.

• Fox up-EP-Design, item no. 1145201: supplementary package consisting of wall duct (500 mm long), fan unit, inner plate and weather-

proof protective hood.

• Fox up-Shell set 500 mm, item no. 1145210: shell set consisting of wall duct (500 mm long) and hollow-wall flush-mounted box.

• Fox up-Shell set 1000 mm, item no. 1145211: shell set consisting of wall duct (1000 mm long) and hollow-wall flush-mounted box.

• Fox up-Shell set 500 mm, item no. 1145212: shell set consisting of wall duct (500 mm long)

• Fox up-Shell set 1000 mm, item no. 1145213: shell set consisting of wall duct (1000 mm long)

• Fox up FMS-GP-Design, item no. 114220: final assembly basic package consisting of fan unit, inner plate, weatherproof protective

hood and electronic control system.

• Fox up FMS-EP-Design, item no. 1145221: final assembly supplementary package consisting of fan unit, inner plate, weatherproof

protective hood and electronic control system.

Fox up ventilation unit complete

1. Weatherproof protective hood (air inlet/outlet opening on outside)

2. EPS wall duct

3. Design valve (air inlet/outlet opening on room side)

4. Fan unit (incl. ceramic heat accumulator and filter insert)

5. Control panel / electronic control system

4

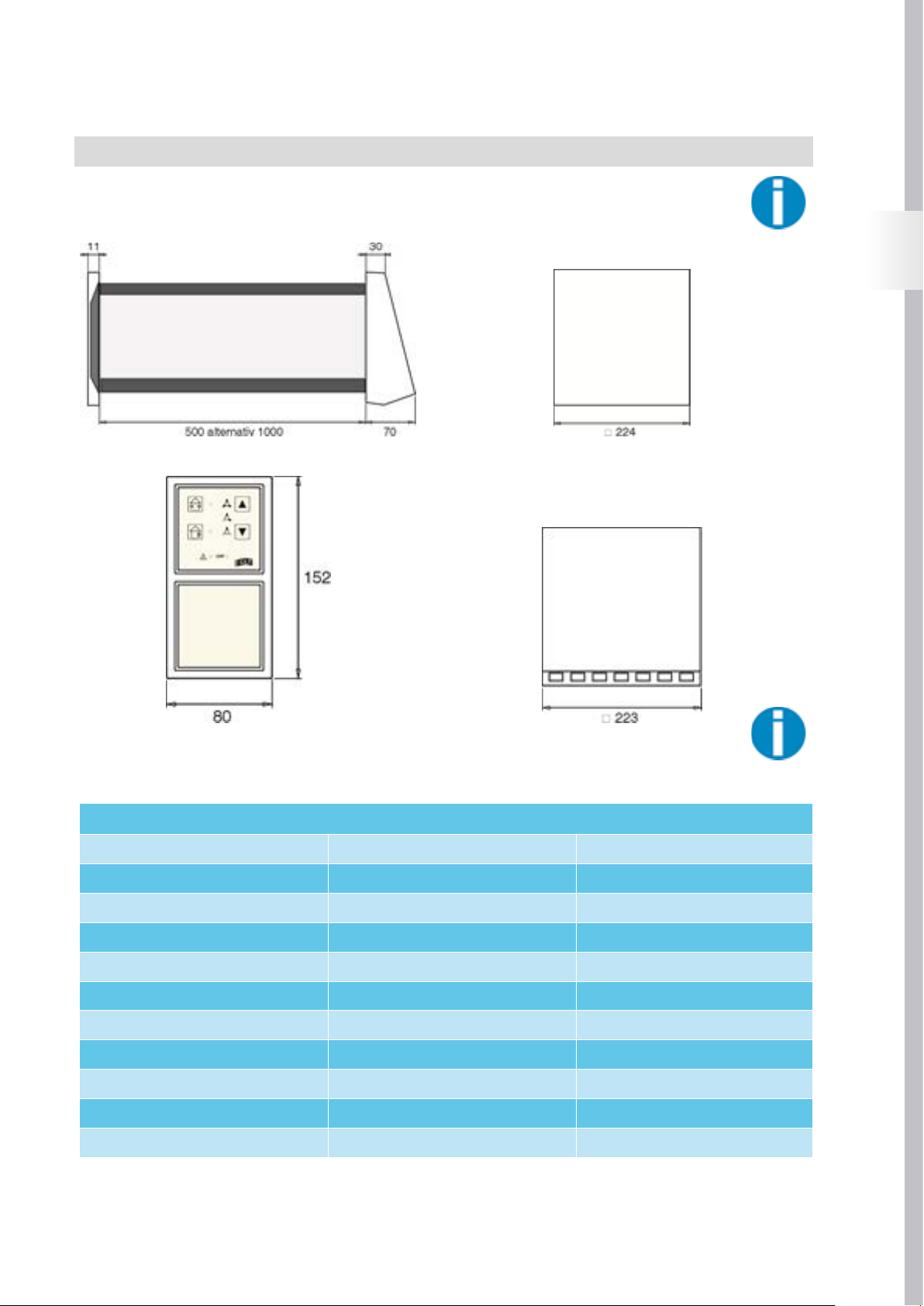

4. DIMENSIONS / TECHNICAL DATA

4.1 Dimensions Fox up ventilation unit - all dimensions in mm -

EN

Fox up inner plate

Fox up electronic control system Fox up inner plate

4.2 Technical Data

Fox up ventilation unit

Airflow: 15 / 30 / 40 m³/h

Efficiency of heat exchanger: <91 %

Supply voltage : 230 V/50 Hz

Power consumption : 1,4 / 2,6 / 3,7 W

Sound pressure level : 19 / 24 / 341 dB(A)

Filter class : G2

Permissible operating temperature: -20 tot +40 °C

IP protection class: 20

Weight: 5,5 kg

ø of wall duct (inner / outer): 153 / 198 mm

Length of wall duct: 500² / 1000³ mm

1. Sound pressure level, factory measurement

2. Fox up shell set 500 mm

3. Fox up shell set 1000 mm

5

R

5. SELECTING INSTALLATION SITE

When selecting the installation position, pay

attention to the outer wall of the building, the units

needs to be positioned esthetical correct in the

building façade. For example: the units should be

installed at the same height as the windows and at equal distances

from windows.

The outside or room-side air inlet/outlet opening is recommended

at a minimum distance of 150 to 200 mm from adjacent façade

components and room corners!

Fox up ventilation units should be installed at a height of 1.6 to 1.8

m above the finished floor level, and the room-side air inlet/outlet

opening must not be covered by furniture or curtains.

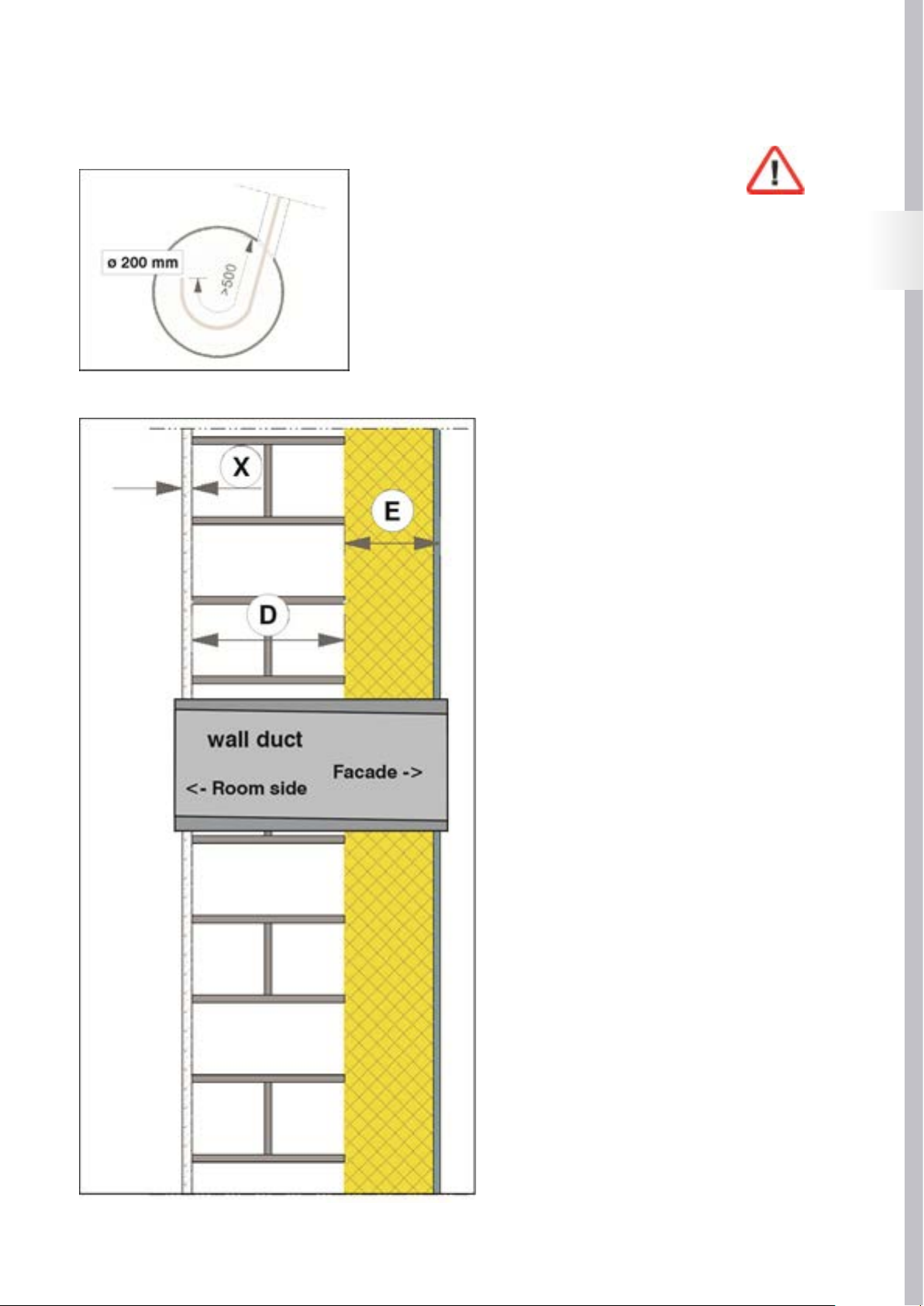

6. INSTALLATION OF WALL DUCT

EPS pipe wall duct

Inner ø 153, outer ø 198 mm, built-in gradient to outside (condensate drainage)

Wall ducts are available in two different lengths for Fox up ventilation units:

• Pipe length 500 mm: Fox up shell set 500 mm, item no. 1145210 or 1145212

• Pipe length 1000 mm: Fox up shell set 1000 mm, item no. 1145211 or 1145213

The delivery units Fox up-GP-Design and Fox up-EP-Design are supplied as standard with 500 mm wall ducts, the wall ducts are manu-

factured with a built-in gradient to the outside for condensate drainage (observe marking of outside, see fig. above).

6

6.1 Tap hole drilling for wall duct

6.2 Installation of wall ducts

Create a hole with a diameter of 200 mm.

Feed the fan connecting lead (min. 3 x 0.25 mm2) into the wall duct.

The fan connecting lead must be perpendicular to the axe of the wall duct.

EN

Determine the overall thickness of the wall structure from

the dimensions of:

- The work measurement (D)

- The outside (E) (e.g. heat insulation + plaster)

- The inside (X) (e.g. plaster + tiles).

- The minimal length might never be shorter then 240 mm

Slide the wall duct into the wall opening, observing the

gradient to the outside / the room-side marking of the wall

duct. Allow the wall duct to stand perpendicular on the

both room and façade sides in accordance with the above

calculation.

Attention:

To ensure good movement of the fan / heat unit in the

wall duct, deformations of the wall duct due to external

pressure/tension should be avoided!

7

R

6.3 Wall duct for insertion of connecting lead of ventilation unit

Feed the electric connecting lead of the ventilation unit (see

view from

room side) into the wall duct.

Check the correct position of the wall duct (overhangs

outside / inside) and close the openings of the wall duct with

the protective covers.

Finally, fill the cavities (if any) between the wall opening and

the wall duct with non-pressurized

expanding foam.

7. INSTALLATION OF ELECTRONIC CONTROL SYSTEM

The electronic control system of Fox up ventilation units

is designed to be installed in a double hollow cavity

flush-mounted box. It can be used to control up to six Fox

up ventilation units.

The electronic control system is to be connected as stationary equipment with fixed wiring.

See page 9 for electrical connection diagram.

The supply voltage of the electronic control system is 230 V/50 Hz. A light-plastic sheathed cable 3 x 1.5 mm2 (e.g. NYM-J 3 x 1.5 mm2) is

recommended as an incoming line.

The ventilation units are supplied by 12 V DC in combination with a PWM controlling signal. Therefore, the ventilation units should not under

any circumstances be connected to the 230 V mains voltage of the electronic control system. A light-plastic sheathed cable 3 x 0.25 mm2

(e.g. LiYY 3 x 0.25 mm2) is recommended as a control line for the ventilation units with a maximum length of 10m.

8

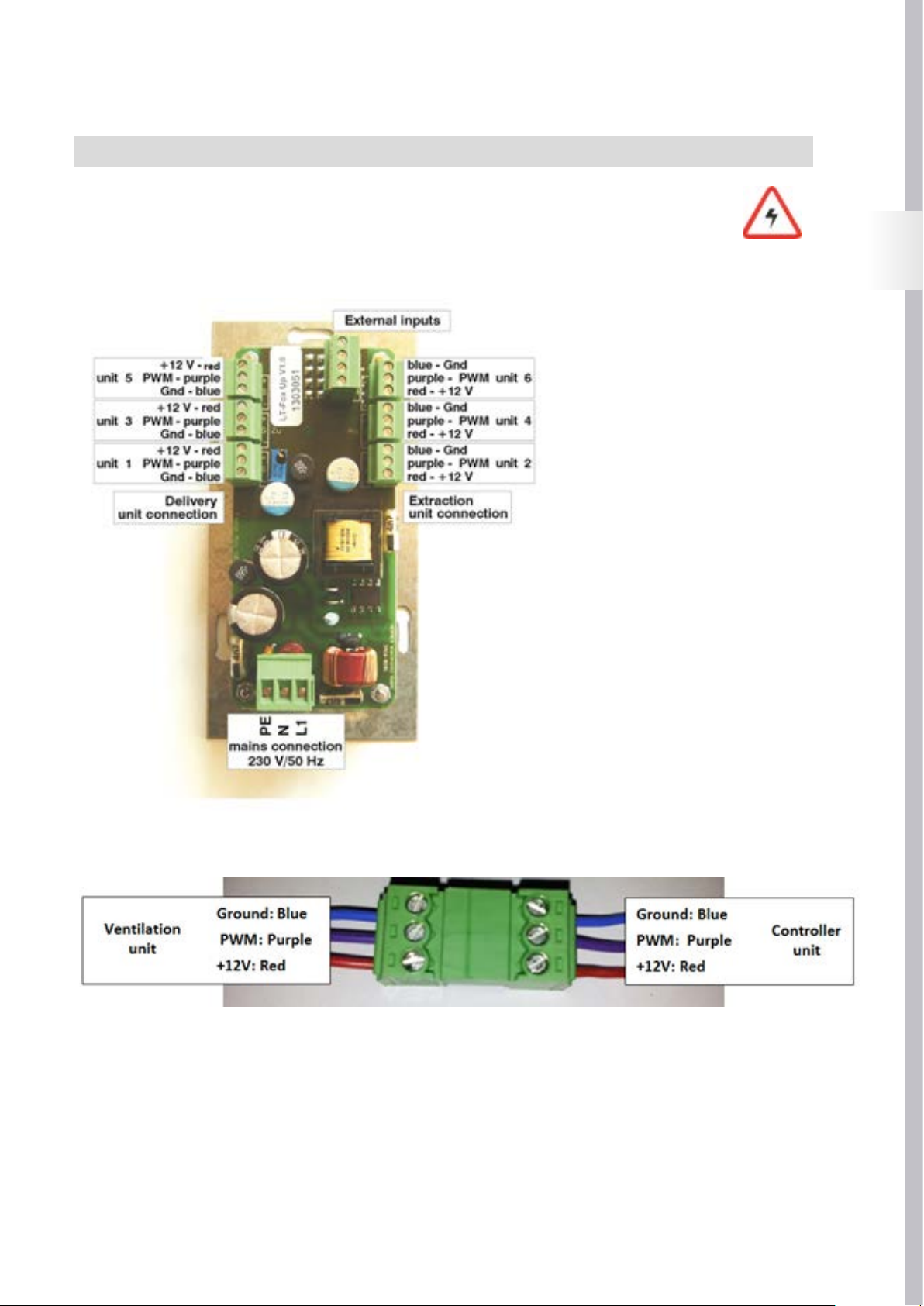

8. ELECTRICAL CONNECTION OF ELECTRONIC CONTROL SYSTEM / VENTILATION UNIT

The electrical connection must be carried out according the local applicable standard. During installation

and maintenance work, all poles must be disconnected from the mains with a contact gap of at least 3 mm.

Disconnections must be immobilised in the open position!

• Connecting the electronic control system:

Connecting a single unit:

A single ventilation unit is connected to the

Unit 1 or Unit 2 plug-in connector as shown in

the figure on the left.

When connected to the Unit 1 plug-in

connector, the unit can be used in “summer

mode” (see Ventilation mode page 16) as

a delivery unit. When connected to the Unit

2 plug-in connector, the unit can be used in

summer mode as an extraction unit.

Connecting several units:

Several units may be connected in pairs to

the plug-in connectors Unit 1 – Unit 2, Unit 3 –

Unit 4, Unit 5 – Unit 6; when used in pairs.

One of the units in the pair operates in delivery

mode, and the second unit operates in extraction mode, with the air direction of both units

swapping in the next interval.

EN

8.1 Connecting ventilation unit(s) – electronic control system

Fox up ventilation units are connected to the electronic control system via a plug-in connector supplied with the ventilation units as shown

above. Please observe polarity of delivery/extraction units (see fig. above)!

9

R

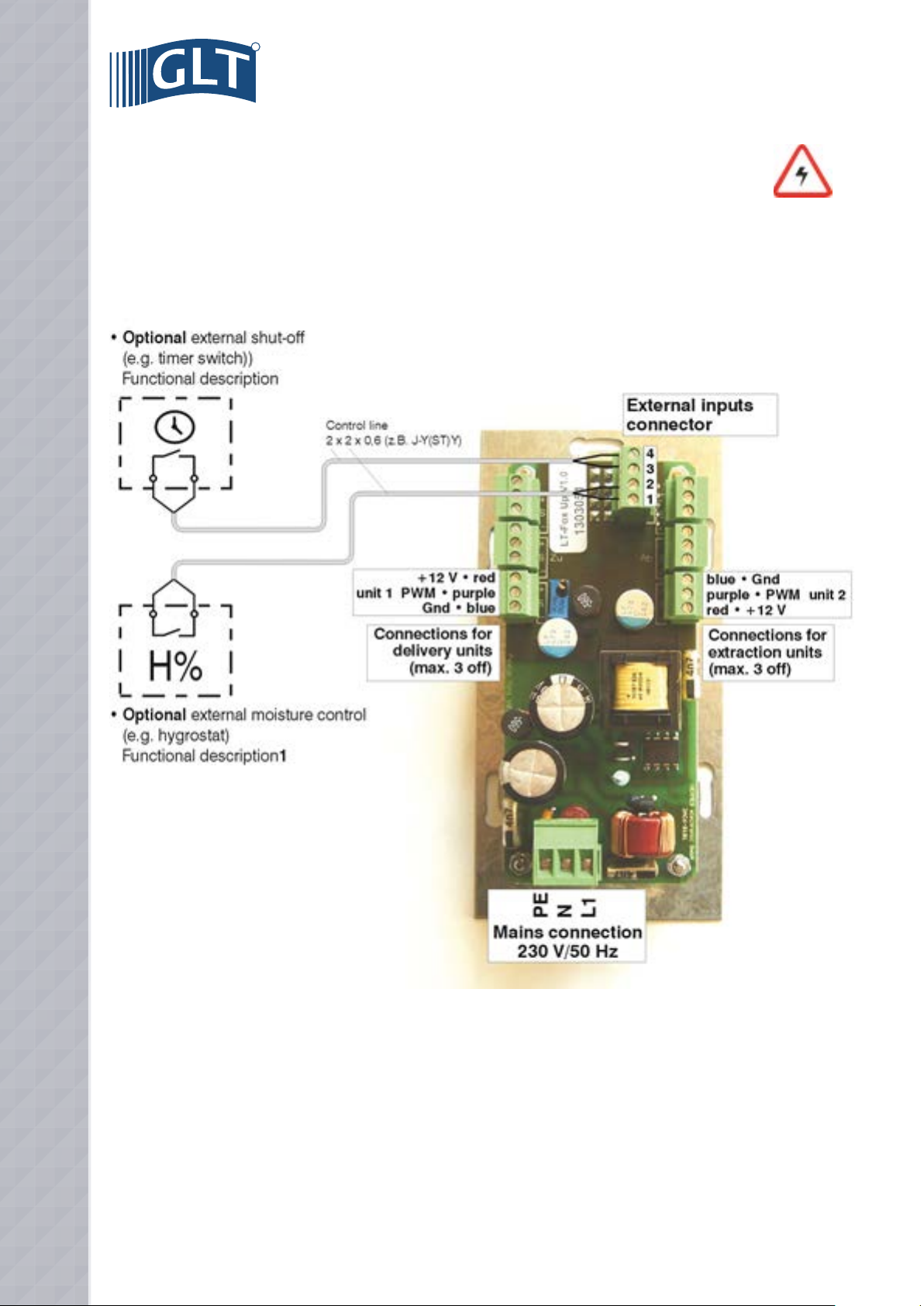

8.2 Electrical connection of external control elements

The operating mode of Fox up ventilation units is set to user-dependently via the control panel of the electronic control

system. Different operating variants can be selected with different power stages.

By connecting optional external control elements, a time- or moisture-dependent unit mode can also be activated. External control

elements are connected as shown above via the “external inputs” connector to the electronic control system of the ventilation units. The

function of the unit when controlled externally is described from page 19 of these instructions.

Connecting external control elements

A data line (e.g. 2 x 2 x 0.6 (e.g. J-Y(ST)Y) is recommended for connecting external control inputs (floating contacts).

10

9. INSTALLATION

9.1 Installation of fan unit

After the electrical connection has been made, the fan unit, consisting of the heat accumulator and fan, is inserted into the

wall duct:

Carefully slide the fan unit (fan towards façade) into the wall duct,

making sure that the fan’s connecting lead is not trapped / damaged.

The strap on the heat accumulator allows the fan unit to be aligned

during installation and removed from the wall duct for maintenance

purposes. Next, connect the plug-in connector between the connecting

leads of the ventilation unit and control unit.

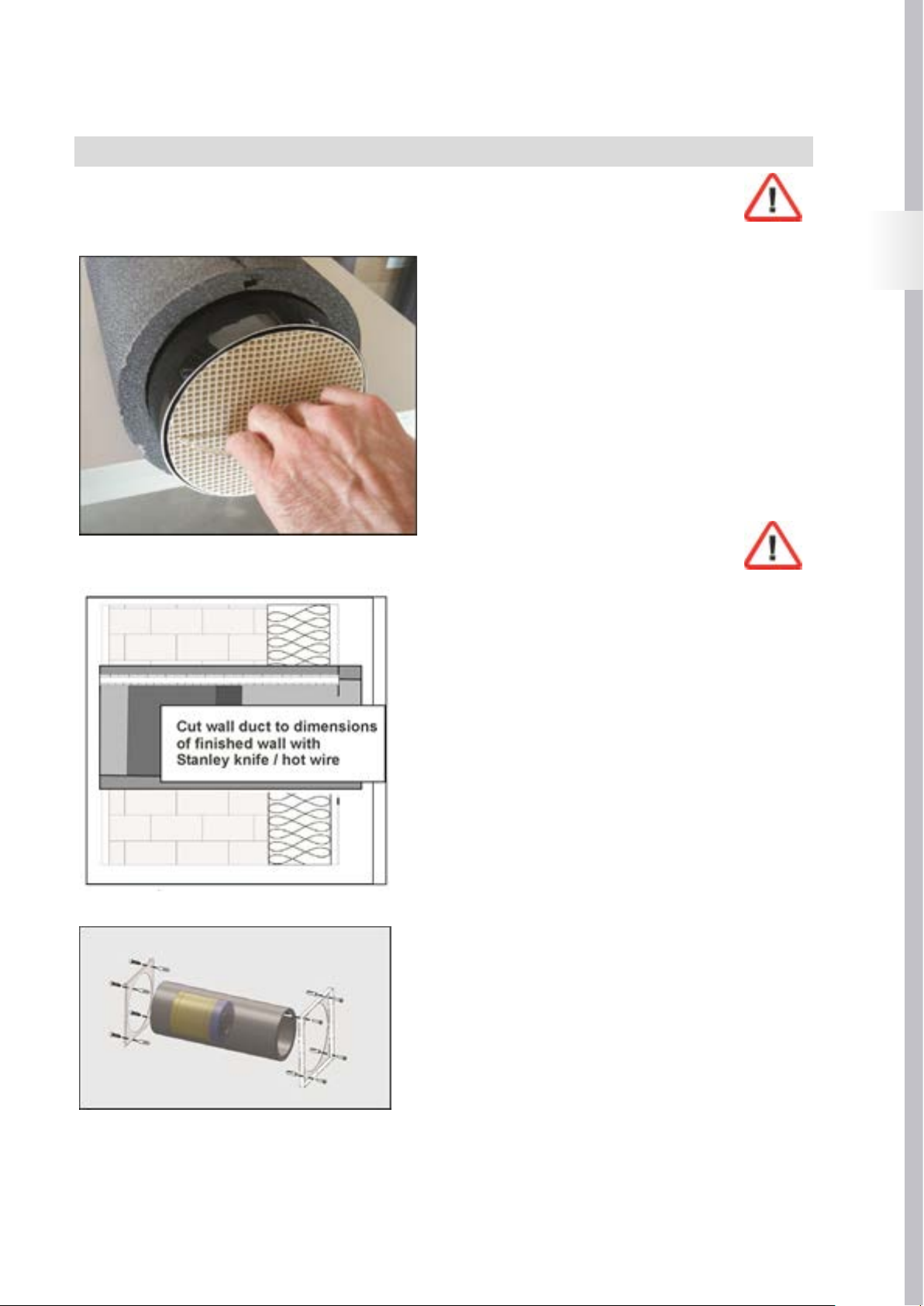

9.2 Final assembly

EN

Once the insulation and plastering work has been completed, the wall duct

must be adapted to the dimensions of the finished wall by being cut with a

Stanley knife or hot wire flush with the wall on both room and façade sides.

Next install the support frame for the internal plate (room side) and the

weatherproof protective hood (façade side) of the ventilation unit using the

mounting materials which are supplied with the ventilation unit.

11

R

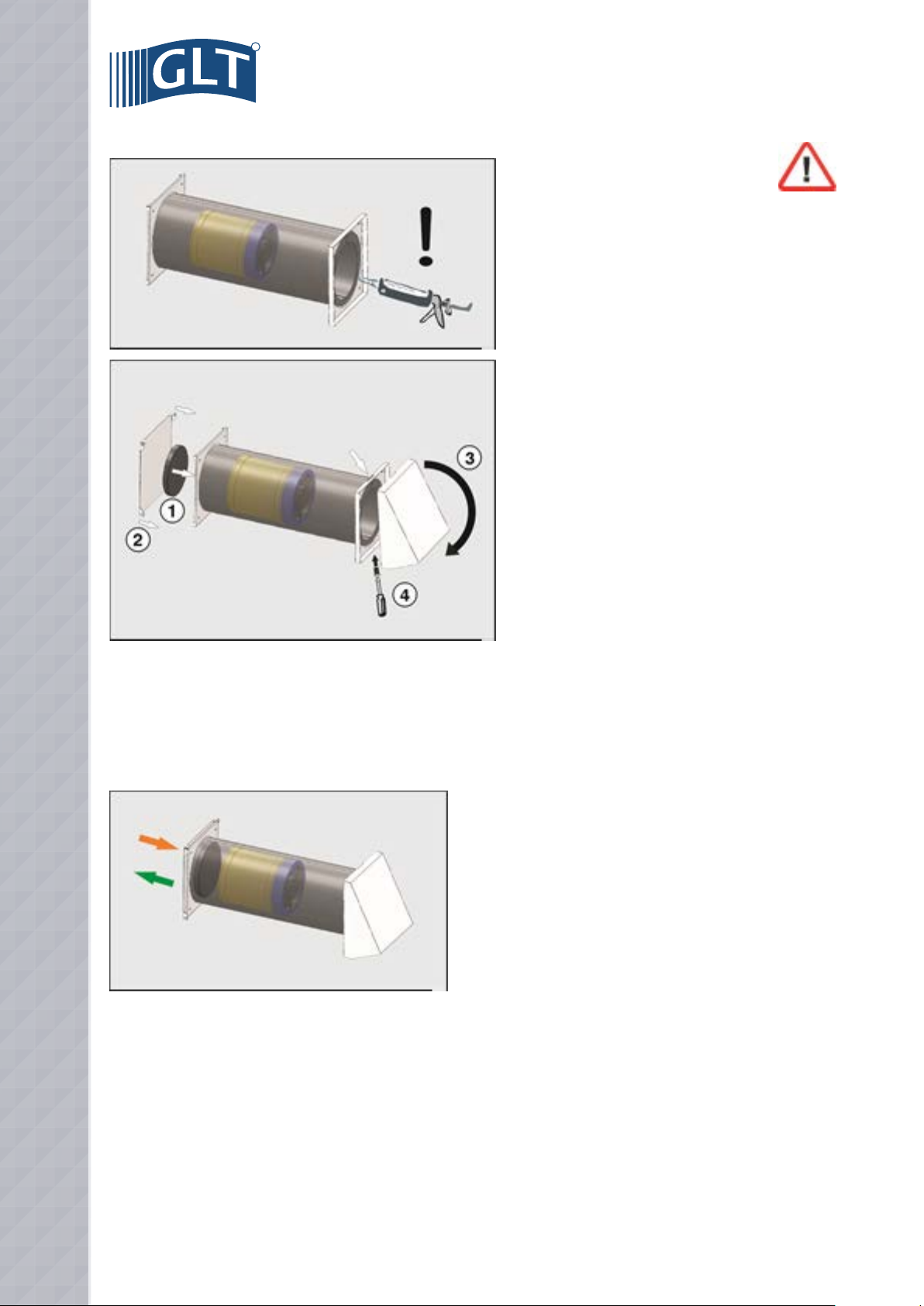

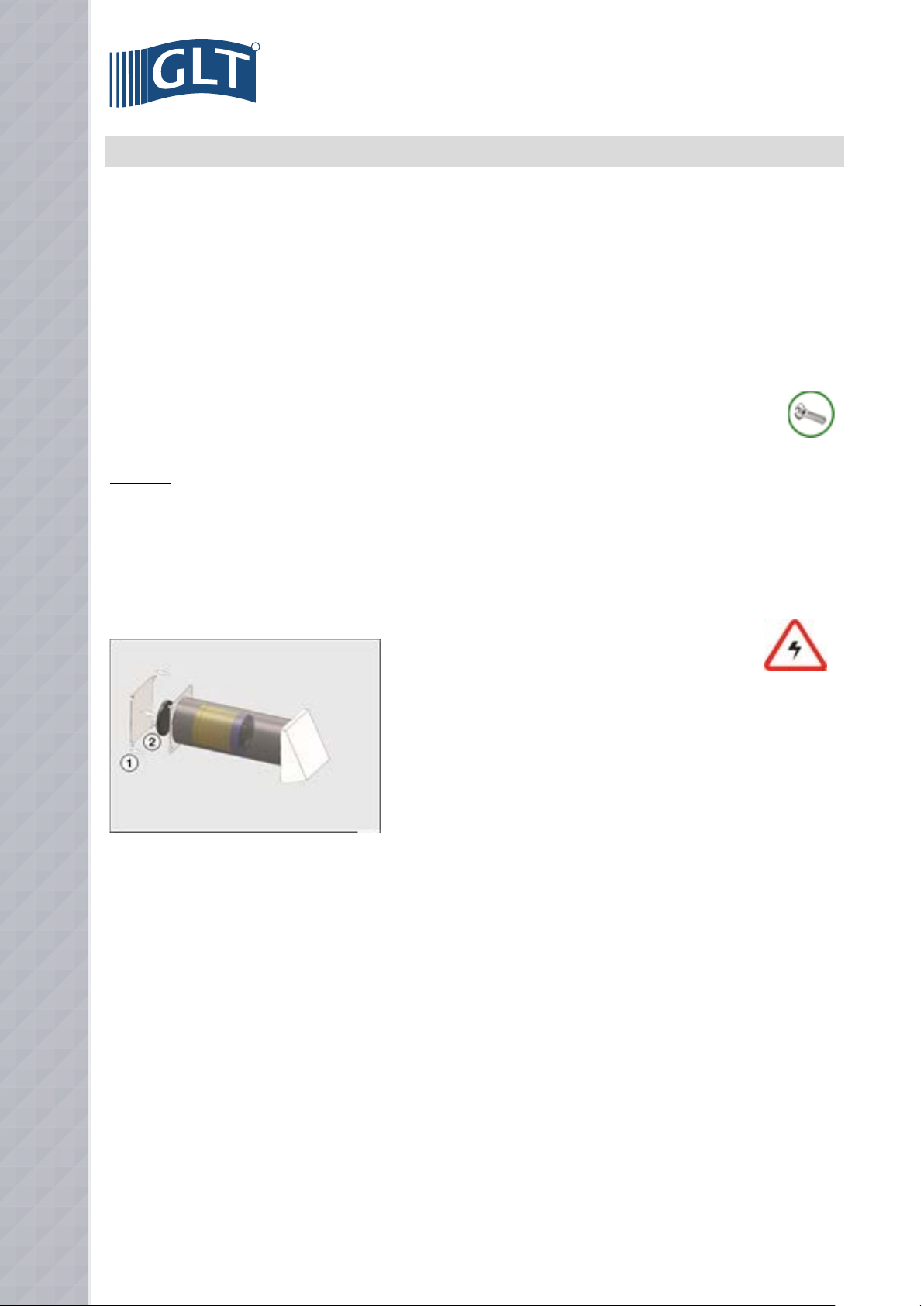

To prevent water from entering the wall opening,

the façade-side transition between the wall duct and the

support frame for the weatherproof protective hood must be

sealed all round with silicone or some other suitable sealant!

Slide the filter insert (1) supplied with the ventilation unit into

the wall duct and close the inner plate (2) of the ventilation

unit (magnetic catch).

Finally, install the unit’s façade-side weatherproof protective

hood (3). The hood is clipped onto a lug on the top of the

support frame and attached to the bottom of the support frame

using the fastening screw as supplied (4).

9.3 Functional test of ventilation unit(s)

Once installed, the function of the unit(s) must be checked. Before carrying out the check, make sure that the air passages of the ventilation unit(s) are free from assembly residues / foreign bodies and that all electrical work was carried out and completed in a technically

correct manner!

After switching on the power supply (generally via the electrical

installation’s automatic circuit-breakers), the ventilation unit can be

started using the electronic control system’s control panel. At start-up,

check all the unit functions as described at page 18 of the operating

instructions, making sure that the fan motor is running quietly and

smoothly.

Any malfunctions or faults found in the ventilation unit must be corrected before the unit is finally put into operation. Possible causes of faults

and their rectification are described in the section entitled Malfunctions

(see page 22).

Document the properly performed installation / functional testing of the ventilation unit(s) in the start-up report on page 13 of these

installation instructions.

12

10. START-UP REPORT

Building project:

Client:

Street:

Postcode / place:

Telephone:

E-Mail:

Ventilation unit(s) installed:

Type:

Number:

:

Fitter:

:

Installer:

Company:

Street:

Postcode / place:

Telephone:

E-Mail:

EN

• Installation work completed

• Electrical connection carried out / tested in a technically correct manner

• Unit function checked

• Filter insert(s) used

• Unit operator instructed (operation, maintenance)

• Unit documentation handed over (installation / operating instructions)

Option when operating units in conjunction with heat-producing appliances:

• Safety devices installed / tested

Place:

Date:

Fitter:

Client:

13

R

11. OPERATING INSTRUCTIONS

1. General notes ..........................................................................................................................................................................................................14

2. Unit description ...................................................................................................................................................................................................... 15

3. Settings for ventilation mode ...............................................................................................................................................................................16

4. Operating and display elements of electronic control system ........................................................................................................................ 18

5. External control inputs for electronic control system .......................................................................................................................................19

6 . Cleaning / Maintenance of the ventilation unit.................................................................................................................................................20

7. Error messages / Malfunctions ...........................................................................................................................................................................22

8. Maintenance report / Filter cleaning .................................................................................................................................................................. 24

1. GENERAL NOTES

Your Fox up ventilation unit allows you to create a healthy, pleasant indoor and ambient climate in your flat or house through

regulated, needs-based ventilation. Thanks to their easy installation and simple operation, the units are ideal for use in new

buildings and in case of refurbishment..

Fox up ventilation units are manufactured in accordance with the latest technological standards and acknowledged safety

regulations. General type approval has been applied for.

Please read these operating instructions carefully before using the unit, and follow the instructions during installation and during maintaining the unit. The operator of the ventilation unit is responsible for the condition and proper operation of the unit, with due regard for the

aforesaid instructions. Improper use, incorrectly carried out repair or maintenance work and structural changes may adversely affect the

function and safety of the unit and invalidate any warranty claims.

Installation and work on the ventilation unit should only be carried out by specially trained staff in accordance with the regulations on

occupational safety and accident prevention.

Fox up ventilation units with heat recovery are designed for the airing and ventilation of one or more rooms. The units should only be

used to deliver air. The delivery of aggressive, flammable or dust-laden media is not permitted. Never operate the unit without the filter

inserted.

The connection of ventilation pipes / connection to other ventilation systems is not permitted. Fox up ventilation units are not suitable for

construction drying, and should only be used once construction work has finished.

Operating the unit in conjunction with heat-producing appliances may require additional safety devices (Fire Regulations). Relevant

information is available from your local chimney sweep.

Prerequisites for optimal ventilation:

1. Where possible, keep doors and windows in the rooms being ventilated closed.

2. If several units are operated, overflow openings are to be provided between the rooms being ventilated (shortening of door

leaves, installation of door air grilles).

3. All ventilation units should be operated simultaneously in a ventilation setting as equal as possible.

14

2. UNIT DESCRIPTION

The Fox up ventilation unit is a decentralized ventilation system for controlled room ventilation with heat recovery. The use of

several units in pairs allows entire housing units / buildings to be ventilated.

The ventilation unit consists of an EPS wall duct that can be cut to length for wall thicknesses up to 500 m (alternatively

1000 mm) and a fan unit inserted into the wall duct. The fan unit consists of a reversible van (12 V/DC) and a ceramic heat accumulator for

heat recovery.

Air is fed into the room through a white, powder-coated design plate with a filter insert (filter class G2), and is carried to the outside

through a white, powder-coated weatherproof protective hood.

The unit is operated via the control panel of a wired electronic control system for flush-mounted fitting, and up to six ventilation units (3 x

delivery, 3 x extraction) can be controlled by the electronic control system.

Fox up ventilation unit complete

EN

1. Weatherproof protective hood (air inlet/outlet opening on outside)

2. EPS wall duct

3. Design valve (air inlet/outlet opening on room side)

4. Fan

5. Ceramic heat accumulator

6. Filter insert

7. Control panel / electronic control system

15

R

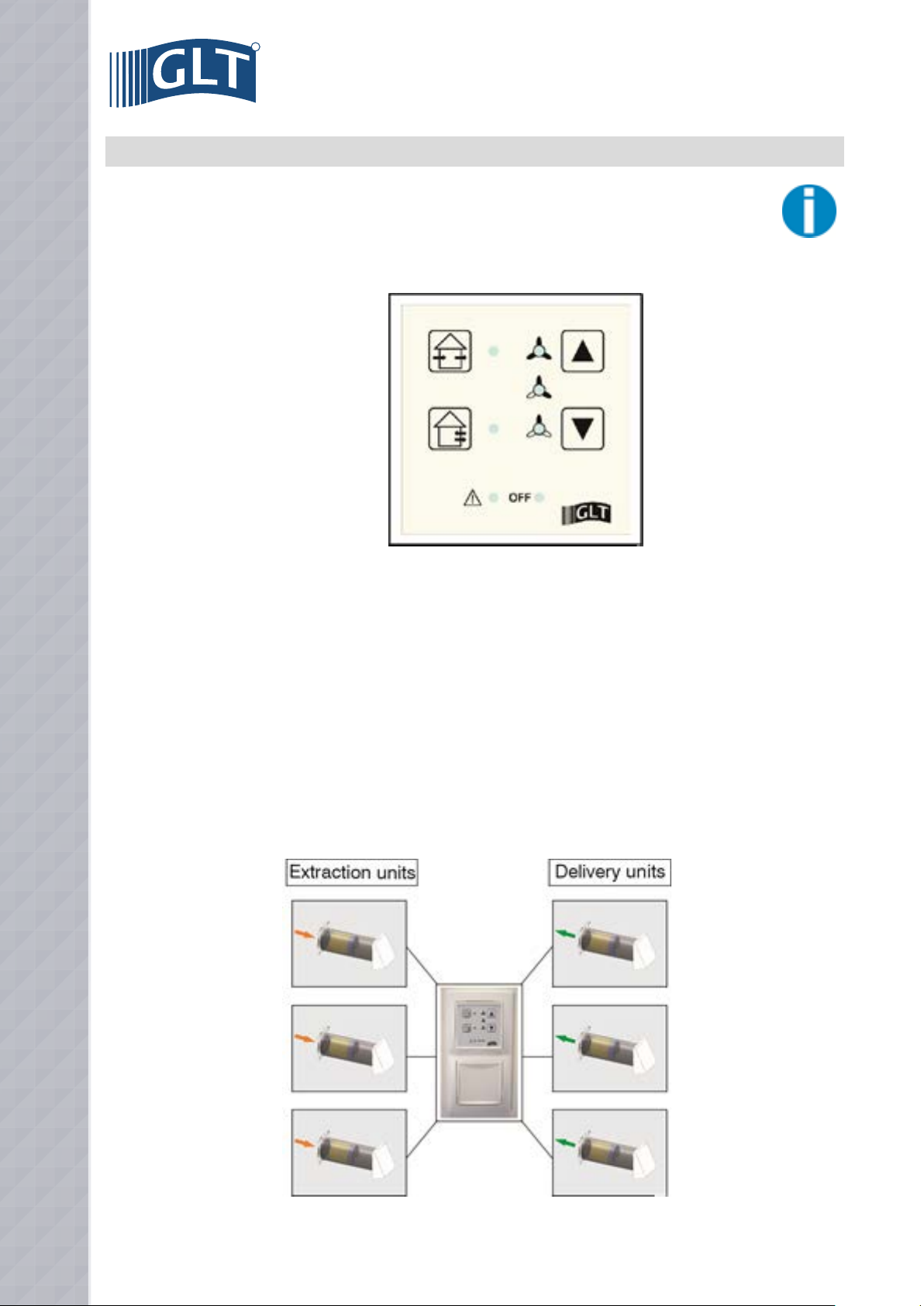

3. SETTINGS FOR VENTILATION MODE

3.1 Settings for ventilation mode

The operating variants of Fox up ventilation units are set using the control panel of the electronic control system of the ventilation units. Two basic functions with different fan powers can be set :

Summer mode function ------->

Winter mode function ------->

1. Summer mode function (delivery or extraction mode without heat recovery):

In this setting, the ventilation unit(s) work constantly in delivery* or extraction* mode, without heat recovery. *The operating mode

is defined by the electrical connection; the unit can be connected to the electronic control system as a delivery or extraction unit (see

Electrical connection page 9)

2. Winter mode function (delivery and extraction mode with heat recovery):

The ventilation unit(s) work alternately in 2 set time intervals. In the first interval (extraction phase), the “used” air in the room is sucked into the ventilation unit and pushed to the outside. During this process, the air flows through the ceramic heat accumulator inside

the ventilation unit, which extracts the heat from the air and stores it.

In the second interval (delivery phase), “fresh” outside air is sucked into the ventilation unit. It passes through the unit, and is heated by

the heat accumulator before entering the room.

If the Fox up ventilation units are used in pairs, the units in a pair work in opposite directions, i.e. the first unit in delivery mode and the

• Fox up ventilation system with 3 delivery and 3 extraction units:

16

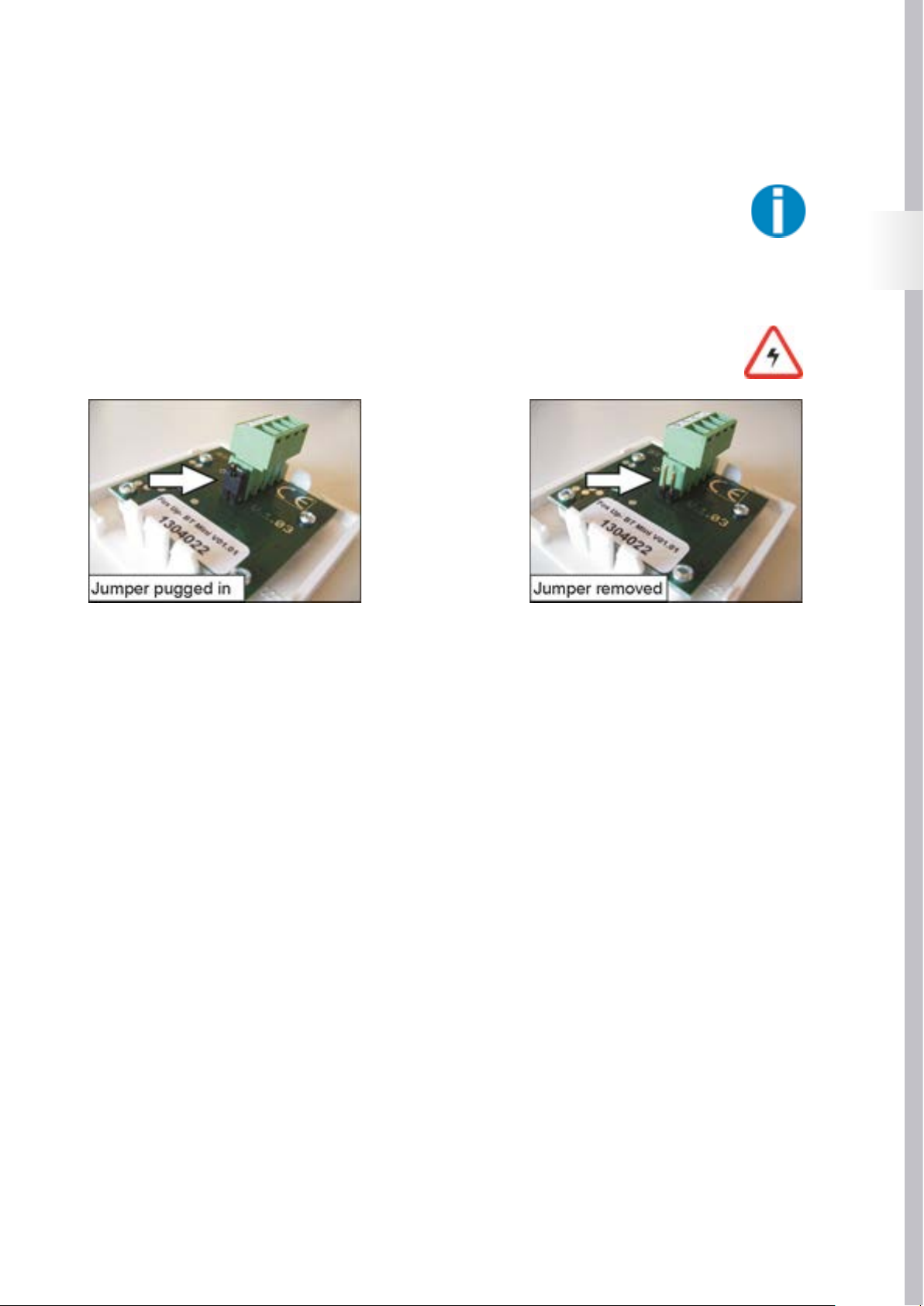

3.2 Minimum ventilation option

To guarantee a permanent minimum ventilation, there is the option with Fox up ventilation units of setting a constant ventilation mode at a minimum power stage. Depending on the setting, the ventilation unit(s) work in summer or winter mode. It is

not possible to switch off the unit using the electronic control system’s control panel.

The minimum ventilation is activated / deactivated by re-plugging a jumper on the back of the control panel of the electronic control system. To activate the minimum ventilation, the control panel of the electronic control system must be detached (carefully remove control

panel), and the minimum ventilation is activated on the disconnected control panel as described below:

Attention:

Before changing the jumper position, all poles of the power supply to the ventilation unit must be disconnected. Disconnections must be immobilised in the open position!

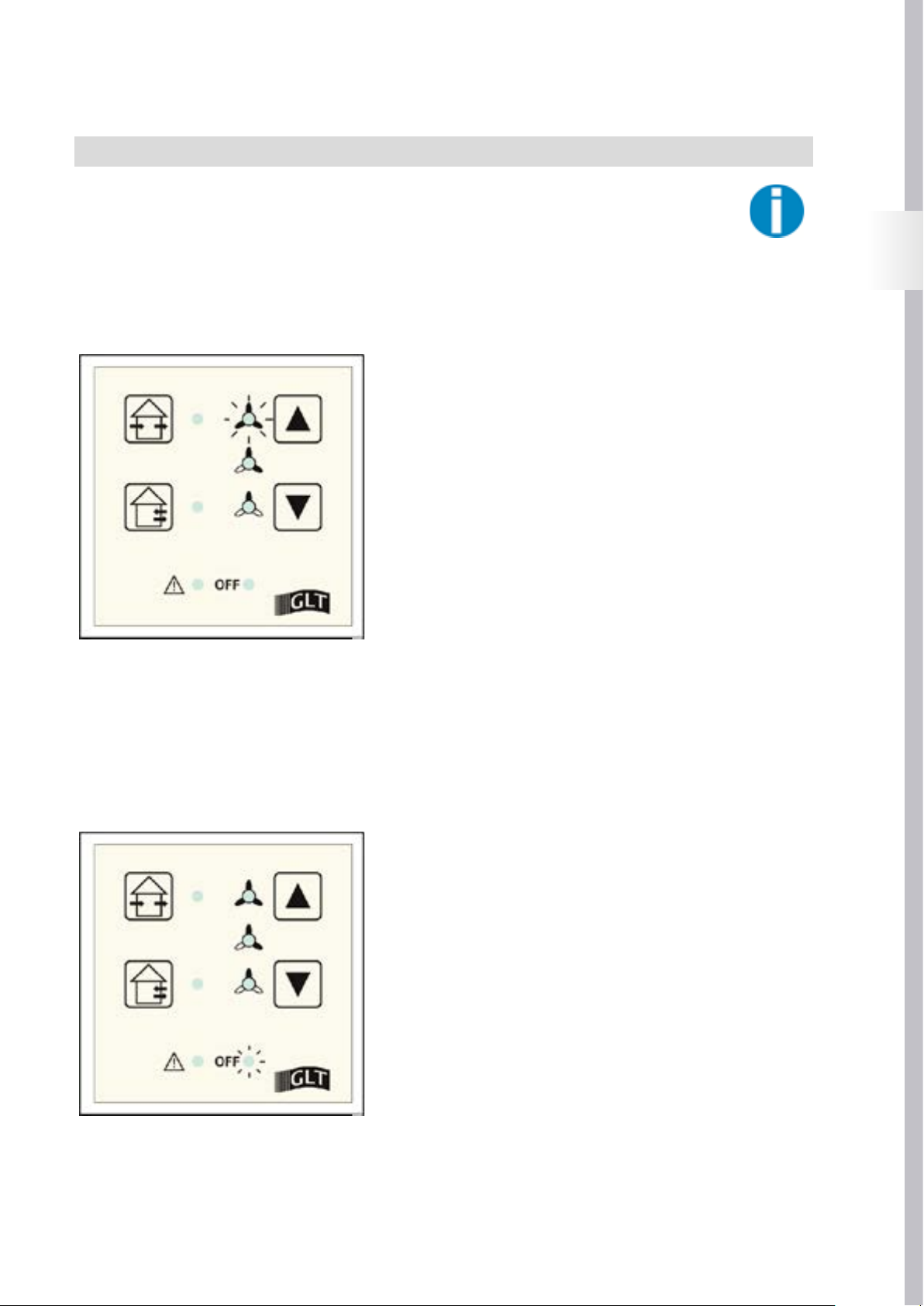

If the jumper on the back of the control panel is

plugged in, the ventilation unit can be switched off

using the “down” arrow key (see fig. page 18).

Ventilation is interrupted, and the “unit off” signal

lamp (see fig. page 18) lights up.

< ---- alternative --->

If the jumper on the back of the control panel has

been removed or is only plugged into one pin, minimum ventilation is activated. The ventilation unit is

not completely switched off using the “down” arrow

key (see fig. page 18), but runs continuously at a

minimum power stage.

The activated minimum ventilation is signaled by

the pulsing “unit off” signal lamp (see fig. page

18).

EN

17

R

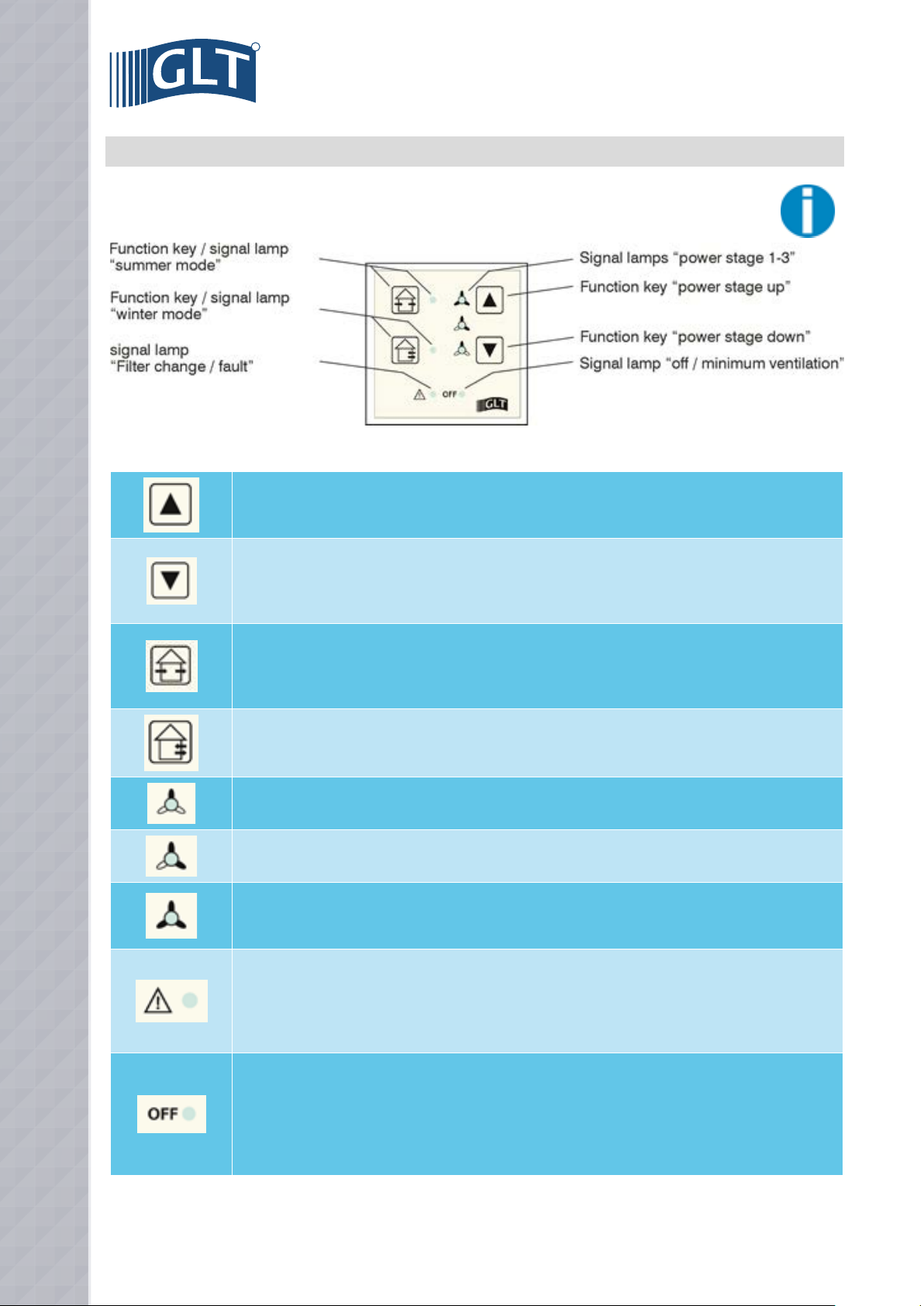

4. OPERATING AND DISPLAY ELEMENTS OF ELECTRONIC CONTROL SYSTEM

Pressing this key sets the unit to power stage 1. Pressing this key again selects the next power stage up.

Pressing this key switches the unit back to the next power stage down. If the unit is at power stage 1, pressing

this key again switches the unit off or returns it to minimum ventilation1.

1 minimum ventilation option, see page 17.

Pressing this key sets the unit to delivery or extraction mode2 without heat recovery (= summer mode). Summer

mode automatically switches back to winter mode, 8 hours after being activated. Pressing this key again

extends the summer mode by a further 8 hours.

2 depending on the electrical connection, see page 9.

Pressing this key sets the unit to alternate delivery/extraction mode with heat recovery (winter mode). During

the heating period, the device should be operated in this mode at all times.

If this symbol lights up, the unit is at power stage 1.

If this symbol lights up, the unit is at power stage 2.

AIf this symbol lights up, the unit is at power stage 3. Power stage 3 automatically switches back to power stage

2 one hour after being activated. If this symbol is flashing, the external moisture mode has been activated3.

3 External moisture mode option, see page 19.

If this indicator is permanently lit it indicates that the ventilation unit’s filter insert is due for inspection /

cleaning. The maintenance of the filter insert is described on page 20.

If this indicator is flashing it indicates a functional fault on the electronic control system’s control panel. The

electronic control system or the control panel must be checked by a qualified electrician, see error messages

page 22.

If this indicator lights up, the unit has been switched off via the “down” arrow key. Ventilation can be switched on

using the “up” arrow key.

If this indicator is pulsing, the unit has been switched to the “minimum ventilation” power stage via the “down”

arrow key (see page 17). The ventilation unit’s power stage can be increased using the “up” arrow key.

If this indicator is flashing, the unit has been switched off externally.

For External off option, see page 24.

18

5. EXTERNAL CONTROL INPUTS FOR ELECTRONIC CONTROL SYSTEM

• External input for moisture control

To quickly remove moisture when ventilating rooms with a high moisture load, e.g. baths, showers, the output of the Fox

up ventilation units can be increased depending on the moisture via an external hygrostat (= moisture-dependent switch).

The switching point (= moisture level) for increasing the power is set on the hygrostat. If the set moisture level (recommended settings,

summer: 65-80% RH, winter: 55-65% RH) is exceeded, the hygrostat activates power stage 3 in the ventilation unit.

Hygrostats are connected to contacts 1 and 2 of the “external inputs” connector on the electronic control system of the ventilation unit as

shown in the connection diagram on page 9.

External moisture mode is displayed on the electronic control system’s control

panel by the flashing of the “power level 3” signal lamp.

If the power level is not changed manually on the control panel, the unit will

continue to operate at the last active power stage after the external contact is

switched off again.

Power stage 3 of the externally activated moisture mode can be reduced to power

stage 2 or 1 using the electronic control system’s control panel. To ensure that the

increased humidity is reduced, it is not possible to switch off the unit or return it to

the “minimum ventilation” power stage.

EN

• “Unit off” external input:

To prevent moisture damage in your rooms, Fox up ventilation units have been designed for continuous ventilation. If the ventilation nevertheless has to be interrupted* at certain times, the ventilation unit can be switched off via an external switch / time switch.

The switch / time switch is connected to contacts 3 and 4 of the “external inputs” connector on the electronic control system of the ventilation unit as shown in the connection diagram on page 9.

A ventilation unit switched off externally* is indicated on the control panel of the

electronic control system by the flashing of the “OFF” signal lamp.

If the power level is not changed manually on the control panel, the unit will

continue to operate at the last active power stage after the external contact is

switched on again.

A ventilation unit switched off externally* can be switched back on by pressing the

“power level up” key on the control panel of the electronic control system.

* The external switching off of the ventilation unit depends on the “minimum

ventilation” jumper setting (see page 17). If minimum ventilation is activated,

the operation of the system is not interrupted when switched off externally, but

reduced to minimum ventilation. Minimum ventilation is displayed on the remote

control by the pulsing of the “OFF” signal lamp.

19

R

6 . CLEANING / MAINTENANCE OF THE VENTILATION UNIT

The mechanical and electrical components of Fox up ventilation units are maintenance-free. Over time, however, airborne grease, particular matter, etc. cause the filter used in the unit to become dirty and leave a fine deposit on the fins of the heat accumulator and the blades

of the fan.

To guarantee the trouble-free operation of the ventilation unit, the filter insert, heat accumulator and fan must be checked and cleaned at

regular intervals as described below.

Dirt on the room- and/or façade-side air inlet/outlet openings (see ventilation unit components page 15) can be removed with a damp

cloth. Never use detergents containing solvents, as these corrode the surfaces (plastic coating) of the air inlet/outlet openings!

6.1 Maintenance of the filter insert

The filter used in the ventilation unit is monitored by an operating time meter in the electronic control system. After 3 months

(2,750 hours’ operation), the “filter change / fault” signal lamp lights up permanently on the control panel of the electronic

control system to indicate it is time to check the filter insert. Checking / cleaning of the filter insert is described below.

Attention:

Before all maintenance work, all poles of the power supply to the ventilation unit must be disconnected. Disconnections must be immobilized in the open position!

To check the filter, the inner valve (1) must be removed. The valve is attached to its support frame with magnets and can easily be pulled

out. After removing the inner valve, the filter insert (2) can be removed from the wall duct for checking.

• Remove filter insert

If only slightly soiled (no or little dust deposits), the filter insert can

be vacuumed or shaken. If there are significant dust deposits, the

filter insert must be rinsed with warm water (max. 60 °C).

In the case of significant grease deposits, the filter insert can be cleaned in water

mixed with detergent (degreaser). Any detergent residues must be completely

rinsed off with clean water.

Before putting the cleaned filter insert back into the ventilation unit, allow it to dry

completely. A damp filter will gather dust straight away!

Place the dried filter insert back into the wall duct of the ventilation unit and re-attach the ventilation unit’s inner valve to its support frame.

After checking / cleaning the filter insert and switching the power supply to the

ventilation unit back on, the operating time meter that monitors the filter insert must

be restarted. This is done via the control panel of the ventilation unit’s electronic

control system:

20

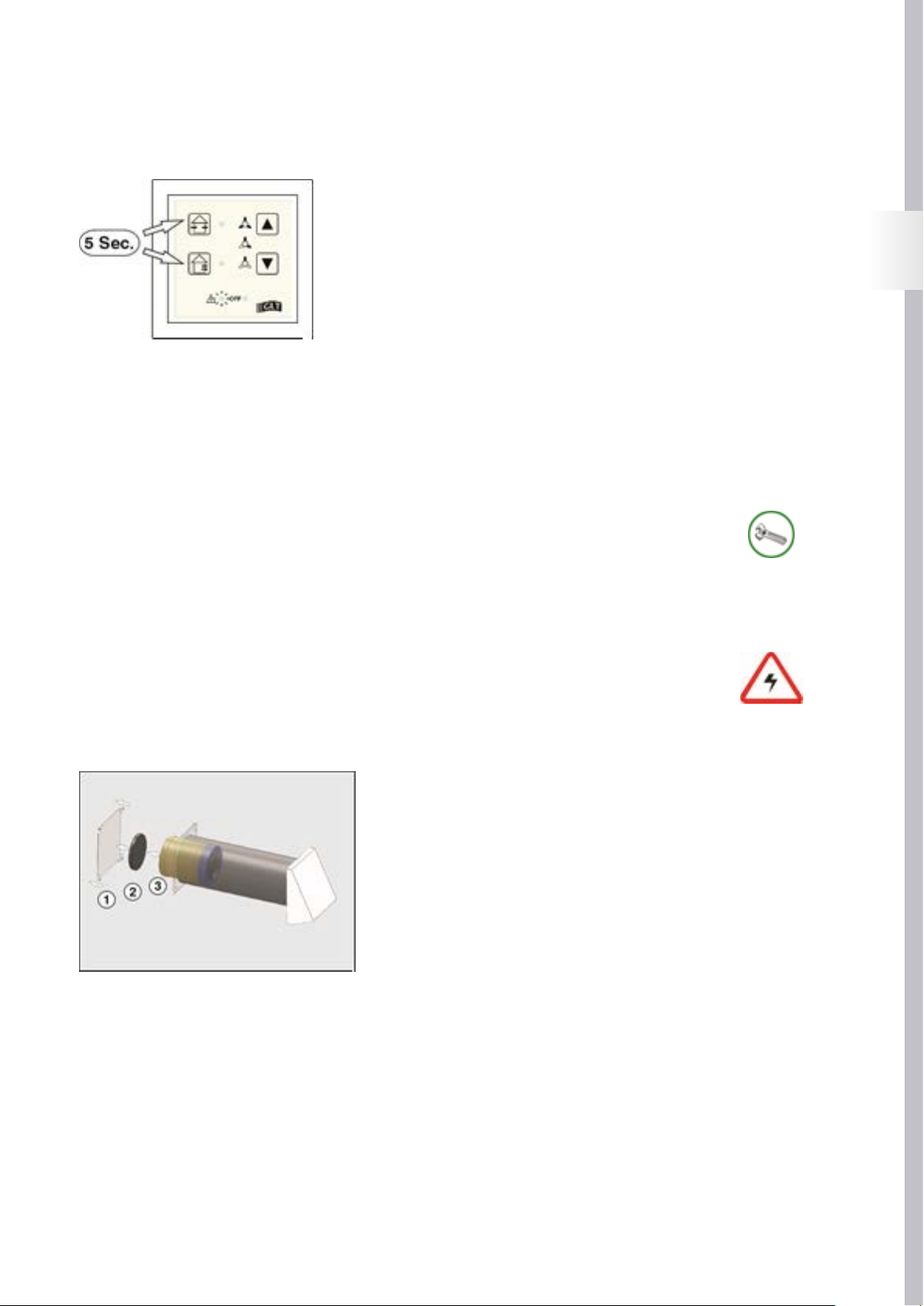

continued 6.1 Remove filter insert

The operating time meter is restarted by jointly pressing the “summer mode” and “winter

mode” keys and holding them down until the red “filter change / fault” LED goes out

(approx. 5 seconds).

Note:

Filter monitoring can also be restarted as described above without prior notice from the

filter change indicator, e.g. in connection with a regular overhaul.

The filter inspection request is issued on a time-dependent basis after 3 months’ operation,

regardless of how dirty the filter actually is. However, depending on the amount of dirt in

the fresh air that is delivered, it may be appropriate to change the filter sooner. It is therefore

recommended that the filter is checked in the first year after the ventilation unit is put into

operation at three-month intervals. The inspection/cleaning interval must be reduced if the

amount of dirt in the filter is clearly higher.

6.2 Maintenance of the heat accumulator / fan

The heat accumulator and fan should only be checked / cleaned by someone with specialist knowledge. It is therefore recommended that the ventilation unit be checked once a year by an expert. During this inspection, the “inner workings” of the unit

should be removed and checked for dirt / damage.

If damage is found, the affected parts are to be replaced before the ventilation unit is put back into use. Spare/replacement parts are

available from us at the address below.

Unit components should only be dismantled by a qualified electrician with the ventilation unit disconnected from the mains

(contact gap at least 3 mm).

EN

To check the heat accumulator and fan, the entire fan unit must be removed from the wall duct:

• Remove fan unit

To remove the fan unit, the ventilation unit’s inner plate (1) must be removed. The

plate is attached to its support frame with magnets and can easily be pulled of.

After removing the inner plate, the filter insert (2) and the fan unit (3) can be

removed from the wall duct.

If only slightly soiled, the heat accumulator / fan can be vacuumed. More significant

accumulations of dirt on the fan can be removed with a small brush or a paintbrush.

If the heat accumulator is heavily soiled, it must be removed from the fan unit and

rinsed with water.

21

R

• Remove heat accumulator

The heat accumulator is inserted inside the fan unit and can be

removed from this for cleaning.

Dirt on the heat accumulator can be removed with a rose (shower /

bathtub) with warm water (max. 70 °C). For heavy soiling / grease

deposits, the heat accumulator can be cleaned in water mixed with

detergent (degreaser). Any detergent residues must be completely

rinsed off with clean water.

After being cleaned, the heat accumulator must be completely

dried (e.g. in the oven, max. 70 °C). A damp heat accumulator will

gather dust straight away!

Place the dried heat accumulator back in the fan unit and position the complete fan unit back in the wall duct.

To ensure the unit functions correctly, a complete functional test of the ventilation unit must be carried out after reinserting cleaned or

repaired components and switching the power back on (see page 19).

7. ERROR MESSAGES / MALFUNCTIONS

7.1 Error messages

Besides reporting that the filter needs checking, the “filter change / fault” signal lamp (see page 19) on the control panel

of the ventilation unit’s electronic control system also indicates a communication error between control unit and electronic

control system.

The communication error is reported by the repeated three-time flashing of the “filter change / fault” LED. If this message appears, the

connection between the ventilation unit’s control panel and the electronic control system must be checked by a qualified electrician.

Attention:

Before all maintenance work, all poles of the power supply to the ventilation unit must be disconnected.

Disconnections must be immobilized in the open position!

To check the connection between the control panel and the electronic control system, the control panel must be removed from the electronic control system. Then check the contacts of the connection for damage / foreign bodies / moisture.

Foreign bodies must be carefully removed from the connection. Mechanically damaged components or components damaged by moisture

must be replaced. Contact our spare/replacement parts department at the address below.

To ensure the unit functions correctly, a complete functional test of the ventilation unit must be carried out after repairing components

(see page 18).

22

7.2 Functional faults

The following table describes possible functional faults and how to solve the problem. Because faults are mainly caused

by errors in the power supply / electrical connection, the faults must be determined / rectified by a qualified electrician.

Therefore, if such faults occur, please contact the installer of your ventilation unit or us at the address below.

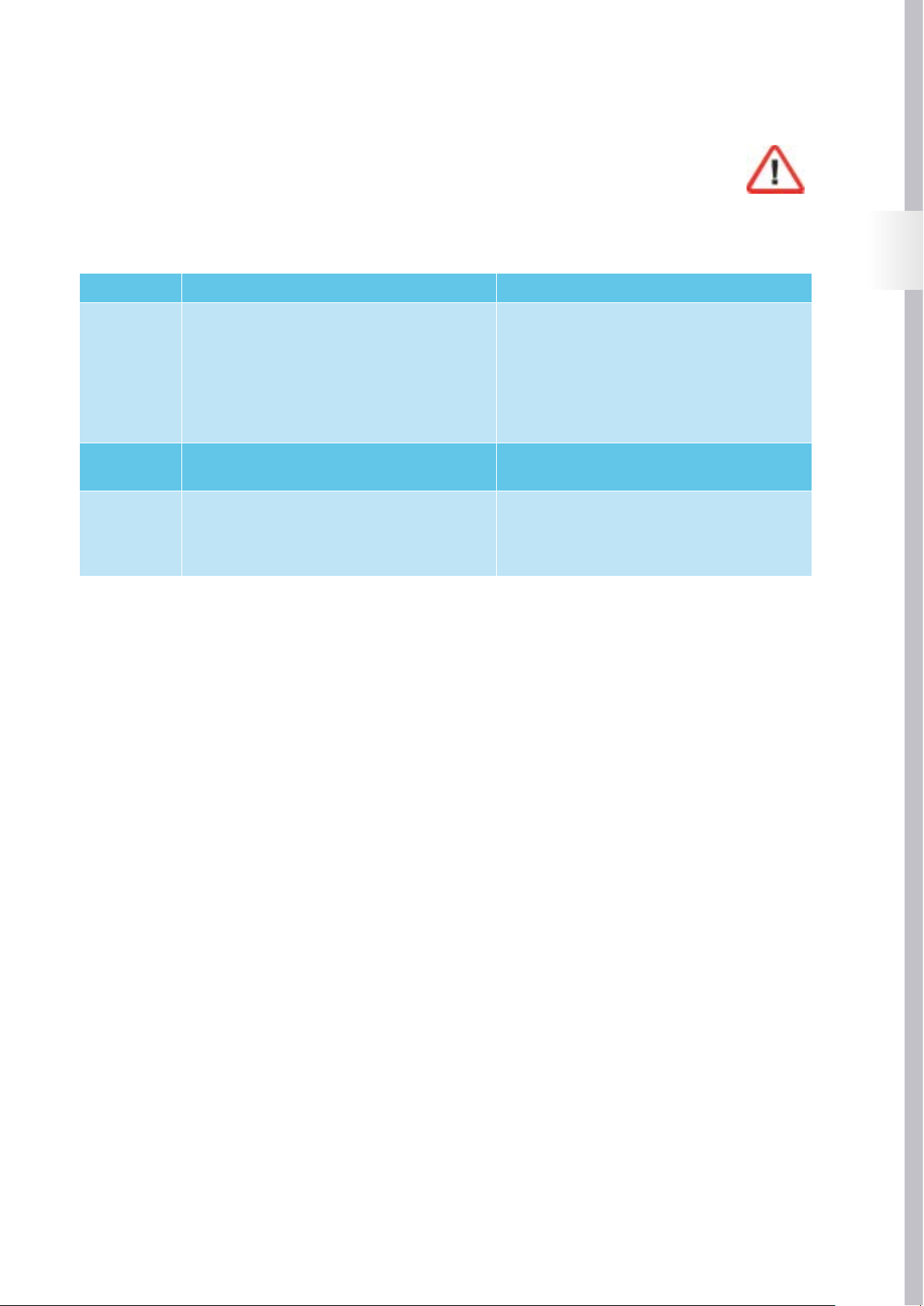

Fault Cause Rectification

- Check power supply (fuse)

Fan not working

- Power failure / interruption

- Connection error

- Fan blocked

- Fan faulty

- Control panel / electronic control system faulty

- Check all wire connections for correct connection,

connector for correct position (see page 9)

- Check fan. Remove blockage / foreign bodies

- Check and if necessary replace fan

- Check and if necessary replace control panel / electronic control system

EN

Noisy fan

Air flow too low

- Fan scraping due to dirt / foreign bodies

- Fan motor mounting faulty

- Filter insert dirty

- Heat exchanger dirty

- Wall duct / weatherproof protective hood dirty / locked

- Remove dirt / foreign bodies

- Replace fan

- Check / clean filter insert (see page 20)

- Check / clean heat exchanger (see page 21)

- Check wall duct / weatherproof protective hood, if

necessary remove dirt / foreign bodies

23

R

8. MAINTENANCE REPORT / FILTER CLEANING

Maintenance report

Maintenance work:

carried out by:

24

Filter cleaning

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

EN

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

Filter element

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

checked cleaned

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

on:

Filter element

Filter element

Filter element

Filter element

checked cleaned

checked cleaned

checked cleaned

checked cleaned

on:

on:

on:

on:

25

R

26

MONTAGE- UND BEDIENUNGSANLEITUNG - DEUTSCH

INHALTSVERZEICHNIS MONTAGEANLEITUNG

1. Allgemeine Hinweise ............................................................................................................................................................................................ 28

2. Funktionsweise / Planungshinweise ..................................................................................................................................................................29

3. Liefereinheiten / Lieferumfang ............................................................................................................................................................................30

4. Abmessungen / Technische Daten .......................................................................................................................................................................31

5. Auswahl des Einbauortes......................................................................................................................................................................................32

6. Montage Wanddurchführung ..............................................................................................................................................................................32

7. Montage Steuerelektronik ................................................................................................................................................................................... 34

8. Elektrischer Anschluß .......................................................................................................................................................................................... 35

9. Montage Ventilatoreinheit / Funktionsprüfung .................................................................................................................................................37

10. Inbetriebnahmeprotokoll......................................................................................................................................................................................39

11. Bedienungsanleitung ...........................................................................................................................................................................................40

DE

Symbolik

Folgende Symbole werden in der vorliegenden Anleitung zur Kennzeichnung

besonderer Hinweise verwendet:

allgemeiner Hinweis / Information

Hinweis Gefahr durch

elektrische Spannung

Warnhinweis

Montage- / Wartungshinweis

27

R

1. ALLGEMEINE HINWEISE

Die Fox up Lüftungsgeräte sind nach aktuellem Stand der Technik und den anerkannten sicherheitstechnischen Regeln gebaut.

Montage- und Wartungsarbeiten am Lüftungsgerät dürfen nur durch ausgebildete Fachkräfte unter Einhaltung der Vorschriften zu Arbeitssicherheit und Unfallverhütung ausgeführt werden.

Der elektrische Anschluß muß nach VDE 0100 durchgeführt werden. Bei Installation und Wartungsarbeiten

muß eine allpolige Trennung vom Netz mit mindestens 3 mm Kontaktöffnungsweite vorgenommen werden, die

Netztrennung ist gegen Wiedereinschalten zu sichern !

Der Einsatz des Gerätes ist nur für den bestimmungsgemäßen Verwendungszweck zulässig, unsachgemäßer Gebrauch, mangelhaft

ausgeführte Installations- bzw. Wartungsarbeiten sowie bauliche Veränderungen können Funktion und Sicherheit des Lüftungsgerätes

beeinträchtigen und führen zum Erlöschen von Gewährleistungsansprüchen.

Lesen Sie vor Beginn von Montage- / Wartungsarbeiten diese Anleitung sorgfältig durch und beachten Sie die zu Montage und Wartung

angegebenen Hinweise.

Überprüfen Sie vor Installation des Gerätes die Lieferung hinsichtlich Vollständigkeit und Unversehrtheit und wenden Sie sich bei

fehlenden oder beschädigten Teilen direkt an unsere untenstehende Adresse.

Verwendungszweck

Fox up Lüftungsgeräte mit Wärmerückgewinnung sind zur kontrollierten Raumlüftung konzipiert. Die Geräte dürfen ausschließlich zur

Förderung von Luft eingesetzt werden, die Förderung von aggres-siven, entzündlichen oder stark staubhaltigen Medien ist nicht zulässig.

Betreiben Sie das Gerät nie ohne den im Gerät eingesetzten Filtereinsatz. Der Anschluß von Lüftungsleitungen anderer Lüftungs-systeme

ist nicht zulässig.

Fox up Lüftungsgeräte sind nicht zur Bautrocknung geeignet, der Betrieb der Geräte sollte erst nach Abschluß der Bautätigkeit erfolgen.

Der Gerätebetrieb in Verbindung mit Feuerstätten erfordert gegebenenfalls zusätzliche Sicher-heitseinrichtungen (Feuerungsverordnung

FeuV), entsprechende Informationen erhalten Sie beim regional zuständigen Schornsteinfeger.

Gerätestandort

Fox up Lüftungsgeräte dürfen nur im Gebäudeinneren montiert und betrieben werden, beachten Sie bei der Auswahl des Gerätestandortes,

daß das Lüftungsgerät für Revisions- und Wartungsarbeiten zugänglich ist. Die Gerätemontage in Nähe zu entzündlichen Flüssigkeiten

oder Gasen ist nicht zulässig. Zum Betrieb der Geräte ist ein Netzanschluß (230 V/50 Hz) erforderlich.

Montage

Beachten Sie bei Montage der Lüftungsgeräte die anerkannten Regeln der Technik (ARdT) bezüglich Geräteinstallation, Elektroarbeiten,

Brandschutz etc; sowie die Vorgaben zur Lüftung von Wohn-räumen (DIN 1946-6).

28

2. FUNKTIONSWEISE / PLANUNGSHINWEISE

2.1 Funktionsweise

Das Fox up Lüftungsgerät ist ein dezentrales Lüftungssystem zur kontrollierten Raumlüftung mit Wärmerückgewinnung. Der

paarweise Einsatz mehrerer Geräte ermöglicht die Lüftung kompletter Wohneinheiten / Gebäude.

Bei Betrieb mit Wärmerückgewinnung arbeitet das Lüftungsgerät in 2 einjustierten Zeitintervallen. Im ersten Intervall

(Abluftphase) wird durch Abluftbetrieb des Ventilators die “verbrauchte” Raumluft in das Lüftungsgerät gesaugt und nach außen abgeführt. Die Luft durchströmt dabei den Keramik-Wärme-speicher im Inneren des Lüftungsgerätes der die Wärme der Raumluft aufnimmt

und speichert.

Im zweiten Intervall (Zuluftphase) wird “frische” Außenluft über die Außenöffnung des Lüftungsgerätes angesaugt, sie durchströmt das

Gerät und wird vor Eintritt in den Raum durch den Wärmespeicher er-wärmt. Auf diese Weise können bis zu 90 % der in der Abluft enthaltenen Wärme an die dem Raum zugeführte Frischluft übergeben werden, das Prinzip des Be- und Entladens eines Wärmespeichers wird als

regenerative Wärmeübertragung bezeichnet.

Bei Betrieb eines Einzelgerätes entsteht im zu lüftenden Raum je nach Betriebsphase ein Überdruck (Zuluftphase) oder ein Unterdruck

(Abluftphase), um ein ausgeglichenes Verhältnis zwischen Zu- und Abluftmenge zu gewährleisten wird der paarweise Einsatz der Fox up

Geräte empfohlen. Die Steuerung der Lüftungsgeräte ermöglicht den gemeinsamen Betrieb von bis zu drei Gerätepaaren.

2.2 Planungshinweise

Vor der Montage von Fox up Lüftungsgeräten sollte ein Lüftungskonzept erstellt werden aus dem die Anzahl der Lüftungsgeräte, deren Einbauort, das Lüftungsprinzip (Querlüftung, Einzelraumlüftung) und die Position / Anzahl der zugehörigen

Steuerelektroniken zu entnehmen sind. Fox up Lüftungsgeräte ermöglichen folgende Lüftungsvarianten:

• Einzelraumlüftung mit einem Lüftungsgerät, im Intervall wechselnder Zu- / Abluftbetrieb mit Wärme rückgewinnung, alternativ Zu-* oder Abluftbetrieb* (* abhängig vom Elektroanschluß, sieheSeite 35).

DE

• Querlüftung mit paarweise betriebenen Lüftungsgeräten, im Intervall wechselnder Zu- / Abluftbetrieb

mit Wärmerückgewinnung (während ein Gerät eines Gerätepaares im Zuluftbetrieb läuft, arbeitet das

zugeordnete zweite Gerät im Abluftbetrieb, Luftrichtung beider Geräte im nächsten Intervall wechselnd),

alternativ Zu-* oder Abluftbetrieb* (* abhängig vom Elektroanschluß, siehe Seite 35).

Fox up Lüftungsgeräte sollten möglichst paarweise betrieben werden (siehe Funktionsweise), die Geräte-paare können sowohl in einem

Raum, als auch raumübergreifend eingesetzt werden, innerhalb einer Nutzungseinheit ist auch eine stockwerkübergreifende Zuordnung

möglich. Durch ausreichend dimen-sionierte Überströmöffnungen (z.B. Türluftgitter oder gekürztes Türblatt) muss eine Luftströmung

zwischen den zu lüftenden Räumen ermöglicht werden.

Damit durch eingeblasene Luft (Zuluftphase Lüftungsgerät) kein Geruchsübertrag in andere Räume erfolgt, sollten bei der Be-/ Entlüftung

von Küchen, Bädern oder Toiletten mit Fenstern immer zwei im Gegentakt arbeitende Geräte installiert werden. In innenliegenden,

fensterlosen Ablufträumen wie Küchen, Bädern und Toiletten dürfen die Fox up Geräte nicht eingesetzt werden da ein Anschluss der

Geräte an einen Schacht oder eine Rohrleitung nicht zulässig ist. Hier empfiehlt sich der Einsatz eines Abluftventilators gemäß DIN 18017

T.3, z.B. der Ventilatortyp BRAVO.

Die Geräteinstallation in Kellerräumen mit Lichtschächten ist ebenfalls nicht möglich, da eine Rezirkulation der Fortluft nicht ausgeschlossen werden kann. Um eine Rezirkulation bei Fassadenmontage der Geräte zu vermeiden, sollte zwischen einzelnen Geräten ein Mindestabstand von 1,2 m eingehalten werden.

Wir empfehlen, bei einer windexponierten Lage des Gebäudes (mittlere Windgeschwindigkeit > 5 m/s) auf den Einsatz des Gerätes zu

verzichten.

Um Zugerscheinungen durch den Betrieb der Lüftungsgeräte zu vermeiden, sollten die Geräte nicht im direkten Aufenthaltsbereich von

Personen (Sitzgelegenheiten, Betten) platziert werden, beachten Sie, daß der raumseitige Luftdurchlaß nicht durch Möbel oder Gardinen

beeinträchtigt wird.

29

R

3. LIEFEREINHEITEN / LIEFERUMFANG

Eine komplette Fox up Lüftungseinheit besteht aus einer EPS-Wanddurchführung und einer in die Wand-durchführung

eingeschobenen Ventilatoreinheit. Die Ventilatoreinheit besteht aus reversierbarem Venti-lator (12 V/DC) und Keramik-Wärmespeicher zur Wärmerückgewinnung.

Der raumseitige Luftdurchlaß erfolgt über eine Designblende mit Filtereinsatz, der Außenluftdurchlaß erfolgt über eine

Wetterschutzhaube.

Die Bedienung des Gerätes wird über eine Steuerelektronik mit Bedienfeld ausgeführt, über die Steuer- elektronik können bis zu sechs

Lüftungsgeräte (3 x Zuluft, 3 x Abluft) angesteuert werden. Die Montage der Elektronik erfolgt in einer Doppelhohlwanddose zur Unterputzmontage.

Für die unterschiedlichen Montageschritte sind folgende Liefereinheiten erhältlich:

• Fox up-GP-Design, Artnr. 18055: Grundpaket bestehend aus Wanddurchführung (500 mm lang),

Ventilatoreinheit, Innenblende, Wetterschutzhaube und Steuerelektronik mit Hohlwand-Unterputzdose.

• Fox up-EP-Design, Artnr. 18056: Ergänzungspaket bestehend aus Wanddurchführung (500 mm lang)

Ventilatoreinheit, Innenblende und Wetterschutzhaube.

• Fox up-Rohbausatz 500 mm, Artnr. 18018: Rohbausatz bestehend aus Wanddurchführung (500 mm lang)

und Hohlwand-Unterputzdose.

• Fox up-Rohbausatz 1000 mm, Artnr. 18022: Rohbausatz bestehend aus Wanddurchführung ( 1000 mm lang)

und Hohlwand-Unterputzdose.

• Fox up FMS-GP-Design, Artnr. 18059: Fertigmontage-Grundpaket bestehend aus Ventilatoreinheit,

Innenblende, Wetterschutzhaube und Steuerelektronik.

• Fox up FMS-EP-Design, Artnr. 18061: Fertigmontage-Ergänzungspaket bestehend aus Ventilatoreinheit,

Innenblende und Wetterschutzhaube.

• Fox up Lüftungseinheit komplett

1. Wetterschutzhaube (Luftdurchlaß Außenseite)

2. EPS-Wanddurchführung

3. Designblende (Luftdurchlaß Raumseite)

4. Ventilatoreinheit (inkl. Keramik-Wärmespeicher und Filtereinsatz)

5. Bedienteil / Steuerelektronik

30

4. ABMESSUNGEN / TECHNISCHE DATEN

4.1 Fox up Lüftungseinheit - alle Maßangaben in mm -

DE

Fox up Innenblende

Fox up Steuerelektronik Fox up Wetterschutzhaube

4.2 Technische Daten

Fox upLüftungseinheit

Luftleistung : 15 / 30 / 40 m³/h

Wirkungsgrad Wärmetauscher : <91 %

Versorgungsspannung : 230 V/50 Hz

Leistungsaufnahme : 1,4 / 2,6 / 3,7 W

Schalldruckpegel : 19 / 24 / 341 dB(A)

Filterklasse : G2

zulässige Betriebstemperatur : -20 tot +40 °C

IP-Schutzart : 20

Gewicht : 5,5 kg

ø Wanddurchführung (innen / außen) : 153 / 198 mm

Länge Wanddurchführung : 500² / 1000³ mm

1 Schalldruckpegel, werkseitige Messung

2 Fox up Rohbausatz 500 mm

3 Fox up Rohbausatz 1000 mm

31

R

5. AUSWAHL DES EINBAUORTES

Achten Sie bei der Auswahl des Einbauortes auf die

Außen-ansicht des Gebäudes, damit sich die Geräte

harmonisch in die Gebäudefassade einfügen, sollten

die Geräte beispiels-weise in gleicher Höhe / mit

gleichem Abstand zu Fenstern montiert werden.

Beachten Sie die Abmessungen der außen- bzw. raum-seitigen

Luftdurchlässe, es wird empfohlen um die Wand-durchführung

einen Mindestabstand von 150 bis 200 mm zu angrenzenden

Fassadenbauteilen / -elementen und Raumecken einzuhalten !

Der Einbau der Fox up Lüftungsgeräte sollte in 1,6 bis 1,8 m Höhe

über dem Fertigfußboden erfolgen, der raumseitige Luftdurchlaß

der Geräte darf nicht durch Möbel oder Gardinen abgedeckt

werden.

6. MONTAGE WANDDURCHFÜHRUNG

Wanddurchführung EPS-Rohr

ø innen 153, ø außen 198 mm, integriertes Gefälle nach außen (Kondensatableitung)

Für die Fox up Lüftungsgeräte sind Wanddurchführungen in zwei unterschiedlichen Längen erhältlich:

• Rohrlänge 500 mm : Fox up Rohbausatz 500 mm, Artnr. 18018

• Rohrlänge 1000 mm : Fox up Rohbausatz 1000 mm, Artnr. 18022

Die Liefereinheiten Fox up-GP-Design und Fox up-EP-Design werden standardmäßig mit 500 mm langen Wanddurchführungen gelie-

fert, alle Wanddurchführungen sind zur Ableitung von Kondensat mit inte-griertem Gefälle nach außen gefertigt (Markierung Raumseite

beachten, siehe Abb. oben.)

32

6.1 Kernlochbohrung Wanddurchführung

6.2 Montage Wanddurchführung

Erstellen Sie eine Kernlochbohrung im Durchmes-ser 200 mm.

Führen Sie die Ventilator-Anschlußleitung (mind.

3 x 0,25 mm²) in den Wanddurchbruch ein. Lassen Sie die Ventilator-Anschlußleitung in Länge der Wanddurchführung überstehen.

DE

Bestimmen Sie das Gesamtmaß des Wandaufbaus aus den Maßen

Wandstärke Rohbaumaß D und den Maßen für den Wandabschluss

außen E (z.B. Wärmedämmung + Putz) und innen X (z.B. Putz + Fliesen).

Schieben Sie die Wanddurchführung in den Wand-durchbruch ein,

beachten Sie das Gefälle nach außen / die raumseitige Markierung

der Wand-durchführung. Lassen Sie die Wanddurchführung entsprechend

Ihrer vorstehenden Berechnung raum- und fassadenseitig überstehen.

Achtung:

Um eine spannungsfreie Montage / Demontage (Wartung) des Ventilators

/ des Wärmespeichers in der Wanddurchführung sicherzustellen, sind

Ver-formungen der Wanddurchführung durch äußeren Druck / Verspannung zu vermeiden !

33

R

6.3 Wanddurchführung Einführung Anschlußleitung Lüftungseinheit

Führen Sie die Elektro-Anschlußleitung der Lüftungseinheit

seitlich (Ansicht Raumseite) in die Wanddurchführung ein.

Überprüfen Sie die korrekte Position der Wanddurchführung

(Überstände außen / innen), und verschließen Sie die

Öff-nungen der Wanddurchführung mit den mitgelieferten

Putz-schutzdeckeln.

Verfüllen Sie abschließend mögliche Hohlräume zwischen

Wanddurchbruch und Wanddurchführung mit nicht-drückendem Montageschaum.

7. MONTAGE STEUERELEKTRONIK

Die Steuerelektronik der Fox up Lüftungsgeräte ist zur

Montage in eine Doppel-Hohlwand Unterputzdose konzipiert, sie kann zur Ansteu-erung von bis zu sechs Fox up

Lüftungsgeräten eingesetzt werden.

Die Steuerelektronik ist als ortsfestes Betriebs-mittel mit

fest verlegten Leitungen anzu-schließen.

Elektrischer Anschluß siehe Seite 35.

Die Versorgungsspannung der Steuerelektronik beträgt 230 V/50 Hz, als Zuleitung wird eine Mantel-leitung 3 x 1,5 mm² (z.B. NYM-J 3x1,5

mm²) empfohlen.

Die Steuerung der Lüftungsgeräte erfolgt durch 12 V Gleichspannung (DC), die Lüftungsgeräte dürfen daher keinesfalls mit der 230 V

Netzspannung der Steuerelektronik verbunden werden. Als Steuerleitung für die Lüftungsgeräte wird eine Mantelleitung 3 x 0,25 mm²

(z.B. LiYY 3 x 0,25 mm²) empfohlen, die Länge der einzelnen Steuerleitungen sollte max. 15 m betragen.

34

8. ELEKTRISCHER ANSCHLUSS

Der elektrische Anschluß muß nach VDE 0100 durchgeführt werden. Bei Installation und Wartungsarbeiten

muß eine allpolige Trennung vom Netz mit mindestens 3 mm Kontakt-öffnungsweite vorgenommen werden, die

Netztrennung ist gegen Wiedereinschalten zu sichern !

• Anschluß Steuerelektronik

+12 V - rot

Gerät 5 PWM - lila

Gnd - blau

+12 V - rot

Gerät 3 PWM - lila

Gnd - blau

+12 V - rot

Gerät 1 PWM - lila

Gnd - blau

Anschluß

Zuluftgeräte

externe Eingänge

siehe Seite 11

blau - Gnd

lila - PWM Gerät 6

rot - +12 V

blau - Gnd

lila - PWM Gerät 4

rot - +12 V

blau - Gnd

lila - PWM Gerät 2

rot - +12 V

Anschluß

Abluftgeräte

DE

• Anschluß Einzelgerät:

Der Anschluß eines einzelnen Lüft-ungsgerätes erfolgt am

Steck-verbinder Gerät 1 oder

Gerät 2 wie in nebenstehender

Abbildung dar-gestellt.

Bei Anschluß am Steckverbinder Gerät 1

kann das Gerät in Funktion „Sommerbetrieb“

(siehe Lüftungs-betrieb Seite 42) als

Zuluftgerät eingesetzt werden, bei Anschluß

am Steckverbinder Gerät 2 kann das Gerät im

Sommerbetrieb als Abluft-gerät eingesetzt

werden.

• Anschluß mehrerer Geräte:

Der Anschluß mehrerer Geräte er-folgt in

paarweiser Zuordnung an den Steckverbindern

Gerät 1 - Gerät 2, Gerät 3 - Gerät 4, Gerät 5

- Gerät 6; im paarweisen Betrieb arbeitet ein

Gerät eines Geräte-paares im Zuluftbetrieb,

das zuge-ordnete zweite Gerät im Abluft-betrieb, die Luftrichtungen beider Geräte werden

im Intervall gewech-selt.

N

L1

PE

Netzanschluß

230 V/50 Hz

8.1 Anschluß Lüftungsgerät(e) - Steuerelektronik

Lüftungsgerät

Gnd • blau

PWM • lila

+12 V • rot

blau • Gnd

lila • PWM

rot • +12 V

Steuerelektronik

Der Anschluß der Fox up Lüftungsgeräte an der Anschlußleitung der Steuerelektronik erfolgt über eine im Lieferumfang der Lüftungsgeräte enthaltene Steckverbindung wie vorstehend dargestellt. Bitte Polung Zu- / Abluftgeräte beachten (siehe Abb. oben)!

35

R

8.2 Elektrischer Anschluß externe Steuerelemente

Die Einstellung der Betriebsweise der Fox up Lüftungsgeräte erfolgt nutzerabhängig über das Bedienfeld der Steuerelektronik, es können unterschiedliche Betriebsvarianten mit verschiedenen Leistungsstufen angewählt werden.

Durch Anschluß optionaler, externer Steuerelemente kann zusätzlich ein zeit- oder feuchteabhängiger Gerätebetrieb aktiviert werden,

der Anschluß der externen Steuerelemente erfolgt wie nachstehend dargestellt über den Anschlußstecker “externe Eingänge” an der

Steuerelektronik der Lüftungsgeräte.

Die Gerätefunktion bei externer Ansteuerung ist ab Seite 45 dieser Anleitung beschrieben.

• Anschluß externe Steuerelemente

• Option externe Abschaltung

(z.B. Zeitschaltuhr)

Funktionsbeschreibung siehe Seite 22

Anschlußstecker

Steuerleitung

externe Eingänge

2 x 2 x 0,6 (z.B. J-Y(ST)Y)

• Option externe Feuchtesteuerung

(z.B. Hygrostat)

Funktionsbeschreibung siehe Seite 21

Gerät 1 PWM • lila

+12 V • rot

Gnd • blau

Anschlüsse Zuluftgeräte

(max. 3 Stck.)

blau • Gnd

lila • PWM Gerät 2

rot • +12 V

Anschlüsse Abluftgeräte

(max. 3 Stck.)

Netzanschluß

230 V/50 Hz

Zum Anschluß der externen Steuereingänge (potentialfreie Kontakte) wird eine Datenleitung (z.B. 2 x 2 x 0,6 (z.B. J-Y(ST)Y) empfohlen.

36

9. MONTAGE VENTILATOREINHEIT / FUNKTIONSPRÜFUNG

9.1 Montage Ventilatoreinheit

Nach Ausführung des Elektroanschlusses wird die aus Wärmespeicher und Ventilator bestehende Venti-latoreinheit in die

Wanddurchführung eingeschoben:

Schieben Sie die Ventilatoreinheit (Ventilator in Richtung Fassade)

vorsichtig in die Wanddurchführung ein und achten Sie darauf, daß die

Anschlußleitung des Ventilators dabei nicht geknickt / be-schädigt

wird.

Mit der am Wärmespeicher angebrachten Halteschlaufe kann die Ventilatoreinheit bei der Montage ausgerichtet und zu Wartungs-zwecken

wieder aus der Wanddurchführung ausgezogen werden.

Verbinden Sie anschließend die Steckverbindung Anschlußleit-ung

Lüftungsgerät - Anschlußleitung Steuergerät.

9.2 Fertigmontage

DE

Wanddurchführung mit

Teppichmesser / Heißdraht

auf Maß Fertigwand kürzen

Nach Abschluß der Dämm- / Putzarbeiten muß die Wanddurchführung dem

Maß der Fertigwand angepaßt werden indem sie mit einem Teppichmesser

oder einem Heißdraht raum- und fassadenseitig wandbündig ge-kürzt wird.

Montieren Sie anschließend die Halterahmen der Innen-blende (Raumseite)

und der Wetterschutzhaube (Fass-adenseite) des Lüftungsgerätes mit dem

im Lieferum-fang des Lüftungsgerätes enthaltenen Montagematerial oder

mit für den speziellen Anwendungsfall geeigneten Befestigungselementen.

37

R

Zum Schutz vor Wassereintritt in den Wanddurchbruch muß der fassadenseitige Übergang zwischen

Wand-durchführung und Halterahmen Wetterschutzhaube

umlaufend mit Silikon oder entsprechend geeignetem

Dichtmaterial abgedichtet werden !

Setzen Sie den im Lieferumfang des Lüftungsgerätes

enthaltenen Filtereinsatz ( 1 ) in der Wanddurchführung ein

und verschließen Sie die Innenblende ( 2 ) des Lüft-ungsgerätes (Magnetverschluß).

Montieren Sie abschließend die fassadenseitige Wetter-schutzhaube ( 3 ) des Gerätes, die Haube wird mit einer angebrachten Lasche an der Oberkante des Halte-rahmens eingehängt

und mit der mitgelieferten Befestig-ungsschraube ( 4 ) an der

Unterkante des Halterahmens fixiert.

9.3 Funktionsprüfung Lüftungsgerät(e)

Nach Abschluß der Montagetätigkeit muß die Gerätefunktion überprüft werden, vor der Überprüfung ist sicherzustellen, daß die Luftwege

des Lüftungsgerätes / der Lüftungsgeräte frei von Montagerückständen / Fremdkörpern sind und sämtliche Elektroarbeiten fachgerecht

ausgeführt und abgeschlossen wurden !

Nach dem Einschalten der Stromversorgung (in der Regel über den

Sicherungsautomaten der Elektro-installation) kann das Lüftungsgerät

über das Bedienfeld der Steuerelektronik in Betrieb genommen werden,

überprüfen Sie bei der Inbetriebnahme alle in der Bedienungsanleitung

ab Seite 44 beschriebenen Gerätefunktionen, achten Sie während

der Überprüfung auf ruhigen, gleichmäßigen Lauf des Ventilatormotors.

Festgestellte Fehlfunktionen bzw. Störungen am Lüft-ungsgerät müssen

vor der endgültigen Inbetriebnahme des Gerätes behoben werden,

mögliche Fehlerursachen und deren Behebung sind im Kapitel Funktions-störungen (siehe Seite 48) beschrieben.

Dokumentieren Sie die ordnungsgemäß ausgeführte Installation / Funktionsprüfung der / des Lüftungs-geräte(s) im Inbetriebnahmeprotokoll auf Seite 39 dieser Montageanleitung.

38

10. INBETRIEBNAHMEPROTOKOLL

Bauvorhaben:

Bauherr :

Straße :

PLZ / Ort :

Telefon :

e-mail :

Eingebaute(s) Lüftungsgerät(e):

Typ :

Anzahl :

Monteur :

Installateur:

Firma :

Straße :

PLZ / Ort ::

Telefon :

e-mail :

DE

• Montagearbeiten komplett abgeschlossen

• Elektroanschluß ordnungsgemäß ausgeführt / geprüft

• Gerätefunktion überprüft

• Filtereinsatz / -einsätze eingesetzt

• Einweisung Gerätebetreiber durchgeführt (Bedienung, Wartung)

• Geräteunterlagen übergeben (Montage- / Bedienungsanleitung)

Option bei Gerätebetrieb in Verbindung mit Feuerstätten:

• Sicherheitseinrichtungen montiert / geprüft

Ort :

Datum :

Monteur :

Bauherr :

39

R

11. BEDIENUNGSANLEITUNG

Inhaltsverzeichnis Bedienungsanleitung

1. Allgemeine Hinweise ............................................................................................................................................................................................40

2. Gerätebeschreibung .............................................................................................................................................................................................. 41

3. Einstellungen Lüftungsbetrieb ............................................................................................................................................................................ 42

4. Bedien- und Anzeigeelemente..............................................................................................................................................................................44

5. Externe Steuereingänge .......................................................................................................................................................................................45

6. Reinigung / Wartung ............................................................................................................................................................................................ 46

7. Fehlermeldungen / Funktionsstörungen ............................................................................................................................................................ 48

8. Wartungsprotokoll / Filterreinigung ...................................................................................................................................................................50

1. ALLGEMEINE HINWEISE

Mit Ihrem Fox up Lüftungsgerät sind Sie durch eine geregelte, bedarfsgerechte Lüftung in der Lage in Ihrer Wohnung oder

Ihrem Haus ein gesundes, angenehmes Raum- und Wohlfühlklima zu schaffen. Die Geräte sind durch ihre unkomplizierte

Montage und einfache Bedienung optimal für den Einsatz in Neubau und Sanierung geeignet.

Fox up Lüftungsgeräte werden nach aktuellem Stand der Technik und den anerkannten sicherheits-technischen Regeln

gefertigt. Eine allgemeine bauaufsichtliche Zulassung ist beantragt.

Lesen Sie bitte diese Bedienungsanleitung vor der Nutzung des Gerätes sorgfältig durch und beachten Sie die Hinweise zu Inbetriebnahme

und Wartung des Gerätes. Der Betreiber des Lüftungsgerätes ist unter Beachtung der angegebenen Hinweise für den einwandfreien Zustand und den bestimmungsgemäßen Betrieb des Gerätes verantwortlich. Unsachgemäßer Gebrauch, mangelhaft ausgeführte Instandsetzungs- bzw. Wartungsarbeiten sowie bauliche Veränderungen können Funktion und Sicherheit des Gerätes beeinträchtigen und führen zum

Erlöschen von Gewährleistungsansprüchen.

Montage und Arbeiten am Lüftungsgerät dürfen nur durch ausgebildete Fachkräfte unter Einhaltung der Vorschriften zu Arbeitssicherheit

und Unfallverhütung ausgeführt werden.

Fox up Lüftungsgeräte mit Wärmerückgewinnung sind zur Be- und Entlüftung von einem oder mehreren Räumen konzipiert. Die Geräte

dürfen ausschließlich zur Förderung von Luft eingesetzt werden, die Förderung von aggressiven, entzündlichen oder stark staubhaltigen

Medien ist nicht zulässig. Betreiben Sie die Geräte nie ohne den eingesetzten Filtereinsatz.

Der Anschluß von Lüftungsleitungen / der Anschluß an andere Lüftungssysteme ist nicht zulässig. Fox up Lüftungsgeräte sind nicht zur

Bautrocknung geeignet, der Betrieb der Geräte sollte erst nach Abschluß von Bautätigkeiten erfolgen.

Der Gerätebetrieb in Verbindung mit Feuerstätten erfordert gegebenenfalls zusätzliche Sicherheits-einrichtungen (Feuerungsverordnung

FeuV), entsprechende Informationen erhalten Sie bei Ihrem ört-lichen Schornsteinfeger.

Voraussetzungen für optimalen Lüftungsbetrieb:

1. Türen und Fenster der zu lüftenden Räume sind möglichst geschlossen zu halten.

2. Bei Betrieb mehrerer Geräte sind Überströmöffnungen zwischen den zu lüftenden Räumen vorzusehen

(kürzen der Türblätter / Einbau von Türluftgittern).

3. Alle Lüftungsgeräte sollten gleichzeitig, auf möglichst gleicher Leistungsstufe betrieben werden.

40

2. GERÄTEBESCHREIBUNG

Das Fox up Lüftungsgerät ist ein dezentrales Lüftungssystem zur kontrollierten Raumlüftung mit Wärmerückgewinnung. Der

paarweise Einsatz mehrerer Geräte ermöglicht die Lüftung kompletter Wohneinheiten / Gebäude.

Das Lüftungsgerät besteht aus einer kürzbaren EPS-Wanddurchführung für Wandstärken bis 500 mm (alternativ 1000 mm)

und einer in die Wanddurchführung eingeschobenen Ventilatoreinheit. Die Ventilatoreinheit besteht aus reversierbarem Ventilator (12 V/