Page 1

Installation and Servicing

Flurocyl

Solar Hot Water Cylinder

14161

200 l

250 l

300 l

www.glow-worm.co.uk

1

Page 2

Guarantee Registration

Thank you for installing a new Glow-worm solar system.

Glow-worm products are manufactured to the very highest standard so we are pleased to offer our

customers a Comprehensive Guarantee.

This product is guaranteed for 24 months from the date of installation or 30 months from the date

of manufacture, whichever is the shorter, for parts and labour.

The second year of the guarantee, from the beginning of the 13th month onwards after installation

or manufacture, is conditional upon the product having been serviced by a competent person (i.e.

clear skies registered engineer),

in accordance with the manufacturer’s recommendations. We strongly recommend regular

servicing of your product, but where the condition is not met, any chargeable spare parts or

components issued within the applicable guarantee period still benet from a 12 month warranty

from the date of issue by the manufacturer.

The “Benchmark” Installation, Commissioning and Service Record must be completed on

installation and kept up to date.

We recommend you complete and return as soon as possible your guarantee registration card.

If your guarantee registration card is missing you can obtain a copy or record your registration by

telephoning the Glow-worm Customer Service number 01773 596510.

Customer Service:

01773 596510

Technical Helpline:

01773 828300

General and Sales enquiries:

Tel. 01773 824639

Fax: 01773 820569

To register your Glow-worm product call:

0800 0732142

2

Page 3

These instructions consist of, Installation, Servicing, Fault Finding and Replacement

of Parts. The instructions are an integral part of the product and must, be handed to

the user on completion of the installation.

CONTENTS DESCRIPTION SECTION PAGE

Warnings 4

Important Information 4

INTRODUCTION

Statutory Requirements 5

Safety Instructions 6

INSTALLATION

MAINTENANCE

Product Specications 1 6

Installation 2 11

Commissioning 3 18

Inspection and Maintenance 4 19

Fault Finding 5 20

3

Page 4

WARNINGS

SAFETY

The urocyl must be installed by a competent person, who is responsible for adhering to

the existing standards and regulations.

ALTERATIONS

Under no circumstances should you ever attempt to make alterations to these

components or any other part of the system

SEALED COMPONENTS

Under no circumstances must the user interfere with or adjust sealed parts.

Important Information

Installation and Use Regulations

In your own interests and that of safety, it is the LAW that this

product is installed by a competent person in accordance

with the current issue of these regulations.

Control of Substances Hazardous to Health

Under Section 6 of The Health and Safety at Work Act

1974, we are required to provide information on substances

hazardous to health.

The adhesives and sealants used in this product are cured

and give no known hazard in this state.

Manual Handling

With regards to the “Manual Handling Operations, 1992

Regulations”, the appliance exceeds the recommended

weight for a one man lift.

Electrical Supply

The product MUST be earthed.

All system components shall be of an approved type and all

wiring to current I.E.E. wiring regulations.

External wiring must be correctly earthed, polarised and in

accordance with the relevant standards.

In GB, this is BS 7671.

In IE, this is the current edition of ETCI rules.

The product MUST be connected to a permanent 230V ac,

50Hz supply.

Connection of the whole electrical system of the product,

including any heating controls, to the electrical supply MUST

be through one common isolator and must be fused 3 Amp

maximum.

Isolation should be by a double pole switched fused spur box,

with a minimum gap of 3mm for both poles. The fused spur

box should be readily accessible and preferably adjacent to

the product. It should be identied as to its use.

Alternatively connection can be made through an unswitched

shuttered socket and 3A fused 3-pin plug both to the current

issue of BS 1363, provided they are not used in a room

containing a bath or shower.

Wiring to the product must be PVC 85°C insulated cable, not

less than 0.75mm2 (24/0.20mm).

Testing and Certification

This product is tested and certicated for safety and

performance. It is, therefore, important that no alteration is

made to the product, without permission, in writing, by Glowworm.

Any alteration not approved by Glow-worm, could invalidate

the certication, warranty and may also infringe the current

issue of the statutory requirements.

CE Mark

The CE mark on the Fluropro solar control indicates that

it complies with the basic requirements of the applicable

directives as stated on the data badge.

“Benchmark scheme”

Glow-worm support the Benchmark initiative. It is very

important that the service record is completed by the

installation engineer and handed over to the user.

4

Page 5

Statutory Requirements

IMPORTANT:

Where no British Standards exists, materials and equipment

should be t for their purpose and of suitable quality and

workmanship.

The installation of this product must be carried out by a

competent person in accordance the rules in force in the

countries of destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

Statutory Requirements

In GB, the installation of the product must be carried out by a

competent person as described in the following regulations:

The manufacturer’s instructions supplied.

The Gas Safety (Installation and Use) Regulations.

The appropriate Buildings Regulations either The Building

Regulations, The Building Regulations (Scotland),The

Building Regulations (Northern Ireland).

The Water Fittings Regulations or Water byelaws in Scotland.

The Health and Safety at Work Act, Control of Substances

Hazardous to Health (COSHH).

The Current I.E.E. Wiring Regulations.

Where no specic instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a competent

person and installed in accordance with the current edition

of I.S.813 “Domestic Gas Installations”, the current Building

Regulations and reference should be made to the current

ETCI rules for Electrical Installation.

GB: the following Codes of Practice apply:

BS4814, BS6798, BS5440 Part 1 and 2, BS5546 Part 1,

BS5449, BS6891, BS6700, BS7074 Part 1 and 2, BS7593,

BS7671.

IE: I.S.813, BS5546, BS 5449, BS 7074, BS 7593.

NOTE: For further information, see the current issue of the

Building Regulations, approved document L1 ( in the UK) and

the following current issues of:

1) Central heating system specication (CheSS)

and

2) Controls for domestic central heating system and hot water.

BRECSU.

Domestic Hot Water

All domestic hot water circuits, connections, ttings must be

in accordance with the relevant standards and water supply

regulations.

GB: Guidance G17 to G24 and recommendation R17 to R24

of the Water Regulations Guide.

IE: The current edition of I.S.813 “Domestic Gas Installations”.

Heating System

In GB, it is necessary to comply with the Water Supply (Water

Fittings) Regulations 1999 (for Scotland, the Water Byelaws

2000, Scotland).

To comply with the Water regulations your attention is drawn

to: The Water Regulations guide published by the Water

Regulations Advisory Service (WRAS) gives full details of the

requirements.

In IE, the requirements given in the current edition of I.S.813

“Domestic Gas Installations” and the current Building

Regulations must be followed.

Solar cylinder and cylinder installation

Pressure equipment directive 97/23/EC Directive of the

European Parliament and Council from 29th May, 1997 for

the approximation of the laws on pressure equipment of the

Member States

EN 12977-3 Thermal solar systems and components; Custom

built systems, Part 3: Performance characterisation of stores

for solar heating systems

EN 12897 Water supply - specication for indirectly heated

unvented (closed) storage water heaters

EN 806-1 Specications for installations inside buildings

conveying water for human consumption - Part 1: General

EN 1717 Protection against pollution of potable water

installations and general requirements of devices to prevent

pollution by backow

EN 60335-2-21 Safety of household and similar electrical

appliances; Part 2: Particular requirements for storage water

heaters (hot water cylinders and hot water boilers) (IEC 335-

2-21: 1989 and supplements 1; 1990 and 2; 1990, modied)

Regulations in Great Britain

Building Regulation, dating from 1991 (England and Wales)

Requirement G3, L1 and Regulation 7

BS 7671 Requirements for electrical installations (IEE Wiring

Regulations, 16th edition)

BS 6759-1 Directive for the usage of the safety assembly for

hot water cylinders

5

Page 6

Safety Instructions

Safety instructions

NOTE: In the event of leaks in the water pipework close the

main cold water stop valve. This is often located under a

kitchen sink.

IMPORTANT: A thermostatic mixing valve must be tted to

the outlet of the cylinder and can be adjusted to the desired

domestic hot water temperature by an installation or service

engineer. Otherwise there is a risk of scalding as the cylinder

outlet temperature at the taps could be up to 85°C.

IMPORTANT: Risk of damage! Do not remove or modify any

components of the solar cylinder.

In the unlikely event of a malfunction occurring of the Flurocyl,

such as hot water owing out of the temperature and pressure

relief valve, switch off the boiler and the immersion heater and

contact Glow-worm or your installer.

Frost protection of the twin coil solar cylinder

You must drain the solar cylinder completely if it is to be shut

down in a room prone to frost. It is drained at the cold water

inlet with a T-piece with tap to be provided by the installer.

Also drain all heat exchangers which are not lled with solar

uid.

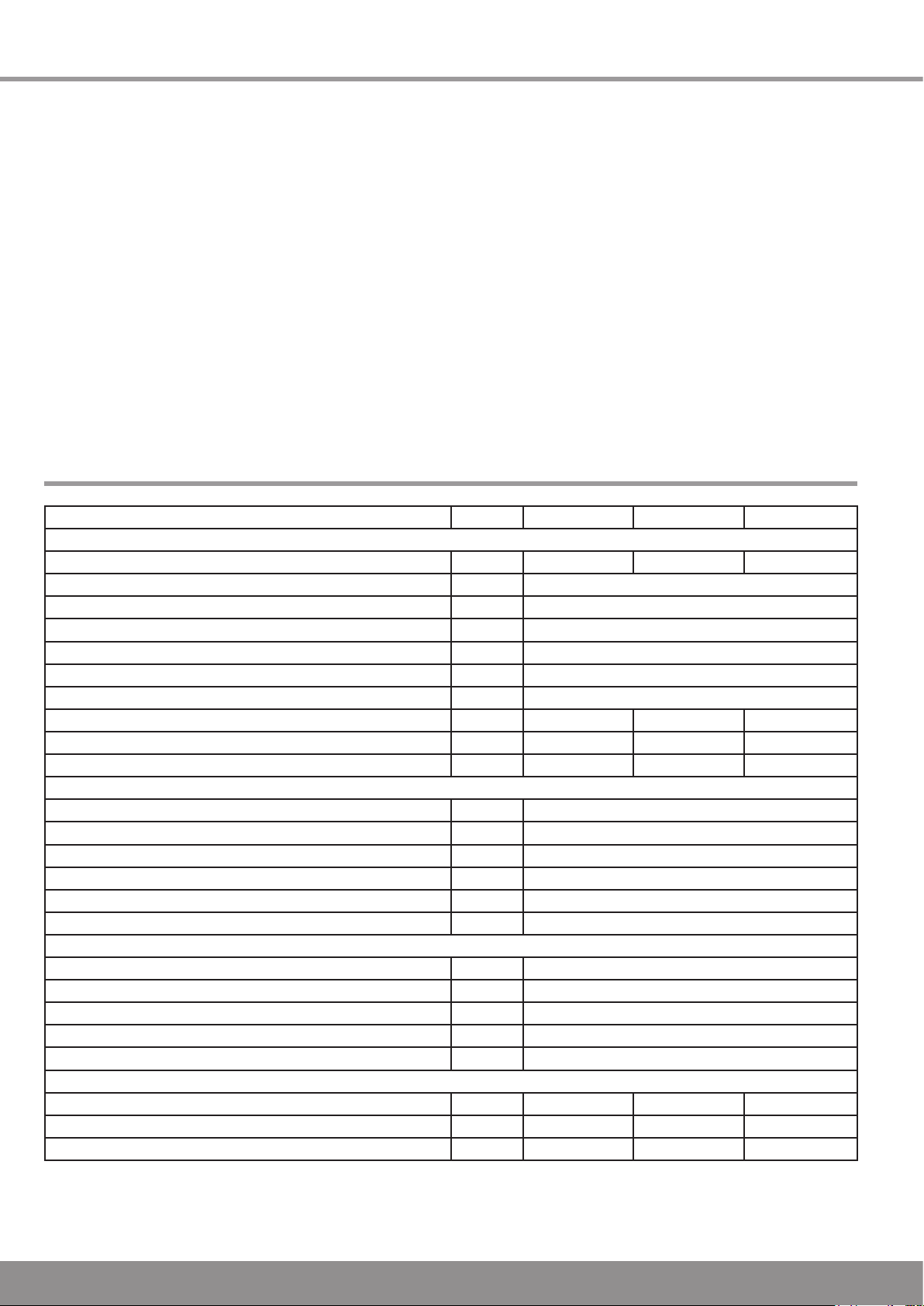

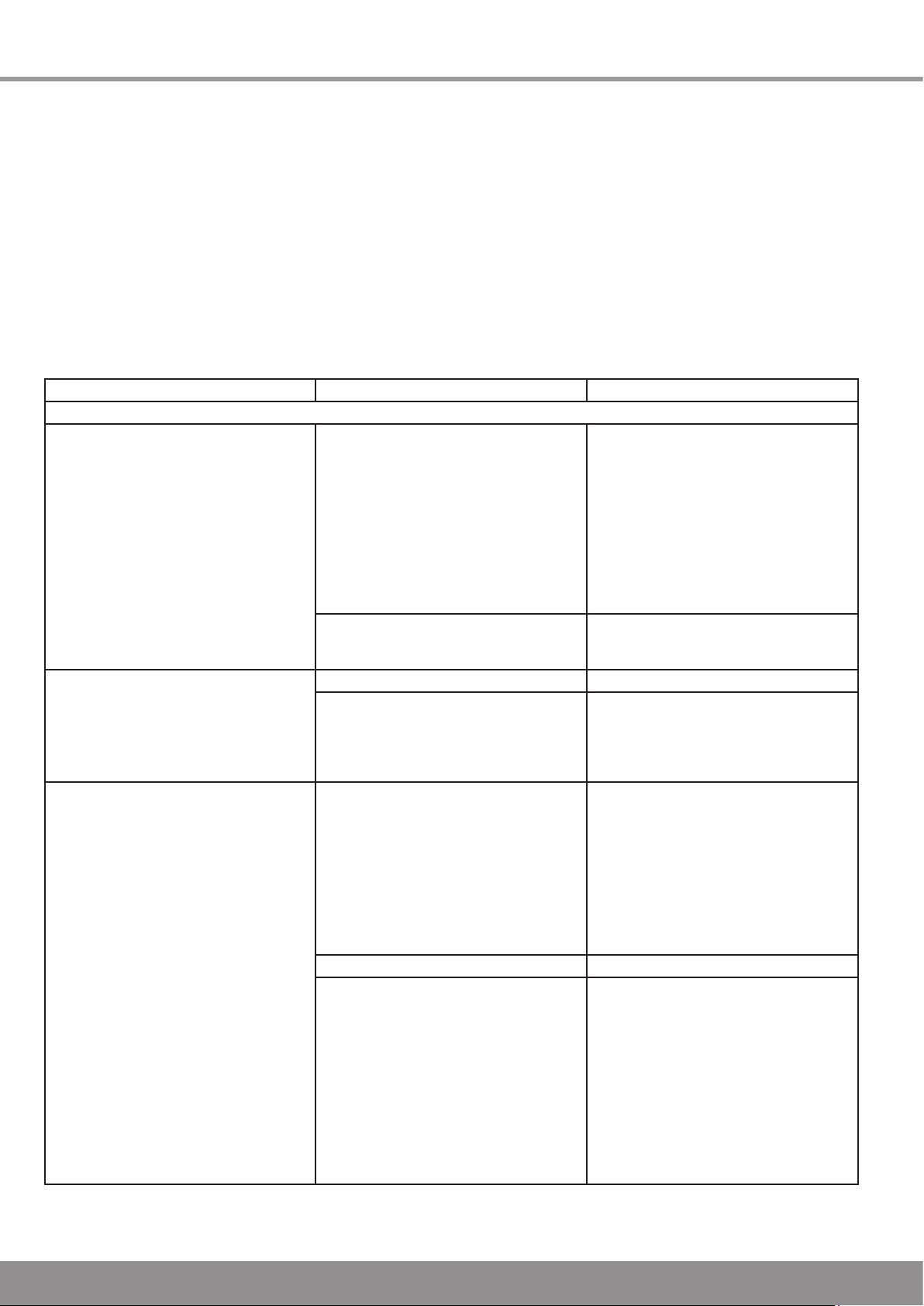

1 Product Specications

Unit Flurocyl 200 l Flurocyl 250 l Flurocyl 300 l

Cylinder:

Size l 200 250 300

Maximum water supply pressure bar 10

Operating pressure bar 3.5

Pressure limiting valve bar 3.5

Expansion relief valve bar 6.0

Hot water expansion vessel admission pressure bar 4.0

Temperature and pressure relief valve °C/bar 95 / 7.0

Net weight kg 39 44 49

Weight (full) kg 245 310 340

Height mm 1499 1789 2109

Cylinder connections:

Cold water supply 22 mm pressure pipe

Hot water connection 22 mm pressure pipe

Pressure-controlled cold water outlet 22 mm pressure pipe

Secondary return Inches G 3/4

Flow (boiler/solar circuit) 22 mm pressure pipe

Return (boiler/solar circuit) 22 mm pressure pipe

Electrical connections:

3 kW immersion heater (according to ENBS 60335) 230/240 V, 50 Hz

Length of the immersion heater mm 430

Motorised 2 port valve 230/240 V, 50 Hz

Cylinder thermostat 230/240 V, 50 Hz

Thermal cut out for solar pump 230/240 V, 50 Hz

Heating coil:

Heat loss kW/24 h 1.9 2.1 2.4

Heat up time (boiler part) mins 21 26 30

Recovery (boiler part) mins 13 16 21

Table 1.1 Technical data

6

Page 7

1 Product Specications

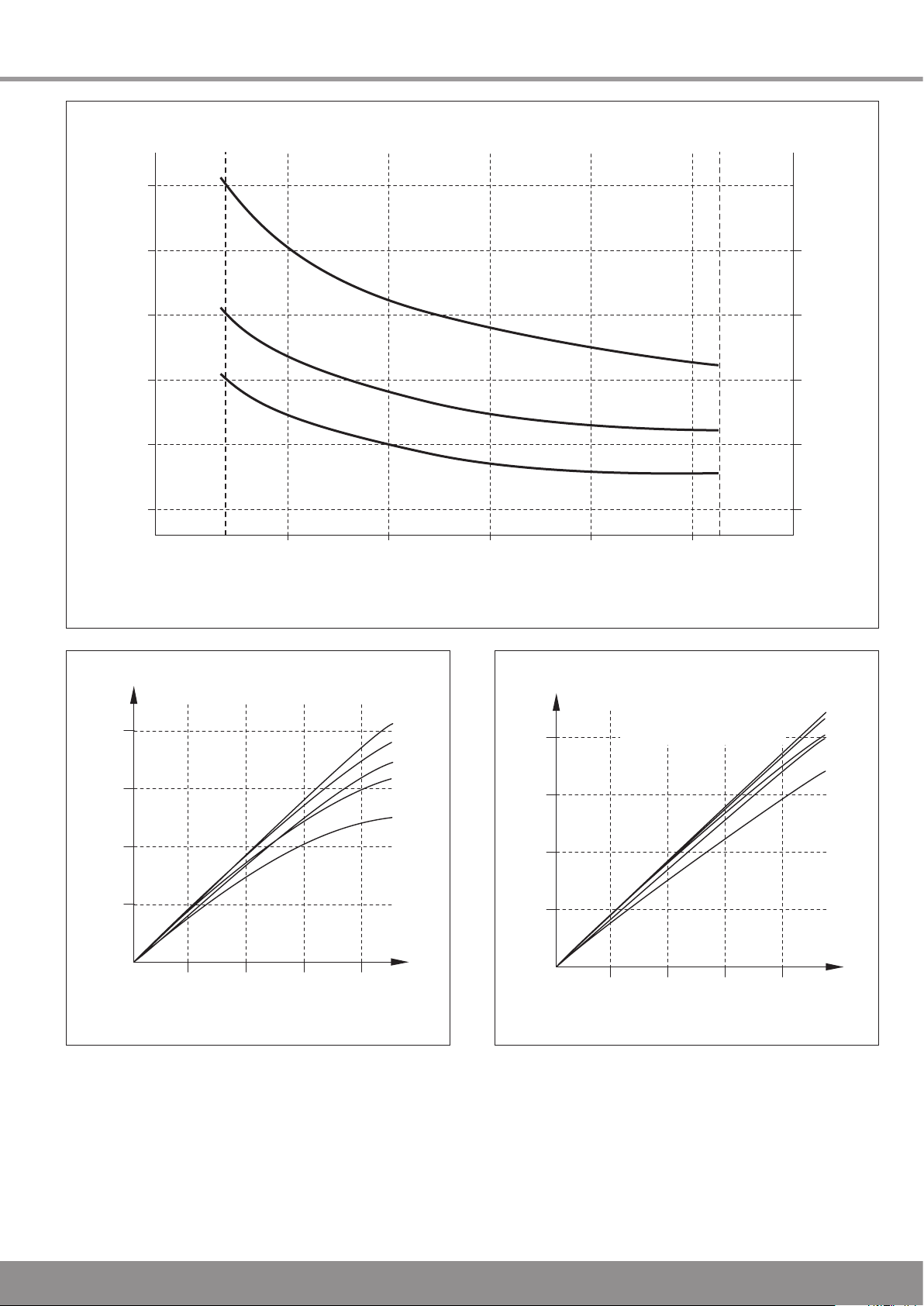

Approximate cylinder heat up time 15 C to 45 C (minutes)

Reheat time for 70 % of cylinder contents (minutes)

10

15

20

25

30

20

25

30

35

40

45

12

Heat input to cylinder (kW)

15 20 25 30 3835

200 l

250 l

300 l

40

40

8 bar

4 bar

3 bar

2 bar

1 bar

30

30

20

20

Flow available (litres/min) at entry to system

Flow out (litres/min) of the system

10

10

0

8 bar

4 bar

3 bar

2 bar

1 bar

Flow available (litres/min) at entry to system

Flow out (litres/min) of the system

40

40

30

30

20

20

10

10

0

Mixed water of 40 °C, mixed from

60 % hot water of 60 °C and

40 % cold water of 10 °C

14177

Flurocyl cylinder heat-up times (boiler part)

14178

Flurocyl DHW flow rates at 60°C Flurocyl mixed water flow rates

NOTE: The heat-up time is based on a primary ow rate of 9

l/min at 80 °C. Temperature rise from 15 °C to 65 °C

Static operating pressure of the cold water supply

The displayed ow rates apply to installations in which the

cold water supply is of appropriate dynamic pressure.

Please contact Glow-worm if the static water pressure is

below 1 bar.

Diagram 1.2

7

Diagram 1.1

14179

Diagram 1.3

Page 8

1 Product Specications

CARRYING

HANDLE

1.1 Intended use

The Glow-worm Flurocyl 200 l, Flurocyl 250 l and Flurocyl 300

l are unvented, indirectly heated hot water cylinders for use

with solar systems and boilers for the provision of domestic

hot water.

IMPORTANT: Risk of damage! The appliances may only

be used to heat up potable water. Damage to the appliance

due to corrosion cannot be excluded if the water does not

correspond to the specications of the water ordinance.

Any other use or extended use is considered to be improper.

The manufacturer/supplier is not liable for any resulting

damage.

Intended use includes the observance of the instructions and

the adherence to the servicing requirements.

1.2 Data badge

The data badge has been applied to the top of the solar

cylinder by the manufacturer.

1.3 Safety devices

The Flurocyl solar cylinder has been provided with all safety

and control devices suitable for operation as part of an

unvented domestic hot water supply system.

Temperature and pressure relief valve (95°C, 7 bar)

Pressure limiting valve (3.5 bar) with line strainer

Expansion relief valve (one port valve, 6.0 bar)

Thermal cut out set to 90°C, connected to the solar pump in

order to isolate this heat source in the event of failure of the

solar control.

Thermal cut out of the immersion heater

Thermal cut out set to 90°C, connected to the motorised 2

port valve, in order to isolate the primary heat source in the

event of failure of the domestic water thermostat.

1.4 Safety regulations

This product has been checked for adherence to the building

regulations for unvented hot water cylinder systems. It may

not be changed or modied in any way whatsoever.

It should be installed by a qualied specialist, who should

observe the applicable regulations of the local authorities, the

building regulations, the building regulations for Scotland, the

building regulations for Northern Ireland and the directives of

the local water supply companies. Only original spare parts

may be used for the replacement of parts.

1.7 Solar Cylinder Charicteristics

Flurocyl solar cylinders are available in three sizes: 200, 250

and 300 litres. The containers are made of stainless steel

and insulated with EPS.The cylinders are equipped with all

necessary cold and hot water control devices and a motorised

2 port valve.

The Flurocyl cylinders are operated at the pressure of the

water supply pipe and do not need a cold water tank for their

supply. They have hot and cold water connections of 22 mm

diameter. A cold water supply of appropriate pressure and

ow rate is required to operate the solar cylinder ideally, refer

to section 2.6.

Temperature control

The solar water heating control thermostat is part of the solar

control with sensor attached to the Flurocyl solar cylinder.

The cylinder includes the boiler and imersion heater control

thermostats that are factory tted and set.

A themostatic mixing valve must be tted to the outlet of the

cylinder and must be adjusted to the desired domestic hot

water temperature.

The cylinder also includes the solar, boiler and immersion

heater thermal cut outs that are factory tted and set.

The solar pump must be connected to the solar control via

the solar thermal cut out (TCO), It ensures the solar pump is

switched off if the hot water temperature in the cylinder rises

above 90°C.

Immersion heater

The Flurocyl solar cylinders are equipped with an additional

immersion heater of 3 kW, including the control thermostat

and thermal cut out. The immersion heater is situated behind

the front plate.

NOTE: In the event of a replacement, only the right immersion

heater equipped with a thermal cut out fur overheating

protection may be used.

1.5 Contents

Check the contents of the pack, see diagram 2.1.

Make sure the cylinder is stored in an upright position in a dry

environment prior to its installation.

1.6 Transport

A cylinder carrying handle is supplied to make the transport to

the installation site easier.

Fasten the carrying handle to the hot water outlet connection

of the solar cylinder.

Carrier handle

8

14180

Diagram 1.4

Page 9

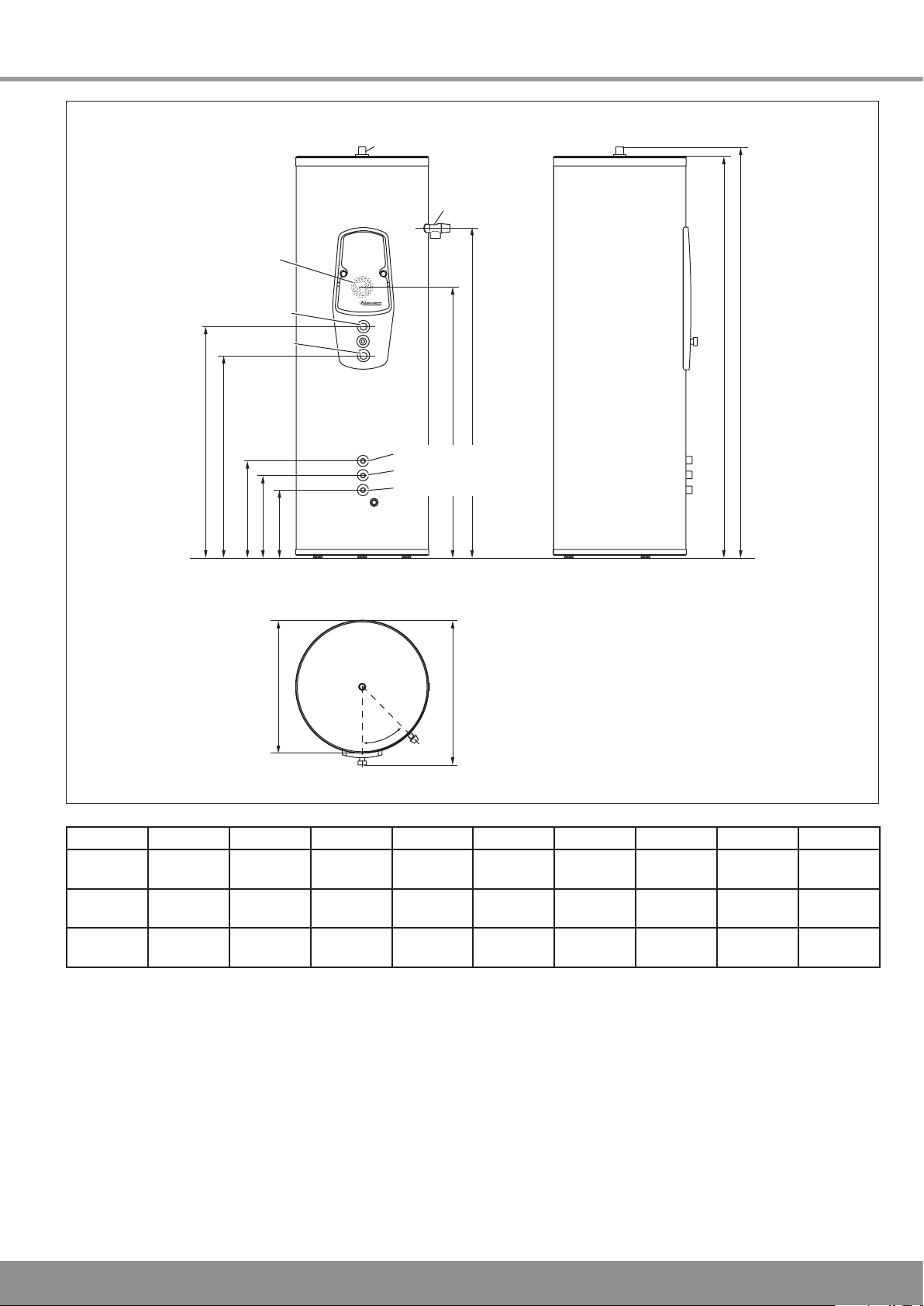

F

D

E

G

C

A

B

554

598

45°

H

ot water connection

Temperature

and pressure

relief valve

Solar circuit Flow

Cold water supply

Solar circuit Return

H

I

Immersion

heater

Boiler Flow

Boiler Return

1 Product Specications

14181

Dimensions

Flurocyl

200 l

Flurocyl

250 l

Flurocyl

300 l

Diagram 1.5

A B C D E F G H I

1468 1499 454 384 314 589 1118 813 953

1758 1789 454 384 314 589 1408 924 1064

2078 2109 454 384 314 589 1648 1101 1241

Table 1.2 Dimensions

9

Page 10

Boiler

Flow Return

Flurocyl

Flurosorb

Solar Pump Unit

Flow

Return

Immersion

Heater

Drinking Water

Expansion Vessel

2 Port Valve

2 Port Valve

Automatic Air

Separator System

M

DHW

M

Protection

Vessel (optional)

Solar Expansion Vessel

1 Product Specications

14162

Diagram 1.6

10

Page 11

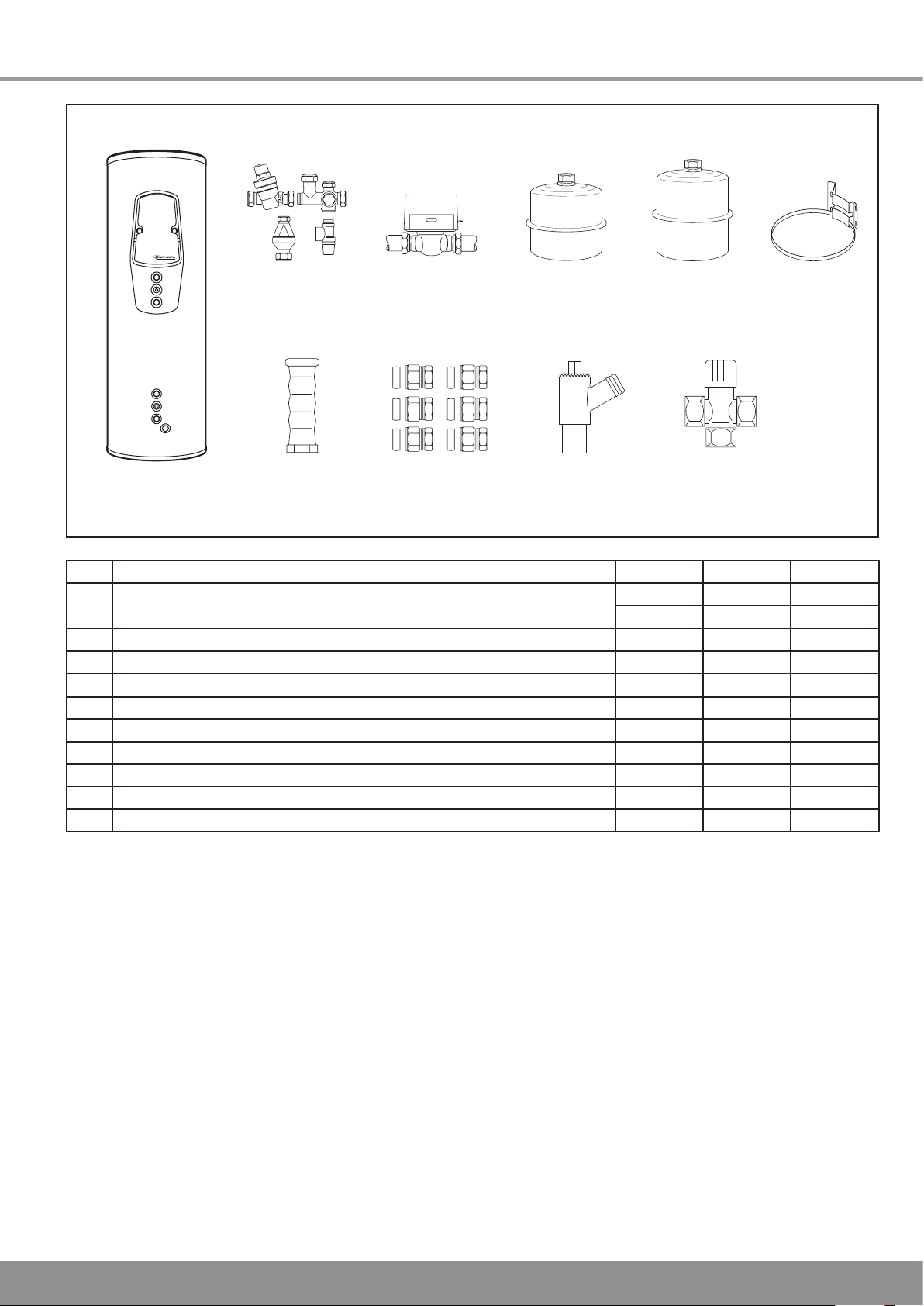

2 Installation

A B

7 8 9 10

2 3 4 5 6

1

14173

Flurocyl pack contents

Item Description Qty. Qty. Qty.

1 Flurocyl solar cylinder

Part no.

2 Cold water control pack with tundish 1 1 1

3 Motorised 2 port valve 1 1 1

4 DHW expansion vessel 18 l 1

5 DHW expansion vessel 25 l 1 1

6 DHW Expansion vessel mounting bracket 1 1 1

7 Carrying handle 1 1 1

8 Compression Fittings 1 1 1

9 Drain valve 1 1 1

Thermostatic Mixing Valve 1 1 1

10

200 l 250 l

307 206 307 207 307 208

Table 2.1 Flurocyl pack contents

Diagram 2.1

300 l

11

Page 12

2 Installation

Legionella loop

return connection

Cylinder

thermostat

Cylinder thermostat

thermal cut out

Immersion heater

thermostat

Immersion heater

thermal cut out

Immersion

heater

Domestic hot water

outlet connection

Temperature and

Pressure relief valve

Expansion vessel

connection

Pressure controlled

cold water outlet

Cold water

supply

Return

(solar circuit)

Adjustable feet

Flow (solar circuit)

Return

(boiler)

Flow (boiler)

Solar pump thermal

cut out

Immersion

heater

switch

Pressure

limiting

valve

Expansion

relief

valve

Tundish

Cylinder drain valve

Temperature sensor immersion sleeve

Expansion

vessel

REAR VIEW

30°

4

0

°

5

0

°

65°

30°

4

0

°

5

0

°

65°

LN

1 2 3

14174

2.1 Locating the cylinder

Locate the solar cylinder at an appropriate place in the

building, while observing the following:

The discharge pipe from the tundish must be installed at a

minimum slope of 1:200 and end at a safe and visible point,

refer to section 2.9.

The installation surface must be level and able to bear the

weight of the full cylinder, refer to table 1.1.

The installation site may not be prone to frost. A frost

protection thermostat must be installed if necessary.

There must be sufcient space to install, check and

repressurise the expansion vessel.

Floor unevenness should not be greater than the

compensation offered by the adjustable feet of the solar

cylinder.

2.2 Boiler heating circuit piping

Copper pipes with a minimum diameter of 22mm should be

used for the pipes in the reheating circuit between the boiler

and the solar cylinder.

Larger pipe diameters may be necessary for relatively large

distances between the boiler and the cylinder.

2.3 Motorised 2 port valve

To prevent the Flurocyl cylinder from overheating the 2 port

motorised valve supplied must be tted to the primary ow to

the indirect coil.

2.4 Domestic hot water pipework

Connect the hot water outlet to the 22mm hot water

connection of the solar cylinder.

Lay a further 22mm pipe to the rst T-piece.

A pipe of 15mm diameter should then be sufcient.

If the pipe is very long or several outlets are supplied,

continue with another 22mm pipe.

2.5 Thermostatic mixing valve

A hot water thermostatic mixing valve ensures the hot water

from the cylinder is mixed with cold water to a desired

maximum temperature between 30°C and 60°C.

Set the thermostatic mixing valve to the desired maximum

temperature during the solar system commissioning.

IMPORTANT: Risk of scalding, Set the thermostat mixer to

60°C or below and check the temperature at a hot water tap

to ensure effective protection against scalding.

Diagram 2.2

12

Page 13

2 Installation

TUNDISH

THERMOSTAT

MIXER

EXPANSION

VESSEL

HOT

WATER

CONNECTION

TEMPERATURE

AND PRESSURE

RELIEF VALVE

(95 °C, 7 BAR)

LEGIONNELLA

LOOP (optional)

FLOW

PUMP

BOILER

PRESSURE

LIMITING VALVE

(3.5 BAR)

WITH LINE

STRAINER

EXPANSION

RELIEF

VALVE

(6.0 BAR)

COLD

WATER

SUPPLY

FLUROCYL

DRAIN VALVE

MOTORISED

2 PORT VAVE

MOTORISED

2 PORT VAVE

RETURN

14244

2.6 Mains water supply

The performance of unvented cylinders depends on the

available mains water pressure and the pipe size.

In order for the performance of the Flurocyl solar cylinder to

be ideal, an appropriate cold water supply must be available.

The measured static pressure must be at least 2.0 bar. A

corresponding ow rate of at least 20 - 25 l/min should be

available.

NOTE: The mains water pressure is reduced during periods of

high water consumption.Make sure you take measurements

during these periods.

Diagram 2.3

Example: The available ow rate of mixed water at 40°C is 25

l/min (15 l/min hot water of 60°C from the solar cylinder mixed

with 10 l/min cold water of 10°C) if the measured static cold

mains water pressure is 2 bar.

The solar cylinder operates satisfactorily at a mains water

pressure of below 2 bar, but at a reduced ow rate.The

unvented solar cylinder should not be installed if the mains

water pressure is below 1 bar.You can obtain information on

alternative hot water supply systems from Glow-worm.

To keep the friction losses at a minimum, a minimum diameter

of 22mm is recommended for the cold water supply in the

building, satisfactory performances can also be achieved with

15mm pipes however.

13

Page 14

2.7 Cold water inlet controls and pipework

COLD

WATER

SUPPLY

PRESSURE LIMITING

VALVE WITH LINER

STRAINER

BALANCED

PRESSURE

COLD WATER

CONNECTION

HOT WATER

EXPANSION

VESSEL

CONNECTION

EXPANSION

RELIEF VALVE

FLUROCYL

CONNECTION

LEGIONELLA

LOOP

CONNECTION

Connect both parts of the water control pack.

When installing the valves, make sure they are aligned in

such a way that the 15mm connection of the expansion relief

valve can be connected to the tundish.

Install the assembled water control pack in the cold water

supply at an appropriate place next to the solar cylinder.

Make sure there is sufcient space for maintenance and the

connection of the discharge pipe from the expansion relief

valve.

Install the drain valve in the cold water supply at the lowest

point between the solar cylinder and the water control pack.

We recommend applying a hose, which reaches about 1m

under the base of the cylinder, to the outlet of the drain valve.

IMPORTANT: Risk of bursts for the solar cylinder! No stop

valve may be installed between the cold water control pack

and the cylinder.

Install the water pack so that a discharge pipe of the

expansion relief valve can be tted with constant outward

slope which can end at a safe, visible point where there is no

risk of freezing.

IMPORTANT: Risk of the solar cylinder bursting due to

overpressure! The outlet of the expansion relief valve must

not be covered or closed.

Test the expansion relief valve regularly to avoid calcication.

To ensure an optimum performance of the solar cylinder, in

particularly buildings in which a pressure controlled cold water

is used, copper pipes with a diameter of at least 22mm should

be used for the pipe from the main stop valve of the building

to the solar cylinder.

If the discharge pipes are all together, the expansion relief

valve may not be installed more than 500 mm away from the

temperature and pressure relief valve.

The Flurocyl solar cylinder is supplied with an external hot

water expansion vessel (DW EV).

Connect this expansion vessel to the installed water control

pack as follows:

Screw the expansion vessel directly onto the water control

pack, via the connection intended for this purpose or

Connect the expansion vessel to the water control pack with a

copper pipe or an appropriate hose. Make sure the expansion

vessel is supported sufciently.

Use the supplied mounting bracket if the expansion vessel is

to be mounted on the wall.

Connect thermostatic mixing valve cold supply to the pressure

controlled cold water connection of the water control pack (if

convenient).

NOTE: In areas with high water pressure (4 bar or more), a

bath or shower mixer valve could also be connected to the

pressure-controlled cold water connection of the water control

pack. This is to ensure the pressure of the hot and cold water

supply to the mixer valve is about the same. Any second

cold water supply connection should be installed between

the water control pack and the solar cylinder by means of a

T-piece.

2 Installation

14187

Diagram 2.4

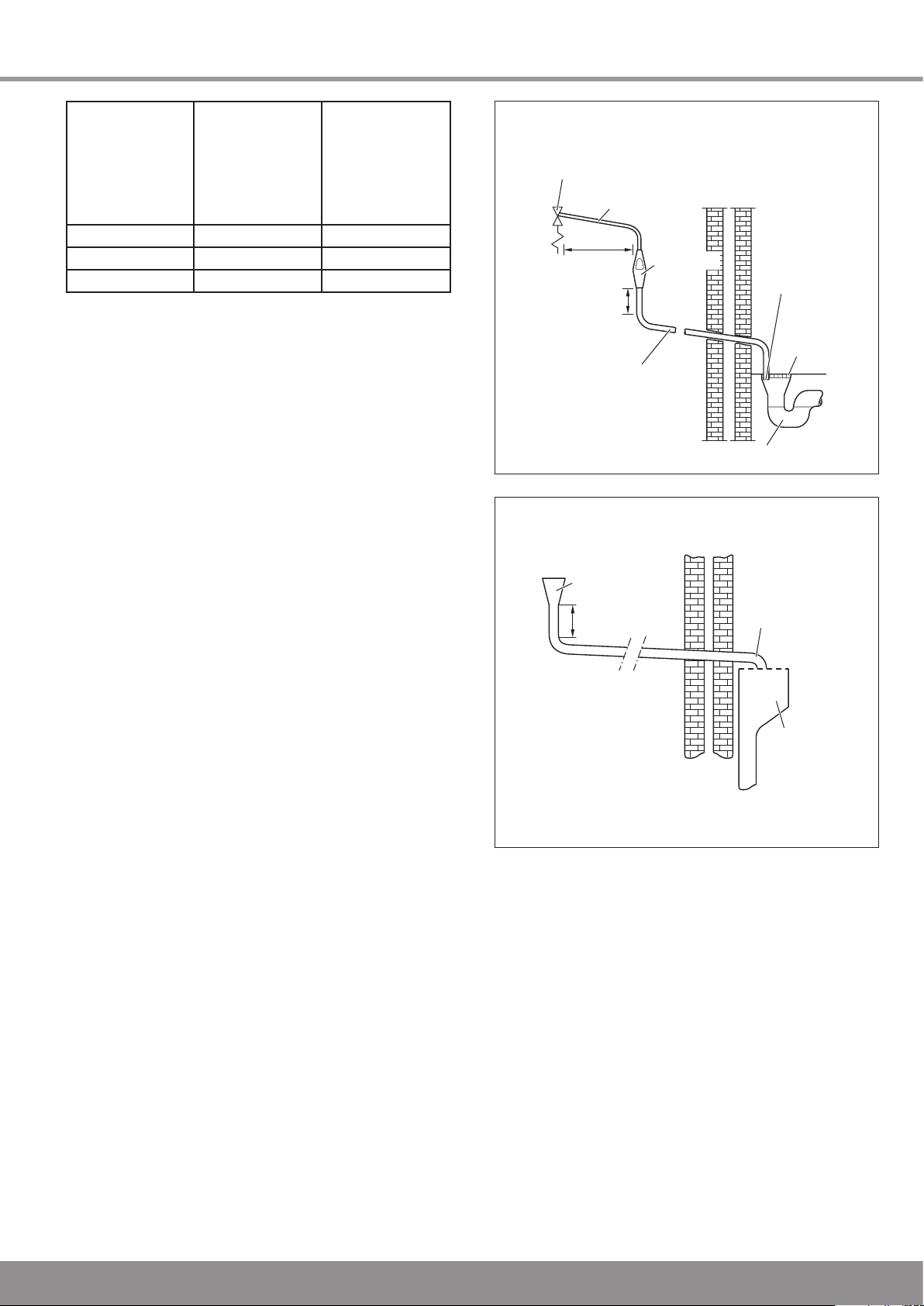

2.8 Discharge pipework

The outlet connections of both the temperature / pressure

relief valve and expansion relief valve should be connected in

15mm copper pipe to the tundish supplied. The tundish should

be installed vertically, as close to the Flurocyl as possible and

within 500mm of the temperature and pressure relief outlet. It

must be positioned away from any electrical components and

installed in the same space as the Flurocyl cylinder, so that

it is visible to the user. The D1 discharge pipe from the T&P

Valve/Expansion valve can be teed together upstream of the

tundish.

The discharge pipework must be installed using minimum

22mm copper pipework from the 22mm connection on the

tundish to a safe and visible discharge point.

There must be a vertical section of pipe at least 300mm

long, below the tundish before any bends or elbows in

the pipework. Increase the diameter of the pipework if the

total resistance of the discharge pipework exceeds the

gures shown in table 2.2. The installation of the discharge

pipework must be in accordance with G3 refer to Statutory

Requirements.

14

Page 15

METAL DISCHARGE PIPE FROM

TEMPERATURE RELIEF VALVE

TO TUNDISH

METAL DISCHARGE PIPE

FROM TUNDISH WITH

CONTINUOUS FALL

TUNDISH

DISCHARGE

BELOW

FIXED

GRATING

FIXED

GRATING

TRAPPED GULLY

SAFETY DEVICE

(E.G. TEMPERATURE

RELIEF VALVE

VENTIL)

500 MM

MINIMUM

300 MM

MINIMUM

TUNDISH

300 MM

MINIMUM

DISCHARGE

PIPE

METAL

HOPPER

HEAD

2 Installation

Minimum diameter

of the discharge

pipe from the

tundish

22mm

28mm Up to 18m 1.0m

35mm Up to 27m 1.4m

Examples:

22mm discharge pipe with 4 elbows and of 7m length from the

tundish to the discharge point:

Resistance for 4 elbows per 0.8m = 3.2m

Resistance for discharge pipe = 7.0m

Total resistance = 10.2m

The total resistance of the discharge pipe is higher than the

maximum permissible value for 22mm pipes (9m). Base your

calculations therefore on the next largest pipe diameter.

28mm discharge pipe with 4 elbows and of 7m length from the

tundish to the discharge point:

Resistance for 4 elbows per 1.0m = 4.0m

Resistance for discharge pipe = 7.0m

Total resistance = 11.0m

The total resistance of the discharge pipe is lower than the

maximum permissible value for 28mm pipes (18m),which

means this pipe diameter can be used.

Water which is almost boiling may escape from the discharge

pipe in the event of an error.

IMPORTANT: Risk of being scalded by escaping hot water!

Make sure the discharge pipe ends at a safe point inside or

outside the building (safe and visible), where there is no risk

of anyone coming in contact with hot water.

A suitable point is, for example, under a xed grating above

the trap of a trapped gully. Low discharge pipes, for example

up to 100mm above external surfaces, such as parking

spaces, grasslands etc., can be used, provided they are

secured by a wire fence or something similar to prevent

children from coming in contact with the waste water, and the

system is visible. No valves or taps may be installed in the

discharge pipe.

Make sure the discharge pipe is at a constant slope of at least

1:200 from the tundish to the discharge point.

The discharge pipe from the pressure relief valve of the boiler

(if applicable) can be connected to the horizontal discharge

pipe of the solar cylinder behind the tundish with a T-piece.

2.9 High level discharge termination

Providing that the point of termination is such that persons

in or around the building will not be endangered should

discharge take place, this method of termination is

satisfactory. Points to consider when deciding whether a

location for the high level of discharge is suitable are:

Maximum

permissible

total resistance,

expressed as

straight pipe

length (without

elbows or bends)

Up to 9m 0.8m

Resistance due

to each elbow

or bend (straight

length equivalent)

Table 2.2 Resistance

14188

Diagram 2.5

14189

Diagram 2.6

The possibility, taking into account wind effect, that someone

may be in the path of the water being discharged and if so,

whether the temperature of the discharge water will have

been sufciently reduced to not be dangerous. Thermal

conductivity of the structure's surface, climatic conditions and

location and orientation of the discharge pipe may or may not

have an effect on reducing the temperature of the discharge

water.

The location of windows and similar openings.

The likelihood of a pram being left beneath the point of

discharge.

The ability of structures surface to withstand near boiling

water.

The possibility of ice formation if water is discharged onto

pedestrian walkways.

15

Page 16

2 Installation

IMMERSION HEATER

THERMAL CUT OUT

WITH RESET BUTTON

REHEAT

THERMAL

CUT OUT WITH

RESET BUTTON

REHEAT

THERMOSTAT

(FACTORY SET)

IMMERSION HEATER

THERMOSTAT

(FACTORY SET)

IMMERSION

HEATER

CONNECTION

230V AC 3 kW

TEMPERATURE SENSORS

IN IMMERSION SLEEVES

230V

AC

3 kW

30°

4

0

°

5

0

°

65°

30°

4

0

°

5

0

°

65°

LN

1 2 3

UPPER

TEMPERATURE

SENSOR

LOWER

TEMPERATURE

SENSOR

TEMPERATURE

SENSOR

GAIN

3

0

°

40

°

50°

65°

3

0

°

40°

50°

65°

LN

1 2

3

DOMESTIC

HOT WATER

DEMAND

WIRING

REHEAT

CONTROL

THERMOSTAT

(FACTORY SET)

SOLAR THERMA

L

CUT-OUT WITH

RESET BUTTON

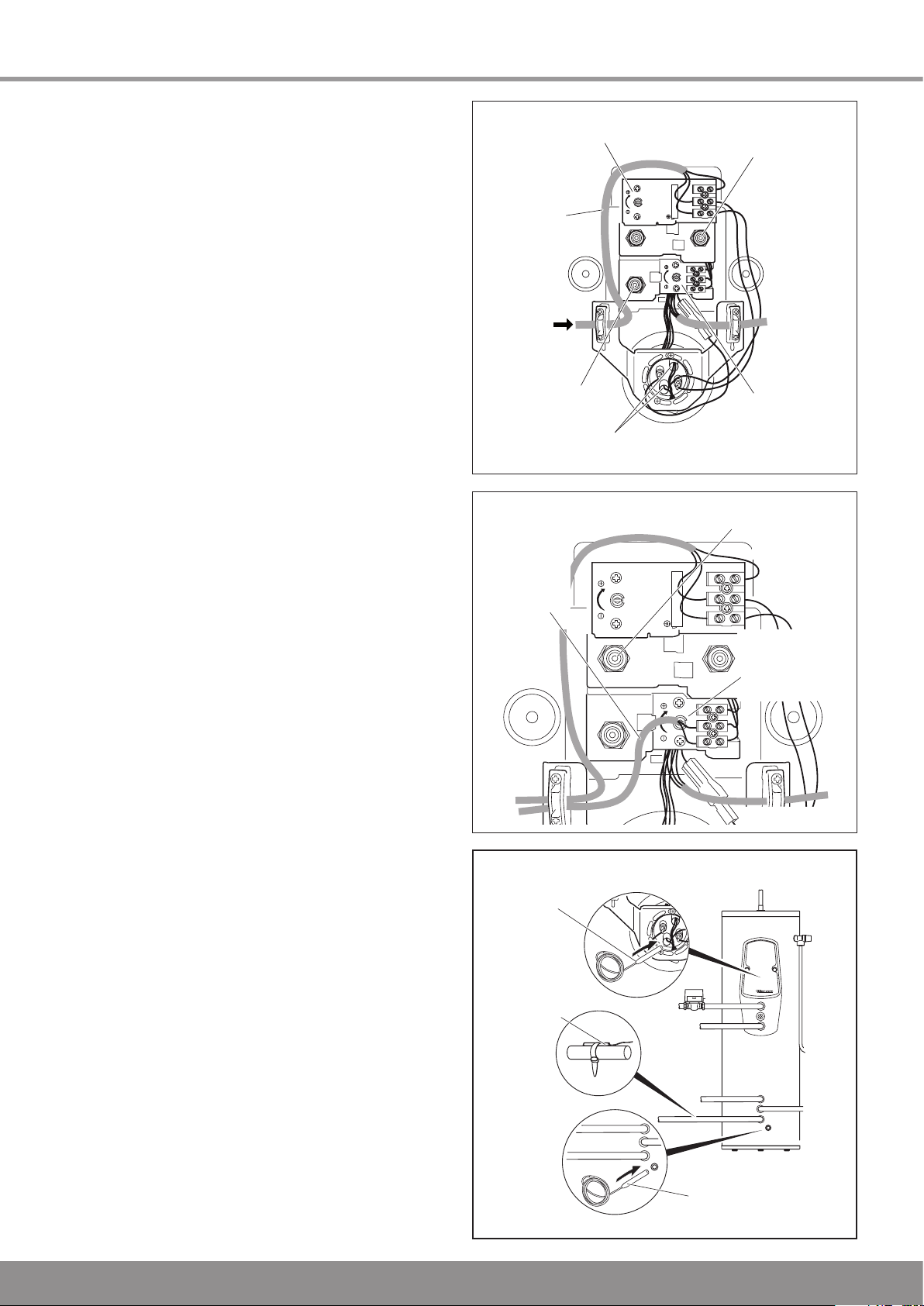

2.10 Electrical installation

Remove the front fascia panel.

Wiring should be performed by a competent person in

accordance with the building regulations, Part P of the

current IEE regulations and further applicable regulations and

directives.

The discharge pipes of the tundish, drain valves, motorised

valves etc. should be laid at a safe distance to electrical

components.

IMPORTANT: Danger of death from electric shock! You must

earth the solar cylinder for potential equalisation.

2.11 Immersion heater

The Flurocyl solar cylinders incorporate an immersion heater.

IMPORTANT: Danger of death from electric shock! You must

earth the immersion heater for potential equalisation.

Install a separate electrical power supply line for the

immersion heater in accordance with current IEE regulations

(BS 7671).

You must lay a heat-resistant line (3 x 2.5 mm

pole isolating switch for the immersion heater. The circuit must

be protected by a 13 A fuse.

The connection of the immersion heater is illustrated in detail

in diagram 2.7.

IMPORTANT: Risk of damage! The immersion heater

is equipped with a thermal cut out and may under no

circumstance be replaced by a standard immersion heater.

Only correct original Glow-worm spare parts are permitted.

2

) from a double

14190

Diagram 2.7

14192

2.12 Thermostat setting

The entire inner wiring has been pre-assembled at the factory.

IMPORTANT: Risk of damage! Switch off the power supply

before resetting the thermal cut out or making any other

changes to the temperature setting of the cylinder thermostat.

The cylinder thermostats for the regulation of the hot water

temperature are factory set at 65°C as the Domestic Hot

Water temperature is controlled by the adjustable thermostatic

mixing valve.Ensure both control thermostats are adjusted

fully clockwise.

Actuate the reset buttons, to reset the thermal cut outs if

necessary, see diagram 2.7.

IMPORTANT: Risk of damage! If the immersion heater is not

connected, you must connect the earth wire to terminal E

on the terminal strip of the immersion heater. You can nd a

wiring sheme on the inside of the cylinder cover.

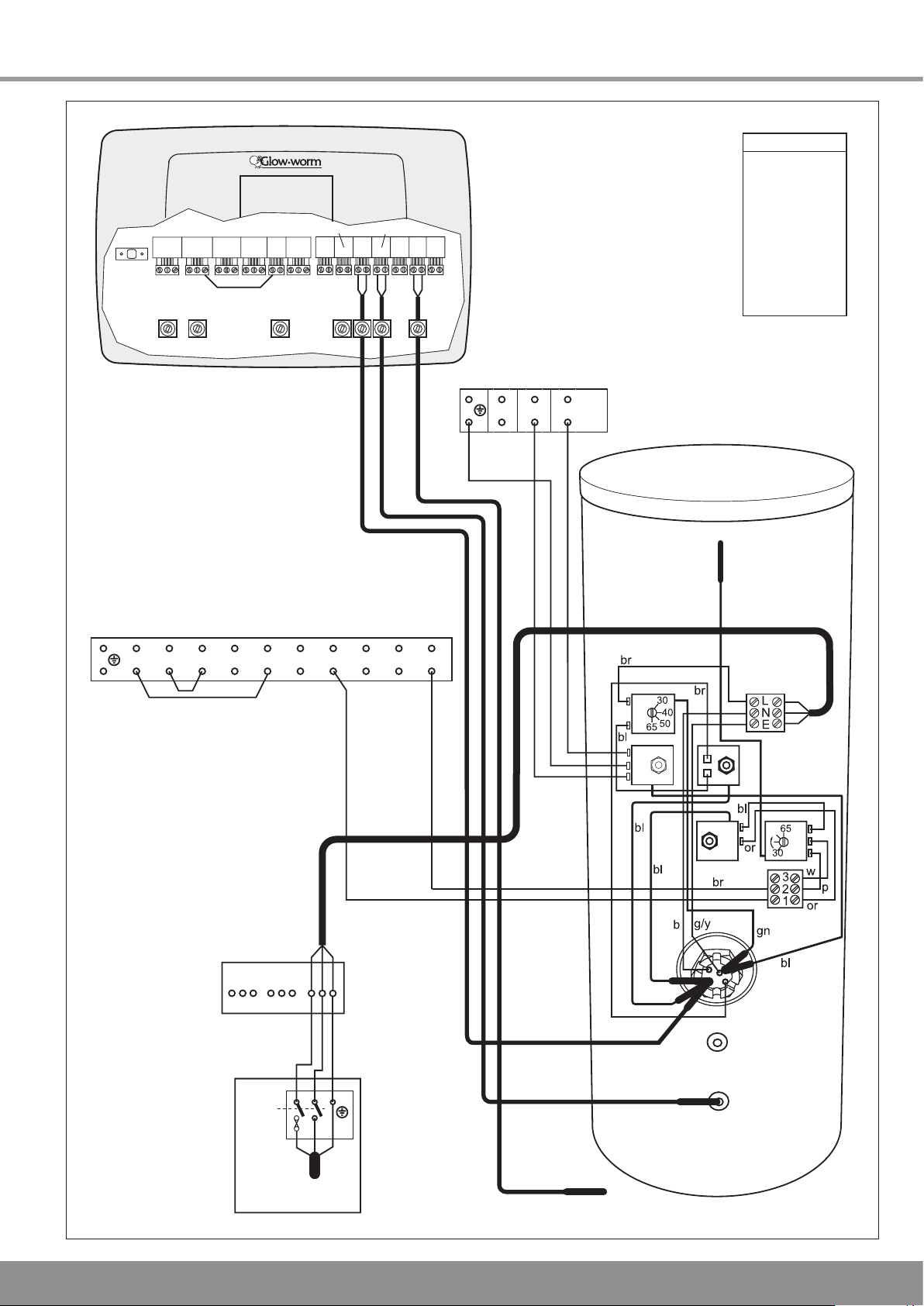

2.13 Thermostat and sensor wiring

Connect the domestic hot water demand wiring to the reheat

control thermostat as shown in diagram 2.8 and 2.10.

Connect the solar pump live via the solar thermal cut out and

ensure this thermal cut out is earthed, as shown in diagram

2.8. and 2.10.

Install the two temperature sensors in the solar cylinder, see

diagram 2.9, and connect to the solar control, see diagram

2.10.

Attach the solar gain sensor to the solar circuit return, see

diagram 2.9.

Replace the front fascia panel.

Diagram 2.8

14194

Diagram 2.9

16

Page 17

FLUROCYL

COMMON 230V

MAINS TERMINAL BLOCK

E

TERMINAL BLOCK

230V~50Hz

MAINS SUPPLY

L

N

E

Double

pole

isolator

RETURN PIPE

AT 3A

FUSED

AT 3A

ENL E N 21L

br

blg/y

N L 3 4 5 6 7 8 9

LINKE N L

10

ADDITIONAL

TERMINAL

BLOCK

FLUROPRO

CONTROLLER

230v~ PCSA

NTCA

TAC1

TAC2

GAINR

L

BROWN br

BLUE b

BLACK bl

ORANGE or

WHITE w

PURPLE p

GREEN gn

GREY g

GREEN

/YELLOW g/y

KEY

bl

2 Installation

14238

Wiring diagram

17

Diagram 2.10

Page 18

3 Commissioning

‘A’ PORT‘B’ PORT

BA

LEVER

3.1 Filling the secondary circuit

IMPORTANT: Risk of damage! Do not manually open the

temperature/pressure relief valve or the expansion vessel for

venting purposes. Any foreign matter in the pipework may

cause damage to the valve seats.

Make sure the cylinder drain valve is closed.

Open all cold and hot water taps and the corresponding

outlets.

Open the mains water supply to the Flurocyl and ll it with

water until it ows freely out of the outlets. Make sure all air

bubbles have been removed.

Close the outlets and check the system for leaks. Check in

particular the immersion heater connection for leaks.

The system must now be ushed thoroughly.

Open the hot water taps at the opposite ends of the systems

and let the water ow out for at least 5 minutes.

Close the hot water taps.

3.2 Setting the thermostatic mixing valve

The hot water from the solar cylinder can be set to a desired

maximum temperature between 30 °C and 70 °C by mixing

hot and cold water.

Set the hot water thermostatic mixing valve with the adjusting

knob to maintain the householders desired temperature at the

hot water taps.

IMPORTANT: Risk of being scalded by hot water! Set the

thermostat mixer to 60 °C or below and check the temperature

at a hot water tap to ensure effective protection against

scalding.

3.3 Reheat circuit (boiler circuit)

NOTE: Do not use the pressure relief valve of the boiler (if

applicable) for bleeding.

Flush the entire primary central heating system with cold and

hot water. Fill and bleed the central heating system according

to the installation manual of the boiler.

Set the lever on the motorised 2 port valve to MANUAL and

lock it in this position, see diagram 3.1.

Fill and bleed the central heating system after draining it

completely.

Unlock the lever on the motorised 2 port valve by setting it

back to AUTO.

Start up the boiler, refer to section 3.4, until the solar cylinder

is at operating temperature and all radiators in the system

are warm. Then drain the entire central heating system again

to remove any residue from the pipes. Fill and bleed it again

afterwards as described above.

3.4 Starting up the boiler

Switch on the main switch of the boiler.

Make sure the control device and the thermostats are set in

such a way that heating is necessary.

Check whether the boiler starts up and the water in the solar

cylinder and radiators is heated up according to the hot water

and room thermostat settings.

Perform the commissioning and testing procedures in

accordance with the installation manual for the boiler.

Motorised 2 port valve

GB: It is a requirement that the “Benchmark” Installation,

Commissioning and Service Record is completed and left with

the user.

IE: it is necessary to complete a “Declaration of Conformity” to

indicate compliance to I.S.813. An example of this is given in

the current edition of I.S.813.

Diagram 3.1

3.5 Handing over to the householder

l Hand over all manuals to the householder.

l Advise the householder to keep the manuals near to the

system.

l Draw special attention to the safety instructions which the

householder must follow.

l Review the user instructions with the householder and

answer any questions.

l Show the householder how to operate the solar control, CH

control and any separate DHW control.

l Inform the householder that the cylinder temperature is

factory set at 65°C and that the DHW temperature can be

adjusted using the TMV by the installer.

l Inform the householder that the immersion heater is

intended as a standby device and should not be used

simultaneously with the boiler to heat the cylinder.

l Inform the householder that they are not permitted to

change the settings made on the solar system.

l Inform the householder that to ensure the continued

efficient and safe operation of the solar system it is

recommended that it is checked and serviced at regular

intervals. The frequency of servicing will depend upon the

installation conditions and usage, but in general, once a year

should be enough.

lInform the householder that the boiler and solar cylinder

should be serviced by a qualied engineer annually.

Leave these instructions and the “Benchmark” Installation,

Commissioning and Service record document with the user.

14184

18

Page 19

4 Inspection and Maintenance

4.1 Checking the temperature / pressure relief

valve and expansion relief valve

Actuate each valve manually by turning the valve cap and

check whether the water ows unhindered to the discharge

point via the tundish. Make sure both valves t properly in idle

position.

4.2 Checking the charge pressure of the

expansion vessel

Block the water supply and open the nearest hot water tap to

reduce the pressure from the secondary water system.

Check the pressure of the expansion vessel at the

measurement point with a pressure gauge. If the pressure

is below 3.0 bar, increase it with an appropriate air pressure

pump.

NOTE: Only use original spare parts from Glow-worm for the

replacement of parts.

4.3 Maintenance Checklist

Reheating

Check the circulation pump annually.

Check the timer/time programme settings annually.

Reheating: does it deliver the desired deactivation

temperature? annually.

Solar cylinder

Bleed the heat exchanger if necessary annually.

Check the connections for leaks annually.

Check the temperature and pressure relief valve annually.

Checking the expansion relief valve annually.

19

Page 20

5 Fault Finding

The following tables provide information on possible

malfunctions during the operation of the solar cylinder as well

as their cause and remedy.

NOTE: Only use original spare parts from Glow-worm. for the

replacement of parts. We recommend making a maintenance

agreement.

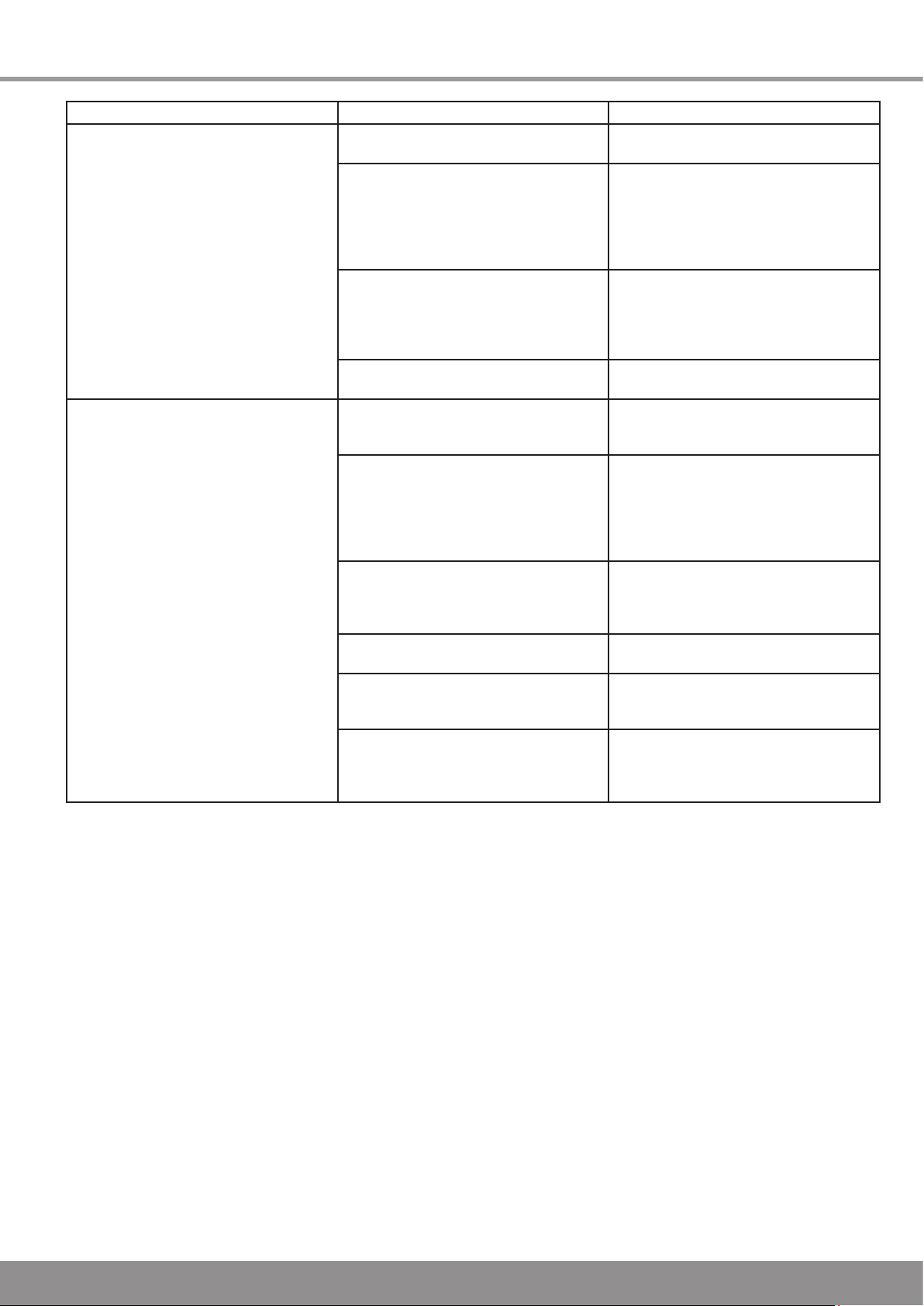

Malfunction Cause Remedy

Solar cylinder

The cylinder cools down at night. The

ow and return temperatures vary after

switching off the pump. The collector

temperature is higher than the air

temperature at night.

Reheating is not working. The boiler

runs for a short time, goes off and then

back on again. This is repeated until the

cylinder is at its target temperature.

Only cold or lukewarm water comes out

of the taps.

1. The gravity brake is blocked. 1. Check the position of the blue handle.

2. Check the gravity brake for tightness

(jammed cuttings, particles of dirt in the

sealing face).

3. Do not connect the solar heat

exchanger directly, rather pull the supply

pipes downwards and then upwards to

the collector (syphon supports the gravity

brake) or install a 2-port valve, which

is switched on at the same time as the

pump.

2. One-pipe circulation in the event of

short pipe networks with low pressure

loss.

1. Air in the reheating heat exchanger. Bleed the reheating heat exchanger.

2. Heat exchanger surface area too small.

1. Cold and hot water connections on the

cylinder have been mixed up.

2. Hot water thermostat mixer set too low.

3. Solar heating insufcient; boiler does

not reheat.

External control device faulty.

Air in the reheating heat exchanger

Cylinder temperature sensor defective.

Install a gravity brake (as close as

possible to the cylinder).

Compare the specications of the boiler

manufacturer with those of the cylinder

manufacturer. The problem may be able

to be solved by a higher setting of the

ow temperature at the boiler.

Turn off the cold water supply, then

let water ow out via the hot water

connection. Only a few litres of water

ow out if the connection is laid correctly.

The inlet of the hot water draw-off pipe

then rests in the air space; no further

emptying is possible. If the entire solar

cylinder runs empty via the hot water

connection, the connections have been

laid incorrectly. Change the connections!

Increase the setting.

Check whether the boiler is working.

Check whether the external control

device is working.

Check whether the two port valve is in the

hot water position.

Replace the two port valve.

Bleed the reheating heat exchanger.

Check the thermal cut out and reset it.

Replace the cylinder thermostat.

Table 5.1 Fault Finding

20

Page 21

5 Fault Finding

Malfunction Cause Remedy

Water ows out of the expansion relief

valve (only when heating up).

Water comes out of the temperature and

pressure relief valve (only when heating

up).

Dirt on the valve seat of the expansion

relief valve.

Pressure limiting valve defective. Switch off the boiler and immersion

Expansion vessel defective. Check the pressure in the expansion

Expansion relief valve defective. If the pressure is normal, replace the

Dirt on the valve seat of the temperature

and pressure relief valve.

Temperature control of the boiler

defective.

Cylinder temperature sensor defective. Check the cylinder temperature sensor

Two port valve defective. Check whether the two port valve is

Temperature and pressure relief valve

defective.

Immersion heater defective. Check the temperature sensor of the

Check the expansion relief valve and

reset it manually.

heater and check whether the pressure

behind the pressure limiting valve is lower

than 3.0 bar if water ows out only when

heating up. If so, replace the pressure

limiting valve.

vessel. If the pressure is insufcient,

re-establish the pressure and check

whether the equalisation tank maintains

the pressure.

expansion relief valve.

Check the seat of the temperature

and pressure relief valve and reset it

manually.

Check the temperature control of the

boiler if water only comes out when

reheating with the boiler. Check whether

the two port valve switches to the heating

position after reaching the cylinder

temperature.

and the corresponding thermal cut outs

and replace the temperature sensor and

reset the thermal cut outs if necessary.

working and replace it if necessary.

Replace the temperature and pressure

relief valve if water only comes out when

heating up with the immersion heater.

immersion heater and the corresponding

thermal cut out and replace the

immersion heater if necessary.

Table 5.1 Fault Finding (continued)

21

Page 22

222324

Page 23

Page 24

Glow-worm, Nottingham Road, Belper, Derbyshire. DE56 1JT

0020055006

Because of our constant endeavour for improvement, details may vary slightly from those shown in these instructions.

0020055006-02 07.07

Loading...

Loading...