Page 1

Instructions for Use

Installation and Servicing

To be left with the user

XTRAMAX

G.C. No. 47-047-15

Unvented Hot Water Storage

Fanned Flue Combination Boiler

4000116705-2.10.02

9088

This is a Cat II

The instructions consist of three parts, User, Installation and Servicing Instructions, which include the Guarantee Registration Card.

The instructions are an integral part of the appliance and must, to comply with the current issue of the Gas Safety (Installation and Use)

Regulations, be handed to the user on completion of the installation.

Appliance

2H3+

Guarantee Registration

Thank you for installing a new Glow-worm appliance in your home.

Glow-worm appliances' are manufactured to the very highest standard so we are pleased to offer our customers' a

Comprehensive Guarantee.

This product is guaranteed for 24 months from the date of installation or 30 months from the date of manufacture, whichever

is the shorter, for parts. In addition this product is guaranteed for 12 months from the date of installation or 18 months from

the date of manufacture, whichever is shorter, for labour.

The second year of the parts guarantee, from the beginning of the 13th month onwards after installation, is conditional upon

the boiler having been serviced by a CORGI registered gas installer, in accordance with the manufacturer's

recommendations. We strongly recommend regular servicing of your gas appliance, but where the condition is not met, any

chargeable spare parts or components issued within the applicable guarantee period still benefit from a 12 month warranty

from the date of issue from the manufacturer.

We recommend you complete and return as soon as possible your guarantee registration return literature, supplied in the

document envelope.

If your guarantee registration return literature is missing you can obtain a copy by telephoning the Heatcall Customer Service

number 01773 828100.

REGISTER YOUR GLOW-WORM APPLIANCE

CALL 0208 247 9857

Hepworth Heating Ltd.,

Nottingham Road, Belper, Derbyshire. DE56 1JT

General/Sales enquiries:

Tel: (01773) 824141 Fax: (01773) 820569

Page 2

Contents

CONTENTS DESCRIPTION SECTION PAGE No.

Important Information 3

INSTRUCTION

FOR USE

INSTALLATION

INSTRUCTIONS

Appliance Introduction 4

Appliance Safety Devices 5

Service and Maintenance 5

Operating the Appliance 6

Xtracom Remote Control 8

Technical Data 1 9

General Information 2 10

Heating System Design 3 11

Domestic Hot Water System Design 4 12

Boiler Schematic 5 12

Boiler Location, Flue and Ventilation 6 13

Safety Discharge 7 15

Fixing Jig 8 15

Piping System Installation 9 16

Boiler Installation 10 18

Horizontal Telescopic Top Flue Installation 11 19

Horizontal Top Flue Installation 11a 20

Electrical Connection 12 22

Commissioning 13 23

Safety Devices 14 26

Changing Gas Type 15 27

Settings 16 27

SERVICING

INSTRUCTIONS

Routine Cleaning and Inspection 17 28

Fault Finding 18 31

Replacement of Parts 19 33

Wiring Diagram 20 34

Spare Parts 21 44

4000116705-2

2

Page 3

Important Information

Gas safety (Installation and use) Regulations

In your interests and that of gas safety, it is the law that ALL gas

appliances are installed and serviced by a competent person in

accordance with the above regulations.

Testing and Certification

This boiler is tested and certificated for safety and

performance. It is therefore important that no alteration is

made to the boiler, without permission, in writing, from

Hepworth Heating Ltd.

Any alteration not approved by Hepworth Heating Ltd., could

invalidate the certification, boiler warranty and may also

infringe the current issue of the Statutory Requirements. The

requirements are: The installation of this boiler must be

carried out by a competent person in accordance with the

current rules in force in the countries of destination at the

time of installation. Manufacture's instructions supplied.

Manufacture's instructions must not be taken as overriding

statutory requirements.

Mandatory WARNING for EEC countries

This appliance is designed, approved and inspected to meet

the requirements of the Intended market. The data label

indicates where the product was manufactured and the

country for which it is intended.

CE Mark

This boiler meets the requirements of Statutory Instrument

No. 3083 The boiler (Efficiency) Regulations, and therefore

is deemed to meet the requirements of Directive 92/42/EEC

on the efficiency requirements for new hot water boilers fired

with liquid or gaseous fuels.

Type test for purposes of Regulation 5 certified by: Notified

body 0086.

Product/production certified by: Notified body 0086.

The CE mark on this appliance shows compliance with:

1. Directive 90/396/EEC on the approximation of the laws of

the Member States relating to appliances burning

gaseous fuels.

2. Directive 73/23/EEC on the harmonization of the Laws of

the Member States relating to the electrical equipment

designed for use within certain voltage limits.

3. Directive 89/336/EEC on the approximation of the Laws of

the Member States relating to electromagnetic compatibility.

Control of Substances Hazardous to Health

The adhesives and sealants used in this appliance are cured

and give no known hazard in this state.

INSULATION PADS/CERAMIC FIBRE

These can cause irritation to skin, eyes and the respiratory

tract.

If you have a history of skin complaint you may be susceptible to irritation. High dust levels are usual only if the material

is broken.

Normal handling should not cause discomfort, but follow

normal good hygiene and wash your hands before eating,

drinking or going to the lavatory.

If you do suffer irritation to the eyes or severe irritation to the

skin seek medical attention.

The insulation is composed of non-combustible material.

Electrical Supply

WARNING: This boiler must be earthed.

All system components shall be of an approved type and shall

be connected in accordance with the current issue of BS7671

and any applicable local regulations.

All external wiring between the appliance and the electrical

supply and earthing requirements shall comply with the current

IEE Regulations.

Connection of the boiler and system controls to the mains

supply must be through a common isolator and must be fused

3A, maximum. This method of connection must be by a fused

double pole isolating switch, with a minimum contact separation

of 3mm on both poles. The switch should be readily accessible

and preferably adjacent to the appliance. It should supply the

appliance only and be easily identifiable as so doing.

Alternatively, an unswitched shuttered socket outlet and 3A

fused 3 pin plug, both to the current issue of BS1363 may be

used provided that they are not used in a room containing a bath

or shower.

Wiring to the boiler must be PVC 85oC insulated cable, not less

than 0.75mm2 (24/0.20mm).

Manual Handling Guidance

During the appliance installation it will be necessary to employ

caution and assistance whilst lifting as the appliance exceeds

the recommended weight for a one man lift.

In certain situations it may be required to use a mechanical

handling aid.

Take care to avoid trip hazards, slippery or wet surfaces.

Spare Parts

REMEMBER, When replacing a part on this appliance, use only

spare parts that you can be assured conform to the safety and

performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised

by Hepworth Heating Ltd.

3

4000116705-2

Page 4

Important Information

Heating System Controls

The heating system must be controlled as described in the

relevant part of the current issue of :

Building Regulations, approved document L1, and the

references:

1) GIL 59, 2000: Central heating system specification (CheSS)

and

2) GPG 302, 2001: Controls for domestic central heating

system and hot water. BRECSU.

3) The domestic heating and hot water guide to the building

regulations 2001.

Thermostatic radiator valves may be installed, however they

must not be fitted in a room where the room thermostat is

located.

Gas leak or fault

If a gas leak or fault exists or is suspected, turn the boiler off and

consult the local gas supply company or your installation/

service company.

Air in the heating system

Persistent air in the heating system may indicate leaks in the

system or corrosion taking place. Call your Installation/Servicing

company.

Draining and filling

Caution: The boiler is installed as part of a sealed system which

must only be drained and filled by a competent person.

If the boiler is to be out of use for any long periods during severe

weather conditions, it is recommended that the whole system,

including the boiler, be drained to avoid the risk of freezing.

If in doubt, consult your servicing company.

Protection Against Freezing

The appliance has a built in frost protection programme as long

as the electricity and gas are left switched on.

This device operates the burner and system pump when the

temperature inside the boiler falls below 6

Any other exposed areas of the system should be protected by

a separate frost thermostat.

If the mains electricity and gas are to be turned off for any long

periods during severe weather, it is recommended that the

whole system, including the boiler, should be drained to avoid

the risk of freezing. Make sure that, if fitted, the immersion

heater in the cylinder is switched off.

If you have a sealed water system contact your installation/

servicing company as draining, refilling and pressurising MUST

be carried out by a competent person.

0

C.

Appliance Introduction

The XTRAMAX

boiler with electronic ignition providing central heating and

stored hot water.

The boiler is of the II

as distributed in the United Kingdom, or Butane (G30), Propane

(G31) with the appropriate conversion kit.

The boiler has a fan assisted balanced flue which both discharges

the products of combustion to and draws the combustion air

from the outside of the room.

The boiler is suitable for horizontal top outlet flue connection

and can be fitted with horizontal flue, vertical flue or twin-pipe

flue. Refer to flue options guide for further information, this is

available from your nearest stockist.

Both the central heating and domestic hot water temperature

are user adjustable.

Domestic hot water demand always has priority over heating

demand.

The boiler is designed for use as part of a sealed water central

heating system with fully pumped circulation. The pump,

expansion vessel and associated safety devices are all fitted

within the boiler.

The boiler can be installed against either an external wall or on

an adjacent inside wall, that is, the flue system will pass directly

to the rear or to either side to the terminal fitted on the outside

wall face.

boiler is a wall mounted modulating combination

category for use with Natural Gas (G20)

2H3+

The installation of this boiler must be carried out by a competent

person in accordance with the rules in force in the countries of

destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

These instructions should be carefully followed for the safe and

economical use of your boiler.

Note: The boiler serial number is marked on the data label

attached to the rear of the control box. The 'Operating the

Appliance' section describes how to safely use the boiler.

Accessories

A range of accessories are available.

For further information contact your supplier.

Flue options

There are various flue systems to choose from, for detailed

information refer to flue options guide, which is available

from your nearest stockist.

4000116705-2

4

Page 5

Appliance Safety Devices

Air flow rate safety device

If the flue is obstructed, even partially, the built in safety system

will turn the boiler OFF, the fan will continue to run. The boiler

will be ready to operate when the fault has been cleared.

Overheating safety

In the event of the boiler overheating the safety devices will

cause a safety shutdown. If this happens, call your Installation/

Servicing company.

In case of power supply failure

The boiler no longer operates. As soon as power supply is

restored, the boiler will be automatically restarted.

Frost protection

The appliance has a built in frost protection device that protects

the boiler from freezing. With the gas and electric supplies ON

and irrespective of any room thermostat setting, the frost

protection device will light the boiler when the temperature of

the boiler water falls below 6°C.

When the temperature reaches 16°C, the boiler stops.

Any other exposed areas of the system should be protected by

a separate frost thermostat.

Heating safety valve

CAUTION: A heating safety valve with a discharge pipe is fitted

to this boiler.

The valve MUST NOT BE TOUCHED except by a qualified

registered person. If the valve discharges at any time, switch the

boiler off and isolate it from the electrical supply. Contact your

installation/service company.

Temperature pressure/ relief valve

CAUTION: A domestic hot water pressure relief valve, with a

discharge pipe is fitted to this boiler.

The valve MUST NOT BE TOUCHED except by a qualified

registered person. If the valve discharges at any time, switch the

boiler off and isolate it from the electrical supply. Contact your

installation/service company.

Service and Maintenance

Servicing and Maintenance

To ensure the continued efficient and safe operation of the

appliance it is recommended that it is checked and serviced as

necessary at regular intervals. The frequency of servicing will

depend upon the particular installation conditions and usage,

refer to guarantee registration on the front cover of this literature.

If this appliance is installed in a rented property there is a duty

of care imposed on the owner of the property by the current

issue of the Gas Safety (Installation and Use) Regulations,

Section 35.

Servicing/maintenance should be carried out by a competent

person in accordance with the rules in force in the countries of

destination.

To obtain service, please call your installer or Heatcall (Glowworm’s own service organisation) using the telephone number

on the front cover of this literature.

Please be advised that the ‘Benchmark’ logbook should be

completed by the installation engineer on completion of

commissioning and servicing.

All CORGI Registered Installers carry a CORGI ID card, and

have a registration number. Both should be recorded in your

benchmark Logbook. You can check your installer is CORGI

registered by calling CORGI direct on: 01256 372300.

Cleaning

WARNING: This appliance contains metal parts (components)

and care should be taken when handling and cleaning with

particular regard to edges of sheet metal parts to avoid any

possibility of personal injury.

The boiler casing can be cleaned with a damp cloth, followed by

a dry cloth to polish.

Do not use abrasive or solvent cleaners.

Boiler casing

CAUTION. Do not remove or adjust the casing in any way, as

incorrect fitting may result in faulty operation. If in doubt, consult

your installation/service company.

5

4000116705-2

Page 6

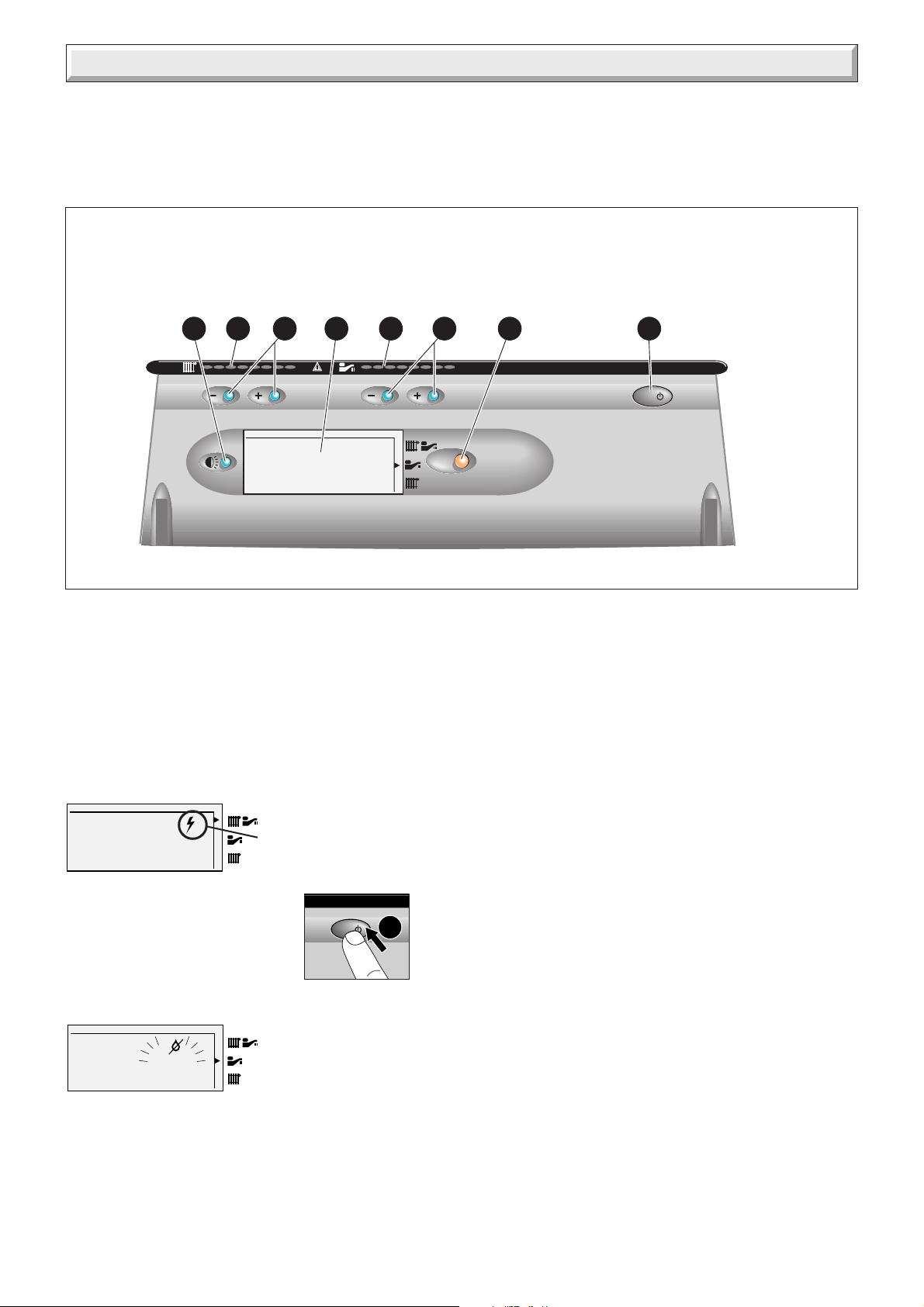

Operating the Appliance

Controls

The control panel, located at the lower front of the boiler casing,

see diagram 1, allows the boiler to be started, shut down,

controlled and monitored during use.

1 - On/Off button

2 - Summer/Winter mode selector

3 - Hot water temperature adjuster

4 - Hot water set point display (must be set at maximum)

mode

1.5 bar

The appliance incorporates a visual display that indicates fault

conditions, should they occur.

In the event of a fault, the display will indicate, by means of

pictograms and/or letters and numbers, exactly in which area

the fault lies.

Should the boiler fail to operate, the most likely fault is that the

gas supply to the boiler has not been turned on or that there is

no pressure in the heating system. These are indicated as

follows :

No gas supply

5 - Graphic display

6 - Heating temperature adjuster

7 - Heating set point display

8 - Display backlight

158 7 26 34

IO

9084

Diagram 1

This will be indicated on the

display as a pictogram of a

spark. To rectify this, proceed

as follows:

• Switch off the boiler at the On/Off

push button.

• Rectify the gas supply problem.

• Restart the boiler by pressing the

On/Off button.

IO

1

Insufficient system pressure

This will be indicated on the

display as a flashing warning

0.3

bar

indicating the system pressure

is low. To rectify this the system

must be re-filled, refer to

'Section 13 Commissioning'.

Other faults

These are indicated on the display by a fault code and a

telephone symbol. Further information on the fault codes can be

found in the 'Section 18 Fault Finding'.

4000116705-2

6

Page 7

Operating the Appliance

Lighting the boiler :

Make sure that:

The boiler is connected to the electrical supply.

The gas service cock is open.

Then follow the instructions below :

Press the On/Off button (1)

1

The pressure must be between 1 and 2 bar. If not, the system must be filled by a competent person.

IO

1

mode

1.5 bar

To stop the boiler : Press button (1)

9087

Setting to the SUMMER position

(Hot water only)

Press the mode button to select the summer symbol

mode

1.5

bar

The flame symbol appears

when the boiler is running

Adjusting the hot water temperature

The domestic hot water must be set at max 60°C.

Press + or - to adjust the maximum temperature

of the hot water.

Visual indication of set temperature

Setting to the WINTER position

2

Press the mode button to select the winter symbol

The actual temperature

of the heating system

Adjusting the heating temperature

3

Press + or - to adjust the maximum temperature

of the heating (38°C to 87°C)

(Heating + hot water)

°C

10

Visual indication of set temperature

1.5

bar

Illuminates when

the boiler lights

mode

°C

50

To obtain domestic hot water, open a hot water tap. Hot water always has priority over central heating.

mode

7

60

°C

mode

4000116705-2

Hab261

Page 8

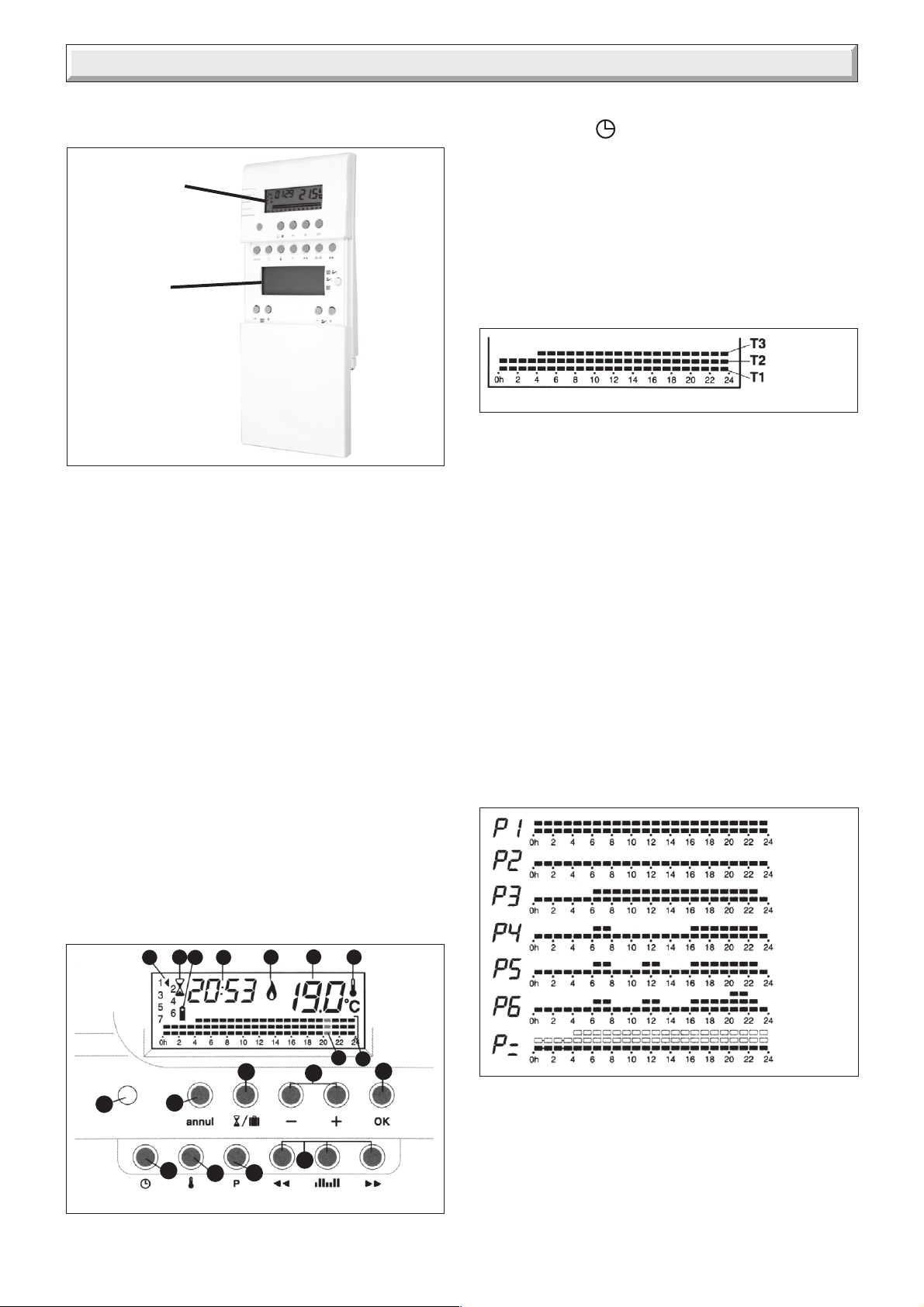

Xtracom Remote Control

Xtracom programmable, roomstat and boiler remote control

panel part No. A20077.

PROGRAMME/

THERMOSTAT

DISPLAY

REMOTE

CONTROL

DISPLAY

REMOTE

CONTROL OPTION

Diagram 2

Clock Timer and Thermostat Controls:

1 - Days of the week

2 - Override indicator

3 - Low Battery indicator

4 - Time display

5 - Heating in operation

6 - Programme temperature

7 - Room temperature

8 - Programme display

9 - Current programme status

10 - Override / Timed Override button

11 - OK/Enter button

12 - Plus and Minus modification buttons

13 - Manual programme setup buttons

14 - Time set button

15 - Temperature settings button

16 - Programme set button

17 - Cancel/Stand-by button

18 - Boiler Fault LED

2

1

3 4

6

5

7

Setting the Time

• Press button 14.

• Press + or - to set the correct hour.

• Press OK.

9091

• Press + or - to set the correct minutes.

• Press OK.

• Press + or - to set the correct day (1 = Mon. 7= Sun).

• Press OK, the clock will start.

Presetting the Temperatures T1, T2 and T3

The programmes use three temperature settings which you can

adjust.

Recommended first use settings are:-

T1=16°, T2=19°, T3=21°

If the radiators in your installation are equipped with thermostatic

valves, the highest temperature you can set on T3 is determined

by the highest setting on the radiator thermostatic valves.

e.g. If the highest radiator thermostat valve setting is 21°C then

you must set T3, 2 or 3°C higher, 24°C.

• Press button 15 T1 is displayed.

• Press + or - to set desired temperature.

• Press OK, T2 is displayed.

• Press + or - to set desired temperature.

• Press OK, T3 is displayed.

• Press + or - to set desired temperature.

• Press OK.

Weekly Programming

9328

9329

Diagram 4

9330

18

4000116705-2

18

14

17

15

10

16

13

12

9

8

Diagram 3

11

Diagram 5

There are 6 preset (P1 to P6) programmes and one manual (P=)

programme which can be assigned to each day of the week (1

to 7), the Factory default setting is P3 on all days. (Programmes

P1 to P6 can not be changed).

• Press button 16 to set day 1 (Monday).

• Press + or - to assign a programme to day 1.

• Press OK

8

Page 9

1 Technical Data

Heating

Heating input adjustable from 12,5 kW

to 30,3 kW

from 42,650 BTU/H

to 103,383 BTU/H

Heating output adjustable from 10,4 kW

to 27,6 kW

from 35,484 BTU/H

to 94,170 BTU/H

Efficiency 82 %

Maximum heating temperature 87 °C

Expansion vessel effective capacity 8 l

Expansion vessel charge pressure 0,5 bar

Maximum system capacity at 75°C 180 l

Safety valve, maximum service pressure 3 bar

Products outlet diameter 60 mm

Fresh air inlet diameter 100 mm

Hot water

Heating input adjustable from 12,5 kW

to 30,3 kW

from 42,650 BTU/H

to 103,383 BTU/H

Hot water output, automatically variable from 10,4 kW

to 27,6 kW

from 35,484 BTU/H

to 94,170 BTU/H

Storage capacity 43 l

Maximum hot water temperature 60 °C

Minimum hot water temperature 37°C

Specific flow rate (for 35°C temp rise) 11,4 l/min.

Threshold flow rate 1 l/min.

Nominal water flow rate 11,3 l/min.

Temp./pressure relief valve opening pressure 7 bar

Temp./pressure relief valve opening temperature 90°C

Cylinder heat up time 4 min.

Time to reheat 70% of storage to 60°C5 min.

Expansion valve setting 6 bar

Expansion vessel charge pressure 3.5 bar

Maximum operating pressure 3.5 bar

Maximum supply pressure 16 bar

Minimum operating pressure 0,7 bar

Natural Gas (G20)

Ø Burner injector 1,20 mm

Inlet pressure 20 mbar

Maxi. Burner pressure 13,8 mbar

Mini. Burner pressure 2,16 mbar

Gas rate maximum 3,20 m3/h

Gas rate minimum 1,32 m3/h

Butane Gas (G30)

Ø Burner injector 0,77 mm

Inlet pressure 29 mbar

Maxi. Burner pressure 23,8 mbar

Mini. Burner pressure 3,6 mbar

Gas rate maximum 2,39 kg/h

Gas rate minimum 0,99 kg/h

Propane Gas (G31)

Ø Burner injector 0,77 mm

Inlet pressure 37 mbar

Maxi. Burner pressure 30,8 mbar

Mini. Burner pressure 3,6 mbar

Gas rate maximum 2,35 kg/h

Gas rate minimum 0,97 kg/h

The Seasonal Efficiency Domestic Boilers UK (SEDBUK)

is, "D" 78.9%.

The value is used in the UK Government's Standard Assesment

Procedure (SAP) for energy rating of dwellings. The test data

from which it has been calculated have been certified by B.S.I.

131

234

Hab322

Weight of appliance when empty 71 kg

Weight of appliance when full 110 kg

Electrical

Electrical supply 230 V

Maximum absorbed power 235 W

Level of protection IP44

Fuse rating 3A

WEIGHT 71 kg

The

separate packages:

• The boiler

• The fixing jig

• The flue system

9

890

XTRAMAX

600

480

is delivered in three

Diagram 1.1

4000116705-2

Page 10

2 General Information

IMPORTANT NOTICE.

Where no British Standards exists, materials and equipment

should be fit for their purpose and of suitable quality and

workmanship.

Refer to Manual Handling Operations, 1992 regulations.

The installation of this boiler must be carried out by a competent

person in accordance with the rules in force in the countries of

destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

1.1 Sheet Metal Parts

WARNING: When installing the appliance, care should be

taken to avoid any possibility of personal injury when handling

sheet metal parts.

1.2 Statutory Requirements

The installation of the boiler MUST be carried out by a competent

person in accordance with the relevant requirements of the

current issue of:

Manufacturer’s instructions, supplied.

The Gas Safety (Installation and Use) Regulations, The Building

Regulations, The Building Standards (Scotland) Regulations

(applicable in Scotland), local Water Company Bylaws, The

Health and Safety at Work Act, Control of Substances Hazardous

to Health, The Electricity at Work Regulations and any applicable

local regulations.

Detailed recommendations are contained in the current issue of

the following British Standards and Codes of Practice, BS4814,

BS5440 Part 1 and 2, BS5449, BS5546, BS6700, BS6798,

BS6891 and BS7074 Part 1 and 2, BS7478, BS7593, BS7671.

Manufacturer’s notes must not be taken as overriding statutory

obligations.

BSI Certification

This boiler certificated to the current issue of EN 483 for

performance and safety.

It is important that no alteration is made to the boiler, without

permission, in writing, from Hepworth Heating Ltd.

Any alteration that is not approved by Hepworth Heating Ltd.,

could invalidate the warranty and could also infringe the current

issue of the Statutory Requirements.

1.3 Gas Supply

The gas installation must be in accordance with the current

issue of BS6891.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

On completion, test the gas installation for soundness using the

pressure drop method and suitable leak detection fluid, purge

in accordance with the above standard.

3 Heating System Design

• The XTRAMAX is for use ONLY with sealed central heating

systems.

• Heating surfaces may consist of radiators, convectors or fan

assisted convectors.

• The appliance

system without the need for a mixing bottle. The maximum

central heating flow temperature can be set to 53°C on the boiler

printed circuit board during commissioning.

Bypass fully shut

1

Open 1/4 turn

2

3

Open 1/2 turn

Open 1 turn

4

Open 2 turns

5

can be piped directly to an underfloor heating

60

50

1

2

40

30

20

10

heating supply and return lines

Available pressure (kPa) between

0

(10 kPa = 1 m WG)

• Pipe sectional areas shall be determined in accordance with

normal practices, using the output/pressure curve

(diagram 3.1). The distribution system shall be calculated in

accordance with the output requirements of the actual system,

not the maximum output of the boiler. However, provision shall

be made to ensure sufficient flow so that the temperature

difference between the flow and return pipes be less than or

equal to 20°C. The minimum flow is 400 l/h.

3

4

5

120010008006004002000

Flow rate through heating system (I/h)

Diagram 3.1

Pom 010 a

4000116705-2

10

Page 11

SUPPLY

PIPE

AIR GAP

TUNDISH

CONTROL

VALVE

CONTROL

VALVE

TYPE CA BACKFLOW

PREVENTION DEVICE

BOILER

RETURN FLOW

HEATING

CIRCUIT

DRAIN

POINT

Method 2

3 Heating System Design

• The piping system shall be routed so as to avoid any air

pockets and facilitate permanent venting of the installation.

Bleed fittings must be provided at every high point of the system

and on all radiators.

• The total volume of water permitted for the heating system

depends, amongst other things, on the static head in the cold

condition. The expansion vessel on the boiler is pressurised at

0,5 bar (corresponding to a static head of 5 m w.g.) and allows

a maximum system volume of 160 litres for an average

temperature of 75°C and a maximum service pressure of 3 bar.

This pressure setting can be modified at commissioning stage

if the static head differs. An additional expansion vessel can be

fitted to the system if required, see diagram 9.2.

• Provision shall be made for a drain valve at the lowest point of

the system.

• Where thermostatic radiator valves are fitted, not all radiators

must be fitted with this type of valve, and in particular, where a

room thermostat is installed.

• In the case of an existing installation, it is ESSENTIAL that the

system is thoroughly flushed prior to installing the new boiler,

using a proprietary product such as Fernox or Sentinel. Contact

the product manufacturers for specific details.

3.1 Bypass

• The boiler is fitted with an adjustable automatic bypass.

Ensure that under no circumstances does the flow rate drop

below the figure specified, see diagram 3.1.

• A bypass is not required on the central heating circuit unless

the system controls could allow the boiler to operate when there

is no flow.

• Where a bypass has to be fitted, the bypass must be placed

at least 1.5 metres away from the appliance, see diagram 9.2.

3.2 Filling the system

• Provision for filling the system must be made, the methods are

shown in diagram 3.2. There must be no permanent connection

to the mains water supply, even through a non-return valve.

Note: It is important that fittings used for connection to potable

water comply with the water undertakings requirements.

TEMPORARY

CONNECTION

Method 1

SUPPLY

PIPE

CONTROL

VALVE

HOSE

UNION

DOUBLE

CHECK

VALVE

HOSE

UNION

RETURN FLOW

CONTROL

VALVE

DRAIN

POINT

BOILER

HEATING

CIRCUIT

11

11594

Diagram 3.2

4000116705-2

Page 12

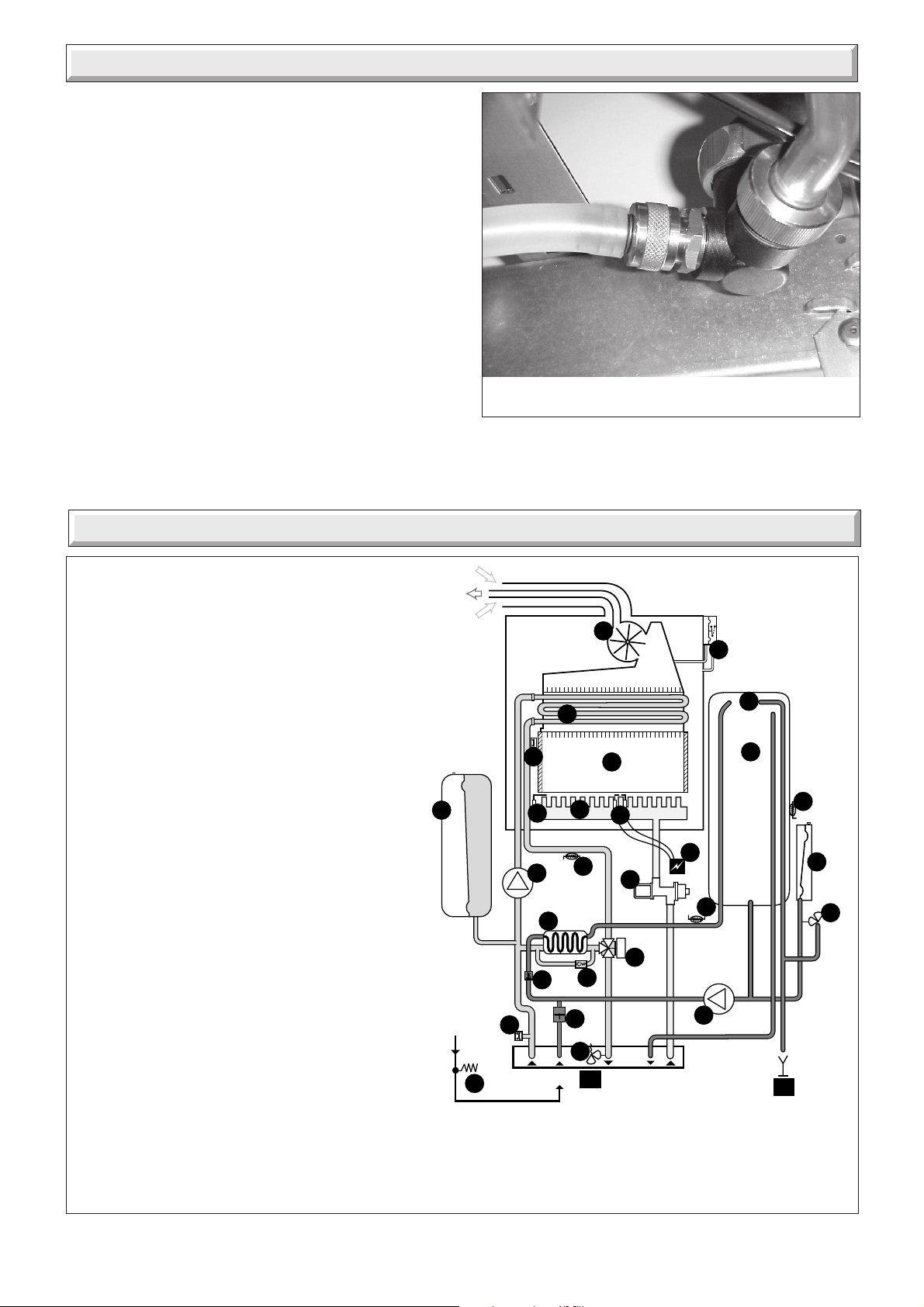

4 Domestic Hot Water System Design

• Copper tubing or plastic Hep20 may be used for the domestic

hot water system. Unnecessary pressure losses should be

avoided.

• A flow restrictor limiting the flow through the boiler to a

maximum of 16 l/min is fitted to the boiler.

• The boiler will operate with a minimum supply pressure of 0,7

bar, but under reduced flow rate.

Best operating comfort will be obtained from a supply pressure

of 1 bar.

4.1 Hard Water Areas

In areas where the water is 'hard', more than 200mg/litre, it is

recommended that a proprietary scale reducer is fitted in the

cold water supply to the boiler.

A pressure reducing valve for the cold water inlet supply is

provided, this is packed inside the boiler. This valve is a

necessary part of the unvented system and MUST be fitted to

the cold water supply, see diagram 8.1.

4.2 Domestic hot water drain point

The DHW drain point is located below the DHW pump, see

diagram 4.1.

9527

Diagram 4.1

1 - Domestic thermistor

2 - Three way valve

3 - Gas control valve

4 - Ignition unit

5 - Temperature sensor for

DHW storage vessel

6 - DHW storage vessel

7 - Burner

8 - Ignition electrode

9 - Combustion chamber

10 - Heating safety valve (3 bar)

11 - Main heat exchanger

12 - Air pressure switch

13 - Water flow sensor

14 - DHW pump

15 - Non return valve

16 - Bypass

17 - Domestic plate to plate heat

exchanger

18 - Heating pump

19 - Heating expansion vessel

20 - Heating thermistor

21 - Overheat safety thermostat

22 - Flame sense electrode

23 - Fan

24 - Expansion valve (6 bar)

25 - Water pressure sensor

26 - Domestic expansion vessel (3.5

bar)

27 - Temperature pressure/ relief valve

(7 bar/90°C)

28 - Pressure reducing valve and

Check valve.

Max. supply pressure 16 bar.

(Supplied)

5 Boiler Schematic

21

19

COLD WATER

SUPPLY

28

A - Heating return

B - Cold water inlet

C - Heating flow

D - Domestic hot water outlet

22

18

17

15

25

AB

11

13

10

7

20

16

D1

23

12

27

9

8

4

3

1

2

14

C

E

D

E - Gas

D1 - Discharge from HTG

safety valves

D2 - Discharge from temp/press

and expansion valve (to tundish)

11749

6

5

26

24

D2

4000116705-2

Diagram 5.1

12

Page 13

6 Boiler Location, Flue and Ventilation

6.1 Boiler Location

The boiler may be installed in any room although particular

attention is drawn to the requirements of the current issue of

BS7671 with respect to the installation of a boiler in a room

containing a bath or a shower. Any electrical switch or boiler

control using mains electricity should be so situated that a

person using the bath or shower cannot touch it. The electrical

provisions of the Building Standards (Scotland) Regulations

are applicable to such installations in Scotland.

The boiler must be mounted on a flat wall, which is sufficiently

robust to take its total weight, see Technical Data.

If in doubt, expert advice should be obtained. In the event of the

wall being found not suitable, a floor standing kit is available,

contact Hepworth Heating for further details.

The boiler is not suitable for fitting outdoors.

Any electrical switch or boiler control using mains electricity

must be positioned so that a person using a bath or shower

cannot touch it.

6.2 Clearances

The position of the boiler must be such that there is adequate

space for servicing.

The recommended clearances are shown in diagram 6.1.

20mm

600mm

25mm

above

elbow

300mm

11771

20mm

6.3 Cupboard or compartment ventilation

The boiler can be fitted in a cupboard or compartment without

the need for permanent ventilation.

Important Note: With regards to the below boiler

dimension of 300mm, please ensure that the site

conditions will allow for the safety discharge pipe to

be installed, if not then the dimension should be

increased to 450mm.

MINIMUM CLEARANCES FROM A

PERMANENT SURFACE.

Diagram 6.1

13

4000116705-2

Page 14

6 Boiler Location, Flue and Ventilation

6.4 Terminal position

The minimum acceptable spacings from the terminal to

obstructions and ventilation openings are shown in diagram

6.2.

The boiler must be installed so that the terminal is exposed to

the external air.

Warning:

Do not obstruct the outside terminal of the boiler.

6.5 Terminal guard, see diagram 6.3

A terminal guard is required if persons could come into contact

with the terminal or the terminal could be subject to damage.

If a terminal guard is required, it must be positioned to provide

a minimum of 50mm clearance from any part of the terminal and

to be central over the terminal.

A suitable terminal guard type K3 can be supplied by:

Tower flue components Ltd.

Morley Road

Tonbridge

Kent

TN9 1RA

11508

6.6 Flue options

There are various flue systems to choose from as follows:

Horizontal telescopic top flue pack.

Horizontal top flue pack.

Horizontal extended flue pack.

Vertical flue pack.

Twin flue pack.

Extensions, 90° and 45° bends.

For detailed information refer to flue options guide. This is

available from your nearest stockist.

MINIMUM SITING DIMENSIONS FOR THE

POSITIONING OF FLUE TERMINALS MM

HORIZONTAL FLUES

A DIRECTLY BELOW, ABOVE OR

HORIZONTALLY TO AN OPENING, AIR BRICK,

OPENING WINDOWS, AIR VENT, OR ANY

OTHER VENTILATION OPENING 300

B BELOW GUTTER, DRAIN/SOIL PIPE 75

C BELOW EAVES 200

D BELOW A BALCONY OR CAR PORT 200

E FROM VERTICAL DRAIN PIPES AND

SOIL PIPES 150

F FROM INTERNAL/EXTERNAL CORNERS

OR TO A BOUNDARY ALONGSIDE THE

TERMINAL 300

G ABOVE ADJACENT GROUND OR

BALCONY LEVEL 300

H FROM SURFACE OR A BOUNDARY

FACING THE TERMINAL 600

I FACING TERMINALS 1200

J FROM OPENING (DOOR/WINDOW)

IN CAR PORT INTO DWELLING 1200

K VERTICAL FROM A TERMINAL 1500

L HORIZONTALLY FROM A TERMINAL 300

VERTICAL FLUES

M FROM ADJACENT WALL TO FLUE 300

N FROM ANOTHER TERMINAL 600

P FROM ADJACENT OPENING OR WINDOW 1000

Q ABOVE ROOF LEVEL 300

Diagram 6.2

4000116705-2

Diagram 6.3

14

Page 15

7 Safety Discharge

Valve outlet

size

G 1/2 15 mm 22mm up to 9 m 0.8 m

G 3/4 22 mm 28 mm up to 9 m 1.0 m

G 1 28 mm 35 mm up to 9 m 1.4 m

Safety

device eg.

temperature

relief valve

Discharge pipe (D2) from

turndish with continuous fall see table

above for size examples.

Minimum size of

discharge to tundish

D1

Discharge pipe (D1) from

temperature relief valve to turndish

500mm

max.

Tundish

(Supplied)

9317

Minimum size of discharge

pipe D2 from tundish

28 mm up to 18 m 1.0 m

35 mm up to 27 m 1.4 m

35 mm up to 18 m 1.4 m

42 mm up to 27 m 1.7 m

42 mm up to 18 m 1.7 m

54 mm up to 27 m 2.3 m

300mm min.

Fixed grating

Trapped

gully

Maximum resistance allowed

expressed as a length of straight

pipe i.e. no elbows or bends

Discharge from

HTG prv on jig

D1 D2

9317

Tundish

(Supplied)

9131

Discharge from

DHW safety

valves

Resistance created

by each elbow

or bend

Gully

9129

Diagram 7.1

8 Fixing Jig

The fixing jig is made up, from left to right, as follows:

A - Heating return fitting with isolating valve (v) and drain knob (u).

B - Cold water inlet fitting with isolating valve (m) and factory fitted flow restrictor and filter (not shown).

C - Heating flow fitting with isolating valve (q) drain knob (r) and safety valve (10).

D - Domestic hot water outlet.

E - Gas service cock.

(Fitted inside) Flow

restrictor and cold water

inlet filter

B

D

u

A

C

r

q

E

➜

m

➜

10

15

9126

Diagram 8.1

4000116705-2

v

Page 16

9 Piping System Installation

9.1 Fixing jig, refer to diagram 8.1

• Remove the contents of the fixing jig pack.

• Secure the left and right hand support brackets to the isolating

valve plate with the securing screws (4 off) supplied.

Connect the copper connections supplied, to the fixing jig

fittings.

• Heating system connections - Pipe Ø 22mm

• Hot water system connections - Pipe Ø 15mm

• Gas connection - Pipe Ø 22mm

• Tundish connection - Pipe Ø 22mm

• Safety valve discharge - Diagram 7.1.

9.2 Cutting the flue hole

• Remove the wall template, follow the instructions given on the

wall template.

• Determine the flue application, length and terminal position

before starting.

• Position the wall template, taking due regard of the minimum

clearances for the selected flue application, see diagram 9.1.

Rear hole cutting

• Mark correct position of top rear flue outlet hole from template.

Side hole cutting

• Mark the horizontal centre line for the hole on the rear wall.

Extend the horizontal centre line to the side wall and mark the

vertical centre line of flue hole as shown in diagram 9.1.

Important: When cutting the flue hole and when extending the

flue centre line to a side wall, remember that the flue system

must have a fall of about 35mm per metre of flue DOWNWARD

towards the terminal. There must NEVER be a downward

incline towards the boiler.

• Making allowance for the slope of the flue, cut hole in external

wall, preferably using a core drill. For installations with internal

and external access use a 105 mm diameter core drill.

For installations with internal access only use a 125 mm

diameter core drill.

• Reposition the wall template over hole in wall.

• Mark the position of the holes for the hanging bracket and jig.

• Drill, plug and fix the hanging bracket to the wall using suitable

screws (not supplied).

• Check that the hanging bracket is level.

• Drill plug and fix the fixing jig to the wall.

9.3 Water connection

Connect the system pipework to the copper connections on the

fixing jig observing the correct flow and return format as shown

in diagram 9.2. Do not subject the isolating valves to heat.

bottom of the boiler (diagram 5.1 and 7.1) (D2). The tundish

(supplied) must be used with this outlet within the normal

guidelines and code of practice and must be installed so that it

is visible to the occupants and positioned away from any

electrical devices.

It is necessary, during installation, to connect a 22 mm diameter

metal discharge pipe to a suitable position outside the building.

It is permissible to use copper pipe, see diagram 7.1.

WARNING. The discharge pipe from the tundish should

terminate in a safe place where there is no risk to persons in the

vicinity of the discharge, be of metal and:

a. Be at least one pipe size larger than the nominal outlet size

of the safety device unless its total equivalent hydraulic resistance

exceeds that of a straight pipe 9m long i.e. discharge pipes

between 9m and 18m equivalent resistance length should be at

least larger than the nominal outlet size of the safety device,

between 18m and 27m at least 3 sizes larger, and so on. Bends

must be taken in to account in calculating the flow resistance.

See table and diagram 7.1.

b. Have a vertical section of pipe at least 300mm long, below the

tundish before any elbows or bends in the pipework.

c. Be installed with a continuous fall.

d. Have discharges visible at both the tundish and the final point

of discharge but where this is not possible or practically difficult

there should be clear visibility at one or these of these locations.

Examples of acceptance discharge arrangements are:

1. ideally below a fixed grating and above the waterseal in a

trapped gully.

2. downward discharges at a low level; i.e. up to 100 mm above

external surfaces such as car parks, hard standing, grassed

areas etc. are acceptable providing that where children may

play or otherwise come in to contact with discharges, a wire

cage or similar guard is positioned to prevent contact, whilst

maintaining visibility.

3. discharges at high level; e.g. into metal hopper and metal

down pipe with the end of the discharge pipe clearly visible

(tundish visible or not) or onto a roof capable of withstanding

high temperature discharges of water and 3m from any plastics

guttering systems that would collect such discharges (tundish

visible).

4. where a single pipe serves a number of discharges, such as

in blocks of flats, the number served should be limited to not

more than 6 systems so that any installation can be traced

reasonably easily. The single common discharge pipe should

be least one pipe size larger than the largest individual discharge

pipe to be connected. If unvented hot water storage systems

are installed where discharges from safety devices may not be

apparent i.e. in dwellings occupied by blind, infirm or disabled

people, consideration should be given to the installation of an

electronically operated device to warn when discharge takes

place.

Note: The discharge will consist of scalding water and steam.

Asphalt, roofing felt and non-metallic rainwater goods may be

damaged by such discharges.

9.4 Safety valve discharge

There are two sets of two safety valves fitted to this appliance.

One is located on the jig diagram 8.1, (10) heating safety valve

3 bar. The other is located inside the boiler (diagram 5.1,) (27)

temperature pressure/relief safety valve 7 bar/90°C, and (24)

expansion valve 6 bar.

9.5 Tundish discharge

The internal safety valves, 24 and 27, have been tee’d together

and the discharge pipe run so that it exits at the right hand

4000116705-2

9.6 Domestic hot water supply options

The domestic hot water storage temperature inside the boiler

must be set 60° C. It is recommended that the boiler storage

temperature is set by the user to the maximum of 60°C - this will

ensure a more plentiful supply of hot water.

It may be desirable to provide hot water to separate outlets at

different temperatures (for example, to provide a limited

temperature to prevent the risk of scalding). To be able to do

this, a thermostatic mixing valve is supplied with the Xtramax

boiler (factory set to 43°C) and can be fitted during the installation

procedure.

16

Page 17

9 Piping System Installation

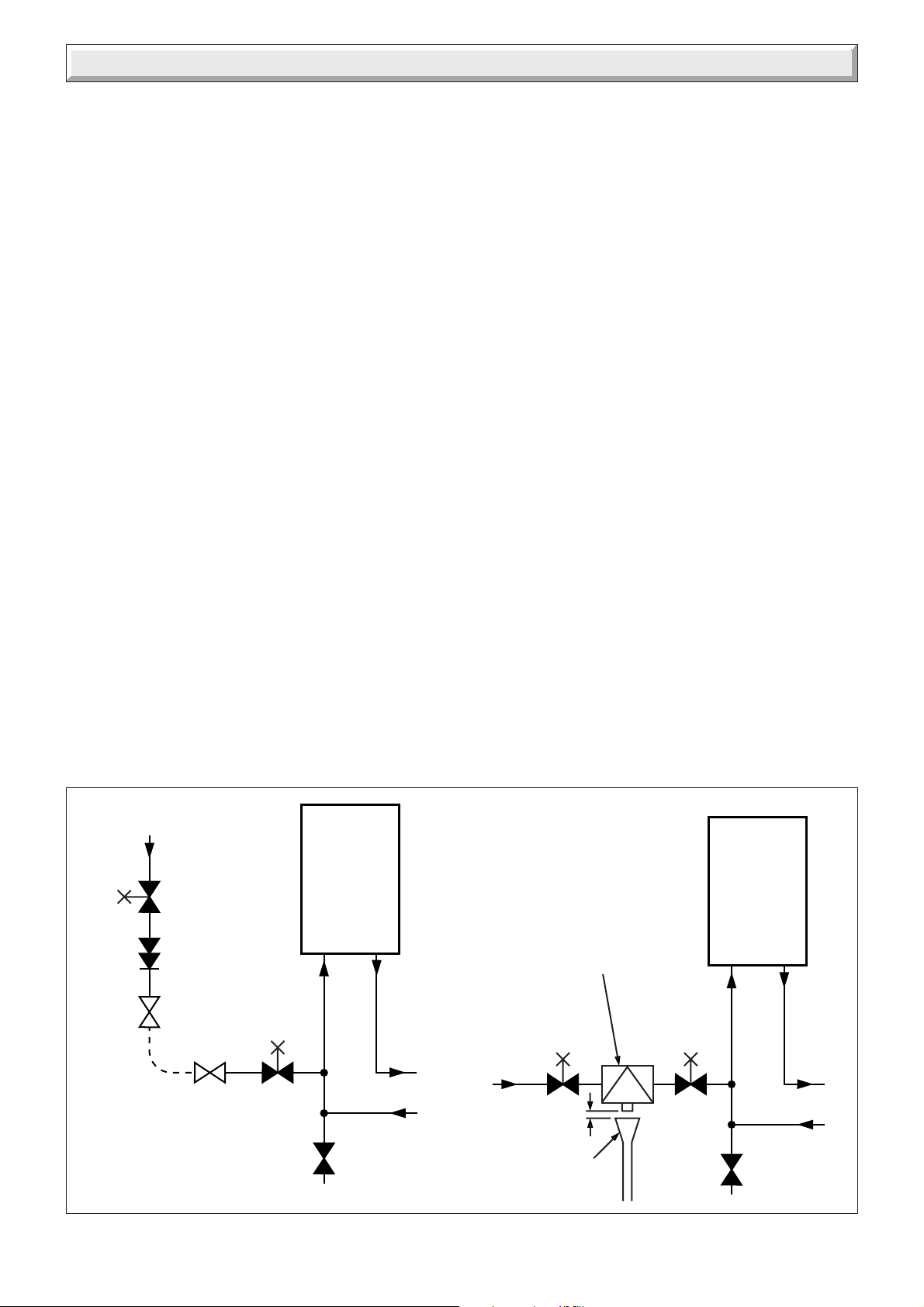

There are 2 options for the domestic hot water supply :

1 - Piping the hot water supply without the use of the mixing

valve to provide hot water to all taps at the same temperature.

2 - Piping the hot water supply using the mixing valve (supplied)

to provide hot water at boiler hot water “set temperature” to one

tap and thermostatically controlled hot water to another tap(s).

To pipe the hot water supply using the mixing valve, refer to

diagram 9.2. This shows one outlet supplying hot water at the

boiler hot water "set temperature" and one hot water outlet at

a temperature pre-set at the mixing valve. The mixing valve can

be set between 35 and 60°C. It is recommended that the valve

is adjusted (and locked) by the installer to the desired

temperature.

Note: The thermostatic mixing valve has 22 mm connections,

22x15 mm reducers will need to be fitted.

The connections to the mixing valve are :

H - Hot water supply from boiler

C - Reduced cold water supply

MIX - Thermostatically controlled outlet

Warning : It is strongly recommended that the cold water

supply to the mixing valve is taken from the reduced side of the

pressure reducing valve (supplied)

Note 1 : The mixing valve is fitted with two in-line strainers, one

on the hot inlet and one on the cold inlet. For servicing details

of these, refer to the separate instructions supplied with the

mixing valve.

Note 2 : The mixing valve incorporates a "rapid fail-safe" device

which will automatically close the valve to safety in the event of

supply failure on either hot or cold water.

• The supply from the governed gas meter must be of adequate

size to provide a constant inlet working pressure of 20 mbar (8

in w.g.).

To avoid low gas pressure problems, it is recommended that the

gas supply is connected using 22 mm pipe.

• On completion, the gas installation must be tested using the

pressure drop method and purged in accordance with the

current issue of BS6891.

Ø 105 or 125 core drill

169

65

=

=

234

20 mm

min.

900

9.7 Gas connection

Gas Safety (Installation and use) Regulations

In your interests and that of gas safety, it is the law that ALL gas

appliances are installed and serviced by a qualified registered

person in accordance with the above regulations.

Additional

expansion

vessel

(if required)

Return

Heating

circuit

control valve

Boiler

Bypass

valve

Filling

device

Flow

Drain point

Domestic

water

Hot

Cold supply

9090

Thermostatic

mixing valve

MIX

H

(supplied)

C

Temperature

adjustment

(supplied)

Pressure

reducing valve

and Check valve.

Max. supply pressure

16 bar.

(supplied)

120

600

Thermostatically

controlled

hot water

20

Diagram 9.1

9130

Boiler

"set temperature"

hot water

Diagram 9.2

17

4000116705-2

Page 18

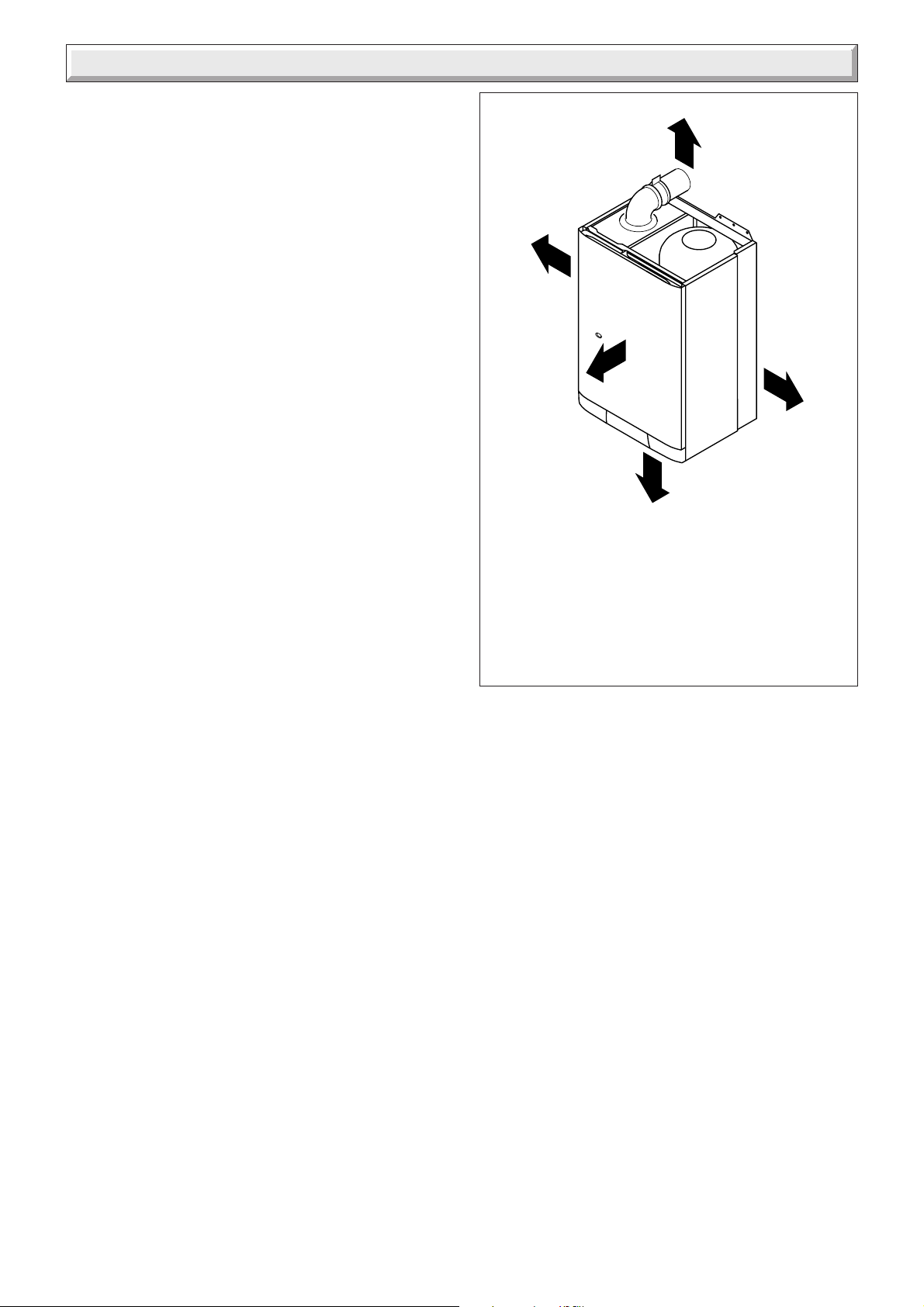

10 Boiler Installation

10.1 Warning to the installer

This installation is subject to building regulation approval, notify

the Local Authority of intention to install.

10.2 Installing the boiler

Prior to starting work, the system must be thoroughly flushed

using a propriety cleanser such as Sentinel X300 to eliminate

any foreign matter and contamination e.g. metal filings, solder

particles, oil, grease etc.

Note. Solvent products could cause damage to the system.

• IMPORTANT: With regards to the manual handling operations,

1992 regulations, the following operation exceeds the

recommended weight for one man to lift.

• Lay boiler on its back.

• Remove all packaging from around the boiler.

• Remove front panel, put in a safe place to avoid damaging it.

• Ensure the plastic plugs are removed from water and gas

pipes. NOTE: There will be some spillage of water.

• Remove transportation timber support bar from bottom rear of

boiler.

• If required the boiler can be stood upright supported by

extending the legs at the front bottom of the boiler.

• Lift the boiler up and engage boiler upper part onto the hanging

bracket.

• Fit the washers between the boiler pipes and the inlet and

outlet fittings on the fixing jig and connect the various couplings

between the boiler and jig.

• Fit the base panel, hook in at the rear secure with the four self

tapping securing screws at the front.

4000116705-2

18

Page 19

11 Horizontal Telescopic Top Flue Installation

The

Horizontal Telescopic Top Flue,

A2004500 is suitable for installations that

require a flue length from 425 minimum to

659.5 maximum. If longer flueing is required

extensions and bends are available, see note

below.

Note: Additional 1 metre extentions, 90° and 45° bends are

available. The maximum extended flue is 3.5m. The use of flue

bends requires the flue lengths to be reduced by 1m. for 90° and

0.5m. for 45°.

Kit No.

A

10322

C

B

11.1 Horizontal Telescopic Top Flue kit of

parts, refer to diagram 11.1.

11.2 Installation of telescopic flue assembly

• Carefully pull to remove the elbow (D) from the air duct pipe

and flue duct pipe (A).

• Remove the backing from the self adhesive gasket (F) and

carefully fit gasket to base of flue elbow.

• Fit the restrictor (a) inside the fan outlet, see diagram 11.3.

• Fit elbow onto boiler and secure with the four screws (G).

• Fit rubber sealing collar (E), see diagram 11.2, into groove at

the outer end of the air duct pipe (A).

• Fit air/flue duct pipe assembly, into wall from the outside with

rubber sealing collar to the outside.

• Pull pipe assembly inwards to bring rubber sealing collar hard

up against external wall.

• If the telescopic flue has been pulled apart care must be taken

not to damage the ‘O’ ring on the flue duct when re-assembling.

• Re-fit the telescopic flue duct pipe to the flue elbow . Secure

with the fixing collar seal (B) and fixing collar (C) using the 2

screws provided.

G

D

E

F

The flue kit A2004500 is 659.5 mm long and comprises:

- Telescopic flue assembly......................................... A

- Fixing collar seal ...................................................... B

- Fixing collar .............................................................. C

- Elbow ....................................................................... D

- External rubber sealing collar .................................. E

- Gasket ...................................................................... F

- Screws .....................................................................G

Diagram 11.1Horizontal telescopic Top flue kit

Pho 087

Diagram 11.2

Horizontal telescopic flue

system (rear and side)

The maximum permissible

length (L) for the telescopic

flue system is 630mm.

The restrictor (a) must be

fitted to inside the fan outlet.

Gasket

a

19

L

65

234

9530

MINIMUM WALL

THICKNESS

192mm

Diagram 11.3

4000116705-2

Page 20

11a Horizontal Top Flue Installation

The

Horizontal Top Flue

suitable for installations that require a flue

length from 190 minimum to 667 maximum

(without extensions). If a shorter flue length is

required the flue can be cut to suit, see

diagrams 11a.1 and 11a.2 for minimum flue

length.

Note: Additional 1 metre extentions, 90° and 45° bends are

available. The maximum extended flue is 3.5m. The use of flue

bends requires the flue lengths to be reduced by 1m. for 90° and

0.5m. for 45°.

11a.1 Top outlet flue - kit 86285H

The boiler is only suitable for top outlet flue connection.

11a.2 Rear flue systems

(Refer to diagram 11a.1). To calculate the length when flueing

to the rear measure wall thickness e plus 140 mm for the outer

air duct and e plus 231 mm for the inner flue duct measurement.

11a.3 To The Right or Left flue systems

(Refer to diagram 11a.1). To calculate the length when flueing

For right hand applications measure wall thickness e plus

inside of wall to side of boiler a add 350(mm) for the outer air

duct and wall thickness e plus inside of wall to side of boiler a

add 445(mm) for the inner flue duct measurement.

(Refer to diagram 11a.1). To calculate the length when flueing

For left hand applications measure wall thickness e plus

inside of wall to side of boiler a minus 25(mm) for the outer air

duct and wall thickness e plus inside of wall to side of boiler a

add 70(mm) for the inner flue duct measurement.

• Refer to diagram 11a.2 (table) for cutting lengths of both inner

and outer flue pipes for each of the various flue options

available.

Important: All flue cutting lengths must be measured from the

terminal end of the flue pipes, see diagram 11a.2.

When the dimension X measured on site is greater than that

given in diagram 11a.2 (table), extensions will be required as

necessary.

Important: All cutting lengths should be measured from the

push fit joint end of the extension pipe. Do not leave any burrs

or sharp edges on the cut ends of the pipes. Note : maximum

horizontal flue length without bends is 3 m.

, Kit No. 86285H is

70mm 70mm

a

X

a

X

Diagram 11a.1

ee

9322

Ven 089

4000116705-2

AIR DUCT PIPE

Cutting length

FLUE DUCT PIPE

Cutting length

11a.2 Table: Flue cutting lengths (mm)

Rear flue

Air Duct pipe : e + 55, Flue duct pipe : e + 217

Note : maximum distance 'x' without extension 770 mm

Right side flue

Air Duct pipe : e + a + 290, Flue duct pipe : e + a + 452

Note : maximum distance 'x' without extension 515 mm

Left side flue

Air Duct pipe : e + a - 48, Flue duct pipe : e + a + 114

Note : maximum distance 'x' without extension 1087 mm

Diagram 11a.2

20

Page 21

11a Horizontal Top Flue Installation

11a.4 Installation of flue assembly

Important: If the flue has been cut, ensure that there are no

burrs that could damage the ‘O’ ring.

• For flue systems less than 0,5 m long, leave the restrictor (a)

fitted in the fan outlet, see diagram 11a.5.

• Remove the backing from the self adhesive gasket (H) and

carefully fit gasket to base of elbow (C).

• Fit both ‘O’ rings (J) into the flue elbow (C), one at the inlet, one

at the outlet. By necessity, they are a loose fit, apply a small

amount of silicone grease to each ‘O’ ring when fitting.

• Fit elbow onto boiler and secure with the four screws (I).

• Fit rubber sealing collar (F), see diagram 11a.3, into groove

at the outer end of pipe (A).

• Insert flue duct pipe (B) into inner end of air duct pipe (A), rotate

flue duct pipe to locate into groove inside air duct pipe.

• Fit air/flue duct pipe assembly into wall from outside with

rubber sealing collar to the outside.

• Fit internal plastic flange (G) onto air duct pipe (A).

• Fit the fixing collar seal (D) onto the air duct pipe (A) ensuring

it is the correct way round (the larger diameter onto the pipe).

• Pull air/flue duct pipe assembly inwards to bring rubber sealing

collar (F) hard up against external wall, while carefully pushing

the fixing collar seal onto the elbow ensuring that the flue duct

pipe locates into the flue elbow outlet while taking care not to

tear the ‘O’ ring.

• Fit the fixing collar (E) around the fixing collar seal (D) and

secure with 2 screws provided.

• Push the internal plastic flange (G) along the air duct pipe (A)

until engaged against internal wall.

G

F

B

E

A

J

H

The flue kit 86285H is 810mm long and comprises:

- Air duct pipe .......................................................... A

- Flue duct pipe ........................................................ B

- Elbow ....................................................................... C

- Fixing collar seal .................................................... D

- Fixing collar .............................................................. E

- External rubber sealing collar ............................... F

- Internal flange ....................................................... G

- Gasket ..................................................................... H

- Screws ....................................................................... I

- 'O' rings ..................................................................... J

Diagram 11a.3

D

11646

C

I

Pho 087

Concentric flue system

The maximum permissible length (L) for

the concentric flue system is 3.5 m. For

flue systems up to 0,5 m length, the

restrictor (a) supplied fitted to the boiler,

inside the fan outlet, must be left in

place. For longer flue systems, the

restrictor must be removed.

For each 90° flue elbow used, (or two

45° elbows) the maximum permissible

length (L) must be reduced by 1 metre.

Gasket

a

L

65

234

Diagram 11a.4

9530

WALL

THICKNESS

21

Diagram 11a.5

4000116705-2

Page 22

12 Electrical Connection

WARNING: This appliance must be earthed and must be wired

in accordance with these instructions. Any fault arising from

incorrect wiring cannot be put right under the terms of the Glow-

worm guarantee.

All system components must be of an approved type.

Electrical components have been tested to meet the equivalent

requirements of the BEAB.

The mains electrical supply must be maintained at all times in

order to provide domestic hot water.

Do not interrupt the mains supply with a time switch or

programmer.

Connection of the whole electrical system and any heating

system controls to the electrical supply must be through a

common isolator.

Isolation should preferably be by a double pole switched fused

spur box fused at 3A having a minimum contact separation of

3mm on each pole. The fused spur box should be readily

accessible and preferably adjacent to the boiler. It should be

identified as to its use.

A three pin plug fused at 3A and shuttered socket outlet may be

used instead of a fused spur box provided that:

a) They are not used in a room containing a fixed bath or

shower.

b) Both the plug and socket comply with the current issue of

BS1363.

12.1 Mains Cable

The boiler is supplied with a mains lead attached, see diagram

12.1.

Standard colours are Brown - Live, Blue - Neutral, Green and

Yellow - Earth.

Important: If a replacement supply cable is required it must be

purchased. Part No. S1008600.

3. Test the polarity of the mains.

Please ensure the “Benchmark” logbook is completed and left

with the user.

Note: For further information, see the building regulations

1991 - Conservation of Fuel and Power - 1995 edition appendix G, Table 4b.

The boiler is supplied with a mains lead attached.

Connect this to the electrical supply.

Ins 060

Diagram 12.1

IMPORTANT

With VOLTAGE FREE

10023

room thermostat

°C

Without room

thermostat

EE

12.2 External controls

WARNING: UNDER NO CIRCUMSTANCES MUST ANY

MAINS VOLTAGE BE APPLIED TO ANY OF THE TERMINALS

ON THE HEATING CONTROLS CONNECTION PLUG.

To gain access to the external control connections, unclip side

clips and hinge up control panel cover.

The boiler will work for heating without a room thermostat being

connected provided that the wire link fitted between the two

terminals of the connector (E) is left in place, see diagrams

12.2 and 12.3.

Alternatively, a 24V room thermostat can be used but do not

make any connection to the compensating resistor, see diagram

12.2.

ON NO ACCOUNT must any electrical voltage be applied to

any of the terminals of the external controls plug.

12.3 Remote control (F)

For extra control or if the boiler is to be sited in a garage or utility

room an optional remote control unit with programmable roomstat

can be obtained part number A20077, see diagram 2. This is

a dual function unit, (a) boiler control (same as boiler facia), (b)

programmable room stat. Full fitting instructions are supplied

with the unit.

12.4 Electrical Connections - Testing

Checks to ensure electrical safety must be carried out by a

competent person.

After installation of the system, preliminary electrical system

checks as below should be carried out.

1. Test insulation resistance to earth of mains cables.

2. Test earth continuity and short circuit of all cables.

Diagram 12.2

Leave link in place for no external controls.

No room thermostat.

Leave link in place

Heating controls

connection plug

E

IMPORTANT

VOLTAGE FREE

room thermostat.

Remove link and connect

to terminals 1 and 2 ONLY,

F

Note: Connection F i s

used when the optional

remote control with room

thermostat Part No.

A20077 is fitted.

DO NOT connect to

terminal 3

Diagram 12.3

11751

4000116705-2

22

Page 23

13 Commissioning

Please ensure the “Benchmark” logbook is completed and left

with the user.

The commissioning and first firing of the boiler must only be

done by a competent person.

Gas installation

It is recommended that any air is purged from the supply at the

gas inlet test point on the gas valve, see diagram 13.1.

Filling the system 1 to 8

Air in pipes

Important: A central heating system can not operate correctly

unless it is filled with water and air bled from the system. If these

conditions are not met the system may be noisy.

Bleed the air in the radiators and adjust the pressure if system

requires. If the system requires filling too often this may be due

to minor leaks or corrosion in the system. Call a qualified service

engineer.

GAS INLET

TEST POINT

11752

Press the mains 'On/Off' button

1

The warning light will illuminate

➜

v

The display will indicate 0 bar pressure in the system

mode

0.0

bar

9126

q

3

Undo cap on

automatic air

vent on top of

pump and

leave undone.

Diagram 13.1

9086

IO

1

Open the boiler isolating valves (v and q),

2

the slot of the screw corresponds to flow

direction.

23

Reg 008

4000116705-2

Page 24

13 Commissioning

o

Open the system filling loop and fill the

4

system until the pressure indicated

on the display is between 1 and 2 bar.

Bleed each radiator to

5

remove the air, re-tighten

bleed screws.

➜

9621

Leave the cap on the

6

pump auto air vent open.

➜

The pressure must be between 1 and 2 bar

1.5

bar

Open various hot water

7

taps to bleed system.

m

Ins 061a

Make sure the display indicates a system pressure of between 1 and 2 bar. Re-fill

8

system as necessary.

The pressure must be between 1 and 2 bar

• Adjust heating temperature to maximum .

• Check that any external controls, if fitted, are calling for heat

(set room thermostat to maximum).

• Allow the temperature to rise to the maximum value, with all

radiator valves open. The temperature rise will cause release of

the gases contained in the water of the central heating system.

• Gases driven towards the boiler will be automatically released

through the automatic air vent.

• The gases trapped at the highest point of the system must be

released by bleeding the radiators. Check the burner gas rate

required, ten minutes from lighting. Refer to Data Label on

electrical controls box. Should there be any doubt about the gas

rate it should be checked at the meter.

Reg 008

1.5

bar

mode

On reaching maximum temperature, the boiler should be turned

off and the system drained as rapidly as possible whilst still hot.

• Refill system to a pressure of between 1 and 2 bar and vent as

before.

• Restart boiler and operate until a maximum temperature is

reached. Shut down boiler and vent heating system. If necessary,

top up heating system and make sure that a pressure of at least

1 bar is indicated when system is COLD.

Flush the domestic hot water system by opening the hot water

taps for several minutes.

Ins 062a

9085

IO

4000116705-2

24

Page 25

13 Commissioning

E

OPERATING PARAMETERS MODE FAULT HISTORY MODE

HEATING

DHW

HEATING

11841

mode

DHW

20 01

5 secs

PARAMETERS

• Press the display light button and keep pressed for 5 seconds and this will give you access to both the operating

parameters or fault history modes. Each press of the display light button accesses each function in turn.

Operating Parameters

The heating + and - buttons allow you to select which

particular parameter to adjust.

The domestic hot water + and - buttons scroll through the

functions as follows:

01 - Heating output settings

02 - Fan settings

T - Maximum heating temperature settings

P - Pump settings

E - External sensor settings

C1 - Service use only

C2 - Service use only

C3 to 18 - Service use only

FUNCTIONS COD

Fault History

The domestic hot water + and- buttons scroll through the last

10 faults recorded and are numbered F9 to F0.

Note : The display will revert back to normal if no changes are

made after 1 minute or if the display light button is again

pressed for more than 5 seconds.

FUNCTIONS CODE

FAULT CODE

11842

Setting the heating output parameter 01

The maximum heating output of the boiler is adjustable

between the maximum and minimum values given in the

Technical Data section.

• Use the heating + and - button to set the desired heating

output in kW.

11843

Note : Adjustment of the heating output does not affect the

hot water output.

For kW conversion refer to table:

kW.......Btu/hr kW.......Btu/hr kW.......Btu/hr

10........34,120 12........40,940 14........47,770

16........54,590 18........61,420 20........68,240

22........75,060 24........81,890 26........88,710

28........95,540

Setting the flue parameters

This adjustment is made to ensure the boiler operates at

maximum efficiency with longer flue lengths.

• Select a parameter between 0 and 10 according to the

table and diagram below :-

Horizontal concentric

flue system (C12)

02

11844

Vertical concentric

flue system (C32)

setting flue length setting flue length

0 0,3m 0 0,5m

1 0,6m 1 1m

21m 2 2m

3 1,2m 3 3m

4 1,5m 4 4,5m

52m 5 6m

6 2,2m 6 7m

7 2,5m 7 8m

83m 8 9m

9 3,2m 9 10m

10 3,5m 10 11,5m

25

4000116705-2

Page 26

13 Commissioning

Setting the maximum heating temperature parameter T

This can be set to one of three values:

500C, 730C and 870C.

For example, 500C can be used for underfloor heating.

11845

Pump operation parameter P

This can be set to one of three values:

1 - Intermittent (with burner)

2 - Permanently on

3 - Intermittent (with room thermostat)

11846

Remote control parameter

Two options are available:

0 - no remote control

1 - With remote control

E

11847

Reminder - Leave these instructions and the “Benchmark”

logbook with the user.

14 Safety Devices

The XTRAMAX incorporates a visual display that indicates fault

conditions, should they occur.

In the event of a fault, the display will indicate, by means of

pictograms and/or letters and numbers, exactly in which area

the fault lies.

Should the boiler fail to operate during Commissioning, the

most likely fault is that the gas supply to the boiler has not been

turned on or purged sufficiently or that there is no pressure in the

heating system. These are indicated as follows :

14.1 No gas supply

This will be indicated on the

display as a pictogram of a

spark. To rectify this, proceed

as follows:

• Switch off the boiler at the On/Off

push button.

• Rectify the gas supply problem.

• Restart the boiler by pressing the

On/Off button.

14.2 Insufficient system pressure

This will be indicated on the

display as a flashing warning

0.3

bar

indicating the system pressure

is low. To rectify this the system

must be re-filled, refer to

'Section 13 Commissioning'.

14.3 Other faults

These are indicated on the display by a fault code and a

telephone symbol. Further information on the fault codes can be

found in the 'Section 18 Fault Finding'.

IO

1

General safety devices

14.4 Air flow rate safety device

If an obstruction, even partial, of the flue occurs, for any reason

whatsoever, the built in safety system of the boiler will turn the

boiler OFF and the fan will continue to run.

The boiler will be ready to operate when the fault has been

cleared.

14.5 Overheat safety

In case of boiler overheating, the overheat thermostat will turn

the boiler off. The thermostat, located on the heat exchanger

flow pipe, will need to be manually reset, see diagram 17.4.

14.6 In case of power supply failure

The boiler no longer operates.

As soon as power supply is restored, the boiler will be

automatically restarted.

14.7 Frost protection

The appliance has a built in frost protection device that protects

the boiler from freezing. If the boiler is to be left and there is a

risk of frost, ensure that the gas and electrical supplies are left

connected. The frost protection device will light the boiler when

the temperature of the boiler water falls below 6°C. When the

temperature reaches 16°C, the boiler stops.

Note : This device works irrespective of any room thermostat

setting and will protect the complete heating system.

4000116705-2

26

Page 27

15 Changing Gas Type

Should it become necessary to change the gas type, a

modification kit will be required.

This modification must only be carried out by a suitably qualified

engineer.

Conversion natural Gas (G20) to G30/G31 Part No. 86631.

16 Settings

Bypass

The XTRAMAX boiler has a built-in bypass, see diagram 16.1.

The boiler is supplied with the bypass open half a turn. It should

not be necessary to adjust the bypass, but if required ensure

that under no circumstances does the flow rate fall below the

figures specified, refer to diagram 1.1. (turn clockwise to close

the valve).

9349

a

Diagram 16.1

27

4000116705-2

Page 28

17 Routine Cleaning and Inspection

To ensure the continued efficient and safe operation of the

boiler it is recommended that it is checked and serviced at

regular intervals. The frequency of servicing will depend upon

the particular installation conditions and usage, but in general

once a year should be enough.

It is the law that any servicing is carried out by a qualified

registered person.

All parts are replaced in reverse order to removal.

17.1 Products of combustion check

Note: To obtain a products of combustion reading, unscrew the

left hand sampling point cap on the flue elbow, located on top

of boiler.

Connect the analyser tube onto sampling point.

Switch on the electrical supply and gas supply, then operate the

boiler.

On completion of the test switch off the electrical supply and the

gas supply, remove analyser tube and replace sampling point

cap.

Car 033

Diagram 17.1

PRODUCTS

SAMPLING

POINT

17.2 Service Check and Preparation.