Glow Brand C140, C95 Installation & Operation Manual

Installation & Operation Manual

Models

C95 & C140

Condensing Combination Boiler

To Installer: Afx this manual adjacent to the appliance.

To Consumer: Retain these instructions for future reference

WARNING If the information in these instructions is not followed exactly, a re or explosion

may result, causing property damage, personal injury or death.

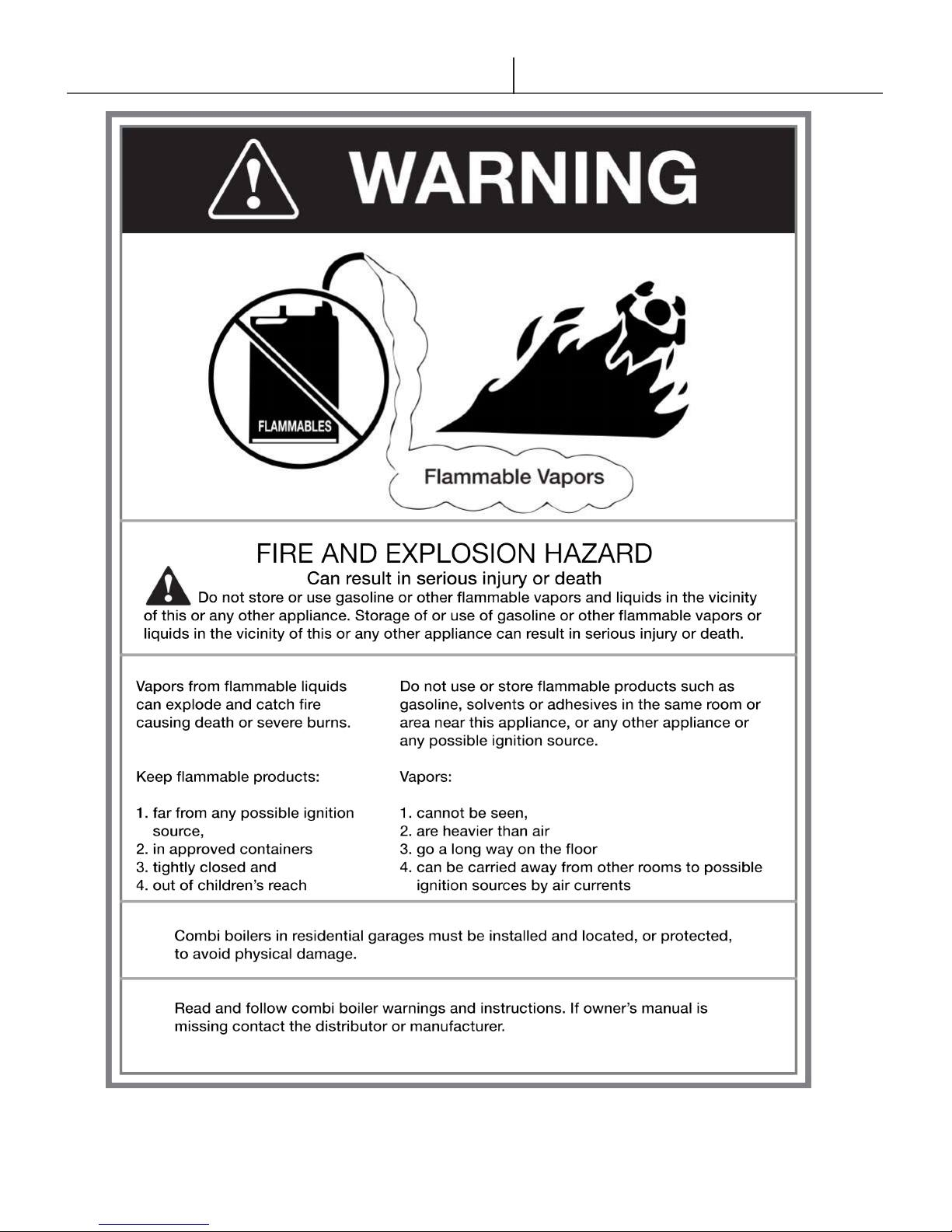

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbour’s phone.

• Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re department.

Installation and service must be performed by a qualied installer, service agency or

the gas supplier.

ANSI Z21.13-2017 CSA 4.9-2017

V.20180807

Glow Brand C95 & C140

Table of Contents

HAZARD SYMBOLS & DEFINITIONS 3

1. General Information

1.1 Prior to Installation 3

1.2 General information 9

2. Technical Characteristics

2.1 Technical Data 11

2.2 Unit Dimensions 12

2.3 Unit Performance 13

3. Storage, Handling & Installation

3.1 Storage 16

3.2 Unpacking 16

3.3 Boiler Location 17

3.4 Wall Mounting Installations 17

4. Venting

4.1 General Venting 18

4.2 Removing an Existing Boiler from Common

Venting System 18

4.4 Venting Guidelines 19

4.5 Direct Vent Installation 20

4.4 Venting Diagrams 24

5. Condensate Drain

5.1 Condensate Drain 30

6. Boiler and Heating System Piping

6.1 Boiler System Preparation 31

6.2 Piping Material 31

6.3 Boiler Water 31

6.5 Plumbing Schematics 35

7. Combi Boiler Operation

7.1 Combi DHW Plumbing & Set-up 39

7.2 Pre-Heat Modes 41

7.3 Glow Combi Boiler w/DHW Storage Tank 41

8. Gas Piping

8.1 Installation 42

8.2 Gas Valve and Burner Setup 42

9. Field Wiring

9.1 Line Voltage Connections 45

9.2 Low Voltage Connections 45

10. Starting Up the Boiler

10.1 Filling the unit 48

10.2 Start-Up & Ignition Safety Shuttoff Test 48

11. Controls

11.1 LCD Display & Button Layout 51

11.2 Initial Power-up 52

11.3 Main Menu 52

11.4 User Settings Menu (0.000) 53

11.5 Information Menu (1.000) 53

11.6 Installer Menu (2.000) 56

11.7 DHW Modes 59

11.8 CH Modes 60

11.9 Special Operations 61

12. Lockout, Blocking Errors & Warnings

12.1 Lockout Error 62

12.2 Blocking Errors 65

12.3 Warnings 67

12.3 Sensor Resistance 67

13. Troubleshooting

13.1 Servicing the Boiler 68

13.2 Diagnosing an Inoperative Boiler 68

14. Maintenance

14.1 General Maintenance & Inspection 71

14.2 Annual Maintenance & Inspection 71

14.3 Condensate Cleaning Instructions 72

14.4 Cleaning Primary Heat Exchanger 74

14.5 Replacing the Gas Valve 75

14.6 Replacing the Fan 76

14.7 Flow Restrictor Maintenance 77

14.8 Plate Heat Exchanger Maintenance 78

15. Part List

15.1 Part List & Diagrams 80

Warranty

Homeowner Registration Form

Warranty Part Form

Commissioning Sheet

Glow Brand C95 & C140

General Information

DANGER

Read and understand this

entire document prior to

proceeding with the

installation of the Glow Combi

Boiler. Failure to follow the

instructions outlined in this

document will result in

property damage, serious

injury or death.

WARNING

This Combi Boiler must be

installed by a licensed,

certied and trained heating

technician or the Warranty is

Void. Failure to properly

install this unit may result in

property damage, serious

injury to occupants, or

possibly death.

HAZARD SYMBOLS & DEFINITIONS

The following safety symbols are used in this manual.

DANGER

Indicates an imminently hazardous situation, which, if not avoided, will

result in severe injury or death.

WARNING

Indicates a potentially hazardous situation, which, if not avoided,

could result in severe injury or death.

CAUTION

Indicates a potentially hazardous situation, that, if not avoided, could

result in minor or moderate injury.

NOTICE

Indicates a potentially hazardous situation, that, if not avoided, could

result in property damage.

1. General Information

1.1 Prior to Installation

1. Safe, reliable operation of this boiler depends upon installation by a

professional heating contractor in strict accordance with this manual and the

requirements of the authority having jurisdiction.

• In the absence of an authority having jurisdiction, installation must be

in accordance with this manual and the National Fuel Gas Code, ANSI

Z223.1. In Canada, installation must be in accordance with the B149.1

Installation Code.

• Where required by the authority having jurisdiction, this installation

must conform to the Standard for Controls and Safety Devices for

Automatically Fired Boilers (ANSI/ASME CSD-1).

2. Read Section 4 “Venting” to verify that the maximum combustion air and

exhaust pipe lengths will not be exceeded in the planned installation.

3. Make sure that the boiler is correctly sized:

• For heating systems employing convection radiation (baseboard or

radiators), use an industry accepted sizing method such as the I=B=R

Guide RHH published by the Air-Conditioning, Heating and Refrigeration

Institute (AHRI).

• For new radiant heating systems, refer to the radiant tubing manufacturer’s

boiler sizing guidelines.

• For system which includes an indirect water heater, make sure the boiler

has the output called for by the indirect water heater manufacturer’s

instructions.

4. All Glow Combi Boilers are shipped from the factory congured for 0 - 4,500

ft. altitude. Use sea level input rate for 0 - 2,000 ft. For high altitude installation

above 4,500 ft., contact Glow Brand Manufacturing.

5. All Glow Combi Boilers are shipped from the factory congured for use with

Natural Gas only. They may NOT be converted for use with LP gas.

3

Glow Brand C95 & C140

WARNING

Crystalline SilicaCertain components conned

in the combustion chamber

may contain this potential

carcinogen. Improper

installation, adjustment,

alteration, service or

maintenance can cause

property damage, serious

injury (exposure to hazardous

materials) or death. Refer to

Section 14 for information

on handling instructions

and recommended personal

protective equipment.

Installation and service must

be performed by a qualied

installer (who must read

and follow the supplied

instructions before installing,

servicing, or removing this

boiler. This boiler contains

materials that have been

identied as carcinogenic,

or possibly carcinogenic, to

humans).

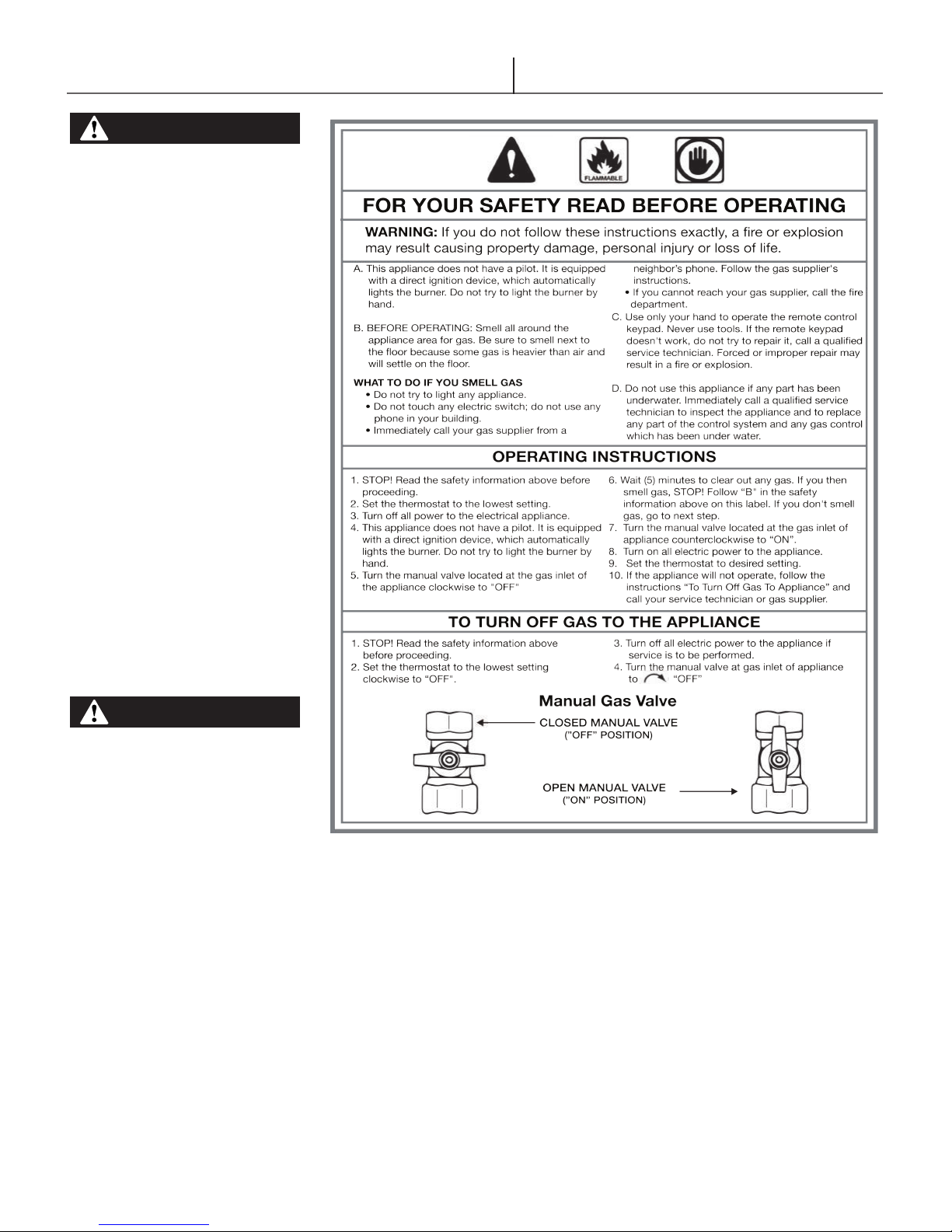

Installation & Operating Instructions

WARNING

VOID WARRANTY-This boiler

must have water owing

through it whenever the burner

is on or it will damage the unit

and void the warranty. Failure

to follow these instructions

may result in serious injury or

death

4

Glow Brand C95 & C140

General Information

“In the State of Massachusetts only”

For all horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole

or in part for residential purposes, including those owned and operated by the Commonwealth and where the

side wall exhaust vent termination is less than seven (7) feet above nished grade in the area of the venting,

including but not limited to decks and porches, the following requirements shall be satised:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall

horizontal vented gas fueled equipment, the installing plumber or gas tter shall observe that a hard wired

carbon monoxide detector with an alarm and battery back-up is installed on the oor level where the gas

equipment is to be installed and on each additional level of the dwelling, building or structure served by the

equipment. It shall be the responsibility of the property owner to secure the services of qualied licensed

professionals for the installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space

or an attic, the hard wired carbon monoxide detector with alarm and battery back-up may be installed

on the next adjacent oor level.

a. In the event that the requirements of this subdivision cannot be met at the time of completion of

installation, the owner shall have a period of 30 days to comply with the above requirements,

provided, however, that during said 30 day period a battery operated carbon monoxide detector with

alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in

accordance with the above provisions shall comply with NFPA 720 and be ANSI/UL 2034 listed and IAS

certied.

3. SIGNAGE. A metal or plastic identication plate shall be permanently mounted to the exterior of the

building at a minimum height of eight (8) feet above grade directly in line with the exhaust vent terminal for the

horizontally vented gas fueled heating appliance or equipment. The sign shall read, in print size no less than

one-half (1/2) inch in size, “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fueled equipment

shall not approve the installation unless, upon inspection, the inspector observes carbon monoxide detectors

and signage installed in accordance with the provisions of 248 CMR 5.08(2)(a) 1 through 4.

Notice prior to installation

This appliance must be installed by a licensed professional in accordance with the Massachusetts Plumbing

and Fuel Gas Code 248 CMR Sections 2.00 and 5.00.

If you are not properly training, you must not install this unit.

5

Glow Brand C95 & C140

Installation & Operating Instructions

6

Glow Brand C95 & C140

General Information

7

Glow Brand C95 & C140

The temperature at which injury occurs varies with the person's age and time of exposure.

Water temperature over 125°F/52°C can cause severe burns instantly or death from scalding.

The slower response time of disabled persons increases the hazards to them. Never allow small children

to use a hot water tap, or to draw their own bath water. Never leave a child or disabled person unattended in a bathtub or shower.

Installation & Operating Instructions

DANGER

The appliance should be located in an area where the general public does not have access to the

temperature control.

Lower water temperatures should be used to avoid the risk of scalding. It is further recommended, in all

cases, that the domestic water temperature be set for the lowest temperature which satisfies the user’s

hot water needs. This will also provide the most energy efficient operation of the water heater and

minimize scale formation in the heat exchanger, thus prolonging the life of the unit.

Setting the domestic hot water temperature at 120°F

jurisdictions require settings at specific lower temperatures. The table below shows the approximate

time-to-burn relationship for normal adult skin.

Hot water temperatures required for automatic dishwasher and laundry use can cause scalds and burns

resulting in serious personal injury and/or death.

/49°C will reduce the risk of scalds. Some

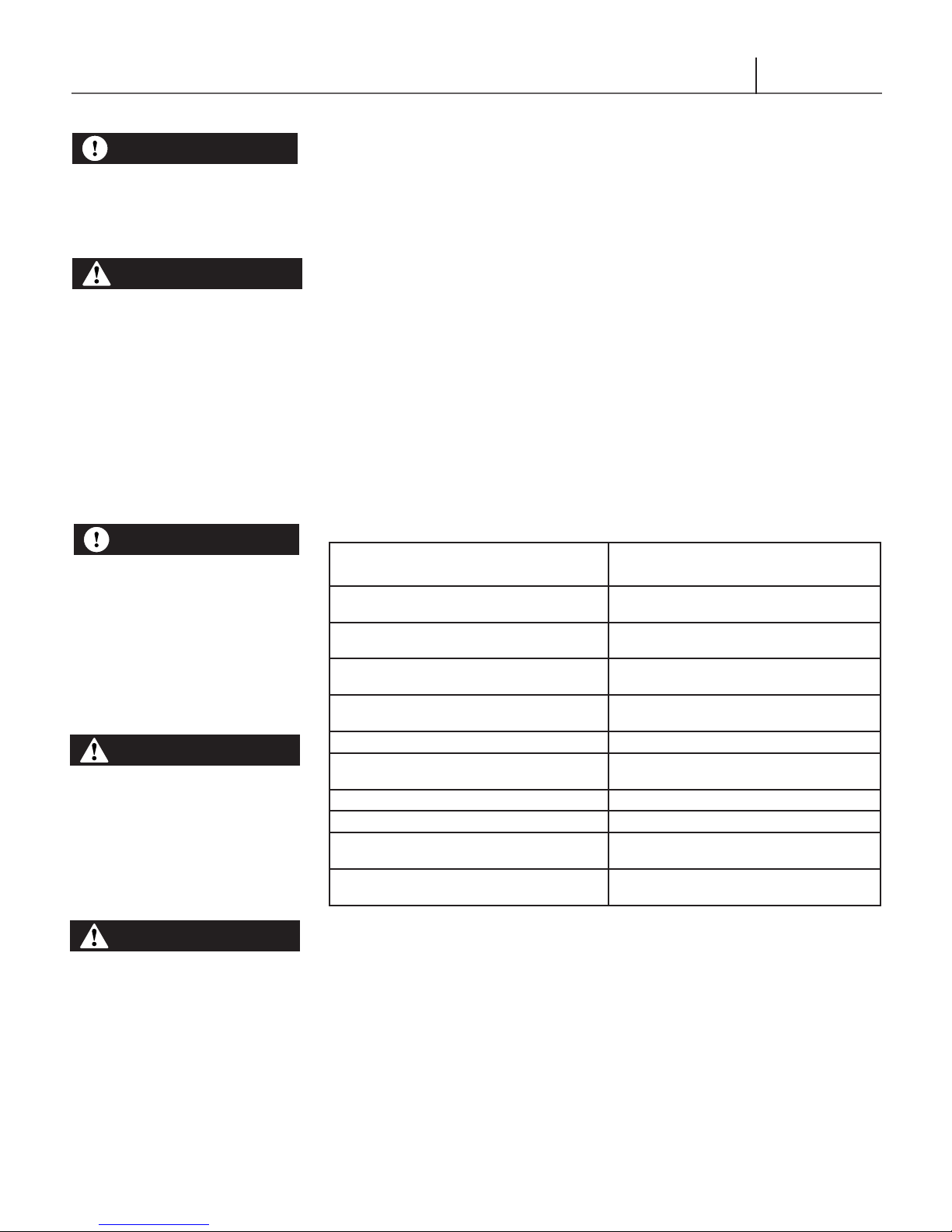

Table - Risks of Scalds

Temperature

Setting

Over 170°F/77°C

160°F/71°C

150°F/66°C

140°F/60°C

130°F/54°C

120°F/49°C or less

Time to Produce 2nd, 3rd

Degree Burns on Adult Skin

Nearly instantaneous

About 1/2 second

About 1-1/2 seconds

Less than 5 seconds

About 30 seconds

More than 5 minutes

To protect against injury, installing a tempering valve in the domestic hot water supply is

recommended. This valve will reduce point of discharge temperature by mixing cold and hot

water in branch supply lines. Such valves are available from the local plumbing supplier.

8

Glow Brand C95 & C140

General Information

DANGER

Read and understand this

entire document prior to

proceeding with the

installation of the Glow Combi

Boiler. Failure to follow the

instructions outlined in this

document will result in

property damage, serious

injury or death.

WARNING

Failure to have the boiler

properly serviced and

inspected on a regular basis by

a qualied service technician

may result in property damage,

serious injury or death.

1.2 General information

1.2.1 General Installation Requirements

The installation of your Glow Brand combination boiler must conform to the

requirements of this manual, your local authority, and the National Fuel Gas Code

ANSI Z223.1 and or CAN/CGA B149 Installation Codes. Where required by the

Authority, the installation must conform to the standard for “Controls and Safety

Devices for Automatically Fired Boilers ANSI/ASME CSD-1.

This document pertains to the correct instruction and installation of the Glow

Brand Combination Boilers C95 and C140. The instructions detailed in this

document supersede any and all previous instructions provided by Glow Brand

Manufacturing, written or otherwise. Each unit is provided with an Installation

Manual and a User Information Manual

1.2.2 User Responsibilities

The Glow Combi Boiler must be installed and serviced by a qualied service

technician and must be serviced and inspected annually when operating in

normal residential applications. Demanding applications or extreme conditions

(i.e. commercial) may require more frequent service and inspection. As the User/

Owner of this equipment, you are responsible for ensuring the maintenance is

performed at the required intervals; see Section 14.2- Annual Maintenance and

Inspection.

WARNING

Failure to keep the Vent and

Combustion Air-inlet clear of

ice, snow, and other debris

may result in property damage,

serious injury, or death.

DANGER

Failure to use the appropriate

gas as listed on the rating

plate when operating the Glow

Combi Boiler may result in

extremely dangerous burner

operation leading to property

damage, serious injury or

death. Always ensure the type

of gas being used corresponds

with what is listed on the

rating plate

1.2.3 Installer Responsibilities

A qualied installer is a licensed person who had the appropriate training and a

working knowledge of the applicable codes, regulations, tools, equipment and

methods necessary to install a boiler. The installer assumes all responsibility

for a safe installation and that it meets the requirements of the boiler instruction

manuals, as well as National and local installation codes. It is also the installer’s

responsibility to inform the User/Owner of their obligation with respect to the

description under “User Responsibilities”. Failure to follow this warning could

result in re, serious injury, or death

Natural Gas to Liqueed Petroleum (Lp) conversions kits are not available.

The materials used, such as copper, brass, stainless steel, etc., form a compact,

homogeneous, highly functional unit that is easy to install and simple to operate.

In its simplicity, the wall-mounted appliance is equipped with all the appropriate

accessories required to make it a fully independent combi boiler capable of

satisfying domestic hot water production and central heating (maximum set

point of 60°C/140°F) needs if installed. All combi boilers are fully inspected. This

manual must be kept in a safe place and must accompany the water heater at all

times.

Glow Brand will not be held responsible for any misinterpretation of this manual.

Glow Brand will not be held responsible for the consequences in the case of

non-observance of the instructions contained in this manual or in the case where

actions not specically described herein are undertaken.

9

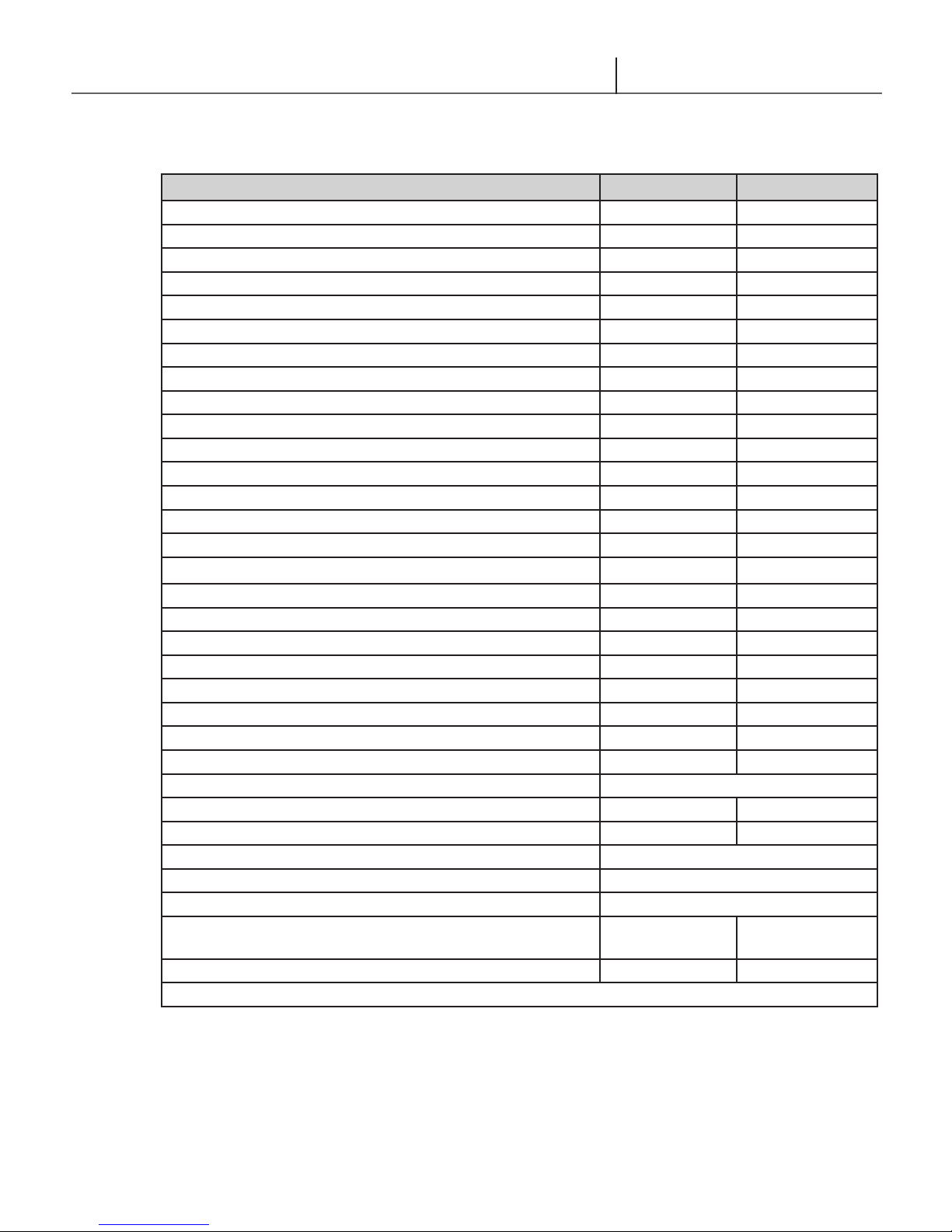

Glow Brand C95 & C140

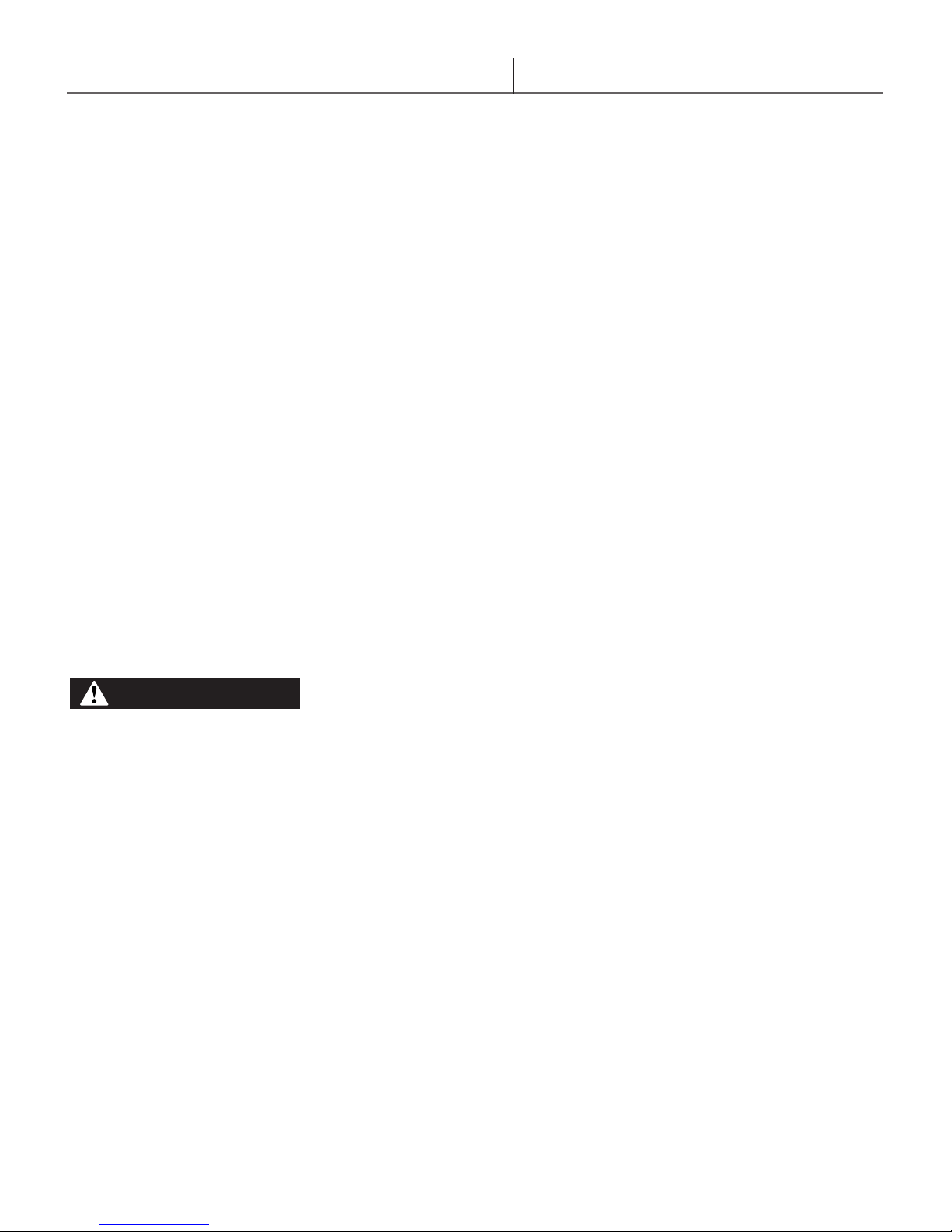

ELEVATIONS

2000 ft [610 m]

3000 ft [914 m]

4000 ft [1219 m]

4500 ft [1372 m]

5000 ft [1524 m]

In Canada

1

de-rate by 10%

de-rate by 10%

de-rate by 10%

de-rate by 10%

de-rate % may vary

In USA 2 -

de-rate by 12%

de-rate by 16%

de-rate by 18%

de-rate by 20%

Notes:

1

Canada: Altitudes between 200-4500 ft [610-1372 m], de-rate by 10%. Consult local authorities for de-rating capacities for altitudes above 4500

ft [1372 m].

2

USA: De-rate capacity by 4% for every 1000 ft [305 m], if altitude is over 2000 ft [610 m].

Installation & Operating Instructions

WARNING

Combustion – At elevations

above 2000 feet, the

combustion of the boiler must

be checked with a calibrated

combustion analyzer to ensure

safe and reliable operation. It

is the Installers responsibility

to check the combustion and

to adjust the combustion in

accordance to Section 9.0.

Failure to follow these

instructions may result in

property damage, serious

injury, or death.

1.2 High Altitude Operations

The Glow Combi boiler is designed to operate at its maximum listed capacity

in installations less than or equal to 2000 ft [610 m] above Sea Level. Since

the density of air decreases as elevation increases, maximum specied capacity

should be de-rated for elevations above 2000 ft [610 m] in accordance with

Table 1.1.

Table 1.1: De-rate % High Altitudes

10

Glow Brand C95 & C140

Domestic Input – Min MBH (KW) 9 (2.6) 13 (3.8)

Domestic Input – Max MBH (KW) 97 (28.4) 139 (40.7)

Domestic Output – Min MBH (KW) 8.4 (2.5) 14.1 (4.1)

Domestic Output – Max MBH (KW) 92 (26.9) 134 (39.3)

Central Heating Input – Min MBH (KW) 9 (2.6) 13 (3.81)

Central Heating Input – Max MBH (KW) 44 (12.9) 71 (20.8)

Central Heating Output – Min MBH (KW) 8.4 (2.5) 14.1 (4.1)

Central Heating Output – Max MBH (KW) 40.8 (11.9) 66 (19.3)

A.F.U.E 94% 94%

Min Gas Pressure (Nat. Gas) – inch w.c. 3.5 3.5

Max Gas Pressure (Nat. Gas) – inch w.c. 10.5 10.5

Power (120Vac/60Hz) - Watts @ full re with internal pump 180 198

Expansion tank water content – USG (Liters) 1.6 (6) 1.6 (6)

Min boiler ow rate – Usgpm (lpm) 2.2 (8.3) 5.3 (20.0)

Min Operating Pressure – Space Heating - psig 10 10

Max Operating Pressure – Space Heating - psig 30 30

Technical Characteristics

2. Technical Characteristics

2.1 Technical Data

Specication C95 C140

Min Operating Pressure – Domestic Hot Water - psig 30 30

Max Operating Pressure – Domestic Hot Water - psig 150 150

Min water Temperature - Space Heating - °F (°C) 95 (35) 95 (35)

Max water Temperature – Space Heating - °F (°C) 176 (80) 176 (80)

Min water Temperature – Domestic Hot Water - °F (°C) 104 (40) 104(40)

Max water Temperature – Domestic Hot Water - °F (°C) 140 (60) 140 (60)

Min ow rate to activate DHW – Usgpm (lpm) 0.5 (1.89) 0.5 (1.89)

Max ow rate DHW– Usgpm (Lpm)1 @77°F rise 2.4 (9) 3.7 (14)

Vent/Air-Intake Pipe Diameter, inches (mm) 2 (51) or 3 (76)

Max equivalent vent length 2" (each side) - ft 100 60

Max equivalent vent length 3" (each side)- ft 125 125

CH Water Connections - NPT, in. 3/4

DHW Connections – NPT, in 1/2

Gas Connection - NPT, in. 3/4

Dimensions H x W x D - inches (mm) 31.2 x 16.9 x 14.0

(81.3 x 430 x356)

Weight (empty) – lbs (Kg) 105 (47.6) 125 (56.7)

1

With restrictor installed. High ow rates can be achieved by changing the ow restrictor.

Table 2.1: Unit Specications

31.2 x 16.9 x 18.0

(81.3 x 430 x 457)

11

Glow Brand C95 & C140

31.2

2.2 Unit Dimensions

16.9

6.8

Installation & Operating InstructionsInstallation & Operating Instructions

5.5

Figure 2.1 - Glow C95 Dimensions

5.6

EXHAUST

VENT

LEGEND

Gas Inlet 3/4” NPT

CH Outlet 3/4” NPT

CH Inlet 3/4” NPT

DHW Inlet 1/2” NPT

DHW Outlet 1/2” NPT

Condensate Outlet 3/4” I.D.

16.9

6.8

5.5

AIR

INTAKE

14.0

4.4

1.7

CONDENSATE

OUTLET

4.7

2.0

2.6

SUPPLY DHW

1.9

3.2

RELIEF

FIXTURE

CH

VALVE

6.3

GAS

SUPPLY

DCW

RETURN

2.62.6 5.2

CH

Figure 2.2 - Glow C140 Dimensions

31.2

5.6

EXHAUST

VENT

LEGEND

Gas Inlet 3/4” NPT

CH Outlet 3/4” NPT

CH Inlet 3/4” NPT

DHW Inlet 1/2” NPT

DHW Outlet 1/2” NPT

Condensate Outlet 3/4” I.D.

AIR

INTAKE

18.0

5.8

0.4

CONDENSATE

OUTLET

6.1

2.0

2.6

SUPPLY DHW

1.9

3.2

RELIEF

VALVE

FIXTURE

CH

2.6

6.3

GAS

SUPPLY

DCW

5.2 2.6

CH

RETURN

12

Glow Brand C95 & C140

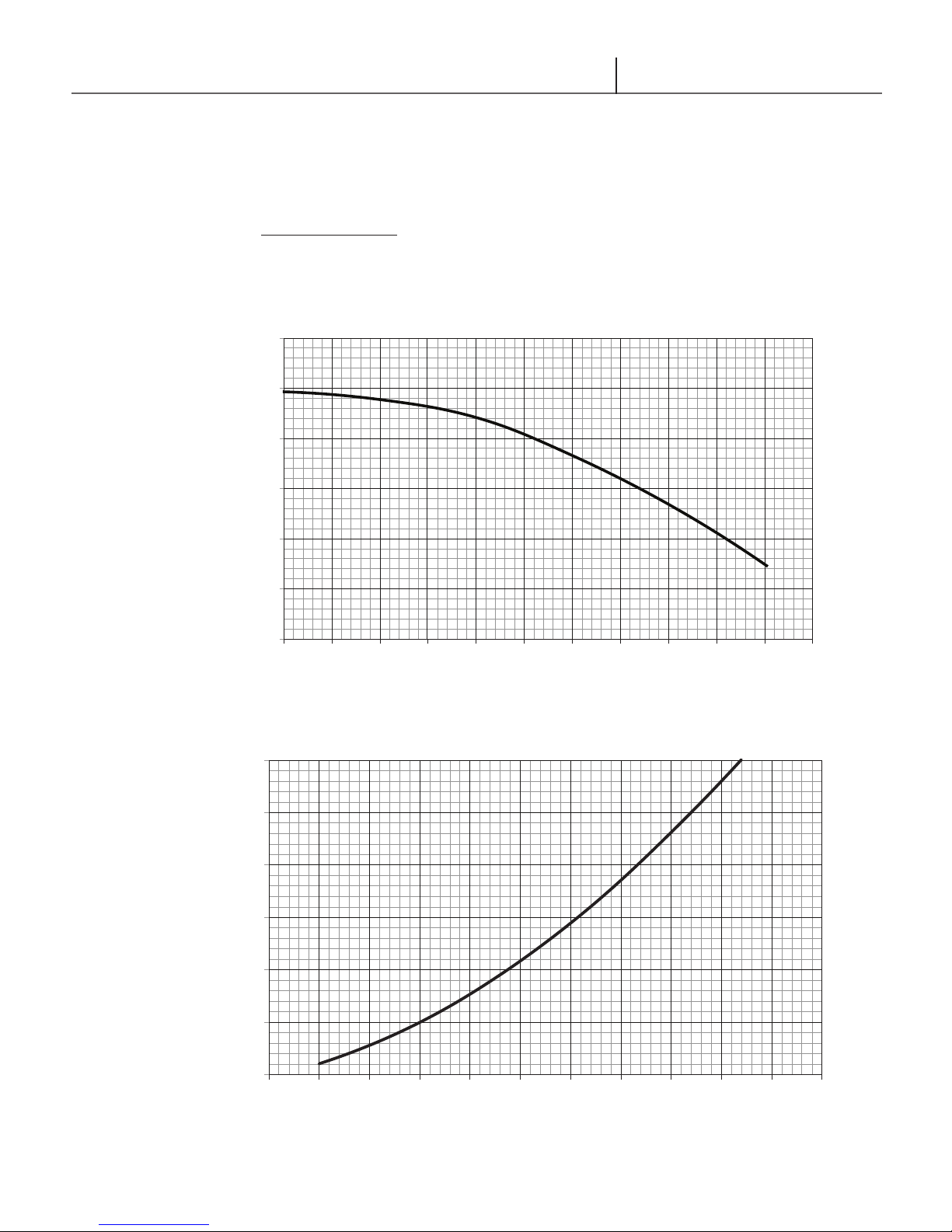

PRESSURE DROP (PSI)

2.3.1 Head Calculation

Example: C95 Target ow of 5 gpm

Figure 2.3 indicates 25.5 ft head available at the desired ow of 5 gpm. Figure 2.4 indicates the

pressure drop in the heat exchanger to be 4.4 psi (10.2 ft) at the target ow of 5 gpm.

Therefore 25.5 - 10.2 = 15.3 ft available for piping and heating device pressure drop.

The C140 unit is supplied with a factory low loss header for eld installation. Therefore external head

is provided by the eld supplied secondary loop circulating (CH) pump.

35

30

25

20

Technical Characteristics

2.3 Unit Performance

C95 CENTRAL HEATING PUMP CURVE

Figure 2.3

HEAD (FEET)

15

10

0

0 1 2 3 4 5 6 7 8 9 10 11

WATER FLOW (GPM)

C95 CENTRAL HEATING PRESSURE DROP VS WATER FLOW

12

10

8

6

4

2

0

Figure 2.4

0 1 2 3 4 5 6 7 8 9 10 11

HEATING WATER FLOW (GPM)

13

Glow Brand C95 & C140

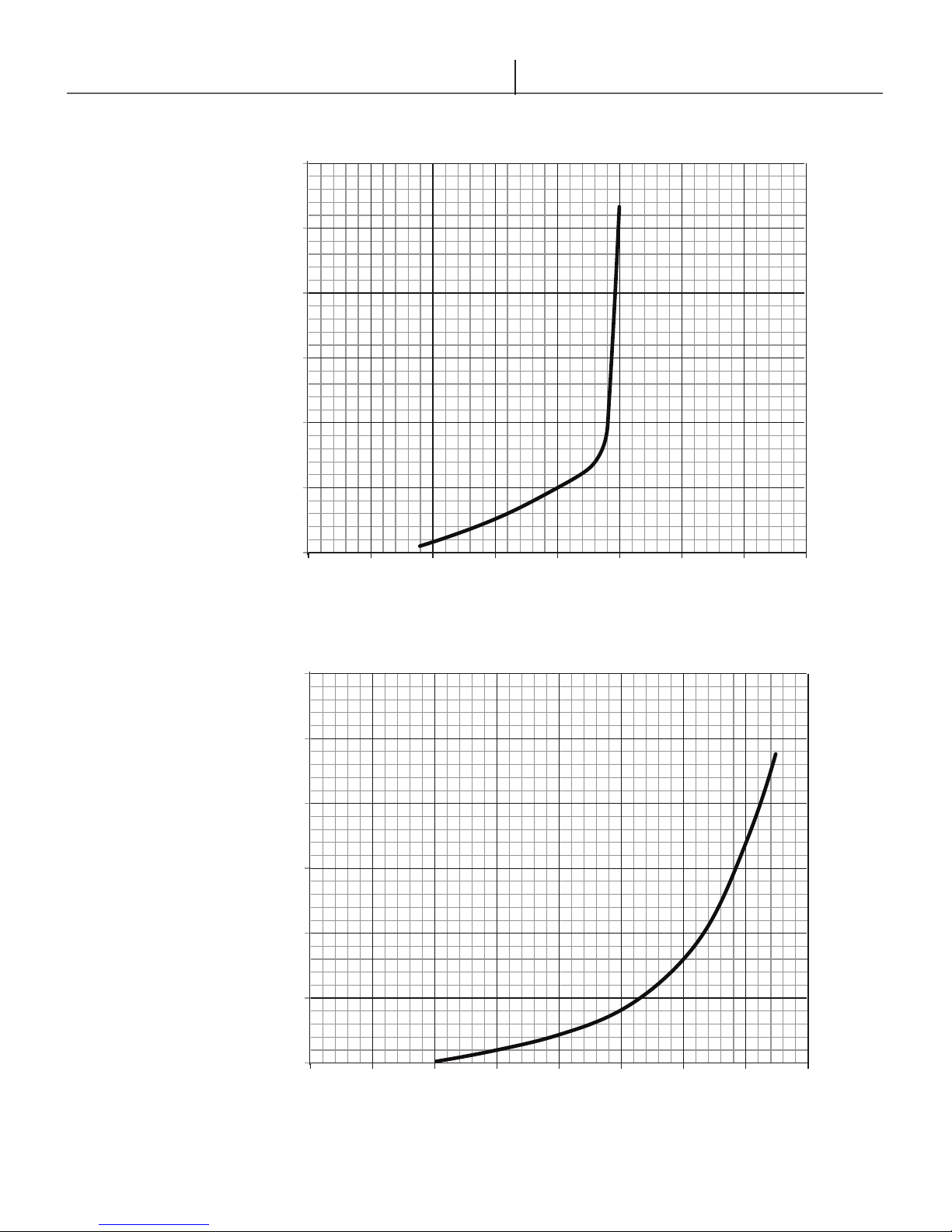

0 1 2 3 4

PRESSURE DROP (PSI)

0 1 2 3 4

PRESSURE DROP (PSI)

60

50

40

30

20

10

Installation & Operating InstructionsInstallation & Operating Instructions

C-95 DOMESTIC WATER PRESSURE DROP VS FLOW

(2.4 GPM FLOW LIMITER)

Figure 2.5

0

DHW WATER FLOW (GPM)

C-140 DOMESTIC WATER PRESSURE DROP VS FLOW

(3.7 GPM FLOW LIMITER)

60

50

40

30

20

10

0

Figure 2..6

14

DHW WATER FLOW (GPM)

Glow Brand C95 & C140

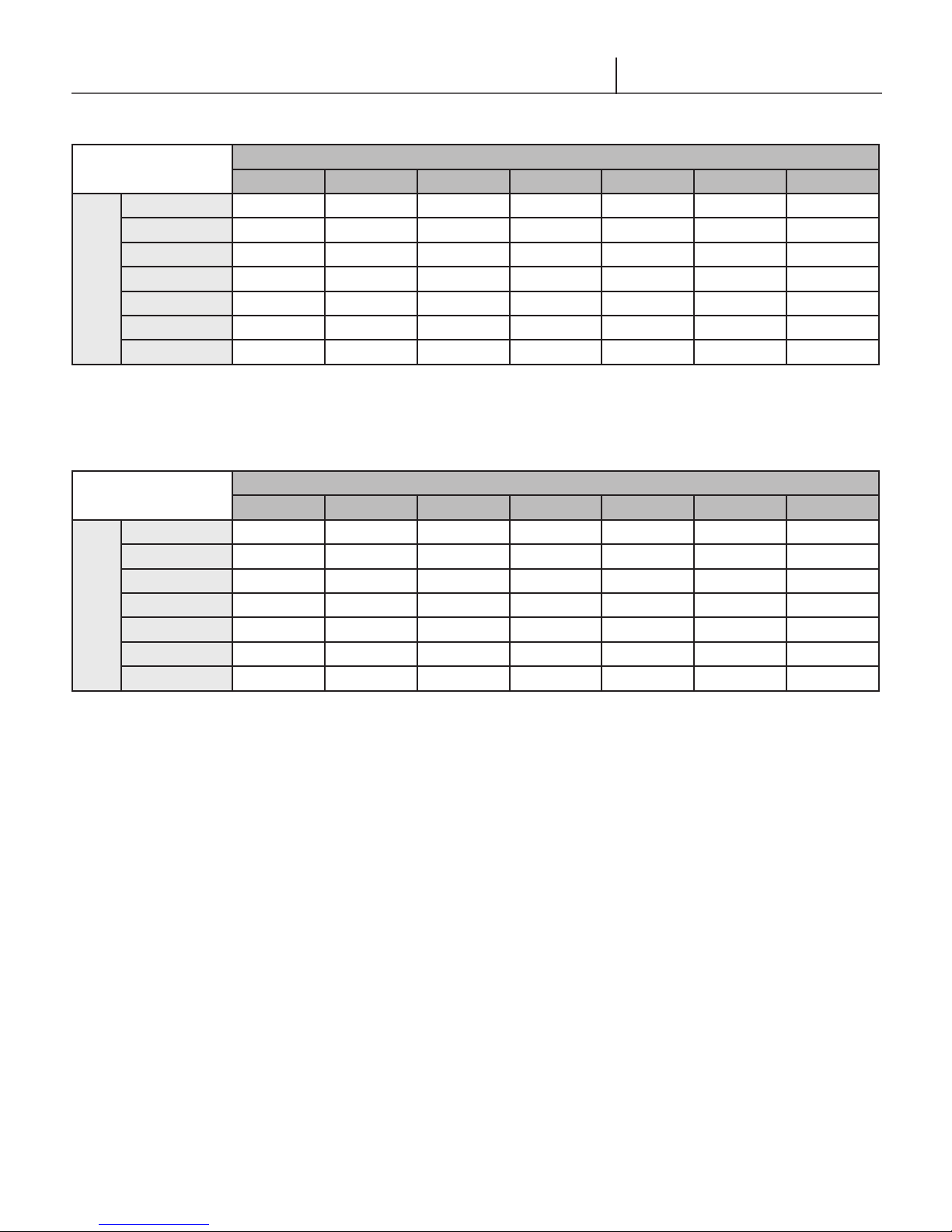

40 45 50 55 60 65 70

2.7 2.9 3.1 3.4 3.7 4.1 4.7

2.5 2.7 2.9 3.1 3.4 3.7 4.1

2.3 2.5 2.7 2.9 3.1 3.4 3.7

2.2 2.3 2.5 2.7 2.9 3.1 3.4

2.1 2.2 2.3 2.5 2.7 2.9 3.1

2.0 2.1 2.2 2.3 2.5 2.7 2.9

1.9 2.0 2.1 2.2 2.3 2.5 2.7

40 45 50 55 60 65 70

3.8 4.1 4.5 4.9 5.4 6.0 6.7

3.6 3.8 4.1 4.5 4.9 5.4 6.0

3.4 3.6 3.8 4.1 4.5 4.9 5.4

3.2 3.4 3.6 3.8 4.1 4.5 4.9

3.0 3.2 3.4 3.6 3.8 4.1 4.5

2.8 3.0 3.2 3.4 3.6 3.8 4.1

2.7 2.8 3.0 3.2 3.4 3.6 3.8

Outlet Water

Temperature (°F)

Table 2.2: C95

Outlet Water

Temperature (°F)

Table 2.3: C140

110

115

120

125

130

135

140

110

115

120

125

130

135

140

Technical Characteristics

C95 Domestic Hot Water Flow vs. Temperature Rise

Inlet Water Temperature (°F)

C140 Domestic Hot Water Flow vs. Temperature Rise

Inlet Water Temperature (°F)

15

Glow Brand C95 & C140

Installation & Operating InstructionsInstallation & Operating Instructions

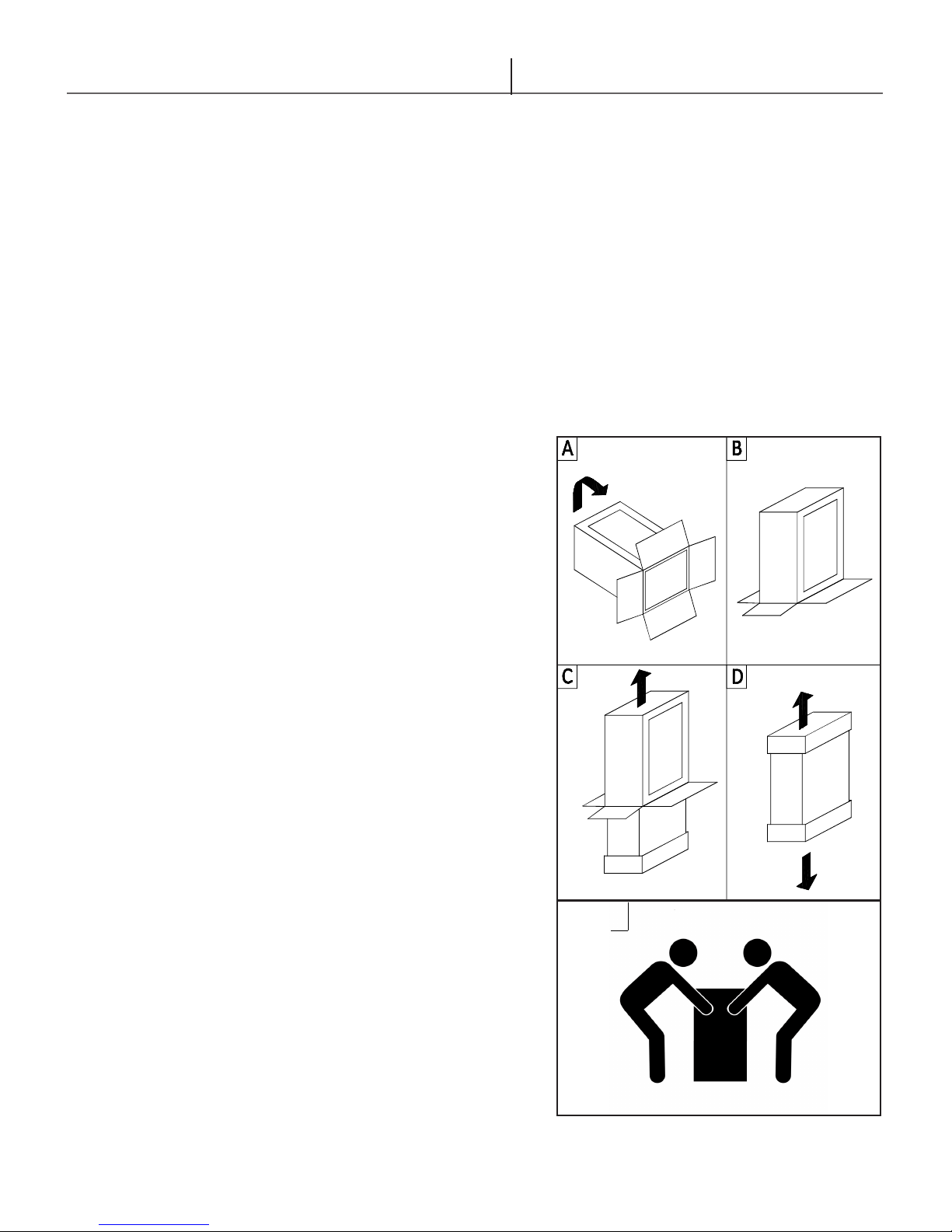

3. Storage, Handling & Installation

3.1 Storage

The Glow Combi Boiler should be stored in the horizontal position with no more

than three units to a stack; Ensure that the units are stored in dry conditions and

the temperature does not drop below 0°C/32°F when in storage.

3.2 Unpacking

• The materials (cardboard) used for packing the appliance are fully recyclable.

• It is recommended that the packing material is only removed prior to installing

the unit. The manufacturer will not be held responsible for damage caused by

incorrect storage of the product.

• Packing materials (plastic bags, polystyrene, etc.) must not be left within

reach of children, in that these items represent a potential hazard.

A. Place the packed appliance

on the oor (see g. 3.1)

making sure that the unit is

in its upright position. Open

out the four aps of the box.

B. Rotate the packed

appliance 180° so that the

top is upside down while

manually supporting it from

underneath.

C. Lift the box and remove the

foam packaging.

D. Firmly grip the unit. Lay the

unit on its back away from

the work area and continue

with the installation.

E. Two people are required to

safely lift this boiler onto the

wall mounting bracket.

E

16

Figure 3.1 - Unpacking the Combi Boiler

Glow Brand C95 & C140

A

D C E

F

B

A D

44 24

12

12

C

E F

B

16.5

WARNING

Water or ood damaged

components must be replaced

immediately with new factory

approved components as

failure to do so may result in

property damage, serious

injury, or death.

WARNING

This boiler must not be

installed on carpeting as

failure to do so may result in

property damage, serious

injury, or death.

Storage, Handling & Installation

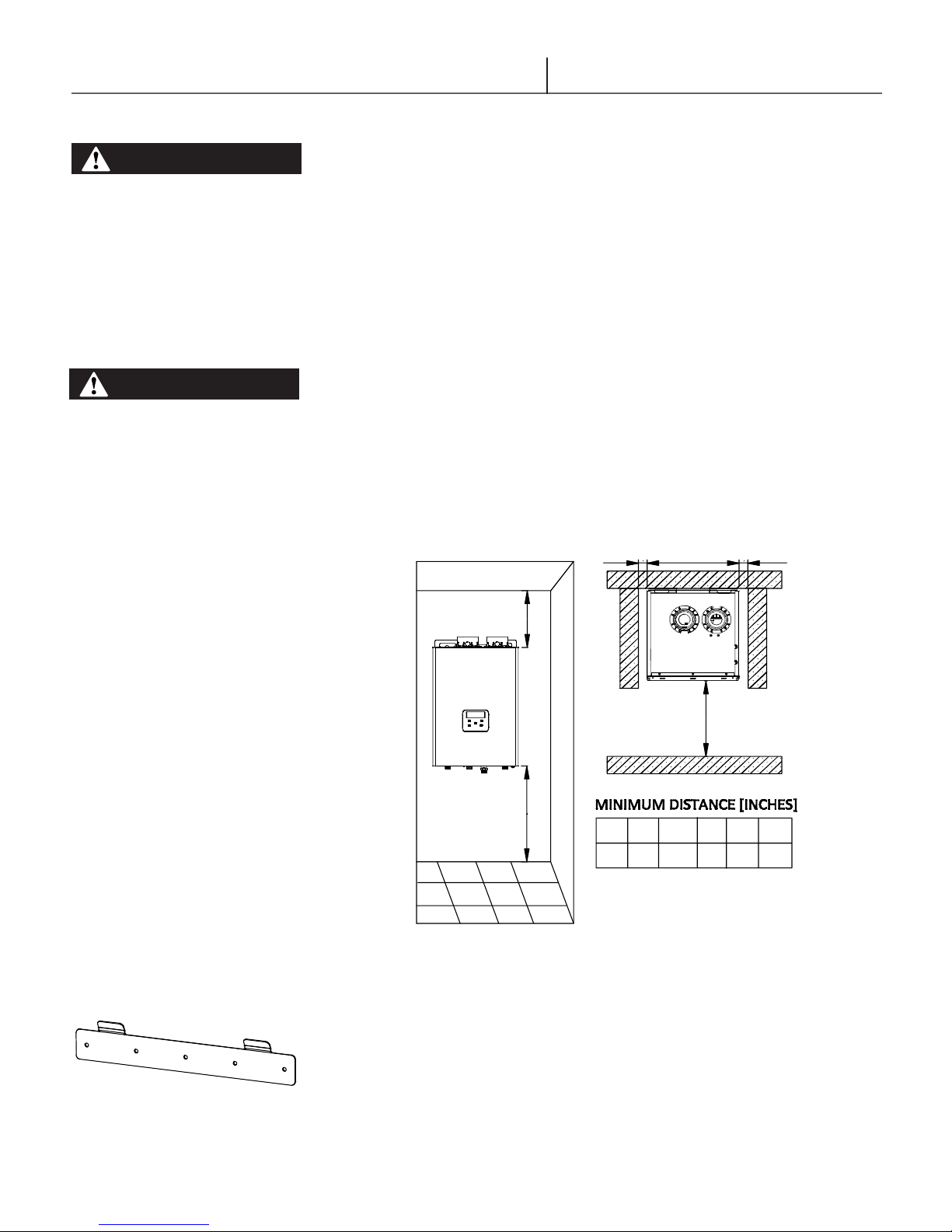

3.3 Boiler Location

In all cases, the Glow Combi Boiler must be installed indoors in a dry location

where the ambient temperature must be maintained above freezing. The gas

components must be protected from dripping and or spraying water. Consider

the proximity of system piping, gas and electrical supply, drain for condensate

disposal, and proximity to vent termination when determining the best boiler

location.

If the Glow Combi Boiler is installed in an unheated area it is recommended to

leave the unit continually powered in order to ensure the frost protection function

is active.

In order to allow access to the interior of the unit for maintenance purposes, it

is important that the minimum distances indicated are respected. See Fig 3.2:

Minimum Installation Clearances

Clearance to Combustibles:

Minimum clearance from combustible or non combustible construction. (Fig. 3.2)

Front – 0 inches

Sides – 0 inches

Rear – 0 inches

Top – 0 inches

Figure 3.3 - Support Bracket

Figure 3.2 - Minimum Installation Clearances

3.4 Wall Mounting Installations

Included within the packaging of the Glow Combi Boiler is a wall mount support

bracket. Mounting the support bracket (g. 3.3) on a eld supplied ¾” piece of

plywood will add additional structural integrity to the installation. Make sure the

supplied wall mounting support bracket is anchored to a structure capable of

supporting the weight of the boiler and attached piping when lled with water.

For mounting on a cement wall, use appropriately sized masonry anchors or

equivalent. Two people are required to safely lift this boiler onto the wall support

mounting bracket.

17

Glow Brand C95 & C140

Installation & Operating Instructions

Installation & Operating Instructions

DANGER

The ue exhaust and

combustion air intake are to be

piped separately. The Glow

Combi Boiler cannot share a

common ue exhaust or

combustion air intake with

multiple appliances. Failure to

comply may result in property

damage, serious injury, or

death.

DANGER

Do not install the Glow Combi

Boiler into a common venting

system with any other

appliances. Failure to comply

with this warning may cause

ue gas spillage and leech

carbon monoxide emissions

into the surrounding air

resulting in serious injury or

death.

4. Venting

4.1 General Venting

The Glow Combi Boiler is certied as a “Category IV” boiler requiring a “Special

Venting System” designed for pressurized venting. The exhaust vent must be piped

to the outdoors, using the vent materials and rules outlined in this section. Under

no conditions may this unit vent gases directly into a masonry chimney, unless it

is vacant, and utilizes the approved venting material and rules described in this

section. Venting into a masonry chimney is only acceptable when the chimney is

no longer being used for its initial intended purpose therefore considering it a chase

for the exhaust and combustion air vent pipe.

4.2 Removing an Existing Boiler from Common Venting System

Upon removal of an existing boiler, the following steps shall be followed for

each boiler remaining in the common venting system; prior to commencing this

procedure, shutdown all boilers remaining in the common venting system.

Steps to Removing an Existing Boiler:

When an existing boiler is removed from a common venting system, the common

venting system is likely to be too large for proper venting of the remaining boilers

connected to it. Instructions have been provided on how to remove the existing

boiler and how to resize the remaining venting system. Failure to follow these

instructions may result in property damage, serious injury or death.

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and horizontal pitch and

determine there is no blockage or restriction, leakage, corrosion and other

deciencies which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and windows and all doors

between the space in which the appliances remaining connected to the

common venting system are located and other spaces of the building. Turn

on clothes dryers and any appliance not connected to the common venting

system. Turn on any exhaust fans, such as range hoods and bathroom

exhausts, so they will operate at maximum speed. Do not operate a summer

exhaust fan. Close replace dampers.

4. Place in operation the appliance being inspected. Follow the lighting

instructions. Adjust thermostat so appliance will operate continuously.

5. Test for spillage at the draft hood relief opening after 5 minutes of main

burner operation. Use the ame of a match or candle, or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each boiler remaining connected to the

common venting system properly vents when tested as outlined above, return

doors, windows, exhaust fans, replace dampers and any other gas burning

boiler to their previous condition of use.

7. Any improper operation of the common venting system should be corrected

so the installation conforms to the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 and/or Natural Gas and Propane Installation Code, CAN/CSA

B149.1. When resizing any portion of the common venting system, the

common venting system should be resized to approach the minimum size

as determined using the appropriate tables in Chapter 13 of the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or Natural Gas and Propane

Installation Code, CAN/CSA B149.1.

18

Glow Brand C95 & C140

NOTICE

The boiler shall be located so

as not to interfere with proper

circulation of combustion,

ventilation, and dilution air

WARNING

Make up air requirements for

the operation of exhaust fans,

kitchen ventilation systems,

clothes dryers, and replaces

shall be considered in

determining the adequacy of a

space to provide combustion

air requirements. Failure to

ensure adequate make up air

to all appliances may result in

personal injury or death

Venting

4.3 Installation Using Indoor Combustion Air

When the installation uses Indoor Combustion Air (i.e. piping is not directly

connecting the appliance air-inlet tting to the outdoors), provisions for

combustion and ventilation air, in accordance with section “Air for Combustion

and Ventilation,” of the National Fuel Gas Code, ANSI Z223.1/NFPA 54 (U.S.),

or Clause 8.2, 8.3 or 8.4 of Natural Gas and Propane Installation Code, CAN/

CSA B149.1 (Canada), or applicable provisions of the local building codes, must

be adhered to.

4.3.1 Contaminated Make-Up Air Will Damage the Unit

Do not to operate the combi boiler in an area that is or will be under construction

or renovation. Combustion air containing dust, debris or air-borne contaminants

will drastically increase the required maintenance and may cause a corrosive

reaction in the Heat Exchanger which could result in premature failure, re, serious

injury, or death. The Glow Brand Manufacturing Warranty will not cover damage

and premature wear caused to the unit due to installation in a contaminated

environment.

All of the exhaust venting connections must be leak checked with a soap solution

upon initial startup of the combi boiler. Any leaks must be repaired before

continuing operation of the unit. Warranty will not be available if the unit is used

for construction heat.

NOTICE

It is BEST PRACTICE to pipe

the combustion air-inlet

directly to the outdoors

(Direct Vent installation) to

avoid contamination often

contained in indoor air.

WARNING

Do not store or use gasoline or

other ammable vapors and

liquids in the vicinity of this or

any other appliance. Failure to

follow instructions may result

in serious injury or death.

WARNING

Use of cellular core Schedule

40 PVC (ASTM F891), cellular

core CPVC, or Radel

(polyphenylsulfone) in nonmetallic venting systems is

prohibited. Covering nonmetallic vent pipe and ttings

with thermal insulation is

prohibited.

Products to Avoid Contaminated Sources to

Avoid

Antistatic fabric softeners, bleaches, detergents,

cleaners

Perchloroethylene (PCE), hydrocarbon based

cleaners

Chemical fertilizer, herbicides/pesticides, dust,

methane

Paint or varnish removers, cements or glues,

sawdust

Water chlorination chemicals (chloride, uoride) Swimming pools, hot tubs

Solvents, cutting oils, berglass, cleaning

solvents

Refrigerant charge with CFC or HCFC Refrigerant repair shops

Permanent wave solutions Beauty shops

Fixer, hydrochloric acid (muriatic acid), bromide,

iodine

Cement powder, crack ll dust, cellulose, ber

based insulation

Laundry facilities

Dry cleaning facilities

Farms or areas with livestock and manure

Wood working or furniture renishing shops

Auto body or metal working shops

Photo labs, chemical / plastics processing

plants

Concrete plant or construction site

4.4 Venting Guidelines

• Keep the vent system as short and straight as possible.

• Locate the unit as close as possible to the vent termination.

• The vent must not be common vented with any other gas appliance or vent

stack.

• Slope vent upwards towards the termination at a minimum rate of 1/4” per

foot (2% slope).

• Vent termination must be a minimum of 12” above grade or expected snowfall.

• Vent and air intake pipe must be supported at least every 5 feet of horizontal

run and every 5 feet of vertical run.

19

Glow Brand C95 & C140

Installation & Operating Instructions

Installation & Operating Instructions

4.5 Direct Vent Installation

Direct Vent installation dictates that the combustion air-inlet must be piped directly

to the outdoors using the methods described in this section and in accordance

with the National Fuel Gas Code, ANSI Z223.1 (U.S.) or CSA B149.1 (Canada)

and local requirements. Install the entire venting system securely cementing all

ttings. This Glow Combi Boiler uses a 2” or 3” diameter exhaust vent pipe made

up of PVC or CPVC System 636. The air intake pipe uses 2” or 3” diameter pipe

made of Schedule 40 ABS, DWV, PVC, or CPVC materials and in accordance

with all applicable local building codes.

4.5.1 Exhaust Vent Pipe Materials

Use only 2” or 3” solid PVC/CPVC schedule 40 PVC/CPVC or ULC S636 pipe

and ttings. Venting requirements in USA and Canada are different. Consult the

most recent edition of the National Fuel Gas Code (ANSI Z223.1 / NFPA 54) or

CAN/CSA B-149.1 as well as local codes for applicable venting regulations and

restrictions.

For installation in Canada, eld supplied plastic vent piping must comply with

CAN/CSA B-149.1 (latest edition) and be certied to the standard for type BH

Gas Venting Systems. ULC S636 components of this listed system shall not

be interchanged with other vent systems or unlisted pipe/ttings. All plastic

components and specied primers and glues of the certied vent system must be

from a single manufacturer and not intermixed with other system manufacturer’s

vent system parts. The supplied vent adapters are certied as part of the

combination boiler.

Units installed with vertical exhaust, must have an additional condensate drain

installed on the exhaust vent pipe. Fittings must be ULC S636 approved. Schedule

40 PVC/CPVC pipe/ttings have been approved for use on this appliance with

zero clearance to combustibles.

WARNING

Flammable Cements and

Primers – It is the installers’

responsibility to familiarize

themselves with the hazards

associated with explosive

solvents and to take all

precautions to reduce these

risks. Failure to follow these

instructions can cause

explosions, property damage,

injury or death.

All venting must be supported

to reduce strain on piping

joints. The exhaust vent shall

maintain a 1/4” slope upwards

towards the vent termination

outlet. In situations when

excessive amounts of

condensate is being produced

maintaining a 1/2” slope

upwards towards the vent

termination may be required.

4.5.2 Intake Vent Pipe Materials

Schedule 40 PVC, CPVC or ULC S636 pipe and ttings and ABS or DWV pipe

and ttings can be used for combustion air intake on Glow Brand products.

Transition cement must be used if ABS or DWV pipe is connected to the PVC

appliance adapters.

All plastic components and specied primers and glues of the certied vent

system must be from a single manufacturer and not intermixed with other system

manufacturers vent system parts.

The vent for this appliance shall not terminate over public walkways, near soft

vents, crawl spaces or other areas where condensate or vapour could create a

nuisance or hazard or cause property damage or where condensate vapour could

cause damage or could be detrimental to the operation of regulators, relief valves

of other equipment.

4.5.3 Flammable Solvents and Plastic Piping

Due to the extremely ammable characteristics of most glues, cements, solvents

and primers used in the process of joining plastic vent and air-inlet pipe, explosive

solvent vapors must be evacuated from the vent and air-intake prior to start-up.

Avoid using excess cement or primer that may lead to pooling inside the pipe

assembly. Freshly assembled piping assembly should be allowed to cure before

operating the gas red appliance.

20

Glow Brand C95 & C140

Venting

Improper venting of the Glow Combi Boiler can result in excessive levels of carbon

monoxide which can result in severe personal injury or death. This unit must be

vented in accordance with the “Venting of Equipment” section of the latest edition

of the ANSI Z223.1 / NFPA 54 Natural Gas Code and/or the “Venting systems and

air supply for appliances” section of the latest version of the CAN/CSA B149.1

Natural Gas and Propane Installation Code in Canada and in accordance with all

applicable local building codes.

4.5.4 Equivalent Lengths

• Reduce the maximum vent length accordingly for each elbow used.

• Each 2” & 3” 45° elbow equates to 2.5 linear feet of vent pipe.

• Each 2” & 3” 90° short radius elbow equates to 7.5 linear feet of vent pipe.

• Each 2” & 3” 90° long radius elbow equates to 5 linear feet of vent pipe.

• The maximum length listed is for ue exhaust vent only. The intake length

should be equal length.

• The total maximum equivalent vent pipe distance cannot exceed the values

indicated in Table 2.1 for horizontal and vertical venting distance.

• The maximum lengths are including elbows. Exceeding the maximum venting

distances will cause the appliance to malfunction or cause an unsafe condition.

AVAILABLE VENT LENGTHS

MODEL C95 C140

Vent Diameter Size 2” or 3” Diameter 2” or 3” Diameter

Max Equivalent 2” Diameter 100ft

3” Diameter 125ft

Exhaust Vent Schedule 40 System 636

PVC/CPVC

Intake Vent Schedule 40 PVC/CPVC,

ABS, DWV

Table 4.3: Available Vent Lengths

2” Diameter 60ft

3” Diameter 125ft

Schedule 40 System 636

PVC/CPVC

Schedule 40 PVC/CPVC,

ABS, DWV

4.5.5 Termination Options

The venting system of the Glow Combi Boiler may be terminated using eld

supplied piping to construct a “Two-Pipe” termination, alternatively, the venting

may be terminated using a manufacturer approved concentric vent kit.

Sidewall Termination

Due to potential moisture building up along the exterior wall, sidewall venting may

not be the preferred venting option. Refer to roof top venting options.

Straight Out Termination – The exhaust vent can terminate straight to an outside

wall. A reducer of 1 pipe diameter smaller can be tted on the exhaust to increase

the velocities of the exiting gases. The reduced diameter pressurizes the exhaust

vent and helps to keep the ue gases from entering the intake. The reduced pipe

diameter of 1 size shall be between 4” to 8” in length.

In the United States (U.S.), provide a minimum of 4 feet (1.22 m) horizontal

clearance from electrical meters, gas meters, gas regulators, and relief equipment

as per National Fuel Gas Code, ANSI Z223.1/NFPA 54. In no case shall the

exit terminal be above or below the aforementioned equipment unless the 4 foot

horizontal distance is maintained.

21

Glow Brand C95 & C140

Installation & Operating Instructions

Installation & Operating Instructions

WARNING

Extra precaution must be taken

to adequately support the

weight of the Vent/Air-inlet

piping in applications using

horizontal or vertical roof

terminations. Failure to follow

these instructions may result

in venting or boiler component

failure resulting in ue gas

spillage leading to property

damage, serious injury or

death.

WARNING

Any time the exhaust vent

passes through an

unconditioned space, care

should be taken to ensure the

vent pipe is insulated in order

limit the amount of condensate

collecting within the vent.

Make certain the system has

been installed in accordance

with the latest version of CAN/

CSA B149.1 Natural Gas and

Propane Installation Code and

in full compliance with all local

codes.

DANGER

Under no circumstances may

an existing chimney or chaseway be used to vent or provide

combustion intake air to a

Glow combi boiler. Failure to

follow these instructions will

result in re, property damage,

serious injury or death.

In Canada, provide minimum horizontal clearance from electrical meters, gas

meters, gas regulators, and relief equipment as per The Canadian Natural Gas

And Propane Installation Code, B149.1.

The vent for this combi boiler shall not terminate over public walkways; or near

soft vents or crawl space vents or other area where condensate of vapor could

create a nuisance or hazard or cause property damage;

Vertical Roof Termination - All terminations that end vertically through the roof

must have an additional condensate tee installed on the vent pipe before the unit.

This condensate line shall include a trap. See Fig. 4.1.

EXHAUST

INTAKE AIR

CONDENSATE

DRAIN

Fig 4.1: Vertical Drain Tee with Trap

EXHAUST

INTAKE AIR

CONDENSATE

DRAIN

4.5.6 Venting Rules and Guidelines

1. Prevailing Winds: Ensure the vent is located where it will not be exposed to

normal prevailing winds.

2. Combustion Air Intake Contamination: Air for combustion must be drawn

from an area free of dust and contaminants. Combustion air containing

chemicals such as chloride, uoride, bromine, iodine or dust and debris will

cause damage of the heat exchanger voiding your Glow Brand Warranty.

3. Vertical Separation: The exhaust outlet must be a minimum of 8” to a

maximum of 24” above the combustion air intake. The combustion air intake

must always be a minimum of 12” plus snow allowance above any surface

that will support snow.

4. Horizontal Separation: The horizontal distance between the intake and

exhaust must be a minimum of 6” center to center.

5. Flue Gas Hazard: The vent for this appliance shall not terminate over public

walkways, near soft vents, crawl spaces or other areas where condensate

or vapour could create a nuisance or hazard or cause property damage.

Condensate vapour could cause damage or could be detrimental to the

operation of regulators, relief valves of other equipment.

22

Glow Brand C95 & C140

Venting

6. Vent Sloping: All exhaust piping must maintain a ¼” per foot upwards

slope towards the outlet of the vent termination. For applications where,

excessive condensation is possible, a ½” per linear foot upward slope is

recommended.

7. Vent Supports: All exhaust and air intake piping shall be secured to the wall

for rigidity. Exhaust and air intake pipe must be supported horizontally and

vertically at a maximum of every 4 feet.

8. Roof Exhaust: In all roof applications the discharge must point away from

the pitch of the roof and must be a minimum 24” apart.

9. Roof Flashing: Install adequate ashing where the pipe enters the roof, to

prevent water leakage.

10. Venting Below Grade: For installations that exit the wall below grade, refer

to the latest version of the CAN/CSA B149.1 Natural Gas and Propane

Installation Code.

11. Vent Screens: Factory supplied vent screens may be installed on the intake

and or exhaust termination. Two ½” by ½” galvanized screens are provided

in a package. Vent screen installation is optional.

12. Condensate Hazard: Do not locate vent over public walkways, driveways

or parking lots. Condensate could drip and freeze resulting in a slip hazard

or damage to vehicles and machinery.

13. Venting Options: Due to potential moisture loading (build-up) along the

exterior wall, sidewall venting may not be the preferred venting option.

14. Wall Thickness: Direct vent terminations are designed to work with any

standard wall thickness. Installation guidelines for min/max wall thickness

are as follows: Min.= 1” [25mm], Max.= 50” [1.27 m].

23

Glow Brand C95 & C140

*All clearance requiremnts are in accordance with ANSI Z21.10.3 and the National

V

X

Legend:

= Vent terminal

= Air supply inlet

= Area where terminal is not permitted

Installation & Operating Instructions

Installation & Operating Instructions

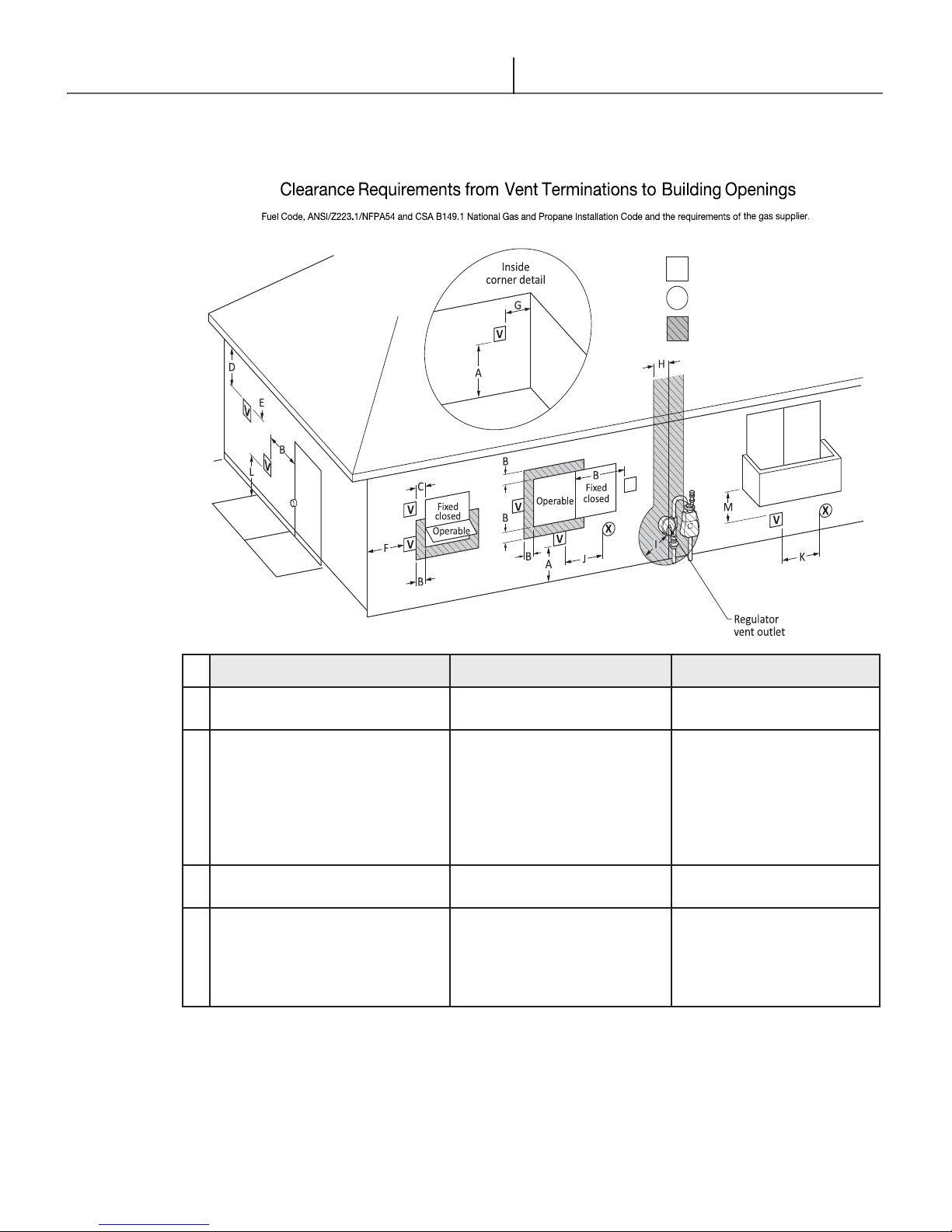

4.4 Venting Diagrams

4.4.1 Venting Clearances- Direct Vent

Canadian Installations

A

Clearance above grade,

veranda, porch deck or balcony

B

Clearance to window or door

that may be opened

C

Clearance to permanently closed

window

D

Vertical clearance to ventilated

soft located above the terminal

within a horizontal distance of

2 feet from the center of the

terminal

Table 4.2: Direct Vent Terminal Clearances (continued next page)

12 in (30 cm) 12 in (30 cm)

6 in (15 cm) for appliances

≤ 10,000 BTUh (3kW),

12 in (30cm) for appliances

> 10,000 BTUh (3kW) and

< 100,000 BTUh) (30kW),

36 in (91 cm) for appliances

> 100,000 BTUh (30kW)

1

US Installations

6 in (15 cm) for appliances

≤ 10,000 BTUh (3kW),

9 in (23 cm) for appliances

>10,000 BTUh (3kW) and

≤ 50,000 BTUh) (15kW),

12 in (30 cm) for appliances

> 50,000 BTUh (15kW)

* *

* *

2

24

Glow Brand C95 & C140

Venting

E Clearance to unventilated soft

F Clearance to outside corner

G Clearance to inside corner

H Clearance to each side of

centre line extended above

meter / regulator assembly

I Clearance to service regulator

vent outlet

J Clearance to non mechanical

air supply inlet or combustion

air inlet to any other appliance

Canadian Installations

* *

* *

* *

* *

Above a regulator within

3 ft (91 cm) horizontally of

the vertical center line of

the regulator vent outlet to a

maximum vertical distance of

15 ft (4.5 m)

6 in (15 cm) for appliances

≤ 10,000 BTUh (3kW),

12 in (30cm) for appliances

> 10,000 BTUh (3kW) and

< 100,000 BTUh) (30kW),

36 in (91 cm) for appliances

> 100,000 BTUh (30kW)

1

US Installations

*

6 in (15 cm) for appliances

≤ 10,000 BTUh (3kW),

9 in (23 cm) for appliances

>10,000 BTUh (3kW) and

≤ 50,000 BTUh) (15kW),

12 in (30 cm) for appliances

> 50,000 BTUh (15kW)

2

K Clearance to mechanical air

supply inlet

L Clearance above paved

sidewalk or paved driveway

located on public property

M Clearance under veranda,

porch deck or balcony

Table 4.2: Direct Vent Terminal Clearances

* For clearances not specied in ANSI Z223.1/NFPA 54 or CSA B149.1, one of the following shall be indicated:

A) a minimum clearance value determined by testing in accordance with Clause 5.21, Draft hoods, or

B) a reference to the following footnote:

“Clearance in accordance with local installation codes and the requirements of the gas supplier.”

+ A vent shall not terminate directly above or sidewalk or paved driveway that is located between two single

family dwellings and serves both dwellings.

++ Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the oor.

Notes:

1) In accordance with the current CSA B149.1, Natural Gas and Propane Installation Code

2) In accordance with the current ANSI Z223.1/ NFPA 54, National Fuel Gas Code

6 ft (1.83 m)

7 ft (2.13 m)

12 in (30 cm)

+

++

3 ft (91 cm) above if within

10 ft (3 m) horizontally

*

*

25

Glow Brand C95 & C140

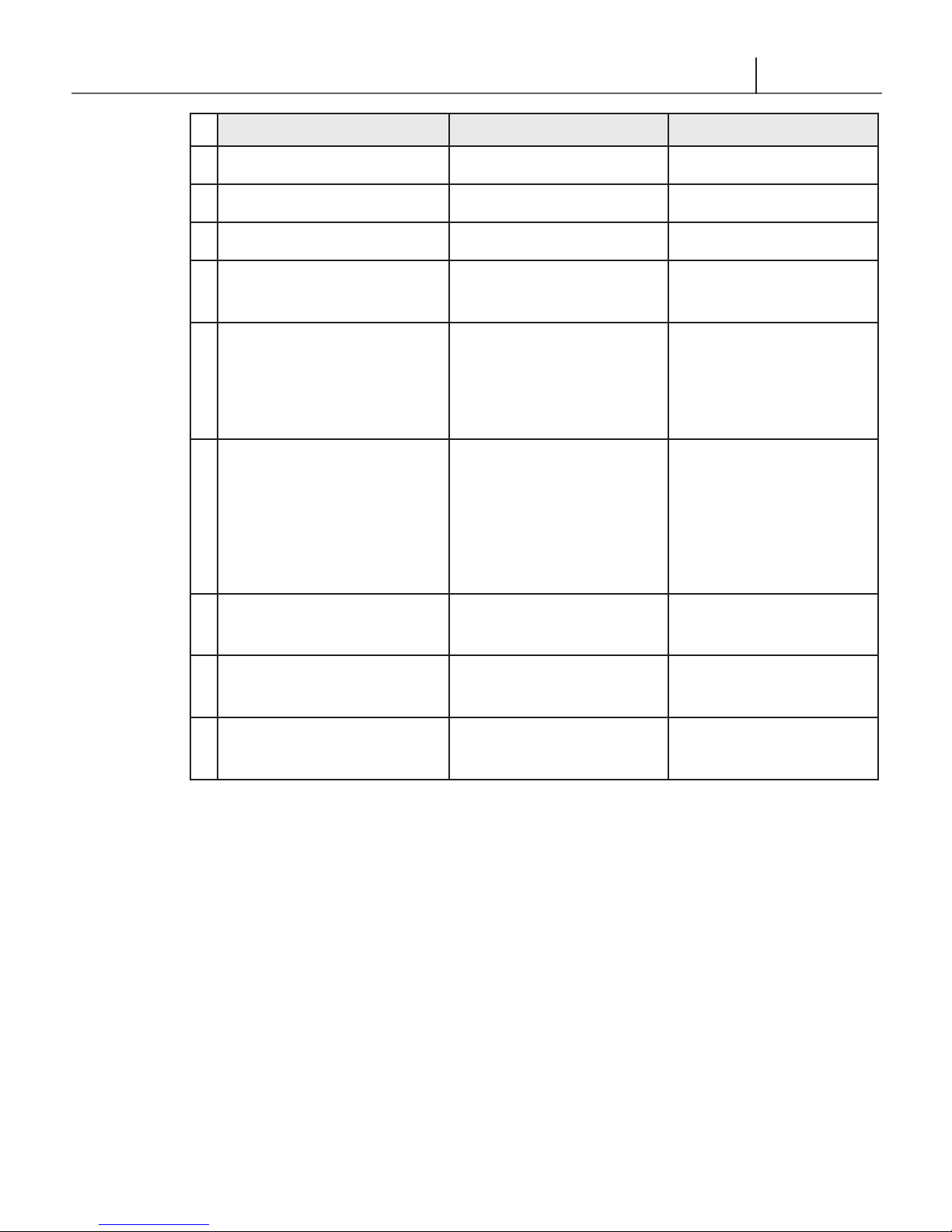

MINIMU

M

24" APART

IN

ANY

DESIRE

D

POSITION

ON

THE

ROOF

1/2" x 1/2" GALVANIZE

D

SCREEN

(SUPPLIE

D BY

MANUFACTURER)

IN

END

OF 45° ELBOW

(OPTIO

NAL)

OPTIONAL

COUPLING

OR 45°

ELBOW

WITH

OPTIO

NAL 1/2" x

1/2" GALVANIZED

SCREEN

(SUPPLIED

BY

MANUFACTURER)

INTO EXHAUST

END

24" (61 cm)

FLASHING

EXHAUST

PVC

OR

CPVC

SUPPORT

INTAKE

ABS/DWV

PVC/

OR

CPVC

Installation & Operating Instructions

Installation & Operating Instructions

4.4.2 Venting Materials

Vertical Vent Termination-PVC/CPVC Material Only 2” or 3”

Vertical Intake ABS/DWV /PVC or CPVC Material 2” or 3”

12" (18" CANADA)

ABOVE HIGHEST EXPECTED

SNOW LEVEL

THE AIR INLET AND EXHAUST PIPE CAN BE LOCATED

*

IN ANY DESIRED POSITION ON THE ROOF, BUT MUST

ALWAYS BE MINIMUM 24" APART.

A PROPER FLASHING SHOULD BE USED TO SEAL THE

PIPE WHERE IT EXITS THE ROOF.

SLOPE VENT

UPWARDS

TO DRAIN & DISPOSE OF

CONDENSATE

ACCORDING TO LOCAL

CODES

HANGER

STRAP

PVC

ADAPTER

THE VENT SYSTEM MUST TERMINATE SO THAT THE

PROPER CLEARANCES ARE MAINTAINED AS CITED IN

LOCAL CODES OR THE CURRENT EDITION OF THE

NATURAL GAS AND PROPANE INSTALLATION CODE

(CAN/CSA-B-149.1) AND ANSI Z223.1/NFPA54.

PROVIDE SUPPORT FOR ALL PIPE PROTRUDING

THROUGH THE ROOF. ALL PIPING SHOULD BE

SECURED. THE VENT SYSTEM SHOULD BE

SUPPORTED EVERY 5 FEET (1.5m) OF VERTICAL RUN

AND EVERY 5 FEET (1.0m) OF HORIZONTAL RUN. ALL

PIPING AND FITTINGS MUST B

PROCEDURES AS DESCRIBED UNDER VENT

PREPARATION.

WHEN USING A HORIZONTAL SECTION, SLOPE THE

HORIZONTAL VENT 1/4" UPWARDS TOWARDS

TERMINATION

TOWARDS THE

EXHAUST VENT PIPE THROUGH AN UNHEATED

MUST BE INSULATED AS PER LOCAL CODES AND

AUTHORITIES.

ALL VERTICAL EXHAUST VENTING MUST HAVE AN

*

ADDITIONAL CONDENSATE DRAIN. ALL FITTING MUST

BE ULC S636 APPROVED.

FOR EVERY 12" (30 cm) (2% SLOPE)

CONDENSATE

E JOINED BY THE PROPER

DRAIN.

SPACE

26

Glow Brand C95 & C140

Venting

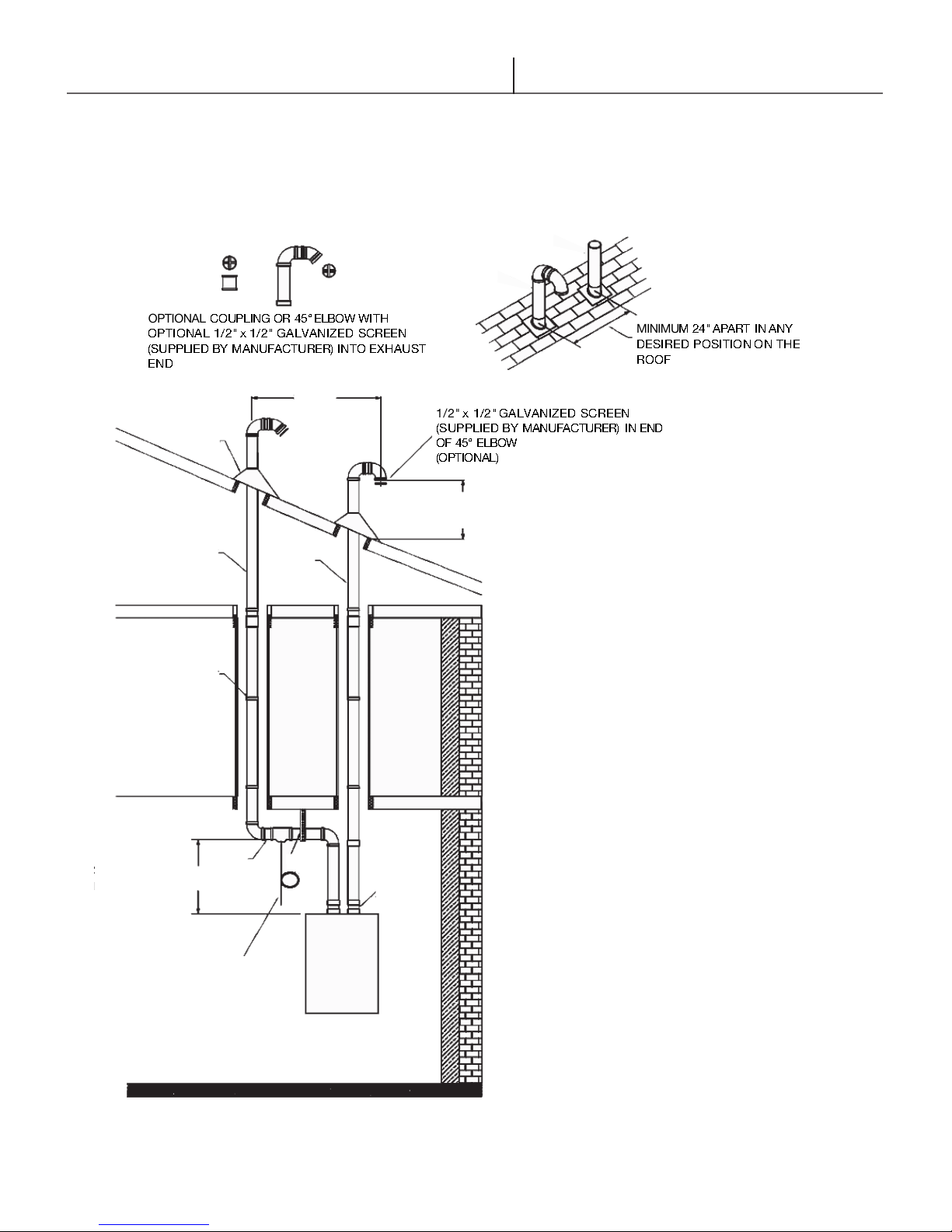

4.4.3 Horizontal Vent Termination

Horizontal Vent Termination-PVC/CPVC Material Only 2” OR 3”

Horizontal Intake ABS/DWV or PVC/CPVC Material 2” OR 3”

EXHAUST PVC/CPVC

OPTIONAL COUPLING

A REDUCER MAY BE USED ON THE

VENT TERMINATION TO INCREASE

THE VELOCITIES OF THE EXITING

GASES AWAY FROM THE INTAKE

THE EXHAUST VENT FITTED WITH

THE REDUCER MAY BY POSITIONED

ABOVE OR BESIDE THE INTAKE PIPE

REDUCER

ABS OR

PVC

MIN. 6” (15 CM)

INSERT 1/2” x 1/2” GALVANIZED SCREEN (SUPPLIED BY

MANUFACTURER) IN END OF 90ELBOW (OPTIONAL).

INTAKE VENT PIPING TO BE SLOPED (DOWN) TOWARD

HEATER TO PREVENT WATER FROM COLLECTING

MIN. 10” (25 CM)

MIN 10"

12” (30cm) ABOVE GRADE

OR EXPECTED SNOW FALL

1/2” x 1/2” GALVANIZED SCREEN

(SUPPLIED BY MANUFACTURER)

INTO THE EXHAUST END (OPTIONAL)

EXHAUST

INTAKE

WINDOW

12” (30cm) ABOVE GRADE

OR EXPECTED SNOW FALL

MIN. 6" (15 cm) CENTER TO CENTER

OUTSIDE WALL

OPTIONAL

LOW PROFILE SIDE WALL

TERMINATION KIT 2” OR 3”

MUST BE ULC S636 APPROVED

EXHAUST

INTAKE

OPTIONAL

SCREEN INTO

90°ELBOW END

OUTSIDE WALL

WINDOW

MIN. 8" (20 cm)

MAX. 24" (60 cm)

12” (30 cm) ABOVE GRADE

OR EXPECTED SNOW FALL

27

Glow Brand C95 & C140

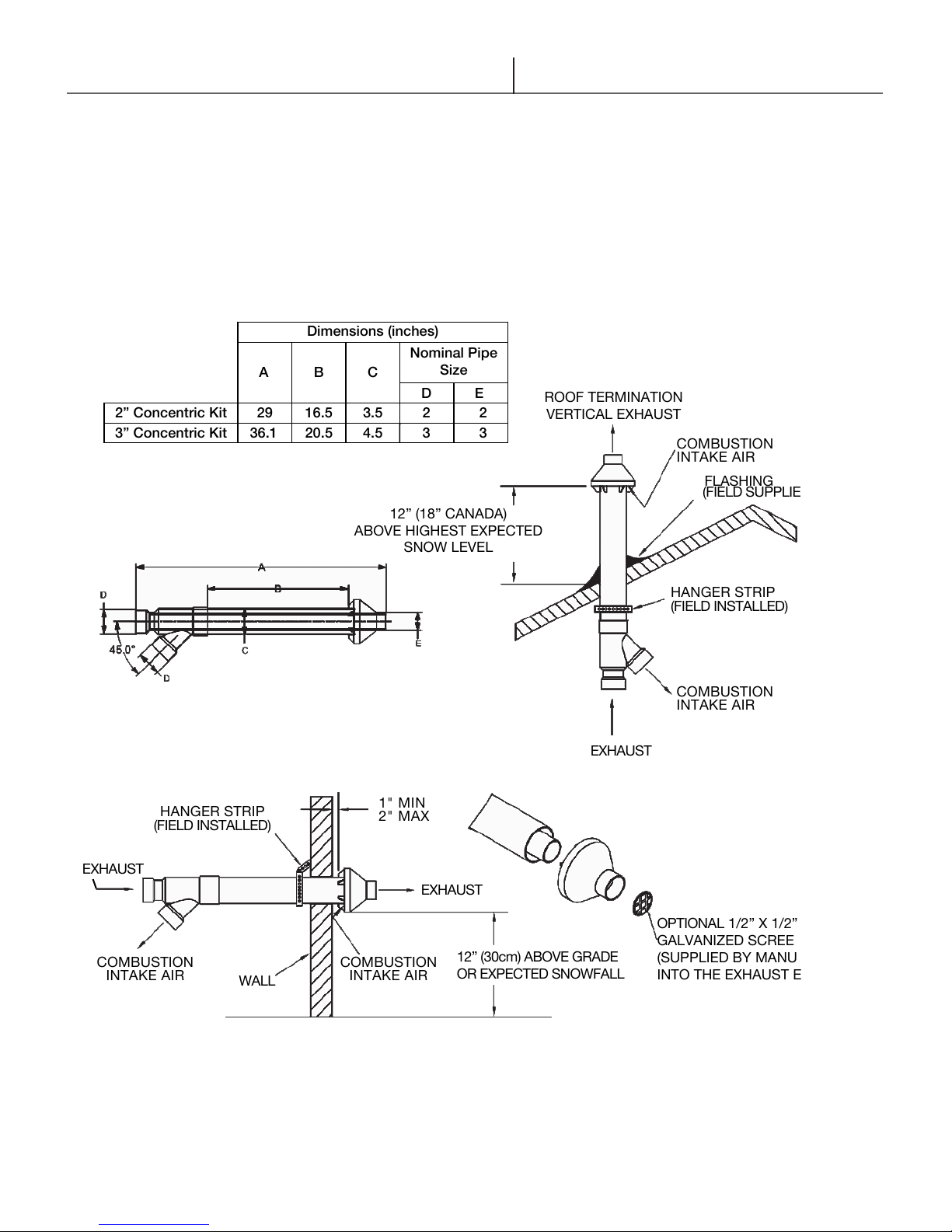

A

2” Concentric Kit 29 16.5 3.5 2 2

3” Concentric Kit

36.1 20.5 4.5 3 3

Installation & Operating Instructions

Installation & Operating Instructions

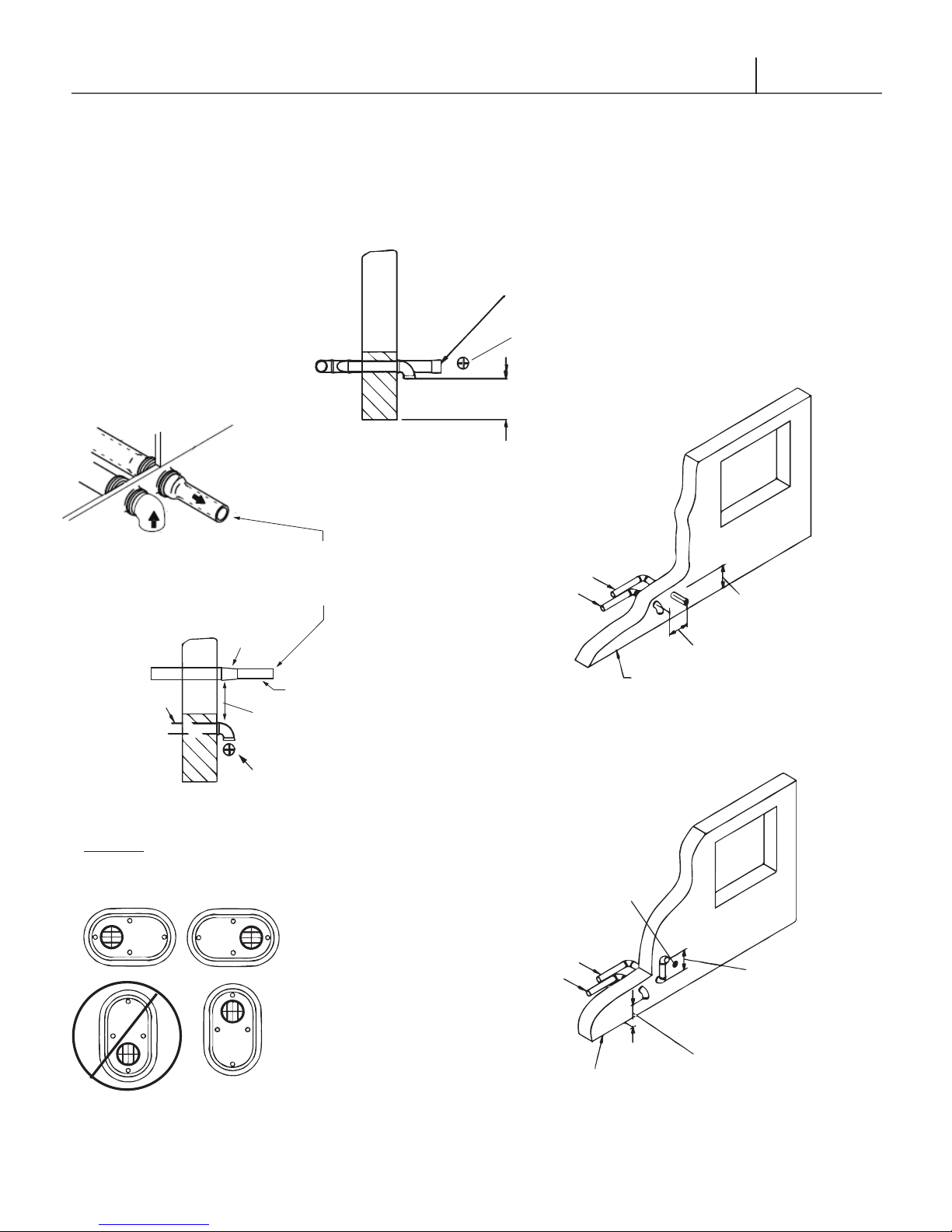

4.4.4 Concentric Venting Materials

Concentric Vent Termination - 2” or 3” PVC/CPVC

Dimensions (inches)

Nominal Pipe

B C

12” (18” CANADA)

ABOVE HIGHEST EXPECTED

Size

D E

SNOW LEVEL

ROOF TERMINATION

VERTICAL EXHAUST

COMBUSTION

INTAKE AIR

FLASHING

(FIELD SUPPLIED)

EXHAUST

COMBUSTION

INTAKE AIR

HANGER STRIP

(FIELD INSTALLED)

WALL

1" MIN

2" MAX

EXHAUST

COMBUSTION

INTAKE AIR

EXHAUST

12” (30cm) ABOVE GRADE

OR EXPECTED SNOWFALL

HANGER STRIP

(FIELD INSTALLED)

COMBUSTION

INTAKE AIR

OPTIONAL 1/2” X 1/2”

GALVANIZED SCREEN

(SUPPLIED BY MANUFACTURER)

INTO THE EXHAUST END

NOTE: USE ONLY ULC S636 APPROVED CONCENTRIC VENT TERMINATION - 2” or 3” PVC

28

Glow Brand C95 & C140

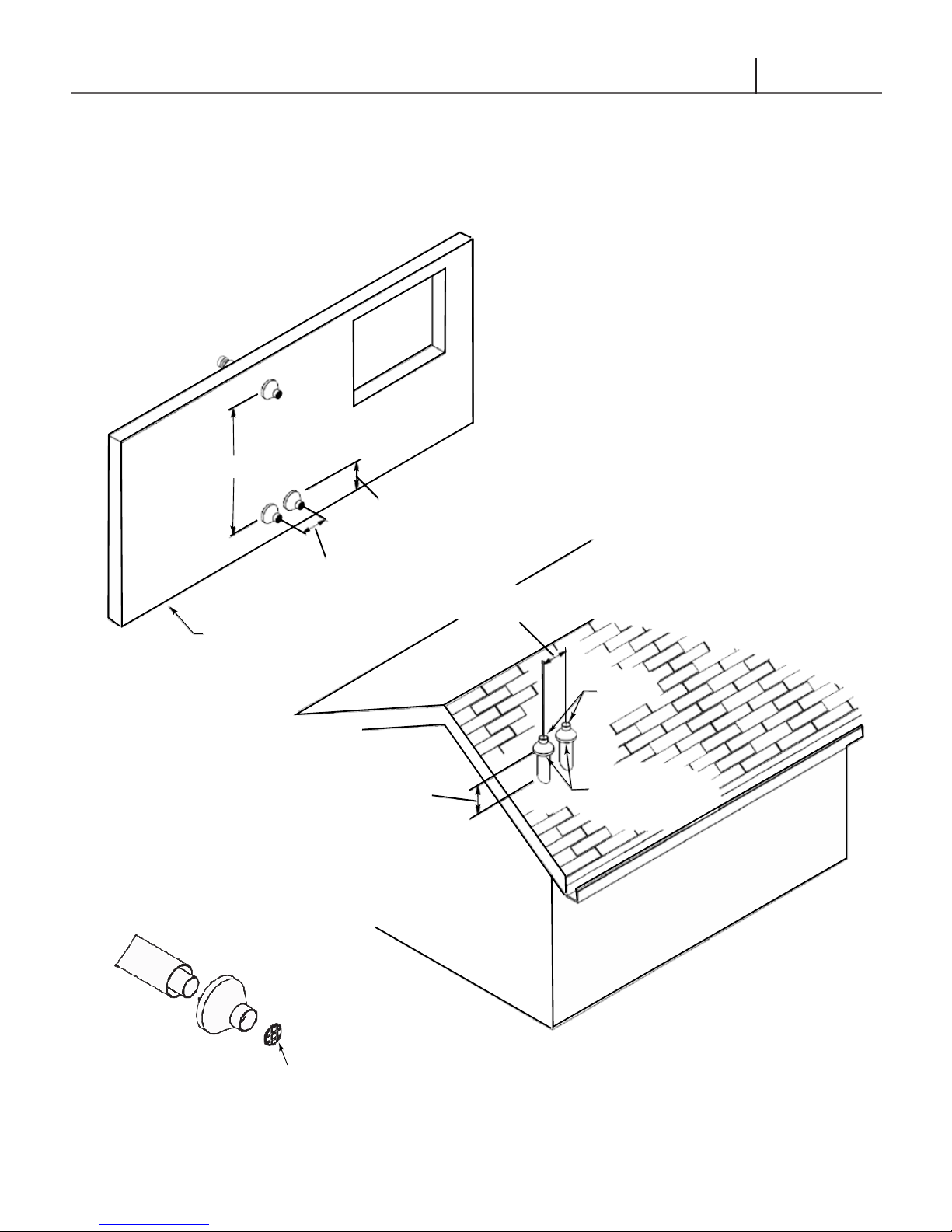

48" MIN.

Venting

4.4.5 Concentric Venting Materials

Concentric Vent Termination - 2” or 3” PVC/CPVC

WINDOW

12" (30 CM) ABOVE

HIGHEST EXPECTED

SNOW LEVEL

MIN 12"

CENTER TO CENTER

OUTSIDE WALL

12" (18" CANADA) ABOVE

HIGHEST EXPECTED

SNOW LEVEL

12" MINIMUM

EXHAUST

COMBUSTION

INTAKE AIR

OPTIONAL 1/2" x 1/2" GALVANIZED SCREEN

(SUPPLIED BY MANUFACTURER)

INTO THE EXHAUST END

29

Loading...

Loading...