Selecting a

two stage, multi-stage

vaneaxial

tubeaxial

propeller

B A

∆P

CFM

0

1 2 3 4

B

A

∆P

CFM

Typical Axial Fan Performance

A1

C

Cooling Fan

As an assistance in selecting the proper

cooling device for your electronic system,

it might be useful to understand the

performance differences among the

various types of axial flow devices.

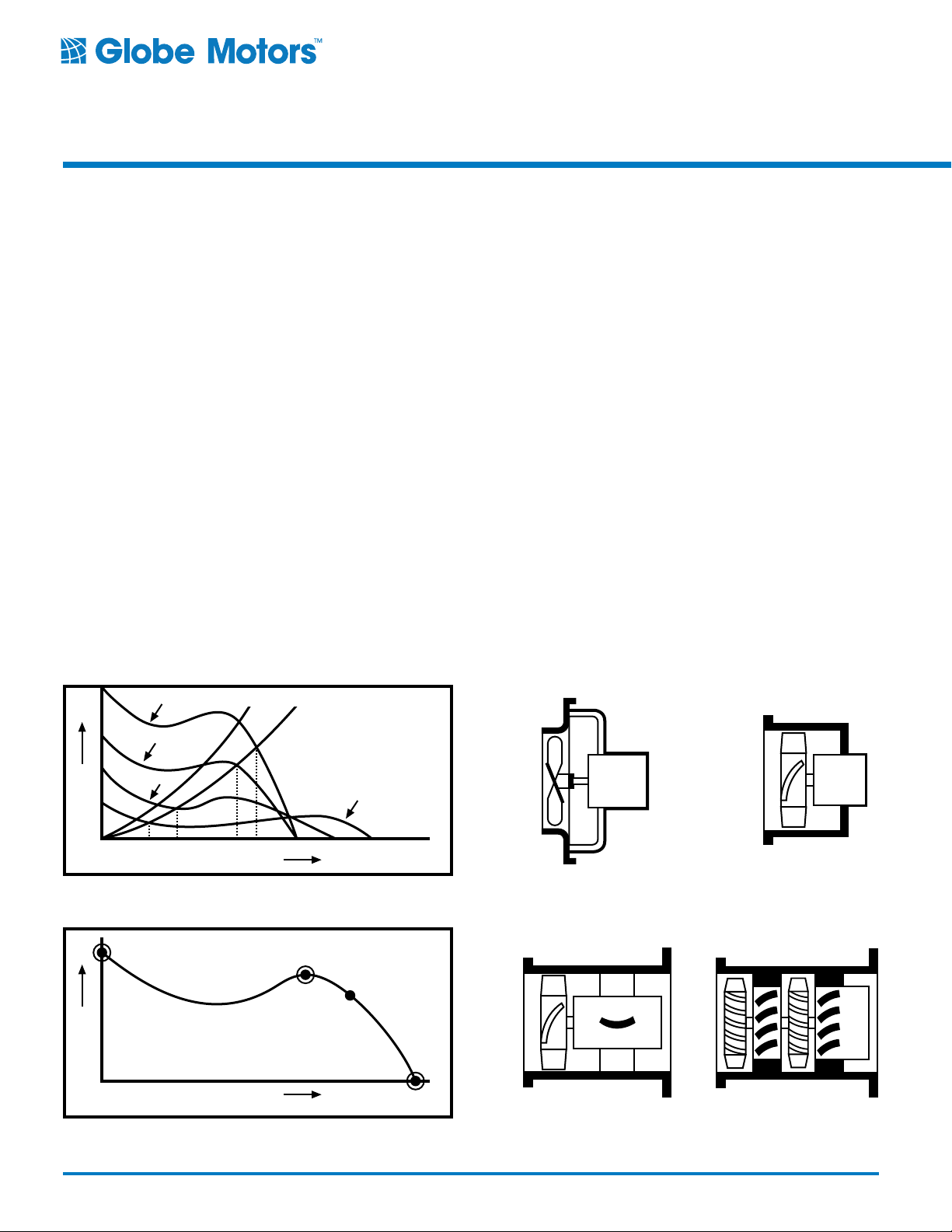

Figure 1 compares the performance

curves of the four types, all of the same

diameter and operating at the same speed.

Device Characteristics

Axial Flow Devices — propeller fans,

tubeaxial fans, vaneaxial fans, and

multi-stage axial blowers have essentially

the same performance characteristics.

All are distinguished by the fact that

pressure is proportional to lift produced by

the rotating airfoils of the impeller.

As for any airfoil, there is a point (B on

Figure 2) beyond which the impeller

stalls, that is, the pressure (lift) decreases

with decreasing flow. This explains the

dip in the performance curves of each

of these types. It is virtually impossible

to operate satisfactorily in this region, B

to C. Flow pulsations, increased audible

noise, and reduced efficiency occur. Stable

performance and maximum efficiency are

in the A to B range. The optimal operating

range is between A1 and B. This is where

the fan operates best and longest life is to

be expected.

Typical Axial Fan Performance

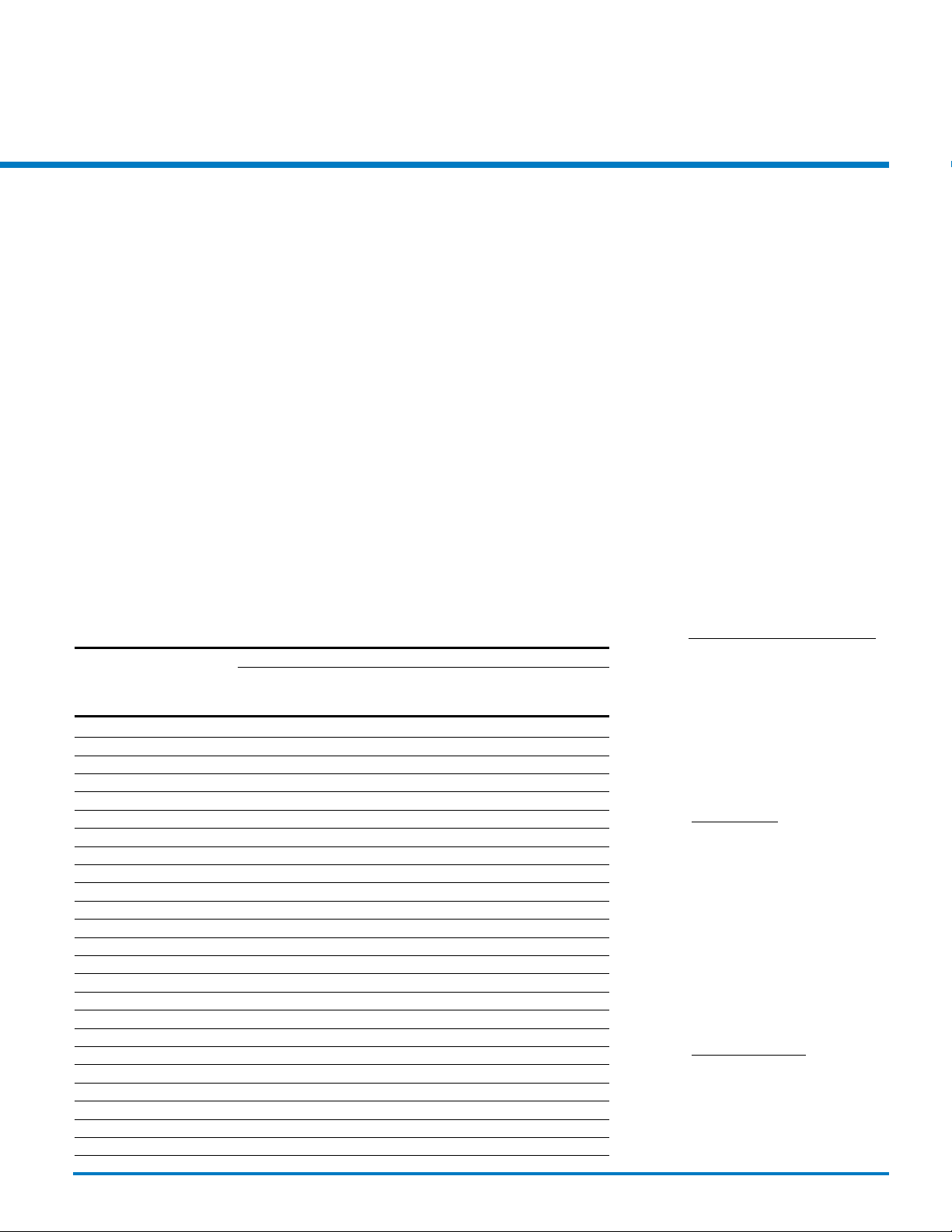

Propeller Fan — consists of a propeller

rotating within a mounting ring or orifice

and includes provision for motor supports.

These are sometimes supplied without the

mounting ring, in which case the customer

mounting panel serves as the fan orifice.

Propeller fans are the simplest, most

economical, and least efficient axial

flow devices.

Tubeaxial Fan — consists of an impeller

rotating within a full cylindrical housing,

which also provides motor support struts.

The term tubeaxial, as presently used by

manufacturers, implies more efficient airfoil

blades, closer tip clearance, and generally

cleaner flow patterns than the propeller fan.

This results in greater pressure capability

and higher efficiency.

Vaneaxial Blower — is the sophisticated

brother of the tubeaxial, just as the tubeaxial

represents an improvement over the

propeller fan. Guide vanes are inclined

on either the inlet or outlet side of the

propeller. The vanes reduce the rotational

or “whirl” pattern of the air stream which

results in:

1. Higher pressure before stall

2. Increased efficiency

Multi-Stage Axial Blower — is essentially

two or more vaneaxial fans mounted on

a common shaft and housing in series.

The first vaneaxial fan, or stage, feeds the

second stage with axial flow at the design

point. Static pressure available is roughly

the product of the number of stages and

stall pressure of a single stage. Multi-stage

units are capable of the highest pressures

attainable by an axial device for a given size

and speed. They are necessarily somewhat

heavier and more expensive than the other

axial units.

For most industrial applications, a tubeaxial

fan provides the best mix of cooling

performance, low noise level, and long,

reliable operation. The fans in this catalog

are tubeaxial. On the following pages, we

provide a simplified approach to selecting

the proper Globe tubeaxial cooling fan for

your system. Globe Motors will provide

technical assistance in solving your

cooling fan requirements that exceed

the capabilities of these tubeaxial fans.

Figure 1.

Figure 2.

6

http://www.globemotors.com/select.pdf

Tubeaxial Fan

Propeller Fan

Vaneaxial Blower

Specifications subject to change without notice.

Multi-Stage Axial Blower

© 2002 Globe Motors

Considerations for the

Cooling Fan Location

A key criterion for fan selection is the

location of the fan in your system. This

has a very important impact on airflow

effectiveness and cooling efficiency.

Globe provides you flexibility with our use

of precision ball bearings. They allow you

to mount our fans in either the horizontal of

vertical position (or somewhere in between)

without negatively impacting bearing wear

and, therefore, life and noise.

Without trying to design your system layout,

here are some general guidelines which we

hope you find helpful:

1. Keep the airflow path as unobstructed

as possible. The air should flow across

components and circuit boards and not

into them. The air entry and exit points

should especially be kept free of

interference to airflow.

2. There are two ways to treat your greatest

sources of heat dissipation.

In a tight cabinet, placing this heat

source near the air exit will have the

least heating effect on the air cooling

your lower power areas. If you have

a large cabinet, like an office copier,

whose interior is relatively uncluttered

but has a significant hot spot, placing

the hot component by the air inlet will

ensure the best cooling. As the air mixes

in the large open cabinet, it will cool

somewhat before exiting past the other

components.

3. To utilize vertical airflow through your

cabinet, place the cooling fan to assist

the natural convection airflow that

moves upward.

4. If you intend to use a filter or an RFI

screen, you must consider the additional

resistance to airflow that these

items create.

By carefully considering your cooling fan

location, you can possibly avoid requiring a

larger fan which would increase your noise

level and power dissipation.

Table 1

Typical Airflow Requirements by End Use Equipment

CFM

0 26 51 76 101 126

to to to to to and

25 50 75 100 125 Up

Office Copiers X X X X X X

Power Supplies X X X X

Micro Computers X X X X

Receivers X X

Terminals X X

Audio Amps X

Pos Terminals X X X

Office Equipment X X X

Recording Equipment X X X

P.A. Systems X X

TV Cameras & Monitors X X

Instrumentation X X X

Medical Equipment X X X

Mini Computers X X

Telecom Equipment X X

Lab Equipment X X X

Computer Peripherals X X X X X

Mainframe Computers X X X

Disc Drives X

Industrial Controls X

Computer Consoles X

Relay Racks X

Instrument Cabinets X

Transmitter Cabinets X

How to Select a Globe Cooling Fan

To aid you in determining your cooling fan

requirements, we would like to provide a

simplified approach to fan selection.

Table 1 provides a general starting point for

typical airflow requirements of industrial

equipment. The following discussion

will enable the user to apply a clear

understanding of airflow in selecting a

suitable unit.

The Essentials

To properly select a particular fan for

a specific application, the detailed

requirements must be known. These

include the normal motor specifications

and those peculiar to air-moving devices,

your system's power dissipation, your

system's resistance to airflow, and the

allowable temperature of your system's

internal air.

Cooling Air Required

The values established by the method

described below tend to be conservative.

For example, the method treats laminar

airflow only. When turbulent flow conditions

exist, the cooling is improved further.

CFM =

watts dissipated x a constant

allowable temperature minus

inlet temperature °F

Standard Air Conditions — Air density,

for many applications, is taken at standard

conditions (70°F at 29.92" of mercury).

The constant 3.16 is a function of the

specific heat of air at these standard

conditions. The formula for standard air

conditions is:

Equation 1.

CFM = x 3.16

watts

Temp. Rise °F

Variable Density — When standard air

conditions cannot be assumed, you may

use the constant 0.1784 as a function

of the specific heat of air near sea level.

Change in the specific heat due to

pressure and temperature changes has

not been considered, and in most cases

it is negligible. However, you might want

to consider high altitude usage, such as in

Denver. To calculate CFM for these nonstandard air conditions, use the formula:

Equation 2.

CFM = x 0.1784

watts x T°R

Temp. Rise °F x Pb

watts = watts dissipated

T°R = Temperature in °Rankine

temperature = 459.6 + °F

Pb = barometric pressure in inches

of mercury

© 2002 Globe Motors

Specifications subject to change without notice.

http://www.globemotors.com/select.pdf

7

Loading...

Loading...