Page 1

4077 Airpark Dr. Standish, MI 48658 • 989-846-4583 • www.globesprinkler.com

Technical Support • 989-414-2600 • techservice@globesprinkler.com

MODEL RCW DRY SYSTEM VALVE

GENERAL DESCRIPTION

The Globe Model RCW* dry valve is a hydraulically operated external resetting differential latching style valve. The

Model RCW dry valve is used as an automatic water control

valve in dry applications. The Model RCW dry valve serves

as the primary water control valve installed in the water

supply to a dry sprinkler system incorporating automatic

(closed) sprinklers with compressed air or nitrogen within

the system piping.

Setting of the Model RCW dry valve requires water pressure

in the pressure chamber being maintained on the plunger

rod. The pressure on the plunger rod forces the lever arm/

roller assembly against the clapper which in turn keeps

the supply water from entering the sprinkler system piping. Water pressure is provided to the pressure chamber

through a connection to the main water supply at a point

upstream of the system main control valve. This connection

also supplies water pressure up to the dry pilot actuator.

The dry pilot actuator is held closed when in the normal set

condition by air pressure in the system piping. When system

air pressure is relieved via one or more operated sprinklers,

the dry pilot actuator will open, allowing the pressurized

water to be evacuated from the pressure chamber.

In the standby condition, the valve is normally closed and

will automatically activate (trip) upon the activation of an au-

tomatic sprinkler, as a result of a re condition. The RCW

valve may also be operated by means of a manual release,

which is provided in the trim, to override the normal activation sequence described above.

When heat from a re opens an automatic sprinkler, water

pressure in the pressure chamber decays resulting in the

movement of the push rod assembly, releasing the lever

arm/roller assembly from the clapper. The system water

supply pressure forces the valve clapper open resulting in

water ow into the system piping. Upon system activation,

re alarm signaling is provided by means of owing water

through the alarm port/intermediate chamber and associ-

ated alarm line trim. The ow of water activates a pressure

switch which in turn noties local alarms and/or an alarm

signaling monitoring service. After the main control valve

has been shut, the system drained, and any operated

sprinklers replaced, the RCW dry valve is easily set/reset by

means of pushing the reset knob. The system is now ready

for the introduction of compressed air back into the system

piping.

If the speed of operation of the dry valve needs to be increased, an optional accelerator can be utilized to decrease

the trip time of the valve from the operation of a sprinkler or

the inspectors test connection.

MODEL RCW DRY SYSTEM VALVE

TECHNICAL DATA

Approvals

• cULus

• FM

Maximum System Working Pressure

• 300 psi (20.6 Bar)

End Connections

• Groove x Groove

Materials of Construction

• See Technical Datasheet H-1 for materials of

construction for the Model RCW Valve

*Patents Pending

MAR 2018 GFV-305 (Formerly H-3) Page 1 of 11

Page 2

MODEL RCW DRY SYSTEM

The dry system trim is one optional trim arrangement for

the Globe Model RCW valve. This arrangement is typically

utilized when the system is subject to areas exposed to

freezing or close to freezing temperatures. With this conguration, the detection system consists of automatic sprinklers spaced throughout the protection area. System air

pressure is used to ensure the integrity of the system piping

and used as the activation method for the valve.

Water pressure is maintained in the valve pressure chamber

up to the dry pilot actuator through a restricted connection

from the main water supply which is taken upstream of the

system main control valve (The pressure chamber supply

valve must remain in the open position at all times when the

system is in service). The dry pilot actuator is normally held

in the closed position by the system air pressure supplied

through the automatic air or nitrogen maintenance device.

When an automatic sprinkler operates, the air ow rate

through the open sprinkler is at a ow rate greater than that

which can be supplied through the automatic air or nitrogen

maintenance device. This causes a pressure drop in the

system and the upper chamber of the dry pilot actuator. An

optional accelerator can increase the rate at which the air

decays on the dry pilot actuator, if a faster time to trip the

Model RCW valve is required.

Once the pressure in the upper chamber of the dry pilot

actuator drops sufciently, the upper chamber can no longer hold the diaphragm in the closed position. The dry pilot

actuator opens and allows water to ow from the pressure

chamber to the drain at a ow rate greater than that which

can be supplied through the restriction in the pressure

chamber supply line. The opening of the dry pilot actuator

results in a drop in pressure in the pressure chamber and

the Model RCW valve operates (trips) allowing water to ow

into the system piping. The automatic actuation of the feature of the valve can be bypassed by manually rotating the

handle on the "Manual Control/ Emergency Release" valve

located on the Model RCW trim to activate the Model RCW

valve.

Note:

See recommended system air/nitrogen pressure and expected trip range below

for the Model GDPA. More detailed information can be found about the Dry

Pilot Actuator in Technical Data Sheet GFV550.

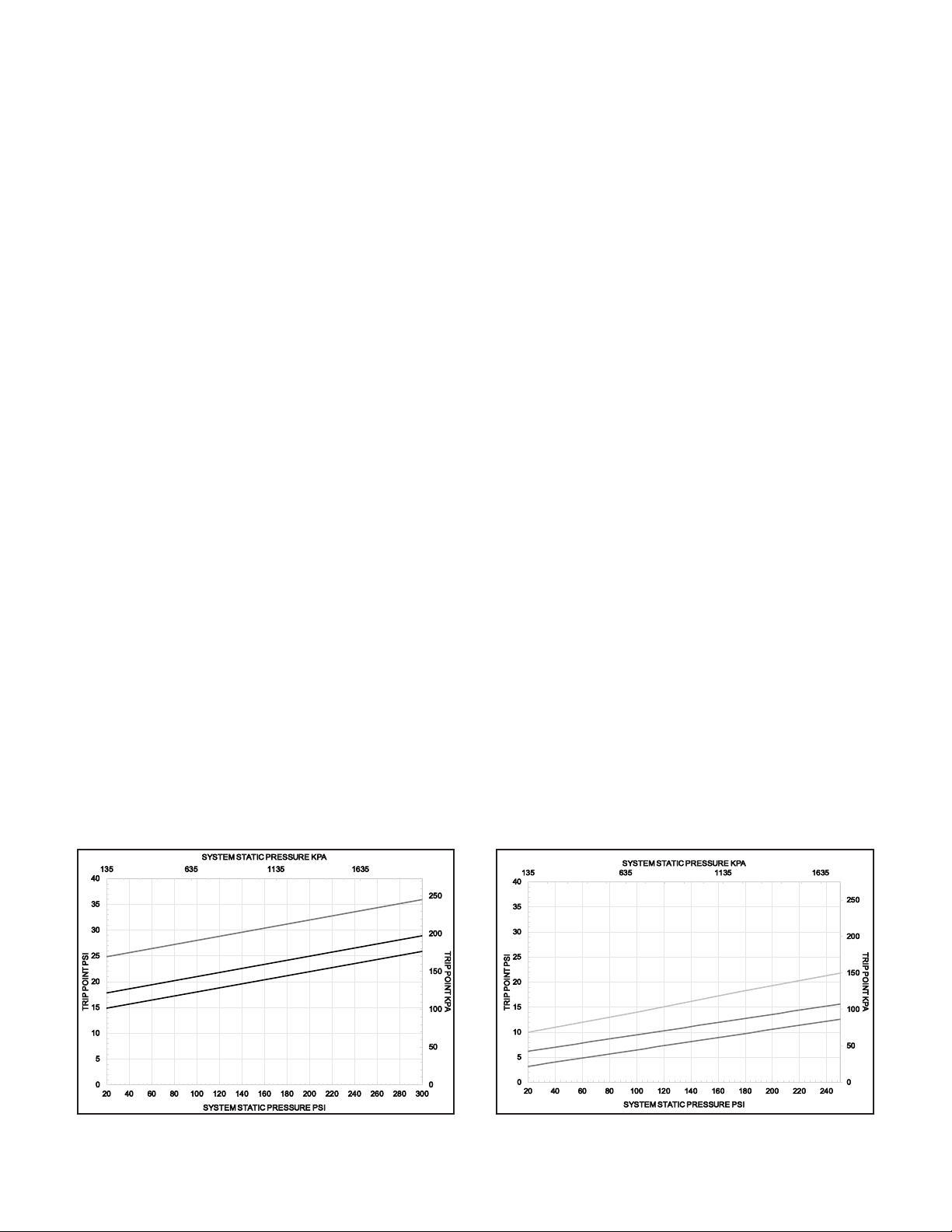

GDPA VS GDPA-LP

When choosing the dry pilot actuator for your system

there are many factors which inuence the uid delivery time. These factors range from system geometry,

riser location, sprinkler orice size, supply pressure,

pump ramping time and more. In certain systems,

higher system air pressure can be advantageous over

lower system air pressure and the opposite can also

be true. Some things to consider when choosing the

GDPA vs the GDPA-LP are discussed below.

The initial air pressure in a system may vary. For example in one system the initial air pressure may be set

for 15 psi (1 Bar) and 45 psi (3.1 Bar) for the other. The

system air pressure will decay at a faster rate with the

higher initial system pressure. For a xed pressure

drop (i.e. 5 psi drop) will be reached more quickly with

the higher initial air pressure than lower initial air pressure.

Unfortunately uid delivery time is not just dependent

on tripping the control valve but also dependent on

the uid moving through the system. As the water lls

the system piping it can create a high pressure pocket

of air at the inspectors test connection. This higher

air pressure can slow the progress of the water progressing towards the inspectors test connection. This

phenomenon typically happens with smaller K-factor

sprinklers. This scenario may lend itself to choosing

to utilize lower system air pressure and the GDPA-LP

actuator.

In other circumstances, systems are center fed, mean-

ing roughly half of the volume of piping is on one side

of the riser and half on the other. In these scenarios,

higher system air pressure can be benecial to system

delivery time as the higher air pressure will actually impede or stop the propagation of water in the direction

opposite the inspectors test connection (ITC) and force

the majority of the available water ow towards the ITC.

It would be impossible to run through every scenario

possible but there are a few generalities which can

be used as guidance. Generally end fed systems will

achieve faster uid delivery times with lower air pressure. Generally center fed systems with moderate to

better than moderate water supplies will have faster

Recommended Air/Nitrogen Pressure

GDPA Trip Range

Recommended Air/Nitrogen Pressure

GDPA-LP Trip Range

FIGURE 1:MODEL GDPA DRY PILOT

TRIP RANGE

MAR 2018 GFV-305 (Formerly H-3) Page 2 of 11

FIGURE 2:MODEL GDPA-LP DRY

PILOT TRIP RANGE

Page 3

uid delivery times with higher air pressure. This is

meant to be general guidance, and should be in no

way taken as a guarantee of uid delivery time. All

systems and congurations are different and there are

always exceptions to the rule.

GDPA-LP

The Model GDPA-LP is only recommended for system

supply pressures up to 250 psi (17.2 Bar). The GDPA-

LP is factory painted green to identify the low pressure

version. The Model GDPA is the standard pressure actuator, while the GDPA-LP can be utilized for low system air pressures. The types of systems where the

use of the GDPA-LP has the potential to be benecial

to system performance are: Dry Systems, and Double

Interlock Electric/Pneumatic Systems. There is little to

no advantage to utilizing the GDPA-LP in Single Interlock Dry Pilot, or Deluge Dry Pilot Systems, as the pilot

lines generally have a very small volume and the valve

trips very quickly no matter the pilot line pressure.

If you have any questions on the application of the

GDPA vs the GDPA-LP contact Globe Sprinkler Technical Services.

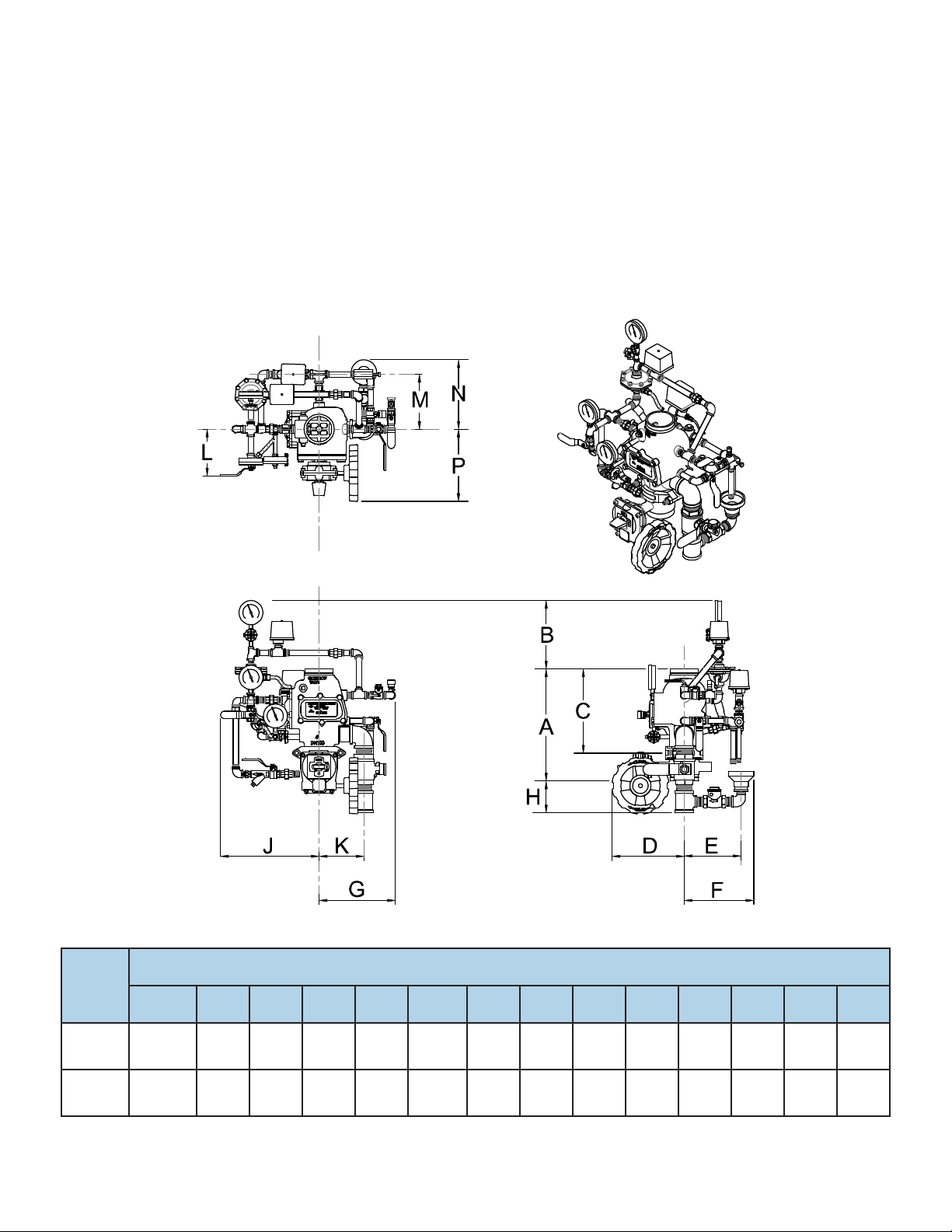

Valve

Size

A

END TO END

TOP VIEW

FRONT VIEW RIGHT SIDE

Nominal Installation Dimensions Inches (mm)

B C D E F G H J K L M N P

4"

(DN100)

6"

(DN150)

17.6

(447.7)

19.75

(501.6)

11

(279)

10

(254)

13.25

(336.5)

14.5

(368.3)

12

(304)

13

(330)

9.0

(228.6)

9.0

(228.6)

11.0

(279.4)

12

(304)

12.0

(304.8)5 (127)

13

(330)

4.4

(111 )

16

(406)

16

(406)

7.125

(181)

8.5

(216)

8

(203)

8

(203)

8.625

(219)

9.75

(247.6)

11.0

(279.4)

11.0

(279.4)

12

(304)

13

(330)

FIGURE 3:DRY ACTUATION TRIM DIMENSIONS

MAR 2018 GFV-305 (Formerly H-3) Page 3 of 11

Page 4

2 1

SYSTEM PIPING WITH AUTOMATIC SPRINKLERS

2 1

LOW AIR PRESSURE

SYSTEM

ALARM SWITCH

PRESSURE

GAUGE

DRY PILOT

DRAIN

ACTUATOR

MANUAL CONTROL/

EMERGENCY

RELEASE STATION

(NORMALLY

CLOSED)

MAIN DRAIN VALVE

(NORMALLY CLOSED)

PRESSURE CHAMBER

SUPPLY CONTROL VALVE

(NORMALLY OPEN)

PRESSURE

CHAMBER

RESTRICTION

GAUGE

MAIN

CONTROL VALVE

(NORMALLY OPEN)

WATER

SUPPLY

AIR SUPPLY

CONTOL VALVE

(NORMALLY OPEN)

WATERFLOW

ALARM SWITCH

ALARM TEST VALVE

(NORMALLY CLOSED)

WATER

SUPPLY

PRESSURE

GAUGE

AUTOMATIC

AIR/NITROGEN

MAINTENANCE

DEVICE

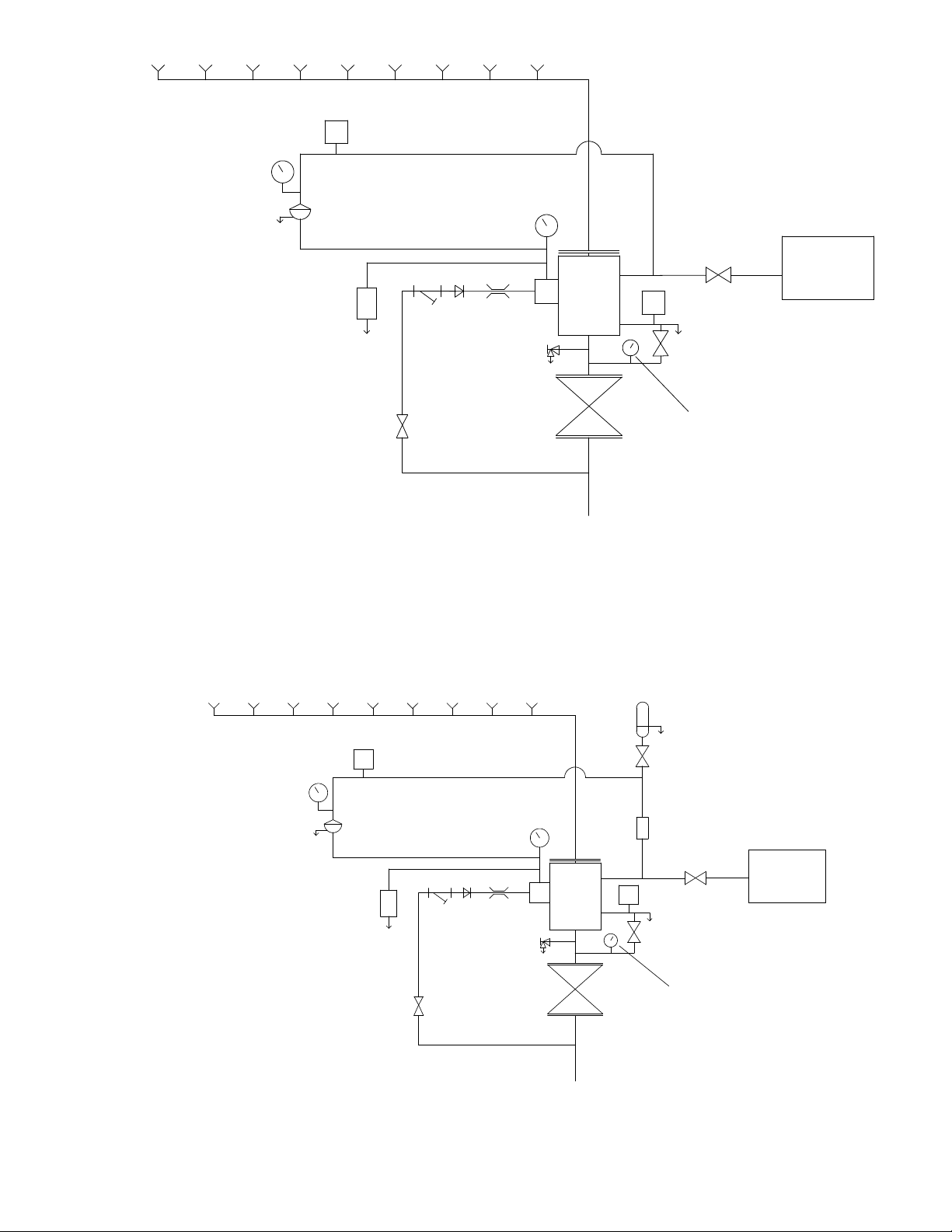

FIGURE 4:DRY SCHEMATIC (NO ACCELERATOR)

SYSTEM PIPING WITH AUTOMATIC SPRINKLERS

LOW AIR PRESSURE

DRY PILOT

ACTUATOR

ALARM SWITCH

PRESSURE

CHAMBER

GAUGE

RESTRICTION

MAIN DRAIN VALVE

(NORMALLY CLOSED)

SYSTEM

PRESSURE

GAUGE

DRAIN

MANUAL CONTROL/

EMERGENCY

RELEASE STATION

(NORMALLY

CLOSED)

PRESSURE CHAMBER

SUPPLY CONTROL VALVE

(NORMALLY OPEN)

ACCELERATOR

ATMOSPHERE

ACCELERATOR

ISOLATION VALVE

(NORMALLY OPEN)

ANTIFLOOD

DEVICE

CONTOL VALVE

(NORMALLY OPEN)

WATERFLOW

ALARM SWITCH

ALARM TEST VALVE

(NORMALLY CLOSED)

MAIN

CONTROL VALVE

(NORMALLY OPEN)

MODEL C

TO

AIR SUPPLY

AUTOMATIC

AIR/NITROGEN

MAINTENANCE

DEVICE

WATER

SUPPLY

PRESSURE

GAUGE

WATER

SUPPLY

FIGURE 5:DRY SCHEMATIC WITH ACCELERATOR

MAR 2018 GFV-305 (Formerly H-3) Page 4 of 11

Page 5

FIGURE 6: 4" RCW DRY TRIM ARRANGEMENT

13

21

4

16

14

5

38

21

7

83

24

47

• NOTE: PREASSEMBLED TRIM WITH BUTTERFLY VALVE SHOWN.

FOR PREASSEMBLED WITHOUT BUTTERFLY VALVE AND NONASSEMBLED TRIM CONFIGURATION, ENSURE PRESSURE CHAMBER

SUPPLY IS CONNECTED FROM BELOW CONTROL VALVE.

TO DRIP

28

56

54

3

17

16

14

26

43

CUP

13

27

15

43

55

25

26

47

TO DRIP

CUP

4

3

20

35

12

41

20

20

4

3

4

45

46

57

44

33

32

11

11

31

29

18

81

20

80

21

22

40

11

A

1

49

23

19

TO DRIP

CUP

8

11

39

REMOVE ITEM 81

IF UTILIZING OPTIONAL

81

4

72

46

50

ACCELERATOR TRIM

47

47

52

4

57

2

50

51

47

B

42

6

79

41

62

TO AIR MAINTENANCE DEVICE

35

47

3

7

34

66

9

52

48

ITEM NO. PART NO. DESCRIPTION QTY. ITEM NO. PART NO. DESCRIPTION QTY.

1 310802-G 2" x 3" GALV. NIPPLE 1 33 311224-G 3/4" x 1/2" GALV. STREET ELBOW 1

2 311208-G 2" GALV. ELBOW 1 34 311801 1" CHECK VALVE (FxF) 1

3 310306-G 1/2" x 4" GALV. NIPPLE 4 35 311314-G 1/2" x 1/2" x 1/4" GALV. TEE 2

4 310301-G 1/2" x 1 1/2" GALV. NIPPLE 6 38 317395 1/2" RESTRICTOR 1

5 310305-G 1/2" x 3 1/2" GALV. NIPPLE 1 39 311404-G 3/4" GALV. UNION 1

6 323300 VELOCITY CHECK VALVE 1 40 310401-G 3/4" x 2" GALV. NIPPLE 1

7 311696-R 1/2" BALL VALVE (MxF) - RED HANDLE 2 41 311794-GR 1/2" BALL VALVE (MxM) - GREEN HANDLE 2

8 311313-G 3/4" x 1/2" x 3/4" GALV. TEE 1 42 310308-G 1/2" x 5" GALV. NIPPLE 1

9 317398 DRIP CUP ASSEMBLY 1 43 311683 1/4" 3-WAY VALVE 2

11 310413-G 3/4" x 1 1/2" GALV. NIPPLE 4 44 1340104 PS-10-2 ALARM SWITCH 1

12 310105-G 1/4" x 3 1/2" GALV. NIPPLE 1 45 1340404 PS-40-2 ALARM SWITCH 1

13 311001-G 1/4" GALV. PLUG 2 46 310304-G 1/2" x 3" GALV. NIPPLE 2

14 300119-D 3 1/2" WATER GAUGE (300PSI) 2 47 311203-G 1/2" GALV. ELBOW 6

15 300120-D 3 1/2" AIR GAUGE (250PSI) 1 48 311207-G 1" GALV. STREET ELBOW 1

16 311210-G 1/2" GALV. STREET ELBOW 2 49 311799-R 2" BALL VALVE (FxF) - RED HANDLE 1

17 300111-G 1/2" GALV. CROSS 1 50 310800-G 2" CLOSE GALV. NIPPLE 2

18 311004-G 3/4" GALV. PLUG 1 51 311338-G 2" x 2" x 1" GALV. TEE 1

19 311786 3/4" CHECK VALVE (MxF) 1 52 310501-G 1" x 2" GALV. NIPPLE 2

20 311403-G 1/2" GALV. UNION 4 54 310302-G 1/2" x 2" GALV. NIPPLE 1

21 311305-G 1/2" x 1/4" x 1/2" GALV. TEE 3 55 310101-G 1/4" x 1 1/2" GALV. NIPPLE 1

22 310161 1/4" TUBE CONNECTOR 1 56 317554 DRY PILOT ACTUATOR 1

23 M-320604 1/4" COPPER TUBE - 57 311303-G 1/2" GALV. TEE 2

24 310346 1/2" ELBOW TUBE CONNECTOR 1 62 317445

1/4" PRESSURE RELIEF VALVE (ADJ. PSI)

FACTORY SET @ 45PSI

1

25 310164 1/2" TUBE CONNECTOR 1 66 310310-G 1/2" x 6" GALV. NIPPLE 1

26 M-320591 1/2" COPPER TUBE - 72 311802 1/2" CHECK VALVE (MxF) 1

27 317397 1/2" Y-STRAINER 1 79 310110-G 1/4" x 6" GALV. NIPPLE 1

28 317396 1/2" SPRING LOADED CHECK VALVE 1 80 310303-G 1/2" x 2 1/2" GALV. NIPPLE 1

29 311794-R 1/2" BALL VALVE (MxM) - RED HANDLE 1 81 310313-G 1/2" x 7 1/2" GALV. NIPPLE 2

31 300112-G 3/4" GALV. CROSS 1 83 310337-G 1/2" x 9 1/2" GALV. NIPPLE 1

32 311212-G 3/4" x 1/2" GALV. REDUCING ELBOW 1

MAR 2018 GFV-305 (Formerly H-3) Page 5 of 11

Page 6

FIGURE 7: 6" RCW DRY TRIM ARRANGEMENT

13

43

55

21

4

56

16

54

14

38

21

82

24

47

• NOTE: PREASSEMBLED TRIM WITH BUTTERFLY VALVE SHOWN.

FOR PREASSEMBLED WITHOUT BUTTERFLY VALVE AND NONASSEMBLED TRIM CONFIGURATION, ENSURE PRESSURE CHAMBER

SUPPLY IS CONNECTED FROM BELOW CONTROL VALVE.

17

5

7

26

TO DRIP

CUP

43

28

13

27

41

47

5

4

16

12

20

15

25

TO DRIP

35

CUP

44

46

57

26

32

68

29

20

42

20

414

5

54

81

20

80

33

11

31

44

21

22

23

40

TO DRIP

19

CUP

8

18

11

39

11

4

4

57

A

46

1

51

42

72

47

47

2

50

49

50

47

B

64

REMOVE ITEM 64

IF UTILIZING OPTIONAL

ACCELERATOR TRIM

6

79

41

7

3

52

34

52

62

TO AIR MAINTENANCE DEVICE

35

47

66

9

48

ITEM NO. PART NO. DESCRIPTION QTY. ITEM NO. PART NO. DESCRIPTION QTY.

1 310802-G 2" x 3" GALV. NIPPLE 1 33 311224-G 3/4" x 1/2" GALV. STREET ELBOW 1

2 311208-G 2" 90° GALV. ELBOW 1 34 311801 1" CHECK VALVE (FxF) 1

3 310306-G 1/2" x 4" GALV. NIPPLE 1 35 311314-G 1/2" x 1/2" x 1/4" GALV. TEE 2

4 310301-G 1/2" x 1 1/2" GALV. NIPPLE 5 38 317395 1/2" RESTRICTOR 1

5 310305-G 1/2" x 3 1/2" GALV. NIPPLE 3 39 311404-G 3/4" GALV. UNION 1

6 323300 VELOCITY CHECK VALVE 1 40 310401-G 3/4" x 2" GALV. NIPPLE 1

7 311696-R 1/2" BALL VALVE MXF - RED HANDLE 2 41 311794-GR 1/2" BALL VALVE MxM - GREEN HANDLE 2

8 311313-G 3/4" x 1/2" x 3/4" GALV. TEE 1 42 310308-G 1/2" x 5" GALV. NIPPLE 2

9 317398 DRIP CUP ASSEMBLY 1 43 311683 1/4" 3-WAY VALVE 2

11 310413-G 3/4" x 1 1/2" GALV. NIPPLE 3 44 1340104 PS-10-2 ALARM SWITCH 1

12 310105-G 1/4" x 3 1/2" GALV. NIPPLE 1 45 1340404 PS-40-2 ALARM SWITCH 1

13 311001-G 1/4" GALV. PLUG 2 46 310304-G 1/2" x 3" GALV. NIPPLE 2

14 300119-D 3-1/2" WATER GAUGE (300PSI) 2 47 311203-G 1/2" GALV. ELBOW 5

15 300120-D 3-1/2" AIR GAUGE (250PSI) 1 48 311207-G 1" GALV. STREET ELBOW 1

16 311210-G 1/2" GALV. STREET ELBOW 4 49 311799-R 2" BALL VALVE (FxF) - RED HANDLE 1

17 300111-G 1/2" GALV. CROSS 1 50 310800-G 2" CLOSE GALV. NIPPLE 2

18 311004-G 3/4" GALV. PLUG 1 51 311338-G 2" x 2" x 1" GALV. TEE 1

19 311786 3/4" CHECK VALVE MxF 1 52 310501-G 1" x 2" GALV. NIPPLE 2

20 311403-G 1/2" GALV. UNION 4 54 310302-G 1/2" x 2" GALV. NIPPLE 1

21 311305-G 1/2" x 1/4" x 1/2" GALV. TEE 3 55 310101-G 1/4" x 1 1/2" GALV. NIPPLE 1

22 310161 1/4" TUBE CONNECTOR 1 56 317554 DRY PILOT ACTUATOR 1

23 M-320604 1/4" COPPER TUBE - 57 311303-G 1/2" GALV. TEE 2

24 310346 1/2" ELBOW TUBE CONNECTOR 1 62 317445

1/4" PRESSURE RELIEF VALVE (ADJ. PSI) FAC-

TORY SET @ 45PSI

1

25 310164 1/2" TUBE CONNECTOR 1 66 310310-G 1/2" x 6" GALV. NIPPLE 1

26 M-320591 1/2" COPPER TUBE -

27 317397 1/2" Y-STRAINER 1

28 317396 1/2" SPRING LOADED CHECK VALVE 1

29 311794-R 1/2" BALL VALVE MxM - RED HANDLE 1

31 300112-G 3/4" GALV. CROSS 1

32 311212-G 3/4" x 1/2" GALV. REDUCING ELBOW 1

68 310402-G 3/4" x 2 1/2" GALV. NIPPLE 1

64 310336-G 1/2" x 7" GALV. NIPPLE 1

72 311802 1/2" CHECK VALVE MxF 1

79 310110-G 1/4" x 6" GALV. NIPPLE 1

80 310303-G 1/2" x 2 1/2" GALV. NIPPLE 1

81 310313-G 1/2" x 7 1/2" GALV. NIPPLE 1

MAR 2018 GFV-305 (Formerly H-3) Page 6 of 11

Page 7

FIGURE 8: OPTIONAL ACCELERATOR TRIM ARRANGEMENT

4" ACCELERATOR TRIM ARRANGEMENT

A

A

ITEM

15

70

55

54

B

63

59

27

59

41

57

46

20

65

• NOTE: FITTINGS LABELED

A AND B ARE INCLUDED ON

DRY TRIM, TIE IN ACCEL-

ERATOR TRIM AT THESE

LOCATIONS

58

NO.

15 300120-D 3 1/2" AIR GAUGE (250PSI) 1

20 311403-G 1/2" GALV. UNION 1

27 317397 1/2" Y-STRAINER 1

41 311794-R "1/2"" BALL VALVE MxM - RED 1

46 310304-G 1/2" x 3" GALV. NIPPLE 1

54 310302-G 1/2" x 2" GALV. NIPPLE 1

55 310101-G 1/4" x 1 1/2" GALV. NIPPLE 1

57 311303-G 1/2" GALV. TEE 1

58 300400 GLOBE MODEL "C" ACCELERATOR 1

59 310300-G 1/2" CLOSE GALV. NIPPLE 2

63 323340 MODEL "D" ANTI-FLOODING DEVICE 1

65 320506 ø.125 RESTRICTED ORIFICE 1

70 311213-G 1/2" x 1/4" GALV. ELBOW 1

PART

NO.

DESCRIPTION QTY.

6" ACCELERATOR TRIM ARRANGEMENT

ITEM

15

70

55

59

B

63

54

27

59

41

57

59

20

65

• NOTE: FITTINGS LABELED

A AND B ARE INCLUDED ON

DRY TRIM, TIE IN ACCEL-

ERATOR TRIM AT THESE

LOCATIONS

58

NO.

15 300120-D 3 1/2" AIR GAUGE (250PSI) 1

20 311403-G 1/2" GALV. UNION 1

27 317397 1/2" Y-STRAINER 1

41 311794-R 1/2" BALL VALVE MxM - RED 1

54 310302-G 1/2" x 2" GALV. NIPPLE 1

55 310101-G 1/4" x 1 1/2" GALV. NIPPLE 1

57 311303-G 1/2" GALV. TEE 1

58 300400 GLOBE MODEL "C" ACCELERATOR 1

59 310300-G 1/2" CLOSE GALV. NIPPLE 3

63 323340 MODEL "D" ANTI-FLOODING DEVICE 1

65 320506 ø.125 RESTRICTED ORIFICE 1

70 311213-G 1/2" x 1/4" GALV. ELBOW 1

PART

NO.

DESCRIPTION QTY.

ACCELERATOR TRIM

The accelerator trim comes in three different options. If the

valve is ordered pre-assembled the appropriate trim con-

guration will be added to the dry valve trim according to

Figure 4 or Figure 5 respectively. If the accelerator trim is

ordered as a separate trim kit, the kit will include all of the

necessary parts and pieces to construct either the 4" or 6"

arrangement. Therefore there is only one part number for

the 4" and 6" accelerator assembly trim kit.

MAR 2018 GFV-305 (Formerly H-3) Page 7 of 11

The dry system trim is approved with the Model C mechanical accelerator. See Technical Datasheet H-8 for more

information on the antiood device and mechanical accelerator.

Page 8

INSTALLATION AND MAINTENANCE

INSTALLATION

Proper operation of the RCW Valve (i.e., opening of the

RCW Valve as during a re condition) is highly dependent

on the correct installation of the trim. It is necessary to in-

stall the trim components as described in the gures above

for the valve to function properly. Failure to do so may

prevent the valve from functioning and could void Listings,

Approvals, and/or the manufacturer's warranty. All tubing

directed to the "drip cup" must have smooth bends. Abrupt

changes in direction or kinks in the tubing could result in a

restriction of ow and an adverse effect on the functionality

of the valve.

The Model RCW Valve must be installed in an accessible

and visible location, which is maintained at or above a minimum temperature of 40ºF (4ºC). The RCW Valve must be

installed in the vertical orientation.

All valves must be installed in accordance with the appropriate installation standard (i.e. NFPA 13, NFPA 15 or other).

All electrical connections must be made per the applicable

installation standard and/or the National Electric Code (i.e.

NFPA 70, NFPA 72 or other).

Proper hydrostatic test procedure must be followed per

NFPA 13. The velocity check valve must be replaced with a

plug temporarily, the pressure chamber must be vented during the hydrostatic test procedure by opening the manual

release valve and the clapper must be latched in the open

position.

DRY VALVE SETTING

PROCEDURE

The following steps are to be followed for initial setting

of the Model RCW dry system valve, after a trip test of

the re protection system or, after any system operation.

STEP 1. Close the main control valve.

STEP 2. Close the pressure chamber supply control

valve and the system air supply valve.

STEP 3. Open the main drain valve, lower body (Aux)

drain valve, all low point drain valves and auxiliary drain valves on the system. Open the manual emergency release control valve. Depress

the plunger of the velocity check valve to verify

that it is not under pressure and that the system piping is completely drained. After system

is completely drained, close all low point and

auxiliary drain valves that are open. The manual emergency release control valve and main

drain valve should remain open until directed in

the following steps.

STEP 4. Depress the reset plunger located at the top of

the pressure chamber to reset the clapper of

the RCW valve (the sound of the clapper falling into position should be heard). Close the

manual emergency release control valve.

STEP 5. Replace any operated automatic sprinklers

with the same type, i.e. orientation, orice, temperature, and thermal sensitivity. Open the

air supply valve to re-establish normal system

pressure. Open the manual emergency release

control valve and then the pressure chamber

supply control valve. Slowly close the manual

emergency release control valve and allow

pressure to increase in the pressure chamber

and also up to the dry pilot actuator.

MAR 2018 GFV-305 (Formerly H-3) Page 8 of 11

STEP 6. Observe all drain tubing at the drip cup. If any

leakage is observed, the source of the leakage

must be identied and corrected.

STEP 7. Partially open the main control valve. Slowly

close the main drain valve when water discharges from the drain connection. Observe

the supply pressure gauge and the pressure

chamber gauge. They should indicate the same

pressure reading. Depress the plunger on the

velocity check valve. If leakage is apparent, the

cause of the leakage must be identied and

corrected. If there are no leaks, open the system control valve fully and the system is set for

service.

MODEL C ACCELERATOR

SETTING PROCEDURE

STEP 1. Close the accelerator shutoff valve

STEP 2. Follow the Dry Valve Setting Procedure

STEP 3. Upon completion of the Dry Valve Setting Pro-

cedure. Open the accelerator shutoff valve

slowly. Watch the pressure gauge on the upper

chamber of the Model C Accelerator for 30 seconds. The pressure should start to increase. If

the pressure increases and the accelerator sets

(no air coming from the discharge of the accelerator), wait for the upper chamber of the accelerator to reach the system air pressure and the

system is set for service. If the pressure does

not increase in 30 seconds continue to step 4.

STEP 4. Close the accelerator shutoff valve. Remove

the lower hand wheel plug. The accelerator interior valve assembly should be removed. This

complete assembly can be pulled out by hand

(if it does not come out with the lower hand

wheel plug when it is unscrewed). This will

allow any water, that may have accumulated

in the upper chamber, to drain out and permit

thorough cleaning of the valve disc, seat as-

sembly, and the orice pin.

STEP 5. The valve assembly can then be replaced and

the lower hand wheel plug screwed back into

position. Open the accelerator shutoff valve

slowly. The accelerator is set for service when

the air pressure gauge on the top of the accelerator reads normal system air pressure. If air

pressure does not rise in the upper chamber of

the accelerator after 1 minute call Globe Technical Support for more detailed instruction.

TESTING

Reference NFPA 25, Standard for the Inspection, Testing

and Maintenance of Water-Based Fire Protection Systems.

Before proceeding with any tests involving water ow, the

following precautions need to be taken:

STEP 1. Check the location where the test connection

discharges to make sure that all is clear and

that there is no possibility of the water ow

causing damage or injury.

STEP 2. Check the end of the test connection to make

sure that it is unobstructed. To achieve a satis-

factory test, there must be an unrestricted ow

of water when the test valve is wide open.

STEP 3. Check for alarm connections to a central sta-

Page 9

tion or re department. If such connections are

found, give proper notice to the signal receiving

station before proceeding with the test.

Note: A main drain test may also operate local re alarms unless they are tem-

porarily disabled.

DRY SYSTEM TRIP TEST

PROCEDURE

Proper operation of the RCW Valve (i.e., opening of the

RCW Valve as during a re condition) must be veried, as

described by the applicable Inspection Testing and Main-

tenance Standard (i.e. NFPA 25) or by the Local Authority

Having Jurisdiction. Globe Sprinkler Corporation recom-

mends performing a trip test annually. The steps to perform

a trip test are as follows:

STEP 1. If a partial ow trip test is necessary, perform

the following additional steps. If a normal ow

test is being performed continue to Step 2:

1. Close the main control valve.

2. Open the main drain valve.

3. Open the main control valve one turn beyond the position

at which water just begins to ow from the main drain valve.

4. Close the main drain valve.

Note: Be sure to close the main control valve quickly after the trip of the valve has

been veried.

STEP 2. Open the inspectors test valve at the end of the

system.

STEP 3. Verify that the RCW Valve has tripped, as indi-

cated by the ow of water into the system and

activation of the water ow alarm.

STEP 4. Close the system’s Main Control Valve.

STEP 5. Close the Diaphragm Chamber Supply Control

Valve.

STEP 6. Reset the RCW Dry Valve in accordance with

the Dry Valve Setting Procedure.

• Where difculty in performance is experienced, the

Clapper Facing. The rubber clapper facing should be

checked for wear or damage to determine that it is free of

dirt and other foreign substances. If found to be worn or

damaged (e.g., foreign matter embedded in the surface),

the facing should be replaced. If it is dirty, it should be

cleaned. Compounds which could damage the rubber facing must never be used.

Seat Ring. The seat ring should be checked for nicks and

for stones, dirt or other foreign matter lodged in the grooves

or holes. It should be cleaned thoroughly. If the seat ring is

found to be damaged, valve should be replaced.

Alarm Line Check Valve. The ¾” check valve connected

to the intermediate chamber should be checked for clapper

and seat condition.

RCW Valve. Main Drain Valve and all controlling valves

which are normally closed when the deluge valve is in the

set position should be checked to be sure that they are fully

closed and not leaking.

manufacturer or its authorized representative shall

be contacted before any eld adjustment is to be

made.

DRY SYSTEM WATERFLOW

ALARM TEST PROCEDURE

Testing of the system water ow alarms must be performed as

described by the applicable inspection testing and maintenance

standard (i.e. NFPA 25) or as described by the local AHJ. To

test the water ow alarm, open the alarm test valve, which will

allow a ow of water to the pressure alarm switch and/or water

motor alarm. Upon satisfactory completion of the test, close the

alarm test valve.

MAINTENANCE

Note:

• All valves should be carefully inspected, tested, and

maintained in accordance with NFPA 25 or other

applicable Standard.

• It is important to ensure a clean water supply free

of debris and solid particles such as sand, gravel,

or mud.

• If, during an inspection of a water control valve,

sediment or free particles of matter are noted,

a further examination of internal valve parts is

necessary.

• All deposits should be removed from all operating

parts and ports. Vent holes through intermediate

chamber should be thoroughly cleaned and ushed

with clean water.

MAR 2018 GFV-305 (Formerly H-3) Page 9 of 11

Page 10

ORDERING INFORMATION

The RCW Valve, Dry System conguration or Dry System

with accelerator conguration can be ordered pre-trimmed

or non-assembled as separate items. All trim comes

standard with galvanized nipples and ttings (Standard

galvanized trim is not domestic). For non-assembled the

following items must be ordered separately:

• RCW Water Control Valve

• Dry System Trim Kit

• Optional Accelerator Trim Kit

• Automatic Air Supply (Air Maintenance Device)

• Accessories (as needed)

PRE-TRIMMED WITH MODEL

GLR300G CONTROL VALVE

RCW Dry Pre-Trimmed (No Accelerator)

Specify: RCW Dry Pre-trimmed w/BFV Control

Valve (specify valve size),

4 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317448-B

4 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317448-B-LP

6 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317493-B

6 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317493-B-LP

DN 150 (165,1 mm) GXG ............317493-D-B

DN 150 (165,1 mm) GXG ............317493-D-B-LP

RCW Dry Pre-Trimmed with Accelerator

Specify: RCW Dry Pre-trimmed (specify valve

size), PN (see Part Number Below)

4 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317449-B

4 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317449-B-LP

6 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317494-B

6 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317494-B-LP

DN 150 (165,1 mm) GXG ............317494-D-B

DN 150 (165,1 mm) GXG ............317494-D-B-LP

Note:

-LP denotes version with GDPA-LP actuator (Lower System Pressure)

PRE-TRIMMED WITHOUT BFV

CONTROL VALVE

RCW Dry Pre-Trimmed (No Accelerator)

Specify: RCW Dry Pre-trimmed (specify valve

size)

4 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317448

4 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317448-LP

6 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317493

6 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317493-LP

DN 150 (165,1 mm) GXG. ............317493-D

DN 150 (165,1 mm) GXG. ............317493-D-LP

6 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317494

6 inch GxG. . . . . . . . . . . . . . . . . . . . . . . . 317494-LP

DN 150 (165,1 mm) GXG ............317494-D

DN 150 (165,1 mm) GXG ............317494-D-LP

Note:

-LP denotes version with GDPA-LP actuator (Lower System Pressure)

NON-ASSEMBLED

• Valve body ordered separately

• Accelerator Trim Kit ordered separately

• Trim Kit includes extra pieces to accommodate different

size valves

RCW Water Control Valve

Specify: RCW Valve Only (specify valve size),

4 inch RCW-2 GxG .................317400

6 inch RCW-2 GxG .................317550

DN 150 (165,1 mm) RCW-2 GXG. .....317550-D

RCW Dry Trim 4 inch or 6 inch or DN 150

Specify: RCW Dry Trim Kit,

Dry Trim Kit .......................317340

Dry Trim Kit .......................317340-LP

Note:

-LP denotes version with GDPA-LP actuator (Lower System Pressure)

Model C Accelerator Trim Kit 4 inch or 6 inch

Specify: RCW Dry Model C Accelerator Trim Kit,

PN ..............................317341

Note:

Trim Kit includes extra pieces to accommodate different size valves

See Technical Data Sheet H-8 for more information on the Model C Accelera-

tor and Antiood Device

Model H-1, H-2 or H-3 Air Maintenance Device

Specify: Model (Specify Model) Air Maintenance Device

(see Part Number below)

H-1 ..............................320585

H-2 ..............................320595

H-3 ..............................320600

See Technical Literature G-1 and G-2 for more information

on Air Maintenance Devices

Note:

300 psi (20.6 Bars) Pressure Gauges Standard (600 psi (41.2 Bars) Ordered

Separately

PN ........................................300121-D

See trim drawings for trim replacement part numbers

See Technical Data Sheet GFV200 for RCW Valve replacement part numbers

RCW Dry Pre-Trimmed with Accelerator

Specify: RCW Dry Pre-trimmed (specify valve

size), PN (see Part Number Below)

4 inch GxG. .......................317449

4 inch GxG. .......................317449-LP

MAR 2018 GFV-305 (Formerly H-3) Page 10 of 11

Page 11

GLOBE® PRODUCT

WARRANTY

Globe agrees to repair or replace any of its own manufactured products found to be defective in material or workmanship for a period of one year from date of shipment.

For specic details of our warranty please refer to Price

List Terms and Conditions of Sale (Our Price List).

4077 Airpark Dr.

Standish, MI 48658

Ph. 989-846-4583

MAR 2018 GFV-305 (Formerly H-3) Page 11 of 11

techservice@globesprinkler.com

Technical Support

1-800-248-0278

www.globesprinkler.com

Loading...

Loading...