Page 1

Model CPF16 Shown

Instruction Manual for the

Countertop Electric Fryers

Models CPF10, CPF16 & CPF32

and ask for contact information for your local service company.

Serial #:

For Service on Your Electric Fryer:

Call the Service Department at:

Phone: 800-347-5423

Or: 866-298-625

- IMPORTANT SAFETY NOTICE -

This manual contains important safety instructions which

must be strictly followed when using this equipment.

Page 2

Page 3

Index

ATTENTION OWNERS AND OPERATORS ................................................................................................................4

INSTALLATION ....................................................................................................................................................... 5-7

SAFEGUARDS & SAFETY INSTRUCTIONS ......................................................................................................... 8-9

OPERATING INSTRUCTIONS .............................................................................................................................. 9-10

HELPFUL HINTS - OIL DETERIORATION ...............................................................................................................11

CLEANING INSTRUCTIONS ....................................................................................................................................12

TROUBLESHOOTING ..............................................................................................................................................13

LIMITED ELECTRIC FRYER WARRANTY ...............................................................................................................14

2153 DRYDEN RD.

DAYTON, OH 45439

PHONE: 937-299-5493

TOLL FREE: 800-347-5423

FAX: 937-299-4147

Printed 12-2010 for Commercial Pro products © 2010

Page 4

Attention Owners and Operators

Commercial Pro products are designed to provide safe and productive processing, cooking and warming of food products

as long as the equipment is used in accordance with the instructions in this manual and is properly maintained. Unless

the operator is adequately trained and supervised there is a possibility of serious injury. Owners of this equipment

bear the responsibility to make certain that this equipment is used properly and safely, and to strictly follow all of the

instructions contained in this manual and the requirements of local, state or federal law.

Owners should not permit anyone to touch this equipment unless they are over 18 years old, are adequately trained

and supervised, and have read and understood this manual. Owners should also ensure that no customers, visitors

or other unauthorized personnel come in contact with this equipment. Please remember that we cannot anticipate

every circumstance or environment in which its equipment will be operated. It is the responsibility of the owner and

the operator to remain alert to any hazards posed by the function of this equipment. If you are ever uncertain about a

particular task or the proper method of operating this equipment, ask your supervisor.

This manual contains a number of precautions to follow to help promote safe use of this equipment. Throughout the

manual you will see additional warnings to help alert you to potential hazards.

Warnings affecting your personal safety are indicated by:

or

Warnings related to possible damage to the equipment are indicated by:

If any warning labels or this manual are misplaced, damaged, or illegible, or if you require additional copies, please

contact your nearest representative or call the service number listed on the front of this manual.directly for these items

at no charge.

Please remember that this manual or the warning labels do not replace the need to be alert, to properly train and

supervise operators, and to use common sense when using this equipment.

Page 4

Page 5

Installation

UNPACKING

Unpack the electric fryer immediately after receipt. If the machine is found to be damaged, save the packaging

material and contact the carrier within fteen (15) days of delivery. Immediately contact service or your local

dealer of the equipment. You have no recourse to damage after fteen (15) days.

TO AVOID SERIOUS PERSONAL INJURY:

• ALWAYS install equipment in a work area with adequate light and space.

• ONLY operate on a solid, level, nonskid surface that is nonammable and away from sinks and water hazards.

• NEVER bypass, alter or modify this equipment in any way from its original condition. Doing so may create

hazards and will void warranty.

• NEVER operate the electric fryer without all warnings attached to it.

NOTICE: Local codes regarding installation vary greatly by area. The National Fire Protection Association, Inc,

states in its NFPA 96 latest edition (see below) that local codes are “authority having jurisdiction” when it comes to

requirements for installation of equipment. Therefore, installations should comply with all local codes. Once your

electric fryer has been removed from the packaging, be certain that all protective plastics and residues are

removed from all surfaces.

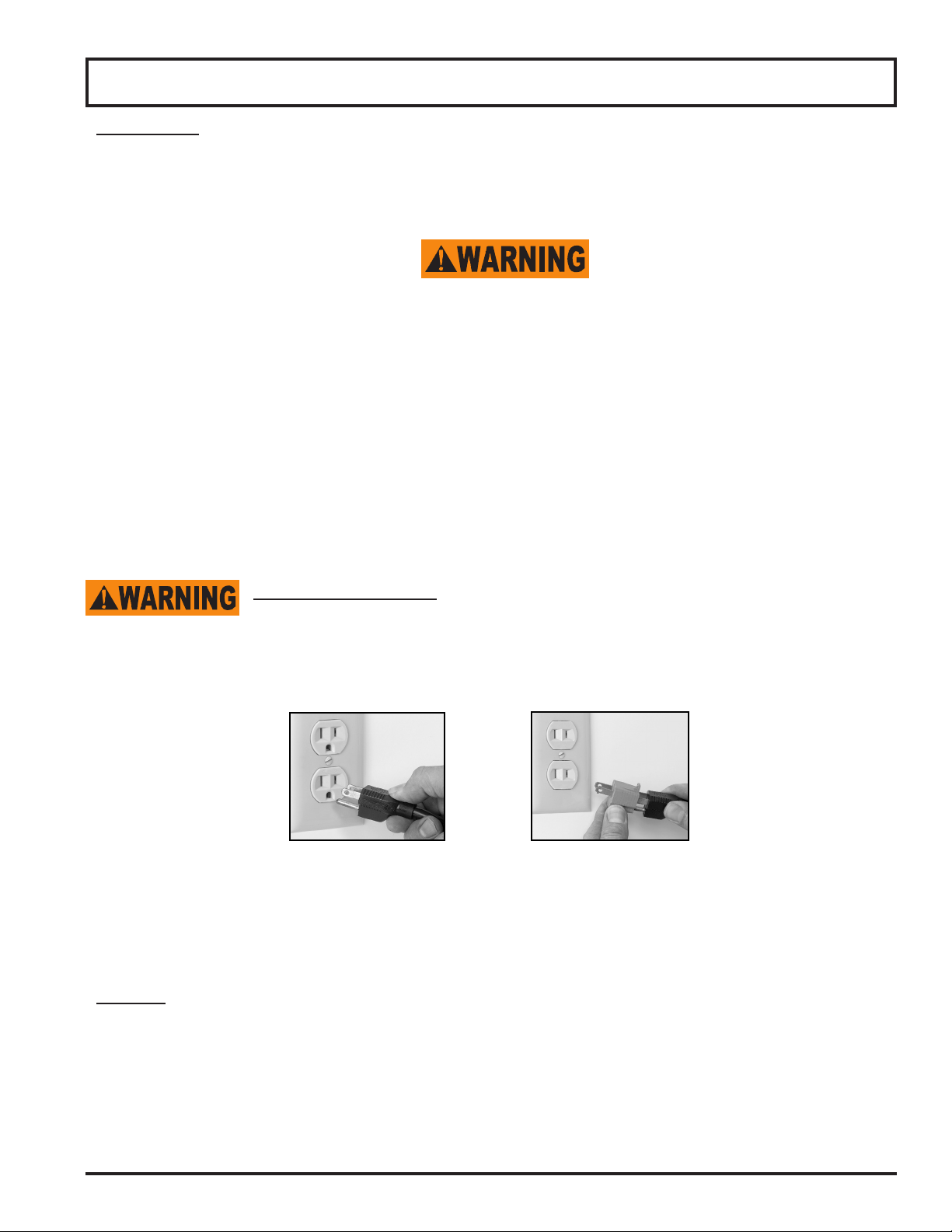

PROPER GROUNDING

THIS MACHINE IS PROVIDED WITH A THREE-PRONG GROUNDING PLUG. THE OUTLET TO WHICH THIS

PLUG IS CONNECTED MUST BE PROPERLY GROUNDED. IF THE RECEPTACLE IS NOT THE PROPER

GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD GROUND PRONG FROM THE POWER CORD OR USE ANY ADAPTER PLUG (Fig. 5-1

and Fig. 5-2).

Fig. 5-1 Correct

1. Complete the warranty card and place it in the mail.

2. Electric fryer outside covering/containment unit, oils and baskets will be HOT during and after use. Use

caution when approaching the unit.

Electrical

Model CPF10

The CPF10 -120V Fryer is wired to use with a standard 120VAC receptacle and may be plugged in any convenient

outlet. This unit requires 14.2 amps to produce 1700 watts and should be used on a dedicated circuit.

Fig. 5-2 Incorrect

Models CPF16 & CPF32

The CPF16E & CPF32E -208/240V Fryers. The CPF16 requires 15.8A to produce 2900W-3800W and should

be on a dedicated service. The CPF32 requires 31.6A to produce 5800W-7600W and should be on a dedicated

service.

Page 5

Page 6

Installation

The installation of the electric fryer must conform to the NATIONAL ELECTRIC CODE AND ALL LOCAL

ELECTRIC CODES AND ORDINANCES AND ALL THE LOCAL ELECTRICAL COMPANY RULES AND

REGULATIONS. APPROVED FIRE SAFETY AND HOOD SYSTEMS SHOULD BE INSTALLED ACCORDING TO

NFPA 96 STANDARDS.

Note: Double Fryers (i.e. CPF32) have individually controlled heating elements, and dual power supply

must be provided.

INSTALLATION AND ASSEMBLY OF THE ELECTRIC FRYER

1. Read this manual thoroughly before installation and operation. DO NOT proceed with installation and

operation if you have any questions or do not understand anything in this manual. Contact your local

representative or call the service number on the front of this manual.

2. Remove the electric fryer from the box. Once your fryer has been removed from the

packaging, be certain that all protective plastics and residues are removed from all surfaces.

3. Inspect the fryer to ensure all parts have been provided.

4. Select a location for the fryer that has a level, solid, nonskid surface that is nonammable and away

from water hazards or sinks, and is in a well-lighted work area away from visitors.

5. Install the fryer in its location with at least 6'' between the appliance and the walls or other objects.

6. Fyers come equiped with a safety chain and loop to attach the fryer to a wall. Attach on end of the chain to the

fryer and the other end to the counter or wall surface behind where the fryer will sit for operation.

7. Proper connections and power supply are essential for efcient performance.

8. Make sure that your fryer is installed in a well ventilated area. Also make sure to take care in placing the fryer

in an area that is open and not underneath a cabinet or any other overhang other than a vent hood.

This equipment, oil and its contents get EXTREMELY HOT so make sure all ammable/

combustible materials are set away from this equipment.

COMMISSIONING:

Commissioning of your new electric fryer is of the utmost importance. Commissioning is the thorough and

methodical testing of the equipment, sub systems, and systems to ensure that the nal product functions properly

and safely at the work site. By identifying any potential problems (i.e.: equipment location, ventilation, local re/

electrical codes, installation, operator training and certication) prior to equipment being placed into service, costly

outages and potential damages may be avoided.

Page 6

SAFETY ALWAYS.

Page 7

Installation

Feet

Install feet by screwing each foot into the threaded openings on the bottom of the Fryer. Failure to use feet will void

warranty and could cause unsafe conditions.

Leveling

Level unit by adjusting the four feet and tighten securely. The adjustable feet have an adjustment of one inch for

lineup with other Commercial Pro countertop lines. Check the feet regularly to ensure they are tight. Also ensure

the work surfaces of the bench/table the fryers sits on are kept clean and maintained to avid any accidents. Ensure

the bench/table is adequately built to hold the weight of your fryer. Empty (without oil/shortening added)

CPF10E = 16.8 lbs, CPF16 = 19.2 lbs, CPF32 = 29.2 lbs.

IMPORTANT:

Suitable Pans: Use only the fry baskets provided with your fryer. DO NOT substitute the baskets with any

other cooling container.

The fryer electrical head has two locating buttons that need to be aligned, (see g 7-1).

Ensure the oil pan is placed into the fryer body evenly, and lower the element into the

bay following the 2 simple steps in (g. 7-2 and g. 7-3). Points A, hold the head to the

fryer body.

Easy push pin to lock and unlock; lift and lower heating element for cooking or cleaning.

Point B determines the position of the head in either the working position or cleaning

position.

Place the electrical head into the supporting brackets by pushing Points A, in and

ensuring they are placed correctly and then click into position.

Point B allows you to keep the fryer head in the raised position, or by pushing and/or

depressing the button and holding the insulated element handle, you can also lower the

element into the pan and its operating position.

These steps can be repeated in reverse for cleaning purposes.

NOTE: Point B has two level options: Fully raised 90°, allows pan to be removed;

raised to 75°, allows for cleaning and draining oil/fat from the element.

The fryer can be lled with the appropriate oil/shortening required. For shortening,

it is advised to breakdown rstly to avoid overheating of the element. Ensure the

element is always submerged.

FIG. 7-1

FIG. 7-2

FIG. 7-3

Page 7

Page 8

Safeguards & Safety Instructions

TO AVOID SERIOUS PERSONAL INJURY:

• DO NOT operate the electric fryer before reading the instruction manual rst.

• ALWAYS disconnect or unplug electrical power before cleaning, servicing or adjusting any parts or

attachments.

• NEVER bypass, alter, modify or attach any unauthorized parts to this equipment.

Doing so may create hazards and will void warranty.

• NEVER operate electric fryer with a damaged power cord or plug.

• NEVER leave the electric fryer on overnight or for prolonged periods of non-use.

• NEVER use the electric fryer as a heating source for your kitchen, space, or room.

• ALWAYS keep hands, hair and cloth away from heating elements.

IMPORTANT SAFEGUARDS & SAFETY INSTRUCTIONS

When using electrical appliances, basic safety precautions should always be followed.

DO NOT operate electric fryer if unit appears damaged or malfunctions in any manner.

Call customer service for assistance.

Including the following:

• Do not touch fryer surfaces while, or after, cooking as it will become hot.

• To protect against electrical shock do not immerse cord, plugs, appliance in water, liquid or dishmachine.

• Close supervision is necessary when electric fryer is being used. Operator must be properly trained

on all operational and safety procedures, especially when using near others.

• Unplug unit when not in use and before cleaning. Allow unit to cool before moving or cleaning.

• The use of any accessories or cooking pans, which are not recommended by the manufacturer, may cause

re or injuries.

• Do not use outdoors. For indoor use only.

• Do not allow power cord to hang over edge of table or counter, or to touch hot surfaces.

• Do not place the fryer in, on, or near open ames, electric burners, heated ovens, or other high

temperature equipment or surroundings.

• To disconnect, turn off all controls, then gently remove plug from wall outlet.

• Do not use fryer for anything other than cooking, with suitable fryer basket(s) and subversion.

• Do not immerse fryer in water, as this will cause permanent damage to unit.

• Do NOT pull/yank on any cord to disconnect

• The fryer does not contain any user-serviceable parts. Commercial Pro product dealers or recommended

qualied technicians should carry out repairs if necessary. Do not remove any components or service panels

on this product.

• We take every care to ensure that all products are safe. Steel cutting procedures used to manufacture

these items results in sharp edges. These sharp edges are removed to the best of our ability however we

insist the operator takes care when in contact with this piece of equipment.

• During operation the fryer reaches very high temperatures in the oil pan, in turn, heating the stainless steel

surfaces. Take extreme care when operating.

• Before Cleaning – Switch off the power and disconnect from the main source whilst cleaning. Unit must be

unplugged and cool to touch. Allow time for the oil/shortening to cool as well; the unit will be too hot to handle

immediately after use.

• This unit has been equipped with a thermal cut-off safety device to avoid over heating and oil ash point.

Page 8

Page 9

Safeguards & Safety Operating Instructions

• ALWAYS BE PREPARED incase of a re, make sure to have the correct rate re extinguisher near by.

DO NOT attempt to spray or pour water on a fryer. This is EXTREMELY

dangerous as water and oil do not mix.

Operating Instructions

Operating the Electric Fryer

Ensure all fryers parts are always cleaned thoroughly before use. Detergents can be use to break down

cooking oil and ensure adequate cleaning. For further cleaning instruction, refer to the cleaning section of the

manual.

Fryer Operation:

1. Fill the pan with oil, fat or shortening until level indicator line is reached.

A. Your choice of oil/fat will inuence the quality of products cooked in this fryer. It will also

inuence the life of the oil/fat. Please be sure to regularly change oil/fat to maintain best cooking

results and to avoid the breakdown down of oil/fat which will eventually lead to the oil igniting.

- A non-golden color or dark, burnt areas on food may indicate that the oil/fat needs to be changed.

B. If solid shortening is used, pack the fat around the heating element and set the thermostat between

200°F and 250°F. This will ensure the fat heats slowly and covers the element. Failure to do so

will trip the Hi Limit protection switch.

C. It is recommended that for preparation heat up, each day, fat is brought up to temperature steadily,

particular when solids fats/shortening is used.

D. Ensure oil/fat levels are maintained according to the indication marks in the pan. Over lling the oil

pans will result in over ow from surge boiling once food product is lowered into the pan for

cooking.

SURGE BOILING CAN RESULT IN PERSONAL INJURY AND PROPERTY DAMAGE.

PLEASE TAKE CAR WHEN COOKING WITH OIL

2. After proper oil/fat levels are obtained, set the thermostat dial for desired cooking temperature.

- While preheating, the amber light will stay on. When the selected temperature is reached, the

indicator light will go out.

3. Once the oil/fat has reached the desired temperature, the baskets with food product can be lowered

carefully into the oil/fat.

4. Only ll the baskets half way to ensure the best cooking results and to avoid surge boiling that can result

in injury.

The fryer is thermostatically controlled and will operate according to the desired temperature setting,

ensuring temperatures are maintained through cooking cycles.

Page 9

Page 10

Operating Instructions

This fryer does not come equipped with a timer; make sure to observe your fryer while cooking each product

every time or use a regular cooking timer, record and repeat your data for cooking of your food

products.

5. Once the food is cooked, carefully lift the baskets from the oil/fat

and allow the baskets to rest on the supports as shown in Fig. 10-1.

This will allow any excess oil/fat to drain back into the oil pan.

NOTE: If the temperature of the fat should get too high or if the

elements are left “ON” in the raised position, or whilst cleaning,

the “HI LIMIT” control will turn off the unit. If this occurs, turn the

thermostat to “OFF” position, allow the fryer to cool and press the

reset button on the back of the control box. Normal operation can

be resumed. Fig. 10-2

NOTE: If the Hi Limit continually turns off the unit, please refer to

the trouble shooting guide.

Fig. 10-1

IMPORTANT: Turn fryer temperature down to 200°F between product frying to avoid burning oil and causing

the fryer to be manually reset.

Fig. 10-2

Page 10

Page 11

Helpful Hints - Oil Deterioration

Signs of Oil Deterioration:

• Oil darkens with use because the oil and food molecules burn when subjected to high / prolonged heat.

• The more an oil batch is used, the slower it will pour. Oil viscosity changes because of its molecular structure.

• Loose absorbent particles accumulate as sediment at the bottom of the fryer storage container or are

suspended in the oil.

• When smoke appears on the oil’s surface (before the temperature reaches 190° C / 375°F) the oil in the fryer

will no longer effectively deep fry food products.

• When the oil in your fryer omits a foul odor or if the oil smells like the food fried/cooked in it, the oil should

be carefully discarded

How to Safely Reuse oil:

• Strain oil through a few layers of cheese cloth to catch any food particles. Only do this once the oil has

cooled. DO NOT attempt to do this when the oil is in use or directly after.

• Shake off excess batter from food before putting into the fryer. This will reduce the amount of excess food

particles.

• Turn off the heat to the fryer once cooking is complete. Exposing oil to prolonged heat accelerates the life of

the oil.

• Store oil in a cool, dark place. Once fryers are off and have cooled, cover the fryer with a guard/cover.

• Avoid iron or copper pots or pans for frying oil that is to be reused. These metals accelerate the life of the oil.

Page 11

Page 12

Cleaning Instructions

• ALWAYS unplug and allow the electric fryer and the oil to cool before cleaning.

• DO NOT use any cleaning uids that can be harmful to you, others around you, or the environment.

• DO NOT hose down, immerse or pressure wash any part of the electric fryer.

• NEVER use a scrubber pad, steel wool or abrasive material to clean the electric fryer.

ALWAYS DISCONNECT OR UNPLUG THE ELECTRICAL POWER FROM THE ELECTRIC FRYER

BEFORE CLEANING.

RECOMMENDED CLEANING

CLEANING & MAINTENANCE

This fryer was designed for ease of disassembly and cleaning. The fryer should be cleaned after each day’s

operation; however, it may require cleaning more often, depending on the volume of production. A clean fryer

performs better and more safely, produces higher quality product and reduces maintenance costs. When cleaning,

always consider safety rst. Ensure all power is off and the unit has been disconnected from the power source.

NOTE: During the cleaning process, check the heating

element for crumbs/debris. If crumbs/debris are caught in

the heating element, it could give the thermal cut out a false

reading and cause the unit to shut down.

Allow the electric fryer and the oil to cool before cleaning.

1. Turn the thermostat to the “OFF” position, switch the on/off switch off, and disconnect from the power.

2. Allow the oil/fat to cool to a safe handing temperature.

3. Remove fry baskets and clean, using standard dish washing detergent. Be sure to rinse thoroughly.

4. Using the insulated handle on the element assembly, raise heating element(s) to the rst stop, allowing the oil/fat

to drain for several minutes and then raise heating element(s) to the full raised position. Be sure that the latch

has properly engaged.

5. Using gloves or potholders, remove the fry tank and drain the fat. Depending on the oil/fat quality, this can either

be replaced of ltered for further use.

6. For detail cleaning, the electrical head can be entirely removed from the fryer body.

NOTE: The body, baskets and pans are dish machine washable or can be submerged in water for cleaning. Ensure

thorough drying before reassembling.

7. During cleaning please be take care to avoid any damage to the elements or switch on the electrical head.

- Regularly check the power cord for any damage.

- For assistance is disassembly or reassembly of the fryer during and after cleaning, refer to the installation section

of this manual.

NEVER run water over the unit.

Page 12

An Authorized Servicer should perform any servicing.

Page 13

Troubleshooting

ISSUE CAUSE SOLUTION

Electric fryer not working Power supply Check power source

Power switch has not been turned onCheck that the unit is correctly

plugged in and turned on

Plug/cord damaged Call for service

Internal wiring fault Call for service

Oil/Fat is not heating up and

indicator light is ON

Food debris stuck on or between

heating element

Thermal cut out has activated Power off fryer, let fryer cool

Thermostat or heating element

has failed

Thermal cut out has activated Power off fryer, let fryer cool

Power off fryer, let fryer cool

and then clean on or arround

elelments removing the food

debris

and then clean on or around

elelments removing the food

debris

Call for service

and then clean on or around

elelments removing the food

debris

or

Refer to Operations section of

this manual. If problem persists,

call for service

Indicator light is ON, but fryer is

not operating normally

If problems persist and the assigned solution does not remedy the issue, please call our Service

Department at: 866-299-8625.

Faulty indicator light Call for service

Oil/fat has reached the desired/

set temperature

Use fryer normally

Page 13

Page 14

Limited Warranty

Commercial Pro products are warranted to the original purchaser of new equipment that said equipment, when

installed in accordance with our instructions within North America and subjected to normal use, is free from defects

in material or workmanship for a period of 1 year. The labor warranty is one year from original installation or 18

months from actual factory shipment date whichever date occurs rst. Unit must be sent prepaid to Globe Food

Equipment (“GFE”) for repair. No mileage or travel time is paid. Call for a Return Material Authorization.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED. WE

EXPRESSLY DISCLAIM ANY IMPLIED WARRANTY OF MERCHANTABILITY OR EXPRESSED OR IMPLIED

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

COMMERCIAL PRO’S PRODUCT OBLIGATION AND LIABILITY UNDER THIS WARRANTY IS EXPRESSLY

LIMITED TO REPAIRING EQUIPMENT WHICH PROVES TO BE DEFECTIVE IN MATERIAL OR WORKMANSHIP

WITHIN THE APPLICABLE WARRANTY PERIOD. All repairs pursuant to this Warranty will be performed by Globe

Food Equipment during normal working hours. IN NO EVENT SHALL WE BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES TO BUYER OR ANY THIRD PARTY, INCLUDING, WITHOUT LIMITATION, LOSS

OF PROPERTY, PERSONAL INJURY, LOSS OF BUSINESS OR PROFITS OR OTHER ECONOMIC LOSSES,

OR STATUTORY OR EXEMPLARY DAMAGES, WHETHER IN NEGLIGENCE, WARRANTY, STRICT LIABILITY,

OR OTHERWISE.

This warranty is given only to the rst purchaser from a retail dealer. No warranty is given to subsequent transferees.

This warranty does not cover product failures caused by: failure to maintain, neglect, abuse, damage due to excess

water, re, normal wear, improper set up and use. Periodic maintenance, not covered.

This warranty is not in force until such time as a properly completed and signed installation/warranty registration

form has been received within 30 days from the date of installation.

Proof of purchase is required if extended more than 1 year from date of shipment from the factory

THE FOREGOING WARRANTY PROVISIONS ARE A COMPLETE AND EXCLUSIVE STATEMENT BETWEEN

THE BUYER AND SELLER. COMMERCIAL PRO NEITHER ASSUMES NOR AUTHORIZES ANY PERSONS TO

ASSUME FOR IT ANY OTHER OBLIGATION OR LIABILITY IN CONNECTION WITH SAID EQUIPMENT.

Example of items not covered under warranty, but not limited to just these items:

1. Acts of God, re, water damage, burglary, accident, theft.

2. Freight damage.

3. Improper installation or alteration of equipment.

4. Use of generic or after market parts.

5. Repairs made by anyone other than a designated servicer.

6. Lubrication.

7. Expendable wear parts, adjustable feet, blown fuses, lamps, etc.

8. Cleaning of equipment.

9. Misuse or abuse.

Page 14

Loading...

Loading...