Page 1

Global Truss ST-132 User Guide

D

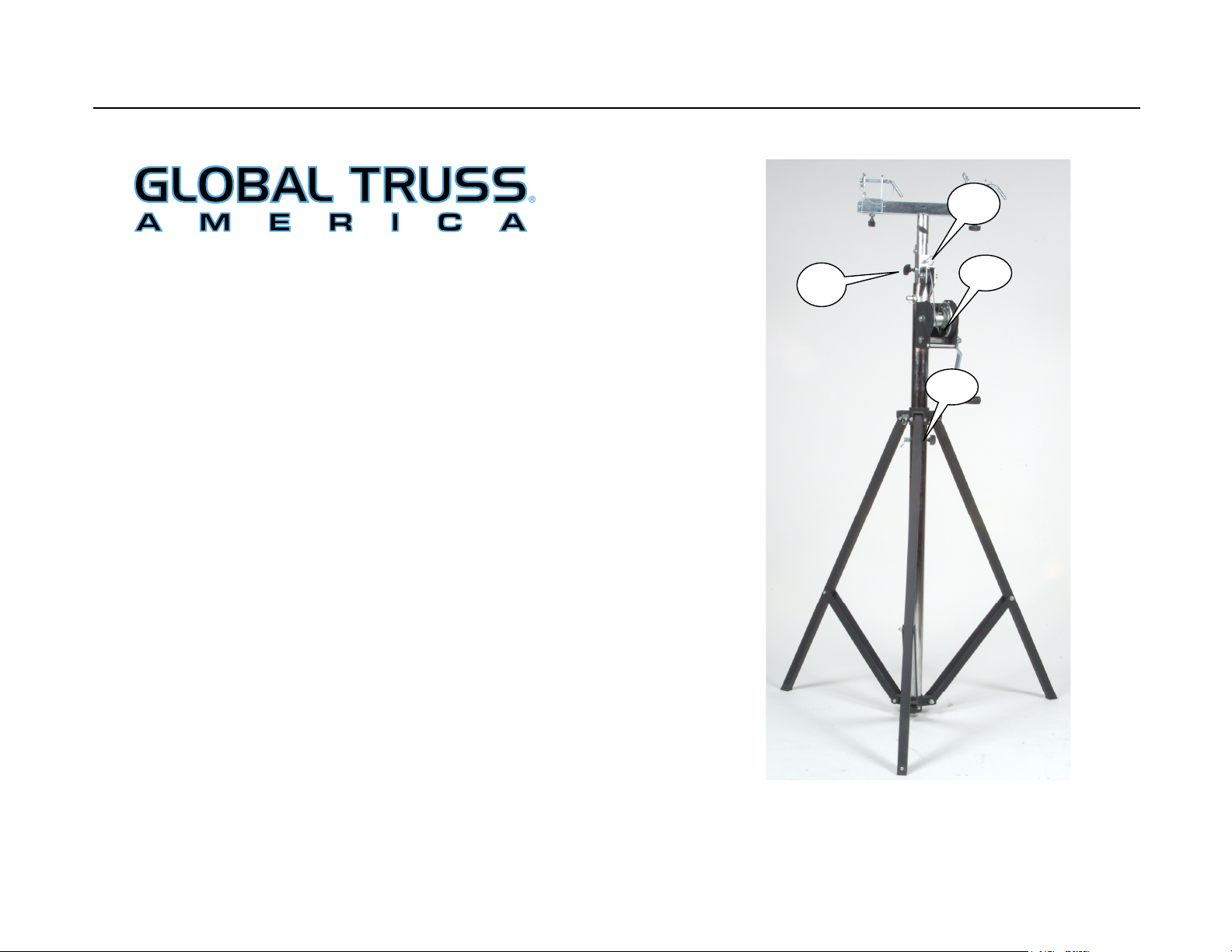

ST-132 CRANK STAND

Thank you for choosing an ST-132 light stand from Global Truss

America. This stand has been designed to have a low loading

height, obtained by a multi-mast configuration. The telescopic

masts are made of treated steel and have been sized in order to

obtain maximum rigidity. The top mast has been designed with a

1-3/8” diameter steel tube which is standard in the industry for lifting

and supporting pro audio speaker cabinets.

been placed on security. The spring loaded safety pins guarantee

extra security when operating the stand. As a third safety device,

each mast can be secured with a tension knob.

The ST-132 is equipped and shipped with:

A: Adjustable metal tripod base with telescoping leg

B: Large tension knobs

C: Manual cable winch with built in safety brake

D: Safety spring loaded pins

E: 4 light Lighting T Bar (Not Shown)

(STSB-005 TRUSS ADAPTOR SHOWN IN THE PICTURE IS NOT INCLUDED)

PRODUCT DESCRIPTION

Special attention has

B

Page 1

Page 2

Global Truss ST-132 User Guide

ST-132 Technical Specification

Maximum load: 100kg 220lb.

Maximum height: 4.0m 13`1.5”

Minimum height: 1.75m 5`9”

Footprint: 1.6m 5`3”

Unit Weight: 25kg 55lb

Transport size: 1.75m 5`9”

Material: Treated Steel

Finish: Epoxy Black Paint/ Electro-Galvanized

ALL SPECIFICATION ARE SUBJECT TO CHANGE WITHOUT NOTICE

POSITIONING THE STAND

1): Place the stand in the vertical position with the tripod base

fully extended.

2): Ensure that the ground is firm enough to prevent the stand from

sinking. The stability of the stand is of prime importance for

secure operation. For outdoor use on a soft surface, 3/4”

plywood pads under each foot is recommended

3): When using the stand on a slopped surface, use the adjustable

leg to level the stand. Once the stand is leveled, release the

spring loaded safety pin into the positioning hole and tighten the

tension knob.

Page 2

Page 3

Global Truss ST-132 User Guide

G

G-2

I-2

RAISING THE MASTS

1): Loosen the tension knob (G) on the top mast.

2): Tighten all other tension knobs to ensure that the stand is lifting

the top masts only. The top mast must be raise first, followed by

the second mast in sequence.

3): Pull the safety spring loaded pin (I) to unlock the top mast.

4): Turn the winch crank (H) clockwise to raise the top mast. When

the desired height has been reached, release the safety spring

loaded pin into the positioning hole on the mast.

5): Tighten the tension knob (G) to secure the mast and to avoid

any lateral movement and further lifting.

6): Repeat steps 1-5 with on the 2nd mast. Loosen the tension knob

(G2) and release the safety spring loaded pin (I-2)

7) Once the desired working height has been obtained and all

spring loaded pins have been locked and the tension knobs

have been tighten, turn the winch crank handle(H) a 1/4 turn

counter clockwise to release tension from the cable.

IMPORTANT

1) All equipment that is being raised by the cranks should be

secure with Global Truss TUV rated clamps and safety cables

prior to raising the mast to the desired working height.

2) One operator per stand is required when using the stands in

pairs to lift trussing.

3) Keep hands and fingers clear of the steel cable and mast

when lifting or lowering the mast.

Page 3

Page 4

LOWERING THE MAST

I-2

1) Turn the winch crank handle (H) a 1/4 turn clockwise to add

tension to the cable. Reverse the lifting the mast steps 1-6 to

lower the masts. All of spring loaded safety pins (I and I-2) must

be locked into the lowest positioning hole and tension knobs

must be tighten (G&G2).

2): Fold up the tripod base and make sure that the spring pin is

locked and the tension knob is tighten.

3): Turn the winch handle (H) until the cable is tight.

5): Your stand is ready for transport.

Global Truss ST-132 User Guide

The steel cable must be correctly and completely rolled on the

winch to avoid crushing the fibers.

The stand can be transported in a vertical or horizontal

position.

Optional Transport bag is available.

G

G-2

Page 4

Page 5

Global Truss ST-132 User Guide

SAFETY NOTES

1) Carefully inspect all parts before each use.

2) Do not exceed the load limitations provided in this guide. The

weight of the truss and the equipment on the truss must be

accounted for as load being supported by the stand. The load

must be evenly distributed on the stands

3) Adequate safety measures must be taken when personnel is

working underneath the loads carried by the truss and the

stands. Safety cables and TUV rated clamps must use on all

equipment being supported by the stands.

4) All electrical devices hung on the stand or by the stand must

conform to the technical codes concerning electrical devices.

5) The stand must only be operated in the vertical position.

6) All moving parts on the stand should be checked regularly for

damaged and wear and tear.

7) The steel cable should be checked regularly for fraying.

8) Do not use the stand if the welds or materials are cracked or if

the unit has been dropped. The structurally integrity may be

compromised.

9) Do not move the stand when it is loaded.

10) Do not use the stand to lift people.

11) Do not lean ladders on the stand.

12) Do not use the stand in extreme outdoor weather conditions.

13) Do not allow the stand to be used on soft surfaces.

DISCLAIMER

1): The use of trussing and lifting equipment in temporary or mobile

applications is the sole responsibility of the operator.

2): During the warranty period, Global Truss or one of our

authorized service centers will repair the stand if the damage is

attributed to faulty materials or manufacturer defects.

3): The warranty does not cover damage due to negligent handling,

overloading or parts subject to normal wear and tear.

4): The use of parts not supplied by Global Truss America or

modifications to our design by third parties will void all

warranties.

Page 5

Loading...

Loading...